Page 1

Operating Instructions

MSP3

Table of Contents

Section 1

1-1 Warranty

1-2 Safety

1-4 FCC Note

1-5 Declaration of Conformity

1-6 Statement of Use

1-7 Lift Procedure

Section 2

2-1 Electronics Overview and Set-up

2-5 Software Setup: SoilViewer

Section 3 Implement Overview and Set-up

Section 4

4-1 Field Operations: DataLogger, OM and pH system checks

4-10 Field Operations: SoilViewer, OM and pH system checks

4-18 Field Operations: EC and OpticMapper

4-26 Field Operations: pH Manager

4-33 Mapping with Datalogger

4-37 Mapping with SoilViewer

4-43 OpticMapper Data Flow

Section 5

5-1 Maintenance and Service: EC

5-3 Maintenance and Service: OpticMapper

5-6 Maintenance and Service: pH

Section 6 Service and Troubleshooting Procedures

6-2 #1 OM Signal Testing

6-3 #2 EC Signal testing

6-4 #3 Testing electrical continuity

6-6 #4 Diagnosing and correcting EC signal problems

6-12 #5 Spring plunger testing and replacement

6-14 #6 Diagnosing GPS-related problems

6-18 #7 Firmware updates and SD card formatting

6-21 #8 Bearing replacement

6-22 #9 Soilviewer troubleshooting

6-23 #10 Optical Wear plate and Side Wear plate replacement

6-24 #11 pH Toubleshooting

6-29 #12 Checking External Controller Power

6-32 #13 Sampler Cylinder Hydraulics

6-35 #14 pH Communication Problems

6-40 #15 Prox Sensor

Pub. #OM17-MSP3

Page 2

Pub. #OM17-MSP3

MSP3

SoilViewer Version 2.46

Sensor DataLogger Version 1.00

Section 1

Warranty

Veris Technologies warrants this product to be free of defects in materials and workmanship for a

period of one (1) year from the date of delivery to the purchaser. Veris Technologies will repair or

replace any product returned to Salina, Kansas, which appears upon inspection to be defective in

materials or workmanship. Veris Technologies shall have no obligation under this warranty for the

cost of labor, down-time, transportation charges, or for the repair or replacement of any product

that has been misused, carelessly handled, modified, or altered.

ALL OTHER WARRANTIES OF ANY KIND, WHETHER EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE AND ALL CLAIMS FOR CONSEQUENTIAL DAMAGES, ARE

SPECIFICALLY DISCLAIMED AND EXCLUDED.

Safety

1-1

Page 3

Pub. #OM17-MSP3

Important! Read the following SAFETY PROCEDURES before operating the Veris system:

• Read and understand all instructions on safety decals

• Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard

by relieving pressure before disconnecting hydraulic lines. Use a piece of paper or card-board,

NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and highpressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result.

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the Veris

implement.

• Install all transport locks before transporting or working underneath.

• Detach and store implements in an area where children normally do not play. Secure implement

by using blocks and supports.

• Read Operations Manual before operating machine

• Review safety instructions with operators before operating machine and at least annually

• Never stand on or use tire as a step

• Do not tow the implement on public roads without the road-kit light package, or without the proper

safety equipment and licensing as required by your State Department of Transportation. Always

use safety chain.

• Riders obstruct the operator’s view. They could be struck by foreign objects or thrown from the

machine.

• Never allow children to operate equipment.

• To prevent possible electrical shock, or damage to the instrument, do not connect to any power

source greater than twelve (12) volts DC.

• Do not grease or oil implement while it is in operation.

• Disk edges are sharp. Be careful when working in this area.

• Disconnect battery ground cable (-) before servicing or adjusting electrical systems or before

welding on implement.

• Remove buildup of mud, oil or debris.

• Be very careful when mapping stubble fields with a gasoline engine vehicle. Be prepared if a fire

starts.

• Keep a first aid kit and fire extinguisher handy.

1-2

Page 4

Excess speed, especially when turning could cause overturning.

Never pull units faster than 15 km/hr.

Use caution when working on implement. Coulter disks are sharp and may

causes cuts.

Don’t allow anyone to climb or ride on implement

The vehicle that pulls the Veris unit thru the field will get hot! There is a chance that

this heat can cause field fires in stubble fields.

Don’t lower unit while any part of body is underneath

Pub. #OM17-MSP3

1-3

Page 5

Pub. #OM17-MSP3

Keep safety chain installed

Install jack before unhitching; do not drop unit on foot

FCC NOTE

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of the equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at this own expense.

1-4

Page 6

Pub. #OM17-MSP3

EUROPEAN DECLARATION OF CONFORMITY

Veris Technologies, Inc., located at 601 N. Broadway in Salina Kansas, certifies that the product:

Veris MSP3

is in conformity with the following directive and standards:

Machinery Directive 2006/42/EC--1st Edition—December 2009

Electromagnetic Compatibility 2004/108/EC —December 2004

EN55022 – Measuring Radiated Emissions

The Technical File is maintained at:

Veris Technologies, Inc.

601 N. Broadway

Salina KS 67401

Date of issue: May 1, 2012

Place of issue: Salina KS USA

1-5

Page 7

Pub. #OM17-MSP3

Statement of Use

Intended use of the Veris MSP3 model

The Veris MSP3 Soil EC, Organic Matter, and pH Mapping System collects geo-referenced soil

electrical conductivity (EC), soil reflectance, and soil pH measurements as it is pulled across a field

by a tractor. An electronic device called the Soil EC Surveyor, powered by vehicle’s 12V DC

electrical system, generates a small electrical current, which is transferred into the soil through a

pair of rolling electrode coulter disks. A second pair of disks measures the drop in voltage which is

proportional to the electrical conductivity of soil medium at a given location. Signal response is due

primarily to soil texture/grain size and soil salinity. Clay soils and soils with high salinity levels are

highly conductive, while coarser soils such as sand do not conduct well. Another electronic device

called the OpticMapper controller, powered by vehicle’s 12V DC electrical system, sends power to

an optical sensor which has two wavelengths of LEDs and measures the amount of light reflected

off the soil surface with a photodiode. The optical sensor is mounted inside a standard row planter,

with two discs to cut a furrow in the soil and two depth gauge wheels to keep the sensor at

constant depth. Signal response is due to soil color, darker soils are generally higher in Organic

Matter; while lighter soils are lower in Organic Matter. A final electronic device called the pH

controller, powered by vehicle’s 12V DC electrical and hydraulic system, measures soil pH using

two electrodes. The pH controller cycles the pH sampling shoe into the soil, where a soil core is

collected and brought up and pressed against the electrodes for a measurement. Once a stable

reading is measured, the sampling shoe moves down to collect another soil segment, and the

electrodes are washed off. This process is repeated every 20-30 seconds, as long as the operator

keeps the system engaged, and ground speed is received. The sampling shoe is controlled by

hydraulic solenoids, while the wash jets are powered by two 150 psi pumps. The system records

the data either on its own datalogger, or on a data recording device such as a laptop computer.

Ultimately, the data are displayed in a map format, and variable applications of crop production

materials, such as seed, fertilizer and other inputs are variably applied to the zones delineated on

the maps. The MSP3 system is designed for use in a farm field, and has no dynamic movement

unless vehicle is pulling it, or operator is manually activating switches, so guarding around soil

engaging components is not needed and would interfere with field operations. Unit should not be

operated when people are present in the field, as coulter disks are sharp and automated

movement could cause injury if contact occurs.

Misuse of the Veris MSP3 model

Misuses of the MSP3 model include operation with people in area, and pulling the system at an

excessive speed. In field position, this could result in poor data collection and possible tractor

overturning at extremely high speeds and sharp turns. In raised position, the chance of

overturning is increased, as the center of gravity is higher, so care must be taken to keep speeds

under 15 km/hr, and less when turning.

Abnormal use of the Veris MSP3 model

Abnormal use of the MSP3 model includes using it as a cart for carrying equipment, tools, or

people. Under no circumstances should anyone ride on the implement. Even though the

implement is similar in appearance to a tillage tool, such as a disk harrow, it was not designed for

that usage and should never be used for any purpose other than soil data collection.

1-6

Page 8

Pub. #OM17-MSP3

MSP3 Lifting Points

Below are the recommended lifting points for the unit. Using two straps you can safely lift the unit.

Make sure the straps used to lift are rated greater than 1200 lbs. Fork extensions maybe required

to lift. Always stay clear when lifting the unit.

Here are the proper lift points for side loading

1-7

Page 9

If lifting from front or back of the unit, use the points shown below.

Pub. #OM17-MSP3

1-8

Page 10

Section 2

USB Serial

Adapter

MSP3 EC

Test Box

pH

Simulator

Mounting

Bracket

OM

Reference

Block

OM test

load

MSP3 EC

test load

SoilViewer

Protective

Case

Three-way

power

adapter

DataLogger

SD card

reader

Power Cord

Figure 2

Electronics Overview and Set-up

The MSP3 electronics kit and optional DataLogger kit are shown below.

Pub. #OM17-MSP3

Figure 1a MSP3 electronics kit Figure 1b MSP3 DataLogger kit

Use protective shipping/storage case to protect electronics components whenever electronics are

shipped. Keep all diagnostics and operations manual with system when mapping.

Mount electronics in a location that is as free as possible from dust, vibration, and electrical

interference. Display should be visible to operator and shielded from direct sunlight. ‘

The supplied GPS(Figure 2) is configured to operate

with the MSP3 electronics.

The use of any other GPS requires the correct

settings. The GPS needs to output only two NEMA

strings(GGA and VTG OR RMC). The system will

not run with more than two strings. The strings

need to output at 4800 baud and 1Hz refresh rate.

2-1

Page 11

Pub. #OM17-MSP3

Data Status:

When lit, this green LED

indicates data is being

recorded to memory

card. If not lit, EC values

are negative or GPS

signal not received.

Power:

When lit, this red LED

indicates Sensor

DataLogger is

powered up.

On/Off:

Turns power to Sensor

DataLogger on and off.

Memory Card slot:

Formatted SD memory card

must be installed when

booting up, and at all times

data is being collected. See

Proc. #6 for formatting

instructions.

EC:

Serial cable from

EC/OM controller

attaches here.

OM/pH:

Serial cable from pH

controller attaches

here.

Reset button:

Can be used to

reboot

DataLogger

Alarm Vol:

Used to adjust volume

of auditory alarm

Fuse:

This allows the fuse to be

replaced, with a 500mA

Fastblow fuse, if blown.

Power port:

The Sensor DataLogger is shipped with an

accessory power cord. If an alternative

connection is desired, make sure that the

unit is properly connected to a power

connection that is not controlled by the

ignition switch. If connecting directly to the

battery, we suggest a 3-amp in-line fuse is

installed between the battery and the

instrument.

Figure 3 DataLogger (rear)

Figure 4 DataLogger (front)

Important – Do not allow moisture to enter the DataLogger, and do not pass strong magnets

near the unit.

2-2

Page 12

Pub. #OM17-MSP3

12V Power

Power cord shipped with the unit that

connects to the vehicle’s battery

On/Off

Turns power to

OpticMapper

Controller On/Off

3A Fuse

Power Indicator

Indicates when power

to the controller is on

Optic Power

Delivers power to

Optical sensor with

cable #46222

EC Signal

Connects to EC

wire harness with

cable #49457

OM Com/GPS Input

Serial communication to Datalogger or

PC and GPS input with cable #49494

The OpticMapper Controller is mounted on the implement, and can remain on the implement due

to weatherproofing.

Figure 5 OpticMapper Figure 6 OpticMapper/EC Controller

Figure 7 OpticMapper Controller (rear)

Figure 8 OpticMapper Controller (front)

2-3

Page 13

Pub. #OM17-MSP3

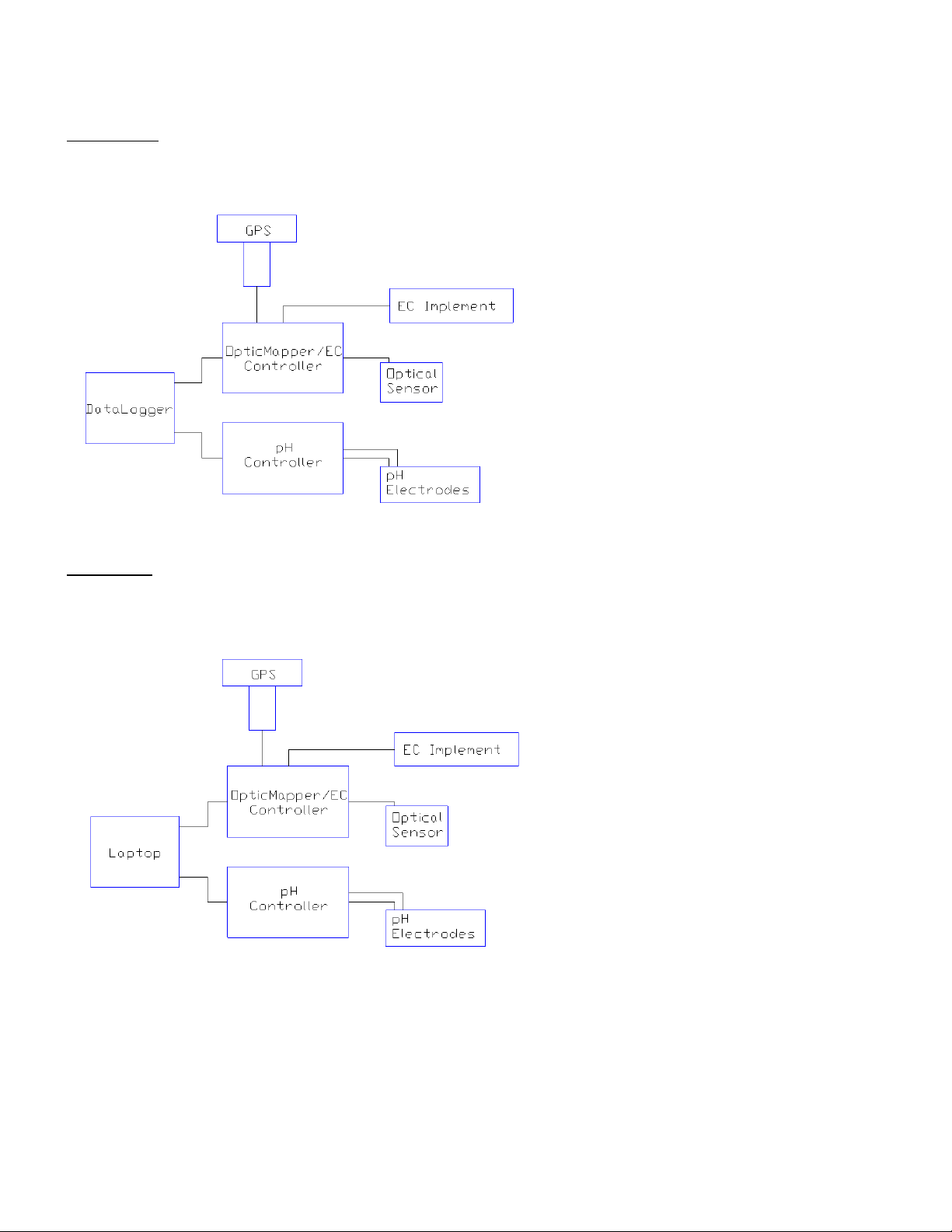

Electronic Configurations

Datalogger – Attach the OpticMapper/EC Controller communication cable to the EC port on the

Datalogger, then the communication cable from the pH Controller to the pH port. Connect EC

signal cable, GPS, and power cords to the OM/EC controller.

