Page 1

Model AR/e – AR/t

& RTR

Water Treatment Control System

Installation &

Operation Manual

BadgerMeter,Inc.

IMPORTANT !!!! Read this manual before

attempting any installation, wiring or operation.

Service Information (File manual for future reference and service.)

Serial Number Date Installed / /

Service Line Operator

IOM-034-13

Part No. 53400-034

3-09

Page 2

■

SCOPE OF THE MANUAL

This manual contains information concerning the installation,

operation and maintenance of the AR/e with AR/t or RTR Water

Conditioning Control System. To ensure proper performance

of the system, the instructions given in this manual should be

thoroughly understood and followed.

Keep the manual in a readily, accessible location for future

reference.

Changes and additions to the original edition of this manual will

be covered by a "Change Notice" supplied with the manual. The

change notice will explain any differences between the product

received and the product described in this manual.

■

TABLE OF CONTENTS

Page

Unpacking and Inspection .................................................. 2

INSTALLATION

Surface Mounting or Pipe Mounting .................................. 3

Panel Mount ......................................................................... 3

Wiring Precautions & Procedures ...................................... 3

Battery Installation ............................................................. 3

AC Power Connections ........................................................ 3

Transmitter Connections (AR/t & RTR).............................. 4

Lockout Signal Connections ............................................... 4

Remote Start & Stop Connections ..................................... 4

Connecting to Other Equipment ........................................ 5

OPERATION

Forced Regeneration ........................................................... 6

Aborting Regeneration cycle .............................................. 6

Overriding Preset Batch Value ........................................... 6

PROGRAMMING

General Programming Procedures ..................................... 5

Setting For Manual/Auto Operation ................................... 5

Setting AR/e to Type & Size of Meter ................................ 5

Batch Size ............................................................................ 6

Output Signal Duration ....................................................... 6

Start-up Check List ............................................................. 6

■

UNPACKING & INSPECTION

To avoid damage in transit, Badger products are shipped to the customer in special shipping containers. Upon receipt of

the product, perform the following unpacking and inspection procedures.

Note: If damage to the shipping container is evident upon receipt, request the carrier to be

present when the product is unpacked.

a. Carefully open the shipping container following any instructions that may be marked on the box. Remove all cushioning material surrounding the product and carefully lift the

product from the container.

Retain carton and packing material for use in re-shipment

or storage of unit.

b. Visually inspect the product and applicable accessories for

any physical damage such as scratches, loose or broken parts

or any other sign of damage that may have occurred during

shipment.

Note: If damage is found, request an inspection by the

carrier's agent within 48 hours of delivery and file a claim

with the carrier. A claim for equipment damaged in transit

is the sole responsibility of the customer.

