Page 1

Operating Instructions

Section 1

1-1 Warranty

1-2 Safety

Section 2

2-1 pH Detector Assembly and Set-up

2-5 Electronics Overview and Set-up

Section 3

3-1 Field Operations

3-4 Data-Logger Display

3-4 Calibration

3-7 pH Controller set-up

3-9 Probing

Section 4

4-1 Maintenance and Service

4-2 Wash system/Winterizing

4-3 Adjustments/Troubleshooting

OM17-pH Detector

pH Detector

Table of Contents

Page 2

OM17-pH Detector

SECTION 1

pH Detector

Sensor DataLogger Version 1.03

Warranty

Veris Technologies warrants this product to be free of defects in materials and workmanship for a

period of one (1) year from the date of delivery to the purchaser. Veris Technologies will repair or

replace any product returned to Salina, Kansas, which appears upon inspection to be defective in

materials or workmanship. Veris Technologies will have shall have no obligation under this

warranty for the cost of labor, down-time, transportation charges, or for the repair or replacement of

any product that has been misused, carelessly handled, modified, or altered.

ALL OTHER WARRANTIES OF ANY KIND, WHETHER EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE AND ALL CLAIMS FOR CONSEQUENTIAL DAMAGES, ARE

SPECIFICALLY DISCLAIMED AND EXCLUDED.

Safety

1-1

Page 3

OM17-pH Detector

Important! Read the following SAFETY PROCEDURES before operating the Veris system:

• Read and understand all instructions on safety decals

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the Veris

implement.

• Install all transport locks before transporting or working underneath.

• Detach and store implements in an area where children normally do not play. Secure implement

by using blocks and supports.

• Read Operations Manual before operating machine

• Review safety instructions with operators before operating machine and at least annually

• Riders obstruct the operator’s view. They could be struck by foreign objects or thrown from the

machine.

• Never allow children to operate equipment.

• To prevent possible electrical shock, or damage to the instrument, do not connect to any power

source greater than twelve (12) volts DC.

• Do not grease or oil implement while it is in operation.

• Probe edges are sharp. Be careful when working in this area.

• Disconnect battery ground cable (-) before servicing or adjusting electrical systems or before

welding on implement.

• Remove buildup of mud, oil or debris.

• Be very careful when mapping stubble fields with a gasoline engine vehicle. Be prepared if a fire

starts.

• Keep a first aid kit and fire extinguisher handy.

1-2

Page 4

OM17-pH Detector

Hand

lever

Foot

lever

Wash

tank

External pH

controller

pH electrode

holder

Probe

chamber

Brake

mechanism

Brake

lever

Figure1

Figure 2

SECTION 2

pH Detector Assembly and Set-up

OVERVIEW:

The pH Detector collects a geo-referenced pH reading each time the pH electrode is inserted into

the soil. Here’s how it works: 1) the operator pushes the probe chamber into the soil with his foot,

2) then pushes down on the hand lever, activating a door that moves soil and creates an opening

for the measurement, 3) continues to push down on the hand lever to insert the pH electrode

holder, 4) the pH electrode measures the soil at the bottom of the opening, and when complete, 5)

the operator raises the probe handle, the electronics record the data and wash the electrode.

