Page 1

VESTA LOG FIRE

VLF45NG, VLF45NG, VLF45P, VLF45P

Manual & Remote Operated Models

THIS IS NOT

A ‘DO-IT-YOURSELF’ PRODUCT

THIS APPLIANCE MUST BE INSTALLED

BY A CORGI REGISTERED PERSON

INSTALLATION, USERS AND

SERVICING INSTRUCTIONS

THESE PRODUCTS ARE APPROVED TO THE EUROPEAN GAS DIRECTIVE

Article I. PLEASE LEAVE THESE INSTRUCTIONS

WITH THE USER

0120

Page 2

2

Contents

Page No.

List of components

3

Appliance Data

3

GENERAL INSTALLATION REQUIREMENTS

3

Fitting the Appliance

4

Fitting the appliance into the optional Radiant Firebox

5

Additional notes for handset remote control model

6

Assembling the fire & the placing of the logs

8

COMMISSIONING

10

Check for spillage

10

Briefing the User

10

USERS GUIDE

11

Useful tips & recommendations

11

Operation of your appliance

11

Manual Appliances

12

Remote Appliances

13

Cleaning your fire

14

SERVICING & MAINTENANCE

15

Spares Parts list

16

Guarantee

17

Installation & Service Record

18

Important Notes – Please read before undertaking the installation

1. This is not a “Do it yourself” product and it must be installed by a

competent person.

2. The chimney must be swept before the appliance is fitted.

3. The Installation Instructions must be adhered to without exception.

Page 3

3

Before fitting this appliance, ensure that the following list of components are

enclosed

(a) Vesta Burner unit

(b) 1 Set Ceramic Base Pieces (1 Base, 1 LH Side, 1 RH Side, 1 Front, 1 Burner.)

(c) 1 Log Set (4 Pieces)

(d) Installation, User & Servicing Instructions

(e) For Handset Remote Models only 1 Handset Control unit c/w 9V alkaline battery

