Page 1

Operating Instructions

Quad 1000

Soil EC Mapping System

Table of Contents

Section 1

1-2 Warranty

1-3 Safety

Section 2

2-1 Electronics Overview and Set-up: EC Surveyor

2-3 Electronics Overview and Set-up: DataLogger

2-4 Software Set-up: SoilViewer

Section 3

3-1 Implement Overview and Set-up

3-2 Additional Assembly Instructions

Section 4

4-1 Field Operations—EC Surveyor

4-2 Field Operations—EC Surveyor with DataLogger

4-4 Field Operations—EC Surveyor with SoilViewer software

4-5 Field Operations--Implement

Section 5

5-1 Troubleshooting

5-2 SoilViewer Troubleshooting

Section 6 Maintenance and Service Procedures

6-1 #1. EC Surveyor signal testing

6-2 #2. Testing electrical continuity

6-4 #3. Diagnosing and correcting EC signal problems

6-10 #4. Spring plunger testing and replacement

6-12 #5. Diagnosing GPS-related problems

6-16 #6. Firmware updates and SD card formatting

6-19 #7. Implement lubrication

6-19 #8. Maintenance

6-20 #9. Micro-chip replacement

OM17-Quad1000

1-1

Page 2

OM17-Quad1000

Quad 1000 Soil EC Mapping System

Soil EC Surveyor Software Version 1.2

Sensor DataLogger Version 1.03

Section 1

Warranty

Veris Technologies warrants this product to be free of defects in materials and workmanship for a

period of one (1) year from the date of delivery to the purchaser. Veris Technologies will repair or

replace any product returned to Salina, Kansas, which appears upon inspection to be defective in

materials or workmanship. Veris Technologies will have shall have no obligation under this

warranty for the cost of labor, down-time, transportation charges, or for the repair or replacement of

any product that has been misused, carelessly handled, modified, or altered.

ALL OTHER WARRANTIES OF ANY KIND, WHETHER EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE AND ALL CLAIMS FOR CONSEQUENTIAL DAMAGES, ARE

SPECIFICALLY DISCLAIMED AND EXCLUDED.

Safety

1-2

Page 3

OM17-Quad1000

DataLogger

Protective

case

Important! Read the following SAFETY PROCEDURES before operating the Veris system:

• Read and understand all instructions on safety decals

• Properly block up implements befor working underneath.

• Detach and store implements in an area where children normally do not play. Secure implement

by using blocks and supports.

• Read Operations Manual before operating machine

• Review safety instructions with operators before operating machine and at least annually

• Never stand on or use tire as a step

• Do not tow the implement on public roads.

• Riders obstruct the operator’s view. They could be struck by foreign objects or thrown from the

machine.

• Never allow children to operate equipment.

• To prevent possible electrical shock, or damage to the instrument, do not connect to any power

source greater than twelve (12) volts DC.

• Do not grease or oil implement while it is in operation.

• Disk edges are sharp. Be careful when working in this area.

• Disconnect battery ground cable (-) before servicing or adjusting electrical systems or before

welding on implement.

• Remove buildup of mud, oil or debris.

• Be very careful when mapping stubble fields using a vehicle with a gasoline engine. Be prepared

if a fire starts. Keep crop residue and other debris from accumulating near the exhaust and in

engine compartment.

• Keep a first aid kit and fire extinguisher handy.

The Veris Electronics kits includes the following items:

Section 2

Electronics Overview and Set-up

1-3

Page 4

OM17-Quad1000

EC

Surveyor

SD

card

reader

Mtg

bracket

Power

cord

Signal test

box

Mtg

bracket

Power cord

Signal test

load

Serial

cable

SoilViewer

software

Figure 1. EC Surveyor kit Figure 2. DataLogger kit

Use protective shipping/storage case to protect electronics components whenever electronics are

shipped. Keep all diagnostics and operations manual with system when mapping.

Mount instrument in a location that is as free as possible from dust, vibration, and electrical

interference. Display should be visible to operator and shielded from direct sunlight. Use

adjustable mounting brackets to position electronics for optimal visibility (Figure 3).

Figure 3.

2-2

Page 5

Figure 4. EC Surveyor (rear)

Power port:

The Soil EC Surveyor is shipped

with an accessory power cord.

If an alternative connection is

desired, make sure that the unit

is properly connected to a power

connection that is not controlled

by the ignition switch. If

connecting directly to the

battery, we suggest a 3-amp inline fuse is installed between the

battery and the instrument.

EC Signal:

EC Signal Cable

extension from

implement attaches

to the EC Surveyor

here. Route cable

properly to prevent

damage. Signal test

load also attaches

here—used to test

EC Surveyor.

EC Data out:

Attach serial cable

here and other end

to Sensor

DataLogger or

laptop PC.

GPS input:

Connect GPS cable here.

It is designed to accept

GPS input in NMEA 0183

format via an RS232

connector.

(GPS must send GGA and

either VTG or RMC strings

at a 1hz rate, at 4800 baud,

8 data bits, 1 stop bit, no

parity.)

Fuse:

This allows the fuse to be

replaced, with a 1A

fastblow fuse, if blown.

Data Status:

When lit, this green LED

indicates data is being sent

out serial port. If not lit, EC

values are negative or GPS

signal not received.

Power:

When lit, this red

LED indicates EC

Surveyor is powered

up.

On/Off:

Turns power to EC

Surveyor on and

off.

Figure 5. EC Surveyor (front)

OM17-Quad1000

Figure 6. DataLogger (rear)

2-3

Page 6

OM17-Quad1000

Data Status:

When lit, this green

LED indicates data

is being recorded to

memory card. If not

lit, EC values are

negative or GPS

signal not received.

Power:

When lit, this red

LED indicates

Sensor DataLogger

is powered up.

On/Off:

Turns power to

Sensor DataLogger

on and off.

Memory Card slot:

Formatted SD memory

card must be installed

when booting up, and

at all times data is

being collected. See

Proc. #6 for formatting

instructions.

EC:

Serial cable

from EC

Surveyor

attaches here.

pH:

Serial cable from pH

Controller (MSP

only) attaches here.

Reset

button:

Can be used

to reboot

DataLogger

Alarm Vol:

Used to adjust

volume of auditory

alarm

Power port:

The Sensor DataLogger is

shipped with an accessory

power cord. If an alternative

connection is desired, make

sure that the unit is properly

connected to a power

connection that is not

controlled by the ignition

switch. If connecting directly

to the battery, we suggest a

3-amp in-line fuse is

installed between the battery

and the instrument.

Fuse:

This allows the fuse

to be replaced, with

a 500mA Fastblow

fuse, if blown.

Figure 7. DataLogger (front)

Important – Do not allow moisture to enter the Soil EC Surveyor or Sensor DataLogger, and

do not pass strong magnets near the unit.

2-4

Page 7

Figure 8.