2-1

Page 5

OM17-pH Detector

Tools required for Assembly and Field Operation adjustments

-3/16” allen wrench

-7/16”, 1/2”, 3/8”, 9/16”, 3/4” wrenches and/or sockets

-pliers

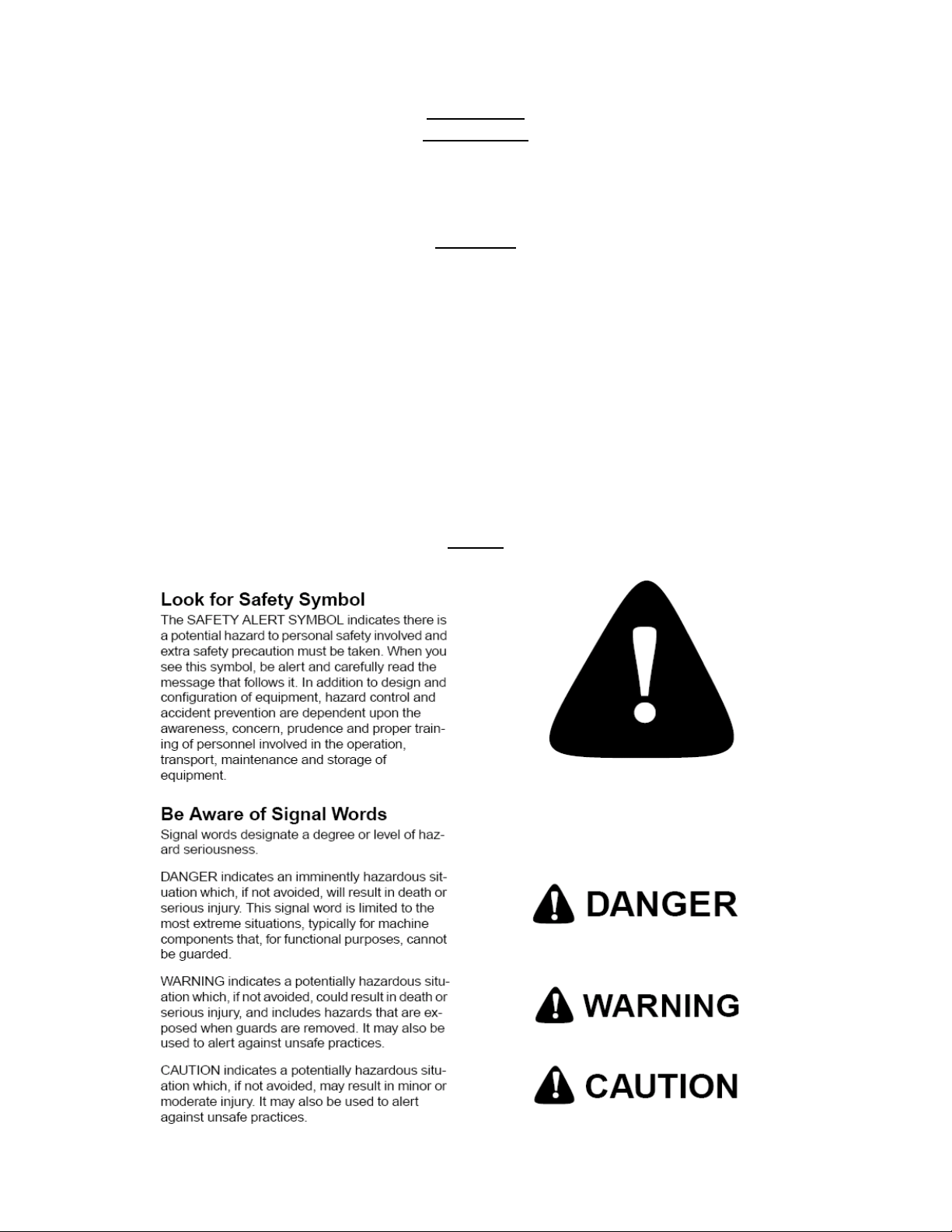

Handle installation: If probe handle was removed for shipping, reinstall by attaching pivot bolt, and

installing pins and cotter hairpins at top and bottom of rod actuator (Figure 3). Install brake lever

using 3/16” allen wrench, and zip-tie cable to handle (Figure 4).

