Page 1

LDRA6 USER GUIDE

RLE TECHNOLOGIES

Page 2

©2008 RLE Technologies 110046 Rev 1.6 (08/2008)

Page 3

SEAHAWK LDRA6

Page 4

PRODUCT REGISTRATION

Product registration helps RLE Technologies inform owners of:

• Product Upgrades

• Firmware Enhancements

• New products and Technologies

• Special Offers Available Only to Registered Users

Submit registration information on the Support/Product Registration webpage at www.rletech.com

**Any information provided to RLE Technologies through the registration form will be regarded as confidential.

To read our Privacy Policy, please visit our website: rletech.com

TECHNICAL SUPPORT

Personal assistance is available Monday through Friday, from 8:00 a.m. to 5:00 p.m. MST.

For more information, please visit the Documentation/Files section on the

LDRA6 webpage of our website at www.rletech.com

A request for assistance may be sent to support@rletech.com

Otherwise, please call us directly at: (970) 484-6510 - press “2” for technical support

The following information is located on the bottom of each LDRA6 unit.

Please have this information available whenever a technical support call is placed:

Product Model Number _____________________________________________________

Product Serial Number _____________________________________________________

Product Manufacture Date ___________________________________________________

.

.

.

©2008 RLE Technologies 110046 Rev 1.6 (08/2008)

Page 5

User Guide: LDRA6 Table of Contents

TABLE OF CONTENTS

Chapter 1: Product Overview ........................................................................................................................................2

1-1 Description......................................................................................................................................................2

1-2 LDRA6 Front Panel Indicators .......................................................................................................................2

1-2.1 Zone LEDs ...........................................................................................................................................2

1-2.2 Power LED...........................................................................................................................................2

1-2.3 Audible Alarm......................................................................................................................................2

1-2.4 Quiet/Test/Reset Switch.......................................................................................................................2

Chapter 2: Connections & Settings ...............................................................................................................................4

2-1 LDRA6 Board .................................................................................................................................................4

2-1.1 TB1 – Power ........................................................................................................................................5

2-1.2 POW1 – Power.....................................................................................................................................5

2-1.3 TB2, TB3 – Zone Inputs.......................................................................................................................5

2-1.4 TB5, TB4 – Zone Alarm Relays...........................................................................................................5

2-1.5 TB6 - Summary Relay..........................................................................................................................6

2-1.6 TB7 – RS485 Connection.....................................................................................................................6

2-2 SW1 - Relays and Alarm.................................................................................................................................7

2-2.1 SW1, Position 1: Summary Relay Supervised / Unsupervised ............................................................7

2-2.2 SW1, Position 2: Relays Latched / Unlatched......................................................................................7

2-2.3 SW1, Position 3: Zone Relay Linkage .................................................................................................7

2-2.4 SW1, Position 4: Zone Relays Supervised / Unsupervised .................................................................. 7

2-2.5 SW1, Positions 5: Leak Alarm Delay...................................................................................................7

2-2.6 SW1, Positions 6: Summary Relay Silence-Ability .............................................................................7

2-2.7 SW1, Positions 7 and 8: Re-alarm Time ..............................................................................................8

2-3 SW2 – Modbus Addressing.............................................................................................................................8

2-4 SW4 through Sw9 ...........................................................................................................................................8

2-5 R1 – Leak Detection Cable Sensitivity Setting ...............................................................................................8

Chapter 3: Installation ...................................................................................................................................................9

3-1 Before You Begin ...........................................................................................................................................9

3-2 Connecting the Water Leak Detection Cable ..................................................................................................9

3-2.1 Secure the Cable to the Floor ...............................................................................................................9

3-2.2 Recommended Cable Installation.......................................................................................................10

3-3 Apply Power to the Unit ...............................................................................................................................11

3-3.1 Power via Wall Adapter .....................................................................................................................11

3-3.2 Power via Direct Line.........................................................................................................................11

Chapter 4: Start-Up......................................................................................................................................................12

4-1 Boot-Up.........................................................................................................................................................12

4-2 Displaying the Help Menu ............................................................................................................................12

4-3 Function Commands .....................................................................................................................................13

4-3.1 c – Contact Closure Settings ..............................................................................................................13

4-3.2 ld – Leak Delay Setting......................................................................................................................13

4-3.3 sens – Leak Zone Sensitivity.............................................................................................................. 13

4-3.4 e – View Eeprom Data .......................................................................................................................14

4-3.5 er – Erase Eeprom Data – Restores Factory Defaults.........................................................................14

4-3.6 mbb – View / Change Modbus Baud Rate ......................................................................................... 14

4-3.7 mbp – View / Change Modbus Parity ................................................................................................14

4-3.8 mr – Reset Modbus Port and Statistics...............................................................................................14

4-3.9 m – View Modbus Port Settings and Statistics...................................................................................14

4-3.10 t – Toggle Modbus Trace On/Off.......................................................................................................15

4-3.11 z – Display Leak Zone Readings........................................................................................................15

4-3.12 sr – summary relay mode ...................................................................................................................15

4-3.13 zr – zone relay mode ..........................................................................................................................15

4-3.14 x – Exit to Bootloader ........................................................................................................................15

www.rletech.com 970 484-6510 i

Page 6

Table of Contents User Guide: LDRA6

Appendix A: Modbus Communications ..................................................................................................................... 16

A-1 Modbus Implementation of the LDRA6....................................................................................................... 16

A-1.1 Modes of Transmission ..................................................................................................................... 16

A-1.1.1 Slave Address Field ................................................................................................................ 16

A-1.1.2 Function Field ......................................................................................................................... 16

A-1.1.3 Data Field................................................................................................................................ 16

A-1.1.4 Error Check Field.................................................................................................................... 16

A-2 Packet Communications for the LDRA6...................................................................................................... 17

A-2.1 Read Output Registers....................................................................................................................... 17

A-2.2 Read Input Registers.......................................................................................................................... 18

A-2.3 Present Single Register...................................................................................................................... 19

A-2.4 Present Multiple Registers................................................................................................................. 19

A-3 RTU Framing ............................................................................................................................................... 20

A-4 Modbus Mirroring ........................................................................................................................................ 21

Appendix B: Troubleshooting .................................................................................................................................... 22

Appendix C: Technical Specifications........................................................................................................................ 23

ii 970 484-6510 www.rletech.com ii

Page 7

User Guide: LDRA6 List of Figures and Tables

LIST OF FIGURES AND TABLES

Figure 1-1: LDRA6 Front Panel Indicators ..................................................................................................................3

Figure 2-1: LDRA6 Board............................................................................................................................................4