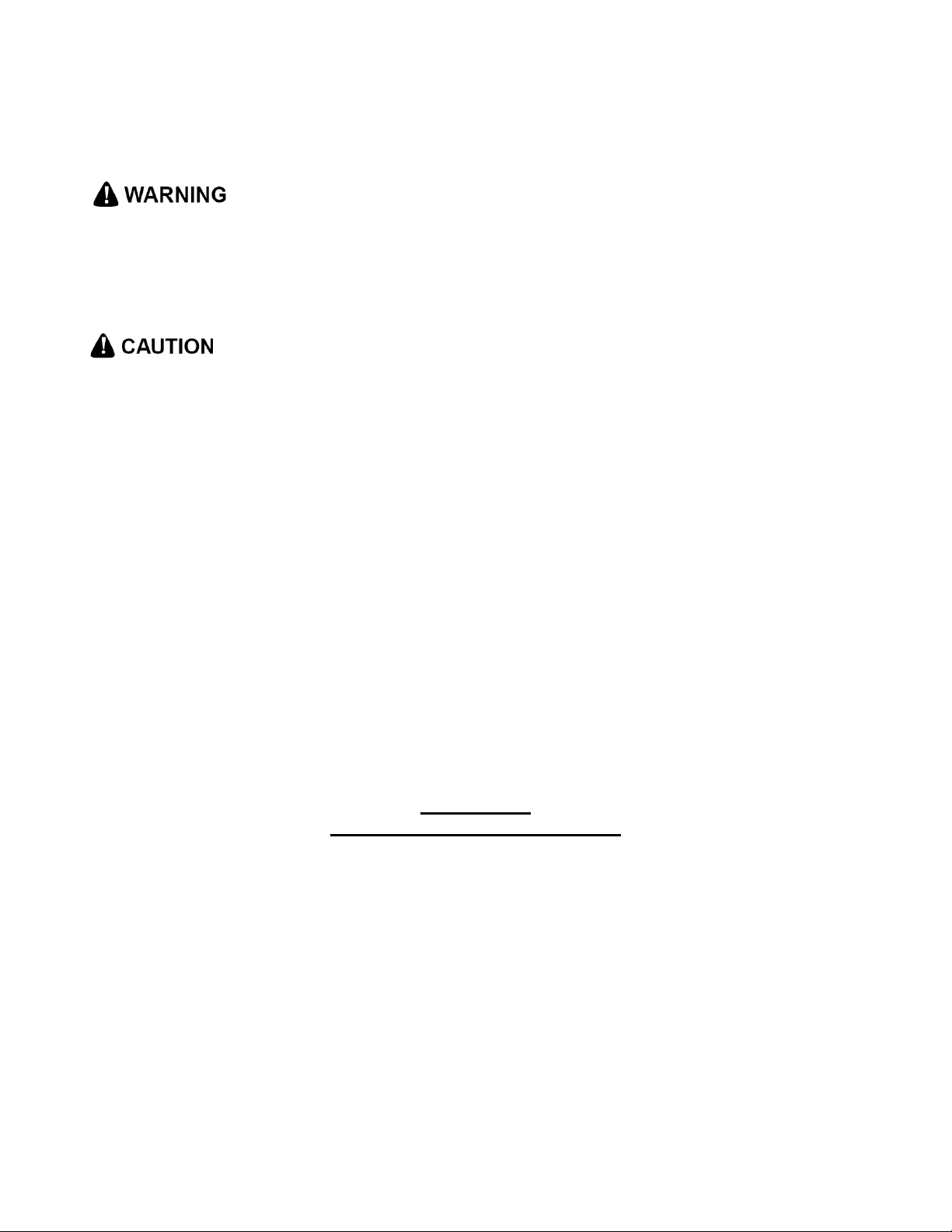

The Veris SoilViewer software will

automatically run the setup once the CD

is inserted into the computer. If not the

installation can be manually started by

double clicking on the setup.exe located

on the CD.

Once the CD has begun select the

installation directory and click Next

Click Next to continue through

installation

Next two license

agreements will need

to be accepted

before continuing.

OM17-Quad1000

Software Setup

Figure 9.

Figures 10a and 10b.

2-5

Page 8

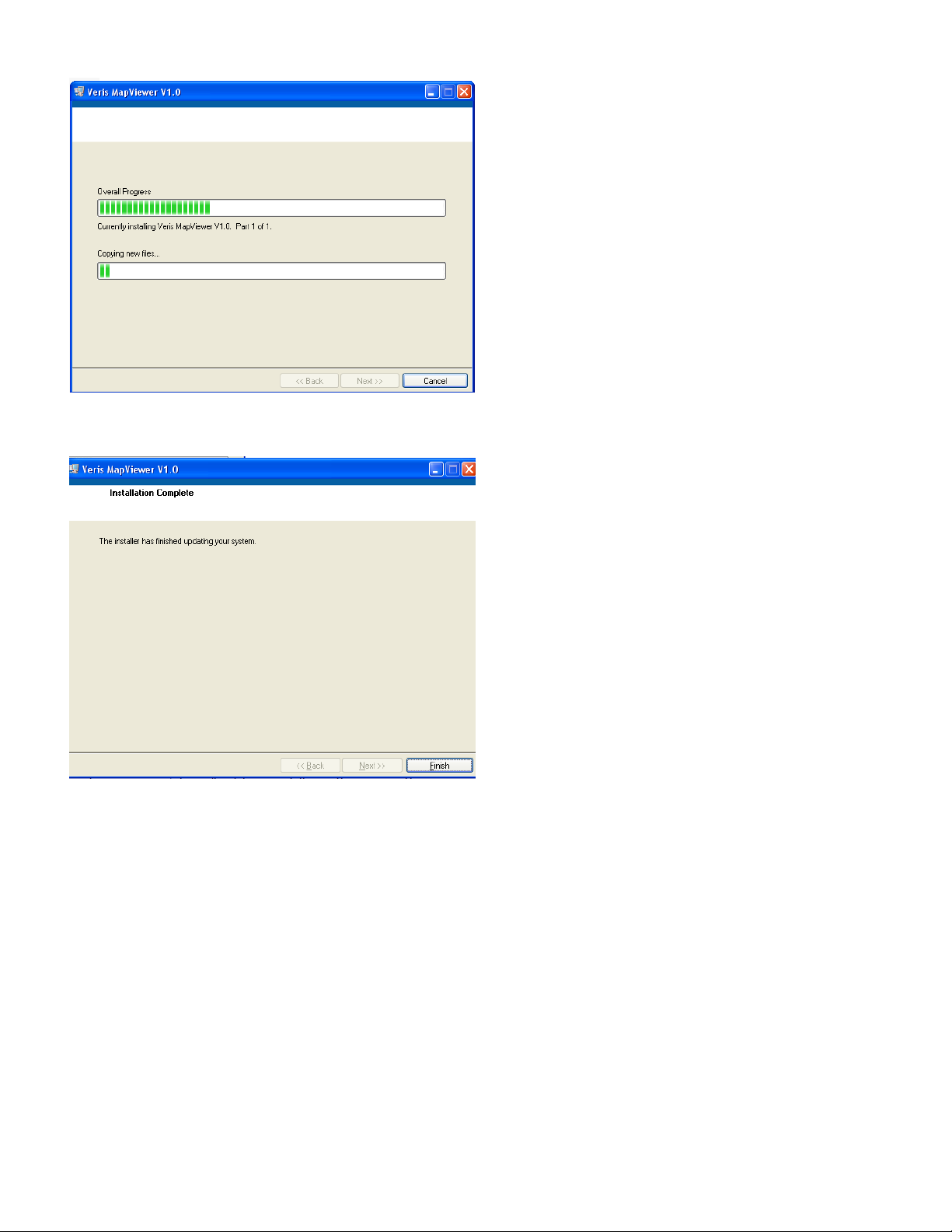

Figure 11.