■

INSTALLATION

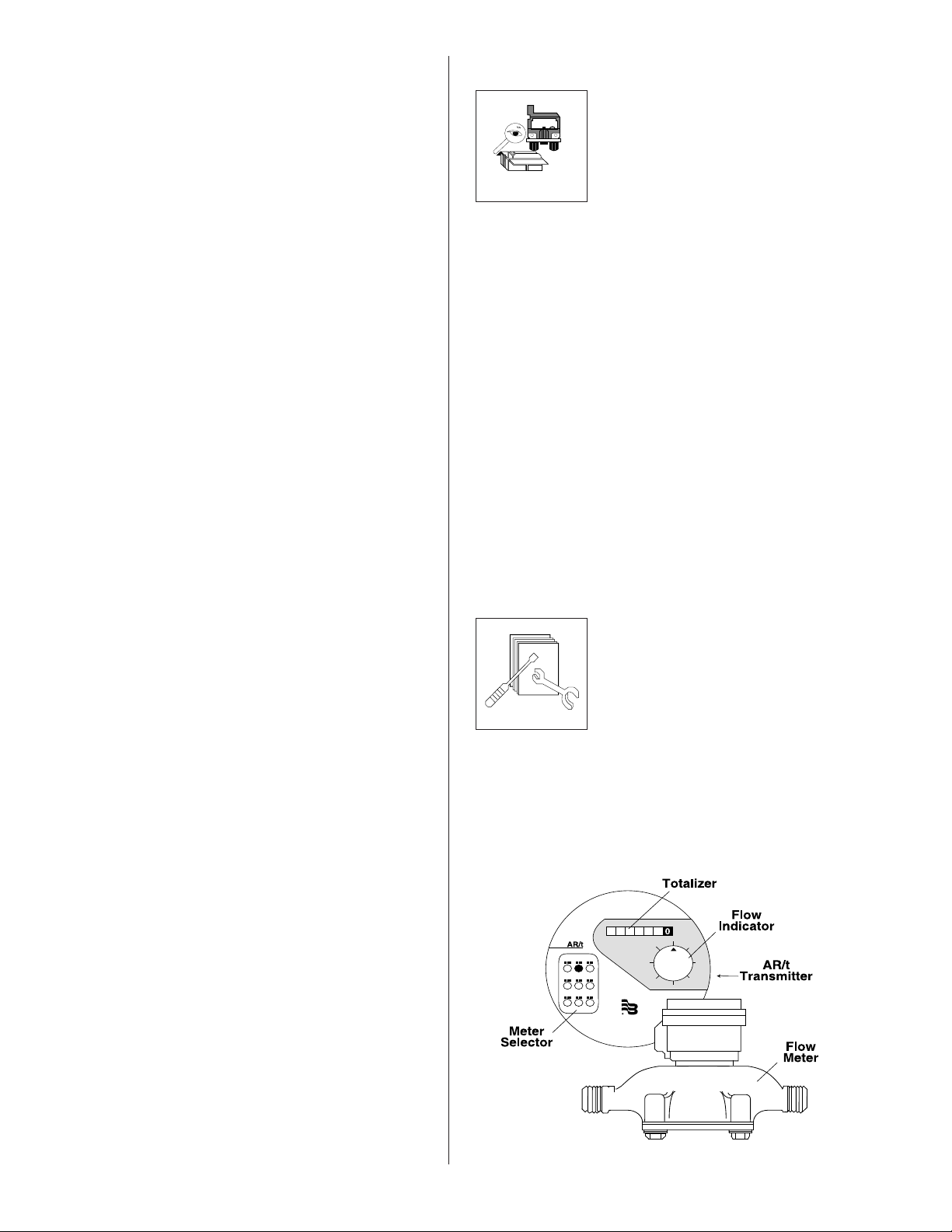

The AR System consists of a Badger Disc

or Turbo meter with the AR/t or RTR

pulse transmitter and the AR/e Condi-

tioning Controller. Normally, the trans-

mitter will be mounted on the meter. It

does not require any additional mount-

ing procedure. All transmitters use a

simple bayonet mount and a seal screw to

attach to the meter.

Note: Always be sure to match the transmitter to the proper

meter. A red dot on the AR/t transmitter dial indicates the

meter model and size for which the transmitter is intended.

The RTR dial face has the model designation of the appropriate meter.

TROUBLESHOOTING

Self-test Procedure .............................................................. 6

Replacement Parts ............................................................... 6

