Page 1

WARNINGS

DANGER OF ELECTROCUTION: BE CERTAIN THAT EVERY

CT IS CONNECTED TO A LOAD AT ALL TIMES WHEN CLAMPED TO AN ENERGIZED

CONDUCTOR. Current mode Current Transformers (CTs) such as those used

in this produc t can be damaged, or generate lethal voltages, if clamped

around current carrying conductors while the output leads are not properly terminated to a shorting device, or loaded, as by the H663SM main

board. Install wiring connec tors in accordance with manufacturer's specifica-

tions and instructions.

• Potential elec trocution hazard exists. Installing sensors in an energized

electrical panel, or on any energized conductor can be ha zardous. CT

outputs should not be connected to Operator Accessible circuits.

• Read instructions thoroughly prior to install

• This product is not intended for life or safety applications.

• This product is not intended for installation in hazardous or classified

locations and must be installed in an electrical and fire enclosure in accordance

with EN 61010-1.

Severe injury or death can result from electrical shock during contact with high

voltage conductors or related equipment. Disconnect and lock-out all power

sources during installation and service. Applications shown are suggested means

of installing sensors, but it is the responsibility of the installer to ensure that the

installation is safe and in compliance with all national and local codes. Installation should be attempted only by individuals familiar with codes, standards,

and proper safety procedures for high-voltage installations.

Installation Instructions

H663 Series

Split-Core Branch

Current Monitor

Easy Installation

■ First split-core solution for branch current monitoring in the indus try!

■ Monitor up to 42 (breakers) poles wi th one product

■ Split-core C T’s provide quick and easy installation...ideal for retrofi t

■ Simple two wire 120 VAC power connection*

Network Ready RS485 Output

■ Retrieve amperage information from up to 42 circuits with one R S485 drop...

easy wiring

■ Global alarm r egister for instant alarm and warning notification

■ Integrates to available network display for local indication

■ Easy to use configuration soft ware simplifies setup and provides flexibilit y to customize

the configuration to meet the application

OPERATION

Designed for the critical load monitoring such as Co-location Data Centers and

lighting panels, the H663 series monitors current on up to 42 branch circuits in

a 120/208/240 VAC electrical panel. By individually reporting current draw and

initiating capacity warnings and alarms, the H663 series allows the user to manage

loading and eliminate power disturbances caused by overloaded breakers.

The H663 series consists of a data acquisition system board and up to 42 individual

split-core current transformers (CTs). The acquisition board should be mounted inside the electrical panel, or in an enclosure mounted near enough for the CT output

leads to reach the acquisition board connectors. The CTs are clipped onto each of the

branch circuit conductors. These CTs transmit amperage data from each monitored

circuit to the acquisition system for processing.

Current and alarm information is transmitted to the user’s Control Data Acquisition

system over an RS485 drop using the Modbus protocol.

Set-up is made easy with a PC based configuration tool which allows for global or

individual selection of breaker size, warning levels, and alarm levels.

The H663 Series is a UL508 Listed open device without enclosure.

*For 240VAC Power connection versions, order catalog number H663SM-xxE

Z202833-0K ©2006 Veris Indus tries 10061

Shop for Power Metering products online at:

www.PowerMeterStore.ca

-1-

1.877.766.5412

Page 2

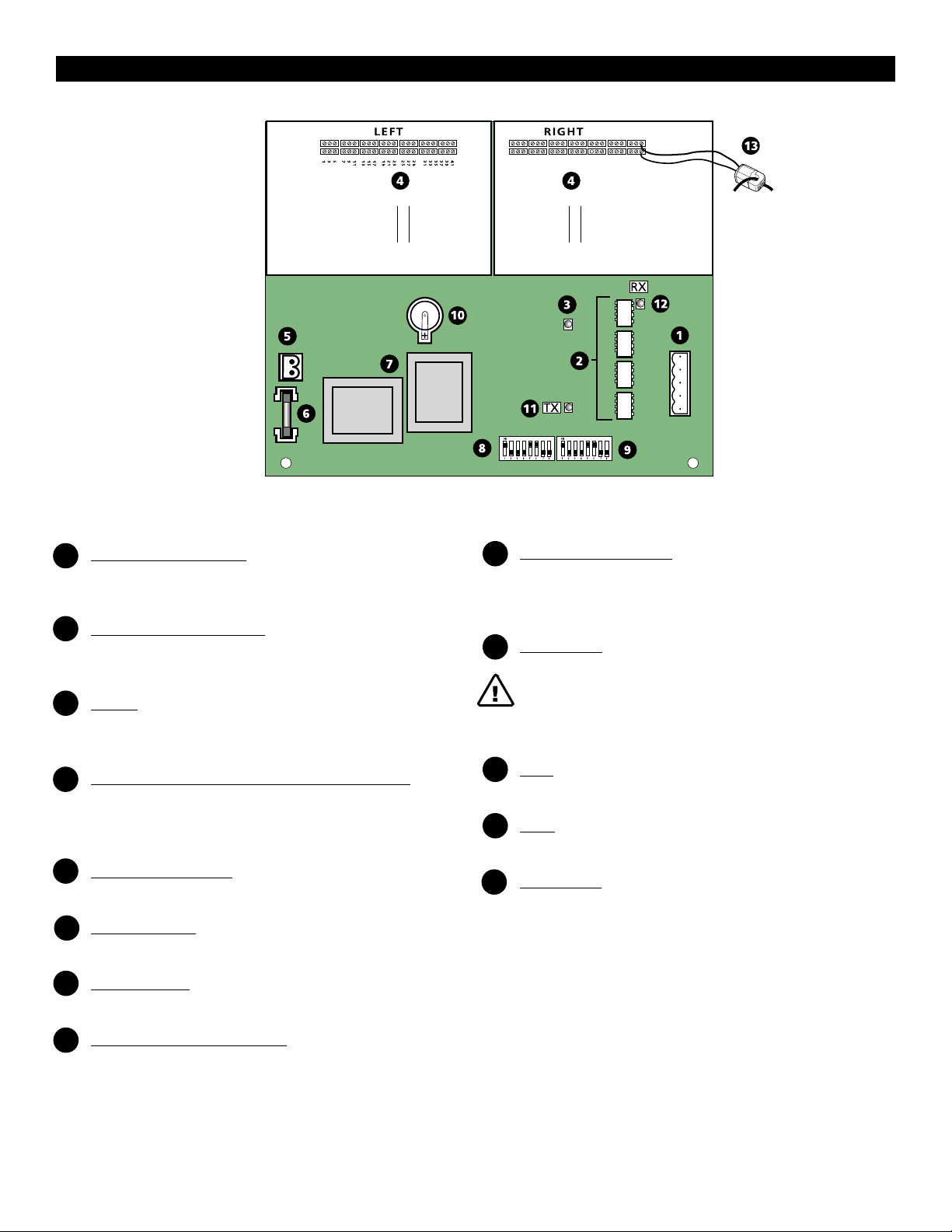

INSTALLATION

64212108181614242220302826363432424038

Figure 1

1 RS 485 2 or 4-Wire Connection

Daisy chain multiple H663's using a 2-wire or 4-wire modbus network. Refer

to Figure 4 on page 7.

2 Optical Communications Isolation

Optical isolators are used to separate 120 VAC portions of the circuit from the

RS485 network.

3 Alive LED

Flashes once per second to indicate correc t operation. If steadily lit or out,

indicates internal failure.

4 Current Transformer (CT) Connectors (Interconnection Boards)

Numbered terminals correspond to the input channels of the acquisition

board. Fasten the current transformer connectors into the terminals as

shown in figure 3 on page 3.

5 120 VAC Power Connection*

Easy 2-wire 120 VAC line to neutral 50/60 Hz.

6 250 VAC 100mA Fuse

Fused power connection for circuit protection.

7 Power Transformer

Linear power supply for reliability and low noise

9 Modbus Address Dip Switches

Each Modbus device must have a unique address. These switches must be set

to assign an individual address before the device is connected to the

network. (See page 5)

10 Lithium Battery

CAUTION! DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY

REPLACED. REPLACE ONLY WITH THE SAME OR EQUIVALENT

TYPE RECOMMENDED BY THE MANUFACTURER. DISPOSE OF

USED BATTERIES ACCORDING TO THE MANUFACTURER'S

INSTRUCTIONS.

11 TX LED

Indicates transmission of information over the Modbus network.

12 RX LED

Indicates data received on the Modbus network

13 Current Sensors

Each current sensor is capable of monitoring conductors carrying up to a

maximum of 50 amps.*

* The H663SM-42H is capable of monitoring conductors up to a maximum of 100 amps.

8 Baud Rate & Parity Selection Switches

Field selectable RS-485 serial interface control.

(See Chart 1 on page 5)

*For 240VAC Power Connection versio n, order catalog number H663SM-xxE.

