Page 1

VERIS INDUSTRIES

CURRENT MONITORING

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices.

See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

DANGER

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

pulse reset

technology™

U.S. Pat. #6,160,697; 6, 522,517; 7,242,157

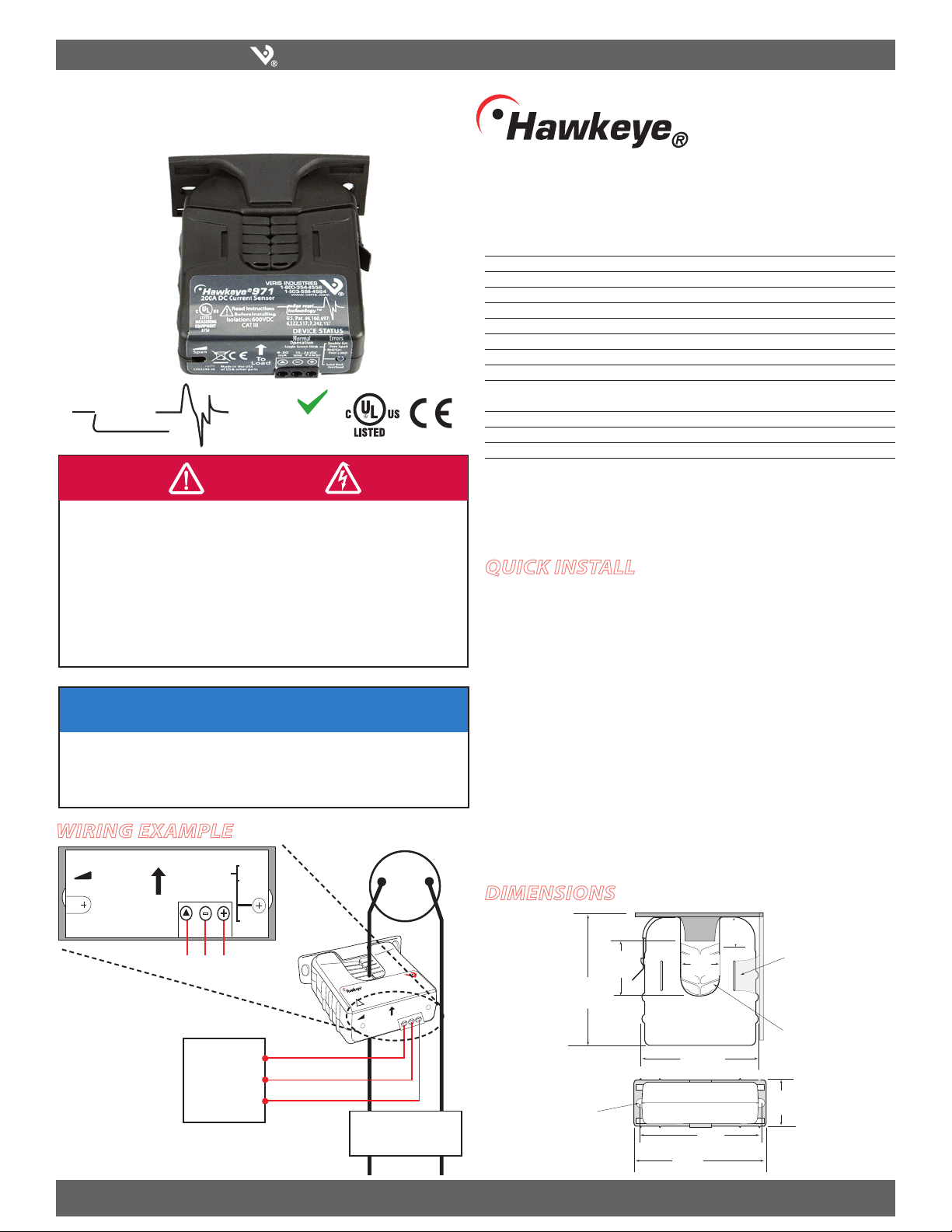

Removable Mounting Bracket

Self-gripping

Iris

1.0”

(25 mm)

0.8”

(21 mm)

1.1”

(26 mm)

3.1”

(79 mm)

2.8”

(70 mm)

Ø = 0.3”

(8 mm)

1.4”

(36 mm)

2.5”

(64 mm)

3.0”

(76 mm)

Bracket can be mounted

on either side for added

installation flexibility.