Troubleshooting Chart ........................................................ 7

2

Page 3

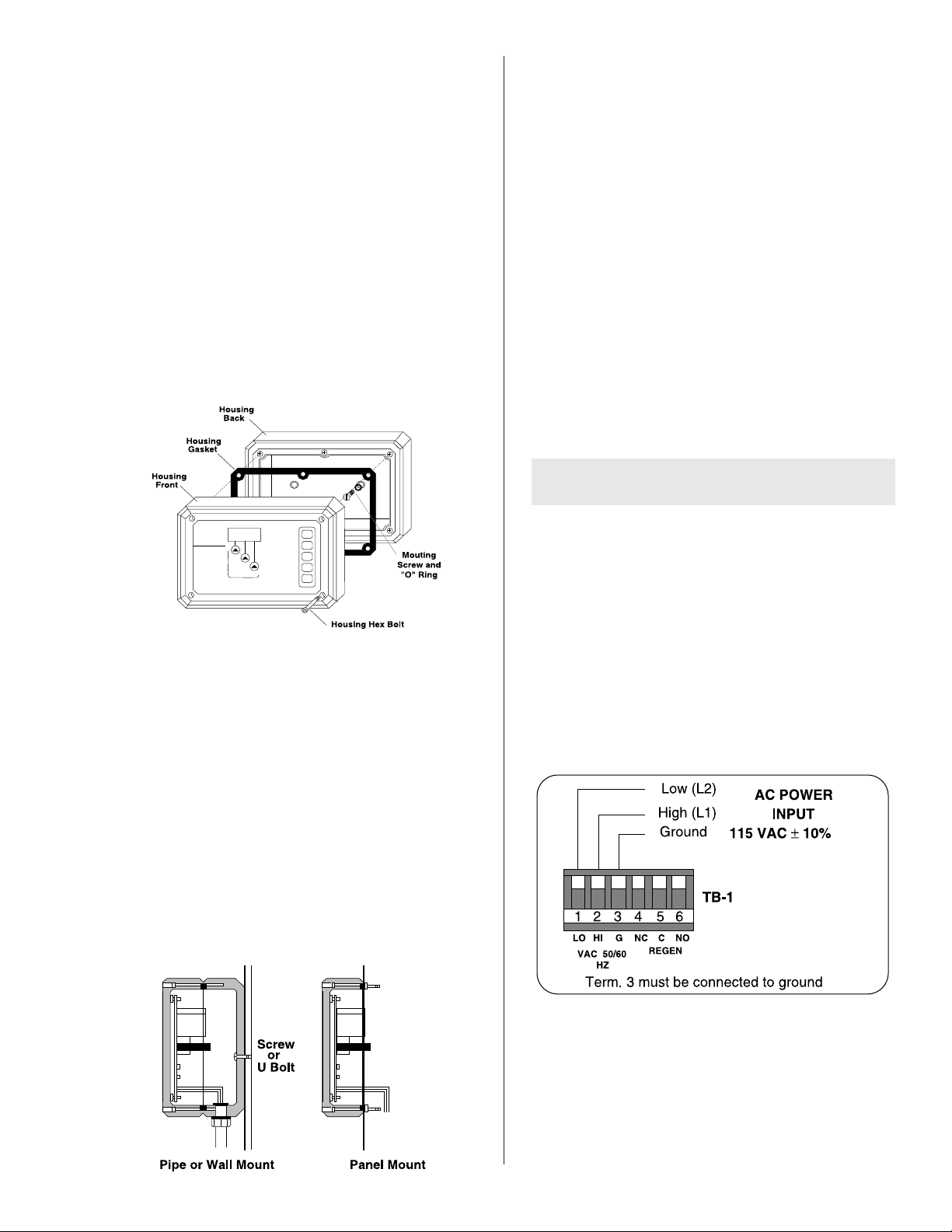

MOUNTING

The AR/e controller comes in a rugged, watertight polycarbonate enclosure intended for wall, pipe or panel mounting. The

package contains two sets of mounting screws and "O" rings

which must be used to maintain the NEMA 4X rating of the

enclosure.

When mounting the unit select a location which has adequate

ventilation, protection against mechanical shock and accessibility for operation and service.

Operating Temperature: 32° to 130° F (0° to 55° C)

Operating Humidity: Up to 85% non-condensing

Using a 5/32'' Allen wrench, remove the four corner screws in

the housing.

Separate the front and rear halves of the housing. Keep the

screws and housing gasket in an accessible location.

WIRING PROCEDURE

Three plug-in terminal block assemblies are provided for

connecting 28 to 14 gauge insulated wire. Solid or stranded

wire can be used.

It is recommended that wiring be carefully planned and laid

out before installation. This will help determine the amount of

space needed for wiring as well as the final location of the unit.

Detail diagrams in this section illustrate proper wiring procedures for all standard and optional functions.

Be sure to comply with the wiring requirements and all applicable electrical codes.

Note: Terminal block assembly unplugs from printed circuit

board for ease in connecting field wiring.

Disconnect all power to the unit before connecting wires to

any of the terminals. Do not use machine power service. A

dedicated or lightning circuit is recommended.

INSTALL BATTERY ON CIRCUIT BOARD ONLY

AFTER WIRING IS COMPLETED.

