Page 1

TM

the user will be required to correct the interference at his own expense.

NETWORK INTEGRATION

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved. NEC2009 Article 100

No responsibility is assumed by Veris Industries for any consequences arising out of the

use of this material.

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found

to comply with the limits for a class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case

Modifications to this product without the express authorization of

Veris Industries nullify this statement.

Control system design must consider the potential failure modes of control paths and, for

certain critical control functions, provide a means to acheive a safe state during and after a

path failure. Examples of critical control functions are emergency stop and over-travel stop.

INSTALLATION GUIDE

H8932/H8936

Network Display

Specifications

AC Power Source Dedicated 120/240 VAC, line-to-neutral; fused

Fuse Ratings 200mA at 250V 5x20 mm f ast blow

AC Power Voltage Tolerance 90-132VAC for 120V

AC Power Frequenc y 50/60 Hz

AC Power Termination 2-position Euro style pluggable connector

(max. wire size 12 gauge)

Terminal Block Torque 4.9 in-lb (0.56 N-m)

Alternate DC Power Source 12VDC, 300mA unfused

Environmental:

Operating Temperature Range 0° to 50°C (32° to 122°F)

Operating Humidity Range <95% RH, non-condensing

Storage Temperature Range -20° to 70°C (68° to 158°F)

Network Communications:

Interface Downstream: RS-485; Upstream: RS- 485, RS-232

Protocol Modbus RTU

Baud Rate UI-selectable 2400, 480 0, 9600, 19200

Parity UI-selectable NONE, ODD, EVEN

Communication Format 8-data-bits, 1-star t-bit, 1-stop-bit

RS-485 ¼ load transceivers; duplex is UI-selectable 2-wire or 4-wire;

5-position Euro-style pluggable connector

RS -232 (Upstream only) DCE, no handshaking; DB-9 connection;

pin 2: transmit ted data from display;

pin 3: received data to display; pin 5: ground

Terminal Block Torque 4.4 in-lb (0.5 N-m)

UI Switch In puts:

Number/Function 4 (Meter, Up, Down, Select)

Auxiliary Input (Remote Alarm):

Type Contact closure or pull-to-ground

Isolation Optical to 2500VAC

Sense UI-selec table N.O. or N.C.

Terminal Block Torque 3.5 to 4.4 in-lb (0.4 to 0.5 N-m)

LCD:

Size 1” x 4” visible area, 2 lines x 16 characters per line

Backlight Green, UI-adjustable br ightness in 10 steps

Status ( Tri-Color LED) Green = normal operation; Yellow = warning; Red = alarm

PRODUCT IDENTIFICATION

MODEL DESCRIPTION

H8932 without enclosure

H8936 with enclosure

SUPPORTED METERS

WARNING

LOSS OF CONTROL

∙ Assure that the system will reach a safe state during and after a control path failure.

∙ Separate or redundant control paths must be provided for critical control functions.

∙ Test the eect of transmission delays or failures of communication links.

∙ Each implementation of equipment using communication links must be individually

and thoroughly tested for proper operation before placing it in service.

Failure to follow these instructions may cause injury, death or equipment damage.

1

For additional information about anticipated transmission delays or failures of the link, refer to

NEMA ICS 1.1 (latest edition). Safety Guidelins for the Application, Installation, and Maintenance

of Solid-State Control or its equivalent in your specic country, language, and/or location.

Z202662-0G PAGE 1 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

1

MODEL DESCRIPTION

H8035/H8036 Enercept Power Meter

H8163 with H8163-CB Energy Meter

H663/H704 Branch Circuit Meter

H8238 Multi-Circuit Monitor

E5xCx Power and Energy Meter, Modbus Protocol versions

E30/E31 Panelboard Monitoring System

Page 2

H8932/H8936

TM

OPERATION

The H8932/H8936 Network Display is designed to provide an easily visible display

for data collected by Modbus metering devices. The H893x is connected in series,

downstream from the Modbus master and upstream from the meters. All data values

collected by all supported meters are viewed, except for a limited data set for E3x

panelboard monitors. See the section titled Data Values for Supported Devices for

lists of data values that are presented on the Network Display.