Figure 3a and 3b

Figure 4

2-2

Page 6

OM17-pH Detector

tighten bolts after

unit has been

positioned and

stabilizer arms

attached

ATV hitch

Attaching pH Detector to ATV

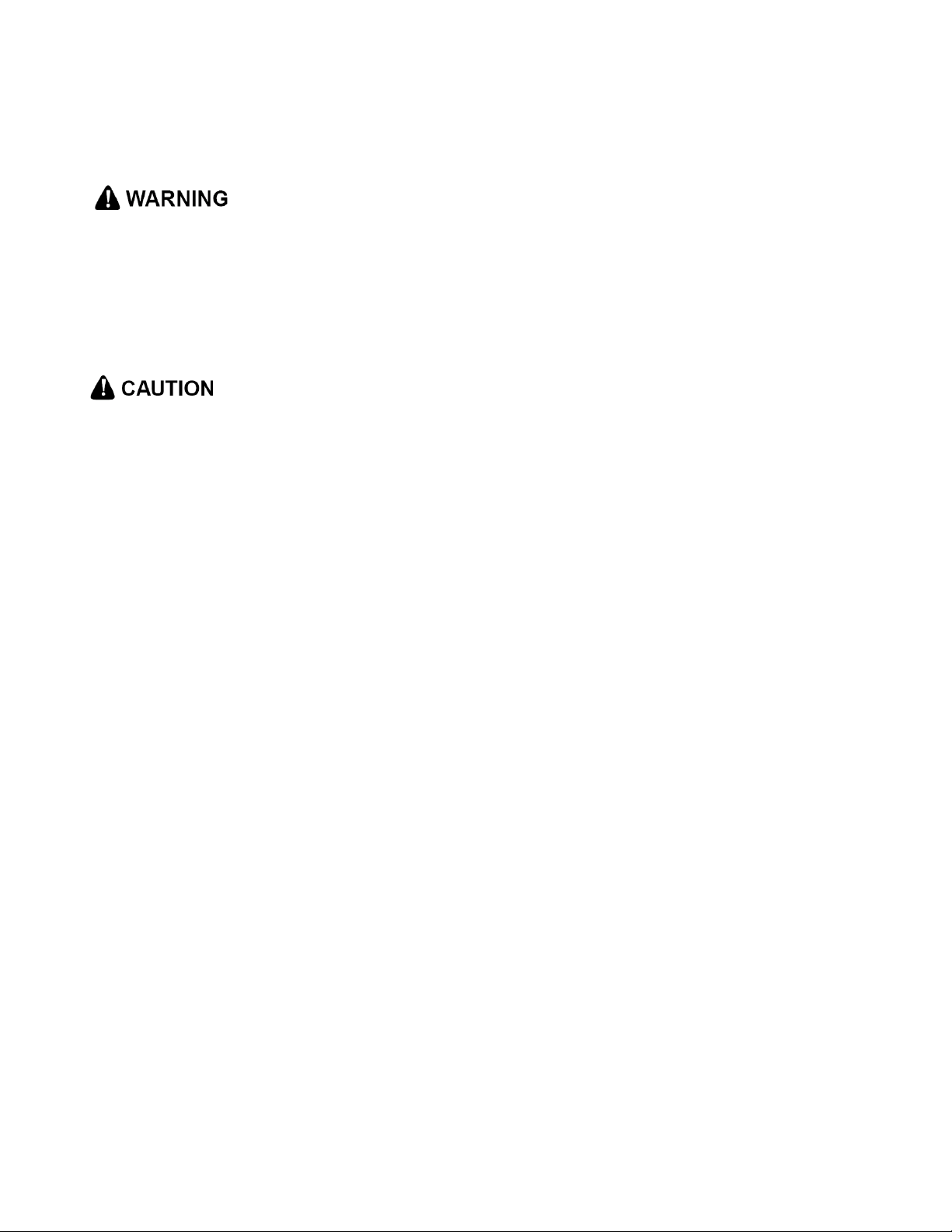

Mount tank to rear rack of ATV using nylon straps or zip ties through holes in tank base(Figure 4).

Figure 5

Slide receiver hitch tubing inside lower main frame tube of pH Detector. If your ATV is equipped

with large receiver hitch, slide receiver hitch tubing directly into ATV receiver hitch and pin (Figure

5). If your ATV has a hole, or small receiver hitch, it will be necessary to use end of hitch tubing

with threaded holes. Attach L-bracket to these holes and bolt to ATV hitch hole (Figure 7).

Figure 6 Figure 7

Position pH Detector as close to rear of ATV as possible but don’t restrict probe movement. Attach

stabilizers to rear rack (Figure 8). These brackets can be bent to fit various racks. Once pH

Detector assembly is in position, tighten all bolts including hitch bracket bolts (Figures 5 and 6).