1 Signal receiver (with mount)

1 Battery Charger c/w lead & jack plug

1 Rechargeable Battery pack & wiring harness

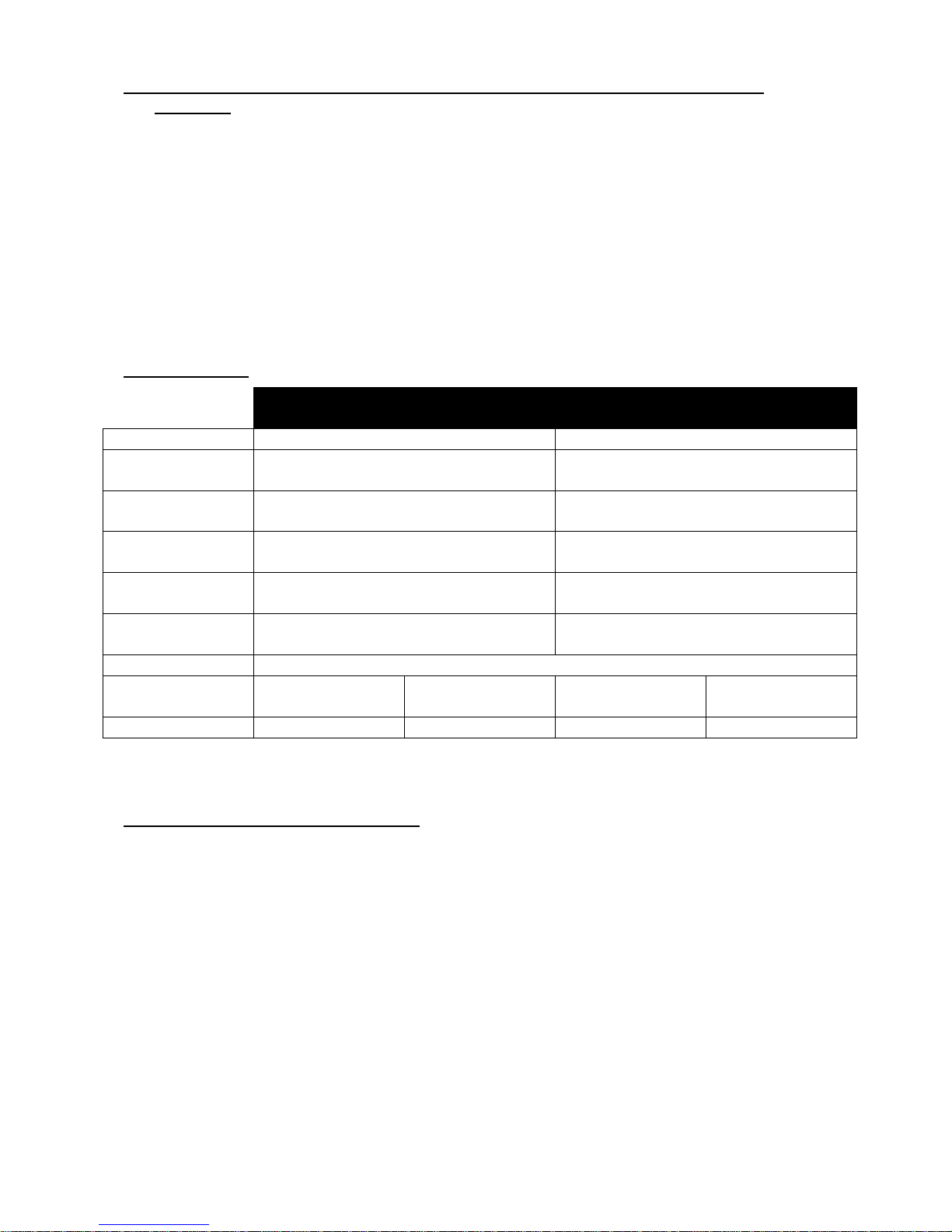

APPLIANCE DATA

VLF45NG

(Manual)

VLF45NG

(Remote)

VLF45P

(Manual)

VLF45P

(Remote)

Gas Type

Natural Gas

Propane

Heat Input

(Gross) (kW)

11.0

10.3

Supply Pressure

(mbar)

20

37

Injector Size

(mm)

2.75

1.6

Injector Setting

(High) (mbar)

14.5

28.0

Injector Setting

(Low) (mbar)

5.5

7.0

Gas Connection

8mm Compression

Fuse Rating

(Amps)

N/A

3

N/A

3

Weight (Kg)

3.5

4.5

3.5

4.5

Dimensions of burner: 450mm wide, 250mm deep, 190mm high.

GENERAL INSTALLATION REQUIREMENTS

1 The law demands that all gas appliances are installed by a qualified installer in

accordance with the current Gas Safety (Installation and Use) Regulations. The

installation must comply with these installation instructions and all relevant parts of

Local and National Building Regulations or Building Standards (Scotland)

(Consolidation) Regulations and those relevant recommendations of the following

British Standards.

BS 5871: Part 2 BS 8303 BS 5440: Parts 1 and 2 BS 1251 BS 6891

The current IEE wiring regulations, Local Building Regulations and the Building

Standards (Scotland) (Remote Models only).

These Installation Instructions must be adhered to without exception.