Wall or Pipe Mount

1. Using the appropriate mounting hardware attach the back

part of the housing to the mounting surface.

2. Wire the unit (see wiring procedures on this page).

3. Carefully place the housing gasket in place and bolt the

front part of the housing to the back part.

Panel Mount

1. Use the housing gasket to mark and drill the panel.

2. Drill a 3/4" hole in the panel for the fuse holder.

3. Wire the unit (see wiring procedures on this page).

4. With the housing gasket properly placed on the front

housing, mount the unit to the panel.

POWER INPUT

The AR/e is designed to work with a 110 VAC power supply. In

case of power failure, the unit will retain all programmed

values and continue to count down (without display or output)

for several hours. When power is restored, the unit will send an

output signal if enough pulses have accumulated during power

outage. If the power down period exceeds the battery capacity,

the last known batch count and other programmed values will

be stored until the power comes back on. (Battery requires a

minimum of 24 hours to recharge from a fully discharged

condition.)

3

Page 4

PULSE INPUT (AR/t)

The AR/t transmitter sends pulse signals to the AR/e controller.

Each pulse represents a specific quantity of water for a

particular meter size.

Meter Pulse Rate

RCDL Models 25, 35 and 40 1 pulse = 1 Gallon

RCDL Models 70, 120, 170 and

Industrial Turbo 2", 3" and 4" 1 pulse = 10 Gallons

Industrial Turbo 6" 1 pulse = 100 Gallons

Reed switch transmitters have two black leads. Connect these

leads to terminals 1 & 2 in any order.

Electronic transmitters have one black lead and one white

lead. Connect these leads as per the diagram at right.

In the Automatic mode, the relay will be energized at the end

of the batch for the amount of seconds programmed via the

SIGNAL DURATION procedure (see page 6). The relay contacts can be wired to a timer or regeneration cycle controller.

REMOTE START & STOP (OPTIONAL)

Remote Start Input

When activated, it will abort a batch before its completion,

initiating tank regeneration at the same time.

In the Manual mode, the output relay will be energized

indefinitely and the display will be reset to zero until the STOP

command is received.

PULSE INPUT (RTR)

The RTR transmitter/register sends pulse signals to the AR/e

controller. Each pulse represents a specific quantity of water

for a particular meter size.

Meter Pulse Rate

RCDL Models 25, 35, 40, & 70 1 pulse = 1 Gallon

RCDL Models 120 and 170 1 pulse = 10 Gallons

RCDL Turbo Series 1 1/2" - 6" 1 pulse = 100 Gallons

These transmitters have one black lead and one red lead.

Connect these leads as per the diagram.

In the Automatic mode, the output relay will be energized for

the programmed duration (see operation section page 6) and

the display will be reset to the batch preset value and continue

to count down when pulses are received.

If a START command is received while the LOCKOUT is active,

the command will be stored in memory and acted upon as soon

as the LOCKOUT signal is terminated.

Remote Stop Input

Is used to terminate the output signal. This function is enabled

after a START command is received or after the output relay

is energized at the end of the batch.

In the Manual mode, it will terminate the output signal, reset

the counter to the batch preset value and enable the transmitter pulse input.

In the Automatic mode, it will only terminate the output signal.

RELAY OUTPUT

The regeneration signal relay is energized at the end of the

batch or when a START command is initiated.

In the Manual mode, the relay will remain energized until the

SIGNAL STOP is initiated. The relay contacts can be used to

activate a warning device to indicate that manual regeneration of the system is necessary.

LOCKOUT INPUT (OPTIONAL)

To avoid simultaneous regeneration of multiple tanks, a lockout signal can prevent a controller from sending a regeneration signal at the end of the batch.

4

Page 5

The regeneration signal will be sent as soon as the lockout

signal is terminated. A lighted decimal point at the lower right

corner of the display will indicate the presence of a lockout

signal. (An open collector/switch contact or a 115 VAC signal

can be used as the lockout signal.) When using a 115VAC

lockout signal, the lockout logic can be reversed. (See settings

for Switch 2 in section below.) If the 115VAC lockout signal is

not used, Switch 2 must be in the off position. The lockout

signal will be ignored if the output is energized.