2-3

Page 7

Figure 8a and 8b

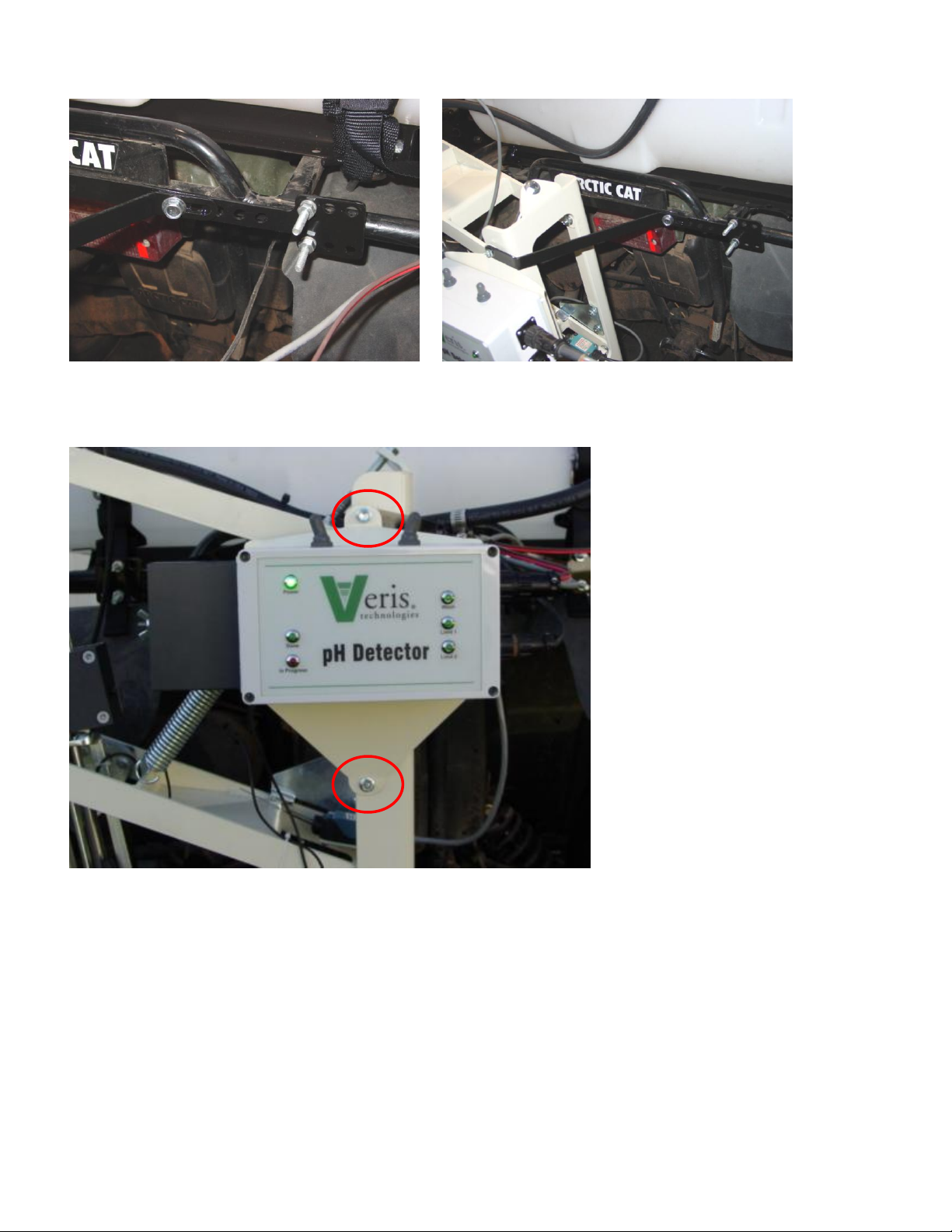

Bolt pH controller to unit (Figure 9).

OM17-pH Detector

Figure 9

2-4

Page 8

Electronics Overview and Set-up

Sensor Data-Logger

Shipping/storage

case

Mounting bracket

Serial cable

Power cord

(cig. lighter end)

USB SD card reader

SD memory card

(shipped in DataLogger card slot)

The Veris Sensor Data-Logger kit includes the items shown in Figure 10.

OM17-pH Detector

Figure 10

Use protective shipping/storage case to protect electronics components whenever electronics are

shipped. Keep all diagnostics and operations manual with system when mapping.

The following electronic-related items are mounted on the pH Detector:

- pH controller

- 12 V power cable (from pH controller to battery)

- power distribution cable (from pH controller to pump and limit switch cables

- limit switches (2)

- wash pump

2-5

Page 9

OM17-pH Detector

Power:

When lit, this red

LED indicates

Sensor DataLogger

is powered up.

On/Off:

Turns power to

Sensor DataLogger

on and off.

Memory Card slot:

SD memory storage

card must be

installed when

booting up, and at all

times data is being

collected.

pH:

Serial cable from

pH Controller

attaches here.

Reset

button:

Can be used

to reboot

DataLogger

Power port:

The Sensor Data-Logger is

shipped with an accessory

power cord. If an alternative

connection is desired, make

sure that the unit is properly

connected to a power

connection that is not

controlled by the ignition

switch. If connecting directly to

the battery, we suggest a 3-

amp in-line fuse is installed

between the battery and the

instrument.

Alarm Vol:

Used to adjust

volume of auditory

alarm

GPS input:

Connect GPS cable here. It

is designed to accept GPS

input in NMEA 0183 format

via an RS232 connector.

(GPS must send GGA and

either VTG or RMC strings at

a 1hz rate, at 4800 baud, 8

data bits, 1 stop bit, no

parity.)

Data Status:

When lit, this green

LED indicates data

is being recorded to

memory card. If not

lit, EC values are

negative or GPS

signal not received.

Fuse:

This allows the fuse to be

replaced, with a 500mA

Fastblow fuse, if blown.

Figure 11 DataLogger (rear)

Figure 12 Data-Logger (front)

2-6

Page 10

OM17-pH Detector

Important – Do not allow moisture to enter the Sensor Data-Logger, and do not pass strong

magnets near the unit.

Mount instrument in a location that is as free as possible from vibration and electrical interference.

Use adjustable mounting brackets to position electronics for optimal visibility.

Figure 13

Attach 12 volt leads to battery, making sure not to reverse polarity. Route wires under tank and

seat but do not allow them to be pinched. Attach main power amp and power distribution cables

connector to pH controller.