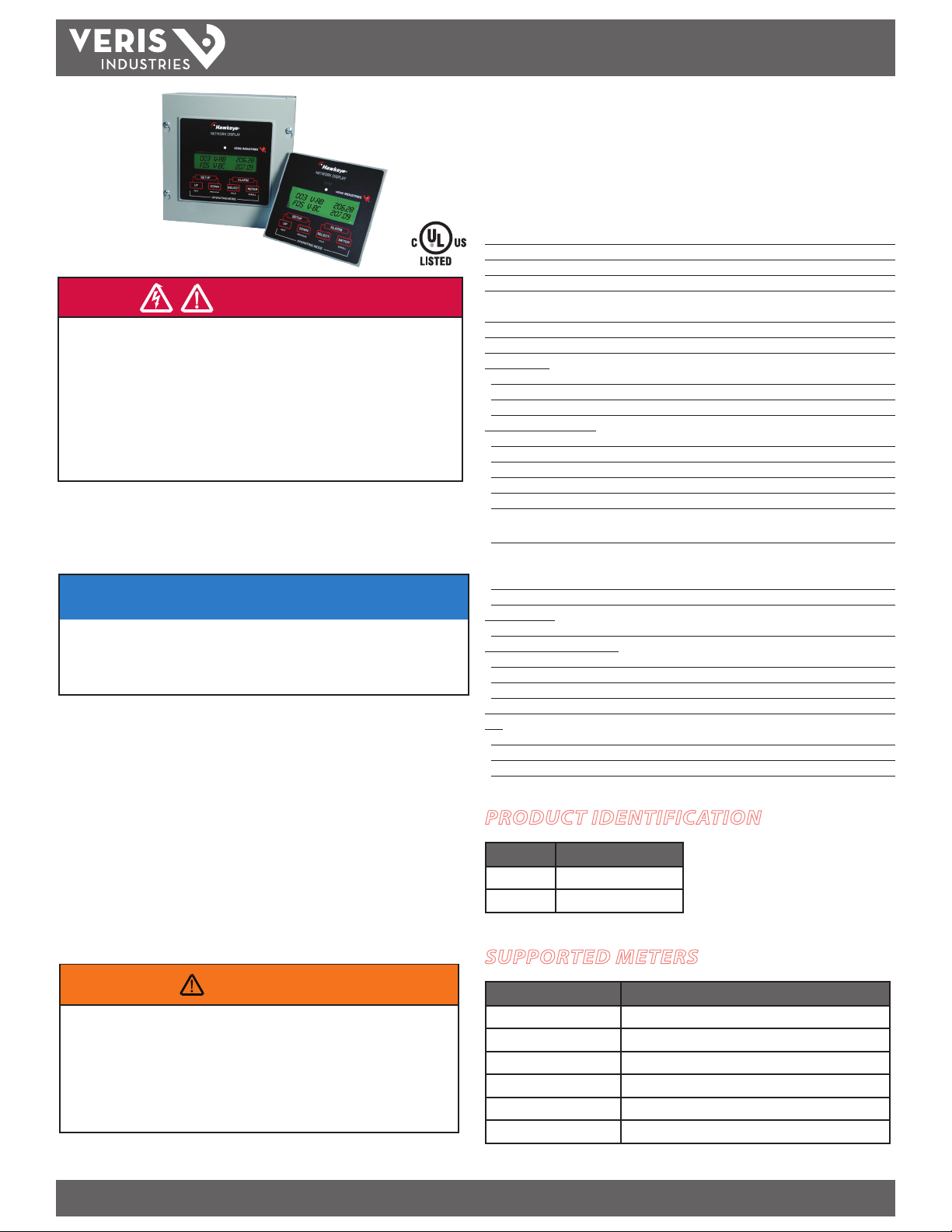

DIMENSIONS

INSTALLATION GUIDE

5.3”

(135 mm)

H8932

Front View Side View

8.0”

(204 mm)

8.0”

(204 mm)

5.8”

(147 mm)

Mounting plate template

(plate not provided with the H8932)

2.2”

(57 mm)

4.8”

(122 mm)

H8936

Front View Side View

8.0”

(204 mm)

8.0”

(204 mm)

Back View

7.0”

(177 mm)

4.2”

(106 mm)

5.0”

(128 mm)

4x Ø 0.28”

(7.1 mm)

