Page 1

Operating Instructions

Mobile Sensor Platform

pH Manager

Table of Contents

Section 1

1-1 Warranty

1-2 Safety

Section 2

2-1 Electronics Overview and Set-up: EC Surveyor

2-2 Electronics Overview and Set-up: DataLogger

2-4 Software Set-up: SoilViewer

Section 3 Field Operations: Electronics

3-1 Field Operations—Mapping pH with DataLogger

3-2 pH calibration and Controller set-up using DataLogger

3-6 Recording Data with DataLogger

3-12 Field Operations—Mapping pH with SoilViewer Software

3-15 pH calibration and Controller set-up using SoilViewer software

3-19 Recording Data with SoilViewer software

Section 4 Set-up and Field Operations: Implement

4-1 12v Power and Hydraulics Set-up

4-5 Implement Set-up and Adjustments

4-7 Field Operation Adjustments

Section 5

5-1 Maintenance and Service Procedures

Section 6 Troubleshooting

6-6 #1: Checking power inside External Controller

6-9 #2. Sampler Cylinder Hydraulics

6-12 #3. Communication between Instrument and External Controller

6-18 #4. Prox Sensor

6-21 #5. Diagnosing GPS-related problems

6-25 #6. Firmware updates and SD card formatting

6-26 #7. Micro-chip replacement

Pub.# OM17-MSP-pH

Page 2

Pub.# OM17-MSP-pH

Mobile Sensor Platform: pH Manager

Soil EC Surveyor Software Version 1.2

Sensor DataLogger Version 1.03

Warranty

Veris Technologies warrants this product to be free of defects in materials and workmanship for a

period of one (1) year from the date of delivery to the purchaser. Veris Technologies will repair or

replace any product returned to Salina, Kansas, which appears upon inspection to be defective in

materials or workmanship. Veris Technologies will have shall have no obligation under this

warranty for the cost of labor, down-time, transportation charges, or for the repair or replacement of

any product that has been misused, carelessly handled, modified, or altered.

ALL OTHER WARRANTIES OF ANY KIND, WHETHER EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE AND ALL CLAIMS FOR CONSEQUENTIAL DAMAGES, ARE

SPECIFICALLY DISCLAIMED AND EXCLUDED.

Safety

1-1

Page 3

Pub.# OM17-MSP-pH

Important! Read the following SAFETY PROCEDURES before operating the Veris system:

• Read and understand all instructions on safety decals

• Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard

by relieving pressure before disconnecting hydraulic lines. Use a piece of paper or card-board,

NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and highpressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result.

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the Veris

implement.

• Install all transport locks before transporting or working underneath.

• Detach and store implements in an area where children normally do not play. Secure implement

by using blocks and supports.

• Read Operations Manual before operating machine

• Review safety instructions with operators before operating machine and at least annually

• Never stand on or use tire as a step

• Do not tow the implement on public roads without the road-kit light package, or without the proper

safety equipment and licensing as required by your State Department of Transportation. Always

use safety chain.

• Riders obstruct the operator’s view. They could be struck by foreign objects or thrown from the

machine.

• Never allow children to operate equipment.

• To prevent possible electrical shock, or damage to the instrument, do not connect to any power

source greater than twelve (12) volts DC.

• Do not grease or oil implement while it is in operation.

• Disk edges are sharp. Be careful when working in this area.

• Disconnect battery ground cable (-) before servicing or adjusting electrical systems or before

welding on implement.

• Remove buildup of mud, oil or debris.

• Be very careful when mapping stubble fields with a gasoline engine pickup. Be prepared if a fire

starts.

• Keep a first aid kit and fire extinguisher handy.

Page 4

Pub.# OM17-MSP-pH

EC

Surveyor

DataLogger

SD

card

reader

Mtg

bracket

Power

cord

Signal test

box

Mtg

bracket

Power cord

Signal test

load

Serial

cable

Soil

Viewer

software

Protective

case

SECTION 2

Electronics Overview and Set-up

The Veris Electronics kits includes the items shown in Figure 1. Additionally, the pH Manager

includes a pH simulator and fuse kit.

Figure 1a EC Surveyor/pH Manager kit Figure 1b. DataLogger kit

Use protective shipping/storage case to protect electronics components whenever electronics are

shipped. Keep all diagnostics and operations manual with system when mapping.

Mount instrument in a location that is as free as possible from dust, vibration, and electrical

interference. Display should be visible to operator and shielded from direct sunlight. Use

adjustable mounting brackets to position electronics for optimal visibility (Figure 2).

Figure 2

2-1

Page 5

Figure 3 EC Surveyor (rear)

Power port:

The Soil EC Surveyor is shipped

with an accessory power cord.

If an alternative connection is

desired, make sure that the unit

is properly connected to a power

connection that is not controlled

by the ignition switch. If

connecting directly to the

battery, we suggest a 3-amp inline fuse is installed between the

battery and the instrument.

EC Signal:

EC Signal Cable

extension from

implement attaches

to the EC Surveyor

here. Route cable

properly to prevent

damage. Signal test

load also attaches

here—used to test

EC Surveyor.

EC Data out:

Attach serial cable

here and other end

to Sensor

DataLogger or

laptop PC.

GPS input:

Connect GPS cable here.

It is designed to accept

GPS input in NMEA 0183

format via an RS232

connector.

(GPS must send GGA and

either VTG or RMC strings

at a 1hz rate, at 4800 baud,

8 data bits, 1 stop bit, no

parity.)

Data Status:

When lit, this green LED

indicates data is being sent

out serial port. If not lit, EC

values are negative or GPS

signal not received.

Power:

When lit, this red

LED indicates EC

Surveyor is powered

up.

On/Off:

Turns power to EC

Surveyor on and

off.

Fuse:

This allows the fuse to

be replaced, with a 1A

fastblow fuse, if blown.

Figure 4 EC Surveyor (front)

Pub.# OM17-MSP-pH

2-2

Page 6

Pub.# OM17-MSP-pH

Data Status:

When lit, this green

LED indicates data

is being recorded to

memory card. If not

lit, EC values are

negative or GPS

signal not received.

Power:

When lit, this red

LED indicates

Sensor DataLogger

is powered up.

Memory Card slot:

SD memory storage

card must be

installed when

booting up, and at all

times data is being

collected.

pH:

Serial cable from pH

Controller (MSP

only) attaches here.

Reset

button:

Can be used

to reboot

DataLogger

Power port:

The Sensor DataLogger is

shipped with an accessory

power cord. If an alternative

connection is desired, make

sure that the unit is properly

connected to a power

connection that is not

controlled by the ignition

switch. If connecting directly

to the battery, we suggest a

3-amp in-line fuse is

installed between the battery

and the instrument.

Alarm Vol:

Used to adjust

volume of auditory

alarm

EC:

Serial cable

from EC

Surveyor

attaches here.

On/Off:

Turns power to

Sensor DataLogger

on and off.

Fuse:

This allows the fuse

to be replaced, with

a 500mA Fastblow

fuse, if blown.

Figure 5 DataLogger (rear)

Figure 6 DataLogger (front)

Important – Do not allow moisture to enter the Soil EC Surveyor or Sensor DataLogger, and

do not pass strong magnets near the unit.

2-3

Page 7

Figure 8

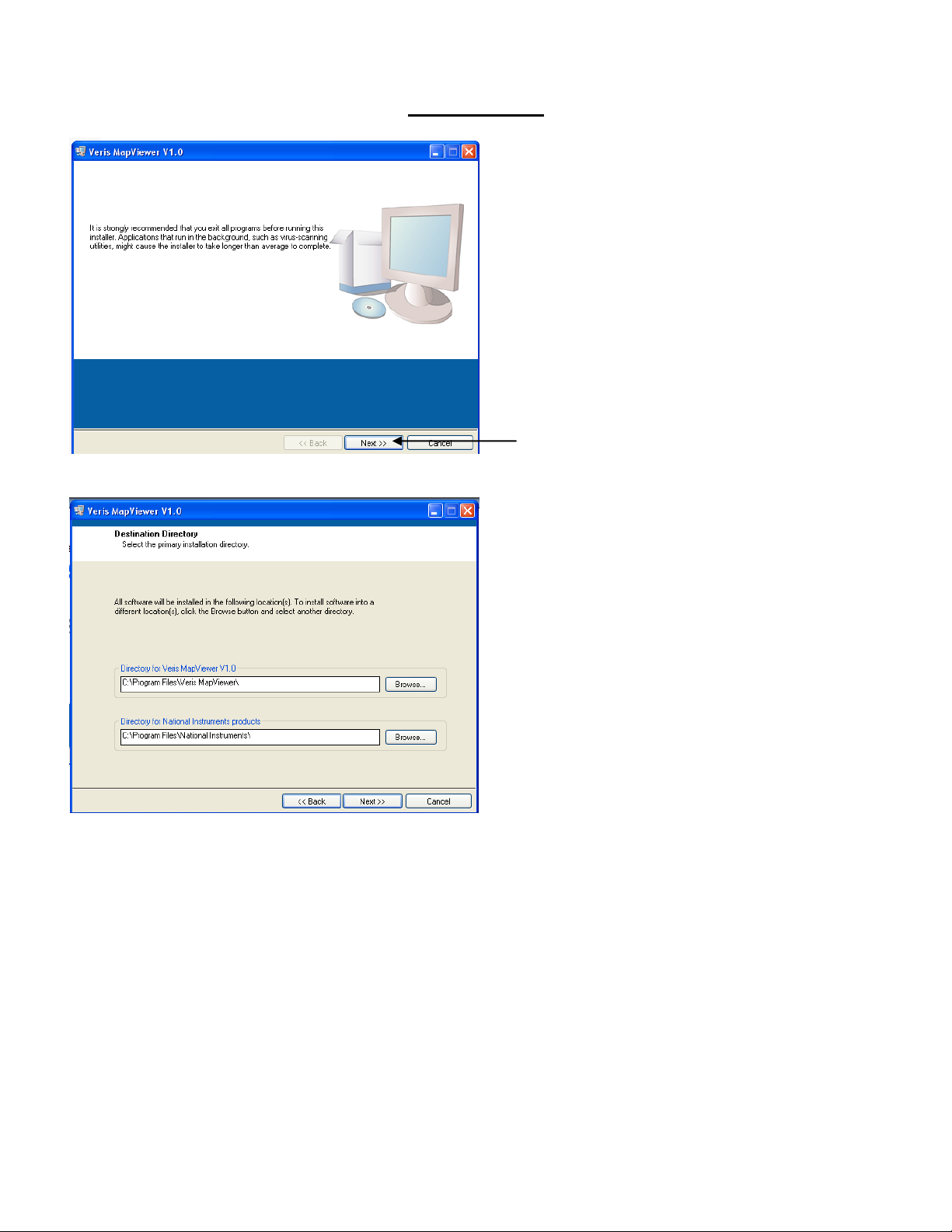

The Veris SoilViewer software will

automatically run the setup once the CD

is inserted into the computer. If not the

installation can be manually started by

double clicking on the setup.exe located

on the CD.

Once the CD has begun select the

installation directory and click Next

Click Next to continue through

installation

Pub.# OM17-MSP-pH

Software Setup

Figure 9

2-4

Page 8

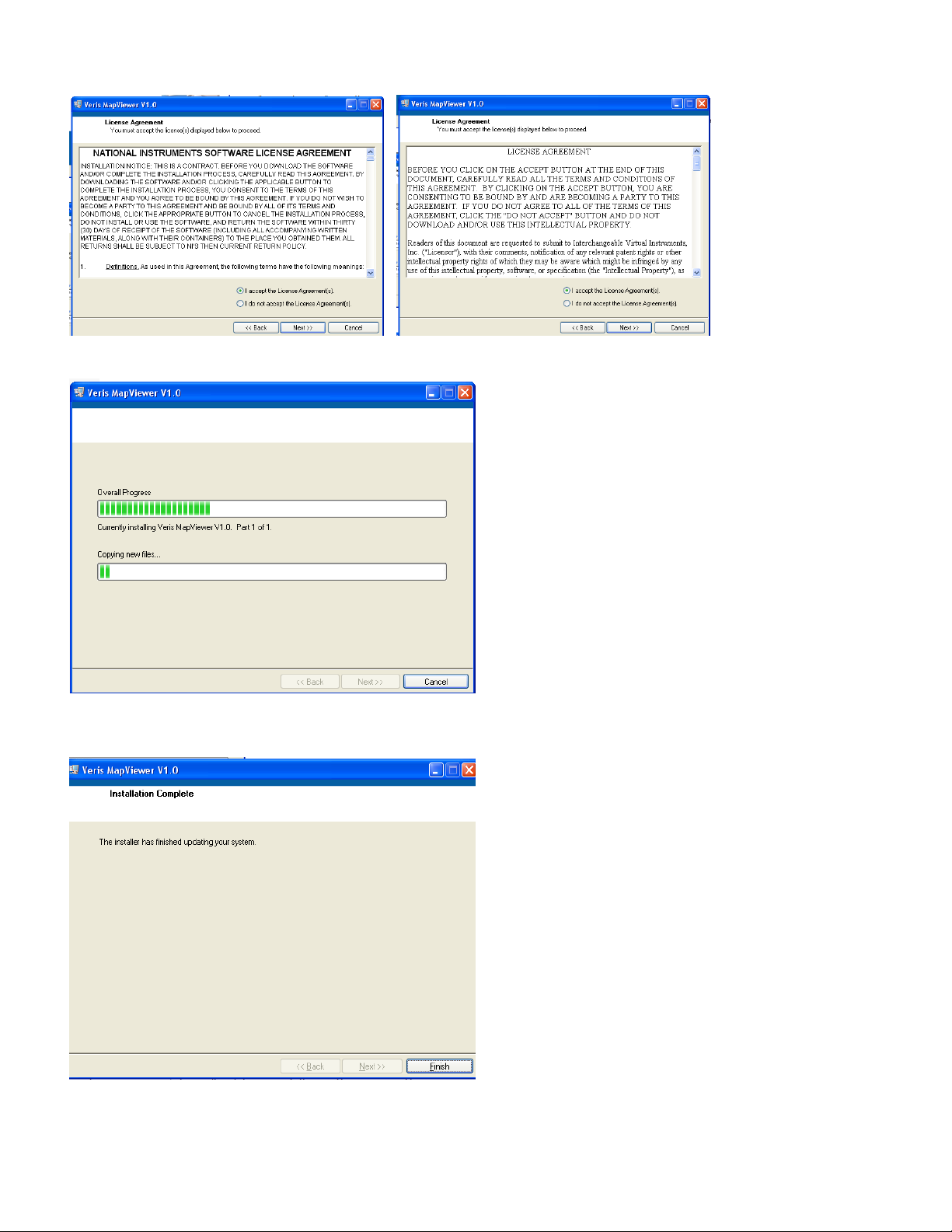

Figures 10a and 10b

Next two license

agreements will need

to be accepted

before continuing.

The installer will

install all necessary

components

Once the installer is completed, click

finish and Restart your computer

before starting the Veris SoilViewer

Software

Pub.# OM17-MSP-pH

Figure 11

Figure 12

2-5

Page 9

Pub.# OM17-MSP-pH

Ground speed

(from GPS) in

miles/hour

GPS status: may

read GPS, DGPS,

RTK, or None. If

None, no GPS signal

is received and no

data will be sent out

serial port.

Shallow (Sh) and Deep (Dp) soil EC

readings. If negative, no data will be sent

out serial port. NOTE: FOR pH MAPPING,

SERIAL STRING WITH GPS AND EC

MUST BE SENT TO DATALOGGER; USE

EC TEST LOAD TO PROVIDE EC DATA

SECTION 3

Field Operations—pH Electronics with Veris DataLogger

Attach the serial communication cable to the pH port on back of DataLogger. Connect EC signal

cable, GPS, and power cords to ports on rear of EC Surveyor. NOTE: EC signal is required for

pH data to be recorded. If no EC data is desired or available, install EC test load on EC

Surveyor signal port to provide a simulated EC signal.