The installer will

install all necessary

components

Once the installer is completed, click

finish

OM17-Quad1000

Figure 12

2-6

Page 9

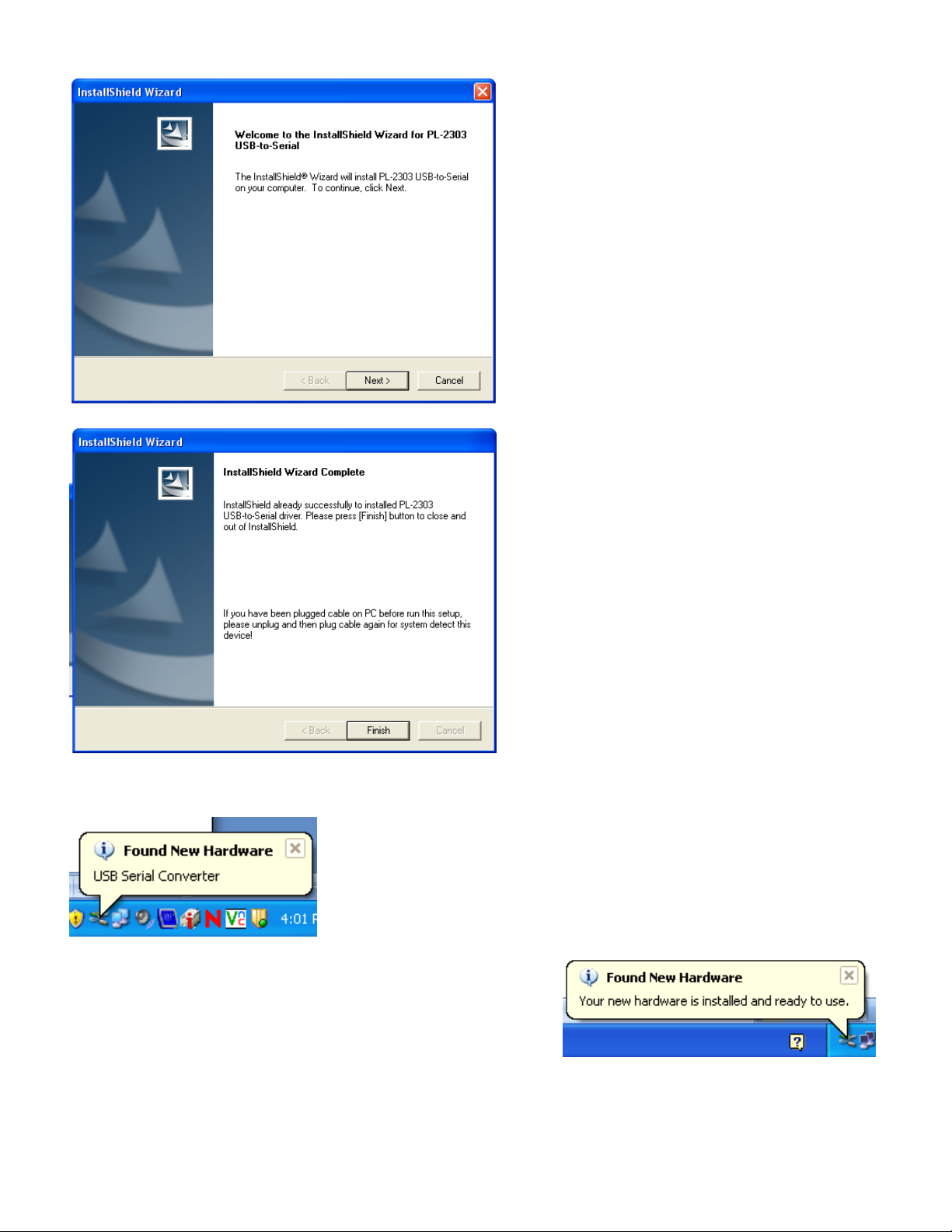

Figure 13

The Veris SoilViewer will now install drivers

necessary to operate the included USBSerial Converter (part #41377). If you do not

want to use the included converter than press

cancel here, otherwise click next. If you have

the USB- Serial converter plugged in be sure

to unplug it before clicking next.

After the drivers are successfully installed

click finish and Restart your computer before

opening Veris SoilViewer.

Once the computer is restarted the USB to

Serial converter cable can be plugged in,

Windows will recognize the new hardware.

Windows will then advice the new hardware

is installed and ready to use.

OM17-Quad1000

Figure 14

Figure 15

Figure 16

2-7

Page 10

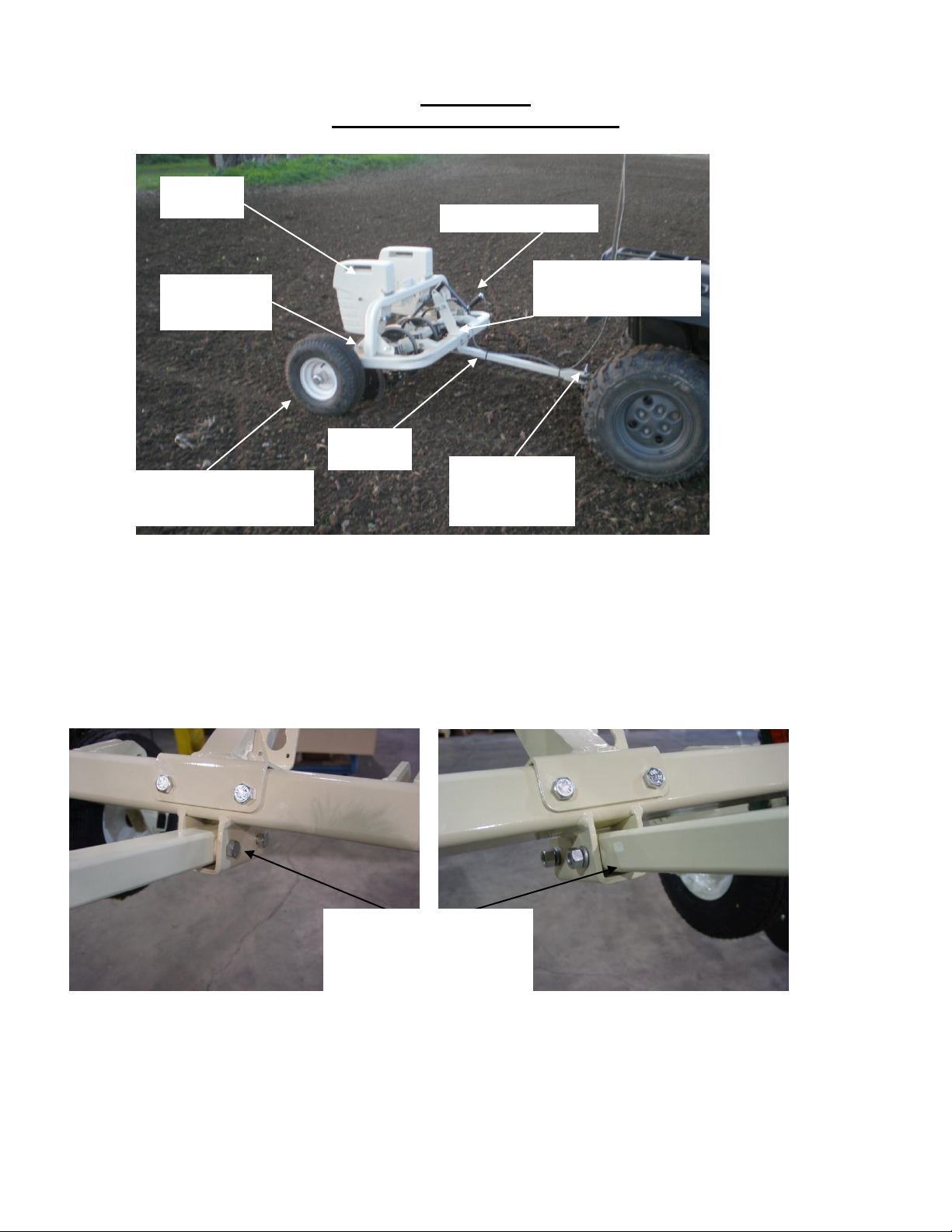

OM17-Quad1000

Signal Cable quickconnect coupler port

Weights

Disk

electrodes

Tongue

Implement

hitch

Tire and Wheel

Assembly

Raise/lower crank

Install tongue with ½” X

3.25” bolts, lock washers

and nuts.