Figure 9

Soilveiwer – Connect both communication cables from OpticMapper/EC Controller and from the pH

Controller to Laptop using the supplied USB to Serial converters. Connect EC signal cable, GPS,

and power cords to the OM/EC controller.

Figure 10

2-4

Page 14

Figure 11

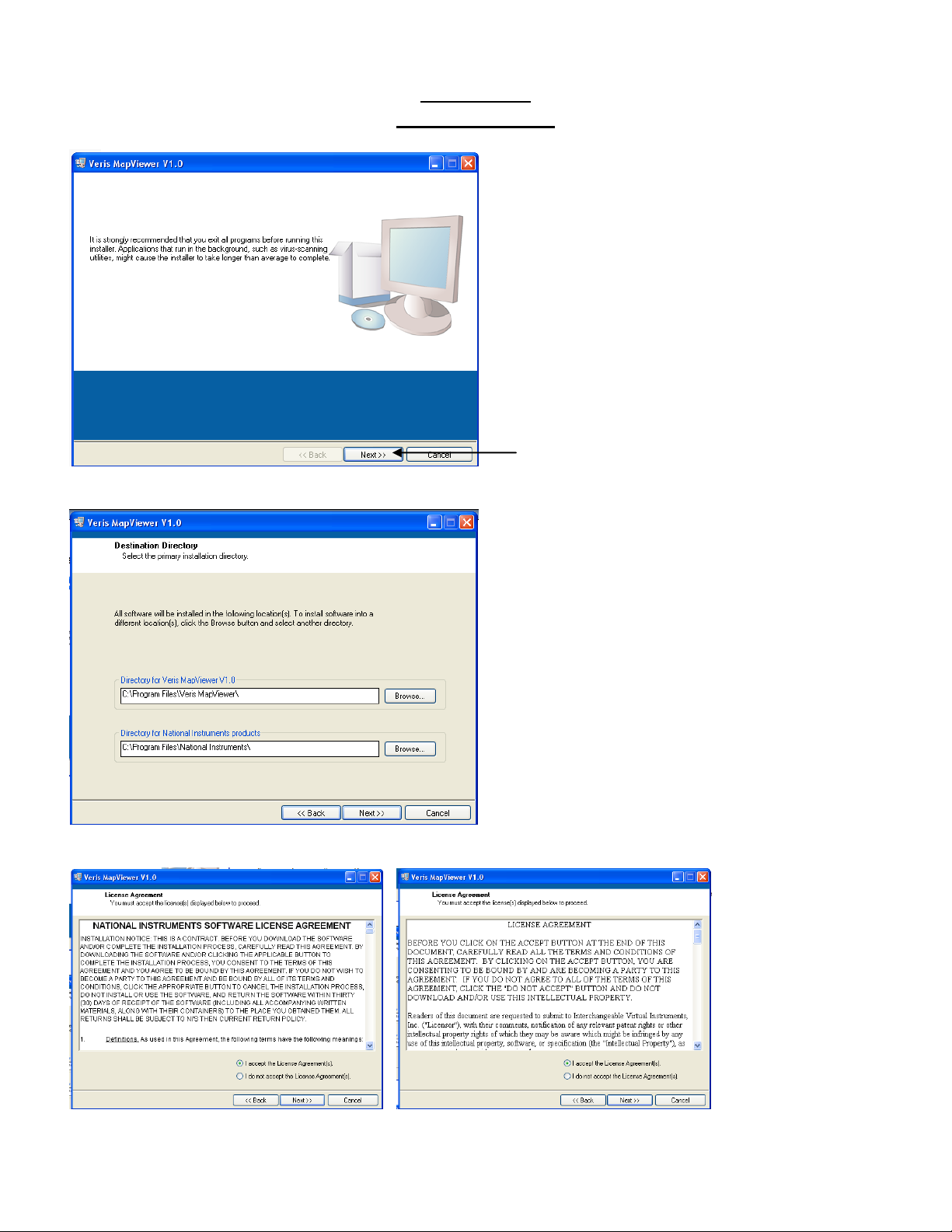

The Veris SoilViewer software will

automatically run the setup once the CD

is inserted into the computer. If not the

installation can be manually started by

double clicking on the setup.exe located

on the CD.

Once the CD has begun select the

installation directory and click Next

Click Next to continue through

installation

Next two license

agreements will need

to be accepted

before continuing.

Pub. #OM17-MSP3

SoilViewer

Software Setup

Figure 12

Figures 13a and 13b

2-5

Page 15

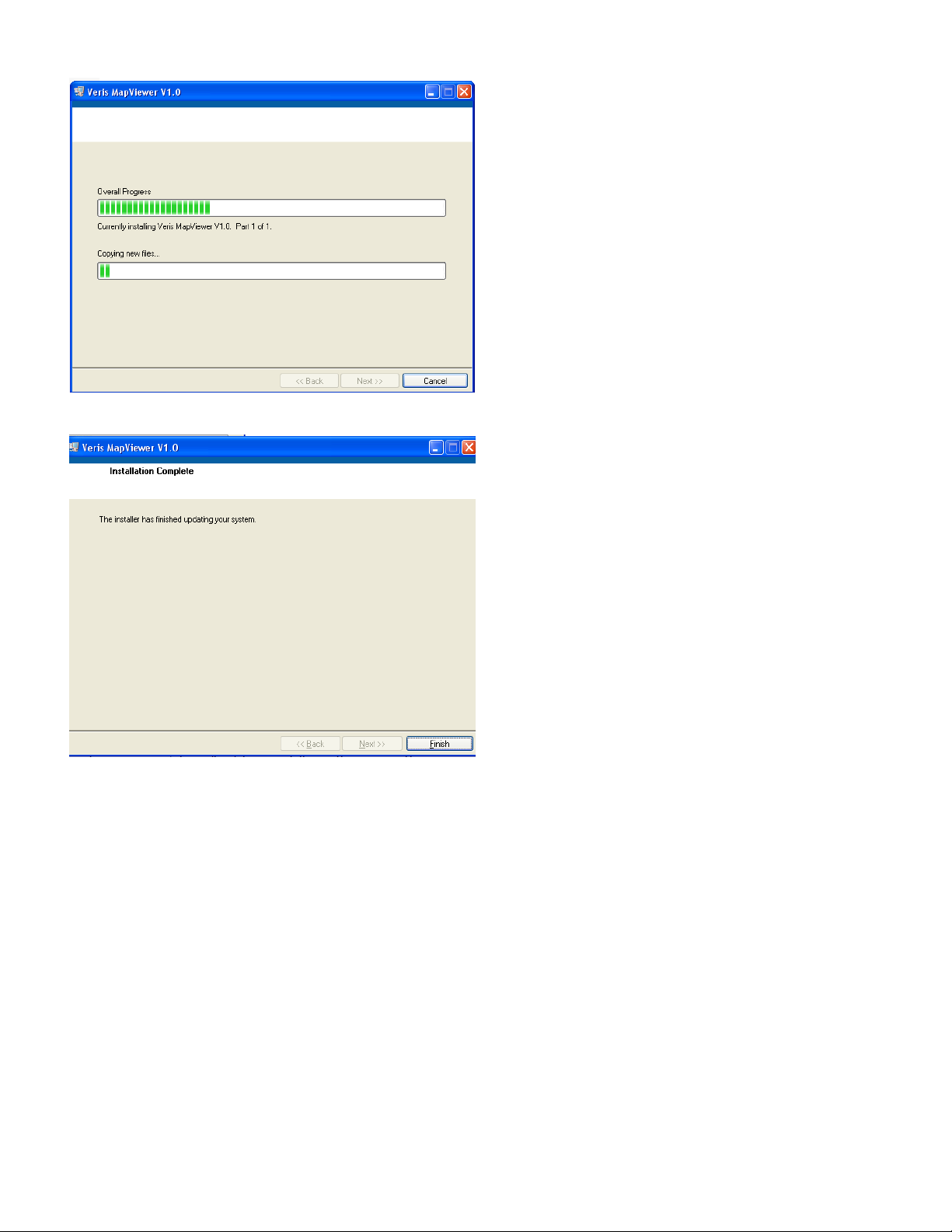

Figure 14

The installer will

install all necessary

components

Once the installer is completed, click

finish

Pub. #OM17-MSP3

Figure 15

2-6

Page 16

Pub. #OM17-MSP3

Section 3

Implement Overview and Set-up

Figure 1 MSP3 with EC, OM, and pH sensor modules

Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the

Veris MSP3.

Install all transport locks before transporting or working underneath.

Always use the service stands when working underneath the MSP3.

3-1

Page 17

Pub. #OM17-MSP3

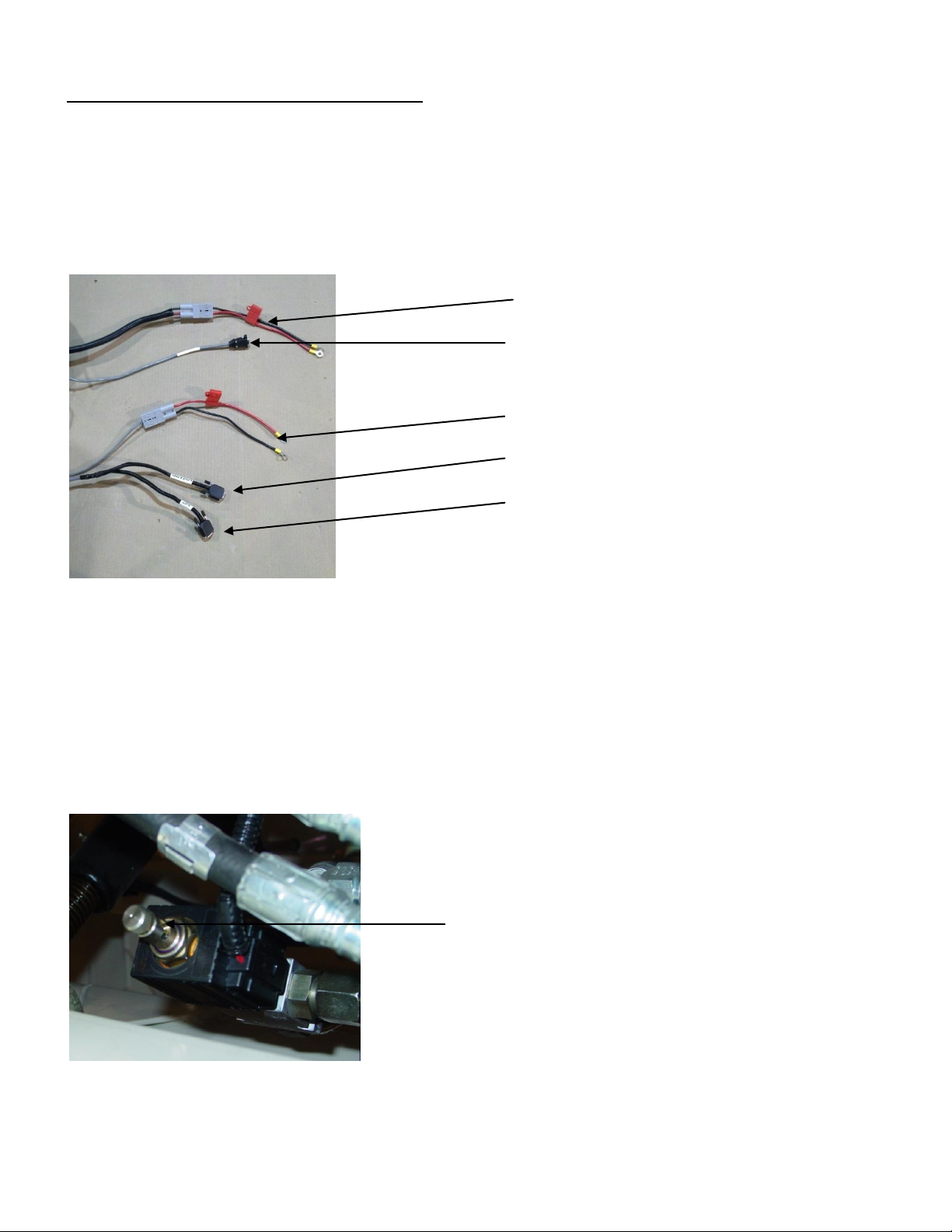

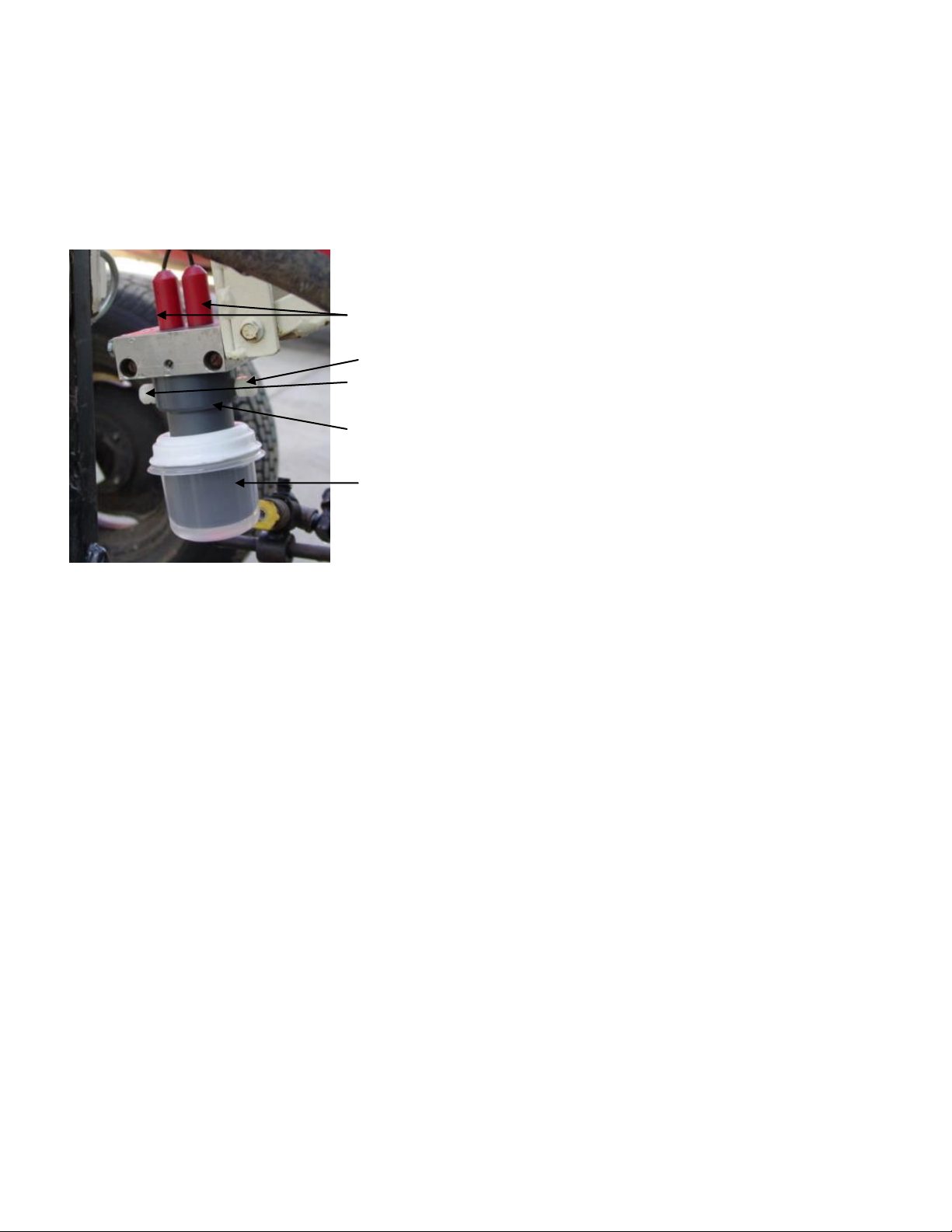

pH 12 V Power leads

pH com cable

Open/Closed center hydraulic poppet valve

-Up (out) for open center tractor hydraulics

-Down (in) for closed center tractor hydraulics

OM 12 V Power leads

OM com cable

GPS Input

12 Volt Power and Hydraulics Set-up

If the unit has been crated and delivered via closed-van commercial freight, the tongue (if

equipped) may need to be installed prior to use. Prior to operating the implement for the first time,

it is important to check all fasteners – some may have loosened during shipment. Route cables

and hydraulic hoses along tongue and through hose guide. Tie-strap securely. Connect electrical

cables to battery. Be careful to attach black cable to negative/ground terminal. DO NOT

REVERSE POLARITY.

