Page 1

Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

TMTMTM

TM

Product Identication

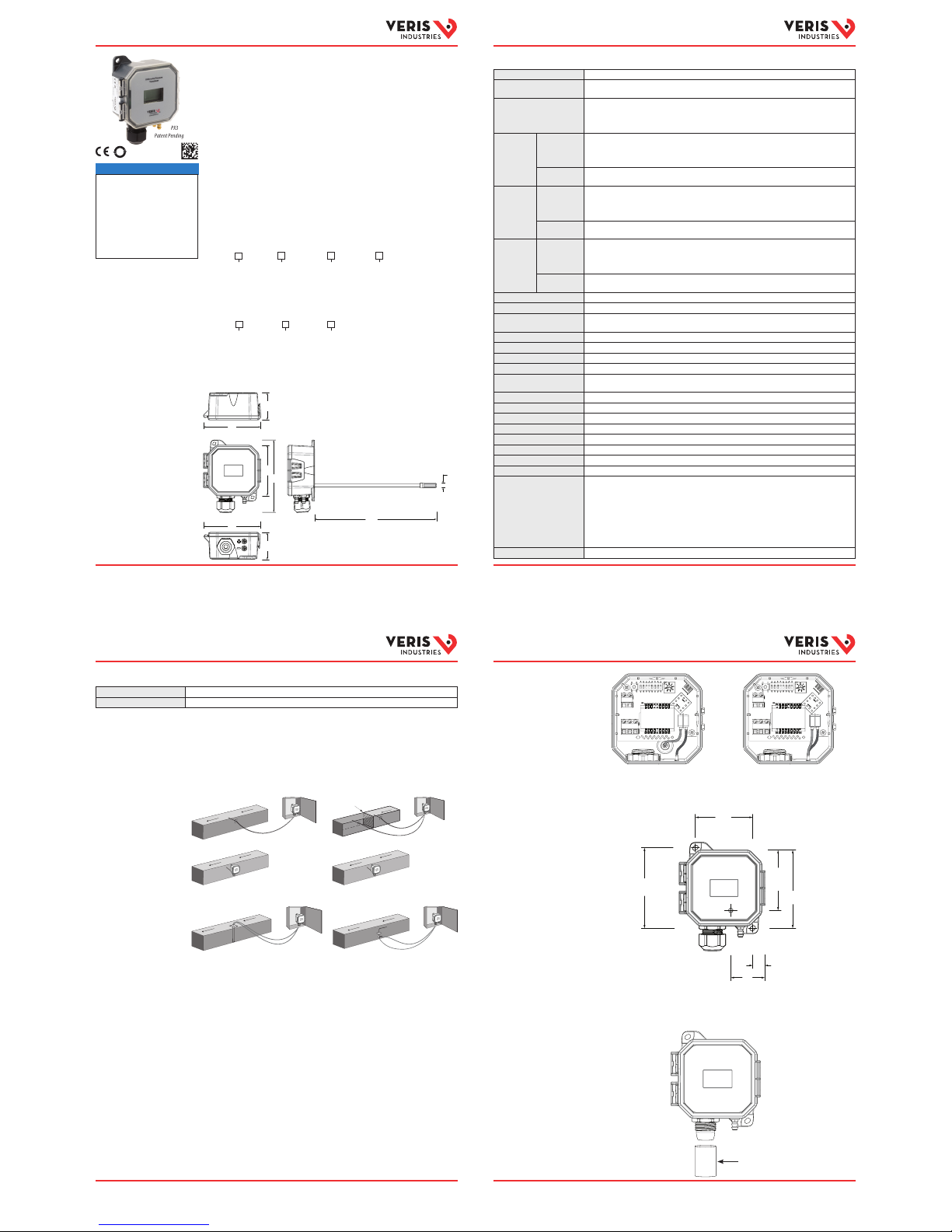

Dimensions

Product Overview

The PX3 transducer c an measure either air pressu re or velocity with the i p of a switch.