Z202662-0G PAGE 2 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 3

TM

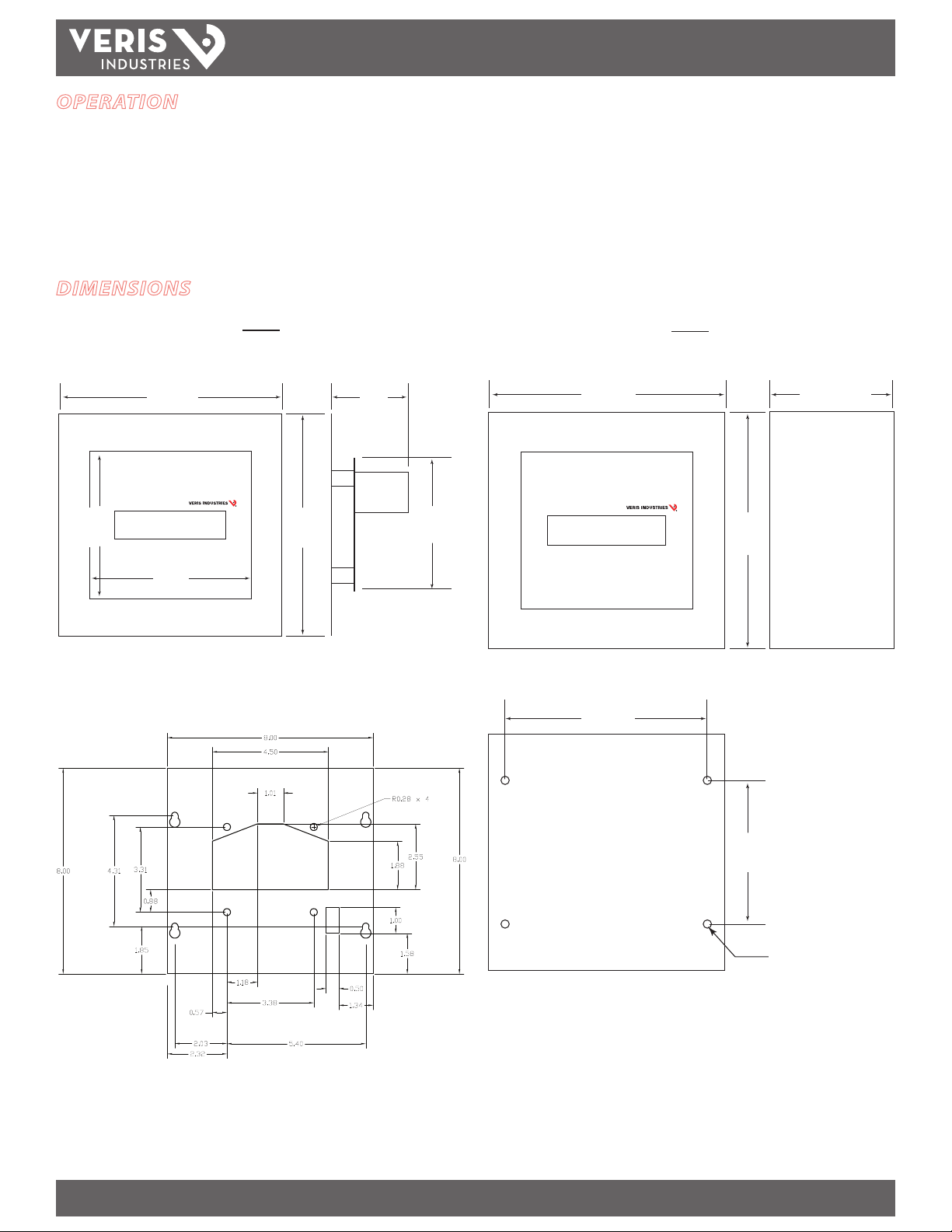

PRODUCT DIAGRAM

1

4

H8932/H8936

INSTALLATION GUIDE

BACK FRONT

2

3

5

Hawkeye

NETWORK DISPLAY

13

14

®

VERIS INDUSTRIES

12

6

8

7

9

10

1. 250 VAC 200 mA Fast Blow Fuse: Fused power connection for circuit

protection.

2. Lithium Battery: On board clock back up.

CAUTION! DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED. REPLACE ONLY WITH THE SAME OR

EQUIVALENT TYPE RECOMMENDED BY THE MANUFACTURER.

DISPOSE OF USED BATTERIES ACCORDING TO THE MANUFACTURER’S INSTRUCTIONS.

3. Power Transformer: Linear power supply for reliability and low noise.

4. 120 VAC Power Supply Terminals: 2-position Euro style pluggable connector

for 120 VAC, 60 Hz line to neutral power connection.

5. Auxiliary Input Status LED: Indicates alarm condition for the auxiliar y input.

SELECT

HOLD

ALARM

METER

SCROLL

11

SETUP

UP DOWN

NEXT

PREVIOUS

OPERATING MODE

15

13. Tri-Color LED: green = normal operation (no networked devices are in warning

or alarm mode); yellow = warning (one or more networked devices are in warning

mode); red = alarm (one or more networked devices are in alarm mode or the

auxiliary input is active).

14. LCD Display: Local data display; high resolution LCD with adjustable backlight

15. Membrane Keypad: Easy front-panel setup

6. Membrane Switch Pin Connector: Connection point for push button panel.

7. Auxiliary Input Contacts: Contact closure or pull-to-ground (10mA max.)

8. Upstream RS-232 Input Jack: Connection point for upstream RS-232 network.

9. Upstream RS-485 Connection Point: 5-position Euro style pluggable

connector for upstream RS-485 network. 2-wire or 4-wire selectable.

10. Downstream RS-485 Connection Point: 5-position Euro style pluggable

connector for downstream RS-485 network. 2-wire or 4-wire selectable.

11. 12 VDC Power Port: Alternate 12 VDC connection point for use with plug-in wall

mount transformer or power supply (auxiliary input is disabled if 12 VDC power is

used).

