Page 1

ENVIRONMENTAL SENSORS

4.8"

(122 mm)

1.2"

(30 mm)

3.5"

(89 mm)

would not be covered under the factory warranty.

TM

HW Protocol HW Protocol

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• Read and understand the instructions before installing

this product.

• Turn off all power supplying equipment before working on it.

• The installer is responsible for conformance to all applicable codes.

PRODUCT IDENTIFICATION

Local Display

HW

L = LCD

X = No Display

Protocol

P

= Protocol

RH Option

1 = RH 1% NIST

2 = RH 2% NIST

H = RH 2%

Temp. Option

T

X = No temp. opti on

T = Temp. Transmitte r

INSTALLATION GUIDE

Wall Mounted Humidity Sensors

with Protocol Communication

Installer’s Specifications

Input Vol tage 12 to 30VDC, 24VAC; 100mA max.

Operating Temperature Range 0° to 50°C (32° to 122°F)

Housing Material High impac t ABS plastic , UL 94 VO

Protocol BACnet or Modbus (selectable)

Connection 2-wire RS- 485

Data Rate 9600, 19200, 38400, 57600 (Modb us), bps (selectable)

9600, 19200, 38400, 76800 (BACnet), bps (selectable)

Parity None/Odd/Even (selectable-Modbus)

None (BACnet)

Address Rang e 1-127

RH Transmitter:

HS Sensor Replaceable digitally proled thin-lm capacitive

(32-bit mathematic s); U.S. Patent 5,844,138

Accuracy* ±1% from 12 to 60% RH; ±2% from 10 to 80% RH;

NIST traceable multi-point calibration

Reset Rate** 24 hours

Stability ±1% @ 20°C (68°F) annually for two years

Hysteresis 1.5% typical

Operating Humidity Range 0 to 100% RH, noncondensing

Operating Temperature Range 10° to 35°C (50° to 95°F)

Temperature Coecient ±0.1% RH/°C above or below 25°C (typical)

Temperature Transmitter Option:

Sensor Type Solid-s tate, integrated circuit

Accuracy ±0.5°C (±1°F) typical

Resolution 0.1°C (0.2°F)

Range 10° to 35°C (50° to 95°F)

Setpoint Slider Resolution Option 1% full scale

Override Button Option Remotely readable and resettable

* Specied accuracy with 24VDC supplied power with rising humid ity.

** Reset rate is the time required to recover to 50% RH after ex posure to 90% RH for 24 hours.

Note: RTD/Thermistors in wall packages are not compensated for internal heating of product.

Temp. Cal. Cert.

Option

Housing

QUICK INSTALL

Observe handling precautions for static sensitive

X = No

1 = 1 pt. cal. cer t.*

2 = 2 pt. cal. cer t.*

3 = 3 pt. cal. cer t.*

* Only availab le if temperature option is sele cted.

DIMENSIONS

Blank = None

1 = Pushbut ton override

2 = Setpoi nt slider

3 = Pushbut ton override +

set point slider

Blank = Clou d white

B = Black

1. Select a mounting location away from ventilation sources. The sensor should be

2. Ax the backplate to the wall.

3. Wire the device. Refer to wiring diagram.

4. Install Cover.

Z205863-0C PAGE 1 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 01122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

devices to avoid damage to the circuitry which

mounted on a vertical wall, about 4 1/2 feet above the oor.

