Page 1

TM

PX SerieS PX SerieS

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• Read and understand the instructions before installing

this product.

• Turn off all power supplying equipment before working on it.

• The installer is responsible for conformance to all applicable codes.

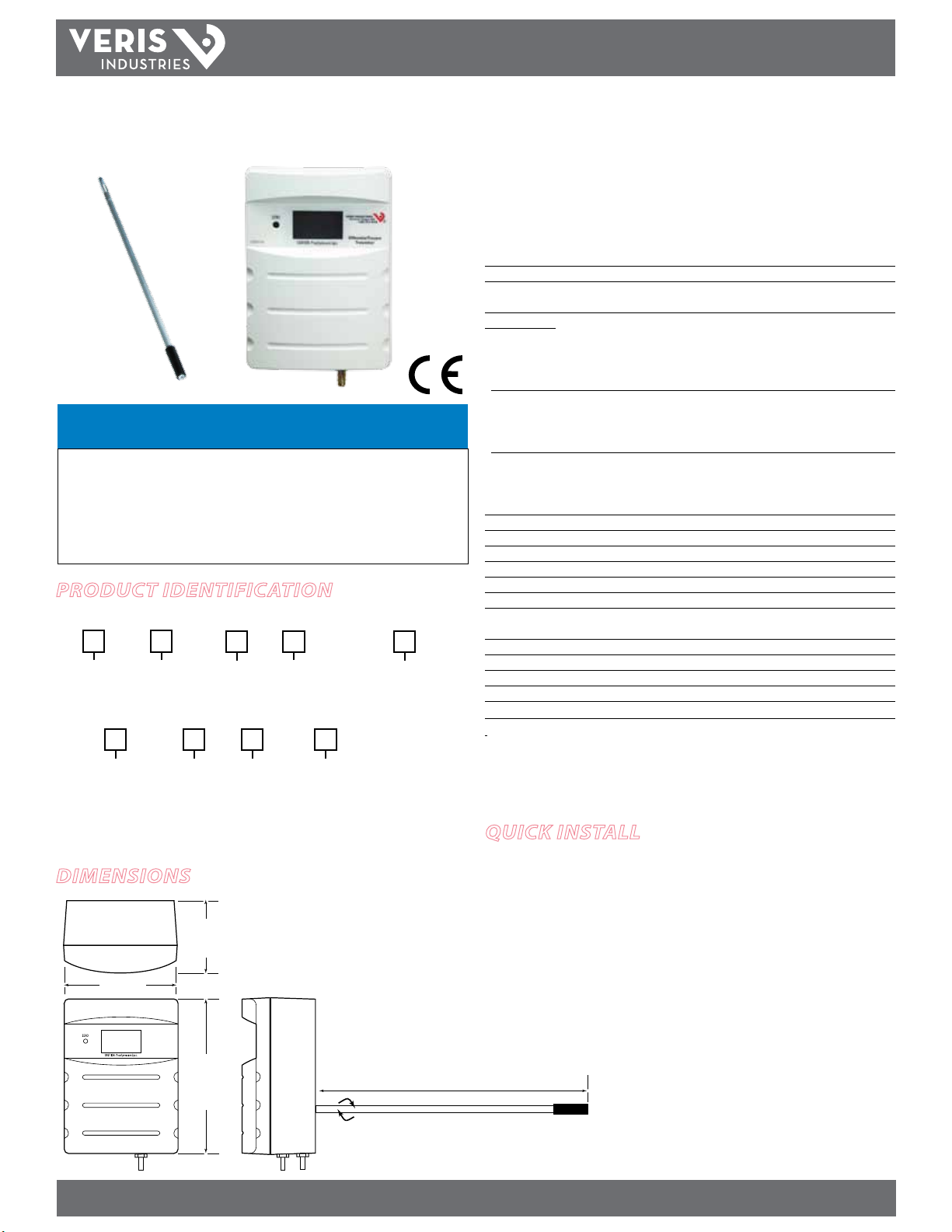

ProDuct iDentification

EnvironmEntal SEnSorS

Enclosure

PX

D = Duct

P = Panel

Local Display

PXU

Local Display

L = LCD Display

X = No Display

L = LCD Display

X = No Display

NIST

N = NIST

X = None

NIST

N = NIST

X = None

Range

01 = 0-1"W.C./0-250Pa

02 = 0-10"W.C./0-2.500kPa

Range

05

= 0-10”/0-2.500kPa

Response

S = Selectable

F = Selectable

Response

S

= Selectable

inStallation GUiDE

Digital Pressure Transducer

Dry Media

Installer’s Specifications

Media Compatibilit y Dry air or inert gas

Input Power 12-30VDC, or 24VAC nominal; 2-wire: 20mA max.; 3-wire: 30mA max.

Output Field-selectable: 2-wire, loop-powered 4-20mA

(DC only, clipped and capped), or 3-wire 0 -5V/0-10V*

Pressure Rang es:

PX: 01 Unidirec tional: 0.1/0.25/0.5/1.0” W.C. F.S., switch selectable

Bidirectional: ±0.1/±0.25/±0.5/±1.0” W.C. F.S., switch selec table

Unidirectional: 25 Pa/50 Pa/100 Pa/250 Pa, F.S., switch sele ctable

Bidirectional: ±25 Pa/±50 Pa/±100 Pa/±250 Pa, F.S., switch selectable

PX: 02 Unidirec tional: 1.0/2.5/5.0/10” W.C. F.S., switch selec table

Bidirectional: ±1.0/±2.5/±5.0/±10” W.C. F.S., switch selectable

