Page 1

SPECIFICATIONS

Minimize Installed Cost

Current Monitoring | Current Switches: Auto Calibration, Narrow Limit Process Control

H10F

Automatically Learns at Initial Power-Up

H10F

Maximize Reliability

The Hawkeye TruStat H10F is a microprocessor based, self-learning, selfcalibrating current switch. It provides calibration-free status, for both

under-current and over-current conditions. At initial power-up,

the H10F automatically learns the average current on the line with

no action required by the installer. Once a current is learned, the switch

monitors for changes in current greater than ±20% of the learned load.

TM

Adjustable trip

point

Automatic adjustable trip point

(3.5 to 100 A)…precise control of

current trip point

100% solid state

No moving parts to fail

Microcontroller

based learning

technology

Automatically learns load upon

initial power-up…minimizes

calibration labor

APPLICATIONS

• Monitoring fans, pumps,

motors, and other electrical

loads for proper operation

• Detecting belt loss and motor

failure…ideal for fan and pump

status

Reduced costs

Automatic calibration…reduced

errors and installation costs

Flexibility

Removable mounting bracket for

installation flexibility

• Verifying lighting circuit loads

• Monitoring critical motors

(compressor, fuel, etc.)

• Monitoring industrial process

equipment status (OEM)

Sensor Power

Isolation

Temperature Range -15 to 60 °C (5 to 140 °F)

Humidity Range 10 to 90% RH non-condensing

Frequency Range 50/60 Hz

Trip Point Calibration Learn Period 30 sec. learn period

Normal-to-Alarm Status Output Delay 1 second max.

Alarm-to-Normal Status Output Delay 30 sec. nominal

Status Output

Terminal Block Wire Size 24 to 14 AWG (0.2 to 2.1 mm2)

Terminal Block Torque 3.5 to 4.4 in-lbs (0.4 to 0.5 N-m)

WARRANTY

Limited Warranty 5 years

AGENCY APPROVALS

Agency Approvals

Induced from monitored

conductor

600 Vac RMS (UL); 300 Vac RMS

1

(CE

)

2

±20% of learned current to trigger

alarm; ±15% of learned current to

release alarm (see graph)

UL 508 open device listing;

CE: EN61010-1, CAT III,

Pollution Degree 2,

basic insulation

PRODUCT FUNCTIONS

ALARM RESET

5% Typical

Upper Alarm

Trip Limit +20%

NOMINAL

LEARNED

CURRENT

NORMAL

ØAAC

POWER

ON

1 . The CE mark indicates RoHS2 compliance. Please refer to the CE Declaration of

Conformity for additional details.

2. If current switch experiences a momentary loss of power, 30 second delay may or may

not apply.

Note: Do not use the LED status indicators as evidence of applied voltage.

LEARN

(MODE)

30 SEC

(CURRENT

MONITOR

MODE)

1 SEC. DELAY 30 SEC. DELAY

ALARM

(MODE)

NORMAL

(CURRENT

MONITOR MODE)

POWER LOSS

ALARM (MODE)

ØAAC

Normal

Current

Lower Alarm

Trip Limit -20%

TM

HQ0001757.F 0117

Page 2

Current Monitoring | H10FCurrent Monitoring | Current Switches: Auto Calibration, Narrow Limit Process Control