12. Membrane Switch Ribbon Cable

Z202662-0G PAGE 3 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 4

H8932/H8936

TM

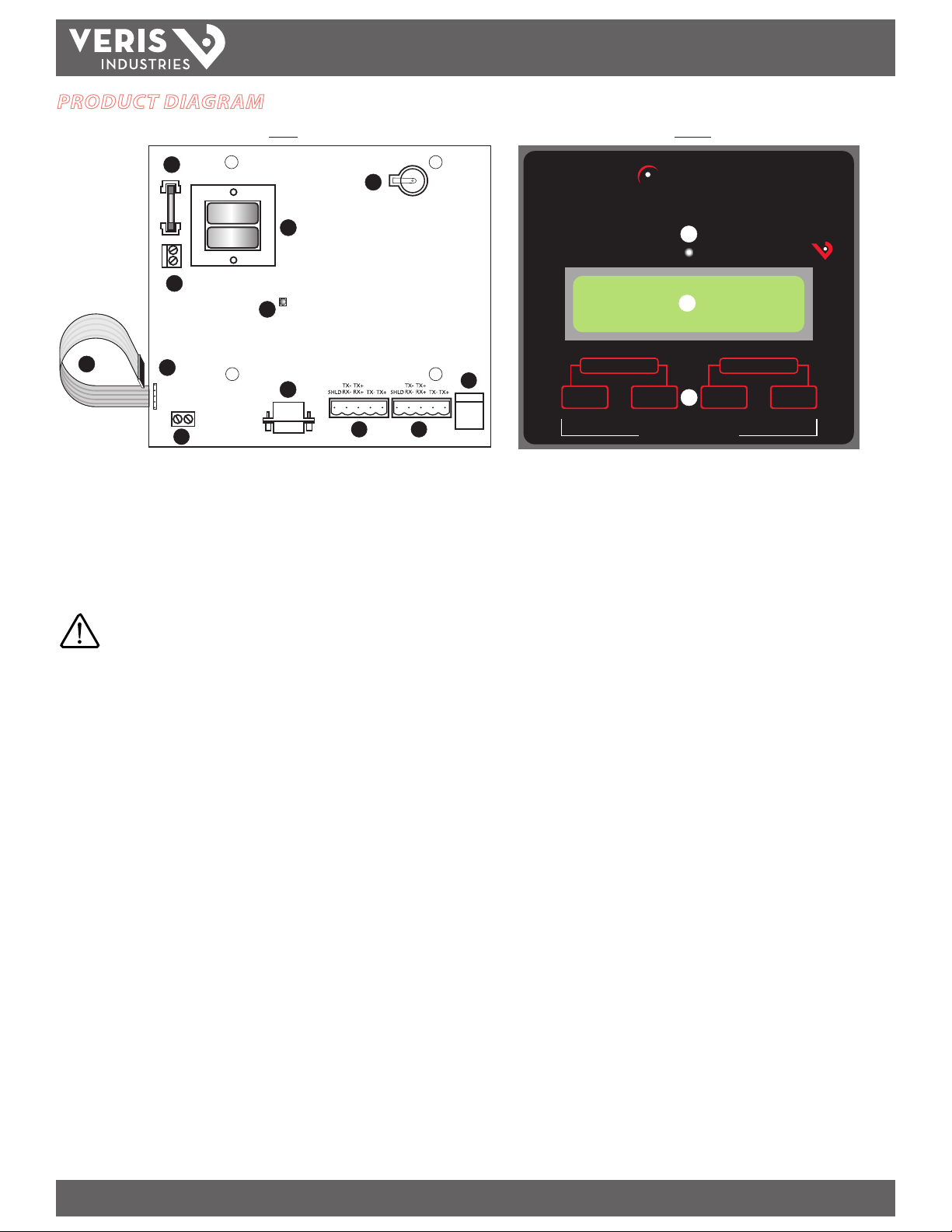

INSTALLATION

Component List

A. Face Plate with membrane switch ribbon cable

B. Box Lid (H8936 only) or panel (not included with H8932)

C. Threaded spacers (H8936 only)

D. Four threaded stand-os

E. Network Display

F. Four #6-32 screws

G. Box (H8936 only)

H8932 Mounting in a Panel (see right)

1. Drill 4 holes in the panel and cut out an area for the H8932.

2. Secure the faceplate by screwing the four threaded stand-os (D) into the face

plate studs from the inside of the door.

3. Attach the Network Display (E) to the threaded studs using four #6-32 screws (F)

provided.

4. Connect the membrane switch ribbon cable to the membrane switch pin

connector.

INSTALLATION GUIDE

Faceplate (A)

Panel (B)

H8932/H8936 Assembly Example:

Faceplate (A)

(4 ea.) Threaded Spacers (C)

(Provided with H8936 only)

Box Lid (H8936) or Panel (H8932)

(B)

(4 ea.) Threaded Stand-Os (D)

Network Display (E)

(4 ea.) #6-32 Screws (F)

Box (G) is provided with the

H8936 only (preassembled)