Page 2

HW PROTOcOL

TM

INSTALLATION GUIDE

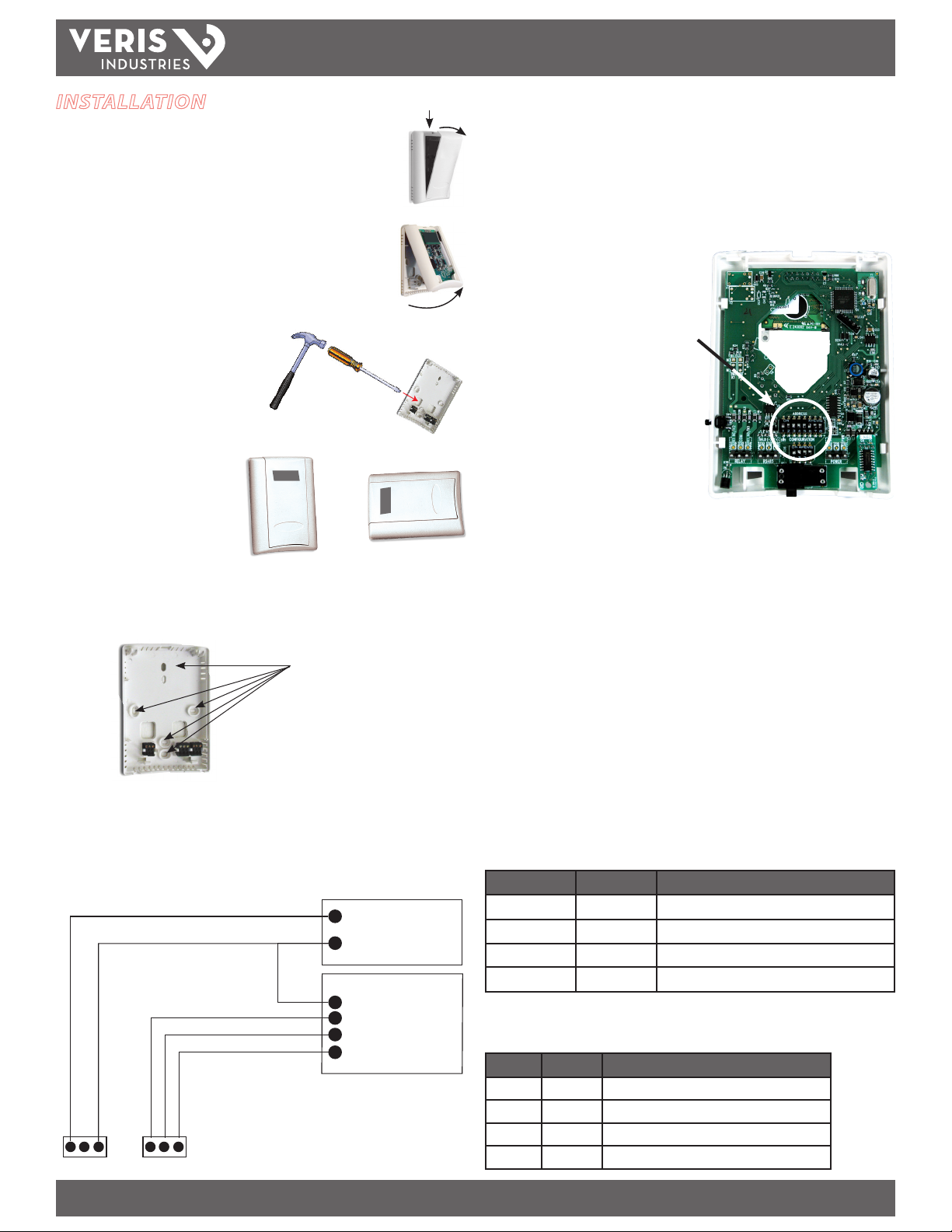

INSTALLATION

1. Remove the cover by pressing the tab at the top of the sensor while

pulling outward from the top of the cover.

2. Remove the backplate by unfastening the sensor from the bottom

of the backplate and pivoting the sensor outward.

3. Punch out openings in the backplate.

4. Position the sensor vertically on

the wall, 4 1/2 feet above the

oor.

correct

incorrect

Ground each unit via the power supply GND terminal or the RS-485 SHIELD terminal

if the power supply is oating. Grounding is necessar y to minimize common mode

voltage on the signal lines and to minimize radio frequency emissions that can

interfere with the operation of nearby radio equipment.

Daisy-chain devices with 120Ω termination resistors between RS-485+ and RS-485on the last device at each end of the chain. Maximum of 63 devices on one daisy

chain.

7. Congure the sensor.

Set the DIP switches on the backside of the

board.

DIP switches, located on backside o f board,

Top row: Address switches

Bottom row: Conguration switches

Select Address DIP switches

1. Up for Modbus, Down for BACnet.

2. Up to add 64 to network address.

3. Up to add 32 to network address.

4. Up to add 16 to network address.

5. Up to add 8 to network address.

5. Mount the backplate onto the wall using the screws provided.

Five screwholes available; use a minimum of two for secure mounti ng.