Figure 14

Attach the serial communication cable from external pH controller to the pH port on back of

DataLogger.

2-7

Page 11

OM17-pH Detector

Power switch

Manual

wash switch

Power LED

Wash LED

Done LED

(measurement

complete)

In Progress LED

(measurement

underway)

Lower limit

switch (#1)

LED

Upper limit

switch (#2)

LED

limit switches:

upper (#2)

lower (#1)

SECTION 3

Field Operations

Testing functions:

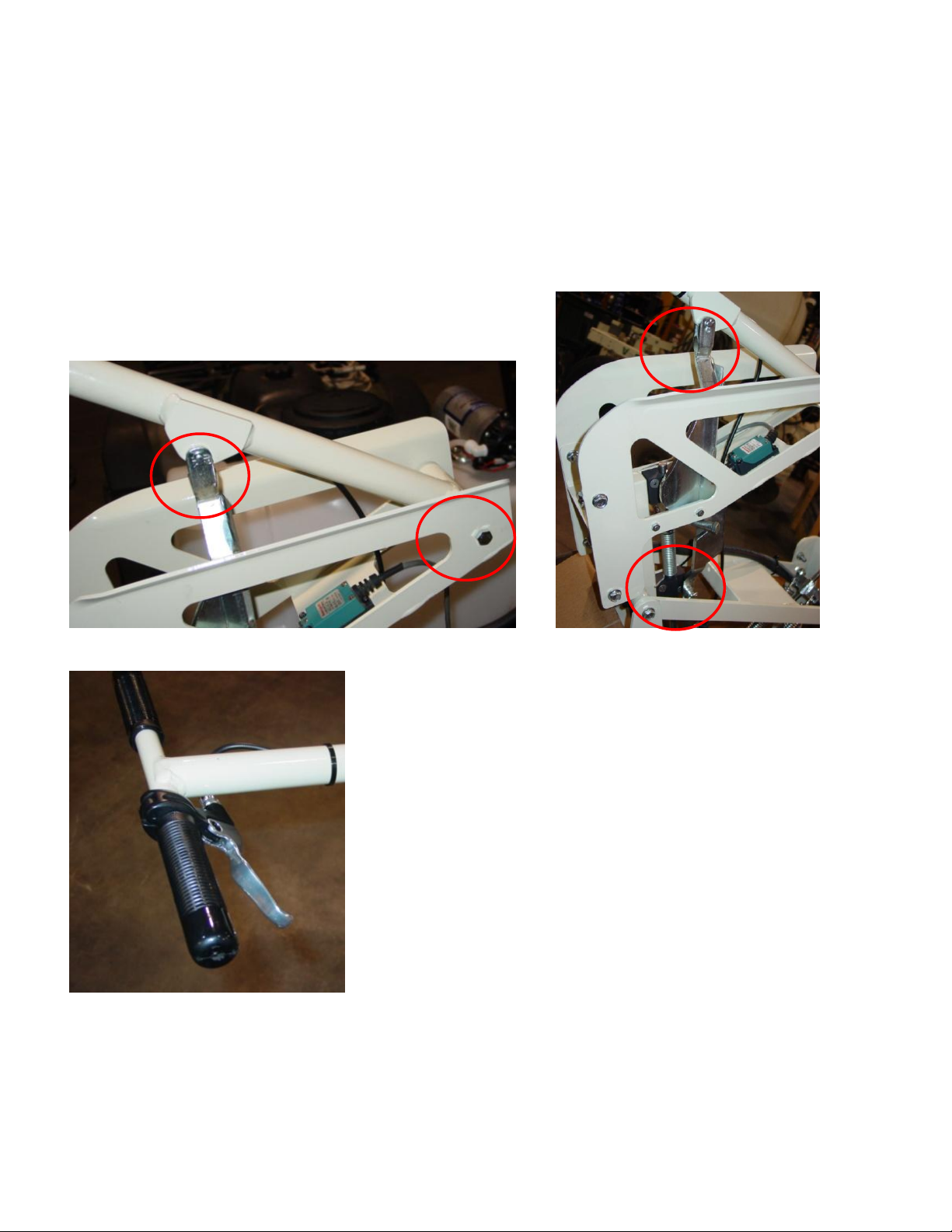

Turn external controller power switch on, and check operation using status LED’s. Power light

should light, wash LED should light when wash pump switch is activated, and limit switch LED’s

should light when they are deployed. (In order to active the lower switch (#1), probe must be in

soil.)

Figure 2a and 2b

Figure 1

3-1

Page 12

OM17-pH Detector

set screws

Quick

coupler

-Flush and fill tanks with tap water; clean any foreign matter out of tank using clean-out cap. Make

sure inlet is in sump (Figure 3), and strainer is attached to end of line (Figure 4).