The PX3 is available in thre e installation congura tions: duct, panel or unive rsal. Duct and

panel models have two p ressure and velocity op tions: 0-1 in. WC / 0-3,000 ft/min or

1-10 in. WC / 3,000-6,000 ft/min w ith four eld-selec table sub-ranges. T he universal

model comes in one pre ssure/velocity ran ge: 0-10 in. WC / 0-7,000 ft/min w ith seven

eld-selec table sub-ranges for p ressure and eight for veloci ty. All variants are available

with and without di splay. The PX3 has an IP65/NEMA 4 environmenta l rating and a 5-year

limited warranty.

PX3 Series

Differential Pressure / Air Velocity Transducer

in. (mm)

PX3

Patent Pending

Media Compatibility Dry air or iner t gas

Input Power Three-wire Volt mod e: 24 Vac or 12-30 Vdc*

Two-wire mA mode: 12-30 Vdc*

Output Power Field-selectable: 2-wire, loop-powered 4-20 mA

Minimum input vol tage for 4 to 20 mA operatio n: 250 Ω loop = 12 Vdc; 500 Ω loop = 19 Vdc

(DC only, clipped and c apped), 24 Vac/dc or 3-wire 0 -5V/0-10V

Minimum load resi stance for Volt operati on: 5 kΩ

01 Pressure

Range

Pressure

Mode

Unidirectio nal: 0.1/0.25/0.5/1 in. WC FS, switch selec table

Bidirectio nal: ±0.1/±0.25/±0.5/±1 in. WC FS, switch selectab le

Unidirectio nal: 25/50/100/250 Pa FS, switch selec table

Bidirectio nal: ±25/±50/±100/±250 Pa FS, switch selectabl e

Velocity

Mode

500/1,000/2,000/3,000 ft/min

2.5/5/10/15 m/s

02 Pressure

Range

Pressure

Mode

Unidirectio nal: 1.0/2.5/5/10 in. WC FS, switch selec table

Bidirectio nal: ±1.0/±2.5/±5/±10 in. WC FS, switch sel ectable

Unidirectio nal: 250/500/1,000/2,500 Pa FS, s witch selectabl e

Bidirectio nal: ±250/±500/±1,000/±2,500 Pa FS, switch se lectable

Velocity

Mode

3,000/4,000/5,000/6,000 ft/min

15/20/25/30 m/s

05 Pressure

Range

Pressure

Mode

Unidire ctional: 0 .1/0.25/0.5/1/2.5/5/10 in . WC FS, switc h select able

Bidire ction al: ±0.1/±0.2 5/±0.5/±1/±2.5/± 5/±10 in. WC FS, sw itch sel ectab le

Unidirec tional: 25/50/100/250/500/1,00 0/2,500 Pa FS, sw itch selecta ble

Bidire ction al: ±25/±50/±100/± 250/±500 k/±1,000/± 2,500 Pa F S, switch select able

Velocity

Mode

500/1,000/2,000/3,000/4,000/5,000/6,000/7,000 ft/min

2.5/5/10/15/20/25/3 0/35 m/s

Response Time Standard: T95 in 20 sec, Fas t: T95 in 2 sec, DIP switch s electable

Mode Unidirectional or bidirectional, DIP switch selectable

Display (Option) Pressure mode: Signed 3 -1/2 digit LCD, indicates pressure, overran ge indicator

Velocity mode : Signed 4-1/2 digit LCD, indicates velo city, overrange indicat or

Proof Pressure 3 psid (20, 600 Pa)

Burst Pressure 5 psid (34, 500 Pa)

Pressure Mode Accuracy ±1% FS (combined lin earity and hysteres is)

Velocity Mode Accuracy ±90 ft/min (±0.45 m/s) plus 5% of measu red value**

Temperature Eect 1” (250 Pa) models: 0.05%/°C; 10” (2,50 0 Pa) models: 0.01%/°C

(Relative to 25 °C) 0 to 50 ° C (32 to 122 °F)

Zero Drif t (1-year) 1” (250 Pa) models: 2.0% max. ; 10” (2,500 Pa) models: 0.5% ma x.

Zero Adjust Pushbutton auto-zero and digital input (2-position terminal block)

Operating Environment 0 to 60 °C (32 to 140 °F)

Altitude of Operation 0 to 3,000 m

Pollution Degree 2

Humidity Range 100% RH, non-condensing

Mounting Location For indoor use only.