Unidirectional: 0.250 kPa/0.500 kPa/1.000 kPa/2.500 kPa, F.S., switch sele ctable

Bidirectional: ±0.250 kPa/±0.500 kPa/±1.000 kPa/±2.500 kPa, F.S., switch select able

PXU: 05 Unidirec tional: 0.1/0.25/0.5/1.0/2.5/5/10” W.C. F.S., switch selec table

Bidirectional: ±0.1/0.25/0.5/1.0/2.5/5/10” W.C. F.S., switch selectable

Unidirectional: 25Pa/50Pa/100Pa/250Pa/0.5kPa/1kPa/2.5kPa F.S., switch selectable

Bidirectional: ±25Pa/50Pa/100Pa/250Pa/0.5kPa/1kPa/2.5kPa F.S., switch selectable

Response Time Standard: T95 in 20 sec , Fast: T95 in 2 sec, jumper selec table

Mode Unidirectional or bidirectional, jumper selectable

Display (option) Signed 3-1/2 digit LCD, indicates pressure, overrange indicator

Proof Pressure 3 psid (20.6kPa)

Burst Pressure 5 psid (34.5kPa)

Accuracy ±1% F.S. of selected range (combined linearit y and hysteresis)

Temperature Eect 1” (250Pa) models: 0.05%/°C; 10” (2.5kPa) models: 0.01%/°C

(Relative to 25°C) 0° to 50°C (32° to 122°F)

Zero Drif t (1-year) 1” (250Pa) models: 2.0% max.; 10” (2.5kPa) models: 0.5% max.

Zero Adjust Pushbutton auto-zero and digital input (2-pos terminal block)

Operating Environment 0°- 60°C (32° to 140°F); 0 to 90 % RH non-condensing

Fittings Brass barb; 0.24” (6.1mm) o.d.

Physical UL 94 V-O Fire Retardant ABS

EMC Conformance: EN 61000- 6-3:2007 and A1:2011 Class B, EN 61000-6-1:2007

EMC Special Note: Connect this produc t to a DC distribution network or an AC/DC powe r adaptor

with proper surge protection (EN 61000-6-1:2007 specication requirements).