Figure 2

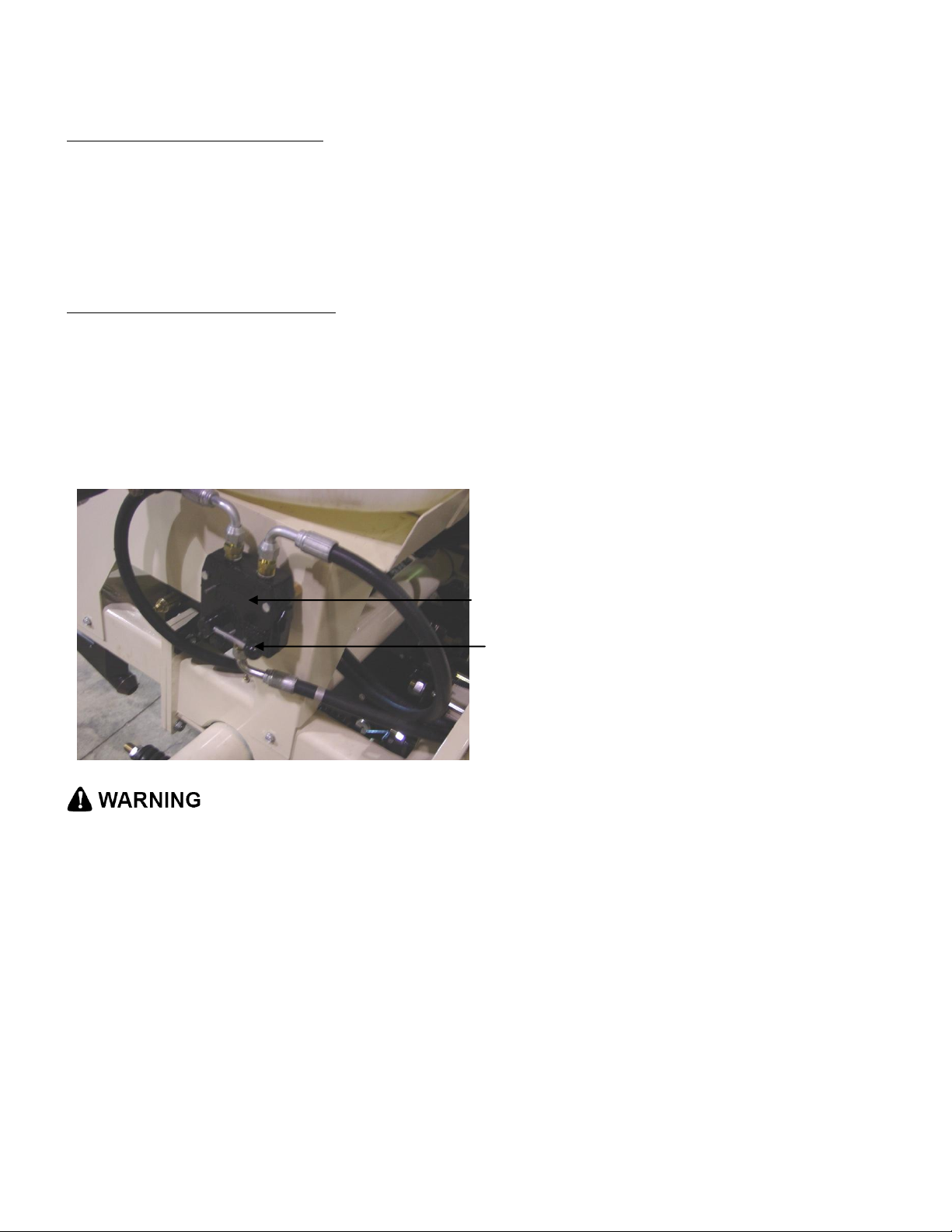

Insert hydraulic ends into quick-couplers, being careful to insert the end marked “P” into the tractor

extension coupler, and the end marked “T” into the tank or return line coupler; in this configuration,

tractor’s hydraulic lever will be secured in raised position. If sampler shoe operates in reverse,

simply reverse hydraulic hoses, or secure lever in lowered position. Note: Be certain whether

tractor or hydraulic power source utilizes open or closed-center hydraulics. Damage to

tractor could occur if not set properly. The poppet knob is set ‘up’ for open systems, and

‘down’ for closed-center systems – (see settings below.) Press down and turn knob to lock down—

press down, turn and release to allow it to move up to open position.

Figure 3

3-2

Page 18

Pub. #OM17-MSP3

Flow control settings:

Open center hydraulic systems

1) Set poppet valve in “up” raised position, this allows flow back to tank

2) Set engine at field rpm

3) Set pH controller to “Manual” and run sampling shoe up and down, timing the cycle time.

4) If sampler raises in approximately 1.5 -2 seconds, leave flow control as is, if not, adjust control

arm upward or downward to achieve desired speed.

Closed center hydraulic systems

1) Set poppet valve in down position. Push down and rotate so that rolled pin locks into closed

position. This blocks flow and allows the pump to de-stroke when the directional valve is in

the neutral position.

2) Adjust flow control valve to full open position.

3) Set engine at field rpm.

4) Run sampling shoe upward and adjust raise time to approximately 1.5-2 seconds using

throttling valve on tractor’s remote coupler

Note: Excessive sampling shoe speed can

damage electrodes.

Flow control valve

Adjustment control arm

Figure 4

• Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard

by relieving pressure before disconnecting hydraulic lines. Use a piece of paper or card-board,

NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and highpressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result.

Flush and fill tanks with tap water; clean any foreign matter out of tank using ball valve clean-out.

Set ball valve to open position, allowing water to flow to pumps.

3-3

Page 19

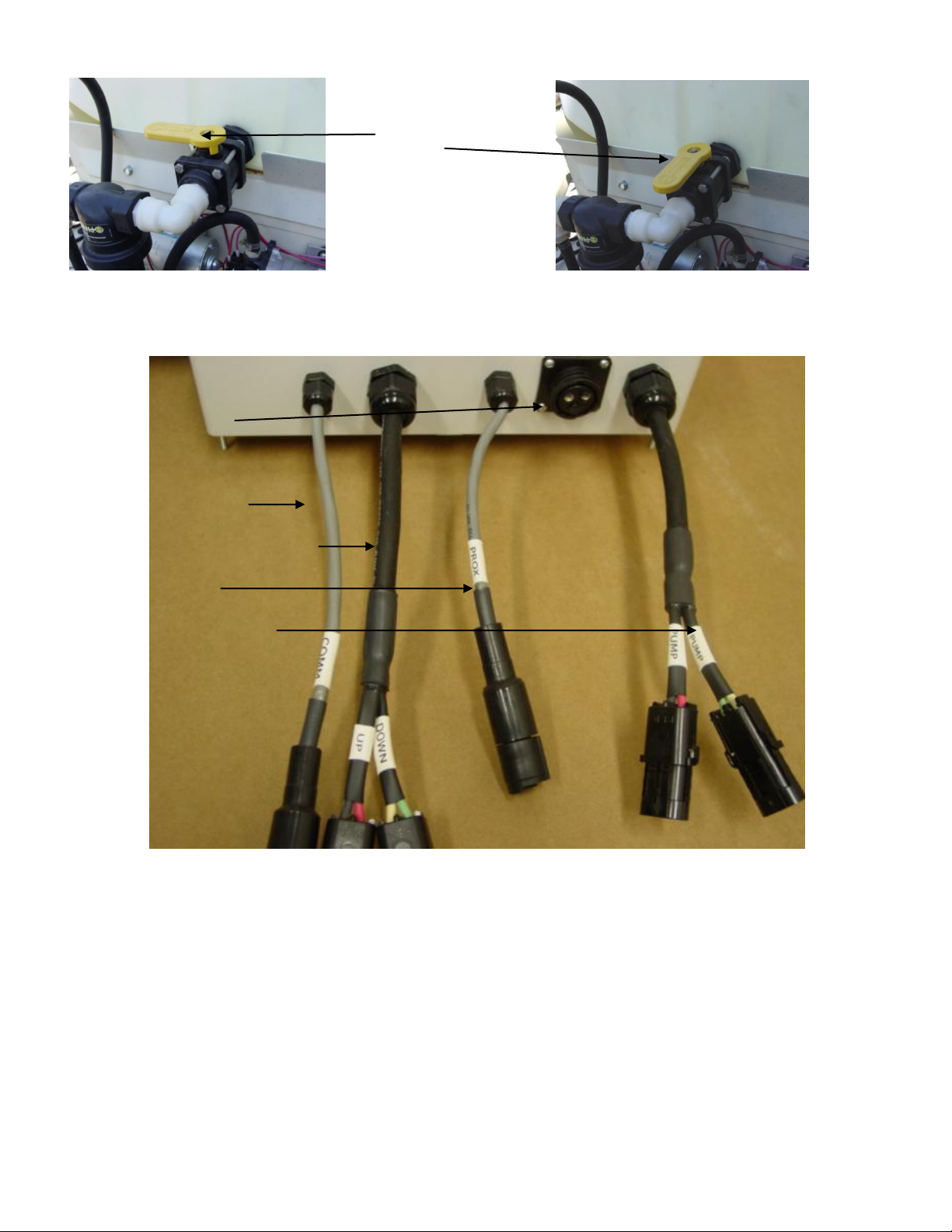

ball valve:

closed

open

12 V power in

Communication

Sampler solenoid power

Prox sensor

Wash pump power

Figures 5a and 5b

Connecting cables to External controller as shown below:

Pub. #OM17-MSP3

Figure 6

3-4

Page 20

Pub. #OM17-MSP3

pH

electrodes

electrode set

screws and

lock nuts

electrode

holder

soaker cup

Remove pH electrodes from individual storage containers and fill soaker solution cup with soaker

solution. Install soaker solution cup on electrode holder. Loosen plastic set screws on electrode

holder and insert pH electrodes into electrode holder. Re-tighten set screws finger tight and lock in

place with lock nuts. Do not overtighten set screws or electrode damage may occur. Always keep

electrodes in soaker solution, either in individual containers or soaking in large cup installed over

electrode holder. Route electrode cables away from sampling mechanisms to prevent damage—

tie-strap excess length of cable as needed.

Figure 7

3-5

Page 21

Pub. #OM17-MSP3

Section 4

Field Operations: DataLogger: OM and pH System Checks

Sensor DataLogger display readings

Here are the display readings shown when operating the Sensor DataLogger:

Starting up…

Figure 1

The unit is ready to operate. The DataLogger is informing you of the firmware version its

programmable interface chip (PIC) contains.

Press any of the four keys, and the next screen will appear:

Figure 2

For Mapping, press the #1 key. For OM System check press the #2 key (page 4-4). #4 Exit

returns you to the initial start-up screen. Pressing #1 brings up the next screen:

Figure 3

For EC and OM mapping, press the #1 key. For EC, OM and pH press the #2. #4 Exit returns you

to the initial start-up screen. Pressing #1 or #2 brings up the next screen:

Figure 4

The DataLogger is displaying the map file number it is creating, in case you want to record it along

with any other information about the field. Press any key to begin new map file. After starting the

file, pressing the #4 key will stop the file. If DataLogger freezes at the screen shown in Figure 6 or

Figure 7, check formatting of SD card—must be FAT format. See Proc. #6 for formatting

instructions.

4-1

Page 22

Pub. #OM17-MSP3

Ground

speed (from

GPS) in

miles/hour

GPS status: may

read GPS,

DGPS, RTK, or

None. If None, no

GPS signal is

received and no

data will be

Shallow (S)

and Deep (D)

soil EC

readings. If

negative, no

data will be

recorded.

pH sampler status

pH readings from

electrodes 1 and

2

OM reflectance

readings the top

is RED the

bottom is IR

Shallow (S) and

Deep (D) soil EC

readings. If

negative, no data

will be recorded.

pH readings

from electrodes

1 and 2

pH sampler status

If memory card was not inserted during boot-up, the following screen will appear:

Figure 5

Install card and re-start DataLogger. NEVER REMOVE CARD WHILE LOGGING DATA.

This is the Data Acquisition screen with GPS status (note:GPS status will blink every second when

engaged to show the OM readings):

Figure 6

Figure 7 The acquisition screen with OM readings

4-2

Page 23

Pub. #OM17-MSP3

There are warning signals programmed into the Veris DataLogger to warn the operator that data is

not being recorded, so that corrective action can be taken. If data is not being recorded, a warning

alarm will sound, and the portion of the screen text that is missing information will blink. For

example, if the DGPS isn’t being received (or the NMEA string containing speed) the Lat/Long text

will blink. If EC values are negative, they will blink. Also, the Data Status LED light on the front of

the DataLogger indicates whether data is being recorded. If this light is not lit, data is not being

recorded. (note: no data is recorded unless unit is moving—receiving speed signal from GPS)

At any time during the mapping process, you can press any key to stop the file. If you create more

than one file from the same field, you can bring the files into a spreadsheet program or GIS and

combine for whole field map display.

After #4 key is pressed during Data Acquisition, the following screen will be displayed: (if data

was collected during Data Acquisition)

Figure 8

DATA IS ONLY STORED ON THE SD CARD. NO INTERNAL FILES ARE CREATED.