Section 3

Implement Overview and Set-up

Figure 1.

The tongue must be installed prior to use. To do so, please take precautions to ensure that the

framework is properly supported to ensure safety.

1) Remove bands that attach tongue and framework to shipping pallet.

2) Install tongue as shown in Figure 2.

Figure 2a. and 2b

3-1

Page 11

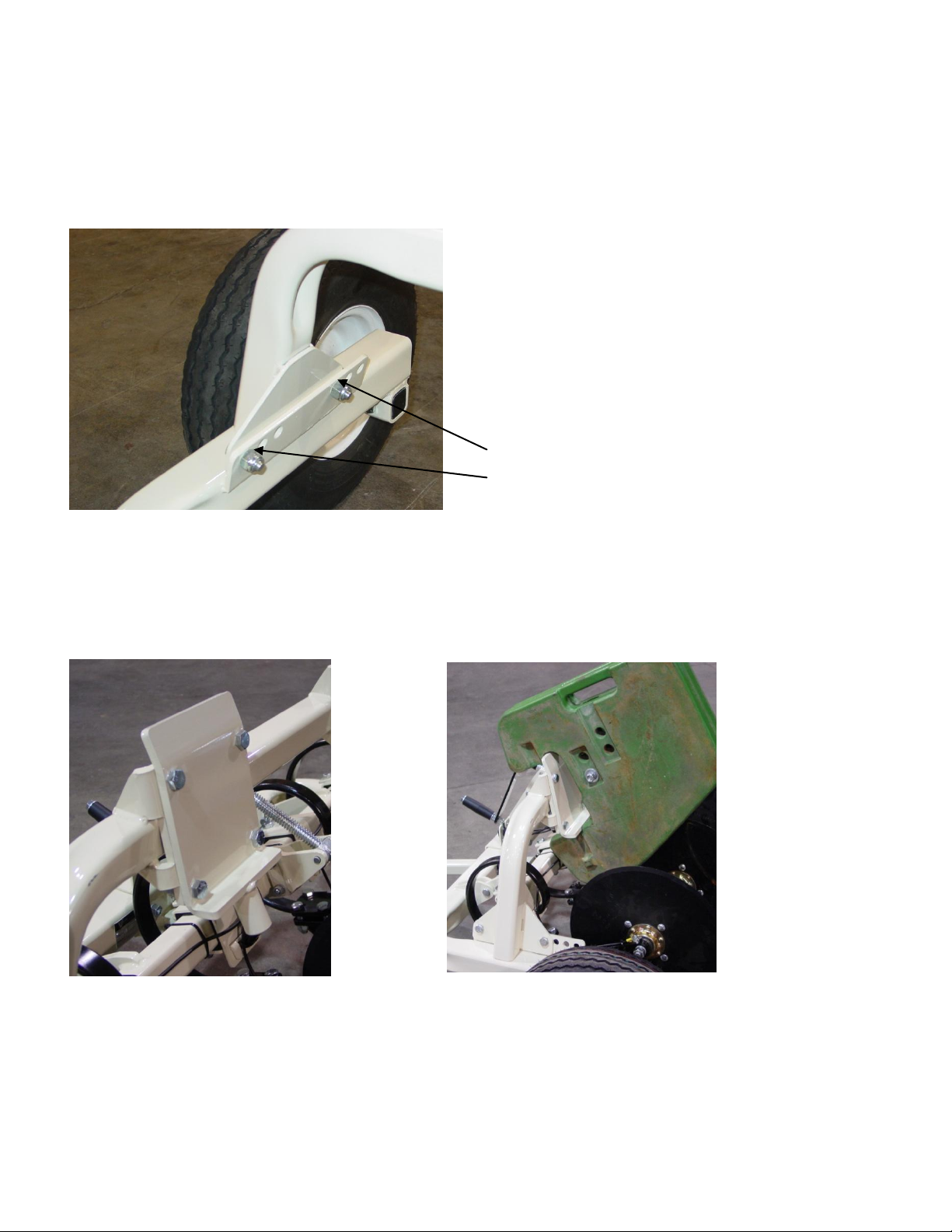

OM17-Quad1000

Attach disk electrode toolbar

with 5/8” Pin and Bowtie clip.

Attach wheels with ½” X 2.75”

bolts with lock washer and

nut.

Attach raise/lower crank rod

by threading rod through

trunion

Install raise-lower crank

bracket with ½” X 3.75” bolts

with lock washer and nut.

Attach wiring harness with #6

machine screws and lock

nuts.

NOTE: Depending on shipping configuration, the unit may need additional assembly. Attach

wheels as shown in Figure 3. Attach raise-lower crank bracket as shown in Figure 4.

Figure 3 Figure 4

Attach raise/lower crank to disk electrode toolbar by threading crank rod into trunion as shown in

Figure 5. Do not attach disk electrode toolbar to frame before crank rod is attached.

Figure 5

Connect the disk-electrode sub-assembly and wiring harness as shown in Figure 6.

Figure 6a and 6b

3-2

Page 12

OM17-Quad1000

Install weight bracket

bar with ½” x 1.25”

bolts and Nylock nuts.

Install weight bracket if included as shown in Figure 7. A choice of assembly positions is available

to accommodate customer-provided suitcase weights. Properly installed weights will provide

positive tongue weight, but still allow user to lift tongue without straining. If tongue weight is

excessive, move bracket to middle or rear holes; if tongue weight is negative (tongue won’t stay

down) move weight bracket forward. For Veris supplied weights, install bracket in the second hole

from the front.

Figure 7

To attach John Deere style suitcase weights, install weight bracket in the front holes using ½” x

1.25” bolts with Nylock nuts. Bolt the John Deere adaptor bracket to weight bracket bar using ½” x

1.5” bolts with lock washer and nut (Figure 8). Clamp weights together using ½” x 3.5” bolts, USS

flat washers, and lock washer and nut (Figure 9).

Figure 8 Figure 9

3-3

Page 13

OM17-Quad1000

Ground speed

(from GPS) in

miles/hour

GPS status: may

read GPS, DGPS,

RTK, or None. If

None, no GPS signal

is received and no

data will be sent out

serial port.

Shallow (Sh) and Deep (Dp) soil EC

readings. If negative, no data will be

sent out serial port.

Note: The EC Surveyor display screens

are the same whether using Veris

DataLogger or laptop PC for recording.