Fittings Brass barb; 0.24” (6.1 mm) o.d.

Suggested Cable Shielded:

Belden #9939 (22 AWG) 3-wi re multi-conduct or (or similar)

Belden #994 0 (22 AWG) 4-wire multi-co nductor (or similar)

Belden #9939 (22 AWG) 5-wi re multi-conduc tor (or similar)

Unshielded:

Belden #84 43 (22 AWG) 3-wire multi-condu ctor (or similar)

Belden #84 44 (22 AWG) 4-wire multi- conductor (or similar)

Belden #84 45 (22 AWG) 5-wire multi-cond uctor (or similar)

Environmental Rating IP65, NEMA 4

Specications

Installation, Wiring

& Conguration

FILTER

LOW

HIGH

AIR FLOW

AIR FLOW

AIR FLOW

AIR FLOW

Static Pressure

Panel Installations

Duct Installations

Dierential Pressure

1. Pl an the installation. Panel or du ct mount?

For velocity app lications, use the VFXP Se ries air velocity/measurem ent probe or AA18,

AA19 or AA20 velocity pitot tub es. For use with the PX3P (panel) a nd PX3U (universal)

models in Velocity mode only. Sold separately.

2. For duc t mount applications, thre ad the probe into the back of the d evice housing, as

shown in the dimensional drawing.

3. Congu re the internal tubing for th e selected installat ion method as describe d below.

Duct mount tubing conguration:

a. Connect the rig ht-side tube to the rear brass bar b marked as “-” on the

underside of the device housing.

b. Connect the lef t-side tube to the probe in the b ack of the device housing.

Panel mount tubing conguration:

a. Connect the rig ht-side tube to the rear brass bar b marked as “-” on the

underside of the device housing.

b. Connect the lef t-side tube to the front bra ss barb marked as “+” on the

underside of the device housing.

Installation, Wiring

& Conguration (cont.)

Specications (cont.)

4. Mount the transduce r (see the screw hole diagram be low).

5. For applicatio ns using conduit, remove the cab le gland nut on the bottom of th e unit.

Thread a standard 1/2-inch N PT female threaded coupler o nto the body of the cable

gland. Connect the o pposite end of the coupler to th e conduit.

Tubing for Duct Mount Tubing for Panel Mount

Tubing for Duct Mount

Tubing for Panel Mount

2.3

(59)

CTR-CTR

3.3

(83)

CTR-CT

R

2.5

(62)

To Pickup

Tube

1.4

(35)

To Pickup Tube

0.5

(13)

3.2

(81)

in. (mm)

NOTICE

•

This product is not intended for life or

safety applications.

• Do not install this product in hazardous

or classied locations.

•

Read and understand the instructions

before installing this product.

• Turn o all power supplying equipment

before working on it.

•

The installer is responsible for

conformance to all applicable codes.

If this product is used in a manner not specied

by the manufacturer, the protection provided

by the product may be impaired. No

responsibility is assumed by the manufacturer

for any consequences arising out of the use of

this material.

AIR FLOW

Z207504-0D Pa ge 3 of 8

©2018

Veris Indus tries 12345 SW L eveton Dri ve, Tualatin, O R 97062 USA / 800. 354.8556 or +1.503.598.456 4 / suppor t@veris .com 0518

Alta Labs, Ener cept, Enspec tor, Hawkeye, Trus tat, Aerosp ond, Veris, an d the Veris ‘V ’ logo are trad emarks or r egistere d trademark s of Veris Indu stries, L. L.C.

in the USA and/or ot her countri es. Other co mpanies’ t rademark s are hereby ac knowledg ed to belong to t heir respe ctive owne rs.

Z207504-0D Pa ge 1 of 8

©2018

Veris Indus tries 12345 SW L eveton Dri ve, Tualatin, O R 97062 USA / 800. 354.8556 or +1.503.598.456 4 / suppor t@veris .com 0518

Alta Labs, Ener cept, Enspec tor, Hawkeye, Trus tat, Aerosp ond, Veris, an d the Veris ‘V ’ logo are trad emarks or r egistere d trademark s of Veris Indu stries, L. L.C.

in the USA and/or ot her countri es. Other co mpanies’ t rademark s are hereby ac knowledg ed to belong to t heir respe ctive owne rs.

