Page 1

Field Reference Guide—pH Manager

Keep with pH System and refer to daily.

(Refer to Operating Instruction Manual for complete instructions)

PRIOR TO MAPPING: PERFORM ROUTINE DAILY

MAINTENANCE

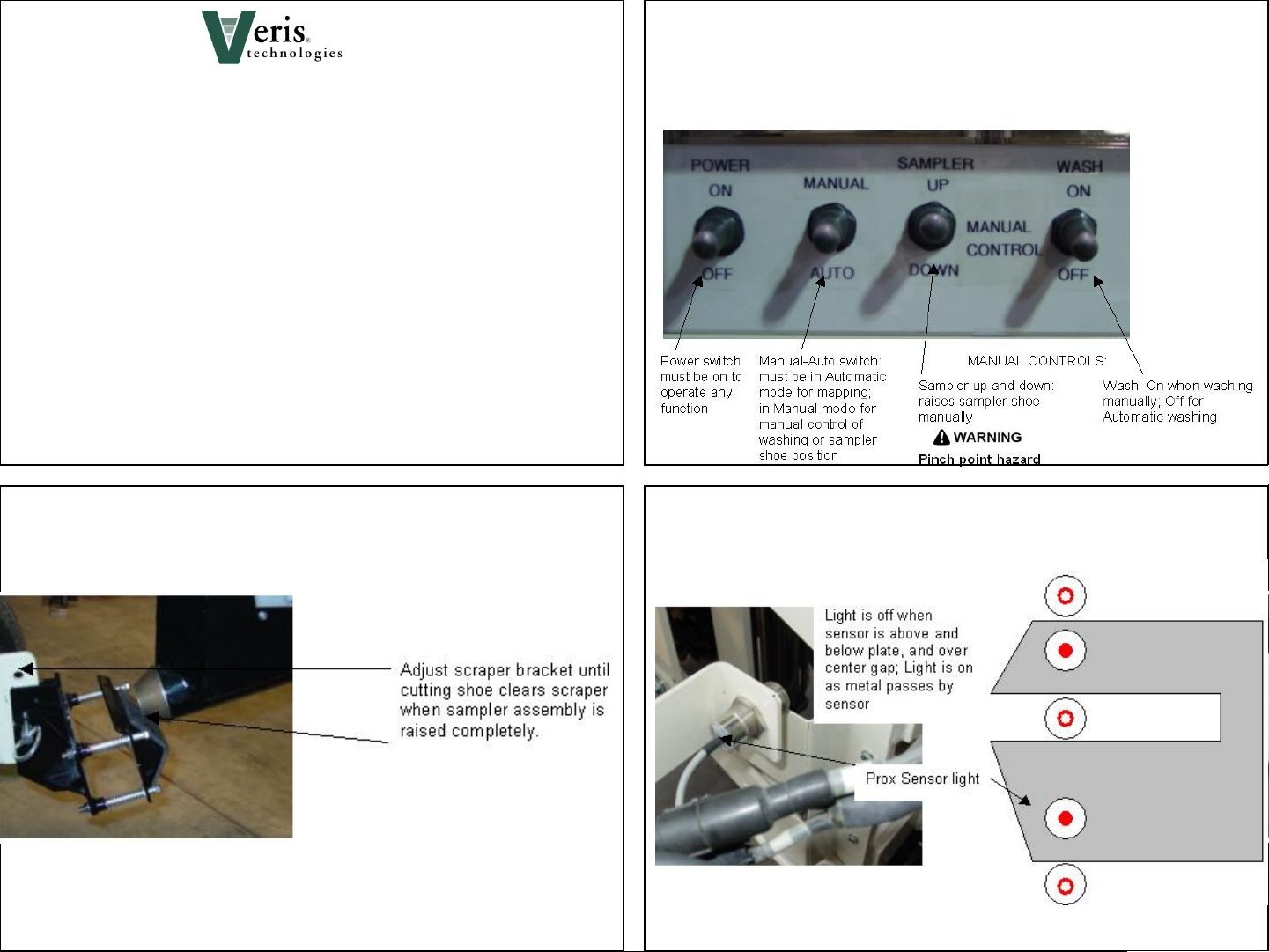

3. In Manual Mode test each function

(washing, raising and lowering):

1. Inspect unit for loose

or missing bolts, other

obvious problems

4. Raise and lower sampling shoe—check scraper for

appropriate contact:

2. Are sampling shoe and

trough completely clean of

soil?