Z202662-0G PAGE 4 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 5

H8932/H8936

Control Panel

or PC

Next Network Display

On to additional Network Displays

Network Display

H663/H704

Branch Circuit Monitor

H8163 with H8163-CB

Energy Meter with

Communication Board

H8035/H8036

Enercept Power Meter

H8238

Multi-Circuit Monitor

E30/E31

Panelboard Monitor

E5xCx

Power and Energy Meter

End-of-Line

Termination Resistor

100 Ohms

Upstream RS-485

or

RS-232

Downstream RS-485

Up to 63 (physical) or 246 (logical) devices

UP DOWN

SELECT

METER

ALARM

OPERATING MODE

NETWORK DISPLAY

VERIS INDUSTRIES

SETUP

NEXT

PREVIOUS

HOLD

SCROLL

UP DOWN

SELECT

METER

ALARM

OPERATING MODE

NETWORK DISPLAY

VERIS INDUSTRIES

SETUP

NEXT

PREVIOUS

HOLD

SCROLL

Network Display

Downstream RS-485

H663/H704

Branch Circuit Monitor

H8163 with H8163-CB

Energy Meter with

Communication Board

H8035/H8036

Enercept Power Meter

H8238

Multi-Circuit Monitor

E30/E31

Panelboard Monitor

E5xCx

Power and Energy Meter

End-of-Line

Termination Resistor

100 Ohms

Up to 63 (physical) or 246 (logical) devices

TM

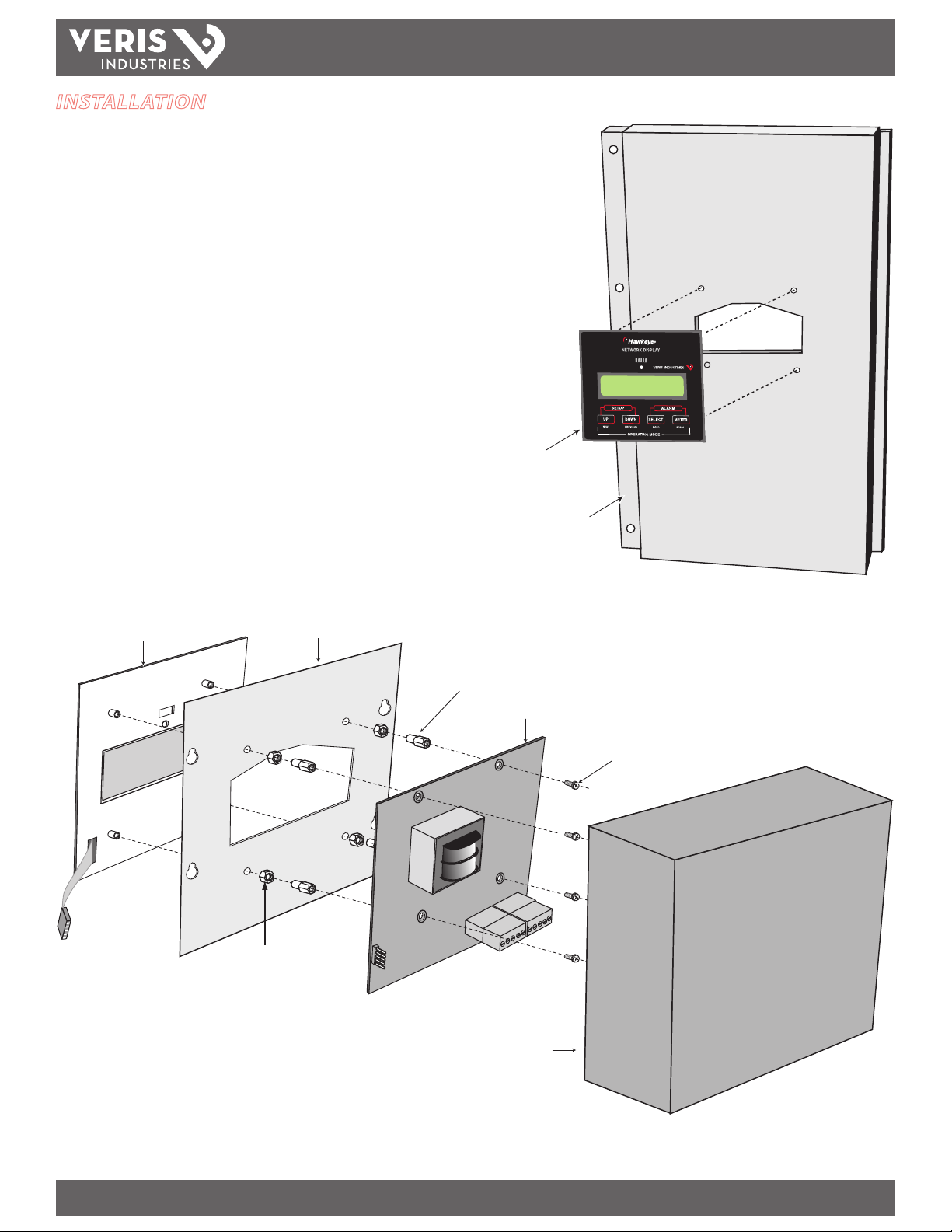

NETWORK CONFIGURATION

Wiring the Network(s)

The H8932/H8936 resides on a Modbus network as a pass-through device. Unlike

most Modbus RTU devices, it is not wired in a daisy chain conguration. This allows

the user to make separate upstream and downstream networks, allowing for exible

data retrieval, as the upstream options include RS-232 or RS-485.

Network Map: Option 1

INSTALLATION GUIDE

Network Map: Option 2

NOTE: The manufacturer does not recommend con necting multiple network displays in serie s on

the downstream network .

NOTE: Other Modbus devices must respond to the “Rep ort Slave ID” command (11h) to allow pass-

through communication from the upstream network.

Z202662-0G PAGE 5 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 6

H8932/H8936

TM

WIRING

1. Connect the upstream RS-485 or RS-232 devices (if used).

2. Connect the downstream RS-485 device daisy chain.

3. Connect the power. Use either 120 VAC (240 VAC if using the E model) 2-wire or 12

VDC as shown below.

4. Terminate the downstream and upstream networks per the RS-485 standard.

RS-232 Upstream

INSTALLATION GUIDE

Master (Network Display) Slave (Downstream Device)

Power Wiring Option #1

120 VAC

4-wire RS-485 Downstream

4-wire RS-485 Upstream

Master or Slave

2-wire RS-485 Downstream

2-wire RS-485 Upstream

Power Wiring Option #2*

12 V DC

*Internal fusing is not active o n the 12 VDC input. Do not connect

both power options at the sam e time.

External ½ A fuse must be provi ded by installer.

Z202662-0G PAGE 6 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 7

H8932/H8936

UP

DOWN

To Enter

(SELECT, DOWN, DOWN, SELECT, UP, UP)

UP

SELECT

DOWN

METER

Show next

submenu

Show previous

submenu

Return to

monitoring

Go to submenu

or start action

Setup Mode

Press Simultaneously

Press

Enter Password

* * * * * * *

Increment

parameter

Decrement

parameter

Return to

setup menu

Go to next

parameter

DOWN

UP

SELECT

METER

Increment

parameter

Decrement

parameter

Return to

setup menu

Go to next

parameter

DOWN

UP

SELECT

METER

Go to the next

parameter set.

Go to the previous

parameter set.

Go to the

next meter

Hold a reading on

the LCD (display will

ash).

For use in automatic

cycle mode (See Setup

Operations).

The current reading does

not update, allowing time

to manually record the

reading. Press any

other button to release

the held reading.

DOWN

UP

SELECT

METER

Go to the

next alarm.

Reset the currently

displayed alarm.

Exit the alarm

display.

To Enter

Alarm Menu

Press Simultaneously

Press

UP

SELECT

SELECT

METER

METER

TM

SETUP

Use the Setup mode to initialize and congure the display to the application

requirements. Use Setup Sub-menus to group parameters for setup.

Entering Setup Mode

Setup Mode Sub-Menus

After entering the password (Select, Down, Down, Select, Up, Up), the device enters

the Setup Mode Sub-Menus. Scroll through these menus using the Up or Down

buttons, and enter a menu by pressing Select.

1. VIEW SYSTEM INFO: Lists the model number and rmware version of the device.

INSTALLATION GUIDE

Status LED and Relay Operation

The status LED displays the condition of the alarm registers on a color cue basis.

Green: normal operation (no networked devices are in warning or alarm

mode)

Yellow: warning (one or more networked devices are in warning mode)

Red: alarm (one or more networked devices are in alarm mode or the

auxiliary input is active).

Monitoring Mode

Monitoring mode is the default mode for the H8932/H8936. In monitoring mode, the

data values are updated at 4-second intervals. The H8932/H8936 can be set either

to cycle automatically through all parameters on all devices or to display a selected

parameter continuously.

2. FIND METERS: Initiates a search and identies meters on the network. Exit the

search by pressing any key (do not exit until all active addresses have been

counted). Unsupported devices are designated as “unknown device,” and

parameters are not displayed.

3. REVIEW METERS: Review all meters on the network.

4. SETUP COMMUNICATIONS: Scroll through this list of available parameters using

the Select button; change a parameter value using the Up and Down buttons.