Before logging any data, make sure the SD card in the Datalogger is clear of any files that

are not Veris .dat files. Any other files will cause the data an error when logging data.

The Veris DataLogger is not compatible with SDHC cards. Only SD cards will work

correctly.

Figure 1 DataLogger (rear)

EC Surveyor display readings

Here are the display readings that you will see when operating the EC Surveyor:

Figure 2

The unit is ready to operate. The Surveyor is informing you of the firmware version its

programmable interface chip (PIC) contains. Immediately the screen will change to the operating

screen below:

Figure 3

3-1

Page 10

Pub.# OM17-MSP-pH

Sensor DataLogger display readings

Here are the display readings that you will see when operating the Sensor DataLogger:

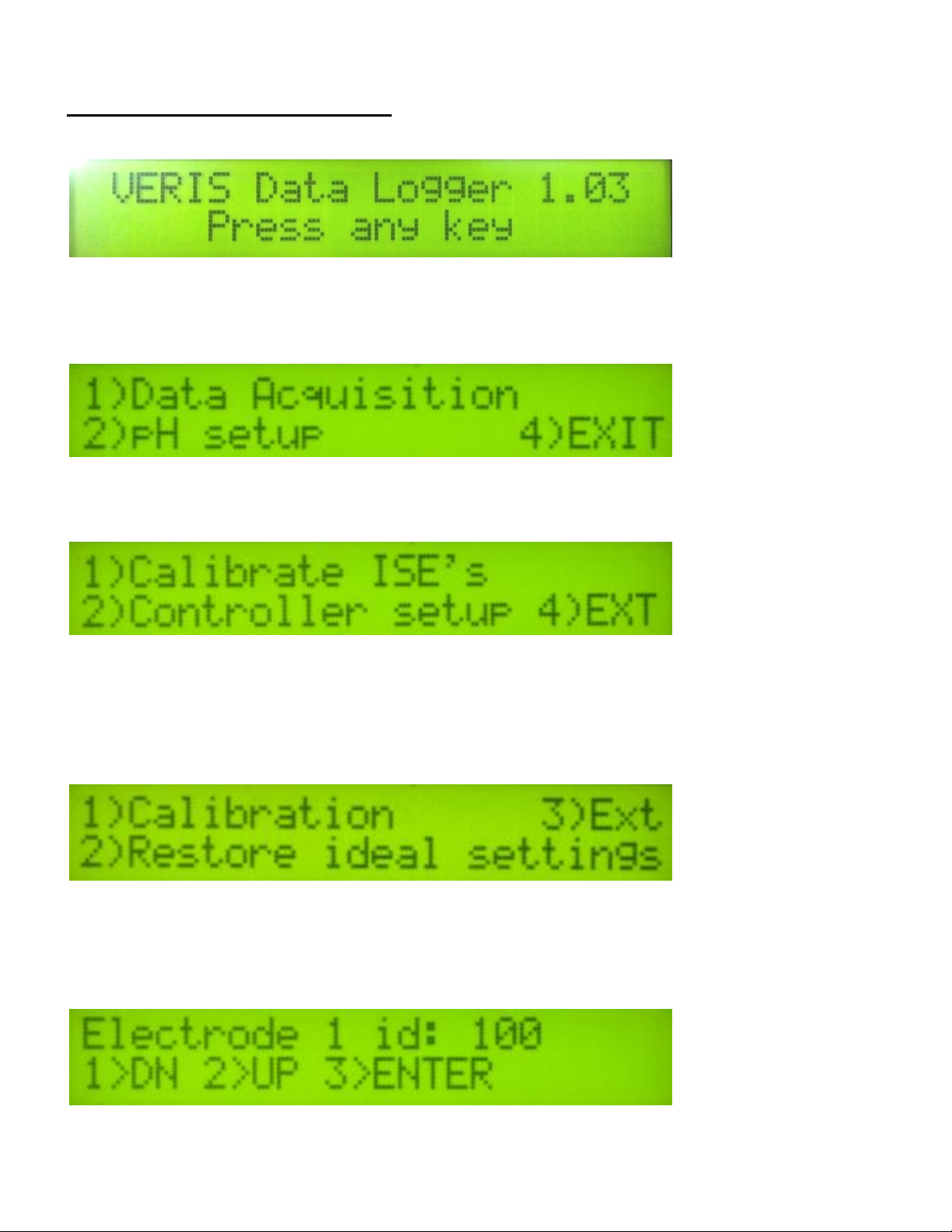

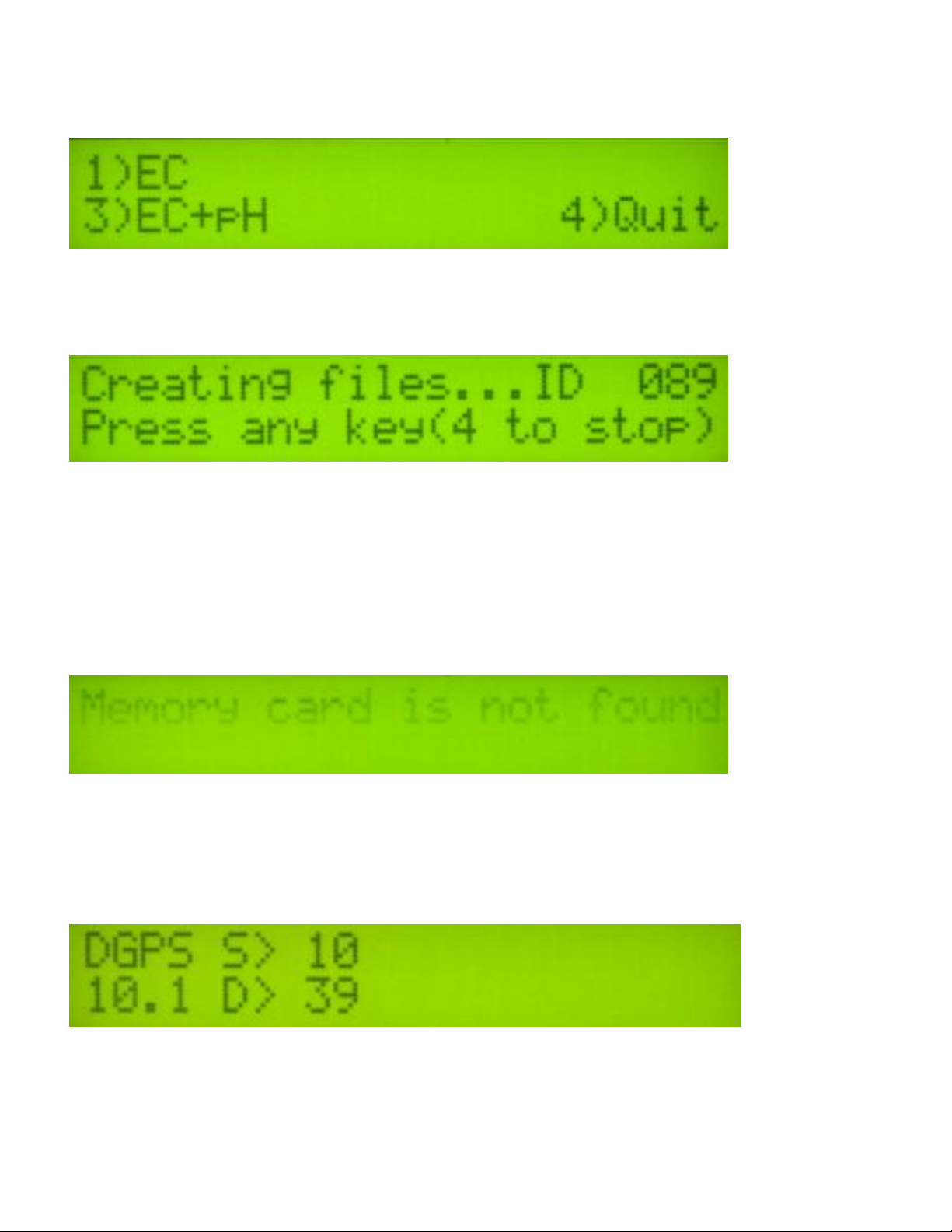

Starting up…

Figure 4

The unit is ready to operate. The DataLogger is informing you of the firmware version its

programmable interface chip (PIC) contains.

Press any of the four keys, and the next screen will appear:

Figure 5

For EC and pH mapping, press the #1 key. Press 1 and begin acquiring data (see below for more

details). Press 2 and enter Setup menu. (Press 4 to Exit this window).

Figure 6

Press 1 to calibrate ion-selective (ISE) pH electrodes

Calibrating pH electrodes

Enter menu option 1) Calibration.

Figure 7

You will be asked for the ID of the electrode connected to channel 1. You may want to add an ID

number to the electrodes, for your own tracking purposes. Use the 1 and 2 keys to change the

number and 3 to confirm:

Figure 8

3-2

Page 11

Pub.# OM17-MSP-pH

Repeat for electrode 2’s ID and press 3 to confirm.

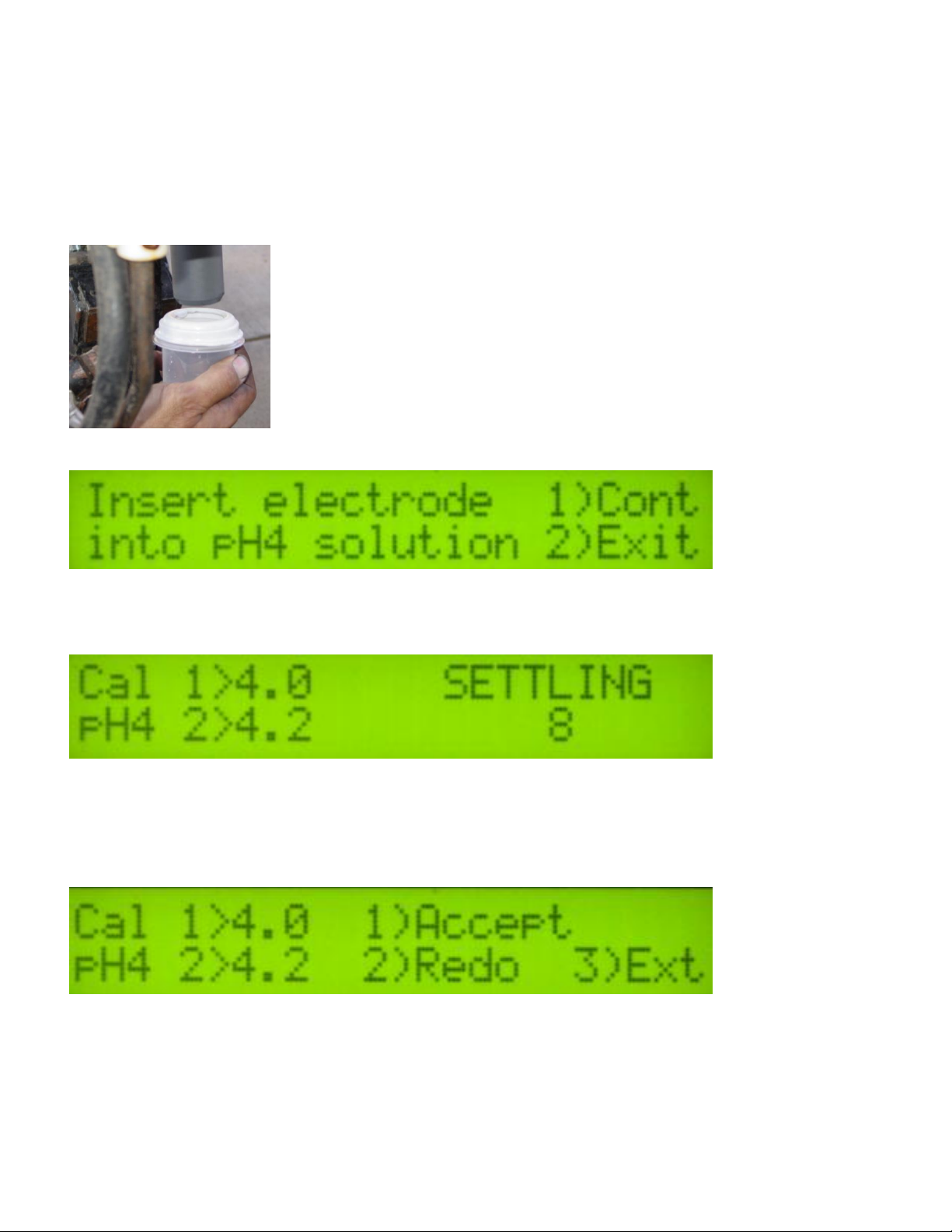

The instrument will prompt for the electrodes to be inserted into pH buffer 4 solution; Slide cup with

pH 4 buffer solution onto electrode holder. Press 1 to continue with calibration or 2 to exit. Tips:

Don’t overfill solution. Cup only needs enough solution to immerse electrode tip and face. Don’t

reuse solutions.

Figure 9

Figure 10

The instrument will read the electrodes for 10 seconds, displaying the output (as it counts

seconds):

Figure 11

After 10 seconds, the instrument will display the final pH reading and offer the options to 1) Accept

pH 4 buffer readings; 2) Redo pH 4 buffer readings; or 3) Exit pH electrode calibration. If the

readings are satisfactory, press 1; if the readings are suspect, press 2 to return to re-do pH 4.

Figure 12

After accepting the pH 4 buffer readings, the Instrument will prompt for the electrodes to be

inserted into pH 7 buffer solution. Remove the pH 4 buffer solution cup from the electrode

holder.Rinse the electrodes, electrode holder, and solution cup using the manual wash for at least

10 seconds. Slide the pH buffer 7 solution cup onto the electrode holder.

3-3

Page 12

Pub.# OM17-MSP-pH

On the DataLogger, press 1 to continue with calibration. The DataLogger will read the electrodes

for 10 seconds, displaying the output. After 10 seconds, the instrument will display the final pH

reading and offer the options to 1) Accept pH 7 buffer readings; 2) Redo pH buffer 7 readings; or 3)

Exit pH electrode calibration. If the readings are satisfactory, log pH 7 reading and press 1; if the

readings are suspect, press 2 to return to pH 7 calibration step.