Figure 3 Figure 4

Pump priming: In order to prime the pumps, loosen quick coupler and operate pump until water

flows (Figure 6).

Wash adjustment: This was set at the factory but may have slipped during shipping. Wash

brackets should be opposite each other, with jets as close as possible to electrode holder, and still

allow electrode holder movement. Jets should be 1/4” (6 mm) below electrodes. When wash jets

are properly aligned, overspray is minimized and water bubbles out top of empty electrode holder

as shown in Figure 5. To adjust wash jets, use 3/16” allen wrench to loosen set screws holding

wash jet blocks and rods (Figure 6).

Figure 5 Figure 6

3-2

Page 13

OM17-pH Detector

Connector

cover

Insert pH electrode into electrode holder. Finger-tighten plastic screw as tightly as possible by

hand. If a wrench is used, be careful not to over-tighten as damage to the electrode may occur

.

Figure 7

Route electrode cables away from sampling mechanisms to prevent damage. Lower probe to

maximum depth and tie strap cable as shown in Figure 8. Do not tighten zip ties until probe has

been moved full stroke to make sure wire slack is in correct area. Extra cable length should be

outside of sampling mechanism, below pH controller (Figure 9).

Figure 8 Figure 9

Install cover on external controller to keep moisture out of BNC and serial connector. When

installing cover, route electrode wire under box; center box on white pad, and tighten wingnut

finger tight. Keep cover installed even when electrode is removed.

3-3

Page 14

OM17-pH Detector

Sensor DataLogger display

Here are the display readings that you will see when operating the Sensor DataLogger:

Starting up…

Figure 10

The unit is ready to operate. The DataLogger is informing you of the firmware version its

programmable interface chip (PIC) contains.

Press any of the four keys, and the next screen will appear:

Figure 11

Press 2 and enter Setup menu. (Press 4 to Exit this window).

Figure 12

Press 1 to calibrate ion-selective (ISE) pH electrode.

Calibrating pH electrodes

Enter menu option 1) Calibration.

Figure 13

The instrument will prompt for the electrode to be inserted into pH buffer 4 solution; Slide cup with

pH 4 buffer solution onto electrode holder, or remove electrode from holder for calibration. Press 1

to continue with calibration or 2 to exit. Tips: Don’t overfill solution. Cup only needs enough

solution to immerse electrode tip and face. Don’t reuse solutions.

3-4

Page 15

OM17-pH Detector

Figure 14

Figure 15

The instrument will read the electrodes for 10 seconds, displaying the output (as it counts

seconds):

Figure 16

After 10 seconds, the instrument will display the final pH reading and offer the options to 1) Accept

pH 4 buffer readings; 2) Redo pH 4 buffer readings; or 3) Exit pH electrode calibration. If the

readings are satisfactory, press 1; if the readings are suspect, press 2 to return to re-do pH 4.

Figure 17

After accepting the pH 4 buffer readings, the Instrument will prompt for the electrode to be inserted

into pH 7 buffer solution. Remove the pH 4 buffer solution cup from the electrode holder. Rinse

the electrodes, electrode holder, and solution cup using the manual wash for at least 10 seconds.

Slide the pH buffer 7 solution cup onto the electrode holder.

On the DataLogger, press 1 to continue with calibration. The DataLogger will read the electrodes

for 10 seconds, displaying the output. After 10 seconds, the instrument will display the final pH

reading and offer the options to 1) Accept pH 7 buffer readings; 2) Redo pH buffer 7 readings; or 3)

Exit pH electrode calibration. If the readings are satisfactory, log pH 7 reading and press 1; if the

readings are suspect, press 2 to return to pH 7 calibration step.

3-5

Page 16

OM17-pH Detector

After accepting the pH 7 buffer readings, the electronics firmware will determine if the electrode’s

response is sufficient to provide suitable readings. A score is displayed for the electrode; the

acceptable score range is between 75 and 102. If electrode is within this range, the instrument will

display the following screen:

Figure 18

If an ‘X’ is displayed beside the electrode’s score, this indicates that the electrode did not perform

well enough for continued reliable use. No calibration settings are changed if calibration is

unsuccessful. The electrode should be removed and either cleaned or replaced and the calibration

procedure repeated.

Figure 19

After calibration is complete, you will have the option to use the calibrated readings or reset to the

ideal settings. Tip: many operators use the ideal settings rather than calibration settings. One

reason is this enables readings from one day to be compared to another. It is still important to

perform the calibration step at least daily, even if ideal settings are used. The calibration process

is important to test electrode quality.

If electrode doesn’t calibrate, check for film that develops on antimony tip after long storage

periods; sand lightly with 80 grit sandpaper or emery cloth.