Communications Parameters:

Address Routing (On, O)

Modbus Address (1-247)

Upstream Type (RS-485, RS-232)

Upstream Duplex (2-wire, 4-wire) (not available for RS-232)

Upstream Baudrate (2400, 4800, 9600, 19200)

Upstream Parity (NONE, ODD, EVEN)

Downstream Duplex (2-wire, 4-wire)

Downstream Baudrate (2400, 4800, 9600, 19200)

Downstream Parity (NONE, ODD, EVEN)

5. SETUP OPERATION: Scroll through this list of available parameters using the Select

button; select a parameter value using the Up and Down buttons.

Alarm Mode

Alarm Mode provides a means of viewing and resetting warnings and alarms on the

downstream network. To enter Alarm mode, press the Select and Meter buttons

simultaneously.

Operation Parameters:

Z202662-0G PAGE 7 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Backlight Brightness (0-9; 0 = o)

Auxiliary Input (open, closed)

Rotate Parameters (Yes, No)

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 8

TM

MAIN MENU NAVIGATION

H8932/H8936

INSTALLATION GUIDE

Default Mode

To Enter

Press Simultaneously

Press

To Enter

Press Simultaneously

Enter Password

MONITORING

UP

Show next

parameter set

ALARM MENU

UP

Show next

alarm

SETUP MENU

UP

* * * * * * *

DOWN

Show previous

parameter set

DOWN

SELECT

Hold reading

SELECT

SELECT

Clear alarm Return to

(SELECT, DOWN, DOWN, SELECT, UP, UP)

METER

next meter

METER

METER

monitoring mode

Go to

Press

UP

Show next

sub-menu

DOWN

Show previous

sub-menu

SELECT

Enter a sub-menu

or start action

METER

Return to

monitoring mode

Z202662-0G PAGE 8 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 9

TM

SUB-MENU NAVIGATION

H8932/H8936

INSTALLATION GUIDE

1st Sub-menu:

View System Info

2nd Sub-menu:

Find Meters

3rd Sub-menu:

Review Meters

SELECT

Enter the sub-menu

DOWNUP

Scroll parameters:

Model Number/Serial Number

Version/Revision

Memory/Clock

SELECT

Find Meters

SELECT

Review Meters

UP

Scroll through meters

METER

Return to setup menu

METER

Return to setup menu

METER

Return to setup menu

4th Sub-menu:

Setup Communications

5th Sub-menu:

Setup Operation

SELECT

Enter the sub-menu

SELECT

Scroll parameters:

Address Routing (On, O)

Modbus Address (1-247)

Upstream Type (RS-485, RS-232)

Upstream Duplex (2-wire, 4-wire) (not available for RS-232)

Upstream Baudrate (2400, 4800, 9600, 19200)

Upstream Parity (NONE, ODD, EVEN)

Downstream Duplex (2-wire, 4-wire)

Downstream Baudrate (2400, 4800, 9600, 19200)

Downstream Parity (NONE, ODD, EVEN)

SELECT

Enter the sub-menu

SELECT

Scroll parameters:

Backlight Brightness (0-9; 0=O)

Auxiliary Input (open, closed)

Rotate Parameters (Yes, No)

METER

Return to setup menu

METER

Return to setup menu

Increment

Parameter

Increment

Parameter

DOWNUP

Decrement

Parameter

DOWNUP

Decrement

Parameter

Z202662-0G PAGE 9 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 10

H8932/H8936

TM

DATA VALUES FOR SUPPORTED DEVICES

H8035 Enercept Power Meter

INSTALLATION GUIDE

H8163 Energy Meter with H8163-CB Board

Display* Units* Description Modbus Address

KWH kWh Energy Consumption 258/259

KW kW Real Power 260/261

H8036 Enercept Power Meter

Display* Units* Description Modbus Address

KWH kWh Energy Consumption 257/258

KW kW Real Power 261/262

KVA R kVAR Reactive Power 263/264

KVA kVA Apparent Power 265/266

PF --- Power Factor 267/268

V-LL Volts Average Voltage, L-L 269/270

V-LN Volts Average Voltage, L-N 271/272

AMPS Amps Average Current 273/274

KW-A kW Real Power, Phase A 275/276

KW-B kW Real Power, Phase B 277/278

KW-C kW Real Power, Phase C 279/280

PF-A --- Power Factor, Phase A 281/282

PF-B --- Power Factor, Phase B 283/284

PF-C --- Power Factor, Phase C 285/286

V-AB Volts Voltage, Phase A-B 287/288

V-BC Volts Voltage, Phase B-C 289/290

V-AC Volts Voltage, Phase A-C 291/292

V-AN Volts Voltage, Phase A-N 293/294

V-BN Volts Voltage, Phase B-N 295/296

V-CN Volts Voltage, Phase C-N 297/298

AM PA Amps Current, Phase A 299/300

AMPB Amps Current, Phase B 301/302

AMPC Amps Current, Phase C 303/304

AVE kW Average Real Power 305/306

MIN kW Minimum Real Power 307/308

MAX kW Maximum Real Power 309/310

Display* Units* Description Modbus Address

KWH kWh Energy Consumption 257/258

KW kW Real Power 261/262

KVA R kVAR Reactive Power 263/264

KVA kVA Apparent Power 265/266

PF --- Power Factor 267/268

V-LL Volts Average Voltage, L-L 269/270

V-LN Volts Average Voltage, L-N 271/272

AMPS Amps Average Current 273/274

KW-A kW Real Power, Phase A 275/276

KW-B kW Real Power, Phase B 277/278

KW-C kW Real Power, Phase C 279/280

PF-A --- Power Factor, Phase A 281/282

PF-B --- Power Factor, Phase B 283/284

PF-C --- Power Factor, Phase C 285/286

V-AB Volts Voltage, Phase A-B 287/288

V-BC Volts Voltage, Phase B-C 289/290

V-AC Volts Voltage, Phase A-C 291/292

V-AN Volts Voltage, Phase A-N 293/294

V-BN Volts Voltage, Phase B-N 295/296

V-CN Volts Voltage, Phase C-N 297/298

AM PA Amps Current, Phase A 299/300

AMPB Amps Current, Phase B 301/302

AMPC Amps Current, Phase C 303/304

* The prex (k) changes to M or G for very la rge readings.