6. Wire the backplate.

Wire the RS-485 connections with shielded, twisted-pair wire, such as Belden Cable

1120A or equivalent. With 2-wire cable, connect the shield at one end only to the

RS-485 SHIELD terminal.

+

POWER SUPPLY

12-30VDC, 24VAC

-

CONTROL SYSTEM

COMMON

-

RS-485+

RS-485 -

SHIELD

PWR

GND

RS-485+

RS-485-

SHIELD

6. Up to add 4 to network address.

7. Up to add 2 to network address.

8. Up to add 1 to network address.

The network address is the sum of the values selected by placing switches 2

through 8 in their UP position. E.g.: If switches are D D D U D U D D, then BACnet

communication is selected, and the address is 16 + 4, for a total of 20. Valid Modbus

addresses are 1 to 127, and valid BACnet addresses are 0 to 127. Each device on the

daisy chain must have a unique address.

Select Configuration DIP switches

Conguration DIP switches 1 and 2 control the parity settings for Modbus and have

no eect on BACnet communication, which never has parity.

Switch 1 Switch 2 Parity

Down Down None (2 stop bits)

Down Up Odd

Up Up Even

Up Down None (1 stop bit; common but non-standard)

Conguration DIP switches 3 and 4 control the data rate for both Modbus and BACnet

modes.

Switch 3 Switch 4 Data Rate

Down Down 9600 bps

Down Up 19200 bps

Up D own 38400 bps

Up Up Modbus: 57600 bps; BACnet: 76800 bps

Z205863-0C PAGE 2 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 01122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 3

HW PROTOcOL

TM

Modbus Configuration

The list of supported Modbus function codes and the Modbus Point Map are in the

Point Map section of this document. The capabilities for controlling the TWxP are

identical with those for BACnet. The functions are summarized here.

Function Description

Coils Used to set temperature (Fahrenheit scale) and override button coil. *

Discrete

input

Input

registers

Holding

registers

* The temperature scale is maintained if power is lost. When delivered, temperature in Farenheit

and calibration lockout is on. Pressing th e override button turns the override button coil on. It can

only be turned o remotely.

** If any sensor option is not installed, th e reading for that sensor will be 0.

The various registers are still present even without the corresponding options

installed. In particular, the discrete input func tion can be used to see if the CO2

setpoint has been reached even if the relay is not in use.

BACnet Configuration

The list of BACnet objects and their implemented properties is in the BACnet

Descriptions section of this document. The capabilities for controlling the CWxP

are identical with those for the Modbus conguration. However, BACnet has some

additional protocol-related settings.

Indicates whether the relay is on.

Used to read the sensor options: RH (in units of 0.1%), temperature (in units

of 0.1°), and the slider (in units of %full scale). **

Used to specify the temperature oset and RH oset. Initial settings are 0°F,

and 0%, respectively. Settings are retained if power is lost.

INSTALLATION GUIDE

VISUAL INDICATORS

The RX light will ash while data is being received. If it isn’t blinking, it can indicate a

bad connection or that the RS-485+ and RS-485– wires are connected backwards.

The TX light will ash while data is being transmitted. For Modbus, if this light isn’t

blinking it can mean that the device isn’t being selected (wrong address) or the

communication parity or bit rate is set improperly.

In a BACnet installation, both the RX and TX lights will ash repeatedly even if no

communication is being per formed. In a Modbus installation, no lights will ash if

there is no communication activity.

MODBUS POINT MAP

Function code Function

01 Read coils

03 Read holding registers

04 Read input registers (if any sensor is not installed, the reading for that

sensor will be 0)

05 Write single coil

06 Write single register

07 Diagnostics (sub-function 00 returns quer y data)

15 Write multiple coils

16 Write multiple registers

17 Report slave ID (returns manufacturer, model name, and serial number)

All of these values correspond to BACnet objects with the same name. See the BACnet

Descriptions section for denitions.

