Page 1

Model HTT

Hot Tap Tool for Badger®

Series 225/226 Flow Sensors

Installation &

Operation Manual

BadgerMeter, Inc.

872822

Rev. 6

4-09

Page 2

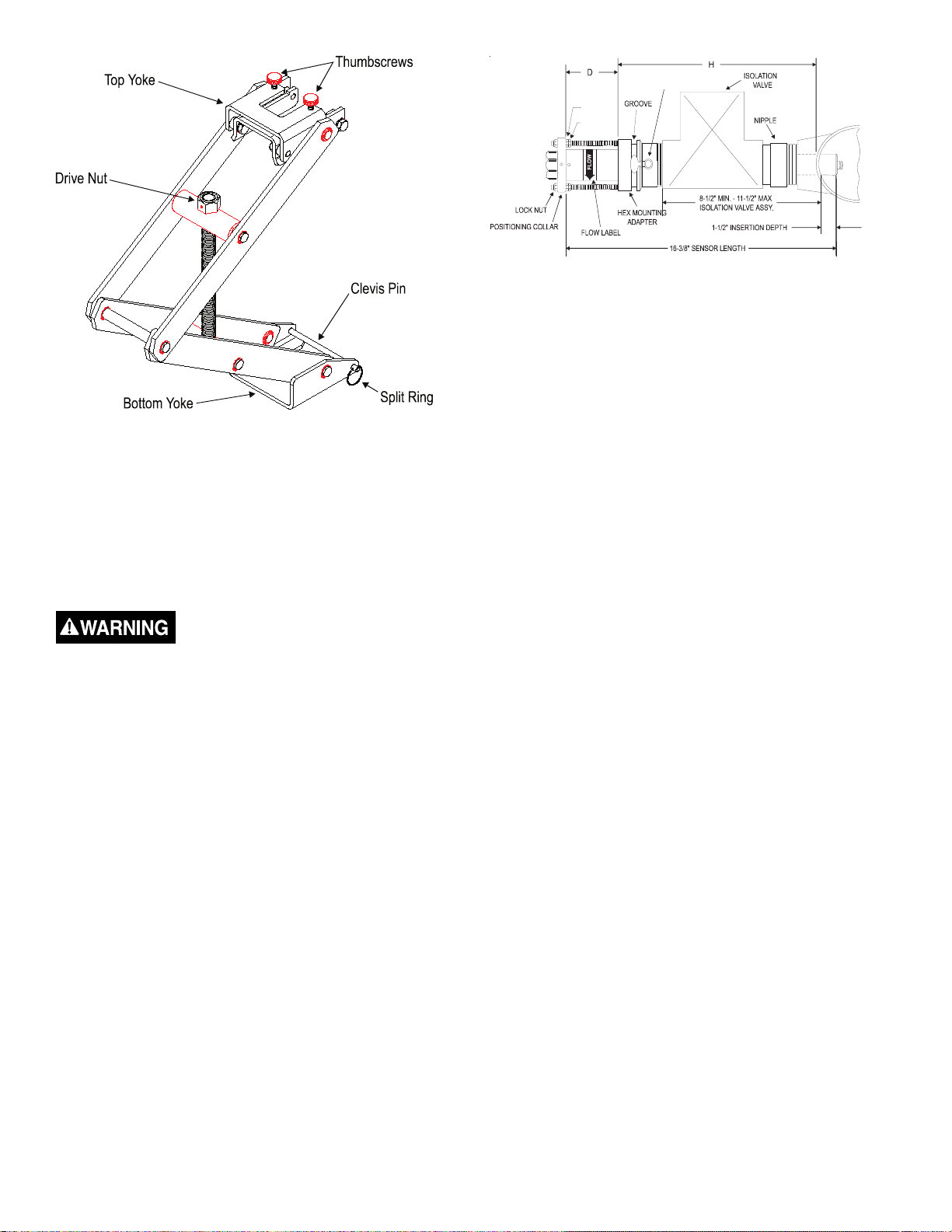

BLEED VALVE

HEX NUT

JAM NUT

Figure 1

Figure 2

Installation into a pressurized pipeline

For pipe sizes 2½ inches and above, all Badger Meter

sensors are inserted 1 1/2 inches from the inside wall of

the pipe. The insertion depth is controlled by the position of

the hex nuts on the three threaded rods. The formula below

defines the distance between the top of the sensor hex

mounting adaptor and the bottom of the positioning collar

(the top of the hex nut). Reference figure 2.