Page 4

4

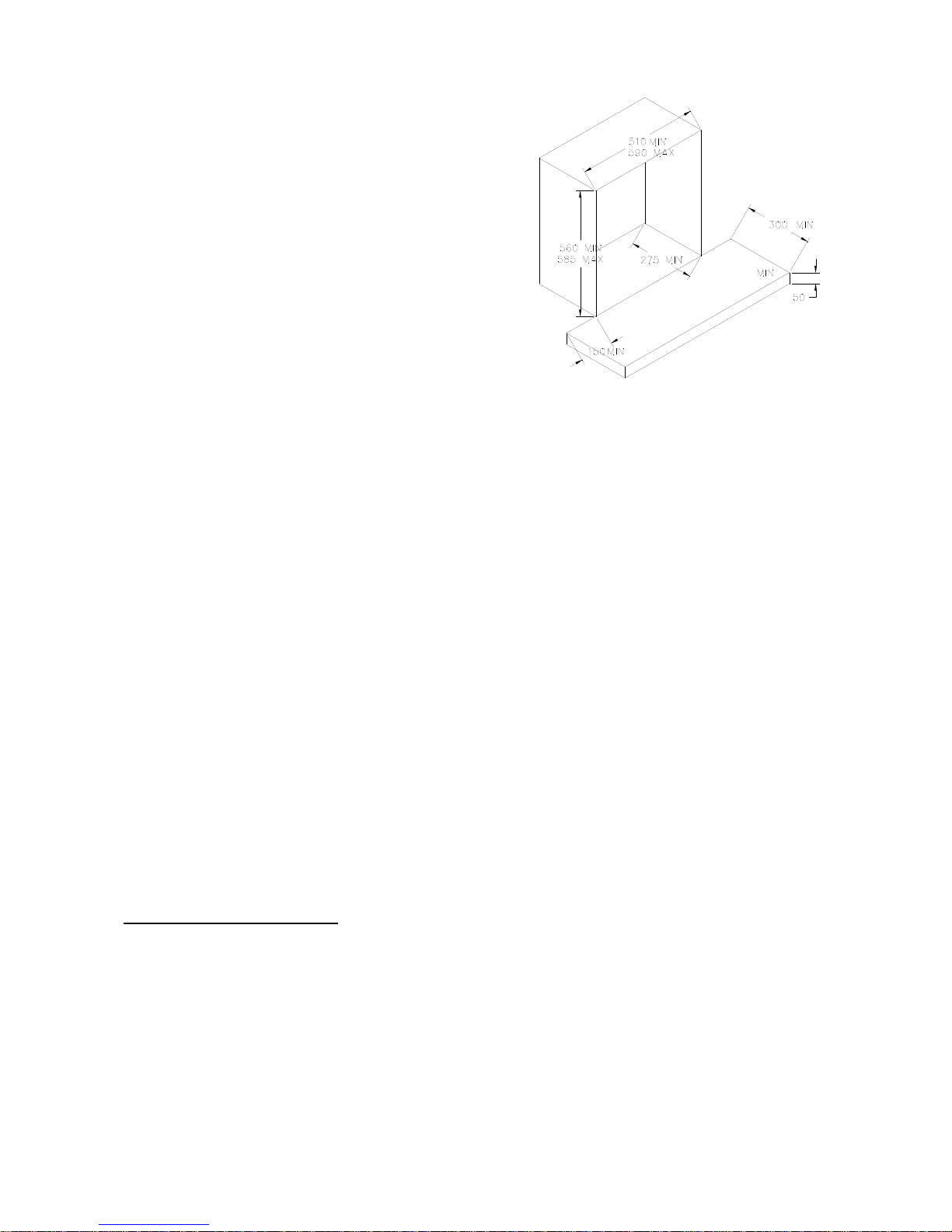

2 FIREPLACE See figure 1

The radiant fireboxes can be fitted to

fireplaces which meet the dimensional

requirements shown in figure 1.

Basket installations require a fireplace

large enough to accommodate the

basket chosen.

Decorative frets should have a

minimum of 50cm2 (8 sq. ins.) of free

air space through the ash cover to

ensure adequate air supply for both

convection air and burner combustion.

3 THE HEARTH

The hearth must be made of a non combustible material at least 12mm in thickness

and must meet the dimensional requirements shown in figure 1. The Heating

Appliances (Fireguards) (Safety) Regulations 1991 are part of the Consumer

Protection Act. It is a criminal offence to fit a Euroglow Inset burner into a fireplace

where the periphery of the hearth is less than 50mm (2”) above the floor level.

