Page 1

EP Series transducers are sold as an open device.

Pressure Monitoring | Electropneumatic Transducers

EP2 SERIES

Micro-Controlled with High-Performance,

Low-Power Coil Poppet Valve Technology

EP2

Field selectable

Field-selectable 4 to 20 mA/

0-5 V/0-10 Vdc input for

application exibility

Quiet operation

Poppet valve technology for quiet

operation

Manual override

Manual override with set and hold

feature…great for commissioning

leaky systems

APPLICATIONS

Multi-point

calibration

Multi-point calibration; 3 to 15 psi

(5-point calibration) and 0 to 20

psi (6-point calibration)

Pressure loss

alarm

Pressure loss alarm provides a

contact closure if the EP3 is unable

to achieve the desired output

within a fixed length of time

Fail-safe vent

Fail-safe vent solenoids bleed

branch pressure on power failure

for added safety

Observe handling precautions for static sensitive

devices to avoid damage to the circuitry which

would not be covered under the factory warranty.

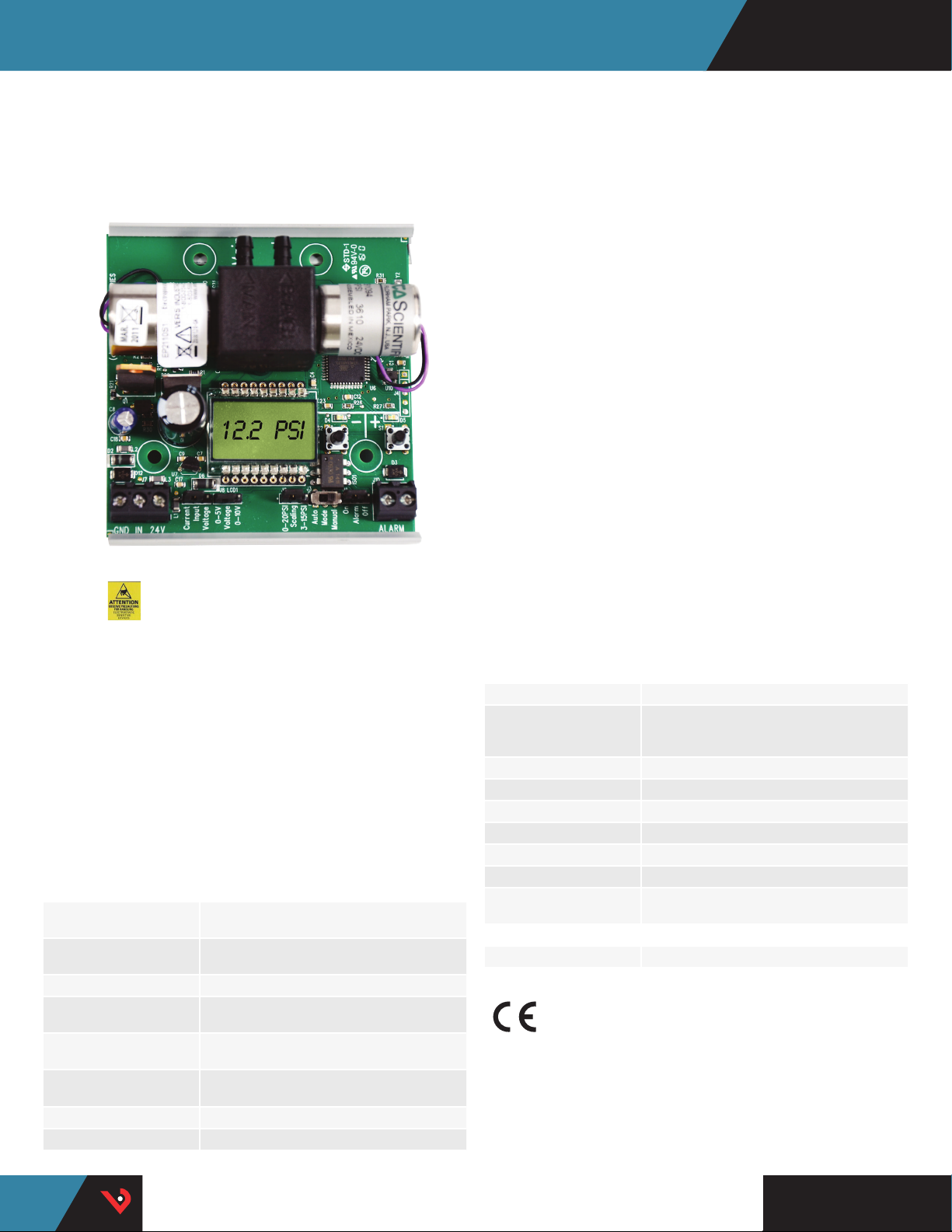

The EP2 Series electropneumatic pressure transducer uses microcontrolled poppet valve technology for highly accurate pressure

sensing in multiple applications. The poppet valves consume no air,

eliminating unnecessary air losses in the system and allowing for stable

and reliable operation. The EP2 comes installed on standard SnapTrack,

and an optional dust cover is available to protect from the environment.

An LCD display and LED indicators make it easy to read system status at

a glance.