• Antimony is harmful if ingested into your skin, mouth, or lungs

-Do not touch antimony electrode tip

-Do not ingest antimony material when sanding tip

3-6

Page 17

OM17-pH Detector

pH Controller Set-up

After calibration, you may wish to change the pH Controller default parameters. Press 2 and enter

Setup menu. (Press 4 to Exit this window).

Figure 120

Figure 21

Maximum log time is the longest time in seconds the pH controller will wait for the pH readings to

settle. The controller usually cycles before this maximum time is reached. The minimum setting

for the maximum log time is 20 seconds. (Tip: use 20 seconds unless there is a special reason to

allow a longer wait time) Press 1 or 2 to adjust the sample time, press 3 to continue to the next

screen.

pH Data Recording

Figure 22

From the screen above, press the #1 key and this screen appears.

Figure 23

Select #2 pH to collect pH data. #4 returns you to the initial start-up screen. Pressing #2 brings up

the next screen:

3-7

Page 18

OM17-pH Detector

Figure 24

The DataLogger is displaying the map file number it is creating, in case you want to record it along

with any other information about the field. Press any key to begin new map file. After starting the

file, pressing the #4 key will stop the file. If DataLogger freezes at the screen shown in Figure 23 or

Figure 24, check formatting of SD card—must be FAT format.

USING A VERIS SD CARD IN OTHER DEVICES CAN CAUSE FILE CORRUPTION.

If memory card was not inserted during boot-up, the following screen will appear:

Figure 25

Install card and re-start DataLogger. NEVER REMOVE CARD WHILE LOGGING DATA.

Figure 26

The display is showing the pH value from the pH electrode, the status of the sampling mechanism

(raised/neutral), and whether you have GPS or DGPS (differentially corrected) signal. At any time

during the mapping process, you can press the 4 key to stop the file. If you create more than one

file from the same field, you can bring the files into a spreadsheet program and combine them prior

to mapping.

3-8

Page 19

OM17-pH Detector

Probe Operations

Release the brake and step on the foot lever to insert the probe chamber into the soil (Figure 27).

This movement will activate the upper limit switch to initiate the electronic process, and a brief

wash burst will occur.

Figure 27a and 27b

Once the probe chamber is in the soil, insert the electrode holder by continuing to lower the

handle. In tight soil, it may be necessary to assist door opening with hand lever (Figure 28). The

software requires full electrode holder insertion indicated by the lower proximity switch in order to

begin logging. Release brake lever when electrode holder is completely inserted into probe

chamber.

Figure 28a and 28b

After the probe has been inserted and while the electrode is being held against the soil, the status

text will change to the following:

3-9

Page 20

OM17-pH Detector

Figure 29

Allow the sampler to remain in the soil while the readings settle, as indicated by the In Progress

red LED (Figure 30). When the Done green LED lights, the measurement is complete (Figure 31).

The pH readings on the display show what the electrode is reading at every second. The minimum

recording time is 7 seconds; the maximum time is determined in the pH settings menu. The pH

value that is recorded is the final values at the end of the logging duration. The final pH value is

logged along with the DGPS position where the sample was collected. When the Ready green

LED lights, release the brake and raise the probe chamber out of the soil and the electrode holder

out of the probe chamber. A spring-loaded pin will hold the probe in the top position for automated

electrode cleaning. DO NOT MOVE VEHICLE WHEN PROBE IS IN SOIL.

Figure 30 Figure 31

If the electrodes take longer than 10 seconds to settle, a warning will appear by the readings that

indicates the number of seconds the reading has required (Figure 32). When the maximum log

time is reached, a T will appear indicating that the measurement has ‘timed out’, and the unit

initiates a new sample cycle (refer to pH Controller settings for adjusting the log time).

Figure 32

This time warning is to let the operator know that a measurement cycle is requiring excessive time.

While an occasional cycle may exhibit this warning. see the troubleshooting section if this occurs

frequently.

3-10

Page 21

OM17-pH Detector

At any time during the mapping process, you can press the #4 key to stop the file. If you create

more than one file from the same field, you can bring the files into a spreadsheet program or GIS

and combine for whole field map display.

After #4 key is pressed during Data Acquisition, the following screen will be displayed: (if data

was collected during Data Acquisition)

Figure 33

DATA IS ONLY STORED ON THE SD CARD. NO INTERNAL FILES ARE CREATED.

