Page 1

POWER MONITORING

TM

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

DANGER

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found

to comply with the limits for a class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Modifications to this product without the express authorization of

Veris Industries nullify this statement.

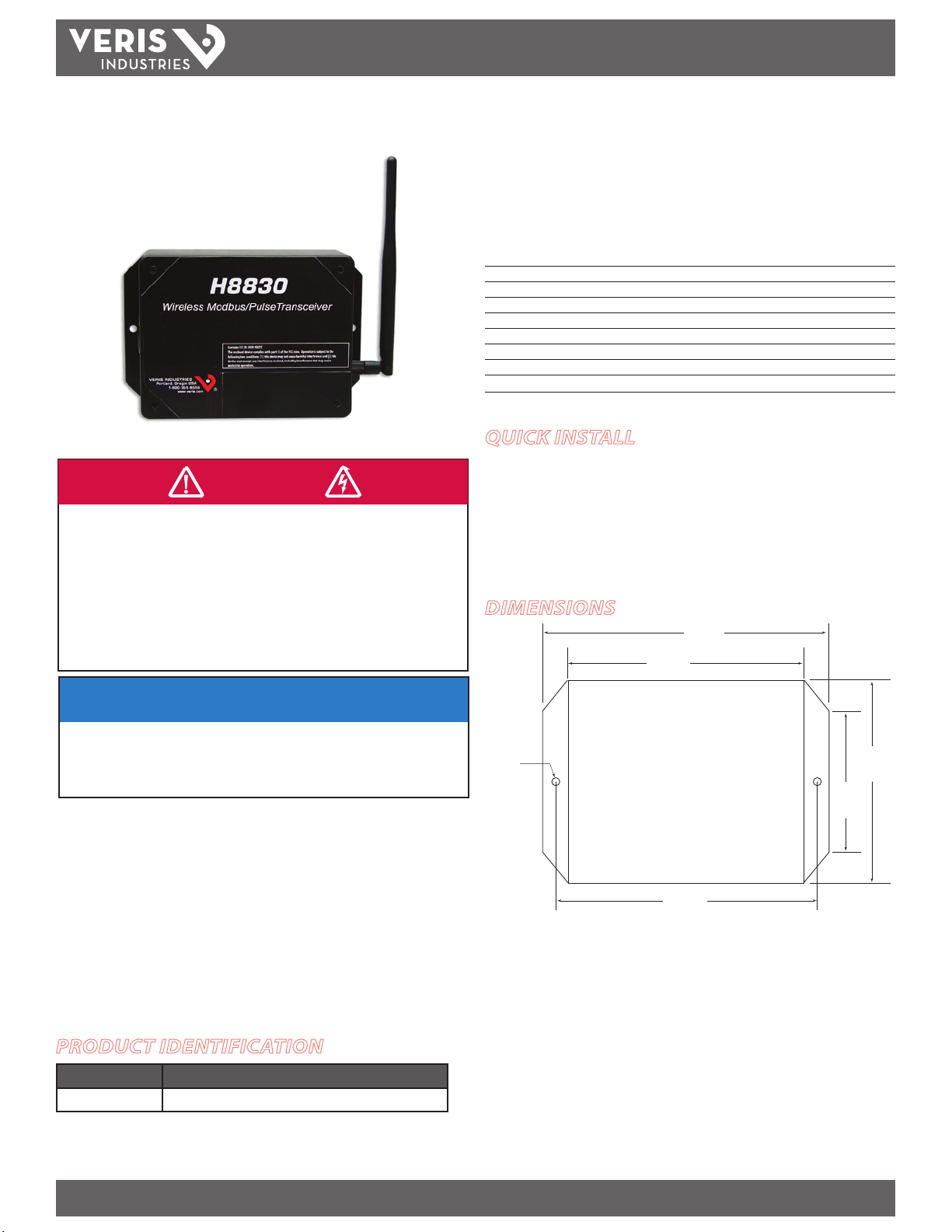

Ø 0.17”

(4.4mm)

5.6”

(143mm)

6.6”

(168mm)

6.1”

(154mm)

3.0”

(76mm)

4.3”

(110mm)

INSTALLATION GUIDE

H8830

H8830

Wireless Modbus/Pulse Transceiver

Installer’s Specifications

Input Power 110 to 120 VAC

Processor ARM

Firmware Field-upgradeable

Inputs Pulse (2x dry contact), Modbus RS-4 85

Modbus Input 2-wire RS-4 85 (9600 or 19200 baud)

LED 2x RF, 2x RS-485, 2x pulse, Alive, Alarm

Radio Frequency 900 MHz ISM band

Radio Output Power 1 mW (optional 150 mW, consult factory)

Radio Max Range 1500 ft. (457 m) per hop

quick install

Set the Modbuss address and system switches.1.