Z202833-0K ©2006 Veris Indus tries 10061

Shop for Power Metering products online at:

www.PowerMeterStore.ca

-2--2-

1.877.766.5412

Page 3

INSTALLATION

Panel Board 1

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

LEFT RIGHT

4139373533312927252321191715131197531

42403836343230282624222018161412108642

Channel 4

Channel 2

Channel 3

Channel 41

Channel 1

"

"

"

"

"

"

"

"

"

"

Channel 42

"

"

"

"

"

"

"

"

"

"

64212108181614242220302826363432424038

L EF T R IG HT

Velcro Strap

holds cable

wire in plac

e

Branch circuit wir

e

6' Lead

64212108181614242220302826363432424038

Physical Installation

1. Snap split-core CT’s on branch circuit wires. (CT’s may need to be staggered).

2. Prepare 120VAC* 50/60Hz power leads and connect to line and neutral

terminals of the acquisition board. Allow wiring length to fit when board is

installed. DO NOT CONNECT LINE VOLTAGE UNTIL LAST STEP!

3. Connect current transformers to interconnection board terminals as shown in

Figure 3.

4. Acquisition Board Installation (see Figure 2)

Find screw holes under panel board in side of chassis or panel. Attach

Data Acquisition Board.

Figure 2

DANGER: Beware of exposed busbars on back o f panelboard when installing circuit boa rd

assembly/mounting bracket. Assure adeq uate clearance between live parts and this prod uct.

*240VAC for H663SM-xxE

Figure 3

Z202833-0K ©2006 Veris Indus tries 10061

Shop for Power Metering products online at:

www.PowerMeterStore.ca

-3--3-

1.877.766.5412

Page 4

INSTALLATION

Data Acquisition Board

11.375"

(289 mm)

1.12"

(28 mm)

5.75"

(146 mm)

Data Acquisition Board

Mounting Bracket Kit

Acquisition and interconnection boards are mounted to the bracket at the factory.

Z202833-0K ©2006 Veris Indus tries 10061

Shop for Power Metering products online at:

-4-

www.PowerMeterStore.ca

1.877.766.5412

Page 5

1

1 2 4 8 16 32 64 128

O

N

1

CONFIGURATION

1

X

X

X

X

X

X

2

On

Off

3

Off

On

Off

On

4

Off

Off

On

On

5 6 7

X

X

X

X

X

X

8

X

X

X

X

X

X

2400 Baud

4800 Baud

9600 Baud

19200 Baud

2 wire

4 wire

Wiring, Baud Rate, Parity

Wi

ring

None

Ev

en

Od

d

Off

Off

On

Off

On

Off

ParityBaud Rate

DESIRED RESULT

Switch #

Baud Rate and Parity Switch Setttings

40

Output Configuration

1. Communications Configuration

Communications parameters for the H663 series are field selectable for your

convenience. Please see Figure 1 (page 2, #8) for selector location. The

following parameters are configurable:

■ Parity: Odd, even or none

■ Wiring: Two or four

■ Baud Rate: 2400, 4800, 9600 or 19200

Chart 1

Example: 2-wire 9600 Bau d No Parity (Default O nly)

2. Address Configuration

Each ModBus device on a single network must have a unique address. The

switch block must be set to assign a unique address before the device is

connected to the ModBus RS485 network. If an address is selected which

conflicts with another device, neither device will be able to communicate.

H663 series can be addressed as any whole number between and including 1-247. Each unit is equipped with a set of 8 dip switches for addressing. See below.

The values of each dip switch are as follows:

1=1

2=2

3=4

4=8

5=16

6=32

7=64

8=128

To determine an address you simply add the values of any switch that is on.

For example:

Switch number 4 has an ON Value of 8 and switch number 6 has an ON Value of 32. (8+32 = 40)

Shop for Power Metering products online at:

See Chart 2 on the following page for a pictorial listing of the first 63 switch positions.

Z202833-0K ©2006 Veris Indus tries 10061

LSB MSB

or

www.PowerMeterStore.ca

-5-

=

=

VALUE

1.877.766.5412

Page 6

ADDRESS SELECTION EXAMPLES

DO NOT

USE ZERO

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40 41 42 43

44 45 46 47 48 49 50 51 52 53 54

55 56 57 58 59 60 61 62 63

Z202833-0K ©2006 Veris Indus tries 10061

Shop for Power Metering products online at:

www.PowerMeterStore.ca

-6-

1.877.766.5412

Page 7

Master (Network Display)

Slave (H663 series)

TX

+

SH

LD

TX

+

RX

+

TX–

RX

–

TX

–

TX

+

SH

LD

TX

+

RX

+

TX

–

RX

–

TX

–

SHIELD

SHIELD

Master or Slave

TX

+

SH

LD

TX

+

R

X

+

TX

–

R

X

–

TX

–

SHIELD

SHIELD

INSTALLATION

1. Connect 2-wire or 4-wire Modbus RS485 network (see Figure 4).

NOTES

A. The Modbus cable should be mechanically secured where it enters the

electrical panel.