Figure 3-1: Water Leak Detection Cable......................................................................................................................9

Figure 3-2: Cable Installation Methods ...................................................................................................................... 10

Table 1: Read Output Registers Packet Structure.......................................................................................................17

Table 2: Output Registers...........................................................................................................................................17

Table 3: Read Input Registers Packet Structure .........................................................................................................18

Table 4: Input Registers..............................................................................................................................................18

Table 5: Status Flags (Register 30001).......................................................................................................................18

Table 6: Status Flags (Register 30008).......................................................................................................................19

Table 7: Present Single Register Packet Structure......................................................................................................19

Table 8: Present Multiple Registers Packet Structure .................................................................................................19

Table 9: Modbus Slave Address................................................................................................................................. 20

Table 10: Query Sample.............................................................................................................................................20

Table 11: Response Sample........................................................................................................................................20

www.rletech.com 970 484-6510 iii

Page 8

Chapter 1: Product Overview User Guide: LDRA6

CHAPTER 1: PRODUCT OVERVIEW

1-1 DESCRIPTION

The LDRA6 is a complete monitoring system that detects and reports the presence of water and other

conductive liquids, as well as monitors dry contact alarm points. The LDRA6 couples SeaHawk Water

Leak Detection Cable (SC) with an advanced control head to monitor six individual zones. When a

conductive liquid comes in contact with the SC cable, an alarm sounds and the summary alarm relay and

zone relay activate. The LED that corresponds with the appropriate zone also illuminates and an audible

alarm is activated. Each LDRA6 input can also be configured to detect a dry contact’s change of state (NO

or NC) and annunciate the alarm on the front panel.

The LDRA6 is a supervised system - it continuously monitors the cable for leaks and cable integrity. A

cable break causes a cable fault indication. An alarm sounds and the appropriate zone relay and the

summary alarm relay activate. The appropriate LED changes to indicate a cable fault has occurred.

The dry contact relays in the LDRA6 may be configured as supervised or unsupervised (see section 2-2 for

configuration options). Each zone can be configured with unique, individual settings. When the user

specified alarm condition occurs, the LDRA6 activates the appropriate relay and alarm LED.

NOTE

The LDRA6 produces an alarm in the following conditions:

:

Leak Detected

Cable Fault

Dry Contact Alarm Condition (User Specified)

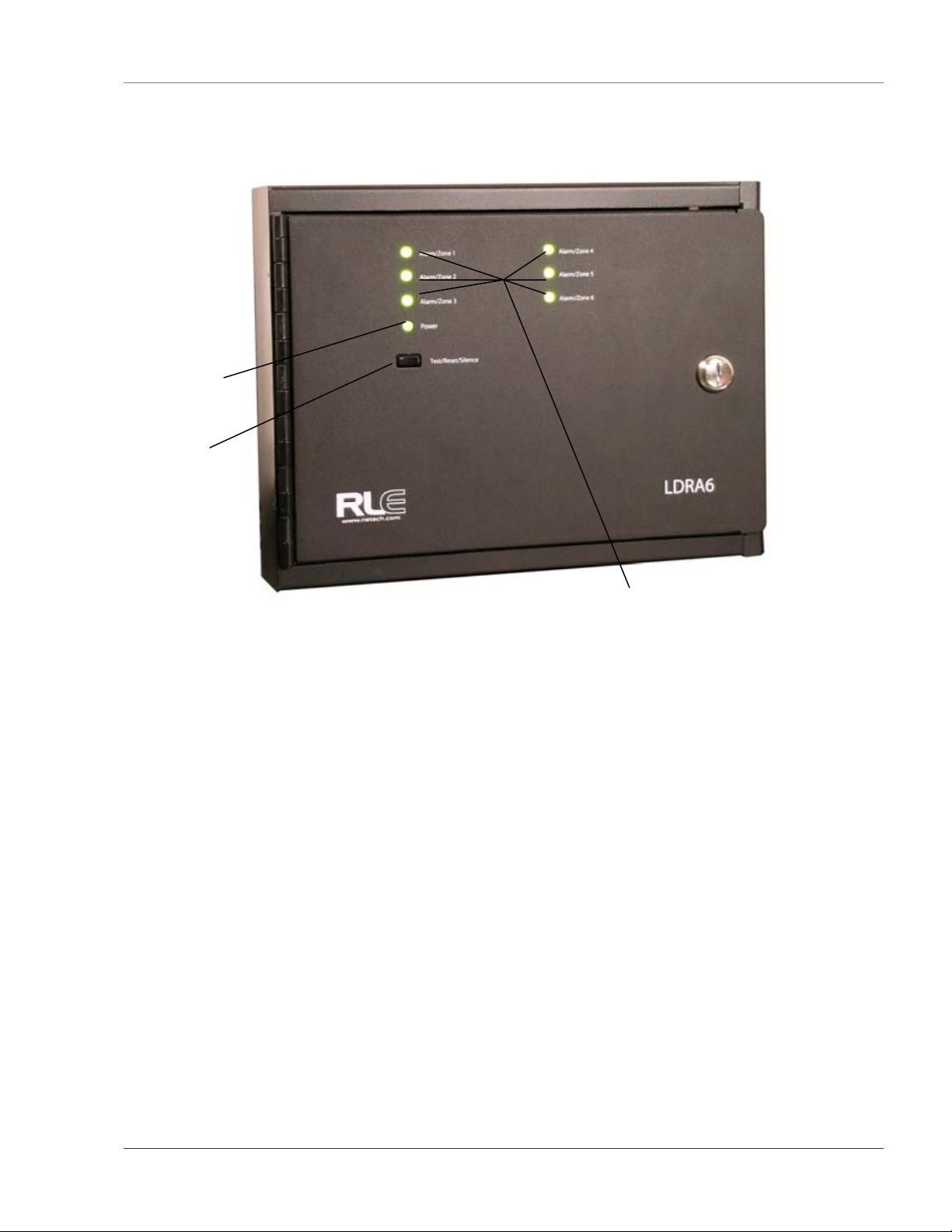

1-2 LDRA6 FRONT PANEL INDICATORS

1-2.1 Zone LEDs

One tri-color LED for each zone.

Default Leak Detection Cable Setting:

On solid and green for normal cable conditions.

Flashes quickly and turns red if a leak is detected in the zone.

Flashes quickly and turns yellow if a cable fault is detected in the zone.

On solid once an alarm is silenced.

Default Dry Contact Setting:

On solid and green for normal, non-alarm conditions.

Flashes quickly and turns red (by default) if an alarm condition is detected in the zone.