Under BS 5871: Part 2 the installation of a fender of 50mm (2”) height will satisfy the

height requirement.

4 THE CHIMNEY FLUE

For radiant firebox installations the chimney should be of the open-flue type and

have a minimum cross sectional dimension of not less than 175mm. For basket

installations the cross section size and the height should be matched to the cross

section of the fireplace opening (See BS 5871 Part 3).

5 The flue must have a minimum effective height of 3 metres.

6 No restrictor plate or flue damper is permitted. Where a variable damper is fitted,

this must be removed or fixed permanently in the fully open position.

7 The chimney must be swept before the appliance is installed and a flue test in

accordance with National Regulations must be carried out.

8 VENTILATION

The room containing the appliance must have a permanent air vent of at least

100cm². The vent must be direct to outside air or to an adjacent room having a

permanent vent of the same area.

FITTING THE APPLIANCE

1 Check that the fireplace is large enough to accept the selected basket. See figure 1.

2 Check that the ignition system functions correctly. Push and turn the control knob

and check that a spark is generated at the pilot burner. If no spark is evident then

check the soundness of the leads.

3 Check the tightness of the nut at the control valve end of the thermocouple.

CAUTION: Do not over tighten.

4 It is recommended that, before proceeding further, a simple smoke test be performed

to check the condition of the chimney. Light a smoke match or a twist of rolled

paper, hold it within the fireplace opening and observe the behaviour of the smoke.

FIGURE 1

Page 5

5

If it is being drawn into the chimney proceed with the installation. If not, preheat the

chimney over the period of a few minutes and recheck. If there is any doubt about

the soundness of the chimney a smoke pellet should be used after preheating the

flue and if smoke still fails to clear, further investigation of the chimney is required

and the appliance MUST NOT be fitted.

5 The gas supply should be routed from the meter or cylinder to a point convenient to

the fireplace.

6 Cut and form a section of 8mm pipe, only rigid and semi-rigid tube is acceptable and

run this into the fireplace opening. If a concealed fitting is required, care must be

taken to sleeve the supply pipe when fitting through masonry.

7 Place the appliance centrally within the fireplace opening. N.B. No part of the

appliance should project beyond the vertical opening of the fireplace opening.

8 Using the nut and olive provided, connect the 8mm supply pipe to the combined

pressure test point and isolator fitting.

Gas Soundness Check

9 With the gas supply connected, all joints should be checked for gas soundness in

accordance with BS 6891.

NOTE: It is permissible to light the fire FOR SHORT PERIODS ONLY when the fire

is not laid with ceramics and logs.

FITTING THE APPLIANCE INTO THE OPTIONAL RADIANT FIREBOX

1 Check that the fireplace or recess is of the correct size to receive the radiant firebox.

See Figure 1.

Note: BS 5871 Part 2: requires a debris collection space of 12 dm3.

2 It is recommended that, before proceeding further, a simple smoke test be performed

to check the condition of the chimney. Light a smoke match or a twist of rolled

paper, hold it within the fireplace opening and observe the behaviour of the smoke.

If it is being drawn into the chimney proceed with the installation. If not, preheat the

chimney over a period of a few minutes and recheck. If smoke still fails to clear,

further investigation of the chimney is required and the appliance MUST NOT be

fitted.

3 In either case, clear the recess of any loose material. Ensure that the base on which

the firebox will stand is level and that the base of the recess and the hearth are

horizontal and non-combustible.

4 Slide the firebox into the opening, ensuring that the flue outlet is unobstructed and

give a clear passage for the products of combustion to the flue. (Do not seal at this

stage.)

5 The firebox should be fitted in such a manner as to be removable, for the purposes

of chimney-sweeping and easy removal of debris.

6 The gas supply should be routed from the meter or cylinder to a point convenient to

the fireplace.