If no data was logged during Data Acquisition, the following screen will be displayed:

Figure 9

Sensor DataLogger OM System Check

Here are the display readings shown when operating the Sensor DataLogger while running OM

system check:

Figure 10

4-3

Page 24

Pub. #OM17-MSP3

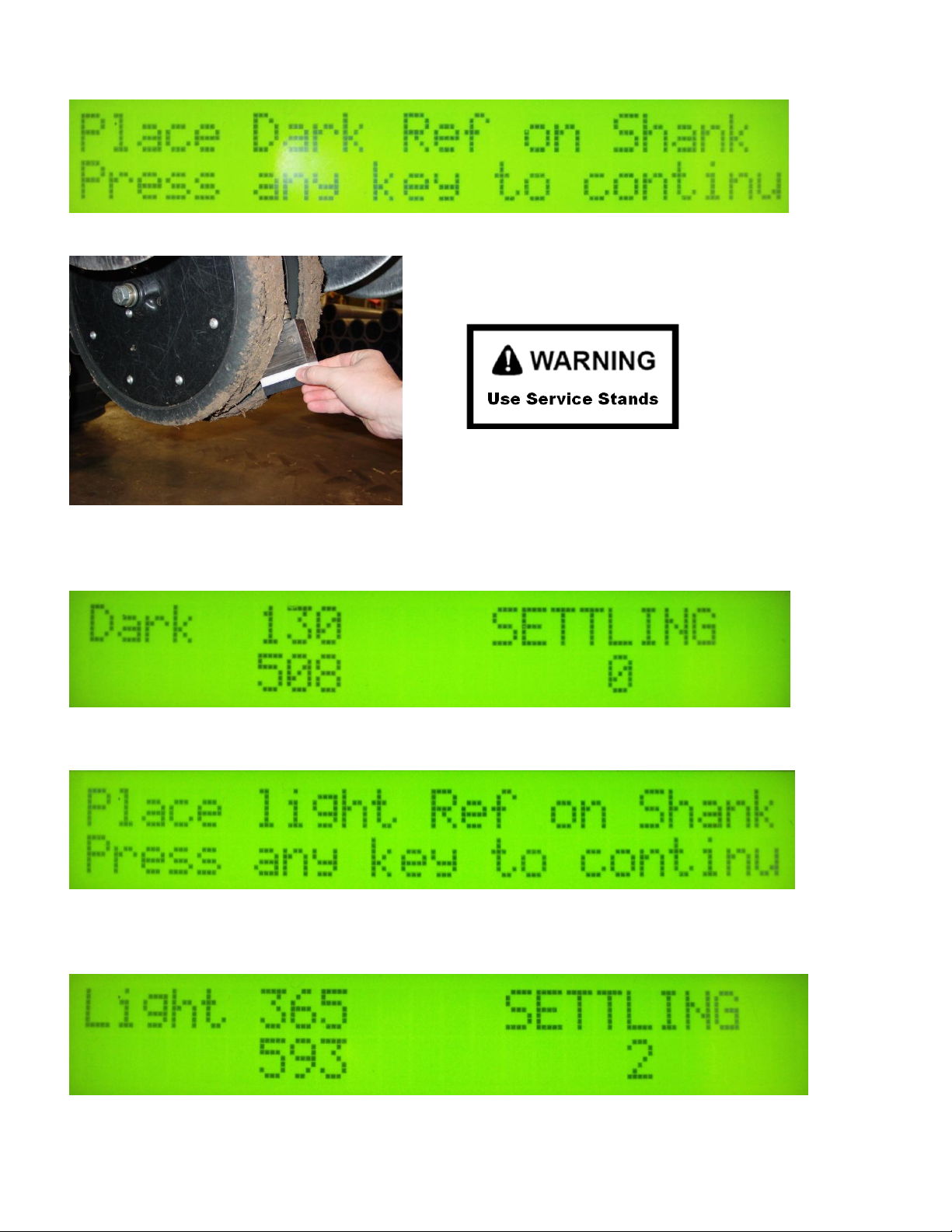

Press #3 to continue with OM System check:

Figure 11

Figure 12

If the window is clean and in good condition (see 4-8), attach the dark side of the Reference to the

sensor. (Figure 12) Press any key to continue:

Figure 13

After the readings have settled the next screen will appear:

Figure 14

Turn the Reference block over and attach the light side of the Reference to the sensor. (Figure 12)

Press any key to continue:

Figure 15

4-4

Page 25

Pub. #OM17-MSP3

After the light reference has been read, the following will appear:

Figure 16

The reference data has now been stored. Once the system is restarted it is ready to start

mapping.

*NOTE: To ensure system is operating correctly always run a system check before

mapping a field.

There should be a difference of 100 or greater from dark reference to light reference for

each wavelength.

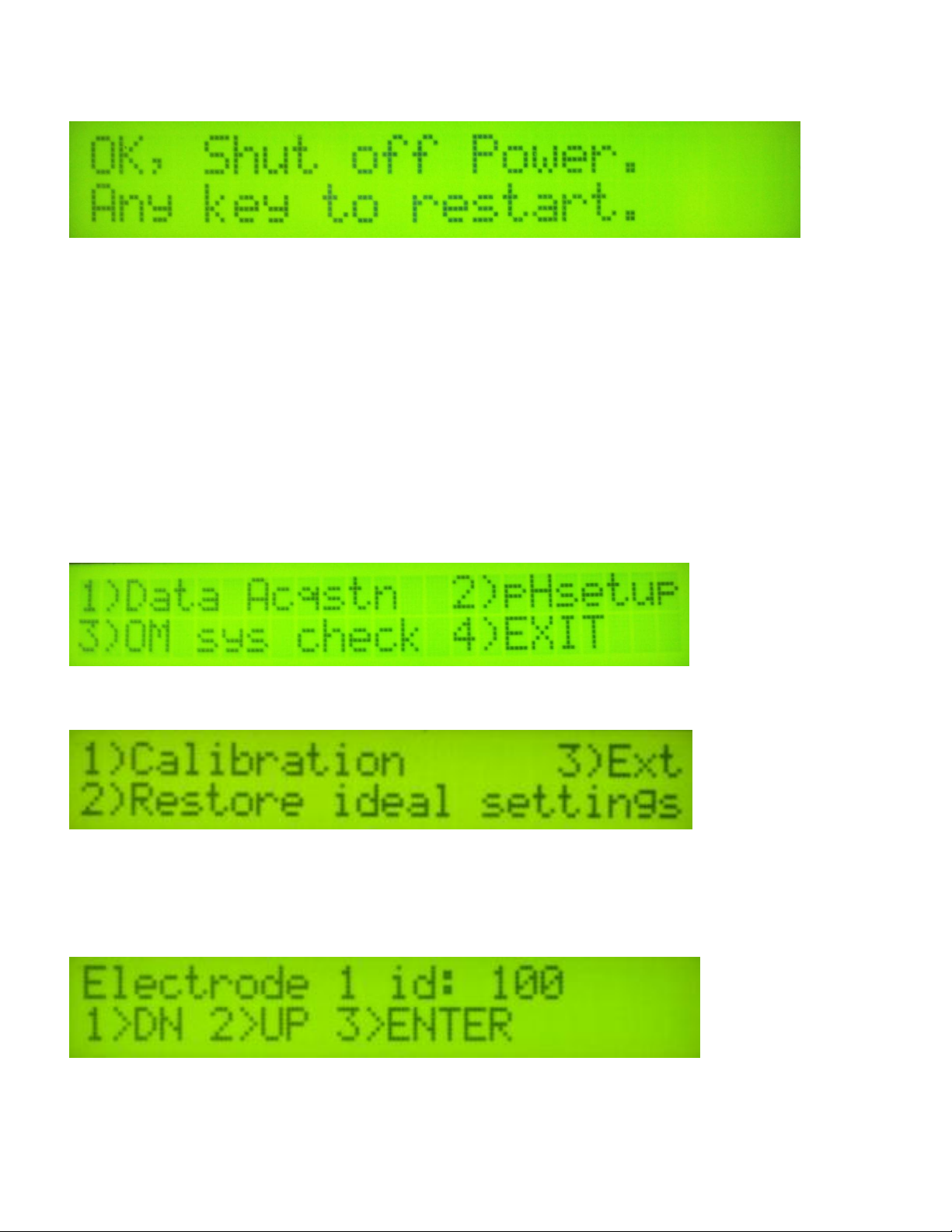

pH System Check

Calibrating pH electrodes

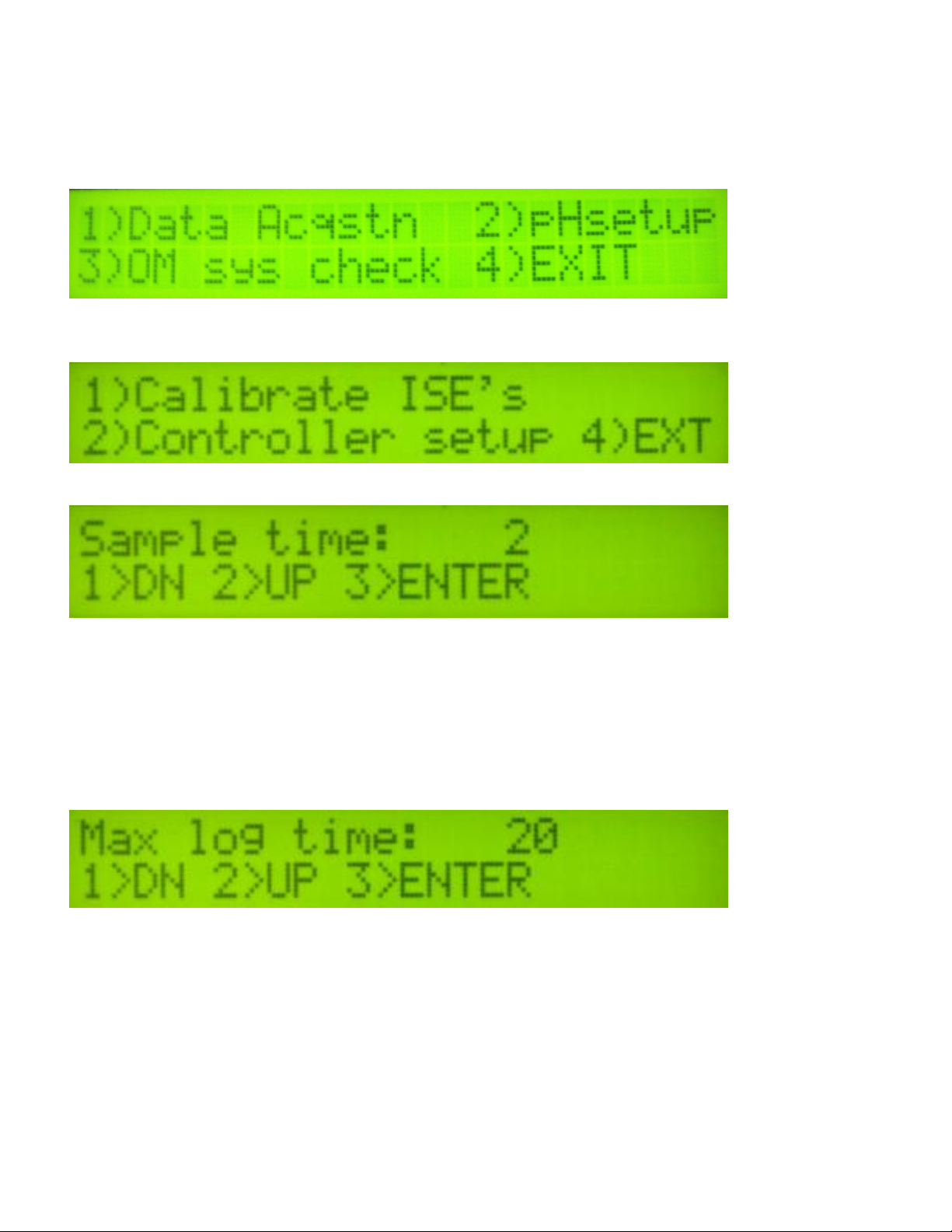

Enter menu option 2) pHsetup

Figure 17

Enter menu option 1) Calibration.

Figure 18

You will be asked for the ID of the electrode connected to channel 1. You may want to add an ID

number to the electrodes, for your own tracking purposes. Use the 1 and 2 keys to change the

number and 3 to confirm:

Figure 19

Repeat for electrode 2’s ID and press 3 to confirm.

4-5

Page 26

Pub. #OM17-MSP3

The instrument will prompt for the electrodes to be inserted into pH buffer 4 solution; Slide cup with

pH 4 buffer solution onto electrode holder. Press 1 to continue with calibration or 2 to exit. Tips:

Don’t overfill solution. Cup only needs enough solution to immerse electrode tip and face. Don’t

reuse solutions.

Figure 20

Figure 21

The instrument will read the electrodes for 10 seconds, displaying the output (as it counts

seconds):

Figure 22

After 10 seconds, the instrument will display the final pH reading and offer the options to 1) Accept

pH 4 buffer readings; 2) Redo pH 4 buffer readings; or 3) Exit pH electrode calibration. If the

readings are satisfactory, press 1; if the readings are suspect, press 2 to return to re-do pH 4.

Figure 23

After accepting the pH 4 buffer readings, the Instrument will prompt for the electrodes to be

inserted into pH 7 buffer solution. Remove the pH 4 buffer solution cup from the electrode holder.

Rinse the electrodes, electrode holder, and solution cup using the manual wash for at least 10

seconds. Slide the pH buffer 7 solution cup onto the electrode holder.

4-6

Page 27

Pub. #OM17-MSP3

On the DataLogger, press 1 to continue with calibration. The DataLogger will read the electrodes

for 10 seconds, displaying the output. After 10 seconds, the instrument will display the final pH

reading and offer the options to 1) Accept pH 7 buffer readings; 2) Redo pH buffer 7 readings; or 3)

Exit pH electrode calibration. If the readings are satisfactory, log pH 7 reading and press 1; if the

readings are suspect, press 2 to return to pH 7 calibration step.

After accepting the pH 7 buffer readings, the electronics firmware will determine if each electrode’s

response is sufficient to provide suitable readings. A score is displayed for each electrode; the

acceptable score range is between 75 and 102. If both electrodes are within this range, the

instrument will display the following screen:

Figure 24

If an ‘X’ is displayed beside one or both electrodes’ scores, this indicates that one or both of the

electrodes did not perform well enough for continued reliable use. No calibration settings are

changed if calibration is unsuccessful. The electrode(s) responsible for failed calibration should be

removed and either cleaned or replaced and the calibration procedure repeated.

Figure 25

After calibration is complete, you will have the option to use the calibrated readings or reset to the

ideal settings. Tip: many operators use the ideal settings rather than calibration settings. One

reason is this enables readings from one day to be compared to another. It is still important to

perform the calibration step at least daily, even if ideal settings are used. The calibration process

is important to test electrode quality.

4-7

Page 28

pH Controller Set-up

After calibration, you may wish to change the pH Controller default parameters.

Enter menu option 2) pHsetup

Figure 26

Enter menu option2) Controller setup

Figure 27

Pub. #OM17-MSP3

Figure 28

Sampling time is the duration that the sampler assembly is in the soil. Typically 2 seconds is

adequate. In soil conditions that do not produce a firm core, this time may need to be set at 3

seconds in order to allow soil to begin flowing through cutting shoe. If soil conditions result in a

very firm core, the sampling time may be reduced to 1 second. In rocky conditions, use 1 second

sample time to reduce likelihood of sampler shoe damage. Press 1 or 2 to adjust the sample time,

press 3 to continue to the next screen.

Figure 29

Maximum log time is the longest time in seconds the pH controller will wait for the pH readings to

settle. The controller usually cycles before this maximum time is reached. The minimum setting

for the maximum log time is 20 seconds. (Tip: use 20 seconds unless there is a special reason to

allow a longer wait time) Press 1 or 2 to adjust the sample time, press 3 to continue to the next

screen.