Section 4

Field Operations—Soil EC Surveyor

Attach the signal cable to the quick connect coupler at front of frame, and to Signal port on back of

EC Surveyor. Connect serial cable, GPS, and power cords to ports on rear of EC Surveyor.

Figures 1a and 1b

EC Surveyor display readings

Here are the display readings that you will see when operating the EC Surveyor:

Figure 2

The unit is ready to operate. The Surveyor is informing you of the firmware version its

programmable interface chip (PIC) contains. Immediately the screen will change to the operating

screen below:

Figure 3

4-1

Page 14

OM17-Quad1000

Field Operations—Soil EC Surveyor with Sensor DataLogger

Before logging any data, make sure the SD card in the Datalogger is clear of any files that

are not Veris .dat files. Any other files will cause the data an error when logging data.

The Veris DataLogger is not compatible with SDHC cards. Only SD cards will work

correctly.

Sensor DataLogger display readings

Here are the display readings that you will see when operating the Sensor DataLogger:

Starting up…

Figure 4

The unit is ready to operate. The DataLogger is informing you of the firmware version its

programmable interface chip (PIC) contains.

Press any of the four keys, and the next screen will appear:

Figure 5

For EC mapping, press the #1 key. #4 Exit returns you to the initial start-up screen. pH Setup is

not used with EC logging. Pressing #1 brings up the next screen:

Figure 6

For EC mapping, press the #1 key. #4 Exit returns you to the initial start-up screen. EC and pH are

not used with EC logging. Pressing #1 brings up the next screen:

Figure 7

The DataLogger is displaying the map file number it is creating, in case you want to record it along

with any other information about the field. Press any key to begin new map file. After starting the

file, pressing the #4 key will stop the file. If DataLogger freezes at the screen shown in Figure 6 or

Figure 7, check formatting of SD card—must be FAT format. See Proc. #6 for formatting

instructions.

4-2

Page 15

OM17-Quad1000

Ground speed

(from GPS) in

miles/hour

GPS status: may read GPS, DGPS, RTK,

or None. If None, no GPS signal is

received and no data will be recorded.

Shallow (S) and Deep (D) soil EC

readings. If negative, no data will be

recorded. (on Quad 1000 ignore

Deep reading)

If memory card was not inserted during boot-up, the following screen will appear:

Figure 8

Install card and re-start DataLogger. NEVER REMOVE CARD WHILE LOGGING DATA.

This is the Data Acquisition screen:

Figure 9

There are warning signals programmed into the Veris DataLogger to warn the operator that data

are not being recorded, so that corrective action can be taken. If data aren’t being recorded, a

warning alarm will sound, and the portion of the screen text that is missing information will blink.

For example, if the DGPS isn’t being received (or the NMEA string containing speed) the Lat/Long

text will blink. If EC values are negative, they will blink. Also, the Data Status LED light on the

front of the DataLogger indicates the whether data is being recorded. If this light is not lit, data are

not being recorded. (note: no data is recorded unless unit is moving—receiving speed signal from

GPS)

At any time during the mapping process, you can press any key to stop the file. If you create more

than one file from the same field, you can bring the files into a spreadsheet program or GIS and

combine for whole field map display.

After #4 key is pressed during Data Acquisition, the following screen will be displayed: (if data

was collected during Data Acquisition)

Figure 10

DATA IS ONLY STORED ON THE SD CARD. NO INTERNAL FILES ARE CREATED.

If no data was logged during Data Acquisition, the following screen will be displayed:

Figure 11

4-3

Page 16

OM17-Quad1000

User selectable

point width

User selectable plot

colors, click on color to

change.

Selectable zoom

functions for viewing

maps

Displays when program is

searching for connection to

EC Surveyor, this only

happens at startup.

Field Operations—Soil EC Surveyor with SoilViewer software

The EC Mapping software will automatically detect which port the Veris EC Surveyor is connected

to, and begin communicating. If the EC Surveyor is not detected, the software will wait 45 seconds

for the connection of the Surveyor and search again; this is repeated until the Surveyor is

connected. If the Surveyor is not found, unplug the serial or USB cable and reconnect it to the PC.

If the connection is still not made refer to SoilViewer troubleshooting. The conditions for mapping

and storing the data are as follows. The user must be going a speed greater than 1 mph, there

must be a GPS signal received, the EC Comm Light must be green, indicating the PC and EC

Surveyor are communicating properly, and either of the EC values has to be greater than -1.

When all these conditions are met, the Saving Data light will be green and the points will be

mapped.

Files may be appended to if mapping has stopped by selecting a previous file when prompted at

the startup of the software.

Figure 12

4-4

Page 17

OM17-Quad1000

Figure 13

Field Operations--Implement

Checking Electrical Signal Continuity and Electrode Isolation

It is recommended that you perform the Electrical Signal Continuity and Electrode Isolation test

procedure before first field use (see Maintenance and Service Procedures 1 and 2). While these

tests were made at the factory, there is the possibility a problem developed during shipping.

Performing these tests on the new implement before it becomes dirty, allows you to get familiar

with the process under ideal conditions. It is strongly advised that you perform this test on a routine

basis (every 10 hours of data collection) to ensure you are obtaining reliable data. KEEP

OHMMETER, TEST LOAD AND TEST BOX WITH THE MACHINE AT ALL TIMES.

Equipment pre-mapping check

Prior to operating the implement for the first time, it is important to check the fasteners – some may

have loosened during shipment. Routine fastener checking should be done weekly during

mapping season and a walk-around check of the implement components should be done each

day.

Setting Operating Depth

Begin field operation by lowering unit into soil. For good

electrical conductivity, all disk electrodes must be in direct

contact with moist soil, at all times and in every region of

the field. A depth of 1-2” (2.5-5 cm) is recommended

(Figure 13). To insure this depth is consistently achieved,

400 lbs (180 kg) of additional weight are normally

required. Veris offers optional weights, or they can be

supplied by the customer. Lower unit until proper disk

depth is achieved, or until wheels are slightly (<.5 inch/ 1

cm) off the ground.

Field Condition

Field should be in a uniform state. Mapping after intensive primary tillage is not recommended. The

soil must have a minimum of 20% available water, and cannot be frozen. If rocky conditions exist,

slow down.

Speed

Proper field operating speed depends on field conditions. Because of the importance of consistent

contact, the unit must not be allowed to bounce over rough fields at high speeds.

• Be very careful when mapping stubble fields using a vehicle with a gasoline engine. Be prepared

if a fire starts. Keep crop residue and other debris from accumulating near the exhaust and in

engine compartment.

4-5

Page 18

OM17-Quad1000

Swath width and Navigation

Setting the swath width and navigation system is at the discretion of the customer. A 50’-75’ (1523 m) swath works well in most areas. Several methods of navigation are possible: following

previous crop rows, swath guidance, or using a field navigation computer. While it is important to

map in a consistent pattern, it isn’t absolutely critical that each pass be exactly the same distance

from the previous pass.

To help insure the quality of your data, please follow these guidelines:

1. Generate and view maps frequently, especially prior to deleting data from Instrument.

2. Listen for auditory alarm from DataLogger, indicating data collection has been interrupted.

3. View DataLogger screen or SoilViewer map frequently during data collecting; watch for:

Negative readings in the Shallow or excessive noise in the data.

EC readings should fluctuate gradually as you drive across the field, relating to

soil changes. If readings change erratically, or show values not typical of soil

conductivity in the area—such as >100, perform tests 4 and 5 below.