Power

Gnd

4-20

mA

15–24 VDC

To

Load

–

Span

+

Red/Gn:

Over Limit

Double Gn:

Over Span

Solid Red:

Overload

Single Green Blink

Errors

Normal

Operation

DIGITAL CONTROL

Gnd

4-20mA

DC

Load

SEIRT

SU

DN

I

S

I

REV

3

227

9 n

o

ge

rO

,d

n

al

t

roP

655

8-4

5

3

-00

8

1

179

!

rosneS tnerruC DC

200A

Span

Current

Flow

4-20

mA

12-24 VDC

Gnd Power

Power

CONTACTOR

RoHS

Compliant

INSTALLATION GUIDE

H971/971S P 971/971S P

Split-Core Bi-Polar 4-20mA Output

DC Current Transducer

Installer’s Specifications

Technology Exclusive Puls e Reset Technology™

Amperage Range ±200 ADC

Sensor Supply Voltage 12 to 24VDC*

Supply Current 35mA max.**

Insulation Class 600VDC

Temperature Range -30° to 60°C (-22° to 140°F)

Humidity Range 10-90% RH non-condensing

Output Bi-polar 4-20mA (adjustable span)***

Accuracy Below 100A Span ±0.5A, combined linearity, hysteresis, and repeatabilit y****

Accuracy Above 100A Span ±0.5% full scale, combined linearity, hysteresis,

and repeatability***

Withstand Current 25,000ADC

Measurement Category III

Rated Altitude 2000m

Pollution Degree 2

* For currents over 120A, supply voltage must be at least 15V.

** At zero load current: 35mA max.; at 200A load current: 55mA to 110mA, depending on supply

voltage and current polarit y.

*** Unless factory se t per customer specifications.

**** For single conductor th rough product (no wraps).

quick install

Wiring ExamplE

Z2 05412- 0D PAGE 1 ©2009 Veris Industries USA 800.354.8556 or +1(0)503.598.4564 / support@veris.com 09091

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

Disconnect and lock out power to the conductor to be monitored.1.

Choose a location for the sensor. The monitored conductor must pass through 2.

the iris, and the sensor must be at least ½” from any conductors as enclosure can

reach 87°C during operation (at 60°C ambient temperature).

Install the adjustable mounting bracket to the back of the enclosure using the 3.

included screws.

Connect 12-24VDC to the terminals marked Power (+) and Gnd (-).4.

Wire the mA output connections between the sensor and the controller.5.

Snap the sensor over the conductor to be monitored and clip the assembly to the 6.

mounting bracket.

H971 only: Set the span set potentiometer to the desired amperage level (see 7.

page 2).

DimEnsions

Use DIN Rail

Mounting clip

(Veris part

number AH01) to

mount on stan-

dard DIN rail.