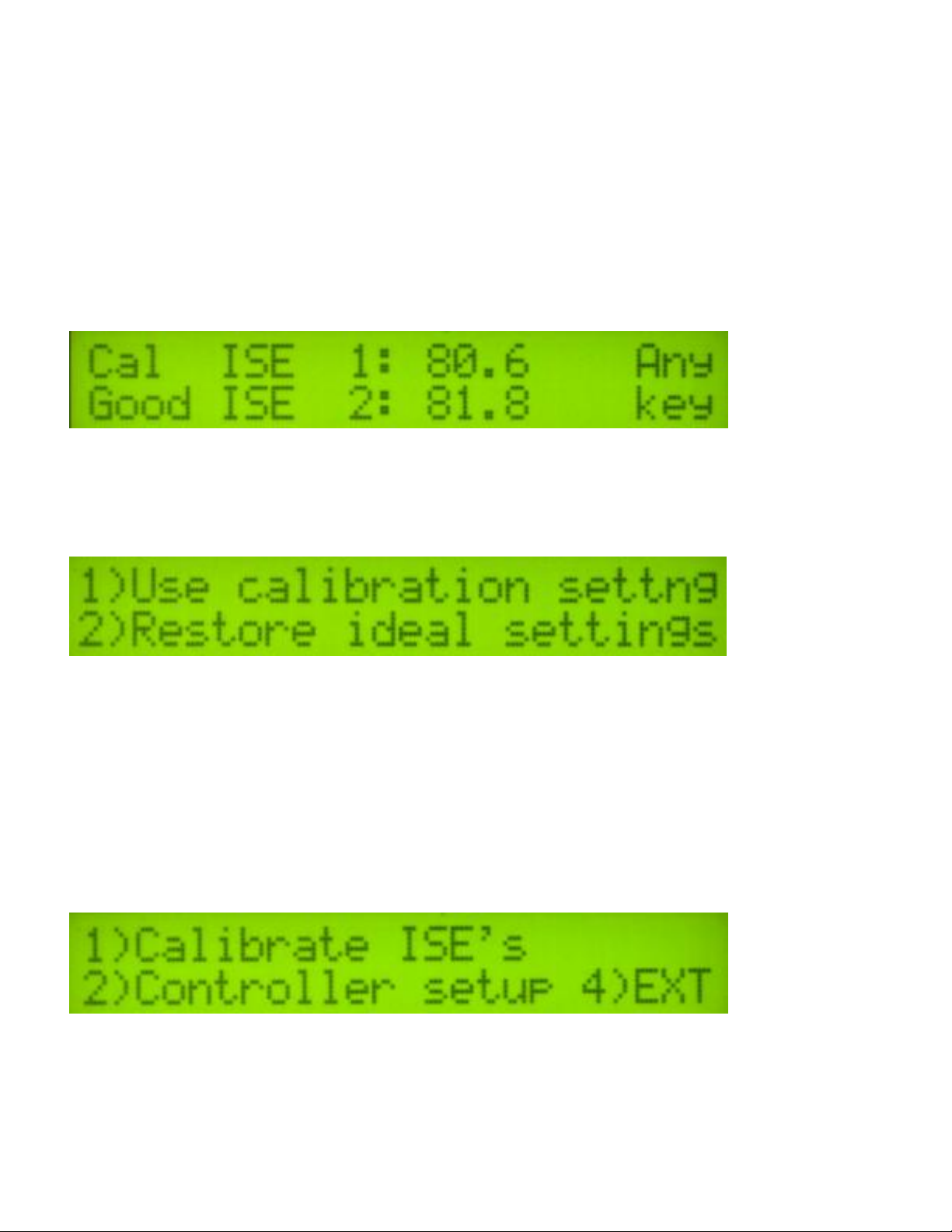

After accepting the pH 7 buffer readings, the electronics firmware will determine if each electrode’s

response is sufficient to provide suitable readings. A score is displayed for each electrode; the

acceptable score range is between 75 and 102. If both electrodes are within this range, the

instrument will display the following screen:

Figure 13

If an ‘X’ is displayed beside one or both electrodes’ scores, this indicates that one or both of the

electrodes did not perform well enough for continued reliable use. No calibration settings are

changed if calibration is unsuccessful. The electrode(s) responsible for failed calibration should be

removed and either cleaned or replaced and the calibration procedure repeated.

Figure 14

After calibration is complete, you will have the option to use the calibrated readings or reset to the

ideal settings. Tip: many operators use the ideal settings rather than calibration settings. One

reason is this enables readings from one day to be compared to another. It is still important to

perform the calibration step at least daily, even if ideal settings are used. The calibration process

is important to test electrode quality.

pH Controller Set-up

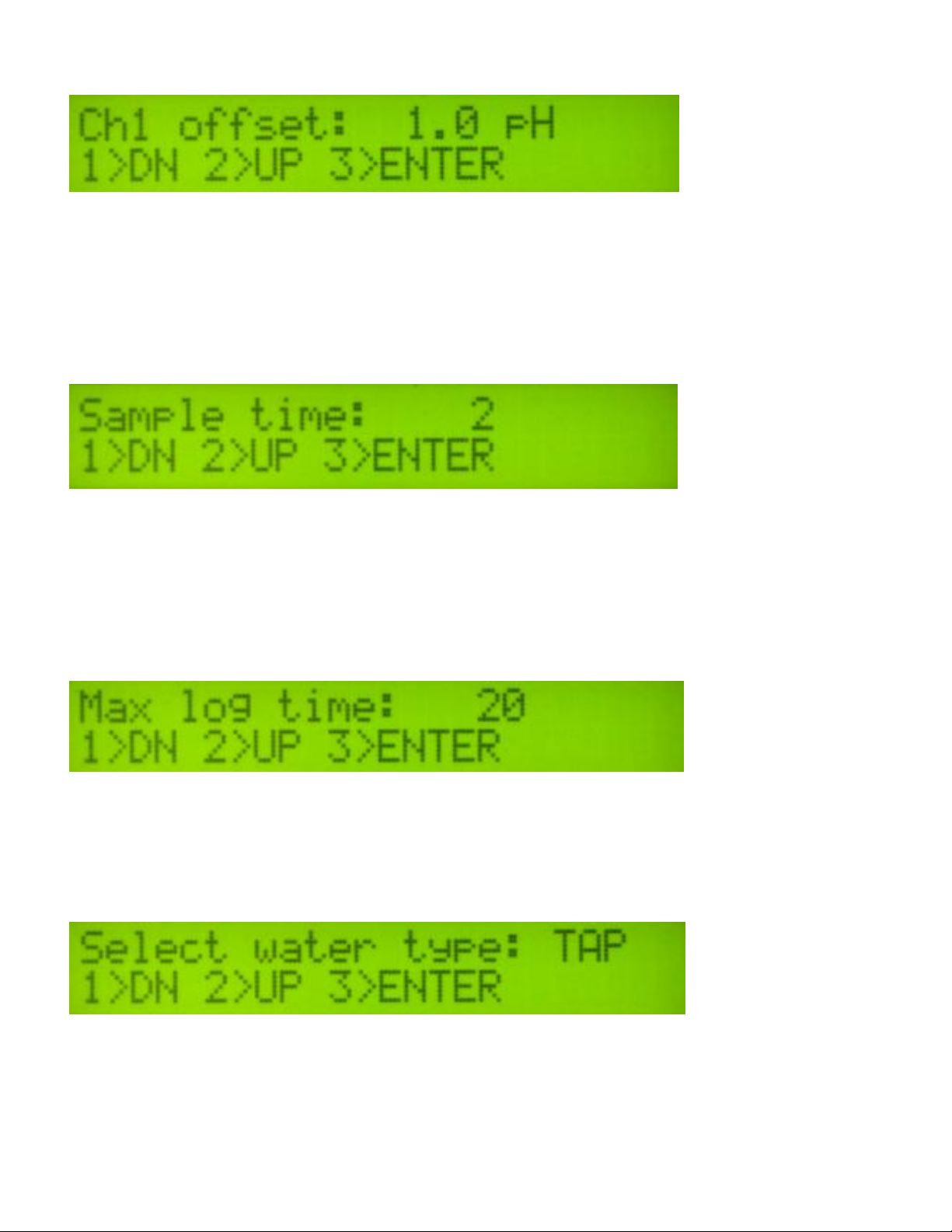

After calibration, you may wish to change the pH Controller default parameters. Press 2 and enter

Setup menu. (Press 4 to Exit this window).

Figure 15

3-4

Page 13

Pub.# OM17-MSP-pH

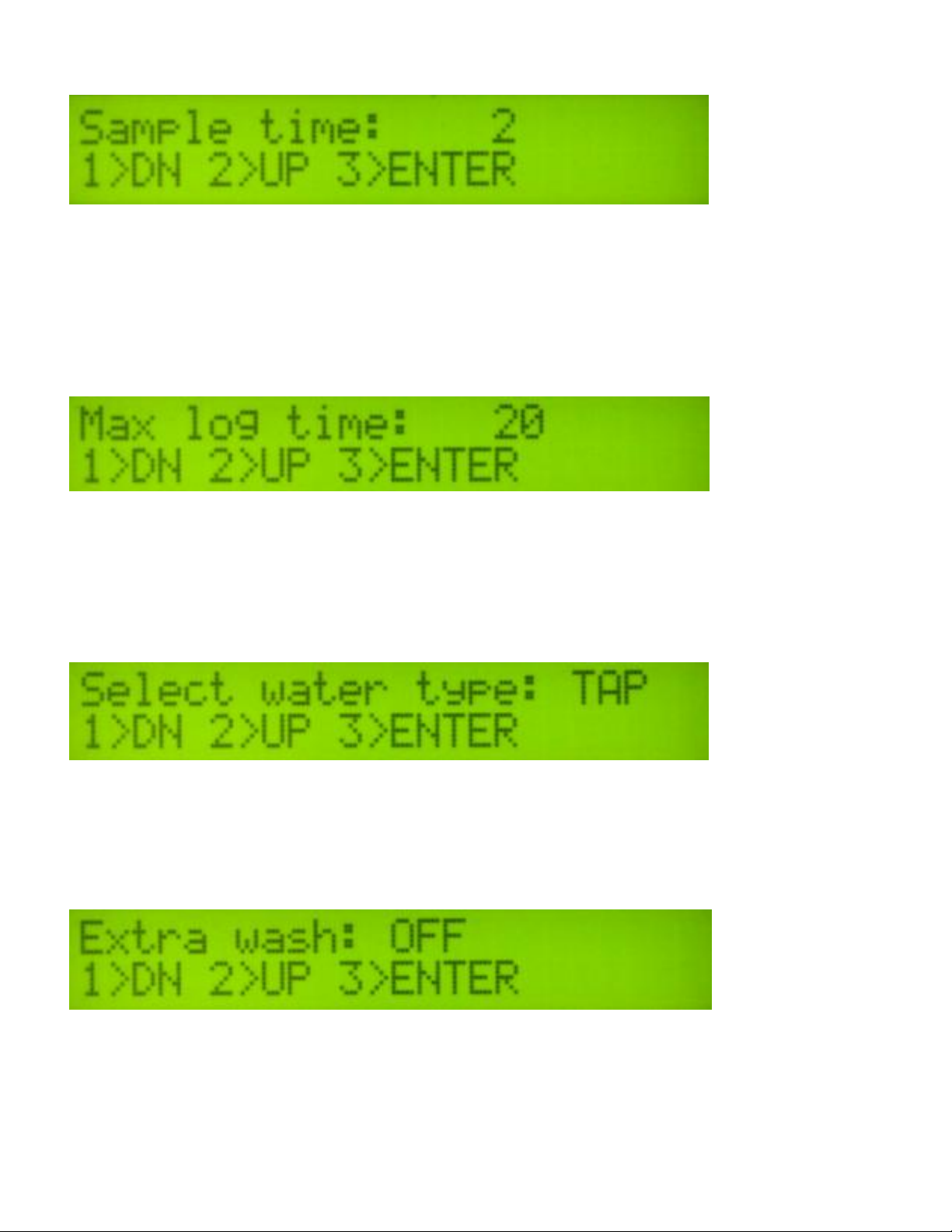

Figure 16

Sampling time is the duration that the sampler assembly is in the soil. Typically 2 seconds is

adequate. In soil conditions that do not produce a firm core, this time may need to be set at 3

seconds in order to allow soil to begin flowing through cutting shoe. If soil conditions result in a

very firm core, the sampling time may be reduced to 1 second. In rocky conditions, use 1 second

sample time to reduce likelihood of sampler shoe damage. Press 1 or 2 to adjust the sample time,

press 3 to continue to the next screen.

Figure 17

Maximum log time is the longest time in seconds the pH controller will wait for the pH readings to

settle. The controller usually cycles before this maximum time is reached. The minimum setting

for the maximum log time is 20 seconds. (Tip: use 20 seconds unless there is a special reason to

allow a longer wait time) Press 1 or 2 to adjust the sample time, press 3 to continue to the next

screen.

Figure 18

Select the type of water you are using to clean the electrodes between samples. The available

types are TAP, RO (reverse osmosis), or DI (de-ionized). Press 1 or 2 to cycle through the water

types, press 3 to continue to the next screen. Tip: If you don’t want a baseline wash performed

every 40 cycles, use RO setting rather than Tap or DI (regardless of actual water being used).

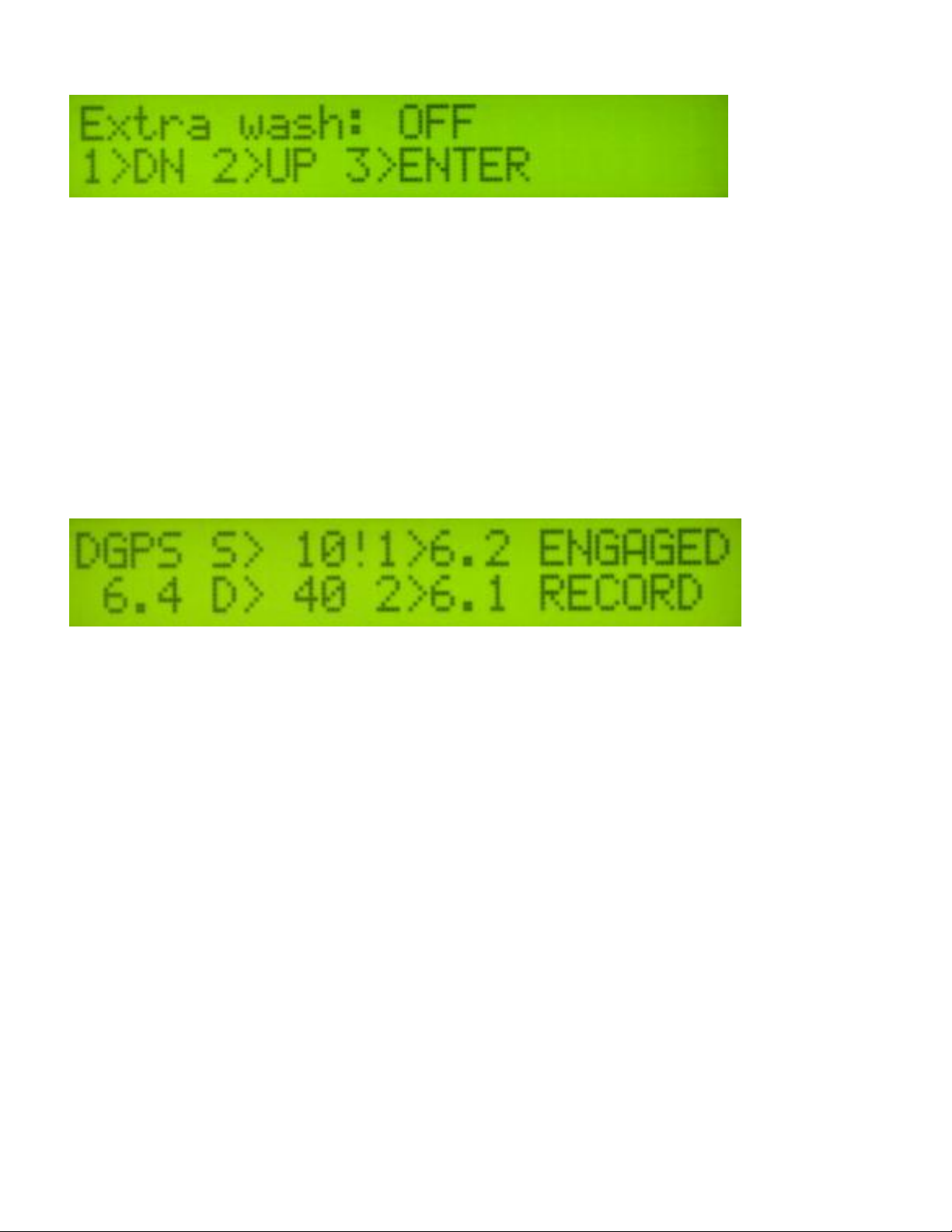

Figure 19

Turning on the extra wash option will add 1.5 seconds of cleaning per cycle. The extra wash is

performed by stopping the shoe briefly during the cycle. Use this feature if you have noticed the

electrodes are not cleaning during the cycle. Press 1 or 2 to choose ON or OFF, press 3 to

continue. Tip: water usage will double if extra wash is used.