SPECIFICATIONS

GENERAL

Input Power Class 2; 24 Vac/dc nominal, 30 Vac max.;

Control Input Class 2; 4 to 20mA/0-5 V/0-10 Vdc;

Input Impedance 4 to 20 mA, 250 Ω; 0-5 V/0-10 Vdc, 10 kΩ

Manual Override Jumper-selectable mode, digital

Alarm Contact 100 mA@30 Vac/dc (pressure loss, manual mode,

Accuracy 1% FS; combined linearity, hysteresis,

Compensated Temp Range -4 to 65 °C (25 to 140 °F)

Temperature Coefficient ±0.05%/°C

150 mA max.

jumper-selectable

pushbutton adjust

jumper selectable)

repeatability

• Hospitals

• Schools

Operating Environment 10 to 90% RH non-condensing

Air Capacity 523 in3/min @ 45 psi (8570 cm3/min @ 310.3

kPa); 333 in3/min @ 20 psi (5456 cm3/min @

137.9 kPa)

Supply Pressure 45 psig max.

Control Range 0 to 20 psig or 3 to 15 psig, jumper-selectable

Pressure Differential 0.1 psig (supply to branch)

Pressure Indication Electronic, 3-1/2 digit LCD

Minimum Tubing Length 15 feet*

Port Connection 1/8” I.D. poly tubing

Media Connection Clean, dry air, or inert gas. Do not use with

oxygen service

WARRANTY

Limited Warranty 5 years

AGENCY APPROVALS

**

Available

*For shorter tubing runs use AA45 Pneumatic Capacitor

EMC Conformance - CE option: Low voltage directive 2014/35/EU; EMC directive 2014/30/EU.

EMC Special Note: Connect this product to a DC distribution network or an AC/DC power

adaptor with proper surge protec tion (EN 61000 -6-1 specification requirements).

**The CE mark indicates RoHS2 compliance. Please refer to the CE Declaration

of Conformity for additional details.