On solid once an alarm is silenced.

1-2.2 Power LED

On (green) as long as power is on.

1-2.3 Audible Alarm

Activates when an alarm condition is detected. Silenced with the Quiet/Test/Reset switch.

1-2.4 Quiet/Test/Reset Switch

During alarm, the audible alarm is silenced, and any LED(s) in alarm will glow solidly. If the alarm goes

away, the LED(s) will flash slowly. Hold down the Quiet/Test/Reset switch to reset all alarms and

complete and self test cycle. If any alarms still exist, the unit will not reset the corresponding zones.

www.rletech.com 970 484-6510 2

Page 9

User Guide: LDRA6 Chapter 1: Product Overview

Power LED

Test / Reset/ Silence Switch

Leak /Cable Detected LEDs

Figure 1-1: LDRA6 Front Panel Indicators

3 970 484-6510 www.rletech.com

Page 10

Chapter 2: Product Overview User Guide: LDRA6

CHAPTER 2: CONNECTIONS & SETTINGS

2-1 LDRA6 BOARD

The LDRA6’s zone connectors, labeled TB2, are found at the bottom of the board on the double-stacked

terminal block. The switches on the board are labeled SW1 and SW2. The unit has one dial, labeled R1,

which is used to manually adjust the sensitivity for all zones. Sensitivity for individual zones may be

configured through the LDRA6’s RS232 Craft Port configuration, labeled P2. The switches for

configuring Dry Contact or Leak Detection monitoring for zones are labeled SW4 through SW9.

P2

RS232

R1

Leak Sensitivit

SW4 – SW9

y

Zone

Configuration

TB7

RS485

TB6

Summary

Relay

TB5

Zone

Alarm

Relays

TB4

Zone

Alarm

Relays

Zone

Figure 2-1: LDRA6 Board

TB3

TB2

Zone

POW1

Power

TB1

Power

www.rletech.com 970 484-6510 4

Page 11

User Guide: LDRA6 Chapter 2: Connections & Settings

2-1.1 TB1 – Power

The LDRA6 connects to a 24VDC power supply using TB1, a two position connector labeled 24VDC.

2-1.2 POW1 – Power

Power can also be supplied to the unit through POW1. This is a wall adapter plug connection. This also

requires 24VDC.

2-1.3 TB2, TB3 – Zone Inputs

SeaHawk Leak Detection Cable (SC) and/or dry contact wires connect to the LDRA6 through TB2. Fifteen

foot (4.57m) leader cables (one is included in each leader cable kit, part #LC-KIT) are required for leak

detection cable connections only. Dry contact wires must be user supplied or may be supplied with your

dry contact device. Connect cables/wires as follows:

Position Leak Detection Cable Dry Contact Wire

TB3-1 Zone 1 White Zone 1 Input-1

TB3-2 Zone 1 Black Zone 1 Input-2

TB3-3 Zone 1 Green N/A

TB3-4 Zone 1 Red N/A

TB3-5 Zone 2 White Zone 2 Input-1

TB3-6 Zone 2 Black Zone 2 Input-2

TB3-7 Zone 2 Green N/A

TB3-8 Zone 2 Red N/A

TB3-9 Zone 3 White Zone 3 Input-1

TB3-10 Zone 3 Black Zone 3 Input-2

TB3-11 Zone 3 Green N/A

TB3-12 Zone 3 Red N/A

TB2-1 Zone 4 White Zone 4 Input-1

TB2-2 Zone 4 Black Zone 4 Input-2

TB2-3 Zone 4 Green N/A

TB2-4 Zone 4 Red N/A

TB2-5 Zone 5 White Zone 5 Input-1

TB2-6 Zone 5 Black Zone 5 Input-2

TB2-7 Zone 5 Green N/A

TB2-8 Zone 5 Red N/A

TB2-9 Zone 6 White Zone 6 Input-1

TB2-10 Zone 6 Black Zone 6 Input-2

TB2-11 Zone 6 Green N/A

TB2-12 Zone 6 Red N/A

2-1.4 TB5, TB4 – Zone Alarm Relays

These are the Zone Alarm Relay output terminal blocks (Form C). A status LED is located above each

relay, which will indicate the state of the relay (on/off). These relays can be configured as supervised or

unsupervised, latched or unlatched (unsupervised and unlatched by factory default). Connect the Zone

Alarm Relay wires to TB3 and TB4 as follows:

TB5-1 Zone 1 alarm relay normally open (NO)

TB5-2 Zone 1 alarm relay common (C)

TB5-3 Zone 1 alarm relay normally closed (NC)

TB5-4 Zone 2 alarm relay normally open (NO)

TB5-5 Zone 2 alarm relay common (C)

TB5-6 Zone 2 alarm relay normally closed (NC)

5 970 484-6510 www.rletech.com

Page 12

Chapter 2: Product Overview User Guide: LDRA6

TB5-7 Zone 3 alarm relay normally open (NO)

TB5-8 Zone 3 alarm relay common (C)

TB5-9 Zone 3 alarm relay normally closed (NC)

TB4-1 Zone 4 alarm relay normally open (NO)

TB4-2 Zone 4 alarm relay common (C)

TB4-3 Zone 4 alarm relay normally closed (NC)

TB4-4 Zone 5 alarm relay normally open (NO)

TB4-5 Zone 5 alarm relay common (C)

TB4-6 Zone 5 alarm relay normally closed (NC)

TB4-7 Zone 6 alarm relay normally open (NO)

TB4-8 Zone 6 alarm relay common (C)

TB4-9 Zone 6 alarm relay normally closed (NC)

2-1.5 TB6 - Summary Relay

This is the Summary Relay output terminal block (Form C). A status LED is located to the right of the

relay, which will indicate the state of the relay (on/off). This relay can be configured as supervised or

unsupervised, latched or unlatched. Connect the Summary Relay wires to TB5 as follows:

TB6-1 Summary alarm normally open (NO)

TB6-2 Summary alarm common (C)

TB6-3 Summary alarm normally closed (NC)

2-1.6 TB7 – RS485 Connection

The LDRA6 can communicate with other devices through the RS485 terminal block. Wire as follows:

TB7-1 + or A wire

TB7-2 – or B wire

TB7-3 Shield or GND wire

www.rletech.com 970 484-6510 6

Page 13

User Guide: LDRA6 Chapter 2: Connections & Settings

2-2 SW1 - RELAYS AND ALARM

2-2.1 SW1, Position 1: Summary Relay Supervised / Unsupervised

Configures the Summary Alarm relay as supervised or unsupervised. If a relay is supervised, the relay

picks until power goes off or until an alarm is detected. The alarm then releases to announce a change in

state. An unsupervised relay picks only when an alarm is detected.

