Page 1

Electrical and Hazardous

Flow Monitoring | Ultrasonic Flow and Energy BTU Meter

FSR & FST SERIES

Accurate Readings From Outside the Pipe

FST4R Transducer

FSR Monitor

Temperature Sensors

FST1, FST2, FST3

Transducers

Ultrasonic Flow and energy metering systems clamp onto the outside

of pipes without contacting the internal liquid. The technology has

many advantages over other products including low-cost installation,

no pressure head loss, no moving parts to maintain or replace,

excellent fluid compatibility, and a wide bi-directional measuring range

that provides reliable readings even at very low and very high flow

rates. Veris ultrasonic metering products are available in a variety of

configurations that permit selection of an ideal system, no matter what

the application.

The monitor is available in two versions: standard flow and energy flow.

Energy versions are used in conjunction with dual clamp-on or insert

RTD temperature sensors. The energy flow meter calculates energy

usage in BTU or tons, and it is ideal for retrofit, chilled water, and other

HVAC and building automation applications.

SPECIFICATIONS

SYSTEM

Velocity Range All models: Bidirectional flow

Flow Accuracy FST1, FST2, FST3: 1” and larger units: 1% of

Flow Repeatability ±0.01% of reading

Flow Sensitivity 0.001 FPS (0.0003 MPS)

Temperature Accuracy

(Energy Versions Only)

Temperature Sensitivity 0.025 °C (0.05 °F)

Temperature Repeatability ±0.05% of reading

MONITOR

Power AC: fused, 95 to 264 Vac, 47 to 63 Hz at 17 VA

FST1, FST2, FST3: 2 to 40 FPS (0.6 to 12.1 MPS);

(min. 2’ per sec.)

FST4, FST5: 1 to 40 FPS (0.3 to 12.1 MPS); (min.

1’ per sec.)

reading from 4 to 40 FPS (1.2 to 12 MPS); ±

0.04 FPS (0.012 MPS) at rates < 4 FPS 91.2 to 12

MPS). Units smaller than 1”: 1% of full scale.

FST4, FST5 : 1% of reading at rates > 1 FPS (0.3

MPS); within 0.01 FPS (0.003 MPS) at lower rates

0 to 100 °C (32 to 212 °F); Absolute 0.25 °C

(0.45 °F), Difference 0.1 °C (0.18 °F)

max.; DC: auto-reset fuse, 10 to 28 Vdc at 5.0 W,

reverse polarity and transient

supression protected

FST4, FST5 Transducer

Wide range of

measurable fluids

Water, brine, sewage, ethylene

glycol, glycerin, and more…

flexibility in commercial and

Communicating

Modbus RTU and BACnet/IP

communications available…easy

integration with existing data

collection systems

industrial applications

Bi-directional

Measure forward flow, reverse

flow, and net total

Rugged housing

Compact, rugged aluminum

housing…long service in harsh

environments

No fluid contact

Safe from fouling and damage

LCD display

Easy to read

from system pressure

APPLICATIONS

• Commercial and industrial

installations involving clean

liquids or liquids containing

Display Two-line backlit LCD

Engineering Units (User

Configured) Rate

Energy Version BTU, MBTU, MMBTU, Ton

Time Sec, min, hr, days

Totalizer Gal, liters, million gal, ft3, m3, acre-ft, oil barrels

Ambient Conditions -40 to +85 °C (-40 to +185 °F), 0 to 95% RH

Response Time (Flow) 0.3 to 30 sec, user configured, for 10% to 90%

Security Keypad lockout, user selected 4-digit password

TRANSDUCERS

Environment IP 67

Pipe Surface Temperature FST1, FST2, FST3: -40 to +85 °C (-40 to +185 °F)

Ambient Conditions -40 to +85 °C (-40 to +185 °F),

Software Compatibility Windows® 95, Windows® 98, Windows® 2000,

WARRANTY

Limited Warranty 1 year

AGENCY APPROVALS

MET

C US

Location Safety

E112904

(FSR Only)

Note: The CE mark indicates RoHS2 compliance.