3-5

Page 14

Pub.# OM17-MSP-pH

pH Data Recording

Figure 20

For EC mapping, press the #1 key. #4 returns you to the initial start-up screen. Select #3 EC+pH

to collect EC and pH data. Pressing #1 or #3 brings up the next screen:

Figure 21

The DataLogger is displaying the map file number it is creating, in case you want to record it along

with any other information about the field. Press any key to begin new map file. After starting the

file, pressing the #4 key will stop the file. If DataLogger freezes at the screen shown in Figure 20 or

Figure 21, check formatting of SD card—must be FAT format.

If memory card was not inserted during boot-up, the following screen will appear:

Figure 22

Install card and re-start DataLogger. NEVER REMOVE CARD WHILE LOGGING DATA.

If you pressed the option #1 for EC, this is the next screen:

Figure 23

3-6

Page 15

Pub.# OM17-MSP-pH

GPS indicator:

NONE, _GPS,

DGPS, RTK

Shallow and

Deep EC

readings

pH readings from each

electrode

Status of pH

sampling

mechanism

Speed in

MPH

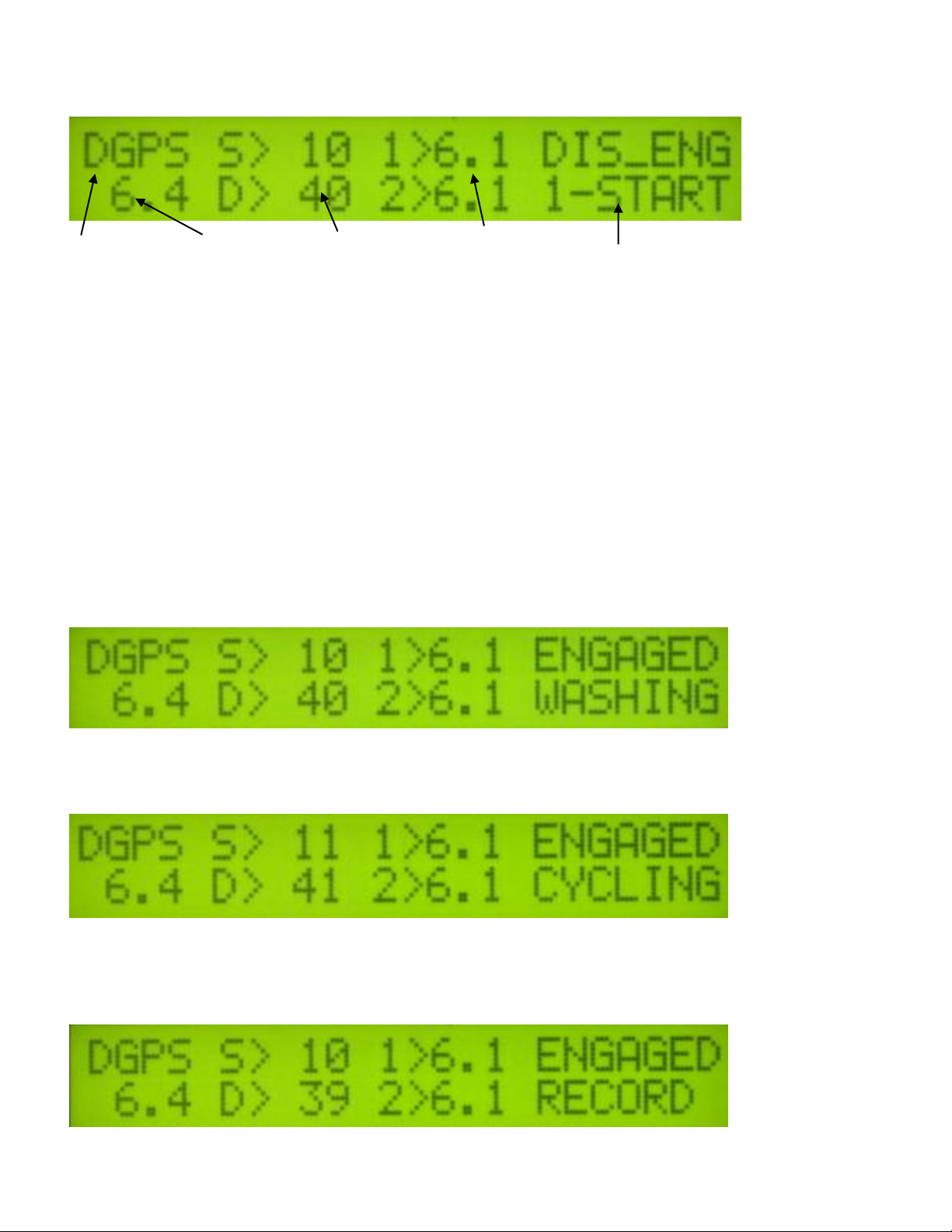

If you pressed the option #3, pH and EC, this is the next screen:

Figure 24

The display is showing the pH values from the pH electrodes, conductivity of the top 1’ (30 cm) and

top 3’ (90 cm) of the soil, and whether you have GPS or DGPS (differentially corrected) signal. At

any time during the mapping process, you can press the 4 key to stop the file. If you create more

than one file from the same field, you can bring the files into a spreadsheet program and combine

them prior to mapping. Note: the #1 key toggles the pH sampler from engaged to disengaged; the

#4 key stops the file.

From this screen, pressing the 1 key as you drive forward will initiate the automatic sampling

process. The software requires movement indicated by the GPS receiver in order to cycle.

Speed must be detected within 5 seconds after pressing 1 or the system will disengage.

If TAP or DI were selected as the wash water type above, the controller will go through a wash

baseline process after engage is pressed for the first time. The status text will change to the

following:

Figure 25

After washing (or immediately if RO was selected as the wash water type), the unit will continue

cycling and display the following screen:

Figure 26

“Cycling” means the sampler assembly is in the process of washing, and lowering for soil sampling.

After a core has been collected and is being held against the electrodes, the status text will change

to the following:

Figure 27

3-7

Page 16

Pub.# OM17-MSP-pH

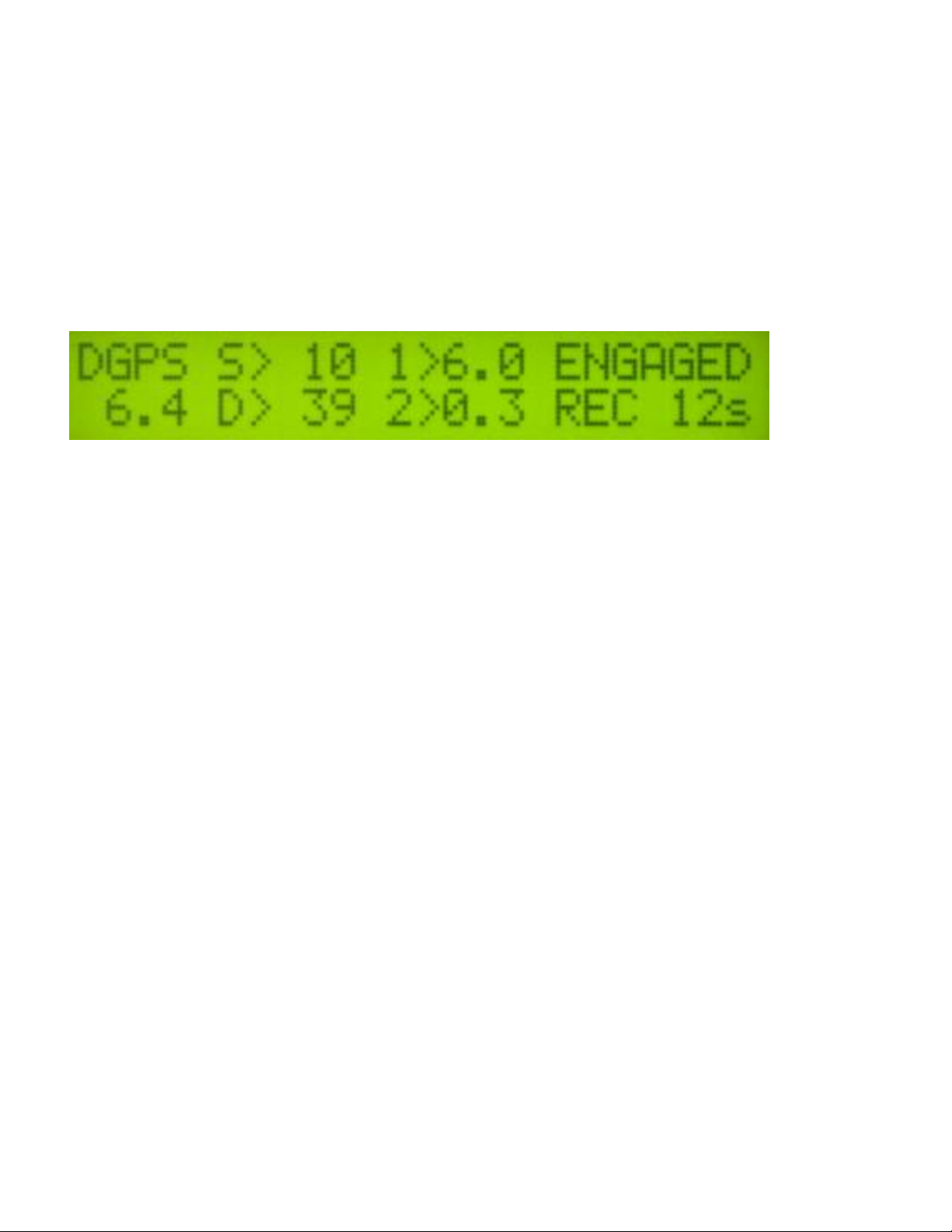

The pH readings on the display show what each electrode is reading at every second. The

sampler will hold the soil against the electrodes and continue to record pH until the readings settle.

The minimum recording time is 7 seconds; the maximum time is determined in the pH settings

menu. The pH values that are recorded are the final values at the end of the logging duration. (last

reading on the display before the “Cycling” status appears). The final pH value is logged along

with the DGPS position where the sample was collected.

If the electrodes take longer than 10 seconds to settle, a warning will appear by the readings that

indicates the number of seconds the reading has required. When the maximum log time is

reached, a T will appear indicating that the measurement has ‘timed out’, and the unit initiates a

new sample cycle (refer to pH Controller settings for adjusting the log time).

Figure 28

This time warning is to let the operator know that a measurement cycle is requiring excessive time.

While an occasional cycle may exhibit this warning. see the troubleshooting section if this occurs

frequently.

The Veris MSP pH Manager uses two electrodes for optimal data quality. If there is a difference of

0.75 or greater between the final electrode readings, an audible alarm will beep, informing the

operator of the erroneous reading.

To pause the data collection process at any time (but keep the same file), press the 1 key. Once

the sampling process has completed its cycle, it will disengage and the status text message will

indicate disengaged (press 1 to start cycling again). If the system no longer senses a speed signal

from the GPS, it will also disengage and return to Neutral. NOTE: do not depend on the GPS

speed signal for disengagement. Before inspecting or working around any component of the

system, press the 1 key and verify status of system is ‘Disengaged’ before exiting the vehicle.

Sporadic GPS signals may simulate movement and initiate the cycling process, resulting in

possible entanglement and injury.

If TAP or DI are selected as the wash water type, the water baseline process will be repeated

every 40 cycles following the next engage press. If the pH during the cycling sequence does not

get within 0.5 of the baseline pH, an audible alarm will sound and the pH labels will blink. This is to

allow operator that the electrodes are not cleaning properly.

pH Offset and Settings Menu

While the instrument is in pH data acquisition, the pH sampler settings can be adjusted without

exiting the current file. For example, it may be necessary to add extra wash or change sampling

time. A correction can be applied to each electrode’s pH shown on the screen. Occasionally, the

pH readings shown on the screen may differ from those expected in the field. A condition that

could cause this is high pH wash water which is elevating all pH readings. If this is the case, the pH

shown on the screen can be adjusted up or down. To enter the settings screen, make sure

message in the upper right of the screen says DISENGAGED. Press the 3 key. The following

screen will display:

3-8

Page 17

Pub.# OM17-MSP-pH

Figure 29

This screen allows you to adjust the offset that will be applied to channel 1’s electrode reading.

The offset is adjustable in 0.5 pH increments up to +/- 2.00 pH. NOTE: The firmware DOES NOT

apply this offset to the extracted file. Only the readings seen on the screen will be affected. Press

1 or 2 to adjust the reading down or up, and 3 to confirm the offset and proceed to the next screen.

Similarly, an offset can be applied to channel 2’s electrode. Press 1 or 2 to adjust the offset down

or up, and 3 to confirm the offset and proceed to the next screen.

Figure 30

Sampling time is the duration that the sampler assembly is in the soil. Typically 2 seconds is

adequate. In soil conditions that do not produce a firm core, this time may need to be set at 3

seconds in order to allow soil to begin flowing through cutting shoe. If soil conditions result in a

very firm core, the sampling time may be reduced to 1 second. In rocky conditions, use 1 second

sample time to reduce likelihood of sampler shoe damage. Press 1 or 2 to adjust the sample time,

press 3 to continue to the next screen.

Figure 31

Maximum log time is the longest time in seconds the pH controller will wait for the pH readings to

settle. The controller usually cycles before this maximum time is reached. The minimum setting

for the maximum log time is 20 seconds. (Use 20 seconds unless there is a special reason to allow

a longer wait time) Press 1 or 2 to adjust the sample time, press 3 to continue to the next screen.

Figure 32

Select the type of water you are using to clean the electrodes between samples. The available

types are TAP, RO (reverse osmosis), or DI (de-ionized). Press 1 or 2 to cycle through the water

types, press 3 to continue to the next screen. Tip: If you don’t want a baseline wash performed

every 40 cycles, use RO setting rather than Tap or DI (regardless of actual water being used).

3-9

Page 18

Pub.# OM17-MSP-pH

Figure 33

Turning on the extra wash option will add 1.5 seconds of cleaning per cycle. The extra wash is

performed by stopping the shoe briefly during the cycle. Use this feature if you have noticed the

electrodes are not cleaning during the cycle. Press 1 or 2 to choose ON or OFF, press 3 to

continue.

After all of the settings have been entered, the instrument will save the settings and return to the

data acquisition screen. You may continue collecting data using the new settings by pressing the

#1 key to engage. Settings are stored in memory and will remain as set until they changed.

pH Data Flags

Numbered “flags” can be added to the pH data by pressing the 2 key while the pH Manager is

CYCLING or RECORDING. If the key is pressed while the pH Manager is in the RECORDING

phase, an exclamation point (!) will appear on the screen next to the pH data labels:

Figure 33

This means the flag will be recorded with the current data point in the pH file. If the key is pressed

while the pH Manager is in the CYCLING phase, the next point will be flagged and exclamation

point will not appear until the RECORDING phase is reached. Tip: Use this function to flag any

sample where a problem has occurred, such as a plugged shoe. Open the pH file in a

spreadsheet program, locate the points that have been flagged, and delete rows of problem data.

There are warning signals programmed into the Veris DataLogger to warn the operator that data

are not being recorded, so that corrective action can be taken. If data aren’t being recorded, a

warning alarm will sound, and the portion of the screen text that is missing information will blink.