1 = Supervised

0 = Unsupervised (factory default)

2-2.2 SW1, Position 2: Relays Latched / Unlatched

Configures all relays as latched or unlatched. If a relay is latched, the relay will remain in an alarm

condition until the Reset switch is pressed. If a relay is unlatched, the relay will remain in alarm until

either the Reset switch is pressed, or the condition that tripped the relay goes away.

1 = Latched

0 = Unlatched (factory default)

2-2.3 SW1, Position 3: Zone Relay Linkage

Configures all Zone Alarm Relays to link together and pick simultaneously upon alarm. When this switch

is turned on, if a zone goes into alarm, all six zone alarm relays and the summary alarm relay will pick.

When this switch is turned off, if a zone goes into alarm, only the zone alarm relay for the zone that is in

alarm and the summary alarm relay will pick.

1 = Individual Zone Alarm Relays Linked

0 = Individual Zone Alarm Relays Not Linked (factory default)

2-2.4 SW1, Position 4: Zone Relays Supervised / Unsupervised

Configures the individual Zone Alarm Relays as supervised or unsupervised. If a relay is supervised, the

relay picks until power goes off or until an alarm is detected. The alarm then releases to announce a change

in state. An unsupervised relay picks only when an alarm is detected.

1 = Supervised

0 = Unsupervised (factory default)

2-2.5 SW1, Positions 5: Leak Alarm Delay

Designates the unit’s leak delay time. Setting this switch to off uses the default leak alarm delay of 15

seconds. Setting this switch to on designate the leak alarm delay to use the value specified through the

unit’s craft port.

1 = Leak Alarm Delay set through Craft Port

0 = Leak Alarm Delay set at 15 seconds (factory default)

2-2.6 SW1, Positions 6: Summary Relay Silence-Ability

Configures the Summary Alarm Relay as silence-able or not silence-able. If the Summary Alarm Relay is

silence-able, the relay returns to normal when the Quiet/Test/Reset button is pressed. If the Summary

Alarm Relay is not silence-able, the relay stays picked until the alarm condition is cleared.

1 = Summary Alarm Relay is Silence-Able

0 = Summary Alarm Relay is Not Silence-Able (factory default)

7 970 484-6510 www.rletech.com

Page 14

Chapter 2: Product Overview User Guide: LDRA6

2-2.7 SW1, Positions 7 and 8: Re-alarm Time

Configures the unit’s re-alarm time. Set the switches as below for desired (approximate) re-alarm times:

1 1 = 24 hours

0 1 = 16 hours

1 0 = 8 hours

0 0 = Disabled; no re-alarming once silenced (factory default)

2-3 SW2 – MODBUS ADDRESSING

Configures the unit’s RS485 address. The unit’s address is set in bits and can range from 00000001 to

11111110 (1-254 in decimal notation).

00000000 = No Address (factory default)

00000001 = 1

00000010 = 2

00000011 = 3

…

11111101 = 253

11111110 = 254

2-4 SW4 THROUGH SW9

Configures each zone as a Leak Detection Cable input or a Dry Contact input. If configured as a Leak

Detection Cable input, the zone requires a 4-wire leak detection cable (SC) to monitor. If configured as a

Dry Contact input, the zone requires a 2-wire dry contact device to monitor. If any zone is not desired to be

used, set the zone to Dry Contact and normally open (factory default) to avoid unwanted alarms.

SW4 Up = Zone 1 is a Dry Contact input

SW4 Down = Zone 1 is a Leak Detection input

SW5 Up = Zone 2 is a Dry Contact input

SW5 Down = Zone 2 is a Leak Detection input

SW6 Up = Zone 3 is a Dry Contact input

SW6 Down = Zone 3 is a Leak Detection input

SW7 Up = Zone 4 is a Dry Contact input

SW7 Down = Zone 4 is a Leak Detection input

SW8 Up = Zone 5 is a Dry Contact input

SW8 Down = Zone 5 is a Leak Detection input

SW9 Up = Zone 6 is a Dry Contact input

SW9 Down = Zone 6 is a Leak Detection input

2-5 R1 – LEAK DETECTION CABLE SENSITIVITY SETTING

This potentiometer allows users to manually adjust the sensitivity setting for all six zones. Turn the dial

clockwise to make the zone less sensitive. This means a leak will be reported in that zone when a large

amount of water is present. Turn the dial counterclockwise to make the zone more sensitive. This means a

leak will be reported for the zone when a small amount of water is present.

This potentiometer can be overridden through the LDRA6’s craft port configuration for individual zones

(see section 4-3.3 for details).

www.rletech.com 970 484-6510 8

Page 15

User Guide: LDRA6 Chapter 3: Installation

CHAPTER 3: INSTALLATION

3-1 BEFORE YOU BEGIN

The LDRA6 is a wall mounted device. To secure the device to the wall, first open the door of the

enclosure. There are knockouts on the top and bottom of the enclosure. Remove as many as necessary.

Use drywall anchors and the holes in the back of the enclosure to secure the unit to the wall.

3-2 CONNECTING THE WATER LEAK DETECTION CABLE

A leader cable kit (part #LC-KIT) is required per zone to connect the LDRA6 to SeaHawk Leak Detection

Cable (SC). A leader cable is included in each LC-KIT; one end of this leader cable connects into the

LDRA6. This end of the cable is finished with stripped, bare wires. The other end features a mating

connector which connects with the SC cable. The end of the cable zone requires a removable end

terminator (EOL) which is also included in a leader cable kit (LC-KIT).

NOTE

A Leader Cable Kit (part #LC-KIT) is required per zone to connect the LDRA6 to

SeaHawk Leak Detection Cable (SC). Each LC-KIT includes a 15 foot (4.57m) leader

cable and an EOL terminator. The kits are NOT included with the LDRA6, and can

be purchased separately.

To connect the leader cable to the LDRA6, connect the wires (4) to the appropriate zone position of the

terminal block connectors (see section 2-1.3 for more wiring details). Adjust the appropriate zone

configuration for Leak Detection input (see section 2-4 for more details).

Once the leader cable is plugged into the terminal block, it is ready to be connected to the SC cable. To do

this, unscrew the EOL terminator from the end of the leader cable. Attach the first length of SC cable to

the leader cable. Route the SC cable according to the cable layout diagram, if provided. Lay the cable

according to figure 3-1 and section 3-2.1. Secure the EOL terminator on the unoccupied end of the SC

cable.