Page 2

VERIS INDUSTRIES

H971/971SP

SENSED AMPS

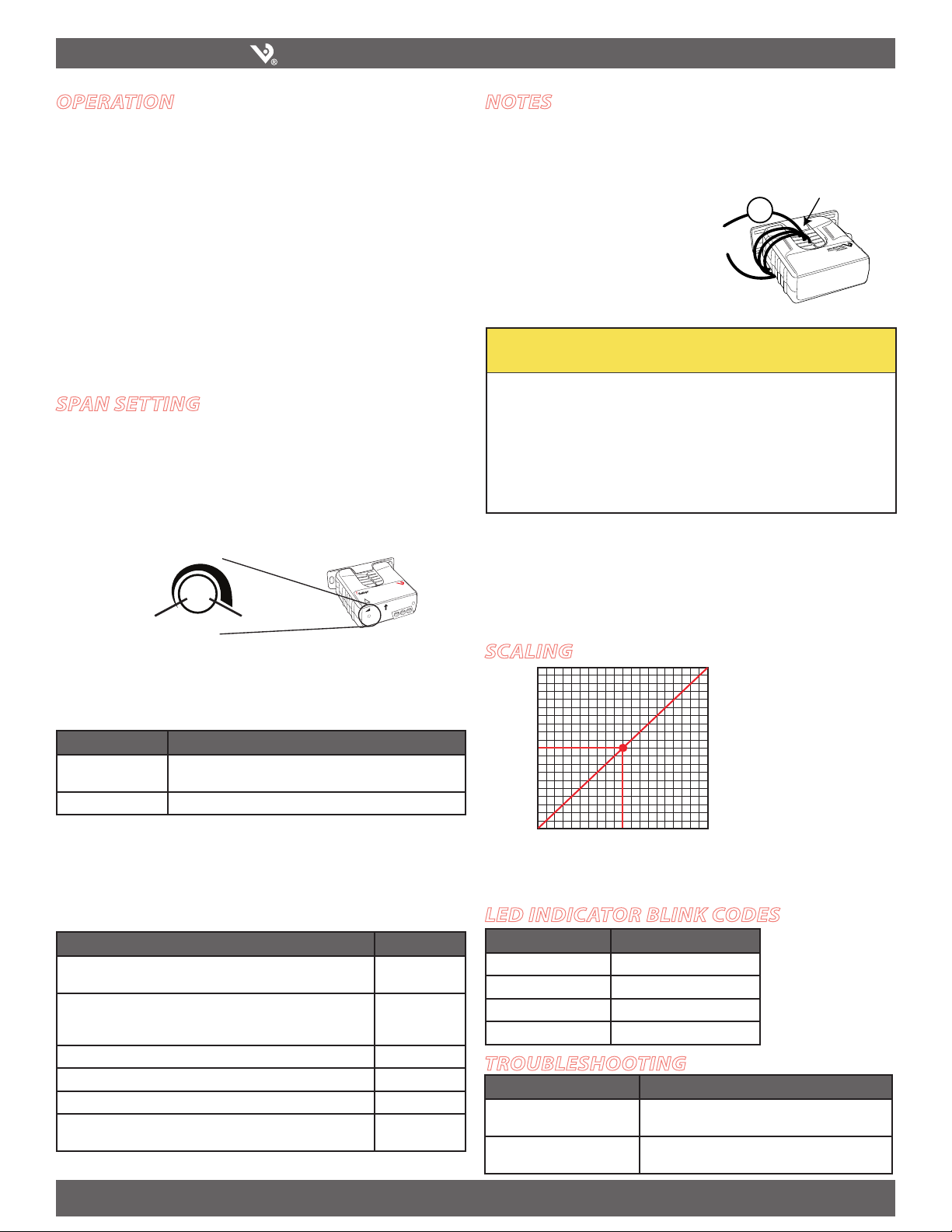

4mA

12mA

-200A* +200A*0A

20mA

SENSOR OUTPUT

*Field Adjustable from ±20A to ±200A

(not applicable to customer-specified factory scaled models)

SEI

R

T

SU

DN

I SIREV

3

227

9 n

o

ge

rO

,d

n

a

l

t

roP

655

8-4

5

3

-00

8

1

179

!

Span

Current

Flow

4-20

mA

12-24 VDC

Gnd Power

200A DC Current Sensor

Fully CCW:

smallest range

(0 to 20A)

Fully CW:

greatest range

(0 to 200A)

4x

1A

CAUTION

RISK OF EQUIPMENT DAMAGE

• Derate the product’s maximum current for the number of turns

through the sensing window using the following formula.

Rated Max. Amps ÷ Number of Turns = Max. monitored Amps

e.g. : 100A ÷ 4 Turns = 25 Amps max. in monitored conductor

• Failure to follow these instructions can result in overheating

and permanent equipment damage.