If no data was logged during Data Acquisition, the following screen will be displayed:

Figure 34

Data Files

The DataLogger records four files for each data collection:

1. VPHFxxx.dat: your data file

2. VPHLxxx.dat: all logged soil data in millivolts

3. VPHWxxx.dat: all logged wash data in millivolts

4. Verisxxx.INF: calibration information for this file

File format for VPHF files is as follows:

Col A:long. Col B: lat. Col. C pH Col. D elevation Col. E: sample #

Figure 35

3-11

Page 22

OM17-pH Detector

Data quality tips

As you collect pH data, monitor the performance of the system by observing the following:

-During ‘Cycling’ phase or during manual washing, does pH electrode readings get close to the

wash water pH? If not, electrode may not be cleaning properly.

-During ‘Recording’ phase, does electrode reading move to expected soil pH level?

-Is there any residue in the cavity prepared by the probe chamber?

-Is depth of probe insertion consistent?

3-12

Page 23

Leave cover on whenever unit is

in operation or stored outdoors.

Do not allow moisture into BNC

or serial connections.

electrode body

reference junctions

electrode face

antimony measurement tip

pH Electrodes

OM17-pH Detector

SECTION 4

Maintenance and Service

Figure 1

• Antimony is harmful if ingested into your skin, mouth, or lungs

-Do not touch antimony electrode tip

-Do not ingest antimony material when sanding tip

-Always use proper soaker solution: Veris part #23395

-Keep moist; put in soaker solution if mapping (washing) is interrupted for one hour of more

-If soaker solutions is unavailable, use pH buffer 4; never soak in distilled or de-ionized water

-remove from holder and place in individual soaker bottles in freezing temperatures and when unit

will be idle for long periods

-keep cover over BNC ports on external controller whether electrodes are attached or unattached

-if film develops on antimony tip, sand lightly with 80 grit sandpaper or emery cloth.

Figure 2

4-1

Page 24

OM17-pH Detector

Clean filter at end of suction line

weekly.

Open up check diaphragms and

allow lines to clear.

Wash System

If wash water develops algae, flush and fill tanks with tap water; clean any algae or other foreign

matter out of tank. Clean filter at least once per week of operation.

Figure 3

Winterizing:

When temperatures are dipping below freezing, prevent freeze damage to the wash system as

follows: drain tank, open up check diaphragms and drain, and run pumps until empty. If unit is to

be left outside for long periods of time over winter, it is advisable to add RV antifreeze to tank and

run pumps for a couple of minutes to fill all lines with anti-freeze. Purge system of anti-freeze

before collecting any pH data.

Figure 4

4-2

Page 25

OM17-pH Detector

Door didn’t

close when

electrode

holder was

raised

Electrode

holder

hitting

door

In up

position,

lever

should be

in notch.

Adjustments/troubleshooting:

Electrode holder won’t go into soil:

1) If door is not completely open when electrode holder tries to enter, electrode breakage may

result (Figure 5). Raise electrode holder and see if door closes completely. If rock or other

obstruction is present, clear it and see if door closes properly.

Figure 5a Figure 5b

2) Verify that door hand lever hasn’t slipped. If door is closed but lever is not in notch, loosen

lever bolt and set screws, reposition lever to notch, and retighten bolt and set screws.

(Figure 6).

Figure 6a Figure 6b

4-3

Page 26

OM17-pH Detector

Hold top of rod

with adjustable

wrench and

tighten jam nut

with 1/2” wrench

limit switches:

upper (#2)

lower (#1)

3) Verify that bottom jam nut on pivot rod hasn’t slipped. If hand lever does not move door,

retightening pivot rod jam nut is required. Retighten by holding top of rod with adjustable

wrench and tightening jam nut on lower end of pivot rod (Figure 7).

Figure 7a Figure 7b

Limit switches aren’t working properly:

-activate manually to see if LED’s light; if LED’s do not light, check power and connections

-if LED’s light, but are reversed from Figure 8, disconnect weather-pack connectors and re-connect

to other switch.

Figure 8 Figure 8b

-If limit switch LED’s show switch is working, check adjustments: In raised position, lower switch

needs to be in activated position, as shown in Figure 9. To adjust, loosen bolt holding switch and

pivot to desire position.

4-4

Page 27

OM17-pH Detector

Figure 9

Upper switch needs to be in activated position only when electrode holder is fully inserted into the

probe chamber (Figure 10). To adjust activation bar, loosen bolt and slide to desired position

Figure10

4-5

Page 28

OM17-pH Detector

Tighten

adjustment bolt

to increase

spring tension

Excessive movement of assembly while driving: tighten up spring tension on main springs (Figure

11).

Figure 11

Probe doesn’t stay locked in up position for washing: tighten spring plunger to increase pressure

(Figure 12.)

Figure 12

4-6

Page 29

Lubrication

Weekly:

Apply dry powdered graphite to slides in wear blocks shown in Figure14.

OM17-pH Detector

Figure 14a Figure 14b

4-7

Loading...

Loading...