:

Figure 3-1: Water Leak Detection Cable

3-2.1 Secure the Cable to the Floor

Secure the cable to the floor with either J-clips (part #JC) or one of the other approved methods shown in

Figure 3-2. J-clips are the manufacturer’s recommended installation method.

Place one J-clip every three feet along the length of the SC cable. Place one J-clip at each turn of

the cable.

9 970 484-6510 www.rletech.com

Page 16

Chapter 3: Product Overview User Guide: LDRA6

If the cable is installed over an obstruction, clip the cable on both sides, as close to the obstruction

as possible.

Do not install the cable directly in front of an air conditioner. Allow a minimum of 6 feet (1.83m)

between the unit and the cable. If the SC cable is too close to the air conditioning unit’s air stream,

the moisture from the humidifier may cause false leak readings. If the cable must be installed in

front of an air conditioning unit, place the J-clips 12 to 18 inches (.305m to .457m)apart.

NOTE

It is important to finish the end of the SeaHawk Leak Detection Cable (SC) with the

end-of-line terminator (EOL). If the EOL terminator is not present, a cable fault will

register. Note any variances between the cable layout diagram and the actual cable

installation. Wait approximately one minute. No alarm should be present.

:

3-2.2 Recommended Cable Installation

Figure 3-2: Cable Installation Methods

www.rletech.com 970 484-6510 10

Page 17

User Guide: LDRA6 Chapter 3: Installation

3-3 APPLY POWER TO THE UNIT

Once cable for all the desired leak detection zones has been connected to the unit, power may be applied.

The LDRA6 operates on 24VDC power supplied by a wall adapter or a direct line. A power supply should

be run to the location of the unit.

3-3.1 Power via Wall Adapter

The LDRA6 can be powered by a wall adapter. Before connecting the wall adapter to the LDRA6, unplug

the adapter from the wall. If the adapter has a connector on the end, feed the cord through one of the

knockouts in the enclosure and plug it directly into the 24VDC receptacle located at POW1. Plug the other

end of the adapter into the wall. The LDRA6 should power up immediately.

3-3.2 Power via Direct Line

If the adapter does not have a connector on the end, strip the end of the adapter line so the two wires inside

are exposed. Strip the end of each of the two wires and feed them into the enclosure. Insert the two wires

into the terminal block labeled TB1. The minus, or ground, wire is placed into the right opening in the

terminal block. The plus, or live, wire is placed into the left opening in the terminal block.

Once all the wires have been placed inside the terminal block, tighten the three screws across the bottom of

the terminal block until the wires are securely held in place. Plug the other end of the wall adapter into the

wall. The LDRA6 should power up immediately.

11 970 484-6510 www.rletech.com

Page 18

Chapter 4: Product Overview User Guide: LDRA6

CHAPTER 4: START-UP

4-1 BOOT-UP

Make sure the RS-232 port is connected to a PC or terminal with a straight through cable. When the

LDRA6 is powered up, the boot ROM and flash program code are verified. Output similar to the screen

displayed below should appear on the terminal or terminal emulation software.

LDZ/Rasp6 Bootloader – LDZ6BOOT V2.1

Firmware Prgm Id: LDZ6/RASP6 V2.1

checksum valid

LDZ/Rasp6 bootup

LDZ6/RASP6 V2.1

Reading EEprom.......................................

..... ok

Modbus Addr:0 9600,8,N,1

4-2 DISPLAYING THE HELP MENU

Once the system reaches this point, type? and press Enter to display the Help Menu. The Help Menu lists

the function commands for the LDRA6.

Help Menu – LDZ6/RASP6 V2.1

c - view/change CC settings

ld - view/change leak delay

sens – view/change leak zone sensitivity

e - view eeprom data

er - erase eeprom data – restores factory defaults

mbb - change modbus baud rate

mbp - change modbus parity

mr - reset modbus port/statistics

m - view modbus port settings/statistics

t - toggle modbus trace on/off

z - display leak zone readings

sr - summary relay mode

zr - zone relay mode

x - exit to bootloader

www.rletech.com 970 484-6510 12

Page 19

User Guide: LDRA6 Chapter 4: Start-Up

4-3 FUNCTION COMMANDS

4-3.1 c – Contact Closure Settings

c displays the current contact closure settings for each zone. To adjust a zone’s configuration, use the

following format: cX/type/offcolor/oncolor/delay

X is the zone number and can range from 1-6 for each input.

type is the contact closure setting; use “no” for normally open, “nc” for normally closed, or “st”

for a status point.

off-color is the normal condition (non-alarm) LED color.

on color is the alarm condition LED color.

The colors for LEDs can be green, yellow or red.

delay is the number of seconds the alarm must be active before annunciated and can range from 0

to 999 seconds.

** 1: CC / 2: CC / 3: CC / 4: CC / 5: CC / 6: CC **

cX/type/offcolor/oncolor/delay

c1/no/green/red/0

c2/no/green/red/0

c3/no/green/red/0

c4/no/green/red/0

c5/no/green/red/0

c6/no/green/red/0

4-3.2 ld – Leak Delay Setting

ld displays the current leak alarm delay in seconds. This is the number of seconds the leak alarm must be

detected before annunciated. The leak alarm delay can range from 0 to 999 seconds.

Use the format ld/x where x is the number of seconds for the leak alarm delay.

This value applies to all zones configured for Leak Detection. SW1 position 5 determines if this RS232

configured value is used (see section 2-2.5).

4-3.3 sens – Leak Zone Sensitivity

sens displays the current leak detection sensitivity settings for each zone. The first value displayed is the

value read from R1, the sensitivity dial on the LDRA6 board. Each zone is displayed in the format x:

yyy/zzz, where x is the zone, yyy is the value currently being used for sensitivity (in micro amps read by

the sensing cable, yyy can range from 25 to 300), and zzz is the manually entered value through the craft

port (factory default is 0). Values shown below uses sensitivity set to High (fully counterclockwise).

Pot: 25 1:25/0 2:25/0 3:25/0 4:25/0 5:25/0 6:25/0

13 970 484-6510 www.rletech.com

Page 20

Chapter 4: Product Overview User Guide: LDRA6

To override the manual sensitivity dial setting, enter a new value for each desired zone. Using a value of 0

will enable desired zone to use manual sensitivity dial setting. Use the format sensX/yyy to override a

zone’s setting. Example: sens1:300 sets Zone 1 to a sensitivity of 300 micro amps. Type sens and press

Enter again to viewing the Leak Zone Sensitivity settings after entering new value displays the following:

Pot:25 1:300/300 2:25/0 3:25/0 4:25/0 5:25/0 6:25/0

4-3.4 e – View Eeprom Data

This function is a reserved command used for advanced diagnostic purposes only.