* Minimum input voltage for 4 -20 mA operation: 250 Ω loop = 13 VDC; 500 Ω loop = 19 VDC

quick install

Dimensions

1. Plan the installation. Panel or duct mount?

2. For duct mounting, thread the probe into the rear of the device housing.

2.2"

(55 mm)

3.3"

(84 mm)

Inch H2O

Differential Pressure

Transmitter

4.5"

(114 mm)

8.0"

(202 mm)

Z103591-0A

Z205213-0D PAGE 1 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

3. Congure the internal tubing for the selected installation method.

4. Mount the housing vertically.

5. Attach pilot tubing.

Page 2

TM

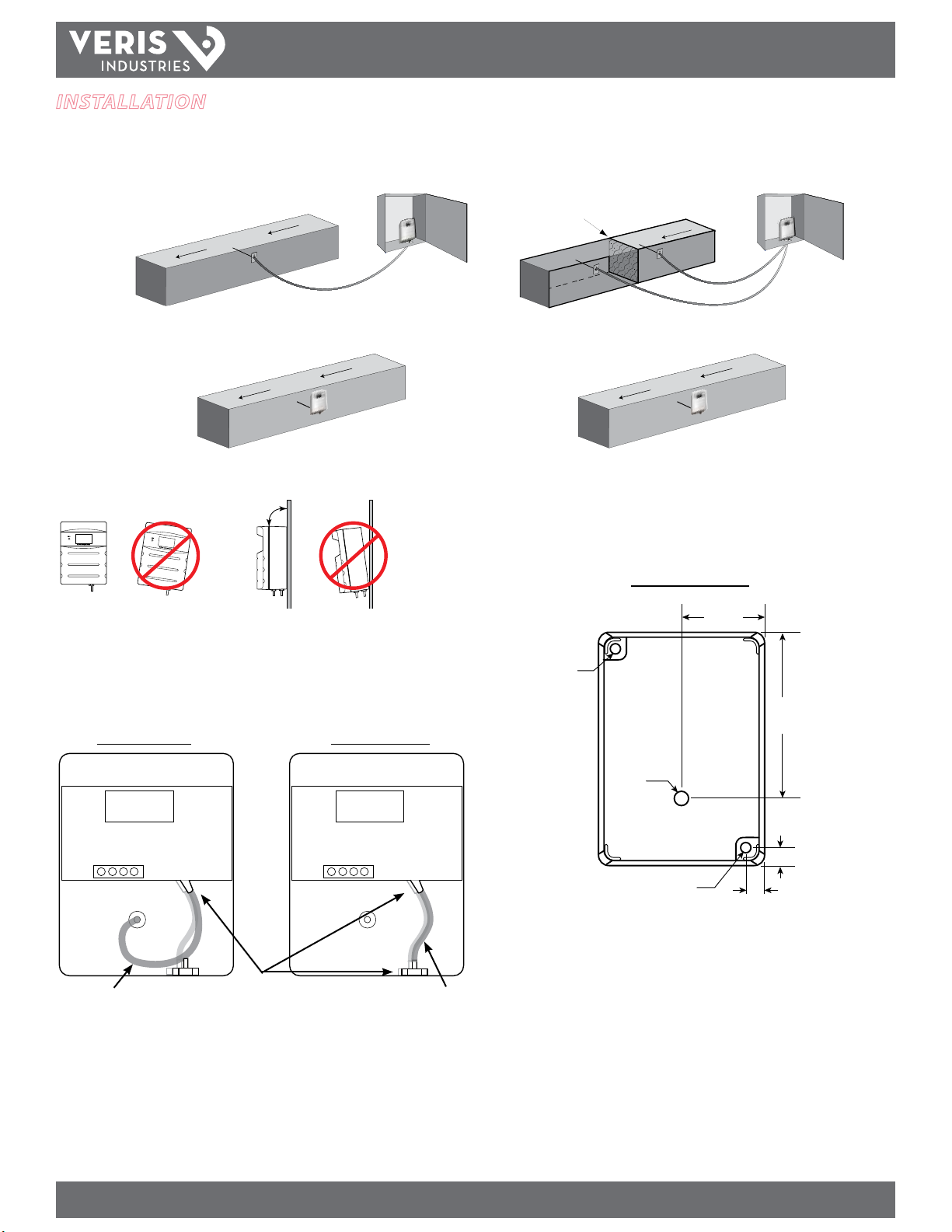

installation

1. Plan the installation. Panel or duct mount?

Static Pressure Differential Pressure

Panel

Installations

Duct

Installations

AIR FLOW

AIR FLOW

PX SEriES

inStallation GUiDE

FILTER

AIR FLOW

HIGH

LOW

AIR FLOW

90˚

Inch H2O

Differential Pressure

Transmitter

Z103591-0A

Inch H

O

2

Z103591-0A

Differential Pressure

Transmitter

YES!