Z202662-0G PAGE 10 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 11

H8932/H8936

TM

INSTALLATION GUIDE

H663 and H704 Branch Circuit Monitors

Display Units Description Modbus Address

CH01 Amps Current, Channel 1 1

CH02 Amps Current, Channel 2 2

CH03 Amps Current, Channel 3 3

CH04 Amps Current, Channel 4 4

CH05 Amps Current, Channel 5 5

CH06 Amps Current, Channel 6 6

CH07 Amps Current, Channel 7 7

CH08 Amps Current, Channel 8 8

CH09 Amps Current, Channel 9 9

CH10 Amps Current, Channel 10 10

CH11 Amps Current, Channel 11 11

CH12 Amps Current, Channel 12 12

CH13 Amps Current, Channel 13 13

CH14 Amps Current, Channel 14 14

CH15 Amps Current, Channel 15 15

CH16 Amps Current, Channel 16 16

CH17 Amps Current, Channel 17 17

CH18 Amps Current, Channel 18 18

CH19 Amps Current, Channel 19 19

CH20 Amps Current, Channel 20 20

CH21 Amps Current, Channel 21 21

CH22 Amps Current, Channel 22 22

CH23 Amps Current, Channel 23 23

CH24 Amps Current, Channel 24 24

CH25 Amps Current, Channel 25 25

CH26 Amps Current, Channel 26 26

CH27 Amps Current, Channel 27 27

CH28 Amps Current, Channel 28 28

CH29 Amps Current, Channel 29 29

CH30 Amps Current, Channel 30 30

CH31 Amps Current, Channel 31 31

CH32 Amps Current, Channel 32 32

CH33 Amps Current, Channel 33 33

CH34 Amps Current, Channel 34 34

CH35 Amps Current, Channel 35 35

CH36 Amps Current, Channel 36 36

CH37 Amps Current, Channel 37 37

CH38 Amps Current, Channel 38 38

CH39 Amps Current, Channel 39 39

CH40 Amps Current, Channel 40 40

CH41 Amps Current, Channel 41 41

CH42 Amps Current, Channel 42 42

H8238 Multi-Circuit Monitor

Display* Units* Description Modbus Address

KWH kWh Energy Consumption 258/259

KW kW Real Power 260/261

KVA R kVAR Reactive Power 262/263

KVA kVA Apparent Power 264/265

PF --- Power Factor 266/267

V-LL Volts Average Voltage, L-L 268/269

V-LN Volts Average Voltage, L-N 270/271

AMPS Amps Average Current 272/273

FREQ Hz Frequency 274/275

KW-A kW Real Power, Phase A 276/277

KW-B kW Real Power, Phase B 278/279

KW-C kW Real Power, Phase C 280/281

PF-A --- Power Factor, Phase A 282/283

PF-B --- Power Factor, Phase B 284/285

PF-C --- Power Factor, Phase C 286/287

V-AB Volts Voltage, Phase A-B 288/289

V-BC Volts Voltage, Phase B-C 290/291

V-AC Volts Voltage, Phase A-C 292/293

V-AN Volts Voltage, Phase A-N 294/295

V-BN Volts Voltage, Phase B-N 296/297

V-CN Volts Voltage, Phase C-N 298/299

AM PA Amps Current, Phase A 300/301

AMPB Amps Current, Phase B 302/303

AMPC Amps Current, Phase C 304/305

AVE kW Average Real Power 308/309

MIN kW Minimum Real Power 310/311

MAX kW Maximum Real Power 312/313

* The prex (k) changes to M or G for very la rge readings.

Z202662-0G PAG E 11 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 12

H8932/H8936

TM

INSTALLATION GUIDE

E50Cx Power and Energy Meter

Display* Units* Description Modbus Address

KWH kWh Energy Consumption 259/260

KW kW Real Power 261/262

KVA R kVAR Reactive Power 263/264

KVA kVA Apparent Power 265/266

PF --- Power Factor 267/268

V-LL Volts Average Voltage, L-L 269/270

V-LN Volts Average Voltage, L-N 271/272

AMPS Amps Average Current 273/274

KW-A kW Real Power, Phase A 275/276

KW-B kW Real Power, Phase B 277/278

KW-C kW Real Power, Phase C 279/280

PF-A --- Power Factor, Phase A 281/282

PF-B --- Power Factor, Phase B 283/284

PF-C --- Power Factor, Phase C 285/286

V-AB Volts Voltage, Phase A-B 287/288

V-BC Volts Voltage, Phase B-C 289/290

V-AC Volts Voltage, Phase A-C 291/292

V-AN Volts Voltage, Phase A-N 293/294

V-BN Volts Voltage, Phase B-N 295/296

V-CN Volts Voltage, Phase C-N 297/298

AM PA Amps Instantaneous Current, Phase A 299/300

AMPB Amps Instantaneous Current, Phase B 301/302

AMPC Amps Instantaneous Current, Phase C 303/304

FREQ Hz Frequency, derived from Phase A 307/308

KVA H kVAh Apparent Energy Consumption 309/310

KVRH kVARh Reactive Energy Consumption 311/312

KVA A kVA Apparent Power, Phase A 313/314

KVA B kVA Apparent Power, Phase B 315/316

KVAC kVA Apparent Power, Phase C 317/318

KVRA kVAR Reactive Power, Phase A 319/320

KVRB kVAR Reac tive Power, Phase B 321/322

KVRC kVAR Reactive Power, Phase C 323/324

PDKW kW Total Real Power Present Demand 325/326

PDKR kW Total Reactive Power Present Demand 327/328

PDKA kW Total Apparent Power Present Demand 329/330

MDKW kW Total Real Power Max. Demand 331/332

MDKR kW Total Reactive Max. Present Demand 333/334

MDKA kW Total Apparent Max. Present Demand 335/336

* The prex (k) changes to M or G for very la rge readings.