For example, if the GPS isn’t being received (or the NMEA string containing speed) the Lat/Long

text will blink. If EC values are negative, they will blink. Also, the Data Status LED light on the

front of the DataLogger indicates the whether data is being recorded. If this light is not lit, data are

not being recorded. (note: no data is recorded unless unit is moving—receiving speed signal from

GPS)

At any time during the mapping process, you can press any key to stop the file. If you create more

than one file from the same field, you can bring the files into a spreadsheet program or GIS and

combine for whole field map display.

3-10

Page 19

Pub.# OM17-MSP-pH

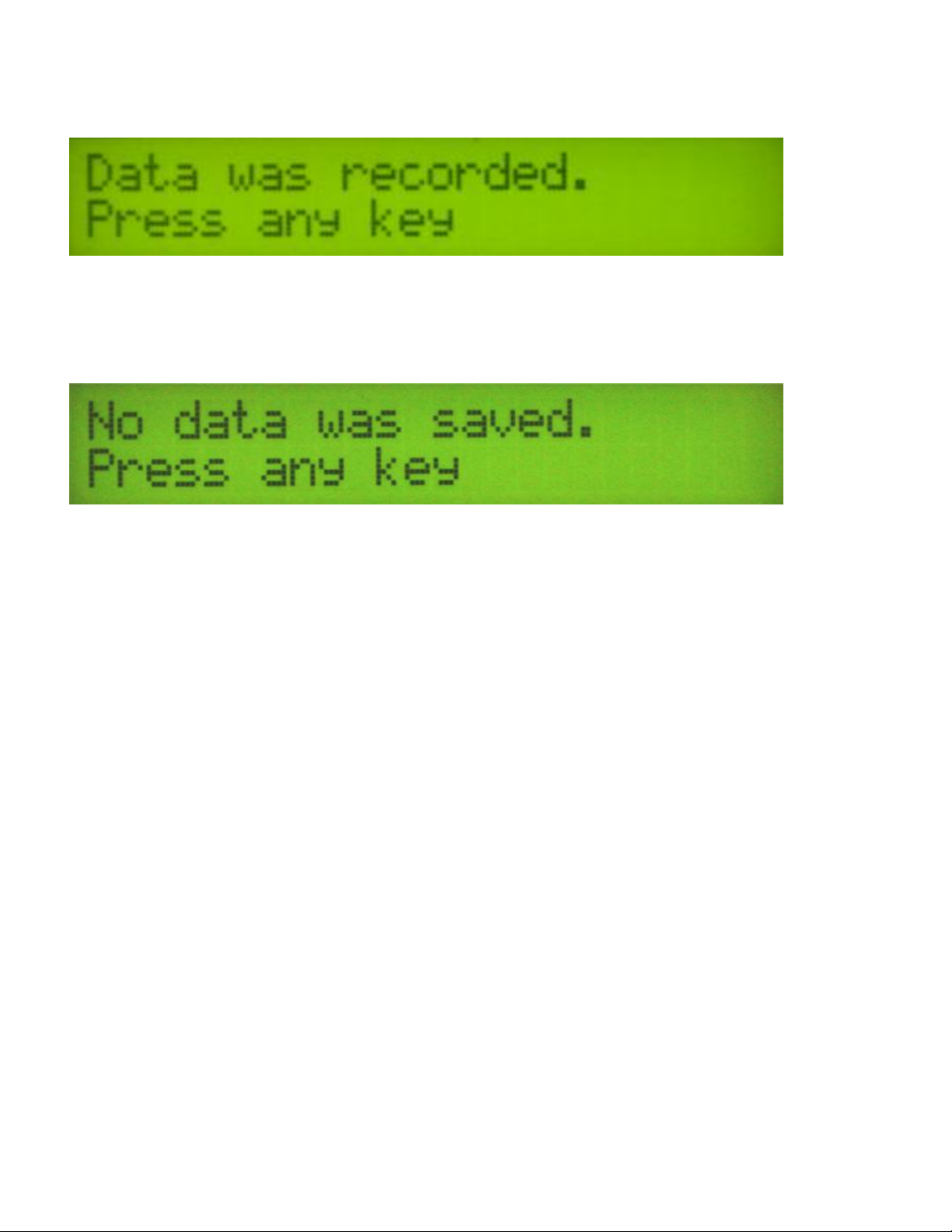

After #4 key is pressed during Data Acquisition, the following screen will be displayed: (if data

was collected during Data Acquisition)

Figure 34

DATA IS ONLY STORED ON THE SD CARD. NO INTERNAL FILES ARE CREATED.

If no data was logged during Data Acquisition, the following screen will be displayed:

Figure 35

DATA QUALITY TIPS

As you collect pH data, monitor the performance of the system by continually asking yourself these

questions:

-During ‘Cycling’ phase, do both pH electrode readings get close to the wash water pH? If not, one

or both electrodes may not be cleaning properly.

-During ‘Recording’ phase, do both electrode readings move to expected soil pH level? If they stay

near wash pH level and/or require more than 10 seconds to settle, one of the following may have

occurred: 1) shoe may have plugged, so no new soil is entering, and the shoe is slowly filling up

with wash water; 2) Excessive speed may have allowed soil core to shoot out the back, or 3) gap

between electrodes and shoe may be excessive, so thinner soil cores aren’t contacting pH

electrodes.

-Operators who monitor the screen, and are alert to pH values that aren’t appropriate for the

Cycling or Recording phase, generate better maps.

-Whenever the final pH readings at a sample location are >.50 apart, an alarm will sound indicating

data for that sample location will likely be eliminated during data extraction. If more than an

occasional, infrequent reading is rejected, inspect the sampler assembly for possible plugging or

other malfunction, and the electrodes for proper cleaning. Re-calibrate electrodes if necessary.

-The speed you travel and your transect width directly affects the sample density: 6 mph (9.6

km/hr) on 50’ (15 m) transects provides approximately 10 samples/acre (24/ha). 5 mph (16 km/hr)

on 75’ (23 m) transects results in approximately 5 samples/acre (12/ha). Collect enough samples

so that the raw pH data maps the underlying spatial structure of the field’s pH—rather than relying

on interpolation methods to fill in the gaps in the map.

3-11

Page 20

Pub.# OM17-MSP-pH

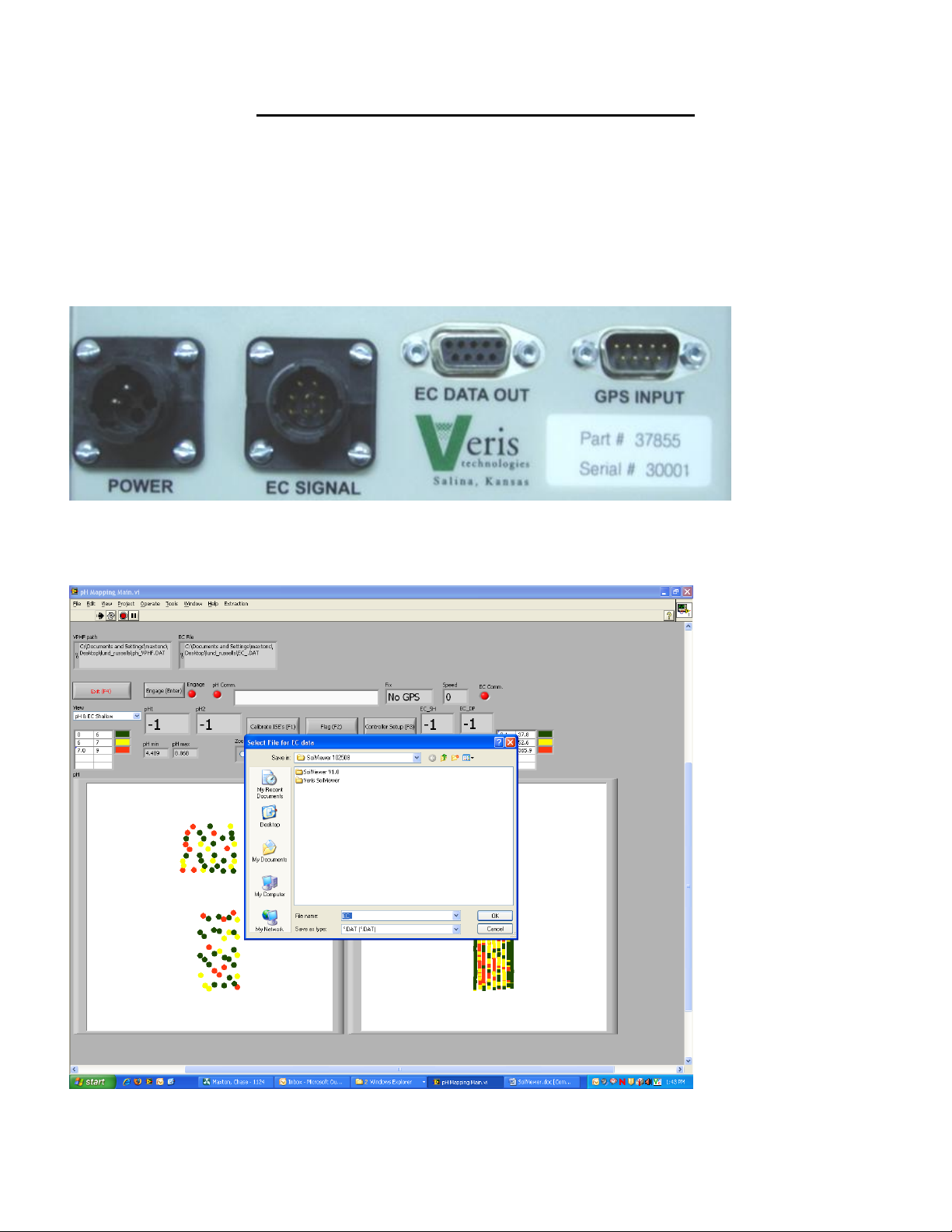

Field Operations—pH Electronics with SoilViewer

Attach the pH serial communication cable to an available COM port on your computer. Connect EC

signal cable, GPS, and power cords to ports on rear of EC Surveyor, then connect EC Data Out to

any available COM port on your computer using a standard serial cable. If serial port is not

available on PC, then a USB to Serial converter can be used with the EC Surveyor provided the

drivers for the converter are installed and functioning properly. NOTE: EC signal is required for

pH data to be recorded. If no EC data is desired or available, install EC test load on EC

Surveyor signal port.

Figure 1 DataLogger (rear)

SoilViewer startup display

Here are the display readings that you will see when operating the EC/pH SoilViewer Software:

Figure 2

3-12

Page 21

Pub.# OM17-MSP-pH

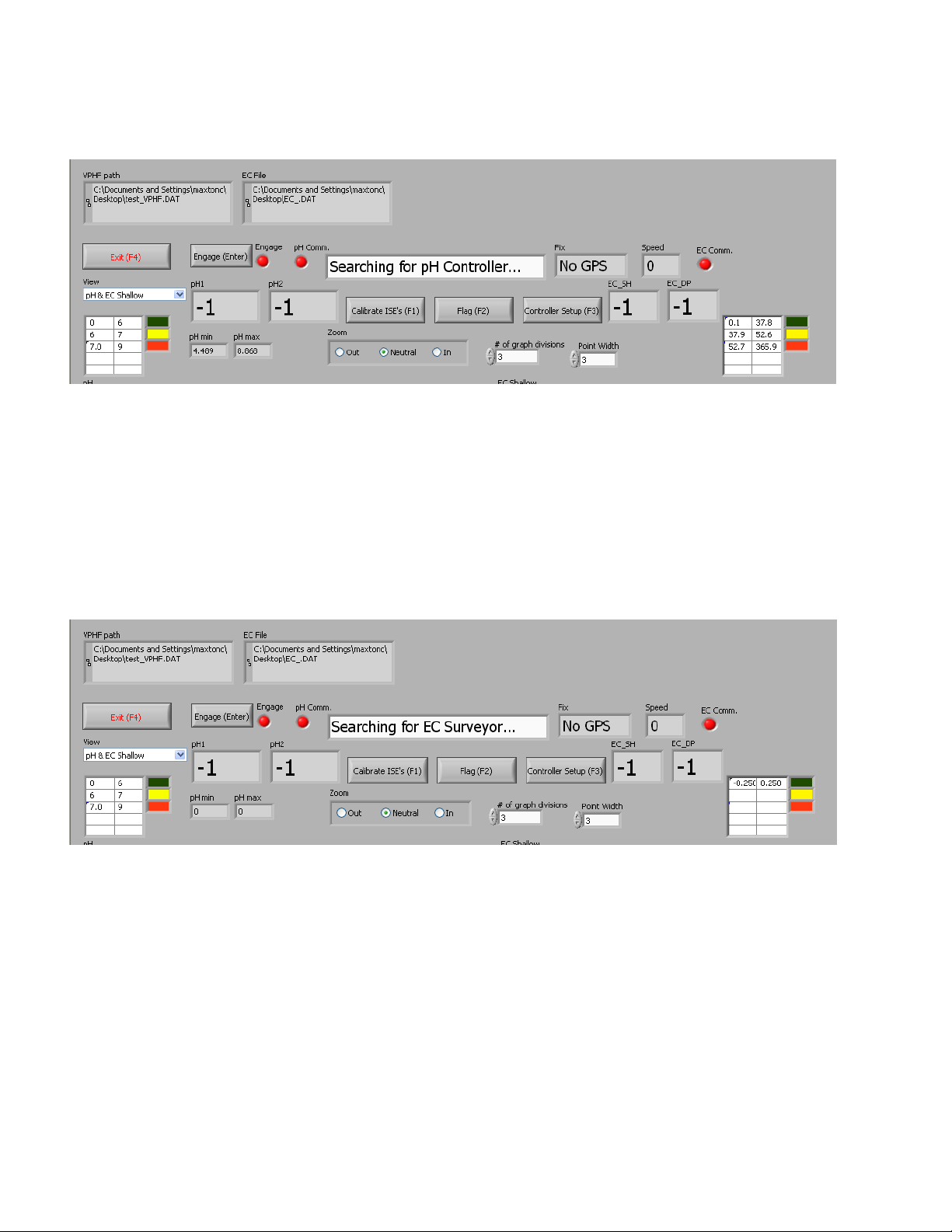

The SoilViewer program will ask the user to select the names of the EC and pH files to be stored.

If desired, a previous file can be appended.

Figure 3

Once the files have been selected, the software will look for communication with the pH controller.

If no communication can be established, check for a secure connection to the computer, and make

sure pH controller is turned on and has power to it. Also, switching to manual mode on the pH

controller will ensure the pH controller is in a recognizable state. After five attempts at

communication are rejected, the software will proceed to looking for communication with the EC

Surveyor, and will check every 45 seconds for the connection of the pH controller. If all

connections are secure and the pH controller power is on, it may be necessary to shut off power to

pH controller and turn it back on.

Figure 4

After the pH controller is found, the software searches for communication with the EC Surveyor,

before continuing on with acquisition. If the EC Surveyor is not found after five attempts, the

software will wait check every 45 seconds for the connection of the EC Surveyor. If the Surveyor is

not found, check for a secure connection to the computer and power to the EC Surveyor, and

reboot EC Surveyor.