B. All Modbus devices should be connected together in a daisy-chain fashion,

and properly terminated.

C. The Modbus cable should be shielded twisted pair wire such as Belden 1120A.

The cable must be voltage rated for the installation.

WARNING: After wiring the

Modbus cable, remove all scraps

of wire or foil shield from the

electrical panel. This could be

DANGEROUS if wire scraps

come into contact with

high voltage conductors!

2-Wire

4-Wire

2. Use Software Configuration Tool to set up breaker size, warning levels, and alarm levels.

3. Power Connection

Disconnect and lock out power source before making any connec tions. Connect 2-wire 120 VAC power to

power terminals. (see #5 on page 2 for location) Obser ve polarity.

SERVICE

Changing the Lithium Battery

1. Normal life expectanc y is approximately 5 years.

2. Disconnect and lock out power to panel.

3. Disconnect and lock out 120 V* power source to Data Acquisition Board.

4. Remove old lithium battery. Take care not to short battery terminals.

5. Replace with new lithium battery. (See specifications for battery type)

6. Reconnect 120V* power source to Data Acquisition Board.

7. Reconnect power.

Note: Do not dispose of lithium battery in fire. Use local recycling facility to dispose of lithium batteries.

Changing the Fuse

1. Disconnect and lock out power.

2. Disconnect and lock out 120V* power source to Data Acquisition Board.

3. Remove old fuse.

4. Replace with new fuse (see specifications for fuse type).

5. Reconnect 120V* power source to Data Acquisition Board.

6. Reconnect power.

7. Check “Alive” LED for proper function (See Figure 1, #3 on page 2 for location).

*240VAC for H663SM-xxE

**If fuse blows repeatedly, check power sou rce to ensure that it is a stable 120VAC source.

Figure 4

Z202833-0K ©2006 Veris Indus tries 10061

Shop for Power Metering products online at:

www.PowerMeterStore.ca

-7-

1.877.766.5412

Page 8

SPECIFICATIONS

General

Operating Temp. Range ......................................... 0 to 60ºC (<95%RH, non-condensing)

Storage Temp. Range ............................................. -40ºC to 70ºC

Power Source ......................................................... 120 VAC (+10/-25%), line-to-neutral, 50/60 Hz. (240VAC for H663SM-xxE)

Measured Current I nputs

Number of Channels ............................................... 42

Frequency .............................................................. 50/60 Hz.

Sample Frequency ................................................. 1280 Hz.

Update Rate ........................................................... 1.2 sec

Accuracy .................................................................±5% from 5A to 50A

10A to 100A (H663SM-42H only)

Connection to Conduc tor ....................................... Inductive split-core CT

Network Commun ications

Type ........................................................................ Modbus RTU

Connection .............................................................DIP switch-selectable 2-wire or 4-wire

Address .................................................................. DIP switch-s electable address 1 to 247

Baud Rate ...............................................................DIP switc h-selectable 2400, 4 800, 9600, 19200

Parity .....................................................................DIP switch-selectable NONE, ODD, EVEN

Communication Format ......................................... 8-data-bits, 1-start-bit, 1-stop-bit

Termination ........................................................... 5-position depluggab le connector

Defaults

Warning Register ...................................................60% of current sensor max. (configurable)

Alarm Register ....................................................... 70% of current sensor ma x. (configurable)

Breaker Size Register .............................................. 20A

Dimensions

Circuit Board(L x W) .................................................7.25” x 5.75”

Split-Core C T’s (6’ leads) ........................................... 1.04" x 1.04" x 1.58"

Lithium Bat tery Life ................................................. 5 years (Replace with t ype CRF 1220 or equiv.)

CAUTION! DANGER OF E XPLOSION IF BATTERY IS INCORRECTLY REPLACED. REPLACE

ONLY WITH THE SAME OR EQUIVALENT TYPE RECOMMENDED BY THE MANUFACTURER. DISPOSE OF

USED BATTERIES ACCORDING TO THE MANUFACTURER'S INSTRUC TIONS.

Measured Currents .............................. Current Range 0-50A or 0 -100A (H663SM-42H)

Primary Fusing .................................... 250VAC/100mA, 5x20mm, (if equipped)Lit tlefuse 218 series or equivalent

Safety

UL Listed under standard 508 as an “open type device”.

Critical components evaluated to UL 1950

U.S. Patent Numb er 6,330,516

Z202833-0K ©2006 Veris Indus tries 10061

Shop for Power Metering products online at:

www.PowerMeterStore.ca

-8-

1.877.766.5412

Loading...

Loading...