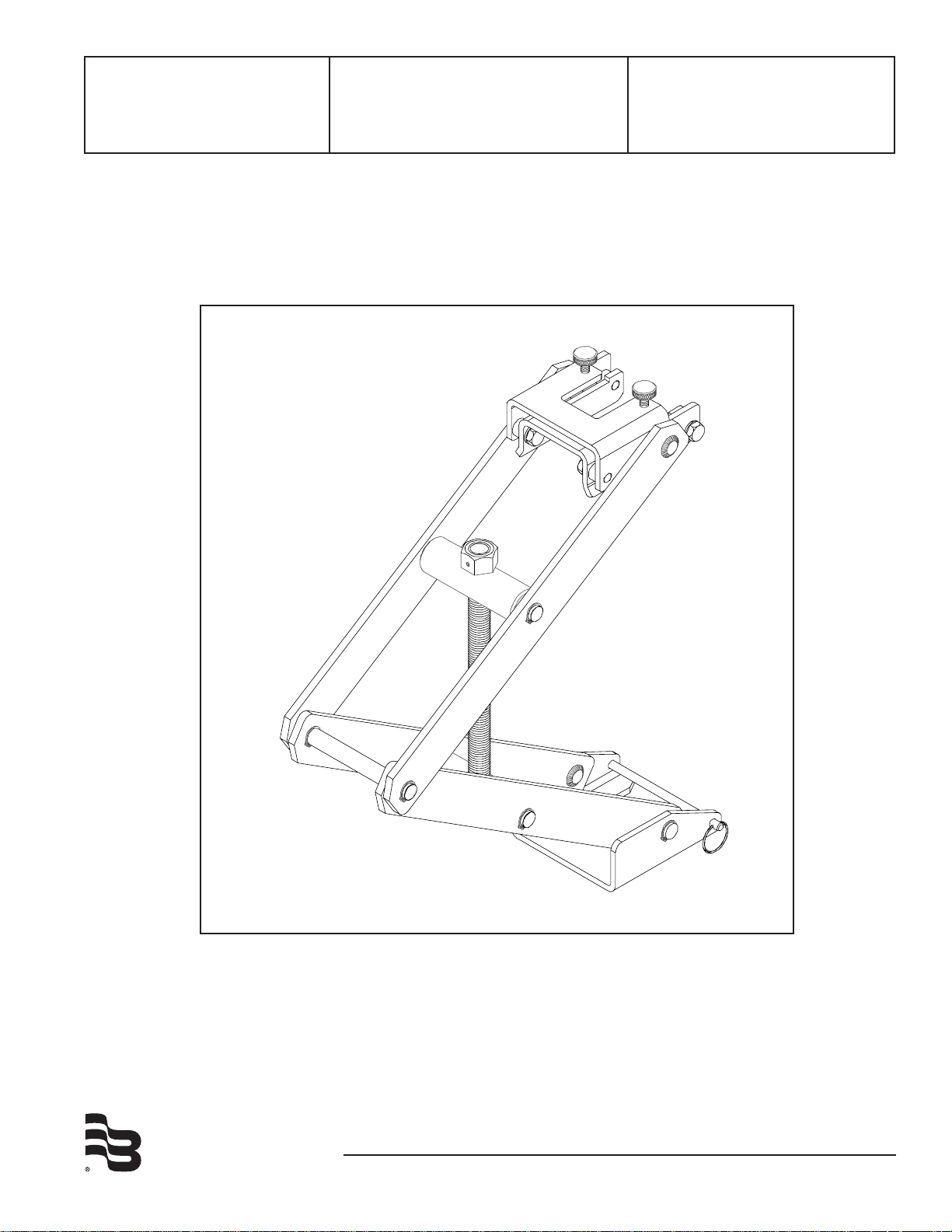

The Model HTT Hot Tap Tool provides the mechanical

advantage required to safely insert and remove a Badger

Meter hot tap sensor from line pressure and provides a

restraint when removing the sensor from a pressurized pipe.

Removal of Badger® Series 225/226 from a pressurized

pipeline.

Do not remove lock nuts from

threaded rods above the positioning

collar without hot tap tool connected.

Serious injury could result.

1. Adjust Hot Tap tool opening by rotating drive nut with a

15/16 socket or box wrench (not provided) until the distance between the top and bottom yoke is approximately

equal to the distance between the groove on the hex

mounting adaptor and the bottom surface of the sensor

positioning collar.

2. Remove split ring and clevis pin.

3. Slide tool bottom yoke into the groove in the hex mounting

adaptor and secure with the clevis pin and split ring.

4. To permit clearance for the top yoke, lower two of the

three pairs of jam nuts under the sensor positioning collar

to a minimum of 1½ inchs below the positioning collar.