YES!

2. For duct mount applications, thread the probe into the back of the device housing.

3. Congure the internal tubing for the selected installation method as shown below.

Use the larger diameter tubing for the duct mount conguration.

Tubing for Duct Mount Tubing for Panel Mount

4. Mount the transducer (see the screw hole diagram). Position the transducer

vertically.

Screw Hole Mounting

Ø 1.6 “

(40 mm)

Ø 0.15 “

(3.7 mm)

Ø 3.3 “

(83 mm)

Ø 0.2 “

(5.2 mm)

+

Ø 0.15 “

(3.7 mm)

+

Ø 0.38 “

(9.7 mm)

Ø 0.38 “

(9.7 mm)

5. Determine the length of pilot tubing needed.

Larger diameter tube

for duct conguration

Use the

front barb

Smaller diameter tube

for panel conguration

Z205213-0D PAGE 2 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 3

TM

PX SEriES

inStallation GUiDE

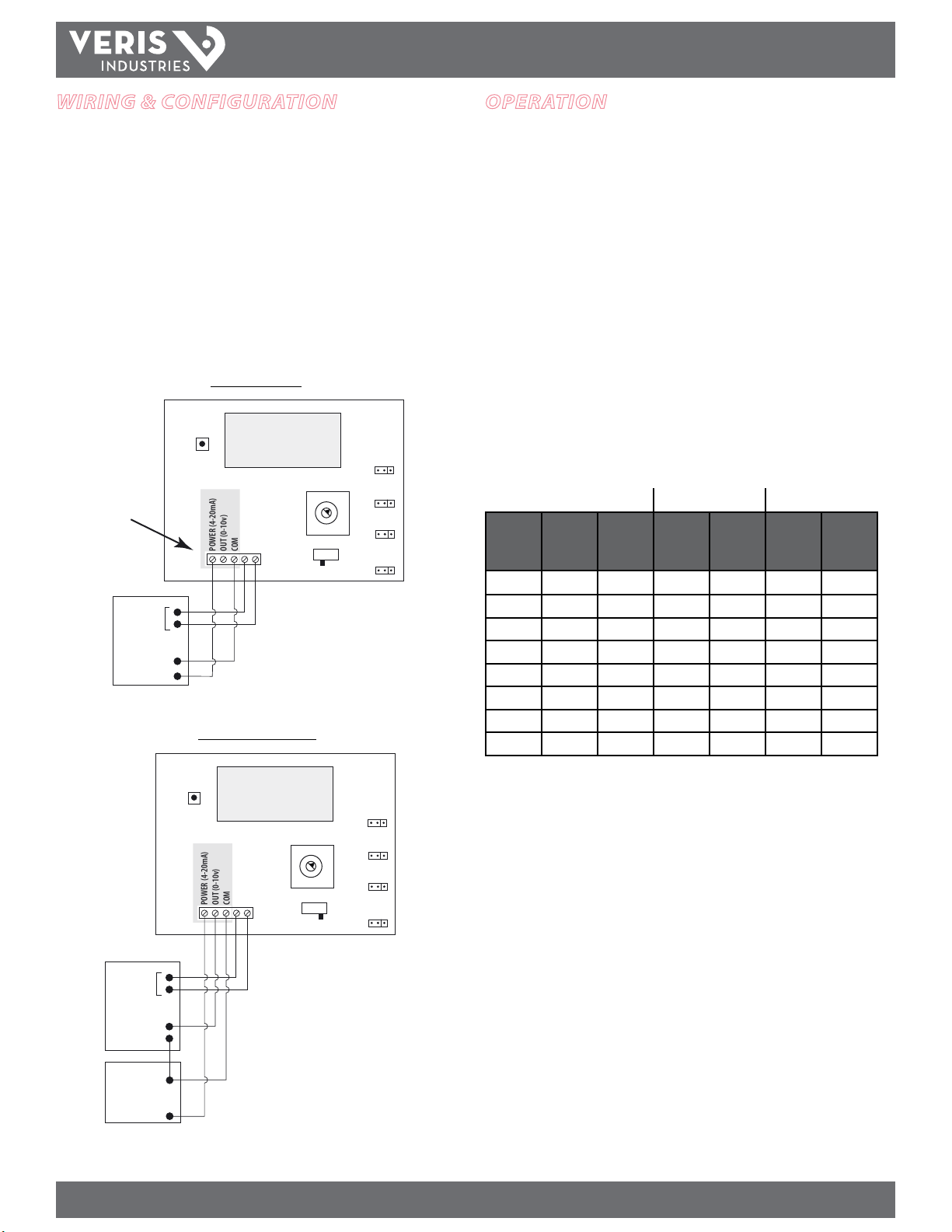

WirinG & confiGuration

Connect the transmitter to the control system and power supply as indicated below.

Optional: Connect the ZERO terminals to the digital output (contact closure) of the

control system.

Use the switch to select voltage (V) or current (mA) mode.

Jumper JP4: select 0-10 V or 0-5 V output span (voltage mode only).

Jumper JP5: select bidirectional or unidirectional mode.

Jumper JP7: select inches W.C. or Pascal scale

Jumper JP8: select fast or standard response time.

Align the arrow (not the slot) on the rotary switch to the desired full-scale range. LCD

models momentarily indicate the selected range.

2-wire, 4-20 mA

ZERO

WARNING:

Do not

apply power

to output terminal!

Permanent damage

will result.

Digital

Output

DIGITAL CONTROL

Return

POWER (4-20mA)

OUT (0-10v)

V+

3-wire, 0-5 V/0-10 V

1.000

ZERO

COM

mA

7

6

5

OUTPUT

RESPONSE

FAST/STD

JP8

UNITS

IN W.C./PA

0

1

JP7