INSTALLATION GUIDE

opEration

The H971 is a current-sensitive device that monitors DC current (amperage) in the

conductor passing through it. The unit uses Pulse Reset Technology™ with proven

transducer circuitry to produce a status output suitable for connection to building

controllers or other appropriate data acquisition equipment. The H971 requires 1224VDC to generate its output. The H971 has a user-adjustable span to allow flexibility.

The H971SP comes factory calibrated at a fixed span for maximum accuracy.

The H971 is ideal for DC current monitoring where accuracy must be maintained in

the presence of magnetic fields, current spikes, and high fault currents (e.g. solar

panels, electroplating equipment).

The H971 housing offers unprecedented mounting flexibility. The mounting bracket

can be attached in three different places. Additionally, the bracket is compatible with

the Veris AH01 DIN Rail clip, allowing DIN mounting.

span sEtting

The H971 comes preset at the maximum (0-200A) span. To adjust the H971 to a

different span, locate the potentiometer on the top of the device. This potentiometer

is a multi-turn device, taking about 23 turns to adjust the span from ±20A to ±200A.

Use the potentiometer to adjust the maximum amperage range used by the sensor.

The smallest amperage range (0 to ±20 A) is set by turning the potentiometer fully

counterclockwise; the greatest amperage range (0 to ±200 A) is set by turning the

potentiometer fully clockwise.

(not applicable to the H971SP models)

notEs

For load currents less than 2A:

Wrap the monitored conductor through the center hole and around the sensor body

to produce multiple turns through the "window." This increases the current measured

by the transducer.

Controller must be programmed to account for

the extra turns. e.g., if four turns pass through

the sensor (as shown) the normal controller

reading must be divided by 4.

Accuracy may be reduced if wraps are used.

Failure to observe the following can result in incorrect output readings:

Observe the arrow on the H971 showing positive current direction so that the 1.

output will have proper polarity for the application.

To determine the best amperage range for an application, first set the load to

the maximum amperage that will be used. Use the LED as a guide to adjust the

potentiometer to its optimum setting. Verif y the measured output current matches

the load current using a current clamp meter.

LED Activity Potentiometer Adjustment

Steady green blink Turn CCW until LED blinks rapidly, then slowly turn CW just until

Rapid green blink Turn CW until LED blinks at a steady rate.

blink returns to steady rate.

An alternate adjustment method that does not require a current clamp meter can

also be used, provided the amperage flowing in the conduc tor is steady for the

duration of the adjustment. In this example, it is assumed that the H971 is initially

set to the maximum 0-200A span, but the installer has decided to reduce the span to

0-120A. Sample numbers are provided to illustrate the calculations.

Action Example

Determine the device output using a portable multimeter or the

automation controller.

The H971 is bi-directional, so a 12mA output corresponds to a 0A

load in the conductor. Determine the output above the 0 level by

subtracting 12mA.

Multiply by the initial maximum span setting before adjustment. 3 x 200 = 600

Divide by the desired maximum span. 600 / 120 = 5

Add 12 to this value to get the new output value. 5 + 12 = 17

Turn the potentiometer counterclockwise until the output reads 17mA.

This is the output for the amperage load at a span of 0-120A.

Z2 05412- 0D PAGE 2 ©2009 Veris Industries USA 800.354.8556 or +1(0)503.598.4564 / support@veris.com 09091

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

15

15 - 12 = 3

17

Do not expose the H971 to continuous current levels greater than 200A RMS (brief 2.

current surges and fault currents should not adversely affect the H971).

scaling

lED inDicator blink coDEs

LED Activity Status Description

Single green Normal operation

Double green Over span

Red/green Over limit

Solid red Overload

troublEshooting

Problem Solution

The LED is off and no signal is

produced

The LED is on solid and the

output is at maximum

Verify that at least 12V supply voltage is applied to PWR

(+) and GND (-) terminals.

Verify that the unit is not attempting to monitor more

than ±200A.

Loading...

Loading...