Then position the top yoke so the threaded rod with the

remaining jam nuts are centered in the yoke. Then slide

on the yoke, adjusting with drive nut as necessary.

5. Make sure the positioning collar is located in the recessed

area of the yoke by adjusting the drive nut until the top

yoke is snug against the bottom of the sensor positioning

collar. Then tighten thumb screws located on the top of

the tool.

6. Remove three lock nuts above the collar and slowly

withdraw sensor by rotating the drive nut of the tool

counterclockwise with a 15/16 socket or box wrench (not

supplied) until drive nut bottoms out on tool.

7. Close gate or ball valve fully.

8. Open bleed valve located on the hex mounting adaptor to

relieve pressure between valve and sensor.

9. Once all pressure is relieved remove tool and remove sensor from the hex adaptor.

D = 16 3/8” - ( H + Pipe Wall Thickness + 1.5 “ )

Example: If sensor is installed in a 8 inch Sch 80 pipe with a

pipe wall thickness of 0.5 inch and the “H” dimension is 10

inch then the calculation would be as below:

D = 16 3/8 - ( 10” + 0.5” + 1.5” )

D = 4 3/8”

1. Set one set of hex/jam nuts so that the distance between

the top surface of the hex nut and the top surface of

the hex mounting adaptor is equal to the “D” dimension

calculated above. Then adjust the other two sets of hex/

jam nuts 1½ inches below the first jam nut to allow

clearance for the tool top yoke.

2. Fully extend tool by turning drive nut counterclockwise

with a 15/16 inch socket or box wrench (not provided) until

drive nut contacts tool and slide the positioning collar into

the tool top yoke.

3. Remove the tool split ring and clevis pin and slide tool

bottom yoke into the groove on the sensor hex mounting

adaptor and secure by replacing the clevis pin and split

ring.

4. Mark sleeve 2 3/4 inchs from impeller end of metal sleeve.

This mark is a stopping point to insure that impeller/

bearing is not damaged. Open the bleed petcock valve

on the hex adapter to relieve the pressure resulting

from the sensor tube insertion. Carefully hand insert the

Badger Meter hot tap flow sensor sleeve assembly into

the hex mounting adapter until the mark lines up with the

top of the hex mounting adapter. At this point the sleeve

will have been inserted past the top two O-rings in the

adapter (approximately 1 - 1 1/4 inches). Take care not

to push the sensor past the mark on the sleeve as the

impeller could be damaged if it strikes the closed valve.

5. Rotate tool so the threaded rod with the adjusted hex/jam

nuts is centered in the top yoke of hot tap tool.

6. Rotate sensor sleeve so positioning collar holes align with

the threaded rods, and flow direction label is in general

direction making sure the positioning collar is located

in the recessed area of the top yoke. Slide the top yoke

2

Page 3

of the tool over the positioning collar and secure by

tightening the two thumbscrews on the top of the yoke.

7. Close the bleed petcock and slowly open the isolation

valve. Slowly turn the 15/16 inch drive nut clockwise to

insert the sensor tube assembly through the valve and

into the pipeline. Carefully guide the three threaded studs

of the hex mounting adapter through the holes of the

sensor positioning collar. Carefully lower the sensor until

the positioning collar contacts the hex nut preset for the

correct depth adjustment. Install the three lock nuts onto

the threaded rods, tightening only the lock nut on the

threaded rod with the preset hex/jam nut; then, bring the

two remaining lock nuts down until they just contact the

positioning collar. Do not tighten at this time

8. Remove the Model HTT Insertion/Removal Tool, by

loosening the two thumbscrews, removing the clevis pin

and then sliding the insertion tool off the sensor. Then

bring the two remaining sets of hex/jam nuts up to the

underside of the positioning collar, and tighten.

9. Align the sensor by first loosening the two set screws in

the side of positioning collar with a 3/32 inch Allen wrench.

Then align the sensor sight holes along the pipe axis

using the alignment rod provided in the sensor installation

kit. Ensure that the flow label arrow on the sensor

matches the liquid flow direction inside the pipe. Tighten

the positioning collar set screws. Note: As a backup to the

flow label arrow, there is a small hole located beside the

sight hole on the upstream side of the sensor.

3

Page 4

Badger® and Data Industrial® are registered trademarks of Badger Meter, Inc.

Due to continuous research, product improvements and enhancements, Badger

Meter reserves the right to change product or system specifications without notice,

except to the extent an outstanding contractual obligation exists.

Please see our website at www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2009. All rights reserved.

BadgerMeter, Inc.

6116 E. 15th Street, Tulsa, Oklahoma 74112

(918) 836-8411 / Fax: (918) 832-9962

www.badgermeter.com

Loading...

Loading...