7 Decide whether the gas supply is to be routed through the sides or back of the

firebox, or across the front of the fireplace. Grommeted holes are provided in the rear

and side of the box. Having determined the position of the gas pipe the appropriate

grommet can be pierced with a knife. Provision will have to be made to pass the

pipe through the masonry of the fireplace. The supply pipe should be run to make

removal for servicing easy.

Page 6

6

8 Cut and form a section of 8mm pipe, only rigid or semi-rigid tube is acceptable, and

run this into the fireplace opening. If a concealed fitting is required, care must be

taken to sleeve the supply pipe when passing it through masonry. Exposed pipe

within the fire opening should be wrapped, painted with bituminous paint, or be

factory sheathed.

9 Seal the firebox into the fire opening using the sealing tape provided or a water

based mastic.

10 Fit the burner unit into its mounting brackets within the firebox.

11 Prior to connecting the burner to the gas supply, it is advisable to blow out the pipe

to clear any dirt that may be present and which could cause a blockage in the control

valve or pilot.

12 Using the nut and olive provided, connect the 8mm supply pipe to the combined

pressure test point and isolator fitting.

13 Complete the installation of the appliance as above.

ADDITIONAL NOTES FOR HANDSET REMOTE CONTROL MODEL

1 The installation of the appliance should be carried out following the procedures as

per the section entitled “Fitting the Appliance” on page 4.

2 After installing the burner, positions must be found for the battery pack and the Infra

Red (IF) signal receiver. The fret and ash pan cover will have to be put in position to

find the best place for these items.

3 Battery

Place the battery pack on the hearth along the front of the fire just behind the ash

pan cover. DO NOT PLACE THE BATTERY PACK UNDER THE FIRE.

4 Plug the small jack plug from the charger into its socket at the end of the battery

pack and plug the charger into the mains and switch on to give the batteries a top up

charge.

FIGURE 2

Page 7

7

5 Charging the battery pack

The charger supplied with the battery pack is a true charger and will not overcharge

the batteries. The charger has a built in switch so that it will switch off when the

batteries in the pack are fully charged. The red LED on the front face of the charger

will light when there is current passing to the batteries.

6 The batteries can be

charged either when

they are run down and

the fire will not light

(the control box under

the fire should emit a

series of ‘beeps’ if an

attempt is made to

light the fire when the

batteries do not have

sufficient charge) or

on a regular basis as

convenient to the

user. The batteries

used are of the nickel

– metal - hydride type

that do not suffer

memory problems if they are not discharged completely before being re-charged. A

20 - 30 minute charge should be enough to enable the fire to be lit but a full charge

will take several hours. It may be convenient to leave the charger connected

overnight. DO NOT LEAVE THE CHARGER CONNECTED TO THE BATTERY

PACK WHEN THE FIRE IS IN USE.

FIGURE 3

FIGURE 4

Page 8

8

FIGURE 5

7 IR Signal Receiver

The signal receiver should be placed on the hearth just behind the ash pan cover

such that it is visible to the user operating the remote control handset. If the

receiver is covered in any way the fire will not operate. The receiver is secured

to a bracket with a screw which can be removed when the burner is taken out for

service. The bracket should be fixed to the hearth with the double sided tape

provided after having selected a suitable position for it with the fret and ash pan

cover in position (See Figure 5). The signal receiver must be positioned on the

bracket with the raised part facing the user.

8 Fitting the Battery to the Handset

Before using the

appliance remove

the access cover in

the rear of the

handset and insert

a 9-volt PP3 size

battery. Connect

the battery by

pushing the

connector on to the

terminals. Make

sure the battery is

connected correctly.

Replace the access cover.

ASSEMBLING THE FIRE AND PLACING THE LOGS

WARNING

This product uses fuel effect pieces containing Refractory Ceramic Fibre

(RCF), which are man-made vitreous silicate fibres along with fibrous glass

and mineral wool. Excessive exposure to these materials may cause temporary

irritation to eyes, skin and respiratory tract; consequently, it makes sense to

take care when handling these articles to ensure that the release of dust is

kept to a minimum.