3-13

Page 22

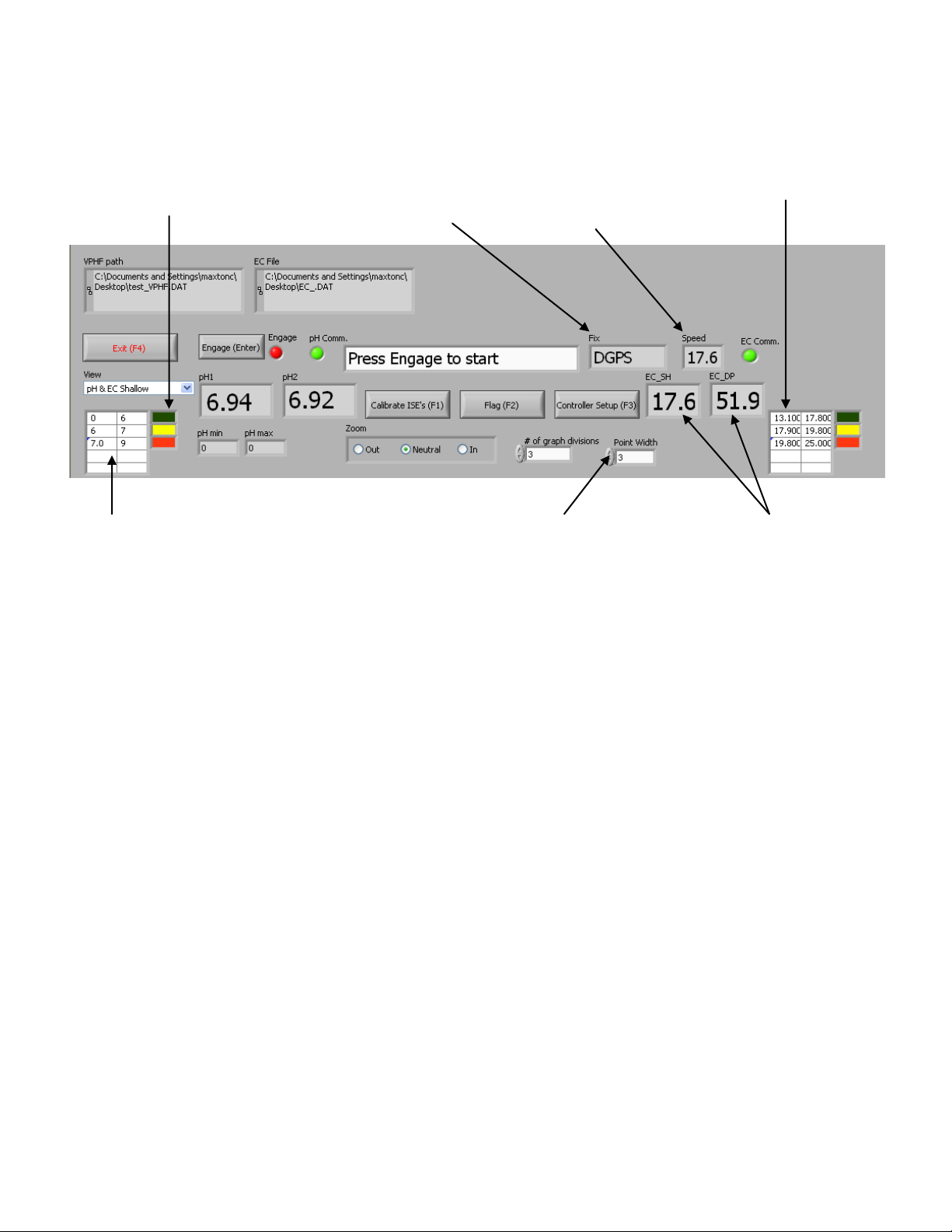

Ground speed

(from GPS) in

miles/hour

GPS status: may

read GPS, DGPS,

RTK, or None. If

None, no GPS signal

is received and no

data will be sent out

serial port.

Shallow (Sh) and Deep (Dp) soil EC

readings. If negative, no data will be sent

out serial port. NOTE: FOR pH MAPPING,

SERIAL STRING WITH GPS AND EC

MUST BE SENT TO COMPUTER; USE

EC TEST LOAD TO PROVIDE EC DATA

IF NECESSARY

Point size for EC

values; adjust point

size to fill transects

and display spatial

structure to map.

Ranges used to map pH values. Each color

should have a unique range associated with it.

These are user-defined ranges and can be

changed at any time. If points appear to be

missing from the map, it could be that they are

out of the ranges selected. pH min and pH max

can be used as guidelines for setting up the pH

ranges. Up to five divisions can be selected

These EC ranges

are not user

selectable and are

set by giving each

range the same

number of EC

points.

Colors for the graphs

can be set here, by

clicking on the color

box and selecting a

new color.

Figure 5

Pub.# OM17-MSP-pH

3-14

Page 23

Calibrating pH electrodes

You will be asked if you want to

continue the calibration or restore

ideal settings.

Click on Calibrate ISE’s or press F1

Figure 6

Figure 7

Pub.# OM17-MSP-pH

Figure 8

You will be asked for the ID of the electrode connected to channel 1. You may want to add an ID

name or number to the electrodes, for your own tracking purposes. Insert the name or number

then press OK to continue.

Figure 9

3-15

Page 24

Pub.# OM17-MSP-pH

The software will prompt for the electrodes to be inserted into pH buffer 4 solution; Slide cup with

pH 4 buffer solution onto electrode holder. Press 1 to continue with calibration or 2 to exit. Tips:

Don’t overfill solution. Cup only needs enough solution to immerse electrode tip and face. Don’t

reuse solutions.

Figure 10

The software will read the electrodes for 10 seconds, displaying the output (as it counts seconds):

Figure 11

After 10 seconds, the software will display the final pH reading and offer the options to Accept pH 4

buffer readings; Redo pH 4 buffer readings; or Cancel pH electrode calibration. If the readings are

satisfactory, press Accept; if the readings are suspect, press Redo to return to re-do pH 4.

Figure 12

3-16

Page 25

Pub.# OM17-MSP-pH

After accepting the pH 4 buffer readings, the software will prompt for the electrodes to be inserted

into pH 7 buffer solution. Remove the pH 4 buffer solution cup from the electrode holder. Rinse

the electrodes, electrode holder, and solution cup using the manual wash for at least 10 seconds.

Slide the pH buffer 7 solution cup onto the electrode holder.

Figure 13

Press continue to proceed with the calibration. The software will read the electrodes for 10

seconds, displaying the output. After 10 seconds, the software will display the final pH reading and

offer the options to Accept pH 7 buffer readings; Redo pH buffer 7 readings; or Cancel pH

electrode calibration. If the readings are satisfactory, log pH 7 reading and press continue; if the

readings are suspect, press redo to return to pH 7 calibration step.

After accepting the pH 7 buffer readings, the software will determine if each electrode’s response

is sufficient to provide suitable readings. A score is displayed for each electrode; the acceptable

score range is between 75 and 102. If both electrodes are within this range, the software will

display the following screen:

Figure 14

If an ‘X’ is displayed beside one or both electrodes’ scores, this indicates that one or both of the

electrodes did not perform well enough for continued reliable use. No calibration settings are

changed if calibration is unsuccessful. The electrode(s) responsible for failed calibration should be

removed and either cleaned or replaced and the calibration procedure repeated.

Figure 15

After calibration is complete, you will have the option to use the calibrated readings or reset to the

default parameters. Tip: many operators use the default parameters rather than calibration

settings. One reason is this enables readings from one day to be compared to another. It is still

important to perform the calibration step at least daily, even if ideal settings are used. The

calibration process is important to test electrode quality.

3-17

Page 26

Pub.# OM17-MSP-pH

pH Controller Set-up

After calibration, you may wish to change the pH Controller default parameters. Press Controller

Setup or F3 and enter Setup menu.

Figure 16

Figure 17

While the instrument is in pH data acquisition, the pH sampler settings can be adjusted without

exiting the current file. Additionally, a correction can be applied to each electrode’s pH shown on

the screen. Occasionally, the pH readings shown on the screen may differ from those expected in

the field. If this is the case, the pH shown on the screen can be adjusted up or down

The offset is adjustable in 0.5 pH increments up to +/- 2.00 pH. NOTE: The instrument DOES

NOT apply this offset to the extracted file. Only the readings seen on the screen will be affected.

Sampling time is the duration that the sampler assembly is in the soil. Typically 2 seconds is

adequate. In soil conditions that do not produce a firm core, this time may need to be set at 3

seconds in order to allow soil to begin flowing through cutting shoe. If soil conditions result in a

very firm core, the sampling time may be reduced to 1 second. Press the up and down arrows to

adjust the sample time.

3-18

Page 27

Pub.# OM17-MSP-pH

GPS indicator:

NONE, _GPS,

DGPS, RTK

Shallow and

Deep EC

readings

pH readings from each

electrode

Status of pH

sampling

mechanism

Speed in

MPH

Status of pH controller Green

means the controller is engaged

while Red means it is

disengaged

Log time is the longest time in seconds the pH controller will wait for the pH readings to settle. The

controller usually cycles before this maximum time is reached. The minimum setting for the log

time is 20 seconds. Press the up or down arrows adjust the sample time. (Tip: use 20 seconds

unless there is a special reason to allow a longer wait time)

Select the type of water you are using to clean the electrodes between samples. The available

types are TAP, RO (reverse osmosis), or DI (de-ionized). Tip: If you don’t want a baseline wash

performed every 40 cycles, use RO setting rather than Tap or DI (regardless of actual water being

used).

Turning on the extra wash option will add 1.5 seconds of cleaning per cycle. The extra wash is

performed by automatically stopping the shoe briefly during the cycle. Use this feature if you have

noticed the electrodes are not cleaning during the cycle. Put a checkmark in the box to turn the

extra wash on and uncheck to turn off the extra wash. Tip: water usage will double if extra wash is

used.

pH Data Recording

Figure 18

The display is showing the pH values from the pH electrodes, conductivity of the top 1’ (30 cm) and

top 3’ (90 cm) of the soil, and whether you have GPS or DGPS (differentially corrected) signal.

3-19

Page 28

Pub.# OM17-MSP-pH

From this screen, pressing the Engage key or Enter as you drive forward will initiate the automatic

sampling process. The software requires movement indicated by the GPS receiver in order to

cycle. Speed must be detected within 5 seconds after pressing 1 or the system will disengage.

If TAP or DI were selected as the wash water type above, the controller will go through a wash

baseline process after engage is pressed for the first time. The status text will change to the

following:

Figure 19

After the pH readings settle (or if RO was selected as the wash water type), the unit will continue

cycling and display the following screen:

Figure 20

“Cycling” means the sampler assembly is in the process of washing, and lowering for soil sampling.

After a core has been collected and is being held against the electrodes, the status text will change

to the following:

Figure 21

The pH readings on the display show what each electrode is reading at every second. The

sampler will hold the soil against the electrodes and continue to record pH until the readings settle.

The minimum recording time is 7 seconds; the maximum time is determined in the pH settings

menu. The pH values that are recorded are the final values at the end of the logging duration. (last

reading on the display before the “Cycling” status appears). The final pH value is logged along

with the DGPS position where the sample was collected.

If the electrodes take longer than 10 seconds to settle, a warning will appear by the readings that

indicates the number of seconds the reading has required. When the maximum log time is

reached, the unit initiates a new sample cycle (refer to Controller setup for adjusting the log time).

Figure 22

3-20

Page 29

Pub.# OM17-MSP-pH

This time warning is to let the operator know that a measurement cycle is requiring excessive time.

While an occasional cycle may exhibit this warning. see the troubleshooting section if this occurs

frequently.

The Veris MSP pH Manager uses two electrodes for optimal data quality. If there is a difference of

0.75 or greater between the final electrode readings, the software will beep and the pH readings

will flash, informing the operator of the erroneous reading.

To pause the data collection process at any time (but keep the same file), press Engage button.

Once the sampling process has completed its cycle, it will disengage and the status text message

will indicate disengaged (press Engage to start cycling again). If the system no longer senses a

speed signal from the GPS, it will also disengage. NOTE: do not depend on the GPS speed signal

for disengagement. Before inspecting or working around any component of the system, press the

Engage key and ensure the engage light is red before exiting the vehicle. Sporadic GPS signals

may simulate movement and initiate the cycling process, resulting in possible entanglement and

injury.

If TAP or DI are selected as the wash water type, the water baseline process will be repeated

every 40 cycles following the next engage press. If the pH during the cycling sequence does not

get within 0.5 of the baseline pH, the computer speakers will beep and the pH labels will blink. This

is to allow operator that the electrodes are not cleaning properly.

pH Data Flags

Numbered “flags” can be added to the pH data by pressing the Flag key or F2 while the pH

Manager is CYCLING or RECORDING. If the key is pressed while the pH Manager is in the

RECORDING phase, the flag light will turn bright green:

Figure 23

This means the flag will be recorded with the current data point. If the key is pressed while the pH

Manager is in the CYCLING phase, the next point will be flagged and exclamation point will not

appear until the RECORDING phase is reached. Tip: Use this function to flag any sample where a

problem has occurred, such as a plugged shoe. Open the pH file in a spreadsheet program, locate

the points that have been flagged, and delete rows of problem data.

There are warning signals programmed into the SoilViewer to warn the operator that data are not

being recorded, so that corrective action can be taken. If data aren’t being recorded, a warning

beep will sound from the computer, and the text indicator of the data that is missing information will

blink. For example, if the DGPS isn’t being received (or the NMEA string containing speed) the Fix

indicator text will blink. If EC values are negative, they will also blink.

3-21

Page 30

Pub.# OM17-MSP-pH

External

controller

Furrow

closers

Tank and pumps

for electrode

cleaning

Wash

nozzles

Sampler shoe

and scraper

EC

coulterelectrodes

Pull-tongue

(opt.)

Hyd. valves

(under tank)

Road kit (opt.)

SECTION 4

pH Manager Implement

Set-up and Field Operations

Implement Overview (MSP)

Figure 1

12 Volt Power and Hydraulics Set-up

If the unit has been crated and delivered via closed-van commercial freight, the tongue (if

equipped) may need to be installed prior to use. Prior to operating the implement for the first time,

it is important to check all fasteners – some may have loosened during shipment. Route cables

(figure 2) and hydraulic hoses along tongue and through hose guide. Tie-strap securely. Connect

electrical cables to battery. Be careful to attach black cable to negative/ground terminal. DO NOT

REVERSE POLARITY.