Connect the pulse and Modbus hookups.2.

Attach the antenna.3.

Connect power to the H8830.4.

Product identification

MODEL DESCRIPTION

H8830 Wireless Modbus/Pulse Transceiver

ZL0069-0A PAGE 1 ©2010 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 10102

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

dimensions

Page 2

H8830

TM

oPeration

The H8830 wireless Modbus®/pulse transceiver from Veris Industries is perfect for

submetering commercial and industrial facilities and adding Modbus devices to

any network without the need for costly communications wiring. The input port

on the H8830 easily connects to new or existing Modbus and pulse devices (meters,

sensors, etc.) to automatically detect the optimum route for reliable and timely data

communications. Data from each H8830 passes from one transceiver to another to

reach its ultimate destination. This self-managed mesh network allows the system

to function with high reliability where other wireless systems fail due to short- or

long-term interference from radio signals

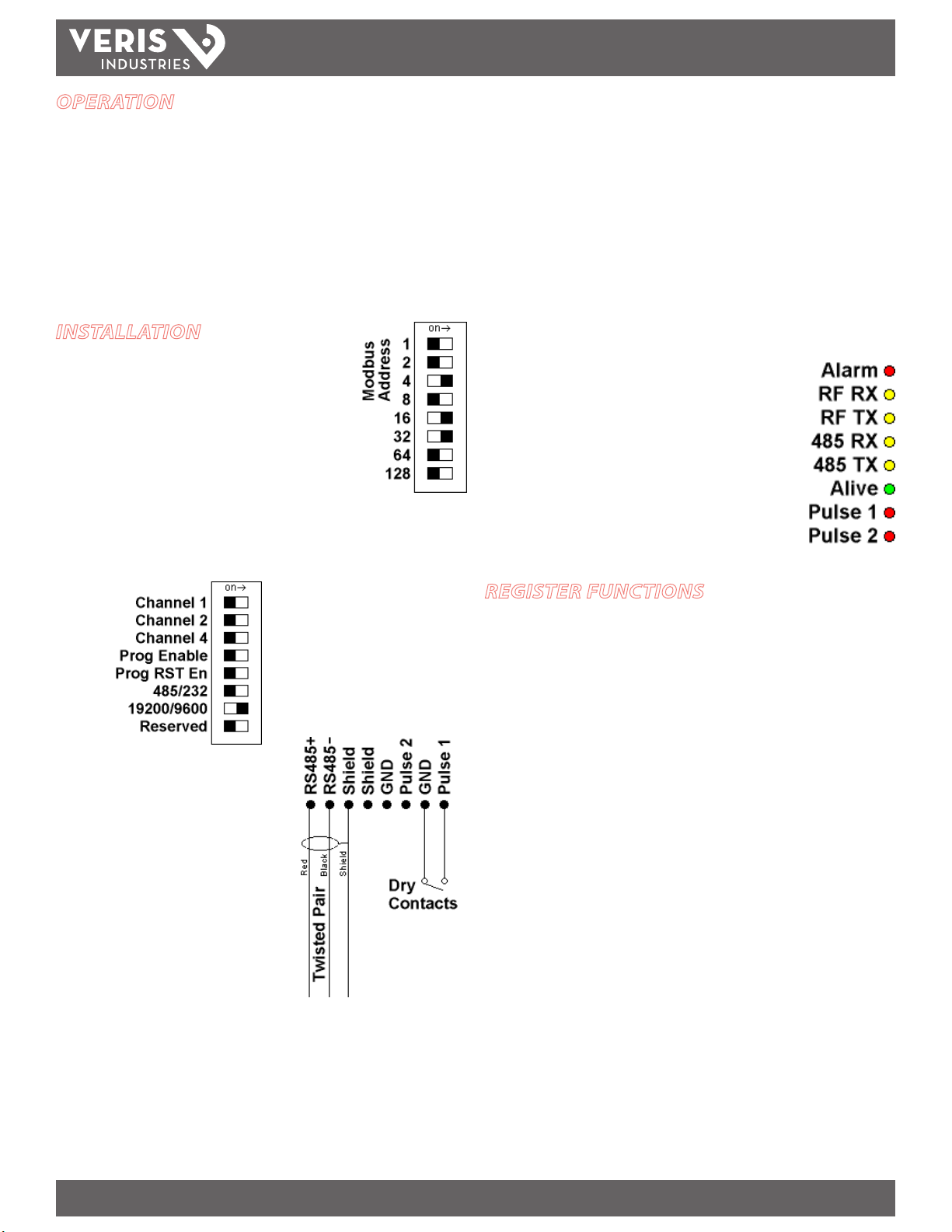

installation

Modbus Address:1. Every Modbus device in the system

must have a unique address. This includes each H8830 and

every attached RS-485/Modbus device. Select an address

and set the DIP switches to match. The sum of the value

of the switches is the address. In the example to the right,

set address 52 by placing switch 4, 16, and 32 to the ON

position.