FIGURE 6

Page 9

9

CAUTION All the ceramic components are fragile and should be handled with

care.

1 The burner tray and base ceramics are illustrated in figure 6. Position the burner

ceramic making sure that the holes are aligned with the burner ports. Take the front

ceramic and place it on the burner tray in front of the burner ports. Lay the base

ceramic on the ramp behind the front ceramic. Place the side ceramics either side of

the base ceramic.

2 With reference to figure 7 on the following page, lay the logs as follows;

a) Place the largest log in its moulded seat at the rear of the base ceramic.

b) Place the small branch log in its seats on the left hand side and front ceramics

and rest it on the upstand of the base ceramic.

c) Place the log with a burnt cut-out on its seat on the right hand side ceramic.

d) Place the small v-shaped log in position on the front ceramic and rest it on the

large log and the front logs.

FIGURE 7

Page 10

10

COMMISSIONING

When commissioning your appliance, remove the cap from the isolator fitting and

unscrew the plug all the way out. Replace the cap making sure that the tab engages

with the slot in the top of the plug. Tighten cap securely. Light the appliance in

accordance with the instructions relevant to the appropriate control. (See following

sections for details)

CHECK FOR SPILLAGE

1 Before briefing the customer on how to use the appliance, a spillage test must be

carried out with the appliance and decorative fret in position. The following

procedure must be followed.

2 Close all doors and windows in the room or space containing the appliance.

3 Light a smoke match and pass completely along the front edge (and just inside the

top edge) of the fireplace or firebox. A visual check should ascertain that all the

smoke generated is drawn back into the firebox.

4 If there is evidence of spillage, the flue should be heated for a period of 5 to 10

minutes and the test repeated.

BRIEFING THE USER

1 Demonstrate the full operation of the appliance to the customer, referring them

specifically to the lay of the logs and the removal of soot, as described in these

instructions.

2 Inform the customer that all cleaning procedures should be carried out only when the

appliance is cold.

3 Leave these instructions with the customer.

4 Advise the importance of having the appliance serviced and the chimney checked for

clearance of combustion products on an annual basis.

Page 11

11

USERS GUIDE

USEFUL TIPS AND RECOMMENDATIONS

Once your fire has been fitted, the following recommendations are made to ensure

you enjoy the best results from your purchase;

1 The installation of this appliance must be carried out by a qualified installer and in

accordance with the requirements of the Gas Safety (Installation & Use)

Regulations

2 The chimney must be swept before the appliance is installed and checked annually

to ensure continued clearance of combustion products and that there is no excessive

build-up of soot.

3 As with any fire, certain components will become hot in use, e.g. the decorative front

fret. Care should be exercised when using the control of the appliance when it is

hot. We also recommend that a fireguard, conforming to BS 6539 or BS 6778, be

fitted for the protection of young children, the elderly or infirm.

4 When new, the ceramic logs may produce a slight odour, but this will completely

vanish after a few hours of use.

5 Handle logs gently (See warning on Page 8). They are fragile. A soft brush can be

used to clean them of any excess soot. UNDER NO CIRCUMSTANCES should logs

be washed.

6 Never throw cigarette ends or other foreign matter onto the fire.

7 Never leave the house unattended, with the fire alight, for long periods.

8 Check periodically that the purpose-made ventilation is free from obstruction.

9 To obtain the best results from your log fire we recommend that the fire be serviced.

In order that the terms and conditions of your warranty (see page 17) are met, this

must be undertaken annually and the Service Engineer must complete the Service

Record. (Page 18)

10 These instructions are provided to assist you to operate the fire correctly and should

be kept in a safe place.

11 This appliance is intended for decorative purposes.

12 This appliance is fitted with a flue blockage device that will shut off the appliance in

the event of abnormal flue conditions. This device is NOT a substitute for an

independently mounted carbon monoxide detector.