■

OPERATION

The basic function of the AR/e controller

is to provide a signal to external equipment once a predetermined amount of

water has been measured by the water

meter. The batch is preset and the display counts down to zero. At this point

the output relay is energized for a programmed period of time providing the necessary signal for

manual or automatic regeneration.

The controller is designed to function with a minimum of

operator control after the initial setup procedures. All displays

and controls are located on the front panel for fast, accurate

and convenient operation.

GENERAL PROGRAMMING PROCEDURE

In addition to the LED display and the digit keys, the front

panel of the AR/e controller has two command keys (START

and STOP) and three program keys (PRESET, SIGNAL DURATION and UP-DOWN COUNT).

SELECTING THE MODE OF OPERATION

Select the mode of operation and maximum batch size required for your particular system. (For location of switches,

see page 7.)

Switch 1: ON (Manual operation)

OFF (Automatic operation)

Switch 2: ON (Lockout when 115VAC is not applied

to TB-3)

OFF (Lockout when 115VAC is applied to TB-3)

Note: Switch 2 must be in the off position when not using 115

VAC lockout function.

Switches 3 & 4: (See chart) Set switches for the maximum

batch size for your particular size of meter.

Example: You have a 2" Industrial Turbo meter and your batch

size is 500000 gallons, set switch 3 to the off position, and set

switch 4 to the off position. (This will allow you to set a maximum

batch size of 999000 gallons.) Attach the X1000 sticker to the

front panel.

Batch Capacity Selection Table

Attach appropriate multiplier label to front panel.

Switch

Position

1234

1234

1234

X100

1234

X1000

Zeros are not displayed.

on

RCDL 25, 35,

40 & 70 (RTR)

X1

X10

(no label)

Max. Preset Value in US Gal.

for Meter Size (inches)

RCDL 70 (AR/t),

120 & 170 and

Ind. Turbo 2", 3" & 4"

999

blank

X10

99900 9990000999000

X1000

9990 99900

X10

999009990 999000

(no label)

X1000

X10000

Turbo Series

1 1/2" - 6" and

Ind. Turbo 6"

(no label)

99900000999000 9990000

X1000

X10000

X100000

To prevent tampering or accidental mistakes, the keys must be

depressed twice in succession for the command to be recognized and acted upon. If the second command is not received

within ten seconds of the first, the unit will revert back to its

previous operation.

PROGRAMMING SEQUENCE

To interrogate the present value of a programmable function,

depress the appropriate function key. The display will show

the function symbol and the present value of the function

alternately for ten seconds and then revert back to normal

operation.

To preset a new value, press the appropriate key and change

the value by using the "digits" keys. Pressing a digit key

continuously will cause the number to scroll. When the desired

number is reached, remove your finger from the digit key.

Change one digit at a time, within ten seconds of each other.

After the new value is displayed, press the key again, to store

it in memory.

The unit will not react to any new values until it counts down

to zero. To accept the new values immediately, "zero" the unit

using the UP/DOWN key.

5

Page 6

■

TROUBLESHOOTING

Most problems encountered when applying the AR/e control

are due to wiring errors, improperly set functions or faulty

transmitter connections. This section provides guidelines for

the detection and correction of these and other problems.

However, should the problem persist, contact our nearest

representative or the factory for further assistance.

SELF TEST PROCEDURE

®

1. Switch power off and on again. If the displays shows

anything but three eights, an error exists in the processor

and the unit has to be replaced.

The START and STOP command

keys have the same effect as the

equivalent remote functions (see

wiring section on page 4). The key

must be depressed twice in succession for the command to be recognized and acted upon.

The PRESET key is used to set the

amount of water to be measured before

tank regeneration is required. The preset value is a three digit variable number times a multiplier.

Depress the key and the display will show the present preset

batch value and the preset symbol. Use the digit keys to set the

new value. Depress the PRESET key again to enter the new

value in memory.

The UP/DOWN key is used to "zero" the

unit or change the present count to a

larger or smaller number in order to

avoid simultaneous regeneration in multi-tank systems. The

new number will affect the batch in progress.

• Depress the key and the display will show the present

batch count and the UP/DOWN symbol.