In SoilViewer, watch for streaks, stripes, unnatural patterns, and missing data points.

4. Perform electrical continuity test on implement wiring:

at least once a day during mapping season

every 10 hours of mapping

after extended periods of non-use

after replacing or repairing disk-electrode components or wiring

whenever readings are questionable

5. Perform Signal Testing Procedures #1 and #2:

at least once a day during mapping season

every 10 hours of mapping

after extended periods of non-use

whenever readings are questionable

6. Keep all electrical connections dirt and moisture-free

7. Limit speeds in rough or rocky field conditions. This will improve data quality, and will also

lengthen the service life of the implement components. NEVER EXCEED 15 M.P.H. FIELD

SPEED.

Remember, the EC data you generate will be used by your customers to make important

management decisions…take the time to make sure that it’s high quality data.

4-6

Page 19

OM17-Quad1000

Section 5

Troubleshooting

EC data seem odd—jumpy, negatives, map doesn’t match known or expected soil types

Perform Maintenance and Service Procedures 1-3.

No GPS or DGPS on display

Perform Maintenance and Service Procedure 5

DataLogger locks up

-SD card not installed or not formatted. See Procedure #6 to format card.

EC Surveyor or DataLogger doesn’t power up (power LED not lit)

-Check barrel fuse in power plug (cigarette lighter)

-Check power to vehicle power port

Data status (green LED) light not lit

-check GPS status: must have GPS, DGPS, or RTK

-check EC status: EC values must be positive

-Unit must be moving to send data out port

Disk spring tines breaking:

-reduce ground speed

5-1

Page 20

OM17-Quad1000

SoilViewer Troubleshooting

EC Surveyor is not found

Check to ensure the com which the EC Surveyor is connected to is present under the device

manager. To get to the device manager go to StartSettingsControl PanelSystem Click on

the Hardware tab and then click on the device manager button. Click on the “+” sign next to Ports

and make sure the port is listed here. In this case a USB to serial converter is being used and the

port is listed as USB Serial Port (COM33)

Figure 1

If the port is not listed here, then unplug and replug the USB – Serial converter cable and ensure

the power is on to the EC surveyor. If USB – Serial port is still unavailable then reinstall the

drivers. If you are using the provided USB-Serial converter part #41377, then the drivers can be

located on the Veris SoilViewer disk see Reinstalling USB-Serial Converter Drivers, if a different

USB- Serial Converter is being used, then follow the manufactures instructions for driver

installation.

5-2

Page 21

Reinstalling USB- Serial Converter (Part# 41377) Drivers

Insert the Veris SoilViewer disk once the Veris SoilViewer appears click cancel.

Open My computer and right click on the CD rom drive then click on Explore

OM17-Quad1000

Figure 2

Double Click on PL-2303 Driver Installer.exe follow the installation guide to install the driver, then

restart your computer and plug in the USB- Serial converter cable to try again.

Figure 3

5-3

Page 22

OM17-Quad1000

Signal Test Load

Section 6

Maintenance and Service

Procedure #1: EC Surveyor Instrument Signal Testing

Perform this test daily or every 10 hours of data collection to ensure you are obtaining reliable

data, and whenever EC data is questionable. The purpose of this test is to insure that the

instrument is performing properly.

The EC Surveyor is shipped with an Instrument Test Load (Part No. 10447) that will enable you

to quickly check the instrument to ensure that it is functioning properly. To perform this test:

1) Disconnect the signal cable from the signal terminal on the EC Surveyor.

2) Connect the test load to the signal terminal.

3) Switch on the EC Surveyor and view display.

4) The display should show:

Shallow: 14

Deep: 21

5) If the readings vary significantly (more than one whole number) contact Veris service

department.

6) Once the test is complete, remove the test load and reinstall the implement signal cable.

Figure 1.1 Signal Test Load installed (display showing proper EC readings for Quad1000)

6-1

Page 23

OM17-Quad1000

Procedure #2: Testing Electrical Continuity

Perform this test daily or every 10 hours of data collection to ensure you are obtaining reliable

data, and whenever EC data is questionable.

The purpose of this test is to insure that each disk-electrode has an uninterrupted signal path from

the EC Surveyor to the disk blade. Think of each disk-electrode and its wire path as a ‘channel’.

On a Quad1000, there are 4 signal channels that must be clear and isolated from each other. You

will first test the complete pathway for each channel—each disk-electrode. One easy-to-take

reading for each channel tests the cable, wiring harness, and each disk-electrode and disk blade.

If no problems surface during this test, there is no need to test individual components. This test

should take only a couple of minutes to perform.

To perform this test, you will need the EC Signal Test Box (part #10759) and an ohmmeter,

sometimes referred to as a multi-meter or voltmeter (Figure 2.1). Make sure the meter is set to

ohms, Ω. If a range of ohms is available, choose the lowest setting--ohms rather than kilo or mega

ohms. If unfamiliar with ‘ohming-out’ or resistance testing, make a few trial tests before performing

the Veris signal test procedure. Touching the meter leads together will display a zero resistance

reading, touching two places on the same piece of metal will produce a nearly zero reading,

touching nothing will produce an OL (overload or over limit) reading—meaning complete

resistance, and no continuity.

Figure 2.1

Remove the signal cable from the EC Surveyor and connect it to the terminal on the test box.

When testing the signal on the Quad 1000, use the center 4 terminals and use the numbers below

the terminals. The outside terminals and numbers above the terminals are for the 6 electrode

models.

6-2

Page 24

OM17-Quad1000

Connect other lead

to disk blade

Ohmmeter

Connect one lead to Signal Test

Box terminal corresponding to

disk blade

Signal extension cable

(from implement)

Figure 2.2

Firmly press one lead of the ohmmeter to the #1 disk blade edge (left hand, standing behind the

unit) and the other lead to the terminal marked #1on the Quad 1000 test box decal. Maintain firm

pressure on the ohmmeter lead touching the disk blade. A reading of less than 2 ohms is normal.

Rotate blade ¼ of a turn back and forth as you view the ohmmeter. Any jump in the readings

above 2 ohms indicates a problem. (Figure 2.3)

Figure 2.3 Testing signal continuity on Quad 1000 #1 disk.

Continue to check each disk electrode in succession, left to right.

If any disk electrode exhibits no continuity or resistance higher than 2 ohms, refer to Procedure #3

Diagnosing EC Signal Problems.

6-3

Page 25

OM17-Quad1000

Procedure #3: Diagnosing and Correcting EC Signal Problems.

Use this Troubleshooting tree to work through the system, locate the problem, and take corrective action.

Figure 3.1

6-4

Page 26

OM17-Quad1000

Connect one lead to test

box terminal and other

lead to corresponding

disk wire connector bolt

Disk Electrode Functions-

Each disk electrode on the implement is part of a pair, and each pair has a distinct function.

a) Disks 1 & 4 are the “charged” disks that inject the voltage into the soil.

b) Disks 2 & 3 are the “Shallow EC” receptors.

If the continuity ohm test indicates a problem on a channel, you will need to determine where the

interruption is located. Listed below are detailed instructions on how to determine exactly where a

continuity or isolation problem is located:

A. Testing Cable and Wiring continuity:

1. Once a high resistance reading on a channel is confirmed, determine whether the problem

is in the wiring or in the disk-electrode. To test all cable and wiring, place one ohmmeter

lead in the Test Box terminal pin for that channel and the other on the corresponding disk

wire connector bolt. Repeat process on all disk-electrodes. If there is a broken wire inside

the insulation, it may be difficult to detect without flexing the wires during this test.