Z207504-0D Pa ge 4 of 8

©2018

Veris Indus tries 12345 SW L eveton Dri ve, Tualatin, O R 97062 USA / 800. 354.8556 or +1.503.598.456 4 / suppor t@veris .com 0518

Alta Labs, Ener cept, Enspec tor, Hawkeye, Trus tat, Aerosp ond, Veris, an d the Veris ‘V ’ logo are trad emarks or r egistere d trademark s of Veris Indu stries, L. L.C.

in the USA and/or ot her countri es. Other co mpanies’ t rademark s are hereby ac knowledg ed to belong to t heir respe ctive owne rs.

Z207504-0D Pa ge 2 of 8

©2018

Veris Indus tries 12345 SW L eveton Dri ve, Tualatin, O R 97062 USA / 800. 354.8556 or +1.503.598.456 4 / suppor t@veris .com 0518

Alta Labs, Ener cept, Enspec tor, Hawkeye, Trus tat, Aerosp ond, Veris, an d the Veris ‘V ’ logo are trad emarks or r egistere d trademark s of Veris Indu stries, L. L.C.

in the USA and/or ot her countri es. Other co mpanies’ t rademark s are hereby ac knowledg ed to belong to t heir respe ctive owne rs.

Velocity with VFXP Probe Velocity with AA18/AA19/AA20 Pitot Tube

AIR FLOW

1.6

(42)

1.6

(42)

3.5

(88)

3.5

(88)

4.4

(112)

7.4

(188)

0.

3

(7

)

3.1

(78)

PX3

Enclosure Local Display

D = Duct

P = Panel

L = LCD Display

X = No Display

NIST Certificate* Range

N = NIST

X = None

01 = Pressure: 0 to 1 in. WC / 0 to 250 Pa

Velocity: 0 to 3,000 ft/min / 0 to 15 m/s

02 = Pressure: 1 to 10 in. WC/250 to 2,500 Pa

Velocity: 0 to 6,000 ft/min / 0 to 30 m/s

*8-point calibration

PX3U

Local Display

L = LCD Display

X = No Display

NIST Certificate* Range

N = NIST*

X = None

05 = Pressure: 0 to 10 in. WC / 0 to 2,500 Pa

Velocity: 0 to 7,000 ft/min / 0 to 35 m/s

*16-point calibration

Flammability Rating UL 94 5VA re retardant A BS, plenum rated

Limited Warranty 5 years

EMC Conformance: EN 61000- 6-3 and A1 Class B, EN 61000-6-1.

* Class 2/II power source.

** For measured valu es between 200 and 700 0 ft/min (1 and 35 m/s).

1/2-inch NPT female threaded coupler

50

Page 2

Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

TMTMTM

TM

2-wire, 4-20 mA Current Loop Output

3-wire, 0-5 V/0-10 V Voltage Outpu t

DIGITAL CONTROL

Digital

Output

Return

V+

1.000

0

1

2

3

4

5

6

7

PWR

mA RTN

{

RMT.

ZERO

ZERO

1.000

0

1

2

3

4

5

6

7

{

RMT. ZERO

ZERO

DIGITAL CONTROL

Digital

Output

V IN

-

POWER SOURCE

24 Vac/dc

-

+

V+/PWR

V-/GND

VOUT

Installation, Wiring

& Conguration (cont.)

Installation, Wiring

& Conguration (cont.)

Installation, Wiring

& Conguration (cont.)

Operation

9. Wait ve seconds, then press and hold the ZERO pu shbutton for two

seconds or provide co ntact closure on the AUX ZERO ter minal. This will reset

the output and display t o zero pressure. For best accu racy, press the ZERO

button while bot h ports are open to atmo spheric pressure. To protect t he unit

from accidental ze ro, this feature is enabled only wh en the detected press ure

is within about 0.1 in. WC (25 Pa) of factor y calibration.

