Page 1

Minimize Installed Cost

SPECIFICATIONS

Current Monitoring | VFD Current Switch: Auto Calibration

H614

Automatically Learns At Initial Power-Up

H614

Maximize Reliability

The Hawkeye H614 is a microprocessor based, self-learning, selfcalibrating current-sensitive switching device designed for use with VFD

systems. At initial power-up, the H614 automatically learns the average

current on the line with no action required by the installer. Once a

current is learned, the switch monitors for changes in current greater

than ±20% of the learned load. When calibrated for a given VFD system,

the H614 is tolerant of gradual drifts in frequency due to expected

conditions, such as an accumulation of debris in a filter, while still

detecting a sudden drop due to a potential abnormal system condition

(e.g., belt loss or other mechanical failure).

TM

Microcontroller

based learning

technology

Automatically learns load upon

initial power-up…minimizes

calibration labor

Automatic trip

point

Automatic trip point (1.5 to 150

Amps, 12 to 115 Hz)…detect

abnormal events

Under- and

over-load

Microcontroller based learning

technology…automatically learns

load

APPLICATIONS

• Monitoring fans, pumps,

motors, and other electrical

loads for proper operation

• Detecting belt loss and motor

failure…ideal for fan and pump

status

Saves space

Small size fits easily inside small

starter enclosures

100% solid state

100% solid state…no moving

parts to fail

Flexibility

Removable mounting bracket for

installation flexibility

• Verifying lighting circuit loads

• Monitoring critical motors

(compressor, fuel, etc.)

• Monitoring industrial process

equipment status (OEM)

Sensor Power

Response Time 1 sec.

Learn Time

Frequency Range in Conductor 12 to 115 Hz

Temperature Range -15 to 60 °C (5 to 140 °F)

Humidity Range 10 to 90% RH non-condensing

Alarm Limits

Normal-to-Alarm Status Output Delay Approx. 7 sec.

Alarm-to-Normal Status Output Delay 1 sec. nominal

O Delay <30 sec. nominal

Contact Ratings 30 Vac/dc, 1 A

Insulation Class 600 Vac (UL); 300 Vac RMS (CE4)

Terminal Block Wire Size 24 to 14 AWG (0.2 to 2.1 mm2)

Terminal Block Torque 3.5 to 4.4 in-lbs (0.4 to 0.5 N-m)

Induced from monitored

conductor

15 sec. learn period after

frequency stabilizes

1

±20% of learned current in every

5 Hz freq. band

TM

2

3

WARRANTY

Limited Warranty 5 years

AGENCY APPROVALS

Agency Approvals

1. VFD systems generate f ields that can disrupt electrical devices. Ensure that these fields

are minimized and are not affec ting the sensor.

2. The H614 is not intended for use in applications where the current is expected to

fluctuate by more than 20% due to acceptable causes other than VFD driven changes.

3. If the H614 experiences a momentary loss of power, the Alarm-to- Normal output delay

may exceed 1 sec.

4. The CE mark indicates RoHS2 compliance. Please refer to the CE Declaration of

Conformity for additional details.

Specification Note: For CE compliance, conductor shall be insulated according to

IEC 61010-1

The product design provides for basic insulation only. Use wire with minimum 75°C rated

insulation. Do not use the LED status indicators as evidence of applied voltage.

This sensor detects abnormal operation by look ing for sudden changes in current across

the entire frequency range. In Learn mode, the sensor calculates a margin 20% above and

20% below the learned frequency curve. An abnormal condition in the circuit is one that

falls outside this margin.

UL508 open device,

CE: EN61010-1, CAT III,

Pollution Degree 2

HQ0002067.G 0117

Page 2

Fan or Pump

CONTROL

Digital

Input

Motor

VERIS INDUSTRIES

Portland, Oregon 97223

1-800-354-8556

Hawkeye

®

614

VFD

BYPASS DEVICE

(if used)

Current Monitoring | H614Current Monitoring | VFD Current Switch: Auto Calibration