System Switches: 2. For most systems, set all of the system switches to the “OFF”

position. The only required switch is the RS-485 baud rate option. Set this to “OFF”

for 19200 or to “ON” for 9600. The example below is a default configuration for

9600 baud on the RS-485 connection.

INSTALLATION GUIDE

Modbus Hookup:4. Attach any Modbus slave or master devices to the RS-485

terminals as shown in the wiring diagram. Multiple Modbus devices may be

attached to each H8830.

Note: When attaching Modbus devices, it is not necessary to specify if the device

is a master (H8820, PLC, etc) or a slave device (power meter, sensor, etc). The

H8830 will automatically detect the master and handle it appropriately.

Attach the Antenna:5. Attach the antenna to the side of the H8830. The antenna

should be finger tight and be placed in a vertical position.

Power up the H8830: 6. Attach the power brick to the power jack on the H8830.

The device should power up and be ready in a few seconds. The LEDs should blink

in the following manner.

The Alive LED should start to blink about once per •

second.

The Alarm LED will blink if transmission errors occur.•

The RF TX/RX LEDs will blink when the radio is •

receiving or transmitting data.

The RS-485 LEDs will blink for local Modbus activity.•

The Pulse input LEDs will light when the •

corresponding pulse input terminals are closed.

Pulse Hookup:3. Attach any dry contact pulse

output meters to the pulse input terminals as

shown in the wiring diagram to the right. The

H8830 can support two pulse devices.

The H8830 can be attached to many types of

pulse output meter. Power, water, gas, etc. For

“KYZ” type power meters, use the normally

open contacts, usually labeled “K and Z”.

register functions

Pulse Count: The pulse count is stored as an unsigned 32-bit integer. This allows 1.

for 232 pulses (4.2 billion) to be counted before rollover. On Modbus systems

that do not allow you to read 32-bit values, you can calculate the pulse count as

follows:

count = MSW * 65535 + LSW

Instantaneous Pulse Rate: The pulse rate values for instantaneous, minimum, and 2.

maximum rates are calculated based on the time between arriving pulses. For

example, if InstPulse1 = 30 and InstPulse count size = 5, then the average rate for

the last 5 pulses is 6 sec/pulse. To convert the register values (in seconds) to a rate

value, use the following formula:

Rate/hour = (N * 60 * 60 / InstRegister)

where InstRegister is any of the 6 register values 4 through 9, and N is the

instantaneous pulse count size at offset 10.

Min/Max Pulse Rate: These 4 registers are calculated from the instantaneous pulse 3.

rate. These latching registers are updated whenever the minimum or maximum

rate fields are exceeded by the instantaneous rate. These four registers may be

cleared by writing a zero to the register. Writing to one min./max. register clears

all four min./max. registers.

ZL0069-0A PAGE 2 ©2010 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 10102

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

Page 3

H8830

TM

INSTALLATION GUIDE

register listing

Offset Point Type Description

0 40001 UINT32 Pulse count 1 MSW

1 40002 UINT32 Pulse count 1 LSW

2 40003 UINT32 Pulse count 2 MSW

3 40004 UINT32 Pulse count 2 LSW (same format as pulse count 1)

4 40005 UINT16 InstPulse 1 time (seconds)

5 40006 UINT16 InstPulse 2 time (seconds)

6 40007 UINT16 (R/W) min. pulse 1 time (seconds) (write clears min./max.)

7 40008 UINT16 (R/W) min. pulse 1 time (seconds)

8 40009 UINT16 (R/W) max. pulse 2 time (seconds)

9 40010 UINT16 (R/W) max. pulse 1 time (seconds)

10 40011 UINT16 (R/W) InstPulse count size (default = 5)

100 40101 UINT16 Serial number (bytes 1, 2)

101 40102 UINT16 Serial number (bytes 3, 4)

102 40103 UINT16 Serial number (bytes 5, 6)

103 40104 UINT16 Firmware version (e.g. v1.03, high byte = major; low byte = minor; 0x8000 flag set for Beta)

104 40105 UINT16 Boot count

105 40106 UINT32 Mfg date MSW

106 40107 UINT32 Mfg date LSW

107 40108 UINT16 Radio group ID setting (0-6)

108 40109 UINT16 Alarm flags (0x01 = boot from watchdog)

109 40110 UINT16 Max. packet buffers used

110 40111 UINT32 Radio up time (seconds) MSW

111 40112 UINT32 Radio up time (seconds) LSW

ZL0069-0A PAGE 3 ©2010 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 10102

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

Loading...

Loading...