2

MODE

3

4

BI/UNI

JP5

VOLT

5V/10V

Volt

JP4

oPeration

PX Series devices employ ceramic capacitive sensors and sophisticated temperature

compensation circuitry. The sensor achieves its best accuracy af ter an initial warm-up

period. During the rst few minutes of operation, readings at zero pressure and the

lowest pressure ranges appear erroneous. Following this initial warm-up period, PX

Series maintains its specied accuracy and stability.

LCD DISPL AY: The display momentarily indicates range “SET” when selec tion is made.

Pressure is normally indic ated on the display. Units are in inches water column (in. W.C.),

Pascals (Pa) or kilopascals (kPa) as indicated on the display. The display shows OVER

when the pressure is over range.

ZERO: Press and hold the ZERO pushbutton for 2 seconds or provide contact closure

on ‘AUX ZERO’ terminal to automatically reset the output and display to zero

pressure. To protect the unit from accidental zero, this feature is enabled only when

the detected pressure is within about 0.1 in. W.C. (25 Pa) of factory calibration.

Range Selection Guide

PX01 PX02 PX05

Rotary

Switch

Position

0 0.1 25 1 250 0.1 25

1 0.25 50 1 250 0.25 50

2 0.5 100 1 250 0.5 100

3 1 250 1 250 1 250

4 1 250 2.5 0.5 kPa 2.5 0.5 kPa

5 1 250 5 1 kPa 5 1 kPa

6 1 250 10 2.5 kPa 10 2.5 kPa

7 1 250 10 2.5 kPa 10 2.5 kPa

Inches

W.C.

Pascal

Inches

W.C.

Pascal

Inches

W.C.

Pascal

ZERO

RESPONSE

FAST/STD

JP8

UNITS

IN W.C./PA

1

JP7

2

3

4

MODE

BI/UNI

JP5

VOLT

5V/10V

Volt

JP4

Digital

Output

DIGITAL CONTROL

V IN

POWER SOURCE

24VAC/DC

1.000

0

7

6

5

ZERO

POWER (4-20mA)

OUT (0-10v)

COM

mA

OUTPUT

-

-

+

Z205213-0D PAGE 3 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Loading...

Loading...