4-8

Page 29

Pub. #OM17-MSP3

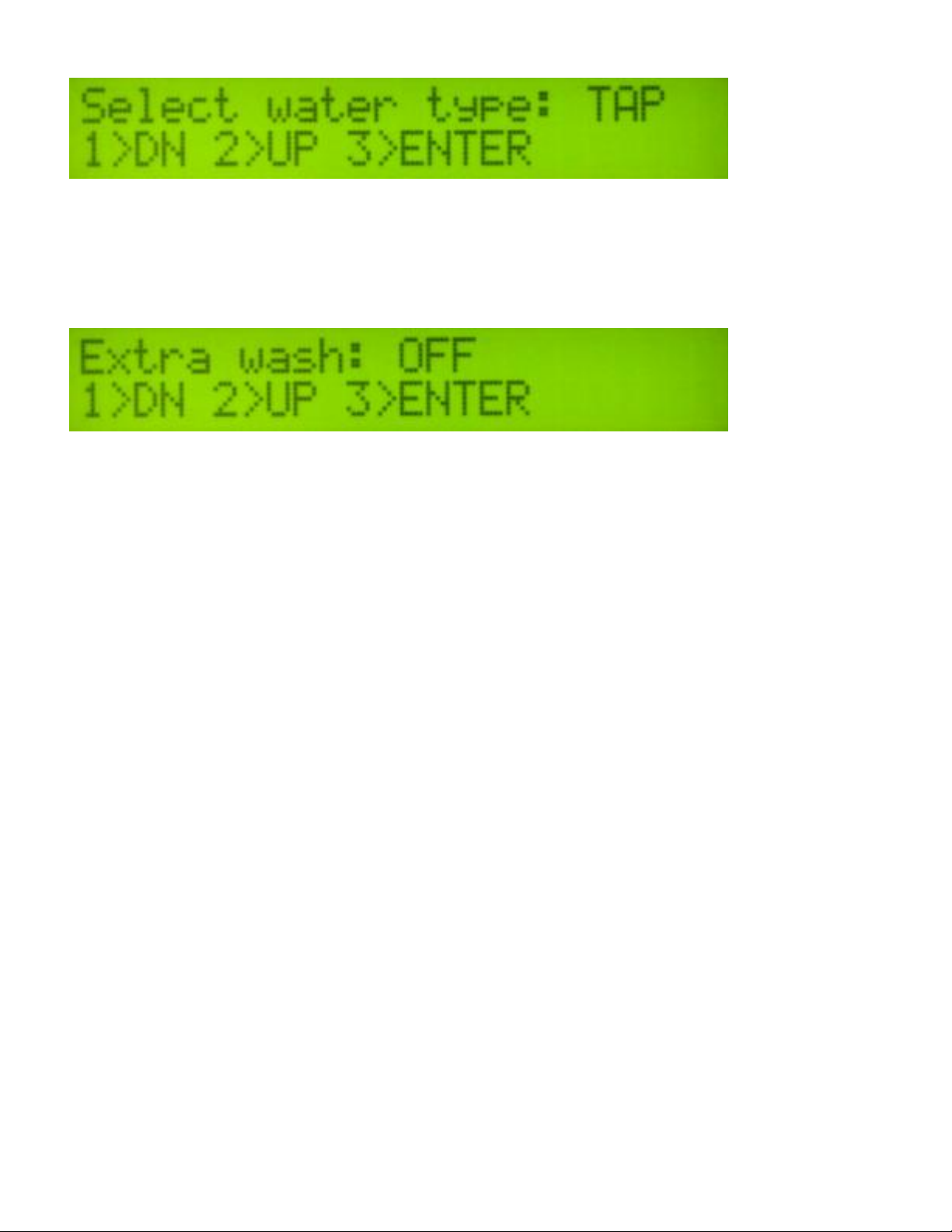

Figure 30

Select the type of water you are using to clean the electrodes between samples. The available

types are TAP, RO (reverse osmosis), or DI (de-ionized). Press 1 or 2 to cycle through the water

types, press 3 to continue to the next screen. Tip: If you don’t want a baseline wash performed

every 40 cycles, use RO setting rather than Tap or DI (regardless of actual water being used).

Figure 31

Turning on the extra wash option will add 1.5 seconds of cleaning per cycle. The extra wash is

performed by stopping the shoe briefly during the cycle. Use this feature if you have noticed the

electrodes are not cleaning during the cycle. Press 1 or 2 to choose ON or OFF, press 3 to

continue. Tip: water usage will double if extra wash is used.

4-9

Page 30

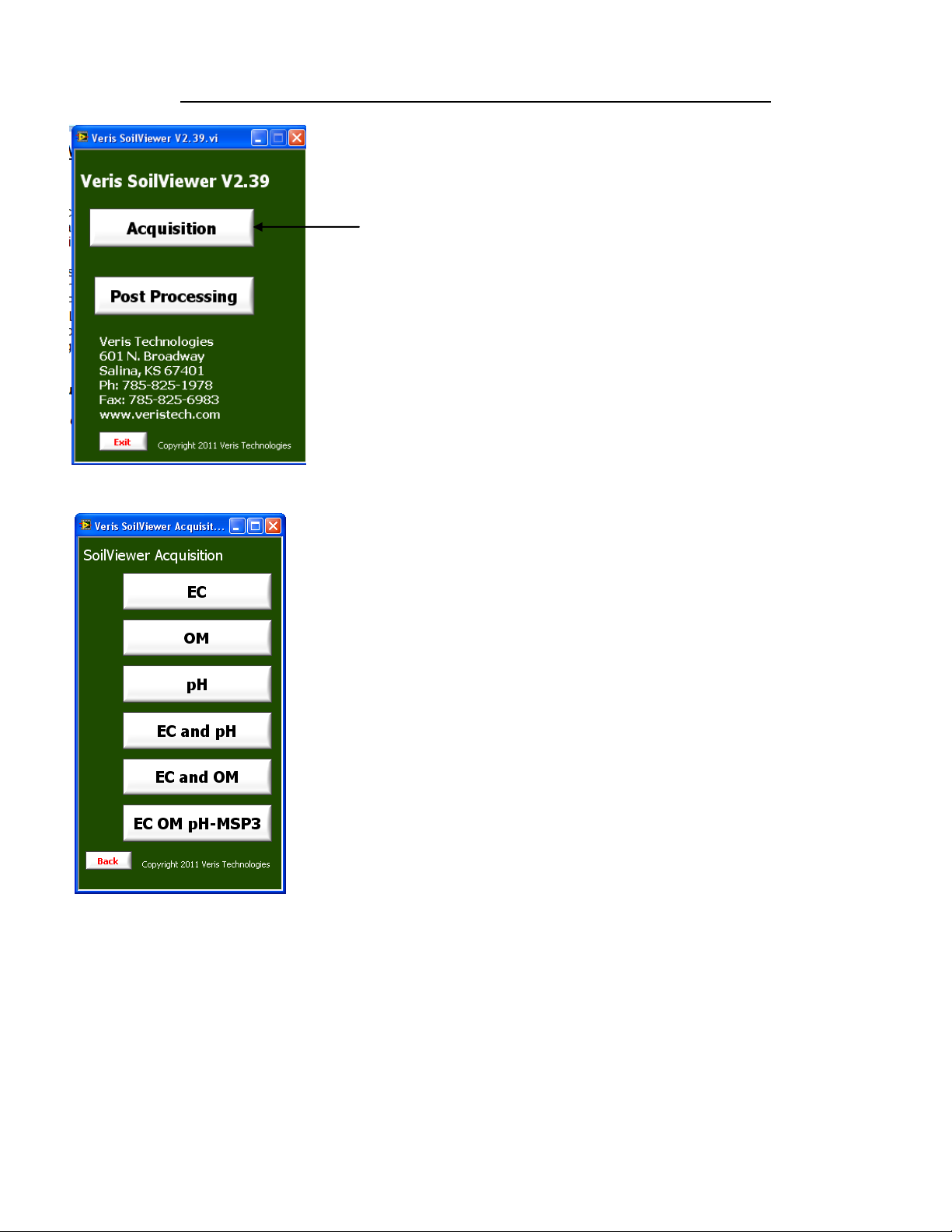

EC – EC Surveyor connected to PC

OM – OpticMapper and GPS connected to PC

pH – pH controller and GPS connected to PC

EC and pH – EC Surveyor and pH controller

connected to PC

EC and OM – EC Surveyor and OpticMapper

connected to PC

EC OM pH-MSP3 – OpticMapper/EC Controller and

pH controller connected to PC

To acquire EC, OM and

pH data select Acquisition

Figure 32

Pub. #OM17-MSP3

Field Operations: SoilViewer: OM and pH System Checks

Figure 33

To acquire data with the MSP3 only EC OM pH- MSP3 can be used. This is the only option that

will work with the MSP3. This will allow the user to collect all three sensor readings, or collect only

EC and OM if desired.

4-10

Page 31

Pub. #OM17-MSP3

After clicking on EC OM

pH- MSP3 the user will

be prompted to input the

EC file name. All OM

and pH files will be

named the same as the

EC. Files may be

appended to by

selecting a previously

created VSEC file.

The EC OM pH-MSP3 Mapping software will automatically detect which ports the Veris

OpticMapper /EC Controller and pH Controller are connected to, and begin communicating. If

either is not detected, the software will wait 45 seconds for the connection of the electronics and

search again; this will repeat until both instruments are connected. If the electronics are not found,

unplug the serial or USB cables and reconnect them to the PC. If the connections are still not

made, refer to SoilViewer troubleshooting. The conditions for mapping and storing the data are as

follows. The user must be going a speed greater than 1 mph, there must be a GPS signal

received that includes position and speed (GGA and either VTG or RMC), the OM/EC Comm Light

must be green, indicating the PC and OpticMapper with EC Surveyor are communicating properly,

and either of the EC values has to be greater than -1.

Before mapping, run the OM system check and pH calibration to ensure everything is

operating correctly. pH controller settings can be modified to adjust the wash and cycle

times for specific field conditions.

Figure 34

Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the

Veris MSP3.

Install all transport locks before transporting or working underneath.

Always use the service stands when working underneath the MSP3.

4-11

Page 32

Pub. #OM17-MSP3

SoilViewer OM System Check

The OM System check ensures the optical sensor and controller are functioning properly. By using

the light and dark reference block the range of the sensor can be determined. For proper

operation the range from the dark to light side for the red and IR readings must be at least 100. If

it is not that may indicate a broken wearplate, inadequte power, or damaged sensor. Run the

system check before mapping each field to ensure proper operation. The results of the system

check are stored in a .inf file specific for each field.

Click the OM System Check button to start system check.

Figure 35

After clicking the System Check button the following will

appear:

Figure 36a and 36b

Make sure the window is clean and in good condition. (see 4-8) Place the dark side of the

reference block under the window, and click continue. The following message will appear.

Figure 37

Turn the reference block over to the light side and place under the window, and click continue.

Either of the following messages will appear:

Figure 38a and 38b

4-12

Page 33

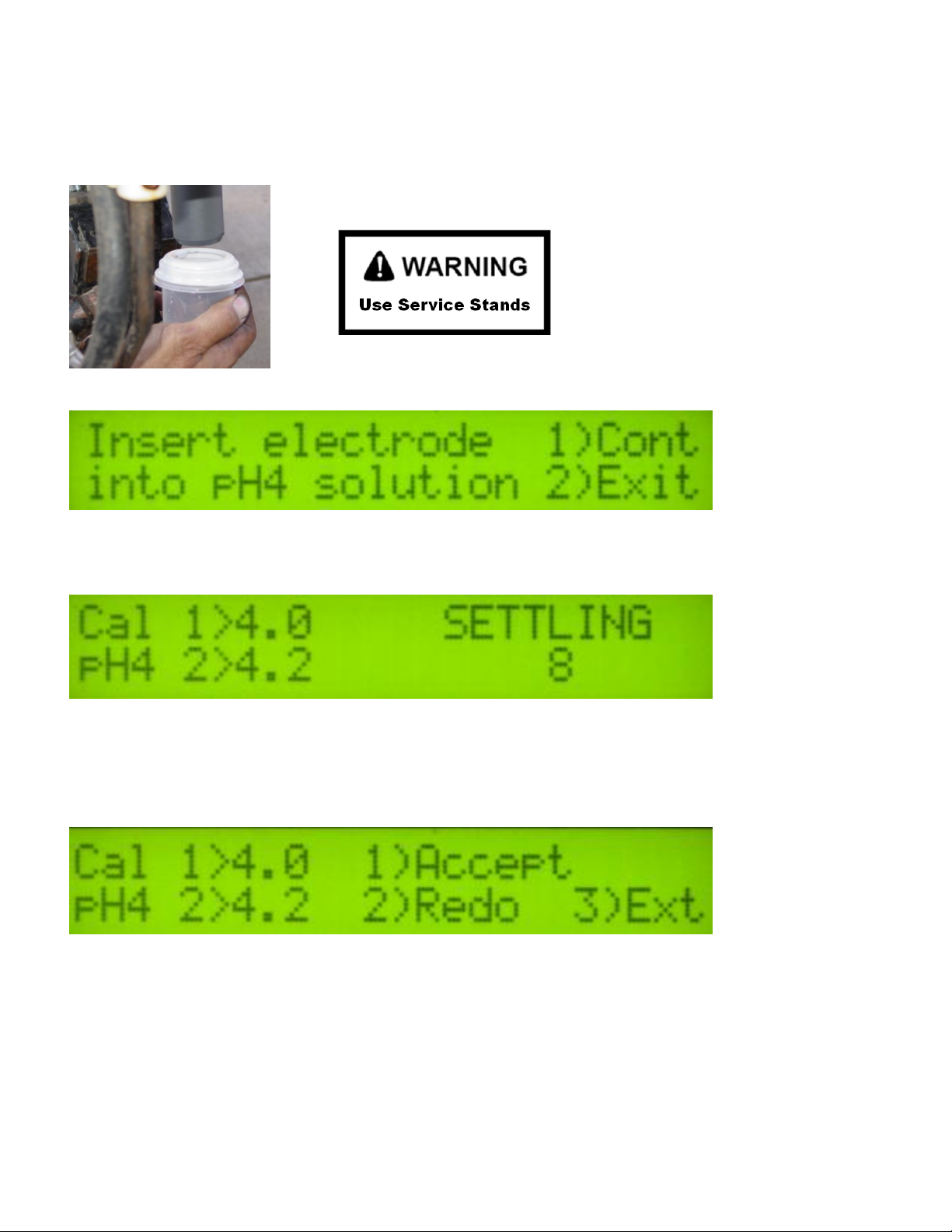

pH System Check: Calibrating pH electrodes

You will be asked if you want to

continue the calibration or restore

ideal settings.

Click on Calibrate ISE’s or press F1

Figure 39

Figure 40

Pub. #OM17-MSP3

Figure 41

You will be asked for the ID of the electrode connected to channel 1. You may want to add an ID

name or number to the electrodes, for your own tracking purposes. Insert the name or number

then press OK to continue.

Figure 42

4-13

Page 34

Pub. #OM17-MSP3

The software will prompt for the electrodes to be inserted into pH buffer 4 solution; Slide cup with

pH 4 buffer solution onto electrode holder. Press 1 to continue with calibration or 2 to exit. Tips:

Don’t overfill solution. Cup only needs enough solution to immerse electrode tip and face. Don’t

reuse solutions.

Figure 43

The software will read the electrodes for 10 seconds, displaying the output (as it counts seconds):

Figure 44

After 10 seconds, the software will display the final pH reading and offer the options to Accept pH 4

buffer readings; Redo pH 4 buffer readings; or Cancel pH electrode calibration. If the readings are

satisfactory, press Accept; if the readings are suspect, press Redo to return to re-do pH 4.

Figure 45

4-14

Page 35

Pub. #OM17-MSP3

After accepting the pH 4 buffer readings, the software will prompt for the electrodes to be inserted

into pH 7 buffer solution. Remove the pH 4 buffer solution cup from the electrode holder. Rinse

the electrodes, electrode holder, and solution cup using the manual wash for at least 10 seconds.

Slide the pH buffer 7 solution cup onto the electrode holder.

Figure 46

Press continue to proceed with the calibration. The software will read the electrodes for 10

seconds, displaying the output. After 10 seconds, the software will display the final pH reading and

offer the options to Accept pH 7 buffer readings; Redo pH buffer 7 readings; or Cancel pH

electrode calibration. If the readings are satisfactory, log pH 7 reading and press continue; if the

readings are suspect, press redo to return to pH 7 calibration step.