10. Connect desired external tub ing to the PX3.

PX3 Series device s employ high performan ce sensors and sophist icated

temperature compensation circuitry. The sensor achieves its best accuracy after

an initial warm-up period. During the rst few minutes of operation, readings

at zero pressure and th e lowest pressure ranges ap pear erroneous. Followi ng

this initial warm- up period, the PX3 device maint ains its specied acc uracy and

sta bilit y.

The LCD momentarily ind icates range ‘SET’ when a sel ection is made. Pressure

is normally indicate d on the display. Units are in inches wat er column (in. WC),

Pascals (Pa) or kilopasc als (kPa) as indicated on the display. The disp lay shows

‘OVER’ when the pressur e is over range.

Rotary Switch Settin gs

Range 01 Model, Field Selec table (WC / ft/min or Pa / m/s)

WC / ft/min Pa / m/s

0 0 to 0.1 in. WC 0 0 to 25 Pa

1 0 to 0.25 in. WC 1 0 to 50 Pa

2 0 to 0.5 in. WC 2 0 to 100 Pa

3 0 to 1 in. WC 3 0 to 250 Pa

4 0 to 500 ft/min 4 0 to 2.5 m/s

5 0 to 1,000 ft/min 5 0 to 5 m/s

6 0 to 2,000 ft/min 6 0 to 10 m/s

7 0 to 3,000 ft/min 7 0 to 15 m/s

Z207504-0D Pa ge 5 of 8

©2018

Veris Indus tries 12345 SW L eveton Dri ve, Tualatin, O R 97062 USA / 800. 354.8556 or +1.503.598.456 4 / suppor t@veris .com 0518

Alta Labs, Ener cept, Enspec tor, Hawkeye, Trus tat, Aerosp ond, Veris, an d the Veris ‘V ’ logo are trad emarks or r egistere d trademark s of Veris Indu stries, L. L.C.

in the USA and/or ot her countri es. Other co mpanies’ t rademark s are hereby ac knowledg ed to belong to t heir respe ctive owne rs.

Z207504-0D Pa ge 7 of 8

©2018

Veris Indus tries 12345 SW L eveton Dri ve, Tualatin, O R 97062 USA / 800. 354.8556 or +1.503.598.456 4 / suppor t@veris .com 0518

Alta Labs, Ener cept, Enspec tor, Hawkeye, Trus tat, Aerosp ond, Veris, an d the Veris ‘V ’ logo are trad emarks or r egistere d trademark s of Veris Indu stries, L. L.C.

in the USA and/or ot her countri es. Other co mpanies’ t rademark s are hereby ac knowledg ed to belong to t heir respe ctive owne rs.

Z207504-0D Pa ge 8 of 8

©2018

Veris Indus tries 12345 SW L eveton Dri ve, Tualatin, O R 97062 USA / 800. 354.8556 or +1.503.598.456 4 / suppor t@veris .com 0518

Alta Labs, Ener cept, Enspec tor, Hawkeye, Trus tat, Aerosp ond, Veris, an d the Veris ‘V ’ logo are trad emarks or r egistere d trademark s of Veris Indu stries, L. L.C.

in the USA and/or ot her countri es. Other co mpanies’ t rademark s are hereby ac knowledg ed to belong to t heir respe ctive owne rs.

Z207504-0D Pa ge 6 of 8

©2018

Veris Indus tries 12345 SW L eveton Dri ve, Tualatin, O R 97062 USA / 800. 354.8556 or +1.503.598.456 4 / suppor t@veris .com 0518

Alta Labs, Ener cept, Enspec tor, Hawkeye, Trus tat, Aerosp ond, Veris, an d the Veris ‘V ’ logo are trad emarks or r egistere d trademark s of Veris Indu stries, L. L.C.

in the USA and/or ot her countri es. Other co mpanies’ t rademark s are hereby ac knowledg ed to belong to t heir respe ctive owne rs.

8. Connect the tran smitter to the control sy stem and power supply as indic ated

below. Optional: Connec t the ZERO terminals to the digital o utput (contact

closure) of the control s ystem.

