Page 1

Field Reference Guide—OpticMapper

Keep with OpticMapper and refer to daily.

(Refer to Operating Instruction Manual for complete instructions)

STEP I. PRIOR TO MAPPING: PERFORM ROUTINE

DAILY MAINTENANCE

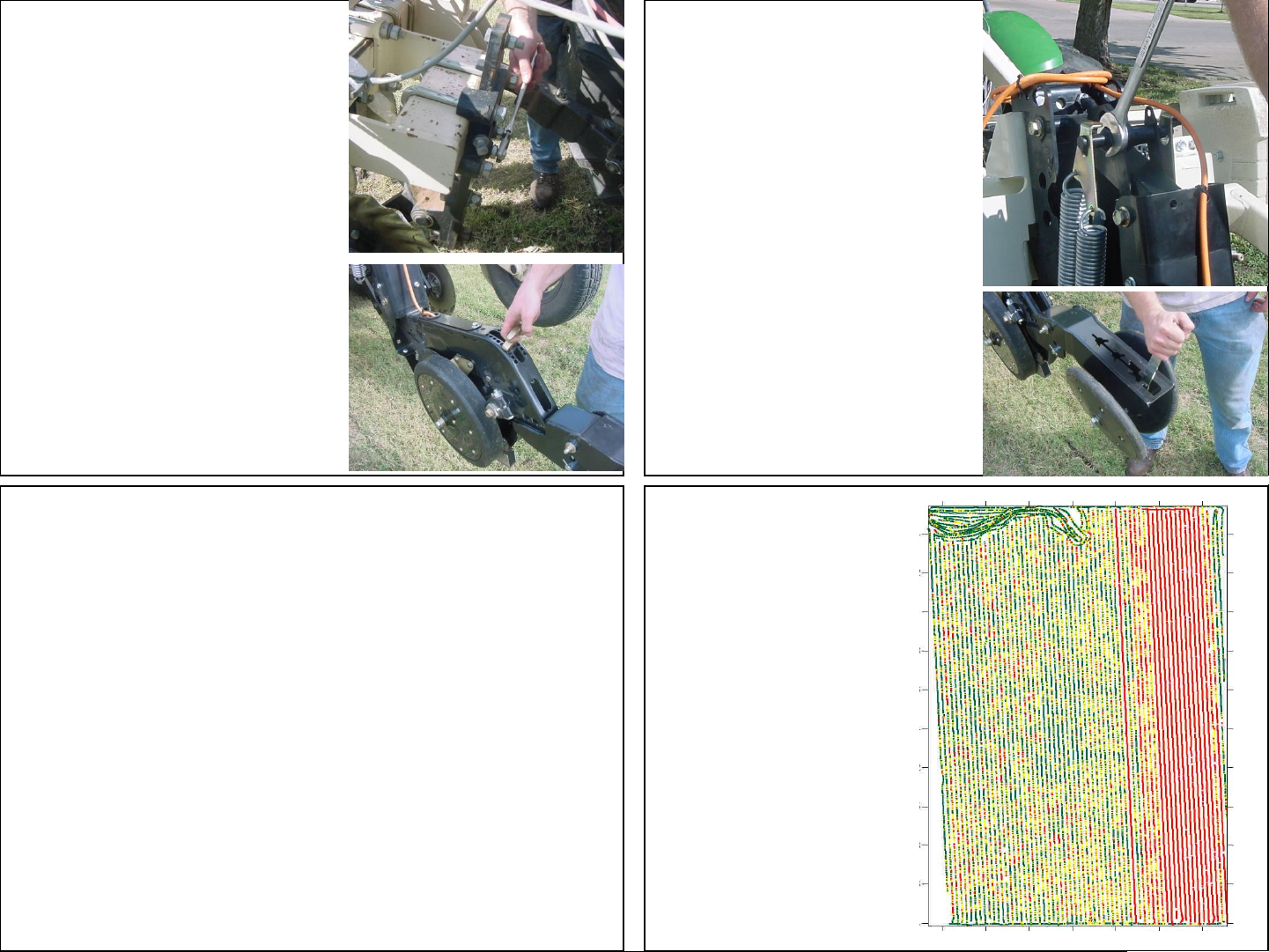

1. Inspect unit for loose

or missing bolts, other

obvious problems

3. Check wear plate and window for excessive wear or

damage

2. Do side depth wheels and

disks rotate freely? If not, clear

mud or other obstructions.

4. Install test load on OpticMapper external controller rear

panel—port marked Optical Power port. Turn power on and go

to data acquisition mode on DataLogger or SoilViewer.

OM values should be:

Sensor 1: 833

Sensor 2: 289

Readings are acceptable if

within 10 numbers from these.

5. Clean sapphire window and install test reference under

window. Click OM System check on Soilveiwer, or press 2

on Datalogger for OM System Check. Follow onscreen

instructions. Reference values bellow.

Sensor 1: Difference of 200 or > between dark and light reference.

Sensor 2: Difference of 90 or > between dark and light reference.

Field operations: (note: in-field adjustments may cause

shifts in sensor data)

6. Lower gauge wheels so EC

coulters and optical row unit

penetrate to desired depth.

7. Adjust top-link so implement

operates level in field position;

in rocky conditions shorten

top-link and tip implement

slightly forward to reduce

pressure on window; if soil

adheres to window, lengthen

top-link to increase pressure

on window.

Page 2

Field operations:

8. Adjust front coulter so it cuts

slightly deeper than mapping

depth

9. Adjust side depth wheels on

optical row unit to allow

deeper or shallower

mapping. Move T-handle

forward for deeper depth.

Depth wheels should be

snug, but freely moving,

against the disks. See

manual for adjustments.

When mapping:

• check depth of sensor; add weights or adjust downpressure on row unit if needed

Field operations:

10. Adjust spring pressure on

row unit as needed. With

implement lifted to reduce

pressure on springs, move

handle forward to reduce

spring pressure and back to

increase. Additional weight

may be required in hard soils.

Reduce pressure in rocky

conditions to prevent damage

to window.

11. Adjust closing wheel pressure

if needed to close slot. Pulling

handle back increases

pressure.

• view OM data when unit is raised; are values within

10% of original readings when starting?

• always raise unit when turning

• make sure window is staying clean and intact

• make sure row unit side depth wheels and disks are

rotating freely, and are clear of excess mud and crop

residue

• check furrow closing; adjust pressure as needed

• always start a new file if adjustments are made or

field conditions change

Example of varying field

conditions, date

change and/or

adjustment changes.

To fix this problem

always start a new file in

any of the above

situations.

Loading...

Loading...