13 It is a characteristic of the re-chargeable Nickel - Metal Hydride batteries that power

the control system is that they deliver almost full power until they are nearly

completely discharged. This means that the first indication that the battery pack

needs charging is that the fire will emit a series of ‘beeps’ when an attempt is made

to light the fire from cold and the pilot burner will not remain alight. A 20 minute

charge will probably be enough to light the fire but this should be followed by full

charge as soon as the fire is not required.

OPERATION OF YOUR APPLIANCE

1 It should be noted that your fire is fitted with a Flame Supervision Device, which cuts

off the gas supply to your fire if, for any reason the pilot light is extinguished. It also

monitors constantly the oxygen in the room. The pilot flame heats the thermocouple

probe and allows gas to flow to the burners. If due to pilot failure, the thermocouple

cools, no gas will flow to the main burner. If the fire is turned off or the flames go

out, wait for AT LEAST 3 MINUTES before attempting to relight the fire.

Page 12

12

2 When the fire is first lit, the flames tend to be rather blue in colour. Once the core of

the fire becomes hot, the flames will become yellow and more lifelike. During this

initial warm-up period it is recommended that the control remains in the ‘MAX’ or

‘HIGH’ position. This permits the fire to reach its optimum condition more quickly.

3 For convenience you will find with the appliance a card giving concise lighting

instructions, please keep this in a safe place. For full details see the relevant

appliance instruction on pages 12 – 14

LIGHTING THE APPLIANCE

Manual Appliances

1 Remove the ash pan cover (if fitted) below the decorative fret in the front of the fire.

2 Push in and turn the control knob (see figure 8) anti-clockwise to the ‘PILOT’

position & hold in for several seconds to purge any air from the system. If the fire

has not been used for some time or is new this may take half a minute or more as

the air can only purge through the very small orifice in the pilot burner injector.

During this purge time you can try lighting the pilot burner (see next paragraph)

every ten seconds or so but after each attempt remember to return the control knob

to the ‘pilot’ position and keep it depressed.

3 Lighting the pilot burner is done by turning the control knob, still depressed, from the

‘OFF’ position to the ‘PILOT’ position when the spark generator will be heard to

‘click’ as a spark is produced which should light the pilot burner. If the pilot does not

light try again after a few seconds. The

pilot may not light at the first attempt.

Waiting a few seconds gives the spark

generator time to recover.

4 Once the pilot burner is alight continue to

depress the control knob for a further 10 –

15 seconds and then release. The pilot

should stay alight. If it goes out repeat the

process, only this time keeping the control

knob depressed for a slightly longer

period.

5 Depress the control knob slightly and turn

anti-clockwise to the ‘MAX’ position. The

main burner should now light.

6 Turn the control knob anti-clockwise to the

‘MIN’ position. The flames will get lower

but the main burner should remain alight.

Turning the fire off

7 To turn off the burners, depress the control knob slightly and turn clockwise to the

‘PILOT’ position. The main burner should go out but the flame should remain alight.

8 Depress the control knob slightly and turn to the ‘OFF’ position. The pilot flame

should go out.

IMPORTANT

After turning ‘OFF’, or if the pilot or the appliance go out for any reason, wait 3

minutes before attempting to relight.

Page 13

13

Remote Appliances

9 Using the handset

When using the handset make sure that it is

pointed at the infra red signal receiver

located under the front of the fire (the small

black pad). Unlike a TV control the fire does

not react to a quick press on the button on

the handset control. The buttons must be

pressed and held until the control box under

the fire acknowledges the signal by emitting

a 'beep' sound (this can take two or three

seconds) and then released. When the

handset is emitting a signal the yellow LED

at the top of the control will flash.

10 Lighting the Fire See Figure 9

To light the fire press the OFF and the

STAND BY buttons together on the handset

until the fire control box answers with a

'beep' and then released. The fire will go

through its start - up procedure by lighting

first the pilot burner and then the main

burner on high fire. This procedure takes

about 30 seconds. If the fire does not light or

there is no reaction when the two buttons are pressed, press the OFF button to reset the control and try again.