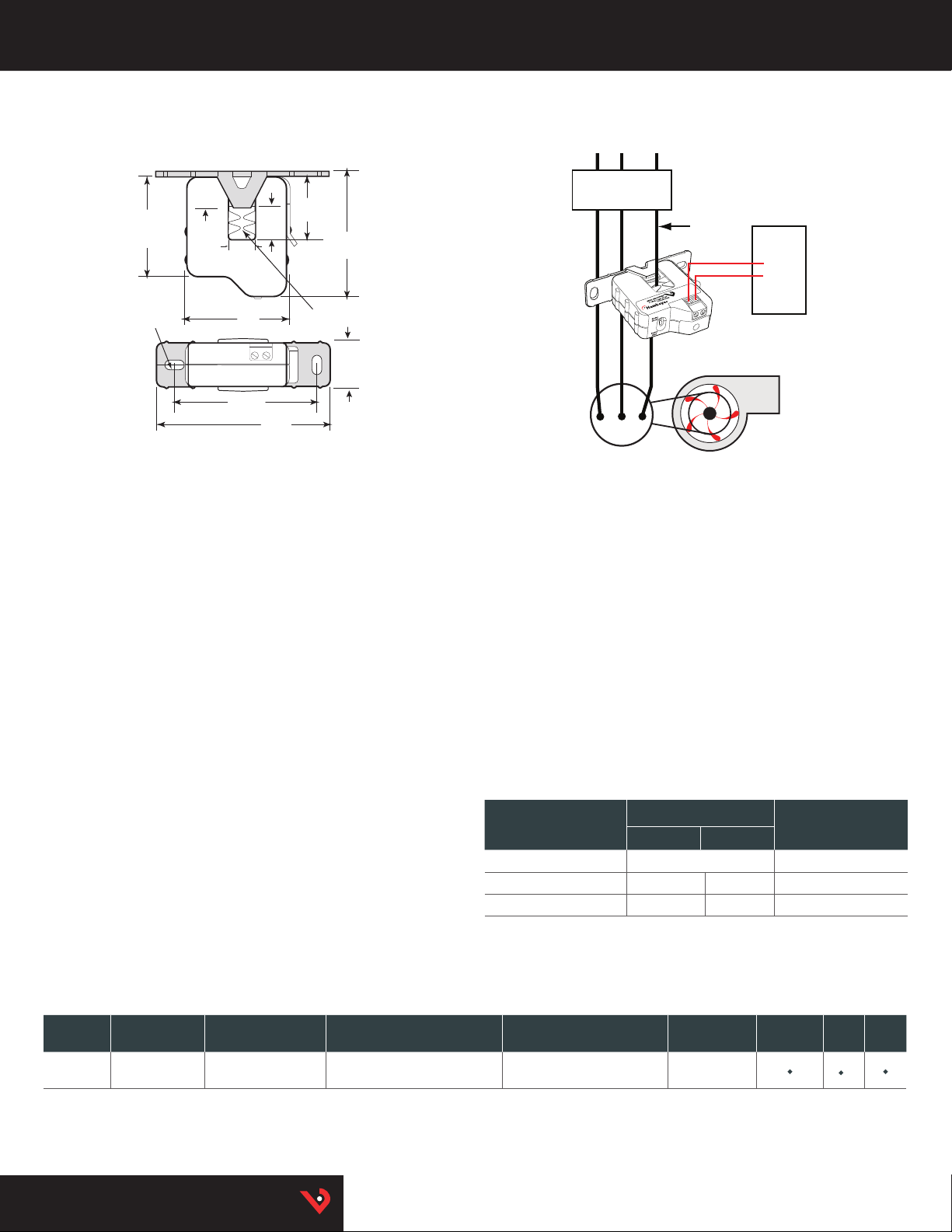

DIMENSIONAL DRAWING MONITORING FAN/PUMP MOTORS FOR

POSITIVE PROOF OF FLOW (H11D)

Wiring Diagram

Removable Mounting Bracket

0.6"

(16 mm)

2.1"

(54 mm)

0.4” x 0.2”

(10 mm x 5 mm)

Slot (2x)

* Terminal block may extend up to 1/8” over the height dimensions shown.

0.5"

(13 mm)

2.1"

(54 mm)

2.9"

(74 mm)

0.7"

(18 mm)

3.5"

(89 mm)

1.2"

(31 mm)

Self-gripping Iris

2.5" *

(64 mm)

1.0"

(26 mm)

HOW IT WORKS

The compact split-core H10F current switch monitors a learned load current

to detect power loss and electrical overload. The push-button initiated

LEARN MODE allows resetting of the monitored current when the load

changes due to system alterations.

Learn Mode

• Unit automatically enters LEARN MODE upon initial power-up

• Auto-calibration is achieved by averaging the load current for

30 seconds

• During this stage, green and red LEDs alternately blink on/o

• STATUS OUTPUT contacts are closed

• LEARN MODE may be initiated manually

Normal Mode

• Initiated after the 30-second learning period, or immediately upon

power-up if sensor has already learned a load

• The red LED is o, and the green LED is blinking

• STATUS OUTPUT contacts are closed

CONTACTOR

Insulated

conductor

only

Motor

DDC CONTROLLER

Digital

Input

Pump or Fan

Alarm Mode

• The ALARM state signals low current, high current, or power loss

conditions

• Initiated within 1 second when any load current excursion exceeds a

nominal ±20%

• ALARM will persist until the load current returns to within a nominal

±15% of the learned current value, or when power is restored to normal

• The 5% ALARM-to-NORMAL MODE reentry margin prevents alarm

signal oscillations. This feature is enhanced by a 30 second delay,

to insure true nominal load current conditions when returning to

NORMAL MODE from an ALARM state

• The green LED is o, and the red LED blinks

• STATUS OUTPUT contacts are open

OPERATING MODES

STAT U S L E DS

STATUS OUTPUT

GREEN RED

LEARN (30 secs) Alternating Blink On/Off Contacts Closed

NORMAL Blink Off Contacts Closed

ALARM* Off Blink Contacts Open

* 1 sec maximum after detection.

ORDERING INFORMATION

MODEL

H10F 3.5 to 100 A

1. For best performance, monitor 5 A or more current. At currents less than 5A, these ranges are approximate. 2. Listed for use on 75°C insulated conductors.

HQ0001757.F 0117

AMPE RAG E

RANGE

STATUS OUTPUT

N.O.1.0 A @ 30 Vac/

dc

NOMINAL TRIP POINT

TARGET RANGE

±20% ±15% Split-core •

TM

1

NOMINAL ALARM

RESET RANGE

1

HOUSING

STAT U S

LED

UL CE

2

•

•

Loading...

Loading...