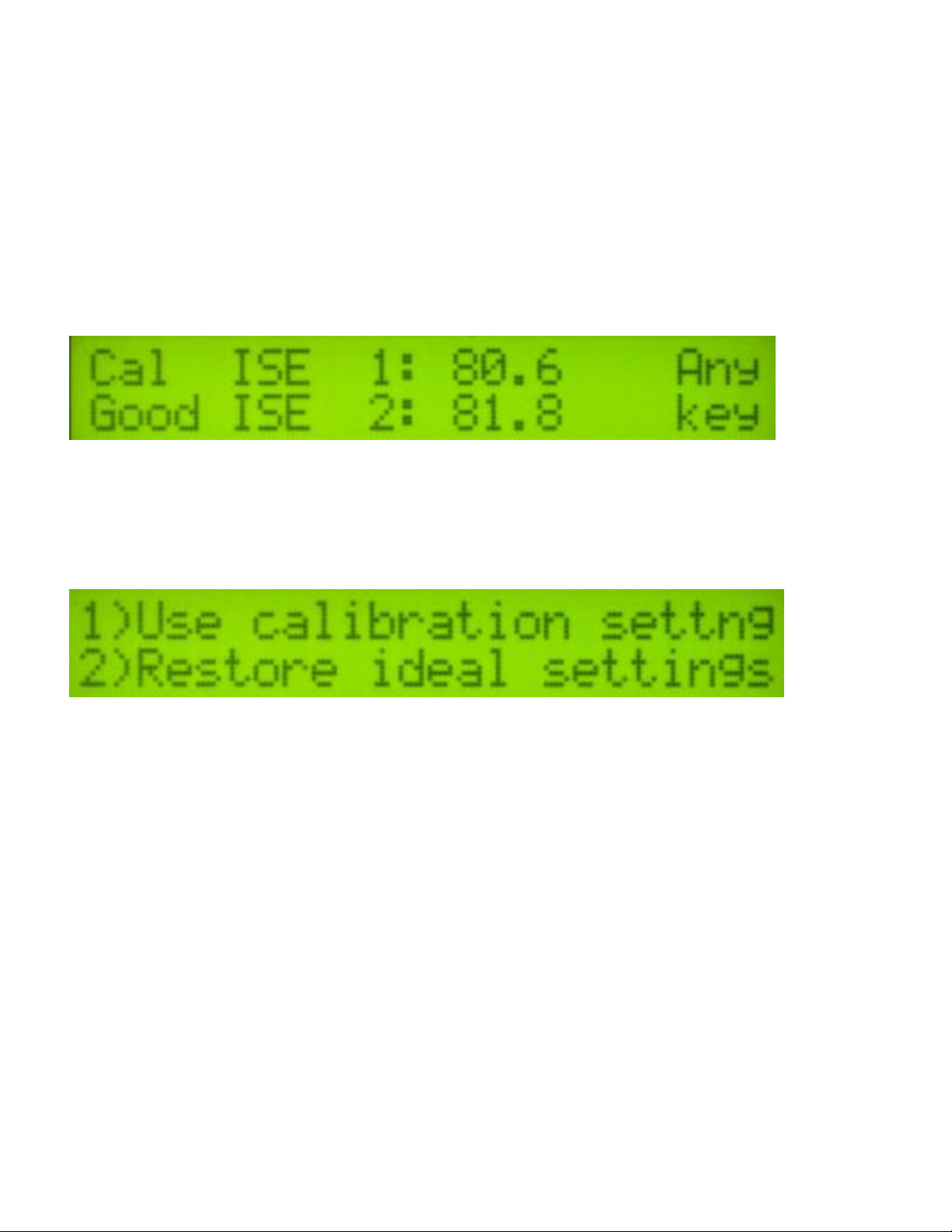

After accepting the pH 7 buffer readings, the software will determine if each electrode’s response

is sufficient to provide suitable readings. A score is displayed for each electrode; the acceptable

score range is between 75 and 102. If both electrodes are within this range, the software will

display the following screen:

Figure 47

If an ‘X’ is displayed beside one or both electrodes’ scores, this indicates that one or both of the

electrodes did not perform well enough for continued reliable use. No calibration settings are

changed if calibration is unsuccessful. The electrode(s) responsible for failed calibration should be

removed and either cleaned (See section 5-7) or replaced and the calibration procedure repeated.

Figure 48

After calibration is complete, you will have the option to use the calibrated readings or reset to the

default parameters. Tip: many operators use the default parameters rather than calibration

settings. One reason is this enables readings from one day to be compared to another. It is still

important to perform the calibration step at least daily, even if ideal settings are used. The

calibration process is important to test electrode quality.

4-15

Page 36

Pub. #OM17-MSP3

pH Controller Set-up

After calibration, you may wish to change the pH Controller default parameters. Press Controller

Setup or F3 and enter Setup menu.

Figure 49

Figure 50

The pH sampler settings can be adjusted without exiting the current file. Additionally, a correction

can be applied to each electrode’s pH shown on the screen. Occasionally, the pH readings shown

on the screen may differ from those expected in the field. If this is the case, the pH shown on the

screen can be adjusted up or down with the pH offset 1 and pH offset 2.

The offset is adjustable in 0.5 pH increments up to +/- 2.00 pH. NOTE: The instrument DOES

NOT apply this offset to the extracted file. Only the readings seen on the screen will be affected.

Sampling time is the duration that the sampler assembly is in the soil. Typically 2 seconds is

adequate. In soil conditions that do not produce a firm core, this time may need to be set at 3

seconds in order to allow soil to begin flowing through cutting shoe. If soil conditions result in a

very firm core, the sampling time may be reduced to 1 second. Press the up and down arrows to

adjust the sample time.

4-16

Page 37

Pub. #OM17-MSP3

Log time is the longest time in seconds the pH controller will wait for the pH readings to settle. The

controller usually cycles before this maximum time is reached. The minimum setting for the log

time is 20 seconds. Press the up or down arrows adjust the sample time. (Tip: use 20 seconds

unless there is a special reason to allow a longer wait time)

Select the type of water you are using to clean the electrodes between samples. The available

types are TAP, RO (reverse osmosis), or DI (de-ionized). Tip: If you don’t want a baseline wash

performed every 40 cycles, use RO setting rather than Tap or DI (regardless of actual water being

used).

Turning on the extra wash option will add 1.5 seconds of cleaning per cycle. The extra wash is

performed by automatically stopping the shoe briefly during the cycle. Use this feature if you have

noticed the electrodes are not cleaning during the cycle. Put a checkmark in the box to turn the

extra wash on and uncheck to turn off the extra wash. Tip: water usage will double if extra wash is

used.

4-17

Page 38

Pub. #OM17-MSP3

Field Operations—EC and OpticMapper

Tools required for Field Operation adjustments

-3/8”, 7/16”, 1/2” 9/16” 3/4” 15/16” wrench

-9/16”, 3/4” 12point socket

-3/8” ratchet

-Ohm meter

Checking Electrical Signal Continuity and Electrode Isolation

It is recommended that you perform the Electrical Signal Continuity and Electrode Isolation test

procedure before first field use (see Maintenance and Service Procedures 1 and 2). While these

tests were made at the factory, there is the possibility a problem developed during shipping.

Performing these tests on the new implement before it becomes dirty, allows you to get familiar

with the process under ideal conditions. It is strongly advised that you perform this test on a routine

basis (every 10 hours of data collection) to ensure you are obtaining reliable data. KEEP

OHMMETER, TEST LOAD AND TEST BOX WITH THE MACHINE AT ALL TIMES.

Setting Operating Depth

Begin field operation by lowering unit into soil. For good electrical conductivity, all coulter

electrodes must be in direct contact with moist soil, at all times and in every region of the field. A

depth of 1-2” (2.5-5 cm) is recommended. To insure this depth is consistently achieved, 400-600

lbs. (180-275 kg) of additional weight are normally required. Carrying water in the pH wash tank

can aid penetration. Also, Veris offers optional weights, or they can be supplied by the customer.

Do not adjust the tension on the coulter electrode springs to increase soil contact or penetration.

They are pre-set at the factory with the proper tension.

Figure 51 Figure 52

4-18

Page 39

Pub. #OM17-MSP3

set screws and

jam nuts

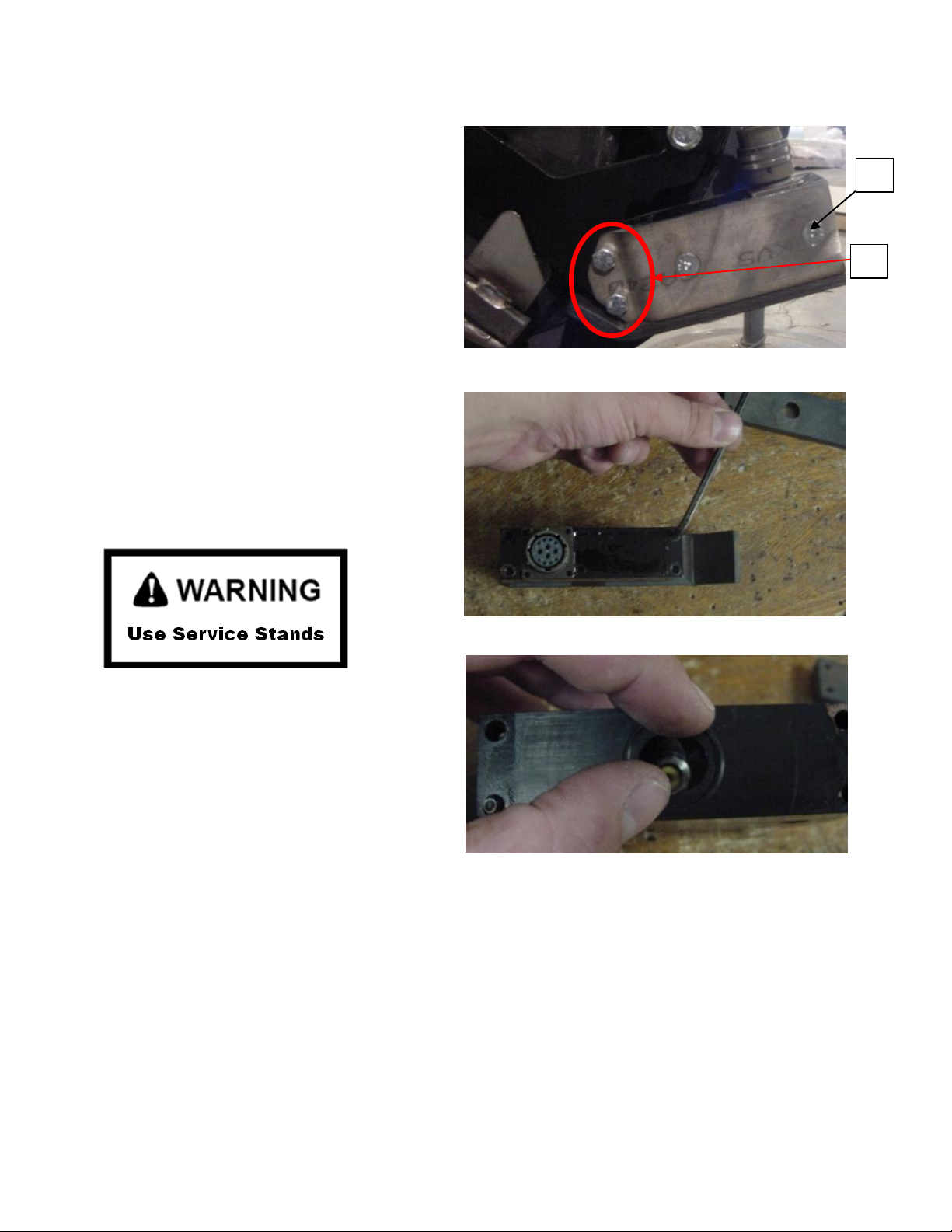

Adjustable Wing Extensions

This feature allows the re-positioning of the electrodes to fit various bed and crop configurations.

Adjustment is made by loosening the jam nuts and set screws located on the lower front of each

side of the toolbar, adjusting the toolbar wing extensions, and re-tightening the set screws. Veris

suggests setting the toolbars at either the maximum or minimum setting, not at a point in between.

A limiter bolt determines full extension, so they cannot extend to the point at which the outside

coulters disconnect from the main frame. Important – do not attempt to combine maps in which two

different investigative depths are used.

Figure 53

Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the

Veris MSP3.

Install all transport locks before transporting or working underneath.

Always use the service stands when working underneath the MSP3.

Figure 54 Figure 55

4-19

Page 40

Top Link

3-point Adjustment

Turn the top link (Figure 60) to adjust the tilt and level the unit.

This is the optimal setting for all fields types. Extending the top

link will cause the rear of the unit to move down. Shortening the

top link will cause the inverse.

Row Unit Adjustment

Adjust side depth wheels on optical row unit to allow deeper or

shallower mapping. Move T-handle (Figure 61) backward for

deeper depth. Depth wheels should be snug, but freely moving,

against the disks. See Section 5-3 for more information.

Pub. #OM17-MSP3

Adjust spring pressure on row unit as needed. With implement

lifted to reduce pressure on springs, move handle forward to

reduce spring pressure and back to increase. Additional weight

may be required in hard soils. Reduce pressure in rocky

conditions to prevent damage to window. (Figure 62)

Row Cleaner Adjustment

The row cleaner needs to be adjusted for your

conditions, crop changes, and as coulters and

openers wear. Ideally, cleaners contact only the

trash, and do not disturb the soil.

To adjust row cleaner loosen bolts, 1, and slide

the down stop, 2, to the desired cleaning depth.

Forward for deeper cleaning and backward for

shallower cleaning.

Figure 63

4-20

Page 41

Pub. #OM17-MSP3

Coulter Adjustment

Adjusting the coulter depth is accomplished by re-mounting the coulter blade in one of the six

mounting holes arranged in a staggered pattern in the coulter bracket.

Figure 64

Raise unit and lower service stands before

working on coulters. Do not attempt to move

blade when the current or new position causes

it to contact the ground during the adjustment.

Be careful around the front end of row units.

Row cleaner tines and coulter blades may be

sharp.

To adjust coulter depth:

1. Determine the present opener and coulter

depths.

2. Note which bracket hole the coulter is

presently using.

3. Determine which new hole will position the

coulter closer to the 1/4in-above depth. See

the table below.

4. Remove the 5/8-11 x 4in bolt, lock washer

and nut ( A in Figure 64).

5. Move the blade to the new position. Insert

the bolt, and tighten on the lock washer and

nut.

6. Re-adjust row cleaners, if installed. If a

worn coulter cannot be adjusted to

satisfactory operating depth, replace coulter.

4-21

Figure 65

Page 42

Pub. #OM17-MSP3

Speed

Proper field operating speed depends on field condition. Because of the importance of consistent

contact, the unit must not be allowed to bounce over rough fields at high speeds.

Field Condition

Field should be in a uniform state. Mapping after intensive primary tillage is not recommended. The

soil must have a minimum of 20% available water, and cannot be frozen. If rocky conditions exist,

slow down and make sure rock guards are in place. Also if the field is rocky and/or muddy the

optical module will needs to be adjusted to make optimum contact with the soil, as well as

decreasing the chance for window breakage.

Swath width and Navigation

Setting the swath width and navigation system is at the discretion of the customer. A 50’-75’ (1523 m) swath works well in most areas. Several methods of navigation are possible: following

previous crop rows, swath guidance, or using a field navigation computer. While it is important to

map in a consistent pattern, it isn’t absolutely critical that each pass be exactly the same distance

from the previous pass.