Figure 3.2a and 3.2b Testing cable at disk electrode #2

2. If you see <2 ohms on all, test the disk electrodes as explained in B below.

3. If you see a > 2ohms reading on any channel, you will need to determine whether problem

is in extension cable (cable from implement to EC Surveyor) or in the wiring harness (cables

attached to implement. Visually inspect the wiring harness and cable extension for damage.

If a visual inspection doesn’t reveal a problem, you will need to test continuity of the wiring

harness and cable by ohming these cables out individually. Disconnect signal extension

cable from implement and insert ohmmeter leads into sockets as shown below.

6-5

Page 27

Coulter 2

Coulter 4

Coulter 3

Coulter 1

Coulter 1

Coulter 4

Coulter 3

Coulter 2

Figure 3.3. Check continuity of signal harness, with one ohmmeter lead contacting pin in

connector and other lead contacting corresponding disk-electrode.

If that test shows < ohms of resistance, test signal extension cable as shown in Figure 3.4

Figure 3.4. Check continuity of signal extension cable with one ohmmeter lead contacting pins

in extension cable end making sure to only touch one pin at a time, and the other lead

contacting corresponding test box terminal.

Note: intermittent electrical problems are difficult to diagnose. Flex wiring and connectors while

checking continuity.

B. Testing Disk-Electrode continuity

1. Place ohmmeter lead on terminal wire bolt and other lead on disk blade. Rotate blade ¼

OM17-Quad1000

turn. If readings are consistently above 2 ohms, check for excessive corrosion at the disk

blade mounting bolts, or the terminal located near the disk pivot. Make sure that high ohm

readings are not due to poor contact between blade and ohmmeter lead. Re-test holding

lead firmly against edge of blade, removing rust or paint if necessary.

6-6

Page 28

OM17-Quad1000

Figure 3.5

2. If ohms jump over 2 ohms when the blade is rotated, and you were careful to maintain good

contact between the lead and the blade, the problem is likely inside the hub. Because

electrical signals cannot be sent consistently through the disk bearing, Veris has designed a

more reliable path for the EC signal to travel. A special hub with a spring plunger presses

against the bolt through the bearing, serving as a commutator. Shown below in Figure 3.6

is a view of the hubcap and plunger assembly. When ohm readings jump during blade

rotation, it is due to the balls on the bearing making intermittent and inconsistent contact.

See Maintenance and Service procedure #4: Spring Plunger adjustment and replacement

on adjusting and replacing spring plungers.

Figure 3.6

6-7

Page 29

OM17-Quad1000

nylon

insulation

C. Testing Disk-Electrode isolation

If continuity tests show no excessive resistance on any channel, yet erratic soil EC readings

continue, or if EC readings do not drop to –1 when unit is out of the soil, it is possible that the

channels are not isolated. This could be the result of a pinched wiring cable, causing channels to

short out. Or, one of the disk-electrodes is no longer insulated properly from the frame or adjacent

disk-electrodes.

1. If EC readings do not drop to –1 when unit is raised, disconnect signal cable extension from

implement. If readings don’t drop to –1, the problem is with the signal cable extension. If

readings show -1, re-insert the signal cable extension into the implement. Disconnect the

connector wire from each disk electrode. If readings don’t drop to –1, the problem is with the

wiring harness. If this is the case, you should replace the wiring harness. If readings do

drop, re-insert the signal cable extension into the implement. The problem is with one or

more of the disk-electrodes. Proceed as follows:

2. Inspect nylon insulation slides under disk-electrode mounting brackets. These nylon

insulators may become worn or brittle, or may slip out from under mounting bracket. Repair

and replace as necessary. Make sure that all electrode disk U-bolts are properly tightened

to clamp mounting bracket and insulation tightly to frame.

Figure 3.7

3. Check so see that no metal part of the any disk electrode is in contact with the implement

frame. This may be by visual inspection or by connecting one lead of an ohmmeter to the

individual disk electrode or wire connector bolt , and the other to a grounded fastener on the

frame (Figure 3.8). If the disk electrode is properly isolated, no reading will be obtained.

Make sure that all electrode disk clamp bolts are properly tightened to prevent lateral

movement of the disk electrode.

6-8

Page 30

OM17-Quad1000

no

continuity

grounded

bolt

disk wire

connector bolt

Figures 3.10 a and b

4. Wet soil on the toolbar could be a pathway for the EC signal to short. Test disk-to-disk and

disk-to-frame isolation by checking resistance between disk-electrodes. Any continuity from

one disk to another is not acceptable. Remove buildup of wet soil, especially if is bridges

across insulation slides. It may be necessary to remove disk mounting brackets and clean

toolbar, if problem persists.

6-9

Page 31

OM17-Quad1000

Procedure #4 Spring Plunger adjustment and replacement

The spring plungers are located in the center of each disk electrode hub cap, and are vital to

maintain good continuity through the disk hub bearings. They are factory preset, and should not

need routine adjustment. If a continuity test shows abnormally high resistance, the plungers

should be checked. This may be performed in the following manner:

1) Check disk hub bearing preload by grasping disk blade and pushing from

side to side. If there is any noticeable movement, bearings are failing --and

this can damage the spring plunger; see procedure #8 for replacement.

2) Remove the locking nut.

3) Remove the plunger by turning counter-clockwise.

4) Depress the spring loaded tip on a hard surface to determine if plunger has

adequate tension and can move freely.

5) If the plunger will not move freely, replace. Coat the threads with di-electric

silicone grease before installation.

6) If the plunger appears to be in good working order, reinstall in the hub, and

adjust until it bottoms against the spindle end. Rotate 1/2 turn backward to

allow adequate clearance. Improper adjustment will result in premature

failure (too little tolerance) or poor continuity (too much tolerance). See

Figure 4.1 below to view proper clearance.

7) Reinstall locking nut and tighten firmly. Do not allow plunger to rotate while

the locking nut is tightened.

8) Re-test disk electrode continuity

Figure 4.1

In some cases, you may have to remove the hub cap to service the spring plunger, if the

plunger is rusted in the cap, or if the readings are still unsatisfactory with the new plunger

installed.

6-10

Page 32

OM17-Quad1000

Procedure:

1) Remove hub cap by removing the four carriage bolts.

2) If plunger is frozen in cap, remove the 3/8” nut on the outside of the hub

cap and apply penetrating oil on both sides of plunger. Let this stand for a

few minutes and try to remove. If it will not back out with allen wrench, lock

vise grips on the inside portion and turn out through inside of hub.

3) Clean all hub cap surfaces, coat plunger with di-electric grease and install

as outlined above.

4) At the same time, inspect the end of the spindle bolt. Over time the plunger

will wear a slight depression in the spindle bolt face. This is common, and

more noticeable on high acreage units, or units that have been operated at

high field speeds. If the depression is 1/16” or more, carefully grind the

head of the spindle bolt or replace the bolt. Clean any metal dust from

around the bearing that may have resulted from sanding.

5) Re-install hub cap and tighten firmly. You may have to re-set the plunger

to compensate for the reduced length on the newly ground spindle bolt.

Re-adjust as outlined above.