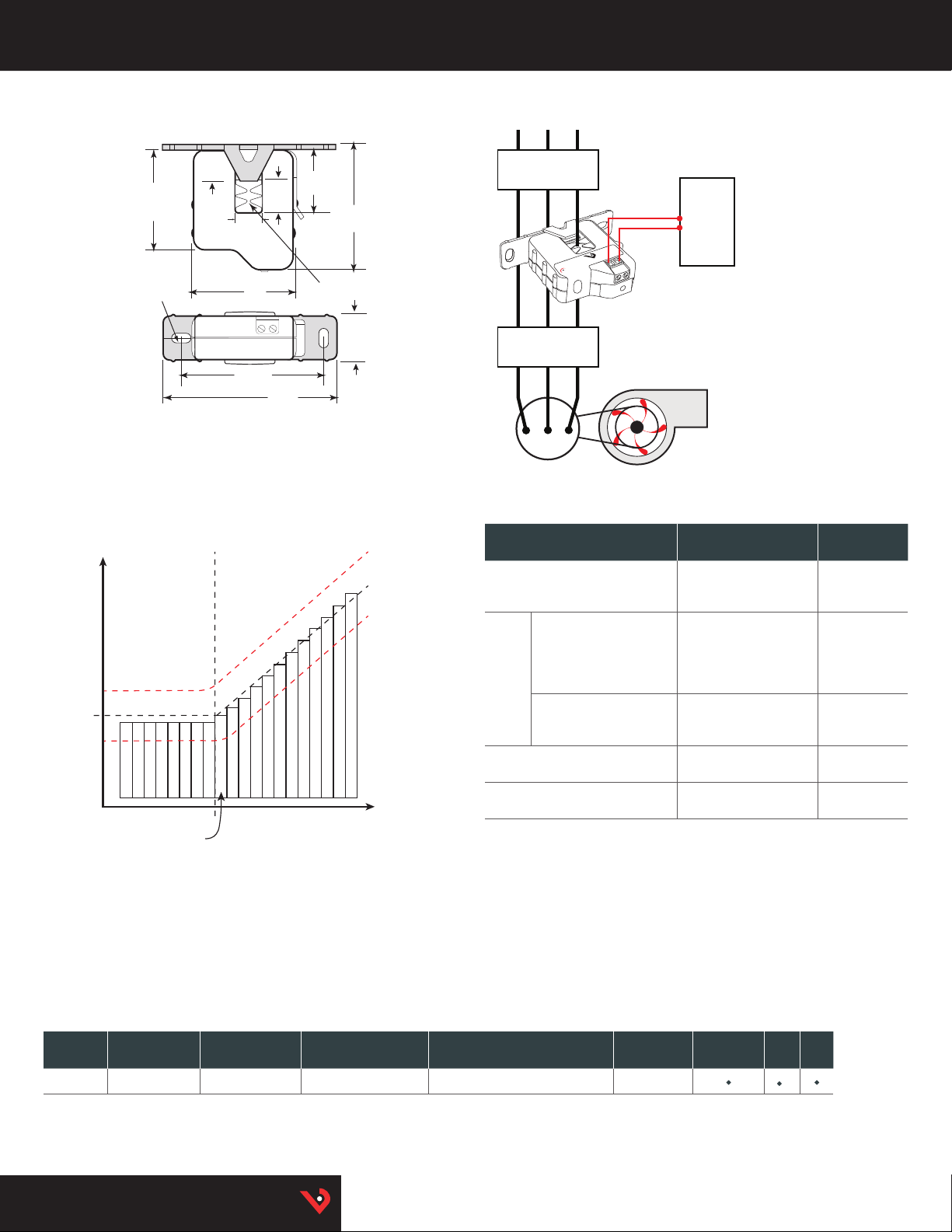

DIMENSIONAL DRAWING

Removable Mounting Bracket

0.6"

(16 mm)

2.1"

(54 mm)

0.4” x 0.2”

(10 mm x 5 mm)

Slot (2x)

* Terminal block may extend up to 1/8” over the height dimensions shown.

0.5"

(13 mm)

2.1"

(54 mm)

2.9"

(74 mm)

PRODUCT FUNCTIONS

0.7"

(18 mm)

3.5"

(89 mm)

1.2"

(31 mm)

Self-gripping Iris

2.5" *

(64 mm)

1.0"

(26 mm)

+20%

(upper trip limit)

Constant Torque Constant Power

Normal

Operation

-20%

(lower trip limit)

Learned Current

Elbow

Current

Band 1

Band 2

Band 3

Band 4

Band 5

Band 6

Elbow

Band

Band 7

Band 8

Band 9

Band 11

Band 10

Band 13

Band 12

Frequency

Band 14

Band 15

Band 16

Band 17

Band 18

Band 19

Band 20

WIRING DIAGRAM

SENSOR MODE

Learning Mode (first 15 sec

of operation after frequency

On/

Off

Status

only

stabilizes)

Learn mode incomplete.

VFD system does

not meet abnormal

condition detection

criteria

Current is not adequate

for the device to detect

abnormal conditions

Status OK

Alarm

NOTE: The H614 is not

intended for use in staged

pump, variable inlet vane,

and other applications in

which the amperage changes

under normal operation,

independent of frequency.

NOTE: (Optional) For added

sensitivity in detecting

amperage changes, use H614

devices on all three phases of

the VFD

STATUS LED

BLINK PATTERN

Alternating Red/Green

(1 per sec.)

Green blink

(5 times per sec. after 15

sec of stable frequency)

No LED Closed

Green blink

(1 per sec.)

Red blink

(1 per sec.)

CONTAC T S

Closed

Closed

Closed

Open

HOW IT WORKS

During setup, the H614 automatically determines the normal

amperage and frequency prole and stores it in memory. Then the

microprocessor monitors for amperage changes greater than ±20%

of this learned curve, indicating a potential system failure.

ORDERING INFORMATION

1. If the current is above 1.5 A, but neither LED is illuminated, the H614 is considered to be in on/off status mode.

2. Listed for use on 75°C insulated conduc tors.

HQ0002067.G 0117

MODEL

AMPE RAG E

RANGE

H614 1.5 to 150 A

FREQUENCY

RANGE

1

12 to 115 Hz N.O. 1.0 A @ 30 Vac/dc ±20% in each of 20 bands Split-core •

STATUS OUTPUT

TM

NOMINAL TRIP POINT

TARGET RANGE

USAGE EXAMPLE

The H614 is designed for HVAC fan and blower systems, as well as some

single stage pumping systems involving consistent viscosity liquids. If an

H614 is installed on one phase of the VFD, it detects changes in that phase

that result from the VFD compensating for changes elsewhere in the system.

Alternatively, for increased sensitivity, H614s can be used on all three phases

for immediate detection of phase balance changes anywhere in the system.

HOUSING

STAT U S

LED

UL CE

2

•

•

Loading...

Loading...