Page 1

USER GUIDE

1. LD1000 Installation

The LD1000 is a wall mounted device, and mounting hardware is supplied with every unit. Select a location for the

LD1000 and place the two screw anchors in the wall 4.25 inches (107.9mm) apart. Screw both screws into the wall

anchors so that approximately 1/8 inch (3.18mm) of each screw is showing. (It may be necessary to adjust the

screws – in or out – so that the unit fits snugly to the wall.) Remove the front cover from the LD1000 and hang the

rear of the unit on the screws. Pull the unit toward the ground, so the screws nestle in the top of each keyhole and

securely fasten the unit to the wall. Before reattaching the front of the unit, make all wiring connections and set all

switches to the desired setting (see below for configurations).

2. Power Connections

The LD1000 requires 24VAC or 24VDC. Make sure to wire the appropriate power to the appropriate terminal blocks

on the LD1000 to avoid damage or injury (ie DC power must only be wired to the terminal blocks labeled “DC IN”

and AC power must only be wired to the terminal blocks labeled “AC IN”). If using DC power, the power supply

must be an isolated power supply (part #WA-DC-24-ST).

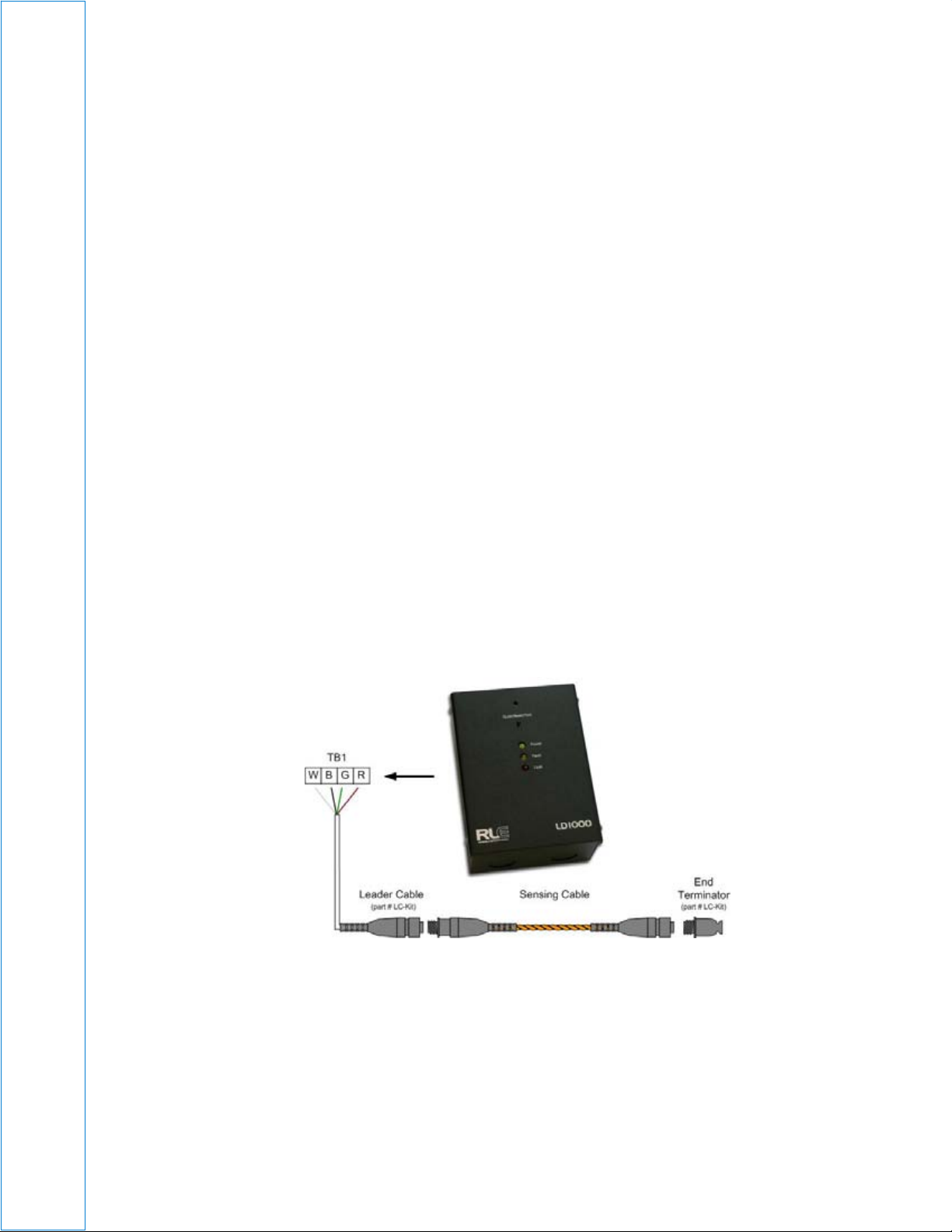

3. Cable Installation

The LD1000 requires a separate leader cable (part #LC-KIT) that connects the sense cable to the unit and