DIP Switch 1: Scale

ON = Pascal (m/s)

OFF = In. WC (ft/min)

DIP Switch 2: Mode

ON = Velocit y

OFF = Pressur e

DIP Switch 3: Direction*

ON = Unidirectional

OFF = Bidirectional

DIP Switch 4: Response

ON = Slow

OFF = Fast

*Velocity mod e is unidirecti onal regardless o f DIP switch set ting.

DIP Switch 5: Output

ON = 4-20 mA

OFF = Voltage

DIP Switch 6: Volt Scale

ON = 0-5 Vdc

OFF = 0-10 Vdc

DIP Switch 7: Unused

DIP Switch 8: Unused

DIP Switch Settings

Scale Mode Direction Response Output Volt Scale

ON

Pascal/MPS VelocityUni Slow mA 5V

OFF

In. WC/FPM PressureBiFast Volt 10V

123456

Unused

Unused

Unused

8

Unused

Unused

Unused

7

7. Set rotary switch to the desired setti ng. Align the arrow (not the slot) on the

rotary switch to the desir ed full-scale range. LCD models momentarily indicate

the selected range.

6.

Set DIP switches to de sired settings.

Rotary Switch Settin gs (cont.)

Range 02 Model, Field Sele ctable (WC / ft/min or Pa / m/s)

WC / ft/min Pa / m/s

0 0 to 1 in. WC 0 0 to 250 Pa

1 0 to 2.5 in. WC 1 0 to 500 Pa

2 0 to 5 in. WC 2 0 to 1,000 Pa

3 0 to 10 in. WC 3 0 to 2,500 Pa

4 0 to 3,000 ft/min 4 0 to 15 m/s

5 0 to 4,000 ft/min 5 0 to 20 m/s

6 0 to 5,000 ft/min 6 0 to 25 m/s

7 0 to 6,000 ft/min 7 0 to 30 m/s

Range 05 Model, Field Sel ectable (P) Pressure or (V) Velocit y Mode,

Field Selectable ( WC / ft/min or Pa / m/s)

(P) Pressure Mode (V) Velocity Mode

0 0 to 0.1 in. WC 0 0 to 500 ft/min

1 0 to 0.25 in. WC 1 0 to 1,000 ft/min

2 0 to 0.5 in. WC 2 0 to 2,000 ft/min

3 0 to 1 in. WC 3 0 to 3,000 ft/min

4 0 to 2.5 in. WC 4 0 to 4,000 ft/min

5 0 to 5 in. WC 5 0 to 5,000 ft/min

6 0 to 10 in. WC 6 0 to 6,000 ft/min

7 0 to 10 in. WC 7 0 to 7,000 ft/min

(P) Pressure Mode (V) Velocity Mode

0 0 to 25 Pa 0 0 to 2.5 m/s

1 0 to 50 Pa 1 0 to 5 m/s

2 0 to 100 Pa 2 0 to 10 m/s

3 0 to 250 Pa 3 0 to 15 m/s

4 0 to 500 Pa 4 0 to 20 m/s

5 0 to 1,000 Pa 5 0 to 25 m/s

6 0 to 2,500 Pa 6 0 to 30 m/s

7 0 to 2,500 Pa 7 0 to 35 m/s

Environment-Friendly Use Perio d (EFUP) Table

China RoHS Compliance

Information

本表格依据SJ/T11364的规定编制。

O: 表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572规定的限量要求以下。

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572规定的限量要求。

(企业可在此处,根据实际情况对上表中打 的技术原因进行进一步说明。)

This table is made according to SJ/T 11364.

O: indicates that the concentraon of hazardous substance in all of the homogeneous materials

for this part is below the limit as spulated in GB/T 26572.

X: indicates that concentraon of hazardous substance in at least one of the homogeneous

X O O O O O

materials used for this part is above the limit as spulated in GB/T 26572

Z000057-0B

部件名称

Part Name

有害物质 - Hazardous Substances

铅 (Pb)

汞 (Hg)

镉 (Cd) 六价铬 (Cr (VI)) 多溴联苯 (PBB) 多溴二苯醚 (PBDE)

电子件

Electronic

Loading...

Loading...