The Device Object must have a unique name. This is set at the fac tory to the model

name, followed by the device’s serial number. The name can be changed if desired.

The device object must also have a unique object identier number. By default, this

is 133nnn where nnn is the current network address. This number can be changed

and the new number will be remembered. Setting the number to -1 (normally not

allowed) will reset the device to the default.

The Reliability property of the analog inputs for temperature, relative humidity, and

slider can be read to determine whether the device has these options installed.

8. Install the sensor onto the backplate.

9. When installation is complete, install the cover

and snap into place.

Coils

1 Fahrenheit (else Celsius)

2 Override (use override button to turn on)

Input Registers

1 Humidity (in tenths of a percent)

2 Temperature (in tenths of a degree; units set by coil 1)

3 Slider (in percent)

Holding Registers

1 Temp Oset (in tenths of a degree, current units)

2 RH oset (in tenths of a percent)

Z205863-0C PAGE 3 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 01122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 4

HW PROTOcOL

TM

BACNET DESCRIPTIONS

All properties read-only unless otherwise noted. Preserved means it is non-volatile.

Present_Value Range Restrictions

Object Name Minimum Value Maximum Value

Device_Instance 0 (but see description, above) 4,194,302

Temp_Oset -5 5

RH_Oset -10 10

Standard Object Types Supported

Object Type Supported Optional

Properties

Analog Input

-- AI

Analog Value

-- AV

Binary Value

– BV

Device -- DEV Description*, Location APDU_Timeout, Description, Location,

* Description is the same as the O bject_Identier. Reliability is “No Se nsor” if no sensor is installed

(applies to humidity, temperature, and slider).

Description*, Reliability

Description* Present_Value

Description* Present_Value

Objects Table

Object

Name

Humidity AI 1 Humidity in percent

Temperature AI 2 Temperature in Fahrenheit or Celsius

Slider AI 3 Slider position in percent.

Device_

Instance

Temp_

Oset

RH_Oset AV 3 Relative Humidity oset. Value rounded to the nearest tenth of

Fahrenheit BV 1 1 if temperature in Fahrenheit, 0 if in Celsius. Initially 1

Override BV 2 1 if override button pressed. Store 0 to reset. Initially 0. Volatile

Type and

Description of Present_Value Property

Instance

AV 1 Alternative way to change object_identier property of

AV 2 Temperature oset. Value rounded to nearest tenth of a

device. A negative value will restore the default device

instance (133nnn). Fractional values are truncated.

degree. Units are current units. Initial value is zero.

a percent. Initial value is zero.

Writable Properties

Max_Master, Object_Identier,

Object_Name

INSTALLATION GUIDE

Device Objects Table

Object

Name

HWxPxxx

CONFORMANCE STATEMENT

Vendor Name: Veris Industries

Product Name: Veris HWxP Environmental Sensor

Product Model Number: HWxPxxx

Application Software Version: 1

Firmware Revision: x.x

BACnet Protocol Revision: 2

Product Description: Environmental Sensor

BACnet Standardized Device Prole (Annex L): BACnet Application Specic Controller

(B-ASC)

List all BACnet Interoperability Building Blocks Supported (Annex K):

Segmentation Capability: Segmentation not supported

Standard Object Types Supported:

Data Link Layer Options: MS/TP master (Clause 9), baud rates: 9600, 19200, 38400,

76800

Device Address Binding: Static device binding is not supported. (No client functionality is included).

Networking Options: None

Character Sets Supported: ANSI X3.4

Type and

Instance

Device

133nnn

Object

Description

Property

Object_Identier

(R/W)

Object_Name

(R/W)

APDU_Timeout Default is 3000, maximum value is 60000

Max_Master Default is 127

Description Maximum length is 64 characters

Location Maximum length is 64 characters

Unique value where nnn initially is MS/TP

Unique name, initially a combination of

model and serial number. Maximum length

is 64 characters

DS-RP-B,DS-RPM-B,DS_WP-B,DM-DDB-B,DM-DOB-B,,DM-DCC-B

No dynamic creation or deletion supported

No proprietary properties or object types

(other information about objec ts on preceding pages)

Z205863-0C PAGE 4 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 01122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Loading...

Loading...