E51Cx Power and Energy Meter

Display* Units* Description Modbus Address

KWH kWh Accumulated Real Energy: Net (Import -

KVA H kVAh Apparent Energy: Net (Import - Export) 271/272

KW kW Total Net Instantaneous Real Power 277/278

KVA R kVAR Total Net Instantaneous Reactive Power 279/280

KVA kVA Total Net Instantaneous Apparent Power 281/282

PF --- Power Factor 283/284

V-LL Volts Average Voltage, L-L 285/286

V-LN Volts Average Voltage, L-N 287/288

AMPS Amps Average Current 289/290

FREQ Hz Frequency 290/291

PUL 1 kW Pulse Counter 1 (Import Real Energy) 313/314

PUL 2 kW Pulse Counter 2 (Export Reactive Energy) 315/316

KW-A kW Real Power, Phase A 365/366

KW-B kW Real Power, Phase B 367/368

KW-C kW Real Power, Phase C 369/370

KVRA kVAR Reactive Power, Phase A 371/372

KVRB kVAR Reac tive Power, Phase B 373/374

KVRC kVAR Reactive Power, Phase C 375/376

KVA A kVA Apparent Power, Phase A 377/378

KVA B kVA Apparent Power, Phase B 379/380

KVAC kVA Apparent Power, Phase C 381/382

PF-A --- Power Factor, Phase A 383/384

PF-B --- Power Factor, Phase B 385/386

PF-C --- Power Factor, Phase C 387/388

V-AB Volts Voltage, Phase A-B 389/390

V-BC Volts Voltage, Phase B-C 391/392

V-AC Volts Voltage, Phase A-C 393/394

V-AN Volts Voltage, Phase A-N 395/396

V-BN Volts Voltage, Phase B-N 397/398

V-CN Volts Voltage, Phase C-N 399/400

AM PA Amps Instantaneous Current, Phase A 401/402

AMPB Amps Instantaneous Current, Phase B 403/404

AMPC Amps Instantaneous Current, Phase C 405/406

PDKW kW Total Real Power Present Demand 293/294

PDKR kW Total Reactive Power Present Demand 295/296

PDKA kW Total Apparent Power Present Demand 297/298

MDWI kW Total Real Power Max. Demand 299/300

MDRI kW Total Reactive Power Max. Demand 301/302

MDAI kW Total Apparent Power Max. Demand 303/304

MDWE kW Total Real Power Max. Demand 305/306

MDRE kW Total Reactive Power Max. Demand 307/308

MDAE kW Total Apparent Power Max. Demand 309/310

Export)

257/258

Z202662-0G PAGE 12 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 13

H8932/H8936

TM

E3x Panelboard Monitoring System

The E3x meters collec t a large amount of data, but only a subset of this data is presented on the H8932/H8936

Network Display, based on phase conguration and model type.

Phase Conguration:

The H8932/H8936 can be congured to display single, two, or three phased readings from the E3x meter,

based on the value selected in Modbus register 536.

Register 536 Value Display Configuration

0 or 1 = Single phase Single phase setup displays channel 1-42

2 = Two phase Two phase setup displays channel 1-21

3 = Three phase Three phase setup displays channel 1-14

Model Type:

INSTALLATION GUIDE

Display* Units* Description

Mains

FREQ Hz Frequency, Phase A

V-AN Volts Voltage, Phase A-N

V-BN Volts Voltage, Phase B-N

V-CN Volts Voltage, Phase C-N

V-AB Volts Voltage, Phase A-B

V-BC Volts Voltage, Phase B-C

V-AC Volts Voltage, Phase A-C

AUX KWH kWh Aux. Total Energy

AUX KW kW Aux. Total Real Power, Phases A, B, C

AUX PF --- Aux. Total Power Factor

AUX AMPS Amps Aux. Average Current, Phases A, B, C

Branch Circuits (1 to 42), Single Phase (xx = channel number, 1 through 42)

Mxx KWH kWh Energy

Mxx KW kW Real Power

Mxx PF --- Power Factor

Mxx AMPS Amps Current

Branch Circuits (1 to 42), Two Phase (xx = channel number, 1 through 42)

Mxx KWH kWh Energy

Mxx KW kW Real Power

Mxx PF --- Power Factor

Mxx AMPS Amps Current

Branch Circuits (1 to 42), Three Phase (xx = channel number, 1 through 42)

Mxx KWH kWh Energy

Mxx KW kW Real Power

Mxx PF --- Power Factor

Mxx AMPS Amps Current

Model

A B C

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• • •

•

•

•

• • •

•

•

•

• • •

•

•

•

• • •

Modbus Address

600/601

606/607

608/609

610/611

612/613

614/615

616/617

618/619

620/621

622/623

624/625

2000 to 2083

2084 to 2167

2168 to 2251

2252 to 2335

5000 to 5041

5042 to 5083

5084 to 5125

5126 to 5167

8000 to 8027

8028 to 8055

8056 to 8083

8084 to 8111

* The prex (k) changes to M or G for very la rge readings.

Z202662-0G PAGE 13 ©2012 Veris Industries USA 800.354.8556 or 1.503.598.4564 / support@veris.com 09126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Loading...

Loading...