4-3.5 er – Erase Eeprom Data – Restores Factory Defaults

er will erase all RS232 configured settings and restore them all to factory default values.

4-3.6 mbb – View / Change Modbus Baud Rate

mbb will display modbus address, baud rate, data bits, parity, and stop bits. Default values are displayed

below.

Modbus Addr:0 9600,8,N,1

To change modbus baud rate, use the format mbb/xxxx where xxxx is the baud rate. Valid selections for

baud rate are 1200, 2400, 9600 and 19200.

4-3.7 mbp – View / Change Modbus Parity

mbp will display modbus address, baud rate, data bits, parity, and stop bits. Default values are displayed

below.

Modbus Addr:0 9600,8,N,1

To change modbus parity rate, use the format mbp/x where x is the parity. Valid selections for parity are:

e – even

o – odd

n – none

4-3.8 mr – Reset Modbus Port and Statistics

mr will reset all RS485 Modbus counters.

4-3.9 m – View Modbus Port Settings and Statistics

m will display the current RS485 Modbus port settings and logged statistics. Initial values appear as:

Modbus Addr:0 9600,8,N,1

overruns: 0

parity_errors: 0

noise_errors: 0

framing_errors: 0

inpackets: 0

crc_errors: 0

for me: 0

not for me: 0

www.rletech.com 970 484-6510 14

Page 21

User Guide: LDRA6 Chapter 4: Start-Up

4-3.10 t – Toggle Modbus Trace On/Off

t will toggle Modbus tracing with packet viewing from the RS485 port over the RS232 port. This is a

command for advanced diagnostic purposes only.

4-3.11 z – Display Leak Zone Readings

z will display the present Leak Detection Cable readings. The Leak Zone table will display the reading for

each leg of cable and the present leakage current reading for each zone.

Z1: Leg1: 0 Leg2: 0 Leakage: 0

Z2: Leg1: 0 Leg2: 0 Leakage: 0

Z3: Leg1: 0 Leg2: 0 Leakage: 0

Z4: Leg1: 0 Leg2: 0 Leakage: 0

Z5: Leg1: 0 Leg2: 0 Leakage: 0

Z6: Leg1: 0 Leg2: 0 Leakage: 0

4-3.12 sr – summary relay mode

sr will display the current configuration of the summary relay. You can select the summary relay to either

change state on leak/fault or just a fault condition. Enter, sr <space> summary for notification on a

leak/fault condition. Enter, sr <space> fault for notification on a fault condition.

sr

sr/summary (summary/fault)

sr fault

sr/fault (summary/fault)

4-3.13 zr – zone relay mode

zr will display the current configuration of the zone relays. You can select the zone relays to either change

state on leak/fault (summary) or just a leak condition. Enter, zr <space> summary for notification on a

leak/fault condition. Enter, zr <space> leak for notification on a leak condition.

zr

zr/summary (summary/leak)

zr leak

zr/leak (summary/leak)

4-3.14 x – Exit to Bootloader

x will exit the application code and only the bootloader will be running.

15 970 484-6510 www.rletech.com

Page 22

Appendix A: Modbus Communications User Guide: LDRA6

APPENDIX A: MODBUS COMMUNICATIONS

This document describes the Modbus communications protocol as supported by the LDRA6. It includes

details and information on how to configure the LDRA6 for communications via Modbus network.

A-1 MODBUS IMPLEMENTATION OF THE LDRA6

The LDRA6 is capable of communicating via the half-duplex RS485 serial communication standard. The

LDRA6 is configured to act as a slave device on a common network. The RS485 medium allows for

multiple devices on a multi-drop network. The LDRA6 is a slave only device and will never initiate a

communications sequence.

A-1.1 Modes of Transmission

The Modbus protocol uses ASCII and RTU modes of transmission. The LDRA6 supports only the RTU

mode of transmission, with 8 data bits, even, odd or no parity and one stop bit.

Every Modbus packet consists of four fields:

Slave Address Field

Function Field

Data Field

Error Check Field (Checksum)

A-1.1.1 Slave Address Field

The slave address field is one byte in length and identifies the slave device involved in the transaction.

Valid address range is between 1 and 254. SW2 on the LDRA6 board sets the address. The firmware

program constantly reads dip SW2. Any changes are updated on the fly. Close the SW2 positions that

correspond to the binary number of the address.

A-1.1.2 Function Field

The function field tells the LDRA6 which function to perform. Function codes are designed to invoke a

specific action by the LDRA6.

A-1.1.3 Data Field

The data field varies in length depending on whether the message is a request or a response to a packet.

This field typically contains information required by the LDRA6 to perform the command specified or to

pass back data to the master device.

A-1.1.4 Error Check Field

The error check field consists of a 16-bit (2 byte) Cyclical Redundancy Check (CRC16). It allows the

LDRA6 to detect a packet that has been corrupted with transmission errors.

www.rletech.com 970 484-6510 16

Page 23

User Guide: LDRA6 Appendix A: Modbus Communications

A-2 PACKET COMMUNICATIONS FOR THE LDRA6

A-2.1 Read Output Registers

To read the LDRA6 parameter values, the master must send a Read Output Registers request packet. The

Read Output Registers request packet specifies a start register and the number of registers to read. The start

register is numbered from zero (40001 = zero, 40002 = one, etc).

Table 1: Read Output Registers Packet Structure

Read Registers Request Packet Read Registers Response Packet

Slave Address (1 byte) Slave Address (1 byte)

03 (Function code) (1 byte) 03 (function code) (1 byte)

Start Register (2 bytes) Byte count (1 byte)

# of registers to read (2 bytes) First register (2 bytes)

Crc Checksum (2 bytes) Second register (2 bytes)

…

Crc Checksum (2 bytes)

Table 2: Output Registers

Register Name Description Units Range

40001 Leak Threshold Zone 1 Trip current for leak alarm uAmps 0-65535

40002 Leak Threshold Zone 2 Trip current for leak alarm uAmps 0-65535

40003 Leak Threshold Zone 3 Trip current for leak alarm uAmps 0-65535

40004 Leak Threshold Zone 4 Trip current for leak alarm uAmps 0-65535

40005 Leak Threshold Zone 5 Trip current for leak alarm uAmps 0-65535

40006 Leak Threshold Zone 6 Trip current for leak alarm uAmps 0-65535

40007 Reserved

40008 Reserved

40009 Reserved

40010 Silence Alarm Set to 1 to silence audible alarm 1 = Silence 0-65535

40011 Reset Alarm Set to 1 to reset alarms 1 = Reset Alarm 0-65535

40012 Reserved

40013 Reserved

40014 Reserved

40015 Reserved

40016 Reserved

40017 Reserved

17 970 484-6510 www.rletech.com

Page 24

Appendix A: Modbus Communications User Guide: LDRA6

A-2.2 Read Input Registers

To read the LDRA6 input values, the master must send a Read Input Registers request packet. The Read

Input Registers request packet specifies a start register and the number of registers to read. The start

register is numbered from zero (30001 = zero, 30002 = one, etc).