4-22

Page 43

Pub. #OM17-MSP3

To help insure the quality of your data, please follow these guidelines:

1. Generate and view maps frequently, especially prior to deleting data from Instrument.

2. Listen for auditory alarm from DataLogger, indicating data collection has been interrupted.

3. View DataLogger screen or SoilViewer map frequently during data collecting; watch for:

Negative readings in the Shallow and Deep or excessive noise in the OpticMapper data.

Sensor readings should fluctuate gradually as you drive across the field, relating to

soil changes. If readings change erratically, or show values not typical of soil

in the area, perform tests 4-6 below.

In SoilViewer, watch for streaks, stripes, unnatural patterns, and missing data points.

4. Perform electrical continuity test on implement wiring:

at least once a day during mapping season

every 10 hours of mapping

after extended periods of non-use

after replacing or repairing coulter-electrode components or wiring

whenever readings are questionable

5. Perform Signal Testing Procedures #1 and #2:

at least once a day during mapping season

every 10 hours of mapping

after extended periods of non-use

whenever readings are questionable

6. Perform black/white reference OM System Check and OM Test Load Procedure #1

Before mapping every field

Whenever readings are questionable

7. Keep all electrical connections dirt and moisture-free

8. Limit speeds in rough or rocky field conditions. This will improve data quality, and will also

lengthen the service life of the implement components. NEVER EXCEED 15 M.P.H. FIELD

SPEED WHEN MAPPING EC/OM. NEVER EXCEED 7.5 M.P.H. WHEN MAPPING PH.

4-23

Page 44

Pub. #OM17-MSP3

OM Data Quality

Check depth of sensor – Make a couple of trial passes to make sure the sensor is running at the

proper depth. Recommended depth is 2-3 inches.

Add weights or adjust down pressure on row unit if needed

Also make sure the row unit side depth wheels and disks are rotating freely, and are clear of

excess mud and crop residue.

For row unit adjustments see page 4-22.

Monitoring the window –Observe OM readings at row ends when unit is raised, if they are not

within 10% of the initial raised readings, check windows for mud, smearing, and/or window

breakage.

Varying Field Conditions – In order to have high data quality the field conditions need to be the

same for an entire data set. Any of the following can affect data quality: in-field soil temperature

and moisture difference, change in down pressure or depth gauge wheel setting. If conditions

change, start a new file.

Figure 66 is an example of how these items can affect data quality.

4-24

Page 45

Pub. #OM17-MSP3

OpticMapper Wearplate

Below is a comparision of two wearplates. The left is a brand new wearplate, and the right has

about 2500 acres on it. Inspect the leading edge,shown below, as the steel wears the window can

chip or crack. As this contiunes to wear it will eventually need replaced.

Figure 67a & b

Wearplates will wear differently in every type of soil, so check it often. To replace wearplate refer

to Procedure #11

4-25

Page 46

Pub. #OM17-MSP3

Field Operation—pH Manager

Tools required for Field Operation adjustments

-3/16” allen wrench

-adjustable wrench: min. 10” (25 cm) length

-3/4” socket and wrench

-9/16” socket or wrench

-15/16” wrench

Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the

MSP3.

Install all transport locks before transporting or working underneath.

Always use the serivce stands when working underneath the MSP3.

Figure 68 Figure 69

4-26

Page 47

Pub. #OM17-MSP3

Power switch

must be on to

operate any

function

Manual-Auto switch:

must be in Automatic

mode for mapping;

in Manual mode for

manual control of

washing or sampler

shoe position

Sampler up and down:

raises sampler shoe

manually

Wash: On when washing

manually; Must be Off

for Automatic washing

Manually Operating Wash and Cycling Functions

After all cables and hydraulic hoses are connected, test power to unit by turning external pH

controller power switch to on position. With control switch in manual position, run wash pump

briefly. If water does not flow from jets within 10 seconds, disconnect quick couplers to help pumps

prime. If water doesn’t spray, but pump is running, see Troubleshooting section for instructions on

priming pump. If pumps don’t operate, recheck power cables and connections. If electrical power

to Controller is functioning, test hydraulics by locking hydraulic lever in position, and raising and

lowering sampler shoe using manual Up/Down switch. Test Raise/Lower functions on main lift

cylinder if equipped. Make sure no one is under unit and keep clear of any pinch points.

Figures 8a and 8b

Figure 70

4-27

Page 48

Pub. #OM17-MSP3

Operate implement parallel

to soil or slightly tipped (up

to ½”) forward never allow

unit to tip backward --this will

decrease shoe penetration.

Begin with a

dimension of

21” pin to pin

Adjust tractor or

implement top link to

level

Initial adjustment of

21”

Three-point Mounted Units

Raise sampling mechanism to full height. Begin depth adjustment process with shank in center

position (pin in one of two center holes). Adjust ratchet jack so that coulters will penetrate 1-2”

deep – 21” pin-to-pin is a good starting point Adjust three-point top link to level unit when in soil.

Figure 71 a,b,c

Figure 72

4-28

Page 49

Pub. #OM17-MSP3

pull adjustment pins and

lower shank if deeper

sampling is needed (and

EC coulter depth is

satisfactory)

sampling depth

is measured

from top of

cutting shoe to

soil surface

Once unit is level, lower sampling mechanism completely, drive forward 10-20’ (3-6 m) to create

soil core. To measure depth of soil core being collected, brush away soil from cutting shoe.

Measure from soil surface to top of cutting shoe. This is the depth of sampling. To increase

sampling depth, shorten ratchet jack; to decrease sampling depth, lengthen ratchet jack. Releveling unit with adjustable top link may be required.

Figure 73

Note: if MSP is equipped with EC Module and EC data is being collected along with pH data,

adjusting the overall height of the unit will affect coulter-electrode depth. If deeper soil sampling is

desired, and shortening ratchet jack would result in excessive coulter-electrode depth, remove

sampler shank pins and lower shank to lowest setting. If shallower soil sampling is required, and

lengthen ratchet jack results in inadequate coulter-electrode depth for EC data collection, raise

sampler shank to highest setting.

Figure 74

Once EC coulter depth and sampling depth are satisfactory, adjust other components in this

sequence:

1. Scraper adjustment: in manual mode hydraulically raise the sampling shoe to maximum height.

Adjust scraper until cutting shoe clears scraper blade when sampler shank is fully raised.

4-29

Page 50

Pub. #OM17-MSP3

Turn crank to raise

or lower electrode

holder

electrode

holder 1”

(2.5cm)

above wash

jets

Adjust scraper bracket

until cutting shoe

clears scraper when

sampler assembly is

raised completely.

½” (1.2 cm) clearance

between electrode holder

and trough liner

Figure 75

2. Adjust electrode holder: with sampling mechanism raised completely, adjust electrode

holder to provide ½” (1.2 cm) clearance between it and sampling trough.

Figures 76a and 76b

3. Wash adjustment: Wash brackets should be parallel to sampling trough, with jets directly

beside electrode holder, jets should be 1” (2.5 cm) below electrodes; when electrodes are

properly aligned.

Figures 77a and 77b

4-30

Page 51

Pub. #OM17-MSP3

Closing Disks

depth adjustment

pin

Closing disk

angle

adjustments

When wash jets are

properly aligned,

overspray is minimized

and water bubbles out

top of empty electrode

holder as shown here.

When installing BNC cover, route

electrode wires under box; center box

on white pad, and tighten wingnut finger

tight. Keep cover installed even when

electrodes are removed.

Figures 78a and 78b

4. Insert pH electrodes into electrode holder. Finger-tighten plastic screws. Install BNC cover

on external controller to keep moisture out of BNC connectors. Leave BNC cover on

whenever unit is outdoors.

5. Row cleaner/coulter: Pull MSP forward and check depth of row cleaner and coulter.

Cleaner should be clearing residue ahead of sampling shoe, but not gouging into soil.

6. Closing disks (if equipped): Adjust closing disks as needed to properly close trench and

bring residue over row-cleaned zone. Do not operate these deeper in soil than necessary.

Figures 80a and 80b

4-31

Page 52

Pub. #OM17-MSP3

1/4 to 3/8” gap

7. Prox sensor: The prox sensor communicates the position of the sampler assembly to the

external controller for automatic cycling functions. Adjust sensor to 1/4”- 3/8” (6-9 mm) gap.

Cycle unit manually to insure that this gap is maintained throughout cycling range. Red

LED light should light whenever prox sensor is near metal and not light when away from

metal. To view LED light, shade ambient light from prox sensor and cycle sampler

assembly manually. Be careful to not strike or damage prox sensor face. NOTE: in manual

mode, hydraulic cylinder opens and closes completely; in automatic mode cylinder stops as

soon as prox sensor clears upper and lower plate. In order for cylinder to set electrodeshoe clearance properly (step 2 above), adjust prox sensor height with sampler shoe

completely raised. Adjust the prox sensor so it barely clears the lower part of the sensor

plate when sampler is completely raised. It may be necessary to reposition the electrode

holder after adjusting prox sensor; see step 2 above.

Figure 81

Figure 82

4-32

Page 53

Pub. #OM17-MSP3

Mapping with Veris Datalogger

Connect EC signal cable and power cords to ports on rear of OpticMapper/EC Controller, connect

the GPS to the GPS in of the OM Comm. cable, then connect the serial output of the OM Comm.

to the EC port on the DataLogger. Attach the pH controller to the pH port on the datalogger.

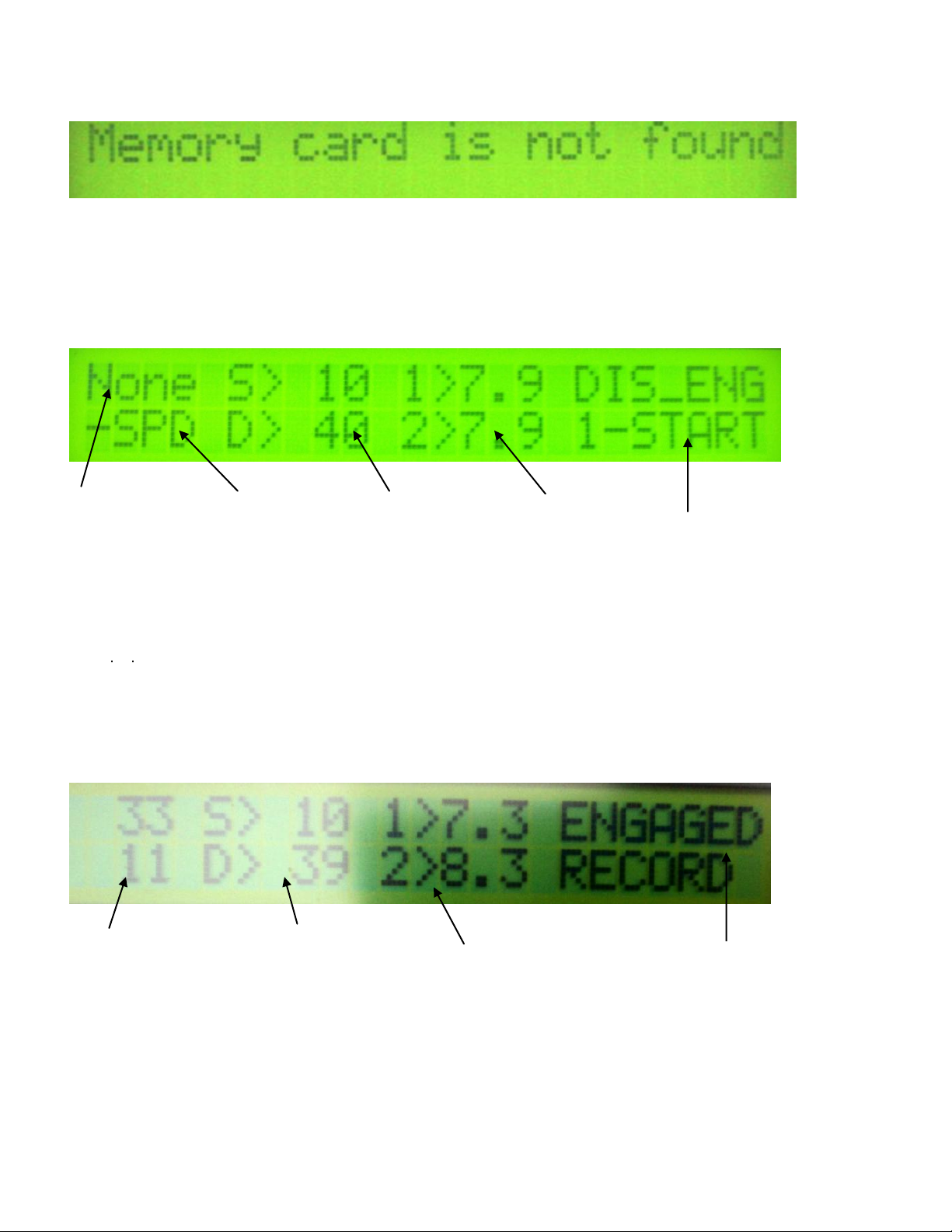

Press any button to continue

Figure 83

Press 1)Data Acqstn

Figure 84

Press 3)EC+OM+pH

Figure 85

Press any key to continue

Figure 86 The DataLogger is displaying the map file number it is creating, in case you want to

record it along with any other information about the field. Press any key to begin new map file.

After starting the file, pressing the #4 key will stop the file. If DataLogger freezes at the screen

shown in Figure 86, check formatting of SD card—must be FAT format.

If memory card was not inserted during boot-up, the following screen will appear:

Figure 87

Install card and re-start DataLogger. NEVER REMOVE CARD WHILE LOGGING DATA

4-33

Page 54

Pub. #OM17-MSP3

Ground speed

(from GPS) in

miles/hour

GPS status: may

read GPS, DGPS,

RTK, or None. If

None, no GPS signal

is received and no

data will be

recorded.

Shallow (S) and

Deep (D) soil

EC readings. If

negative, no

data will be

recorded.

pH sampler status

pH readings

from electrodes

1 and 2

OM reflectance

readings the top

is red the

bottom is IR

Shallow (S) and

Deep (D) soil

EC readings. If

negative, no

data will be

recorded.

pH readings

from electrodes

1 and 2

pH sampler status

This is the Data Acquisition screen with GPS status (note: GPS status will blink every second when

engaged to show the OM readings):

Figure 88

The acquisition screen with OM readings (note: GPS status has changed to show the OM

readings) The Datalogger will change from OM reflectance readings to GPS during mapping

Figure 89

The display is showing the pH values from the pH electrodes, conductivity of the top 1’ (30 cm) and

top 3’ (90 cm) of the soil, and whether you have GPS or DGPS or OM(differentially corrected)

signal. At any time during the mapping process, you can press the 4 key to stop the file. If you

create more than one file from the same field, you can bring the files into a spreadsheet program

and combine them prior to mapping. Note: the #1 key toggles the pH sampler from engaged to

disengaged; the #4 key stops the file.

From this screen, pressing the 1 key as you drive forward will initiate the automatic sampling

process. The software requires movement indicated by the GPS receiver in order to cycle.

Speed must be detected within 5 seconds after pressing 1 or the system will disengage.

If TAP or DI were selected as the wash water type above, the controller will go through a wash

baseline process after engage is pressed for the first time. The status text will change to the

following:

Figure 90

4-34

Page 55

Pub. #OM17-MSP3

After washing (or immediately if RO was selected as the wash water type), the unit will continue

cycling and display the following screen:

Figure 91

“Cycling” means the sampler assembly is in the process of washing, and lowering for soil sampling.