terminates the line of sensing cable properly. Connect the stripped end of the 15 foot (4.57m) leader cable to the

terminal block labeled TB1 on the main board of the LD1000. From left to right, with the screws of the terminal

block connector facing up, the leader cable wires should be connected white, black, green, and red. Once the

leader cable is plugged into the terminal blocks, it is ready to be connected to the leak detection cable. To do this,

unscrew the end terminator from the end of the leader cable. Attach the first length of water leak detection cable to

the leader cable. Route the water leak detection cable according to a cable layout diagram, if provided. Secure the

end terminator on the unoccupied end of the leak detection cable.

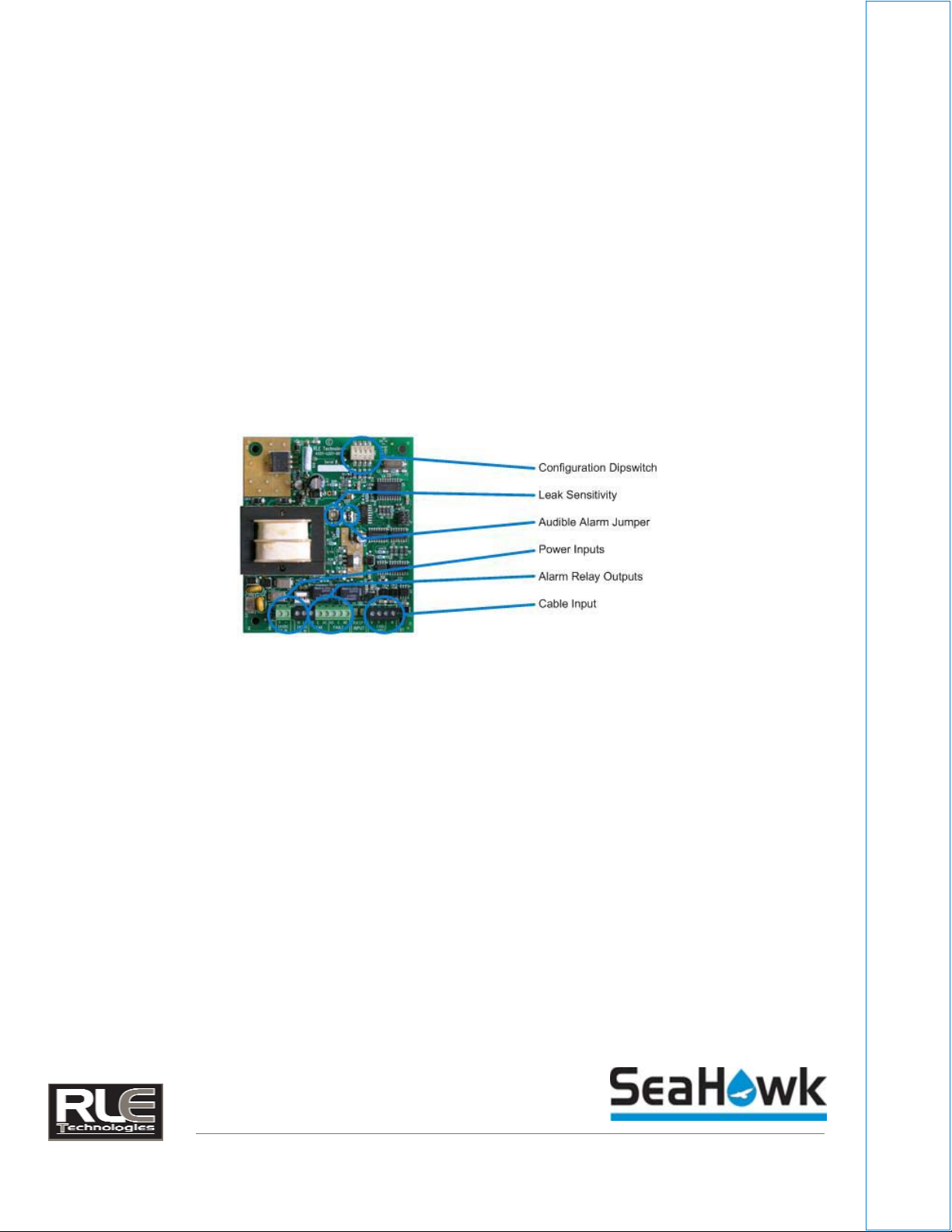

4. Leak Sensitivity

Adjust R25 (see diagram below) to set the desired leak sensitivity. By default, it is set to the mid-sensitivity setting

(150uA) and may be adjusted to the low (300uA) or high (25uA) sensitivity setting by turning the dial.

Dipswitch Settings

SW1-1: Configures the output relays as supervised or non-supervised. If the relays are supervised, the relays will

remain on until either power is disabled or an alarm is detected (relay will turn off). If the relays are non-supervised,

the relays will turn on upon an alarm being detected.

L D 1 0 0 0

Off – Non-supervised (Factory Default) On – Supervised

LD1000

Page 2

A

SW1-2: Configures the relays as latching or non-latching. If the relays are latching, then the relay will remain in

alarm state (depending on SW1-1, supervisory setting) upon alarm until the Quiet/Reset/Test switch is pressed. If

the relays are non-latching, then the relay will remain in an alarm state upon alarm until the Quiet/Reset/Test switch

is pressed or the condition that caused the alarm returns to normal.

SW1-3: Configures the two output relays as a summary alarm or as two separate leak and fault alarms.

On – Relay One is a Summary Alarm and Relay Two is unused

SW1-4: Configures the Alarm Delay setting. This is the response time it takes for the unit to report an alarm

condition (Leak or Fault) once detected. The alarm must be present during this entire period.