4-1

Page 31

Pub.# OM17-MSP-pH

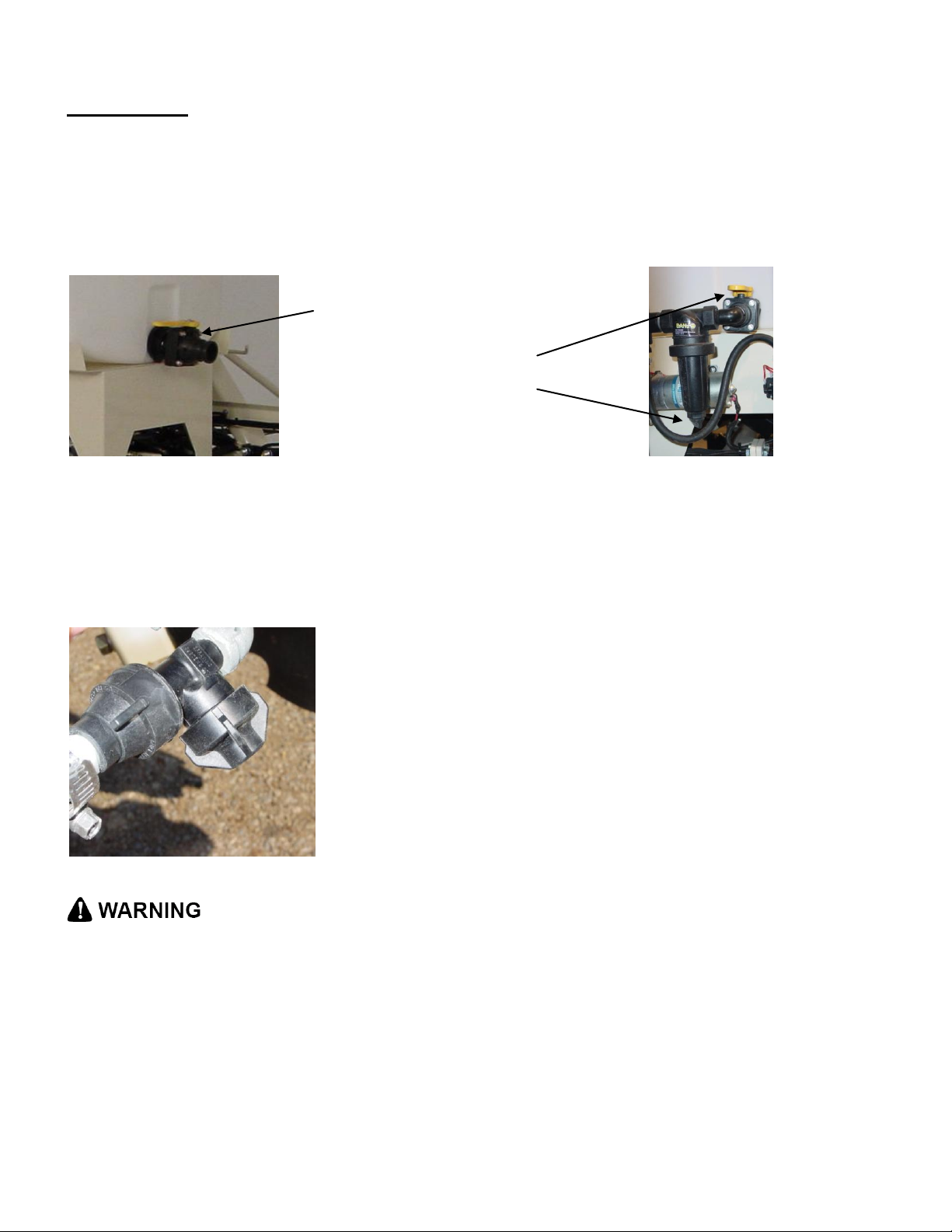

Open/Closed center hydraulic poppet valve

-Up (out) for open center tractor hydraulics

-Down (in) for closed center tractor hydraulics

12 V Power leads

pH signal cable

EC signal cable

Figure 2

Insert hydraulic ends into quick-couplers, being careful to insert the end marked “P” into the tractor

extension coupler, and the end marked “T” into the tank or return line coupler; in this configuration,

tractor’s hydraulic lever will be secured in raised position. If sampler shoe operates in reverse,

simply reverse hydraulic hoses, or secure lever in lowered position. Note: Be certain whether

tractor or hydraulic power source utilizes open or closed-center hydraulics. Damage to

tractor could occur if not set properly. The poppet knob is set ‘up’ for open systems, and

‘down’ for closed-center systems – (see settings below.) Press down and turn knob to lock down—

press down, turn and release to allow it to move up to open position.

Figure 3

4-2

Page 32

Pub.# OM17-MSP-pH

Flow control settings:

Open center hydraulic systems

1) Set poppet valve in “up” raised position, this allows flow back to tank

2) Set engine at field rpm

3) Set pH controller to “Manual” and run sampling shoe up and down, timing the cycle time.

4) If sampler raises in approximately 1.5 -2 seconds, leave flow control as is, if not, adjust control

arm upward or downward to achieve desired speed.

Closed center hydraulic systems

1) Set poppet valve in down position. Push down and rotate so that rolled pin locks into closed

position. This blocks flow and allows the pump to de-stroke when the directional valve is in

the neutral position.

2) Adjust flow control valve to full open position.

3) Set engine at field rpm.

4) Run sampling shoe upward and adjust raise time to approximately 1.5-2 seconds using

throttling valves on tractor’s remote coupler

Note: Excessive sampling shoe speed can damage electrodes.

Flow control valve

(Standard equipment on 2008 and later models)

Adjustment control arm

Figure 4

• Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard

by relieving pressure before disconnecting hydraulic lines. Use a piece of paper or card-board,

NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and highpressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result.

4-3

Page 33

Pub.# OM17-MSP-pH

ball valve:

closed

open

12 V power in

Communication

Sampler solenoid power

Prox sensor

Wash pump power

Flush and fill tanks with tap water; clean any foreign matter out of tank using ball valve clean-out.

Set ball valve to open position, allowing water to flow to pumps.

Figures 5a and 5b

Connecting cables to External controller as shown below:

Figure 6

Remove pH electrodes from individual storage containers and fill soaker solution cup with soaker

solution. Install soaker solution cup on electrode holder. Loosen plastic set screws on electrode

holder and insert pH electrodes into electrode holder. Re-tighten set screws finger tight and lock in

place with lock nuts. Do not overtighten set screws or electrode damage may occur. Always keep

electrodes in soaker solution, either in individual containers or soaking in large cup installed over

electrode holder. Route electrode cables away from sampling mechanisms to prevent damage—

tie-strap excess length of cable as needed.

4-4

Page 34

Figure 7

pH

electrodes

electrode set

screws and

lock nuts

electrode

holder

soaker cup

Tools required for Field Operation adjustments

-3/16” allen wrench

-adjustable wrench: min. 10” (25 cm) length

-3/4” socket and wrench

-9/16” socket or wrench

-15/16” wrench

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the Veris

MSP. Disengage automatic cycling function before working around unit. Install all transport locks

before transporting or working underneath.

Manually Operating Wash and Cycling Functions

After all cables and hydraulic hoses are connected, test power to unit by turning external pH

controller power switch to on position. With control switch in manual position, run wash pump

briefly. If water does not flow from jets within 10 seconds, disconnect quick couplers to help pumps

prime. If water doesn’t spray, but pump is running, see Troubleshooting section for instructions on

priming pump. If pumps don’t operate, recheck power cables and connections. If electrical power

to Controller is functioning, test hydraulics by locking hydraulic lever in position, and raising and

lowering sampler shoe using manual Up/Down switch. Test Raise/Lower functions on main lift

cylinder if equipped. Make sure no one is under unit and keep clear of any pinch points.

Pub.# OM17-MSP-pH

Implement Set-up and Adjustments

4-5

Page 35

Manual-Auto switch:

must be in Automatic

mode for mapping;

in Manual mode for

manual control of

washing or sampler

shoe position

Wash: On when washing

manually; Must be Off

for Automatic washing

Sampler up and down:

raises sampler shoe

manually

Begin with a

dimension of

21” pin to pin

Adjust tractor or

implement top link to

level

Power switch

must be on to

operate any

function

Center position

Initial adjustment of 21”

Adjust top link to

level in soil

Figure 8

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the Veris

MSP. Disengage automatic cycling function before working around unit. Install all transport locks

before transporting or working underneath.

Three-point Mounted Units

Raise sampling mechanism to full height. Begin depth adjustment process with shank in center

position (pin in one of two center holes). Adjust ratchet jack so that coulters will penetrate 1-2”

deep – 21” pin-to-pin is a good starting point Adjust three-point top link to level unit when in soil.

Figure 9 a,b,c

Pub.# OM17-MSP-pH

4-6

Page 36

Pub.# OM17-MSP-pH

sampling depth

is measured

from top of

cutting shoe to

soil surface

begin with shank

in one of two

middle positions

begin with 2-3”

(5-7.5 cm) of

depth stops

Adjust tractor or

implement top link to

level

Operate implement parallel to soil or

slightly tipped (up to ½”) forward never allow

unit to tip backward --this will decrease shoe

penetration.

Towed Units

Raise sampling mechanism to full height. Begin depth adjustment process with shank in center

position (pin in one of two center holes). Install 2-3“ (5-7.5 cm) of cylinder depth stops on main lift

cylinder. Lower implement into soil until main lift cylinder bottoms out against depth stops. Adjust

threaded top link to level unit.

Figures 10 a,b,c

Figure 11

Once unit is level, lower sampling mechanism completely, drive forward 10-20’ (3-6 m) to create

soil core. To measure depth of soil core being collected, brush away soil from cutting shoe.

Measure from soil surface to top of cutting shoe. This is the depth of sampling. To increase

sampling depth, remove cylinder stops; to decrease sampling depth, add stops. Re-leveling unit

with adjustable top link may be required.

Figure 12

4-7

Page 37

Pub.# OM17-MSP-pH

pull adjustment pins and

lower shank if deeper

sampling is needed (and

EC coulter depth is

satisfactory)

Adjust scraper bracket

until cutting shoe

clears scraper when

sampler assembly is

raised completely.

Note: if MSP is equipped with EC Module and EC data is being collected along with pH data,

adjusting the overall height of the unit will affect coulter-electrode depth. If deeper soil sampling is

desired, and removing cylinder stops would result in excessive coulter-electrode depth, remove

sampler shank pins and lower shank to lowest setting. If shallower soil sampling is required, and

adding cylinder stops results in inadequate coulter-electrode depth for EC data collection, raise

sampler shank to highest setting.

Figure 13

Once EC coulter depth and sampling depth are satisfactory, adjust other components in this

sequence:

1. Scraper adjustment: in manual mode hydraulically raise the sampling shoe to maximum height.

Adjust scraper until cutting shoe clears scraper blade when sampler shank is fully raised.

Figure 14

4-8

Page 38

Pub.# OM17-MSP-pH

Turn crank to raise

or lower electrode

holder

electrode

holder 1”

(2.5cm)

above wash

jets

When wash jets are

properly aligned,

overspray is minimized

and water bubbles out

top of empty electrode

holder as shown here.

½” (1.2 cm) clearance

between electrode holder

and trough liner

When installing BNC cover, route

electrode wires under box; center box

on white pad, and tighten wingnut finger

tight. Keep cover installed even when

electrodes are removed.

2. Adjust electrode holder: with sampling mechanism raised completely, adjust electrode

holder to provide ½” (1.2 cm) clearance between it and sampling trough.

Figures 15 and 16

3. Wash adjustment: Wash brackets should be parallel to sampling trough, with jets directly

beside electrode holder, jets should be 1” (2.5 cm) below electrodes; when electrodes are

properly aligned.

Figures 17a and 17b

Figures 18a and 18b

4-9

Page 39

Pub.# OM17-MSP-pH

Closing Disks

depth adjustment

pin

Closing disk

angle

adjustments

Adjust height of cleaner

relative to firming wheel by

removing adjustment pin

and re-positioning disk

attachment.

4. Insert pH electrodes into electrode holder. Finger-tighten plastic screws. Install BNC cover

on external controller to keep moisture out of BNC connectors. Leave BNC cover on

whenever unit is outdoors.

5. Row cleaner/firming wheel: Pull MSP forward and check depth of row cleaner and firming

wheel. Cleaner should be clearing residue ahead of sampling shoe, but not gouging into

soil. Adjust height of cleaner relative to firming wheel by removing adjustment pin and repositioning disk attachment.

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the Veris

MSP. Disengage automatic cycling function before working around unit. Install all transport locks

before transporting or working underneath.

Figure 19

6. Closing disks (if equipped): Adjust closing disks as needed to properly close trench and

bring residue over row-cleaned zone. Do not operate these deeper in soil than necessary.

Figures 20a and 20b

4-10

Page 40

Pub.# OM17-MSP-pH

1/4 to 3/8” gap

7. Prox sensor: The prox sensor communicates the position of the sampler assembly to the

external controller for automatic cycling functions. Adjust sensor to 1/4”- 3/8” (6-9 mm) gap.

Cycle unit manually to insure that this gap is maintained throughout cycling range. Red

LED light should light whenever prox sensor is near metal and not light when away from

metal. To view LED light, shade ambient light from prox sensor and cycle sampler

assembly manually. Be careful to not strike or damage prox sensor face. NOTE: in manual

mode, hydraulic cylinder opens and closes completely; in automatic mode cylinder stops as

soon as prox sensor clears upper and lower plate. In order for cylinder to set electrodeshoe clearance properly (step 2 above), adjust prox sensor height with sampler shoe

completely raised. Adjust the prox sensor so it barely clears the lower part of the sensor

plate when sampler is completely raised. It may be necessary to reposition the electrode

holder after adjusting prox sensor; see step 2 above.

Figure 21

Figure 22

4-11

Page 41

Pub.# OM17-MSP-pH

electrode body

reference junctions

electrode face

antimony measurement tip

SECTION 5

Maintenance and Service

Clean-up—ISE storage, wash

If you are going to interrupt your pH mapping for 30 minutes or longer, clean off the electrodes and

the electrode holder with the wash wand, and install the soaker solution container on the electrode

holder. Replace soaker solution (Veris part #23395) weekly, or more frequently if it is diluted or

dirty.

Figures 23a and 23b

pH Electrodes

Figure 24

5-1

Page 42

Pub.# OM17-MSP-pH

Leave BNC cover on whenever unit is in

operation or stored outdoors. Do not

allow moisture into BNC connections.

• Antimony is harmful if ingested into your skin, mouth, or lungs

-Do not touch antimony electrode tip

-Do not grind or sand antimony tip

-Always use proper soaker solution: Veris part #23395

-Keep moist; put in soaker solution if mapping (washing) is interrupted for 15 minutes

-Replace soaker solution every week or more frequently if it gets diluted with tap water or dirty

-If soaker solutions is unavailable, use pH buffer 4; never soak in distilled or de-ionized water

-remove from holder and place in individual soaker bottles in freezing temperatures and when unit

will be idle for long periods

-keep cover over BNC ports on external controller whether electrodes are attached or unattached

Figure 25

5-2

Page 43

Pub.# OM17-MSP-pH

open check

diaphragm

and drain

water in line to

prevent freeze

damage

ball valve on

plug removed

tank clean-out

ball valve

Wash System

If wash water develops algae, flush and fill tanks with tap water; clean any algae or other foreign

matter out of tank using clean-out ball valve (right side). Set wash system ball valve (left side) to

open position, allowing water to flow to pumps. Clean filter at least once per week of operation.

Remove plug and turn on ball valve to clean.

Figures 26a and 26b

When temperatures are dipping below freezing, prevent freeze damage to the wash system as

follows: close ball valve between tank and pumps, open up check diaphragms and drain,

disconnect quick couplers and run pumps until empty. If unit is to be left outside for long periods of

time over winter, it is advisable to add RV antifreeze to tank and run pumps for a couple of minutes

to fill all lines with anti-freeze. Purge system of anti-freeze before collecting any pH data.

Figure 27

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the

Veris MSP. Disengage automatic cycling function before working around unit. Install all

transport locks before transporting or working underneath.

5-3

Page 44

Pub.# OM17-MSP-pH

knock worn shoe off

from rear

tap new shoe on

with 2x4

Pivot grease

zerks (2 per

hangar; 4 total )

Wear Item Replacement

Inspect cutting shoe for wear and gouges, replace as needed. Knock old shoe off with punch and

tap new shoe on, as shown here. TIP: Rotate cutting shoe to prolong wear life.

Figures 28a and 28b

Replace sampling trough liner, scraper cutting edge when wear is apparent.

Lubrication

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the Veris

MSP. Disengage automatic cycling function before working around unit.

• Install all transport locks before transporting or working underneath.

Rockshaft pivot points – Each pivot (located at the left and right) contains

an upper and lower grease zerk. Due to the limited motion of the

rockshaft, these should be lubricated on 40-hour intervals. This may

vary based on the number of times the unit is raised and lowered.

Figure 29

5-4

Page 45

Pub.# OM17-MSP-pH

grease zerks

Rachet jack --

Figure 30

Front Row Cleaner and Closing Disks-

Figure 31 Row Cleaner grease zerks Figure 32Closing Disk grease zerks

5-5

Page 46

Pub.# OM17-MSP-pH

Figure 3

SECTION 6

pH Module Troubleshooting

1. Unit doesn’t cycle when “1” key is pressed (in Automatic Mode)

-check to be sure you are in Data Acquisition mode—screen below:

Figure 1

-check to be sure that external controller is in Automatic mode. If it isn’t, this screen will

appear:

Figure 2

-follow troubleshooting flow chart below and see related Procedures in Maintenance and

Procedure Section

6-1

Page 47

Pub.# OM17-MSP-pH

Figure 4

2. Functions Aren’t Working in Manual Mode

-follow troubleshooting flow chart below and see related procedures in Maintenance and

Service Procedure Section.