After a core has been collected and is being held against the electrodes, the status text will change

to the following:

Figure 92

The pH readings on the display show what each electrode is reading at every second. The

sampler will hold the soil against the electrodes and continue to record pH until the readings settle.

The minimum recording time is 7 seconds; the maximum time is determined in the pH settings

menu. The pH values that are recorded are the final values at the end of the logging duration. (last

reading on the display before the “Cycling” status appears). The final pH value is logged along

with the DGPS position where the sample was collected.

If the electrodes take longer than 10 seconds to settle, a warning will appear by the readings that

indicates the number of seconds the reading has required. When the maximum log time is

reached, a T will appear indicating that the measurement has ‘timed out’, and the unit initiates a

new sample cycle (refer to pH Controller settings for adjusting the log time).

Figure 93

This time warning is to let the operator know that a measurement cycle is requiring excessive time.

While an occasional cycle may exhibit this warning. see the troubleshooting section if this occurs

frequently.

4-35

Page 56

Pub. #OM17-MSP3

The Veris MSP pH Manager uses two electrodes for optimal data quality. If there is a difference of

0.75 or greater between the final electrode readings, an audible alarm will beep, informing the

operator of the erroneous reading.

To pause the data collection process at any time (but keep the same file), press the 1 key. Once

the sampling process has completed its cycle, it will disengage and the status text message will

indicate disengaged (press 1 to start cycling again). If the system no longer senses a speed signal

from the GPS, it will also disengage and return to Neutral. NOTE: do not depend on the GPS

speed signal for disengagement.

Before inspecting or working around any

component of the system, press the 1 key and

verify status of system is ‘Disengaged’ before

exiting the vehicle. Sporadic GPS signals may

simulate movement and initiate the cycling

process, resulting in possible entanglement and injury.

If TAP or DI are selected as the wash water type, the water baseline process will be repeated

every 40 cycles following the next engage press. If the pH during the cycling sequence does not

get within 0.5 of the baseline pH, an audible alarm will sound and the pH labels will blink. This is to

allow operator that the electrodes are not cleaning properly.

4-36

Page 57

Pub. #OM17-MSP3

EC – EC Surveyor connected to PC

OM – OpticMapper and GPS connected to PC

pH – pH controller and GPS connected to PC

EC and pH – EC Surveyor and pH controller connected to

PC

EC and OM – EC Surveyor and OpticMapper connected to

PC

EC OM pH-MSP3 – OpticMapper/EC Controller Surveyor

and pH controller connected to PC

To acquire data with the MSP3 only EC OM pH- MSP3

can be used. This will allow the user to collect all three

sensor readings, or collect only EC and OM if desired.

To acquire EC, OM and

pH data select Acquisition

Mapping with SoilViewer

Attach the pH serial communication cable to an available COM port on your computer. Connect EC

signal cable and power cords to ports on rear of OpticMapper/EC Controller, connect the GPS to

the GPS in of the OM Comm. cable, then connect the serial output of the OM Comm. to any

available COM port on your computer using a standard serial cable. If serial port is not available

on PC, then a USB to Serial converter can be used with the OpticMapper with EC Surveyor

provided the drivers for the converter are installed and functioning properly.

SoilViewer startup display

Figure 94

Figure 95

4-37

Page 58

Pub. #OM17-MSP3

After clicking on EC OM

pH- MSP3 the user will

be prompted to input the

EC file name. All OM

and pH files will be

named the same as the

EC. Files may be

appended to by

selecting a previously

created VSEC file.

The EC OM pH-MSP3 Mapping software will automatically detect which ports the Veris

OpticMapper/EC Controller and pH Controller are connected to, and begin communicating,

provided the power to the OpticMapper and pH is turned on. If either is not detected, the software

will wait 45 seconds for the connection of the electronics and search again; this will repeat until

both instruments are connected and powered on. If the electronics are not found, unplug the serial

or USB cables and reconnect them to the PC and make sure the power to the OpticMapper and

pH controllers are turned on. If the connections are still not made, refer to SoilViewer

troubleshooting. The conditions for mapping and storing the data are as follows. The user must be

going a speed greater than 1 mph, there must be a GPS signal received that includes position and

speed (GGA and either VTG or RMC), the OM/EC Comm Light must be green, indicating the PC

and OpticMapper with EC Surveyor are communicating properly, and either of the EC values has

to be greater than -1.

Before mapping, run the OM system check and pH calibration to ensure everything is

operating correctly. pH controller settings can be modified to adjust the wash and cycle

times for specific field conditions.

Figure 96

4-38

Page 59

Pub. #OM17-MSP3

pH readings

from each

electrode

Status of pH

controller; Green

means the

controller is

engaged while

Red means it is

disengaged and

will not

automatically

cycle

Ground

speed (from

GPS) in

miles/hour

GPS status:

may read

GPS, DGPS,

RTK, or None

Shallow (Sh) and

Deep (Dp) soil EC

readings. If negative,

no data is being

saved.

Point size for EC,

OM and pH values;

adjust point size to

fill transects and

display spatial

structure to map.

Ranges used to map pH values. Each color

should have a unique range associated with

it. These are user-defined ranges and can

be changed at any time. If points appear

to be missing from the map, it could be that

they are out of the ranges selected. pH min

and pH max can be used as guidelines for

setting up the pH ranges. Up to five

divisions can be selected

These EC and OM

ranges are not user

selectable and are

set by the software

which gives each

range the same

number of points.

Colors for the graphs

can be set here, by

clicking on the color

box and selecting a

new color.

Control used to

change

between EC

arrays

Status of pH

sampling

mechanism

OM/EC Comm.

and pH Comm.

Lights; when

green these

indicate there is

communication

with the

controllers.

Cancel Search

– This stops

the software

from searching

for the pH or

OM controllers.

This is helpful

when the

operator only

wants to map

EC and OM, or

in previewing

data that was

previously

collected.

Figure 97

4-39

Page 60

Pub. #OM17-MSP3

Press Engage

to start pH

sampler

cycling.

Figure 98

From this screen, pressing the Engage key or Enter as you drive forward will initiate the automatic

sampling process. The software requires movement indicated by the GPS receiver in order to

cycle. Speed must be detected within 5 seconds after pressing enter or the system will disengage.

If TAP or DI were selected as the wash water type above, the controller will go through a wash

baseline process after engage is pressed for the first time. The status text will change to the

following:

Figure 99

After washing the unit will continue cycling and sampler status will display Cycling, while the

Engage light is green:

Figure 100

4-40

Page 61

Pub. #OM17-MSP3

“Cycling” means the sampler assembly is in the process of washing, and lowering for soil sampling.

After a core has been collected and is being held against the electrodes, the status text will change

to the following:

Figure 101

The pH readings on the display show what each electrode is reading at every second. The

sampler will hold the soil against the electrodes and continue to record pH until the readings settle.

The minimum recording time is 7 seconds; the maximum time is determined in the pH settings

menu. The pH values that are recorded are the final values at the end of the logging duration. (last

reading on the display before the “Cycling” status appears). The final pH value is logged along

with the DGPS position where the sample was collected.

If the electrodes take longer than 10 seconds to settle, a warning will appear that indicates the

number of seconds the reading has required to settle. When the maximum log time is reached, the

unit initiates a new sample cycle (refer to Controller setup for adjusting the log time).

Figure 102

This time warning is to let the operator know that a measurement cycle is requiring excessive time.

While an occasional cycle may exhibit this warning; see the troubleshooting section if this occurs

frequently.

The Veris MSP pH Manager uses two electrodes for optimal data quality. If there is a difference of

0.75 or greater between the final electrode readings, the software will beep and the pH readings

will flash, informing the operator of the erroneous reading.

To pause the data collection process at any time (but keep the same file), press Engage button.

Once the sampling process has completed its cycle, it will disengage and the status text message

will indicate disengaged (press Engage to start cycling again). If the system no longer senses a

speed signal from the GPS, it will also disengage. NOTE: do not depend on the GPS speed signal

for disengagement.

Before inspecting or working around any

component of the system, press the Engage key

and ensure the engage light is red before exiting the

vehicle. Sporadic GPS signals may simulate

movement and initiate the cycling process,

resulting in possible entanglement and injury.

4-41

Page 62

Pub. #OM17-MSP3

If TAP or DI are selected as the wash water type, the water baseline process will be repeated

every 40 cycles following the next engage press. If the pH during the cycling sequence does not

get within 0.5 of the baseline pH, the computer speakers will beep and the pH labels will blink. This

is to allow operator that the electrodes are not cleaning properly.

There are warning signals programmed into the SoilViewer to warn the operator that data are not

being recorded, so that corrective action can be taken. If data aren’t being recorded, a warning

beep will sound from the computer, and the text indicator of the data that is missing information will

blink. For example, if the DGPS isn’t being received (or the NMEA string containing speed) the Fix

indicator text will blink. If EC values are negative, they will also blink.

pH Data Flags

Numbered “flags” can be added to the pH data by pressing the Flag key or F2 while the pH

Manager is CYCLING or RECORDING. If the key is pressed while the pH Manager is in the

RECORDING phase, the flag light will turn bright green:

Figure 103

This means the flag will be recorded with the current data point. If the key is pressed while the pH

Manager is in the CYCLING phase, the next point will be flagged and flag light will not turn green

until the RECORDING phase is reached. Tip: Use this function to flag any sample where a problem

has occurred, such as a plugged shoe. Open the pH file in a spreadsheet program, locate the

points that have been flagged, and delete rows of problem data.

4-42

Page 63

Pub. #OM17-MSP3

4-43

Page 64

Pub. #OM17-MSP3

4-44

Page 65

SECTION 5

Pivot grease

zerks (2 per

hangar; 4 total )

grease zerks

Maintenance and Service

Soil EC

Rockshaft pivot points Each pivot (located at the left and right) contains

an upper and lower grease zerk. Due to the limited motion of the

rockshaft, these should be lubricated on 20-hour intervals. This may

vary based on the number of times the unit is raised and lowered.

Pub. #OM17-MSP3

Figure 1

Rachet jack 20 hour intervals

Figure 2

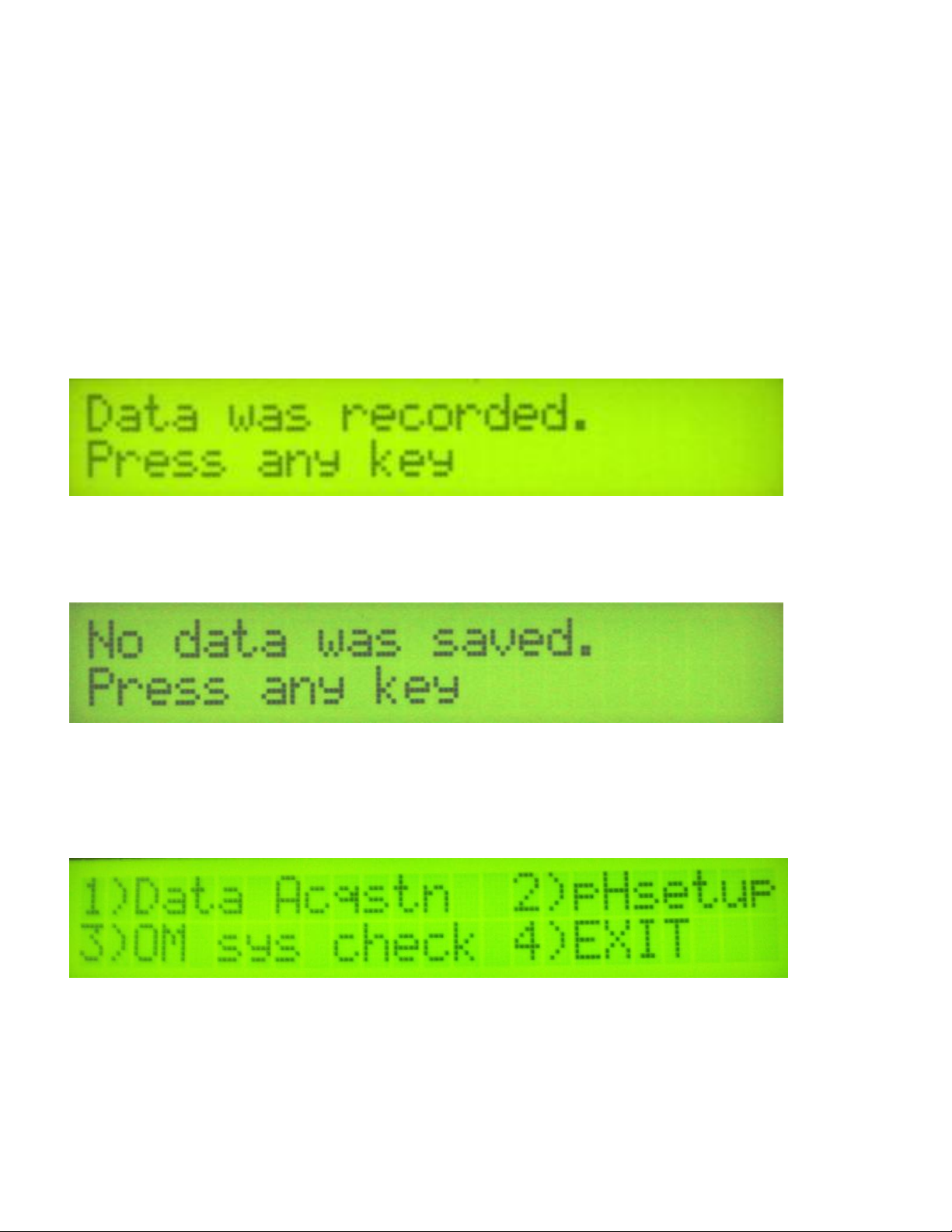

Electrode coulters Pivot --In all but the most extremely rocky conditions, the coulter electrodes

should not flex in the field, thus minimal movement will be realized at the pivot. 80-hour intervals

should be sufficient.

5-1

Page 66

Pub. #OM17-MSP3

grease zerk

Figure 3 Figure 4

Hubs --Use good quality wheel bearing or lithium grease for lubrication, but we suggest that you

grease the hubs sparingly. Over-lubricating the hub will result in pre-mature seal failure, and an

excessive amount of grease in the hub cap/commutator. On an interval of 150 hours, 1-2 strokes

of grease should be sufficient.

Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the

Veris MSP3.

Install all transport locks before transporting or working underneath.

Always use the service stands when working underneath the MSP3.

Figure 5 Figure 6

5-2

Page 67

OpticMapper Row unit

Figure 7

Figure 8

Figure 9

Setting Sensor Depth

Refer to Figure 7

The “T” handle (1) sets sensing depth by limiting the how

high the side depth gauge wheels ride relative to the

opener disks. To adjust sensing depth, pull the “T” handle

(1) up and back,move it forward or aft, and set it back in a

different pair of holes in the scale.

• For shallower sensing, move the “T” handle (1) forward.

• For deeper sensing, move the “T” handle (1) back.

Opener Disc Contact Region

Refer to Figure 8

Opener disc angle and stagger is not adjustable, but

disc-to-disc spacing is, and may need attention as discs

experience normal wear. Spacers will need to be reset

when blades are replaced.

The ideal spacing causes the blades to be in contact for

about one inch (4) . If you insert two pieces of paper

between the blades, they should slide to within zero

(touching) to 1.5in (3.8cm) of each other. If zero, the gap

between the blades should not be significantly greater

than the thickness of two sheets of paper.

If the contact region is significantly larger or there is a

large gap, it needs to be adjusted by moving one or more

spacer washers.

Adjusting Disc Contact

Refer to Figure 9

1. Raise the Implement.

2. Remove the side gauge wheels (5) on the row unit in

need of adjustment.