• Use the digit keys to change the count value.

• Depress the UP/DOWN key again to enter the new count

value in memory.

2. If self test is satisfactory proceed to test the input switches

as follows:

a. Press the hidden test switch twice. At first the display

will show three fives then one eight.

b. Press all keys once in the following sequence: Signal

START (7) , Signal STOP (6), Signal Duration (5), UP/

DOWN (4), PRESET (3), Hidden Test Switch (2), least

significant digit (1), center digit (0), and most significant digit (Batch Count). Each time a key is depressed

the appropriate number will be displayed. If one of the

numbers remain in display after the next key is depressed, that particular input is defective.

■

START-UP CHECKLIST

1. Set DIP switch 1 for manual or automatic operation.

2. Set DIP switch 2 for proper lockout operation. (Set to "off"

position if not used.)

3. Set internal DIP switches (3 & 4) for meter size and

maximum batch size.

4. Install NiCad battery.

5. Program unit for batch size wanted.

6. Program unit for output signal duration wanted.

The SIGNAL DURATION key is used to

preset the time period for which the

output relay will remain energized at

the end of a batch, or when a START

command is received. The default value for signal duration is

5 seconds. This function is valid only if the control is set to

operate in the automatic mode. The duration can be programmed from 1 to 999 seconds.

• Depress the key and the display will show the present

signal duration period and the function's symbol.

• Use the digit keys to change the period.

• Depress the SIGNAL DURATION key again to enter the

new value in memory.

The SELF TEST key is used to run a self

test procedure in case of malfunction.

The procedure itself and the diagnostic

is explained in the Troubleshooting section on this page.

7. "Zero" the unit using UP/DOWN key.

■

FIELD REPLACEABLE PARTS

The following parts can be obtained locally. Brand names and

model numbers are for reference only.

Relay: Potter & Brumfield® T81H5D212-05 (or equal)

Fuse: Fusetron® slow blowing 1/10 amp MDL series

(or equal)

Battery: Eveready® CH22 7.2 volt NiCad rechargeable

battery

(Do not use non-rechargeable battery.)

If you find it necessary to send unit to factory, contact your

Badger representative or dealer for material return authorization. Package the unit properly, and include a brief description of the problem.

6

Page 7

PROBLEM POSSIBLE CAUSES REMEDIES

Display does not light when 1. No power on terminals 1 and 2. 1. Connect terminals 1 and 2 to power source.

AC power is turned on. 2. Blown fuse. 2. Replace fuse.

3. Shorted power wiring. 3. Remove short circuit.

Counter does not decrement 1. No flow through meter. 1. Establish flow through meter.

when transmitter is activated. 2. Defective transmitter. 2. Replace transmitter

3. Transmitter improperly connected. 3. Correct wiring error.

4. Dip switches improperly set. 4. Verify switch settings for your meter size.

Regeneration output is not 1. Defective relay. 1. Replace relay. (See page 7.)

energized at end of batch or 2. Lockout is active. 2. Check switch 2 position and wiring to

when a START command is lockout terminals.

received. (Signal indicator is lit.)

Cannot change programmed 1. Function key is not being pressed 1. Refer to page 6 for proper programming

values. twice. sequence.

2. Unit not "zeroed" with UP/DOWN 2. Use UP/DOWN key to "zero" unit, which will

key. force acceptance of new values.

Regeneration signal is active 1. Output is improperly wired. 1. Correct wiring errors.

when signal light is off. 2. Unit is defective. 2. Replace unit.

Test procedure does not work. 1. Unit is defective. 1. Replace unit.

Memory does not function 1. Battery is defective. 1. Replace battery.

during power outage.

AR/e Circuit Board

7

Page 8

Please see our website at

www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2009. All rights reserved.

Due to continuous research, product improvements and enhancements,

Badger Meter reserves the right to change product or system specifications

without notice, except to the extent an outstanding bid obligation exists.

BadgerMeter,Inc.

P.O. Box 245036, Milwaukee, WI 53224-9536

Telephone: (414) 355-0400 / (800) 456-5023

Fax: (414) 355-7499 / (866) 613-9305

www.badgermeter.com

Loading...

Loading...