• Pneumatic dampers/actuators

TM

HQ0001828.F 0117

Page 2

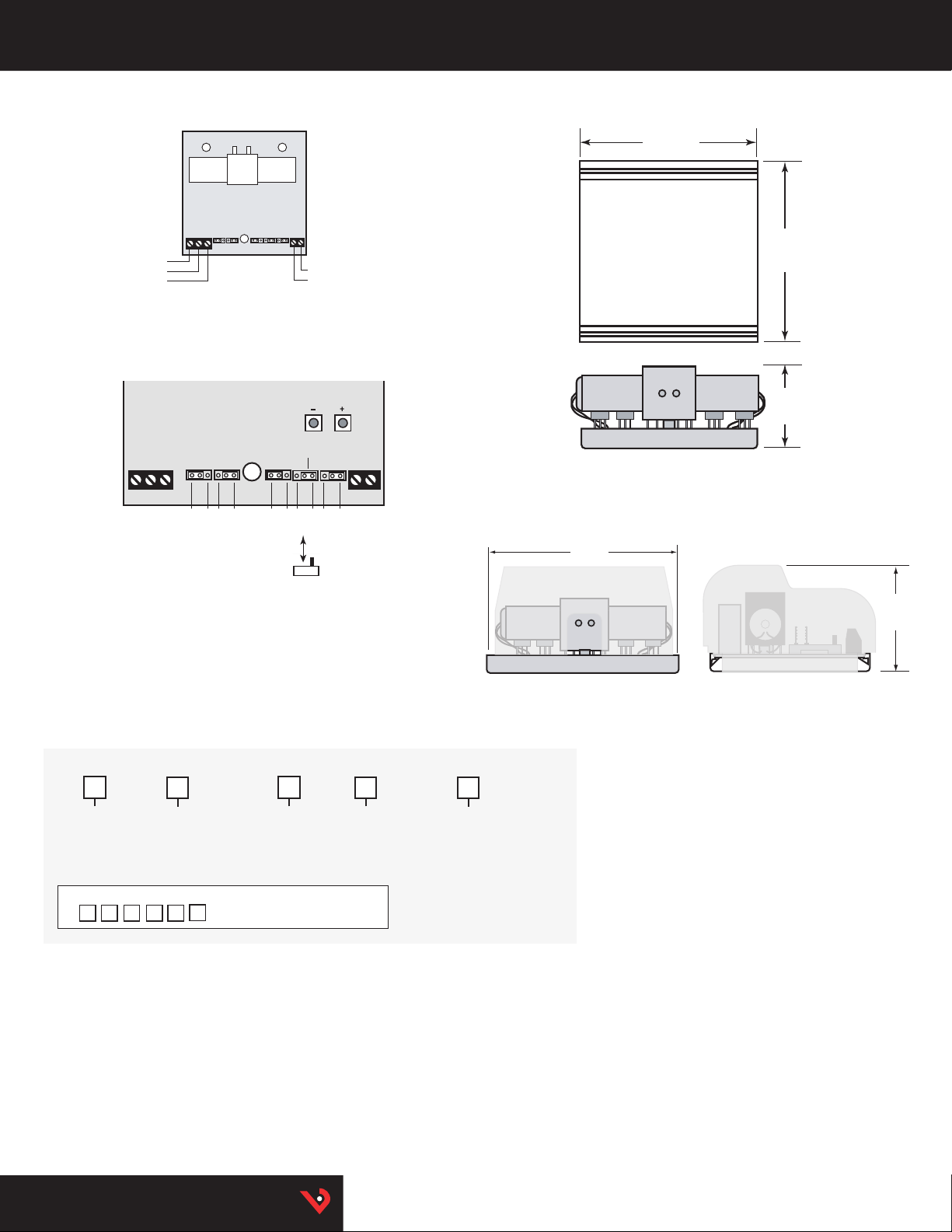

INPUT SIGNAL

Pressure Monitoring | EP2 Series

WIRING DIAGRAM

FROM CONTROL

SYSTEM

GND/COMMON

INPUT SIGNAL

POWER

CONFIGURATION

GND/COM

POWER

INPUT

MODE

Current

VOLTAGE

MODE

0-5V

Voltage

0-10V

TO DIGITAL INPUT - OPTIONAL

PRESSURE LOSS ALARM

MANUAL ADJUST

OPERATION

MODE

PRESSURE

RANGE

0-20psi

Auto

3-15psi

ALARM

MODE

Manual

ON

PRESSURE

OFF

(OPTIONAL)

LOSS

ALARM

DIMENSIONAL DRAWINGS

(84 mm)

DUST COVER

Dimensional Drawings (Front View)

4.9"

(125 mm)

3.3"

3.5"

(89 mm)

1.8"

(46 mm)

Side View

ORDERING INFORMATION

Output

EP2

1

= Selec table

3-15 /0-2 0 psi

Example:

EP 2 1 0 0 S 1

Feedback

0 = None

1 = Pressure Loss Alarm

2 = Manual Mo de Alarm

Option = Sl ide Switch Auto Manua l Mode

Slide Switch Option Available

Fails afe

0 = None

1 = Vent on

Powe r Fail

US or EU

S = Standard

C = CE, includ es

cover plate

If the dust cover is ordered, the EP2 is mounted to a longer Snaptrack .

Option

Blank = non e

1 = Slide Switc h/Auto/Manual

2 = EP Cover Plate

3 = Slide Switch/Auto/M anual

plus EP cover p late

2.1"

(53 mm)

HQ0001828.F 0117

TM

Loading...

Loading...