5. Audible Alarm Setting

The audible alarm may be disabled for the LD1000. Remove the jumper cap from JMP2 to disable. This jumper

cap is required if audible alarms are desired.

Off – Non-latching (Factory Default) On – Latching

Off – Relay One is a Leak Alarm and Relay Two is a Fault Alarm (Factory Default)

Off – 10 Seconds (Factory Default) On – 2 Minutes

L D 1 0 0 0

Specifications

Power 24VAC/VDC (±10%) @ 300mA max.; requires power supply: WA-DC-24-ST (not included)

Inputs

Water Leak Detection Cable

Cable Input

Maximum Length

Detection Response Time

Outputs

Relay

Alarm Notification

Audible Alarm

Front Panel Interface

LED Indicators

Push Buttons

Operating Environment

Temperature

Humidity

Altitude

Storage Environment -4° to 158°F (-20° to 70°C)

Dimensions 4.125"W x 5.5"H x 2.25"D (105mmW x 140mmH x 58mmD)

Weight 27.0 oz. (765.4g)

Mounting Vertical wall mount

Certifications CE; UL508A / CUL508A; FCC Part 15; RoHS compliant

Compatible with SeaHawk SC Cable (not included)

Requires SeaHawk LC-KIT: 15ft (4.57m) leader cable and EOL (LC-KIT not included)

1,000ft (305m)

Configurable for 10sec or 2min, ±10%

1 Form C Leak Relay, 1 Form C Cable Fault Relay, configurable to 2 Summary Alarm Relays; 1A @ 24VDC, 0.5A resistive @

120VAC; configurable for supervised or non-supervised, latched or non-latched

85DBA @ 2ft (0.6m); Selectable

Power: 1 green (on/off); Cable Fault: 1 amber; Leak Detected: 1 red

Quiet: 1; Reset: 1; Test: 1

32° to 122°F (0° to 50°C)

5% to 95% RH, non-condensing

15,000ft (4,572m) max.

FORT COLLINS CO

970 484-6510

970 484-6650 FAX

WWW.RLETECH.COM

©2008 RLE Technologies 110048 Rev 1.0 (07/2008)

lthough the information contained in this document is believed to be accurate and correct, RLE Technologies assumes no responsibility, and disclaims

all liability, for any damages resulting from the use of this information or any error or omission in this document. RLE Technologies does not warrant,

guarantee, or make any representations as to the performance, fitness for use, safety, or reliability of any existing or future wiring, equipment, additions

or modifications to equipment, or any other component of the original or modified system.

Loading...

Loading...