Gal, liters, million gal, ft3, m3, acre-ft, oil barrels

(42 gal); liquor barrels (31.5 gal), ft, m, lb, kg

(42 gal), liquor barrels (31.5 gal), lb, kg

(non-condensing)

step change in flow

code

FST4, FST5: -40 to +121 °C (-40 to +250°F);

0 to 95% RH (non-condensing)

Windows® XP, Windows® Vista

®

small amounts of suspended

solids or aeration

TM

HQ0001789.G 0117

Page 2

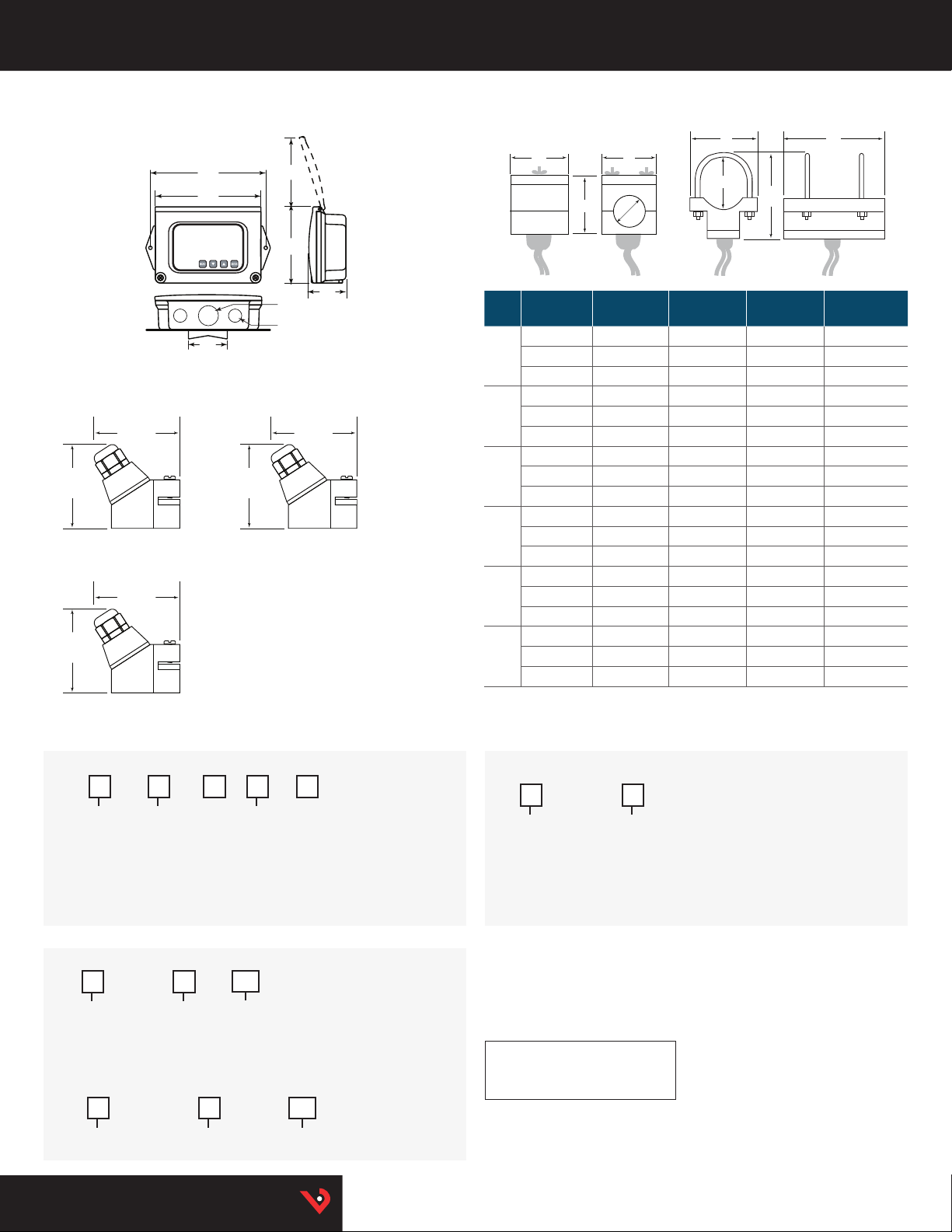

FSR & FST Series

(2” Pipe Only)

3.0”

3.0”

3.4”

Flow Monitoring | FSR & FST Series

FSR MONITOR

Dimensional Drawing

FST4 TRANSDUCER

Dimensional Drawing

(76.2 mm)

2.75”

(69.8 mm)

FST4R TRANSDUCER

Dimensional Drawing

(76.2 mm)

2.75”

(69.8 mm)

6.4”

(163 mm)

6.0”

(153 mm)

1.4”

(35 mm)

4.1”

(105 mm)

4.3”

(110 mm)

0.75”

(19 mm)

2x 0.5”

(13 mm)

FST5 TRANSDUCER

Dimensional Drawing

(86.4 mm)

2.94”

(74.7 mm)

2.1”

(53 mm)