3. Sampling mechanism locks up or mis-cycles

-press “1” to disengage, turn external controller to Manual and check prox sensor adjustment

(see Procedure #4 in Maintenance and Service Procedure Section.)

-check DGPS signal

-if status of sampler shows “Cycling” for long periods, set sampler shank to shallower position.

In hard soil, sampler shoe may not be able to penetrate to the depth needed to move plate off

prox sensor. (see Procedure #4 in Maintenance and Service Procedure Section.))

6-2

Page 48

Pub.# OM17-MSP-pH

Use pH simulator to test external controller and Veris

instrument.

On/Off key (Turn pH simulator OFF when test is completed)

Attach to each BNC port to test each circuit

Press Select button to toggle from 4 to 7 to 10. Light above pH

value will light. View Veris display to confirm these readings

at each simulator setting:

4 should read -2, 7 should read .6, and 10 should read 3.9.

(Note: the simulator is designed for glass electrodes; for

antimony the readings are those listed above)

4. Wash system malfunctioning: no water being pumped

-are there at least 10 gallons of water in tank?

-are pumps running? If not, check electrical connections and 12 volt power to them

-check pressure switch on pump—wiggle wire, disconnect and reconnect; direct wire if needed

-is filter plugged?

-is ball valve open?

-disconnect quick couplers to help pumps prime

5. pH readings seem erroneous or won’t calibrate

-Use pH simulator to test External Controller and Veris instrument. Re-test with pH simulator

set to High Impedance

Figure 5

-check for moisture around BNC connectors and for proper installation and fit of the BNC cover

over BNC connections (if the pH simulator readings are not close to the default settings, blow

compressed air into BNC ports on external control module)

6. Sampling shoe plugging

-verify if shoe is plugged: wash electrodes to create a wet sample in the shoe; in manual mode

lower sampler to full depth and drive forward; if soil in the sampling trough is now dry, fresh soil

has entered and the shoe isn’t plugged

-to clean plugged shoe, raise implement, lower shoe manually to maximum depth, and drive

forward at high rate of speed as you lower the implement completely; if it doesn’t clear, clean

manually (put transport locks in before working under unit)

-clean cutting shoe thoroughly, especially if it has dried mud in it

-check cutting shoe and scraper for wear; replace as needed

-check scraper adjustment by manually raising and lowering sampler assembly. Does scraper

completely clean the cutting shoe face? See Field Operation section for proper adjustment

-adjust row cleaner to clear residue more completely

-adjust firming wheel down to firm soil

-lower sampling depth to engage soil with better coring properties

7. pH readings are repeatedly >.5 different or are slow to settle,

-check shoe for sample quality. If only a small amount of soil is present, reduce field speed to

retain adequate core. If crop residue is present, adjust cleaning disks to reduce crop residue in

sampling area.

6-3

Page 49

Pub.# OM17-MSP-pH

LED Description

D1 Main board power (Red)

D2 Fuse F2 (Green)

D3 Fuse F1 (Green)

D4 Water pumps relay coil (Red)

D5 Water pumps relay contact (Green)

D6 Up solenoid relay contact (Green)

D7 Up solenoid relay coil (Red)

D8 Down solenoid relay contact (Green)

D9 Down solenoid relay coil (Red)

D10 5V power 1 (Green)

D11 5V power 2 (Green)

8. pH electrodes are not being cleaned of soil adequately

-check wash system in manual mode—are both pumps operating properly?

-check alignment of wash jets

-check wash function operation while in automatic mode

-increase wash time in Controller set-up menu; this can be done either by selecting the extra

wash option, by extending the cycle time to 3 seconds—or both.

9. Too many pH points are rejected

-check electrodes and wash system for adequate cleaning

-recalibrate the electrodes

10. Electronic controller not functioning:

remove metal plate covering external controller and inspect the LED lights for following

functions:

Figure 6

OVERVIEW

When the power is turned on and the pH controller is in automatic mode, LEDs D1, D2, D3, D10,

and D11 will light up. When the controller is switched to manual mode, LEDs D4 and D5 will light if

the wash switch is turned on; LEDs D6 and D7 will light if the manual control hydraulic switch is in

the up position (raising sampler shoe); and LEDs D8 and D9 will light if the manual control

hydraulic switch is in the down position (lowering sampler shoe) .

Power is turned on but no LEDs are lit...

-Turn off pH controller.

-Check fuse at battery connection.

-Check all plugs for a secure fit and check cables for damage before turning on pH controller.

Power is turned on but only LED D1 is lit...

-Turn off pH controller.

-Remove cover from pH controller.

6-4

Page 50

Pub.# OM17-MSP-pH

-Replace fuse F2 with supplied cylindrical fuse. Part #8496

-Check all power connections and check cables for damage before turning on pH controller.

Power is turned on but only LEDs D1 and D2 are lit...

-Turn off pH controller.

-Remove cover from pH controller.

-Replace fuse F1 with supplied miniature fuse. Part #22611

-Check all power connections and check cables for damage before turning on pH controller.

In manual mode, red LED (D4, D7, or D9) lights but green LED (D5, D6, D8) does not light when

switch is thrown for wash or hydraulics up/down...

-Relay supplying power to the water pumps or up/down solenoid is not receiving power

-The relay or another component on the board may be damaged and the pH controller needs to be

returned for repair. Contact Veris service department (785) 825-1978

In manual mode, red LED and green LED light when switch is thrown for wash or hydraulics

up/down but water is not sprayed or the sampling shoe does not move...

-The relay supplying power to the water pumps or up/down solenoid is functioning normally.

-Ensure that all pumps and solenoids are connected.

-See Section 2 above and follow troubleshooting flowchart.

11. No GPS or DGPS on display

Perform Maintenance and Service Procedure 5.

12. DataLogger locks up

-SD card not installed or not formatted. See Procedure #6 to format card.

13. EC Surveyor or DataLogger doesn’t power up (power LED not lit)

-Check barrel fuse in power plug (cigarette lighter)

-Check power to vehicle power port

14. Data status (green LED) light not lit

-check GPS status: must have GPS, DGPS, or RTK

-check EC status: EC values must be positive

-Unit must be moving to send data out port

6-5

Page 51

Pub.# OM17-MSP-pH

Procedure #1: Checking power inside External Controller

The Veris pH module requires a minimum of 12 volts at all times. 12 volts at the battery terminals

is NOT sufficient power for the system to function, due to the significant current draw when the

pumps and solenoids are engaged. Reduced voltage can be caused by corroded or dirty terminals,

and an inadequately charged battery or failure in the charging system. Because there is often a

voltage drop found in tractor power ports, you should hook the pH module power cables directly to

the battery. TIP: if automatic cycling is erratic, disconnect wash pump power from pH external

controller. If system cycles normally, the cause is most likely due to inadequate electric power.

If the Veris electrical system is not functioning properly, the Troubleshooting flowcharts will direct

you through the most logical steps to identify the cause of the problem. If the problem persists, you

will likely need to check the power inside the External Controller in order to isolate power system

problems. An overview of this procedure is shown in Figure1.

Figure 1.1 Flowchart for checking power in External Controller.

1. Inspect LED’s on External Controller circuit board.

Remove metal plate covering external controller and inspect the fuse LED lights, as shown in

Figure 2. If the green LED for its fuse is lit, the fuse is working.

6-6

Page 52

Pub.# OM17-MSP-pH

POWER (12V)

FUSE 2 (10A)

and its LED

FUSE 1 (500 mA)

and its LED

5V 2

Figure 1.3 Using

voltmeter to check

voltage at External

Controller power supply

Figure 1.2 External Controller circuit board (metal cover removed)

2. Turn off power to External Controller, remove clear lid and remove and replace any fuse

that has failed.

3. Check voltage with a digital voltmeter at power supply connection

All functions must be engaged during this test. In manual mode turn on wash pumps and cycle

sampler shoe hydraulics while holding voltmeter leads on power supply connector shown in Figure

3. Keep moisture from entering External Controller. It may be necessary to reposition the spray

nozzles or shield the overspray from the Controller. It is critical that the pumps are under full load

(pumping water through the nozzles) during this test. Be careful to not let your fingers or voltmeter

leads touch any other component inside the External Controller.

6-7

Page 53

Pub.# OM17-MSP-pH

If voltage at power connector drops below 12 volts during this test:

a) clean battery terminals

b) check disconnect contacts

c) hook power leads directly to battery—not through tractor power port

d) charge battery

4. Check voltage at power cable (Figure 4). If 12V at cable but not on circuit board—call

Veris Service Dept.

Figure 1.4: Using voltmeter to check voltage at power supply cable

6-8

Page 54

Pub.# OM17-MSP-pH

Procedure #2: Trouble-shooting Sampler Cylinder Hydraulics

The Veris pH module uses electro-hydraulics to perform the cycling functions. If the sampling shoe

hydraulic cylinder is not functioning properly, the cause of the problem must be traced to either the

electronic or the hydraulic side. This Procedure will guide you through the steps necessary to

identify the problem when the sampler cylinder in manual mode is not moving or only moves in one

direction. An overview of this procedure is shown in Figure1. (Erratic movement or cycling

problems in automatic mode are addressed in Procedure #1.)

Figure 2.1 Flowchart for trouble-shooting sampler hydraulics.

1. If cylinder doesn’t move at all in manual mode, check hydraulic flow. Does main lift

cylinder function? If not, check tractor hydraulic lever position. If necessary, check flow with

pressure gauge.

2. Inspect LED’s on External Controller circuit board. Remove metal plate covering external

controller and inspect the solenoid LED lights, as shown in Figure 3. Do not remove clear lid at

this time. The LED’s on the UP circuit should light when the sampler up-down switch is raised

and the LED’s on the down circuit should light when the manual up-down switch is lowered. If

the four LED’s on the solenoid circuit do not light in that sequence, see Procedure #1 to test

power inside External Controller.

6-9

Page 55

Pub.# OM17-MSP-pH

5V 2

SOLENOID

LED’s

UP

DOWN

Figure 2.2 External Controller circuit board (metal cover removed)

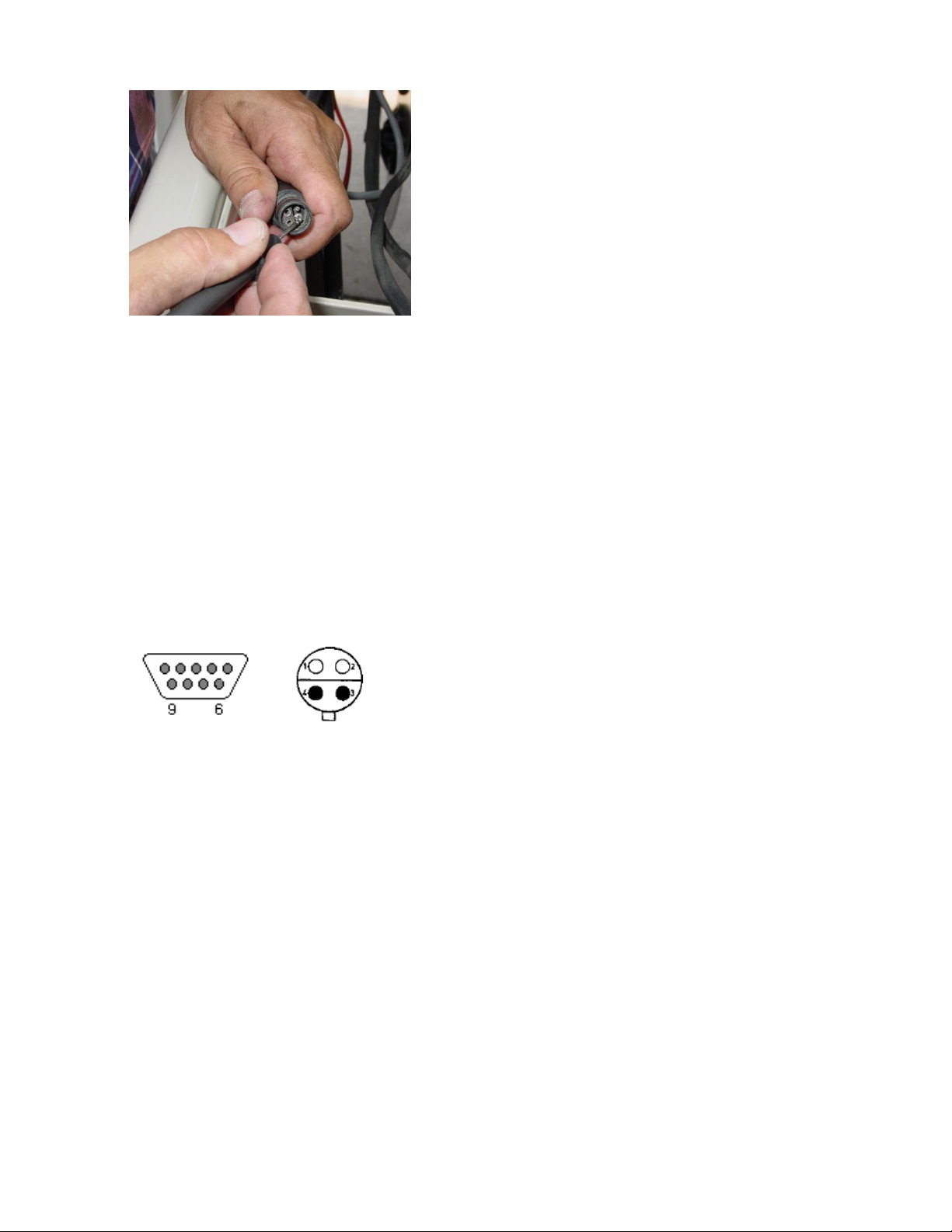

3. Test voltage coming out of External Controller to solenoids. Disconnect the weather-pack

connectors in line from Controller to the solenoids. Using a digital voltmeter set to read voltage,

insert leads into connector coming from Controller. Activate manual raise-lower switch and

read voltage. (Figure 4) Voltage should be 12 volts.

Figure 2.3 Testing voltage on power leads to solenoid.

6-10

Page 56

Pub.# OM17-MSP-pH

4. Test continuity of coil. With voltmeter set to ohms

(resistance), insert both leads into the weatherpack

connector leading to each solenoid. Start at the

jumper wire (at first connection from external

controller) and move to connector at solenoid. This

tests the continuity of the signal through the coil.

You should have continuity if the coil is working.

Test both solenoids.

Figure 2.4 Testing continuity of solenoid coil (at

weather-pack connector on jumper-wire)

5. Determine if coil is energizing. (This test integrates the previous two steps—if you have 12

volts going to the coil and the coil is functioning (has continuity), the coil should energize.)

Touch a small screwdriver or other metal object to the coil as shown in Figure 6, and activate

manual raise/lower switch. When the coil energizes it will hold the metal magnetically. If one

coil doesn’t energize, swap coils to determine whether it’s a bad coil or power problem.

Figure 2.5: Using screwdriver to test energizing of coils.

6. Clean solenoid valve. If coils energize and the cylinder doesn’t move, there must be

contamination in the solenoid cartidge. Remove and clean thoroughly with compressed air—be

careful not to damage or lose O-rings.

Additonal Tips…

If your system is equipped with lift hydraulics, you can swap coils or valves to verify the failed

part, before ordering a replacement.

If sampler shoe moves in reverse direction, disconnect solenoid wires (from external controller)

and reverse.

6-11

Page 57

Pub.# OM17-MSP-pH