5. Inspect prox sensor light during manual cycling:

Adjust hydraulic flow so cycling time is 1.5-2 seconds

Page 2

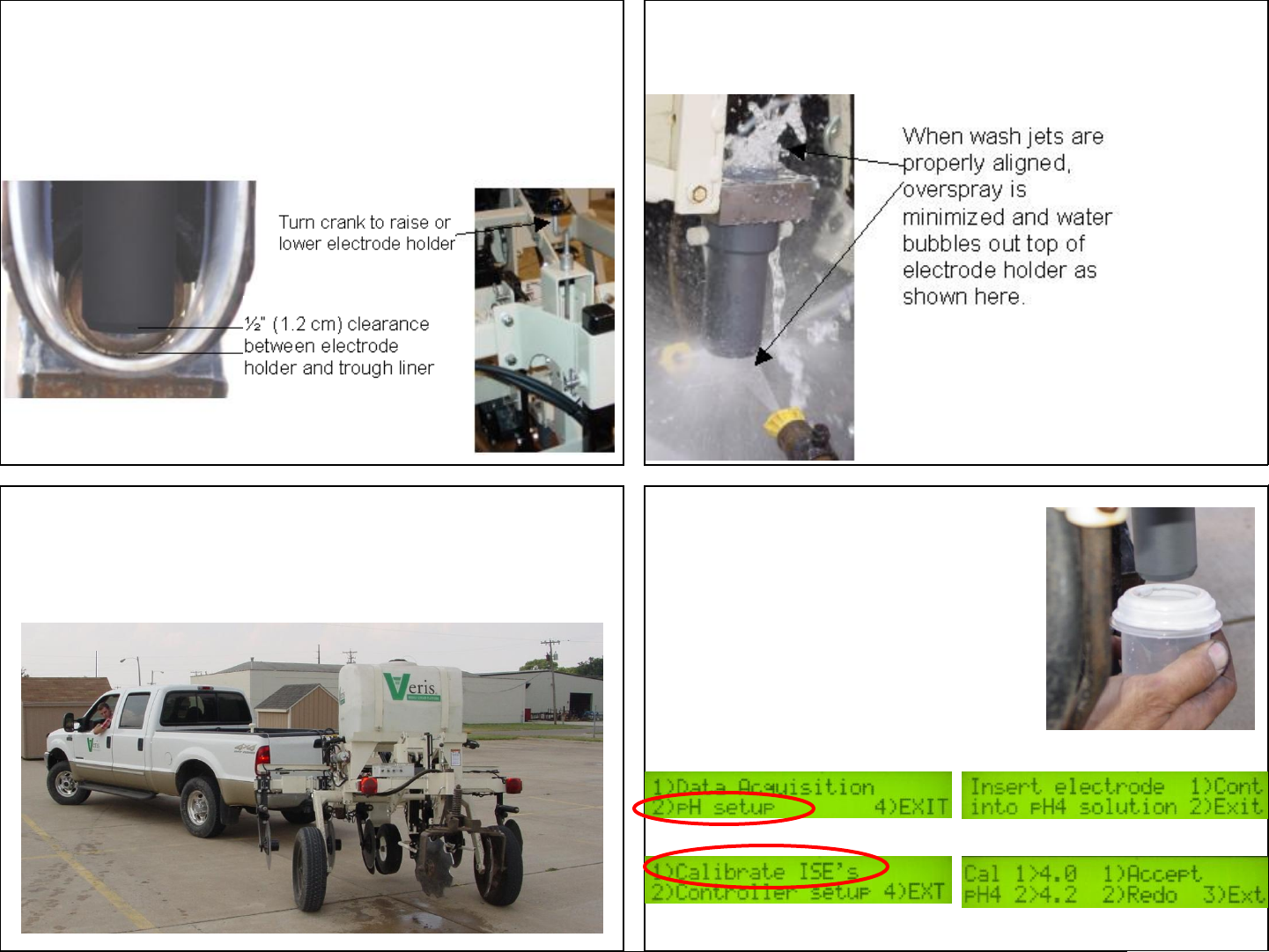

6. Raise sampling shoe—check for ¼” to ½” clearance

between electrodes and trough; make sure this is where

the shoe will stop in automatic mode (see prox sensor

adjustment section in Operating Instructions)

7. Operate wash jets and check alignment; does water

bubble out of top when electrodes are removed?

9. Calibrate electrodes

8. Raise unit and drive slowly in semi-circle with unit cycling

to check automated functions

Insert electrodes into holder and fingertighten set screws. Follow menu

prompts to “pH Setup”. The instrument

will prompt for the electrodes to be

inserted into pH buffer 4 solution; Slide

pH 4 buffer solution container onto

electrode holder. Press 1 to continue

with calibration or 2 to exit. Repeat with

pH 7 buffer solution.

Page 3

10. Set operating depth: 2-3” of cylinder stops (21” length

of ratchet, machine level, sampler shank in 2ndor 3rdhole

typically.

DATA QUALITY TIPS

-All pH mapping requires calibration samples to be collected from the field.

-Before logging any data, make sure the SD card in the Datalogger is clear of any files that are not Veris .dat files.

-During „Cycling‟ phase, do both pH electrode readings get close to the wash water pH? If not, one or both electrodes may not be

cleaning properly.

11. Cycle unit in soil at desired field speed (4-8 mph) and

inspect sampler shoe for core. Slow down if full core was

not retained.

-During „Recording‟ phase, do both electrode readings move to expected soil pH level? If they stay near wash pH level and/or

require more than 10 seconds to settle, one of the following may have occurred: 1) shoe may have plugged, so no new soil is

entering, and the shoe is slowly filling up with wash water; 2) Excessive speed may have allowed soil core to shoot out the back, or

3) gap between electrodes and shoe may be excessive, so thinner soil cores aren‟t contacting pH electrodes.

-Operators who monitor the screen, and are alert to pH values that aren‟t appropriate for the Cycling or Recording phase, generate

better maps.

-Whenever the final pH readings at a sample location are >.50 apart, an alarm will sound indicating data for that sample location will

likely be eliminated during data extraction. If more than an occasional reading is rejected, inspect the sampler assembly for possible

plugging or other malfunction, and the electrodes for proper cleaning.

-The speed you travel and your transect width directly affects the sample density: 6 mph (9.6 km/hr) on 50‟ (15 m) transects provides

approximately 10 samples/acre (24/ha). 5 mph (16 km/hr) on 75‟ (23 m) transects results in approximately 5 samples/acre (12/ha).

-If a soil core is not present in trough, slow down and inspect again. Excessive field speed can cause core to eject before sampling.

-If possible, double your transect width and fill back in to return to starting point. ISE drift will be evident and should be correctable.

-Make map as soon as possible and inspect for quality; map should have spatial structure and minimal streaks or lines

Loading...

Loading...