FST1, FST2, FST3 TRANSDUCERS

Dimensional Drawing

C

PIPE

SIZE

1/2”

3/4”

1”

1 1/4”

1

1/2”

2”

1. U-bolt only.

2. Varies due to U-bolt f eature.

PIPE

MATERIAL

ANSI 2 .46” (63 mm) 2.36” (60 mm) 2.66” (68 mm) 0.840 (22 mm)

Copper 2.46” (63 mm) 2. 36” (60 mm) 3.33” (85 mm) 0.625” (16 mm)

Tub ing 2.46” (63 mm) 2.28” (58 mm) 3.33” (85 mm) 0.500 ” (13 mm)

ANSI 2 .46” (63 mm) 2.57” (66 mm) 2.66” (68 mm) 1.050” (27 mm)

Copper 2.46” (63 mm) 2.50 ” (64 mm) 3.56” (91 mm) 0.875” (23 mm)

Tub ing 2.46” (63 mm) 2.50 ” (64 mm) 3.56” (91 mm) 0.750” (19 mm)

ANSI 2 .46” (63 mm) 2.92” (75 mm) 2.86” (73 mm) 1.315” (34 mm)

Copper 2.46” (63 mm) 2.87 ” (73 mm) 3.80” (97 mm) 1.125” (29 mm)

Tub ing 2.46” (63 mm) 2 .75” (70 mm) 3.80” (97 mm) 1.000 ” (26 mm)

ANSI 2 .79” (71 mm) 3.18” (81 mm) 3.14” (80 mm) 1.660 ” (43 mm)

Copper 2.46” (63 mm) 3.00 ” (77 mm) 4.04” (103 mm) 1.375” (35 mm)

Tub ing 2.46” (63 mm) 3.00 ” (77 mm) 4.04” (103 mm) 1.250” (32 mm)

ANSI 3. 02” (77 mm) 3.42” (87 mm) 3.33” (85 mm) 1.900 ” (49 mm)

Copper 2.71” (69 mm) 2.86” (73 mm) 4. 28” (109 mm) 1.625” (42 mm)

Tub ing 2.71” (69 mm) 3 .31” (85 mm) 4 .28” (109 mm) 1.500 ” (39 mm)

ANSI 3.71” (95 mm) 3.42” (87 mm) 5.50” (140 mm) 2. 375” (61 mm)

1

Copper 3.71” (95 mm) 3.38 ” (86 mm) 5.50” (140 mm) 2 .125” (54 mm)

Tub ing 3.21” (82 mm) 3. 85” (98 mm) 4.75” (121 mm) 2.000” (51 mm)

A

B

D

A B C D

ORDERING INFORMATION

Monitors Energy/BTU Included Temp. Sensor

Typ e

FSR

1 = Flow Meter

2 = Energy/B TU

Meter

Transducers:

Pipe Type

FST

1 = ANSI pipe, 1/2 to 2 ”

2 = Copper pi pe, 1/2 to 2”

3 = Rigid tub e, 1/2 to 2Ӡ

Pipe Type

FST

4 = most mate rials 2” to 24”

5 = most mate rials >24”

Power

A = AC, 95-264 V

D = DC

C = AC, 20-28 Vac

Pipe Size

A = 1/2”

B = 3/4”

C = 1”

D = 1 1/4”

E = 1 1/2”

F = 2”

Pipe Size

Output

K

1 = Analog 4 to 20 m A,

Modbus , frequency

or temperature*

2 = 10/100 Base-T,

ethernet, BACnet,

Modbus , TCP-IP

3 = BACnet MS/ TP;

10/100 Base -T,

ethernet, BACnet,

Modbus , TCP-IP

Cable Length

020

= 20 ft. (6.1 m)‡

A

= greater th an 2Ӡ

X

Cable Length

020

= 20 ft. (6.1 m)‡

Temp. Sensor

Cable Length

02 = 20 ft. (6.1 m)

05 = 50 ft. (15.2 m) **

10 = 100 ft. (30.4 m) **

*If Flow ver sion is select ed, this option inc ludes frequen cy; if Energy ver sion is selecte d, this option

includes temperature (not frequency).

**Contact the factory for availability.

† Works wi th most pipe mater ials.

‡ Call for other length options.

Examples:

Exampl e Monitor: FSR1AK1X or FSR2DKX02A

Example Transducer: FST2C020

Temp. Sensor Type

A = Clamp- on RTD (up to 130 °C)

B = Inser tion RTD (up to 260 °C)

A

D

U-Bolt Connection

C

B

2

2

2

HQ0001789.G 0117

TM

Loading...

Loading...