Table 3: Read Input Registers Packet Structure

Read Registers Request Packet Read Registers Response Packet

Slave Address (1 byte) Slave Address (1 byte)

04 (Function code) (1Byte) 04 (Function code) (1 byte)

Start Register *2 bytes) Byte count (1 byte)

# of register to read (2 bytes) First register (2 bytes)

Crc Checksum (2 bytes) Second register (2 bytes)

…

Crc Checksum (2 bytes)

Table 4: Input Registers

Register Name Description Units Range

30001 Status Bit Level Status (see Table 5) None 0-65535

30002 Leak Current Zone 1 Leakage current on cable uAmps 0-65535

30003 Leak Current Zone 2 Leakage current on cable uAmps 0-65535

30004 Leak Current Zone 3 Leakage current on cable uAmps 0-65535

30005 Leak Current Zone 4 Leakage current on cable uAmps 0-65535

30006 Leak Current Zone 5 Leakage current on cable uAmps 0-65535

30007 Leak Current Zone 6 Leakage current on cable uAmps 0-65535

30008 Input Selection Bit Level Status (see Table 6) None 0-65535

30009 Reserved

30010 Version Firmware version xx.xx X 100 0-65535

Table 5: Status Flags (Register 30001)

Bit Read Registers Response Packet

00 1 = Zone 1: Leak is Detected / Contact Closure Alarm

01 1 = Zone 2: Leak is Detected / Contact Closure Alarm

02 1 = Zone 3: Leak is Detected / Contact Closure Alarm

03 1 = Zone 4: Leak is Detected / Contact Closure Alarm

04 1 = Zone 5: Leak is Detected / Contact Closure Alarm

05 1 = Zone 6: Leak is Detected / Contact Closure Alarm

06 0

07 0

08 1 = Zone 1 Cable Break Alarm

09 1 = Zone 2 Cable Break Alarm

10 1 = Zone 3 Cable Break Alarm

11 1 = Zone 4 Cable Break Alarm

12 1 = Zone 5 Cable Break Alarm

13 1 = Zone 6 Cable Break Alarm

14 0

15 0

www.rletech.com 970 484-6510 18

Page 25

User Guide: LDRA6 Appendix A: Modbus Communications

Table 6: Status Flags (Register 30008)

Bit Read Registers Response Packet

00 0 = Zone 1 Configured for Leak Detection / 1 = Zone 1 Configured for Dry Contact

01 0 = Zone 2 Configured for Leak Detection / 1 = Zone 2 Configured for Dry Contact

02 0 = Zone 3 Configured for Leak Detection / 1 = Zone 3 Configured for Dry Contact

03 0 = Zone 4 Configured for Leak Detection / 1 = Zone 4 Configured for Dry Contact

04 0 = Zone 5 Configured for Leak Detection / 1 = Zone 5 Configured for Dry Contact

05 0 = Zone 6 Configured for Leak Detection / 1 = Zone 6 Configured for Dry Contact

06-15 0

A-2.3 Present Single Register

To set a LDRA6 parameter value, the master must send a Preset Single Register request packet. The Preset

Single Register request packet specifies a register and the data to write to that register. The register is

numbered from zero (40001 = zero, 40002 = one, etc).

Table 7: Present Single Register Packet Structure

Preset Registers Request Packet Preset Registers Response Packet

Slave Address (1 byte) Slave Address (1 byte)

06 (*Function code) (1 byte) 06 (Function code) (1 byte)

Register (2 bytes) Register (2 bytes)

Data (2 bytes) Data (2 bytes)

Crc Checksum (2 bytes) Crc Checksum (2 bytes)

A-2.4 Present Multiple Registers

To set multiple LDRA6 parameter values, the master must send a Preset Multiple Registers request packet.

The Preset Multiple Register request packet specifies a starting register, the number of registers, a byte

count and the data to write to the registers. The register is numbered from zero (40001 = zero, 40002 =

one, etc).

Table 8: Present Multiple Registers Packet Structure

Preset Registers Request Packet Preset Registers Response Packet

Slave Address (1 byte) Slave Address (1 byte)

16 (Function code) (1 byte) 16 (Function code) (1 byte)

Start Register (2 bytes) Start Register (2 bytes)

# of registers to write (2 bytes) # of registers (2 bytes)

Byte Count (1 byte) Crc Checksum (2 bytes)

Data (2 bytes)

…

…

Crc Checksum (2 bytes)

19 970 484-6510 www.rletech.com

Page 26

Appendix A: Modbus Communications User Guide: LDRA6

Table 9: Modbus Slave Address

Address SW2 (1..8) Address SW2 (1..8) Address SW2 (1..8) Address SW2 (1..8)

0 00000000 16 00010000 32 00100000 48 00110000

1 00000001 17 00010001 33 00100001 49 00110001

2 00000010 18 00010010 34 00100010 50 00110010

3 00000011 19 00010011 35 00100011 51 00110011

4 00000100 20 00010100 36 00100100 52 00110100

5 00000101 21 00010101 37 00100101 53 00110101

6 00000110 22 00010110 38 00100110 54 00110110

7 00000111 23 00010111 39 00100111 55 00110111

8 00001000 24 00011000 40 00101000 56 00111000

9 00001001 25 00011001 41 00101001 57 00111001

10 00001010 26 00011010 42 00101010 58 00111010

11 00001011 27 00011011 43 00101011 59 00111011

12 00001100 28 00011100 44 00101100 60 00111100

13 00001101 29 00011101 45 00101101 61 00111101

14 00001110 30 00011110 46 00101110 62 00111110

15 00001111 31 00011111 47 00101111 63 00111111

For address’s 64-127, set SW1-7 to on, then subtract 64 from the address and use the table.

For address’s 128-191, set SW1-7 to off, #8 to on, then subtract 128 from the address and use the table.

For address’s 192-254, set SW1-7 & 8 to on, then subtract 192 from the address and use the table.