Note: If you are still unable to obtain favorable resistance readings, check for excessive corrosion

at the disk blade mounting bolt, or the disk connector wire terminal. Also, it may be necessary to

grind the spindle bolt end smooth, if a dimple has developed.

6-11

Page 33

OM17-Quad1000

Procedure #5: Diagnosing GPS-related problems

If you do not see a GPS, DGPS, or RTK in the upper left-hand corner of the EC Surveyor screen,

you do not have GPS coming in, and no data will be sent out the serial port for logging.

Figure 5.1

Insure your GPS receiver is powered and outputting NMEA strings GGA, and either VTG or RMC

at a 1hz rate; 4800 baud, 8 data bits, no parity, 1 stop bit. Verify that your GPS cable is sending

GPS data through pin 2, pin 5 is ground, and no other pins have signal or power on them. The

most common issue is hz rate. If the GPS has been used for lightbar guidance it may have been

set to a 5 or 10 hz rate. It will need to be changed to 1 hz in order for the EC Surveyor to accept it.

Shown below is a Troubleshooting tree for diagnosing GPS signal problems. It is not meant to

replace your GPS receiver user manual—it merely shows how to determine if your receiver is

sending the GPS signal that the EC Surveyor needs.

Figure 5.2

6-12

Page 34

OM17-Quad1000

If it becomes necessary to send GPS data into your PC, you will use a program called

HyperTerminal. This program is in all Windows software. It is designed to record serial data

streaming into a serial or USB port on the computer. The purpose of this is two-fold: 1) it verifies

whether your GPS and cables are delivering the proper messages, and 2) it give Veris

Technologies support personnel a GPS data file to test.

Here’s how to use HyperTerminal

1. Plug the GPS output cable into the laptop serial input (or USB-serial hub); no null modem is

needed

2. Verify in Device Manager which Com port the GPS is connected to (Start--Settings—Control

Panel—System—Hardware—Device Manager—Ports

3. Start the “HyperTerminal” program under “Accessories” in Windows.

Figure 5.3

4. Give your HyperTerminal session a name such as gps trial when the program prompts you

for the name of your connection and then hit “OK”.

Figure 5.4.

6-13

Page 35

OM17-Quad1000

5. The program will then ask you for a phone number. Instead of entering a phone number,

specify the proper serial port number. For example, if Com 1 of the laptop is being used,

specify “Direct to Com 1” under “connect using:” at the bottom of the entry area.

Figure 5.5.

6. HyperTerminal will then display a configuration menu where you can specify 4800 bits per

second, 8 data bits, no parity, 1 stop bit and no flow control.

Figure 5.6

6-14

Page 36

OM17-Quad1000

7. At this point, upon clicking ok, legible strings of GPS data should begin appearing on the

laptop screen. Here’s an example of a typical set of strings:

$GPGGA,191528.00,3851.0333,N,09737.2342,W,2,08,1.3,372.7,M,27.3,M,10.0,0100*69

$GPRMC,191528.00,A,3851.0333,N,09737.2342,W,0.1,0.0,090998,6.3,E*48

8. If GPS data doesn’t appear, recheck the port and configuration settings to make sure they

are correct. If the data won’t appear correctly in HyperTerminal, consult your GPS supplier

to see what adjustments (connectors or software) are necessary to bring the signal into a

computer.

9. If the signal appears correctly on HyperTerminal and it shows that the required strings are

being output, highlight a page of strings, copy and paste into Word or Wordpad before

exiting HyperTerminal.

10. Retry the unit with the Veris instrument. If it still doesn’t work, please email the page of GPS

strings from HyperTerminal to Support@veristech.com, along with your contact information.

6-15

Page 37

OM17-Quad1000

Procedure #6: SD card formatting and firmware updates

USING A VERIS SD CARD IN OTHER DEVICES CAN CAUSE FILE CORRUPTION.

Insert a standard SD card (not SDHC type) into a SD card reader which connected to your

computer.

Open “My Computer” folder. Right click on the SD card icon, and select the “Format”.

Figures 6.1 a and b.

In the format window, click on the file system tab and select “FAT” not “FAT32”.

Then press “Start”.

When complete, remove the card.

Updating Data Logger Firmware

1. Shut off the power of the Data Logger.

2. Copy the firmware on the SD card. (firmware found at veristech.com software download site)

3. Put the SD card into the Data Logger.

4. Turn on the power of the Data Logger.

5. Press the RESET button on the rear panel and (1) key simultaneously.

6-16

Page 38

OM17-Quad1000

Figure 6.2.

6. Hold the (1) key and release the RESET button.

7. If you can see the following messages, then release the (1) key.

Figure 6.3

8. If you want to update new software, press (2) key.

6-17

Page 39

OM17-Quad1000

9. Then you can see the following messages in sequence.

Figures 6.4 a and b.

10. Do not shut off the power, but repeat from step 5 to 9 again.

11. Press the RESET button or shut off and turn back on the power.

12. Check the LCD display. If nothing shows up in the LCD, or if display doesn’t contain the new

firmware version number, please repeat from step 1 to 11.

6-18

Page 40

OM17-Quad1000

Procedures #7: Lubrication and #8: Maintenance

Raise/lower crank: this should be lubricated on 20-hour intervals. This may vary based on the

number of times the unit is raised and lowered.

Figure 7.1

Disk and bearing: Bearings are sealed and do not require any maintenance. Under normal use,

the blade and bearing are an assembly and have approximately the same life. Under rare

circumstances, it may be necessary to replace them separately. Contact Veris Service Department

for the parts needed for individual bearing or blade replacement.

6-19

Page 41

OM17-Quad1000

Procedure #9: Removing EC Surveyor Cover: Microchip Replacement and Q1000 to 3150

Resistor Change

It may be necessary to open the EC Surveyor to perform one of the service functions listed below.

Disconnect power cable. Remove four screws in front end plate, and pull end plate slightly to free

up top panel. Be careful not to pull too hard and disconnect any wires.

Figures 9.2 a and b.

Slide top panel out to reveal circuits.

Figure 9.3

6-20

Page 42

OM17-Quad1000

Replacing microchip. If microchip fails, or if unit needs updated firmware, it will be necessary to

remove chip and replace with new one. Before chip removal and installation, touch grounded metal

to discharge your static electricity. Remove chip with pliers or chip puller. Install new chip, making

sure that notch in plastic housing is to the right. Be careful to not damage pins of new chip as it is

installed

Figure 9.4

Figure 9.5 a and b. Notch on chip must be to the right, matching notch on chip socket

Q1000 to 3150 Resistor Change. Because the disk-electrode spacing on a Quad1000 model is

different than a 3150, there are unique constants applied to the EC measurement values for each

model. The EC Surveyor Instrument Signal Test Procedure #1 shows the different signal test load

readings for each. For Q1000, 2000XA and 3100 models, a resistor is installed on the circuit

board. For 3150 models the resistor is not used. When the EC Surveyor is purchased with a

Q1000, 2000XA or 3100 models, the resistor is installed, and removed for the 3150 models. If it

becomes necessary to change this in the field, disconnect power cord, remove cover as shown

above and remove or install resistor as shown below.

6-21

Page 43

OM17-Quad1000

Figures 9.5 a, b, c 9a: Resistor installed for Q1000, 2000XA and 3100 models; 9b and c: position

for 3150 models: resistor in storage position—not being used; 9c resistor removed

Resistor can be removed or installed by hand as shown below.

Figure 9.6

6-22

Loading...

Loading...