A-3 RTU FRAMING

The example below shows a typical Query/Response from a LDRA6 module.

Table 10: Query Sample

Slave

Address

02 03 00 32 00 03 E5 FA

Slave

Address

02 03 06 01 58 00 FA 00 54 1B 0D

Slave address 2 responds to Function Code 3 with 6 bytes of hexadecimal data and ends with CRC16

checksum.

Register Values:

Functions

Code

Function

Code

Starting

Register

“Msb”

Starting

Register

“Lsb”

Number of

Registers

“Msb”

Table 11: Response Sample

Count

Bytes of

Data

Register

Data

Msb Lsb

Register

Data

Msb Lsb

40051 = 0158 (hex) = 344 (decimal)

40052 = 00FA (hex) = 250 (decimal)

40053 = 0054 (hex) = 84 (decimal)

Number of

Registers

“Lsb”

Register

Data

Msb Lsb

CRC 16

“Lsb”

CRC 16

“Lsb”

CRC 16

”Msb”

CRC

16”Msb”

www.rletech.com 970 484-6510 20

Page 27

User Guide: LDRA6 Appendix A: Modbus Communications

A-4 MODBUS MIRRORING

A-4.1 To use the EIA-485 Modbus mirroring feature set the address on the master LDRA6 to address 255

and then set the address on the slave LDRA6 to 1. The Master unit will then repeat (mirror) any zone

alarms that come into the Slave Unit. When using this feature none of the local Alarm/Zone inputs will

work on the Master unit, The Master unit is only a repeater for the single slave unit being used.

21 970 484-6510 www.rletech.com

Page 28

Appendix B: Troubleshooting User Guide: LDRA6

APPENDIX B: TROUBLESHOOTING

Trouble Action

No Power

Power On LED is Not On

Cable Fault on Zone(s)

Check Power Supply

Check for supply power at TB1 pins 1 and 2 on the bottom right hand corner of

PCB.

1) If power is not present at TB1 pins 1 and 2, check DC input voltage to

wall adapter, if used.

2) If power is not present at TB1 pins 1 and 2, check DC voltage at DC

supply source distribution panel.

3) If voltage (power) is present at TB1, please contact RLE Technologies.

Check for Proper Wiring to Zone Terminal Block

Wiring order should be as follows from left to right for each leak detection zone:

White, Black, Green and Red.

1) If wiring order is correct, disconnect the End-of-Line terminator (EOL)

from the end of the orange SC cable. Then connect the EOL terminator

to the end of the leader cable (non-sensing). Hold down

Quiet/Test/Reset for two seconds to reset control head.

Leak Detected on Zone(s)

2) If the cable fault condition goes away, there is a faulty or damaged

section of orange SC cable.

3) If the fault condition does not clear, remove the respective zone

terminal block and remove the input wires from the leader cable.

Install a jumper wire between pins 1 and 2, and another jumper wire

between pins 3 and 4.

4) If condition still exists, please contact RLE Technologies for extra

support. If the condition clears, the leader cable or EOL terminator is

faulty (open wire(s)).

Be sure there is No Water Present on or around the Zone in Alarm

1) If water is present, dry affected area and reset the controller. If the

condition does not clear follow the step below.

2) Remove the End-of-Line terminator (EOL) from the end of the orange

SC cable and install it onto the end of the leader cable. If the condition

clears, there is a water leak or damage to the sense cable. Start moving

the EOL terminator to the end of each cable section until the waterdetected fault reoccurs. If the condition is still present once the EOL

terminator has been placed on the end of the leader cable, follow the

step below.

3) Disconnect the proper terminal block from the zone in alarm. Place a

jumper wire between pins 1 and 2, and place a jumper wire between

pins 3 and 4. Plug the terminal block back into the proper socket and

push reset on the control head. If the condition is corrected, there is a

problem with the leader cable. If the water leak condition is still

present, contact RLE Technologies for support.

www.rletech.com 970 484-6510 22

Page 29

User Guide: LDRA6 Appendix C: Technical Specifications

APPENDIX C: TECHNICAL SPECIFICATIONS

Power

Inputs

Water Leak Detection Cable

Cable Input

Maximum Length

Detection Response Time

Outputs

Relays

Communications Ports

RS232

RS485

Protocols

Terminal Emulation (RS232) VT100 compatible

Modbus (RS485) - Optional Slave; RTU Mode; Supports function codes 03, 04, 06 and 16 (Modbus optional)

Alarm Notification

Audible Alarm

Front Panel Interface

LED Indicators

Push Buttons

Operating Environment

Temperature

Humidity

Altitude

Storage Environment

Dimensions

Weight

Mounting

Certifications

24VAC Isolated @ 600mA max., 50/60Hz

24VDC@ 600mA max.; requires power supply: WA-DC-24-ST (not included)

Compatible with SeaHawk SC Cable or SeaHawk spot detectors (not included)

Each input requires SeaHawk LC-KIT: 15ft (4.57m) leader cable and EOL (LC-KIT not

included)

1000ft (305m) per zone

20-3600sec, software adjustable in 10sec increments; ±2sec

1 Form C Summary Alarm Relay,

1 Form C Alarm 1 Relay,

1 Form C Alarm 2 Relay.

1 Form C Alarm 3 Relay,

1 Form C Alarm 4 Relay,

1 Form C Alarm 5 Relay,

1 Form C Alarm 6 Relay;

1A @ 24VDC, 0.5A resistive @ 120VAC;

Configurable for supervised or non-supervised, latched or non-latched

9600 baud; Parity none; 8 data bits, 1 stop bit

1200, 2400, 9600 or 19,200 baud; Parity none, odd, even (programmable); 8 data bits, 1

stop bit

85DBA @ 2ft (0.6m); re-sound (disabled, 8, 16, or 24 hours)

Power: 1 green (on/off); Status (1 per zone): 6 tri-color (Power On: green; Alarm: red;

Cable Fault: yellow)

Quiet/Test/Reset: 1

32° to 122°F (0° to 50°C)

5% to 95% RH, non-condensing

15,000ft (4,572m) max.

-4° to 158°F (-20° to 70°C)

10.5”W x 8.0”H x 2.0”D (267mmW x 203mmH x 51mmD)

6 lbs. (2.72kg)

Vertical wall mount

CE; ETL listed: conforms to UL STD 61010-1, EN STD 61010-1; certified to CSA

C22.2 STD NO. 61010-1; RoHS compliant

23 970 484-6510 www.rletech.com

Page 30

FORT COLLINS CO

970 484-6510

WWW.RLETECH.COM

970 484-6650

FAX

Loading...

Loading...