11 Adjusting the Flame Height

To turn the fire from high to low, press and release the low fire button as soon as the

'beep' is heard and the flame height will reduce. If the fire is set at high and a flame

height between high and low fire is desired, press and continue to hold the low fire

button after the 'beep' has sounded. The flame height will gradually decrease.

Release the button when the desired height of flame is achieved. To turn the fire

from low fire to high fire press and (after the 'beep' is sounded) release the high fire

button. To gradually increase the flame press and hold the button as described

above for the low fire button.

12 Turning the Fire OFF

To turn the fire off but leave the pilot burner alight press the STAND-BY button until

the 'beep' is heard. Use this facility to conserve battery life if the fire is going to be

used again later in the day. To turn the fire completely off press the OFF button. The

STAND-BY button and the OFF button can be pressed when the flame is at any

height. To light the main burner from the STAND-BY position press either the HIGH

FIRE or LOW FIRE buttons.

13 Manual OFF Facility

If, whilst the fire is alight, the handset control is lost or its battery becomes

discharged the fire can be turned off by pressing and holding the manual off button

situated on the fascia underneath the front of the burner. This button disconnects the

battery from the control box and the fire will go out after the button has been held in

for about a minute. Care should be taken as the fret / ash pan cover as well the

burner facia will be hot.

Figure 11

FIGURE 9

Page 14

14

14 Replacing the batteries

As stated above, the batteries are of the nickel – metal - hydride type which have a

long life and are able to be re-charged many times. Eventually, due to age and use,

a point will come when they need recharging at inconveniently short intervals and

they will have to be replaced. The batteries are AA size and should be of 1.2 volts

and at least 1300mAH capacity. This type of battery is readily available through retail

and trade outlets.

15 To change the batteries

a) When the fire is cold lift away the ash pan cover.

b) Locate the battery pack under its heat shield.

c) Invert the battery pack and bend the securing tab outwards. Slide the battery holder

out of the heat shield.

d) Remove the batteries from their holder and replace with new batteries. Observe the

correct polarity of the batteries in their holder.

e) Slide the battery holder back into the heat shield and re-bend the securing tab.

f) Plug the charger into the battery pack and to the mains. The red LED on the charger

should come on. If it does not, check the polarity of the batteries and all connections.

Charge the batteries overnight, or as indicated by the instructions that were included

with the new batteries.

CLEANING YOUR FIRE

1 Ensure that the fire is cold before undertaking any cleaning. Remember that heat is

retained for some time after the fire is switched off. In normal use your fire requires

only minimal cleaning. Soot may form on the logs but this is generally harmless and

can easily be removed by lifting the relevant logs from the fire and cleaning them

with a soft brush. If it is necessary to remove all logs for cleaning then any soot or

debris should be removed from the ceramic element and from the burner.

2 As with all metal products, the trim on the fire may tarnish over a period of time. The

metal finish is covered with a lacquer and should only be washed with mild

detergent. On no account use any abrasives or metal polish on the trim.

3 If large pieces of debris are found in the fire, sufficient to alter the appearance or

operation of the appliance, the chimney / flue should be inspected and the appliance

serviced before further use.

4 In any event, the chimney should be checked annually to ensure continued

clearance of the combustion products and that there is no excessive build-up of soot.

Page 15

15

SERVICE AND MAINTENANCE

WARNING

This product uses fuel effect pieces containing Refractory Ceramic Fibre (RCF),

which is man-made vitreous silicate fibres along with fibrous glass and mineral wool.

Excessive exposure to these materials may cause temporary irritation to eyes, skin

and respiratory tract; consequently, it makes sense to take care when handling these

articles to ensure that the release of dust is kept to a minimum.

The appliance should be serviced annually by a CORGI registered engineer.

This is the basic procedure.

1 The ceramic pieces should be taken off the fire and shaken to remove any debris

and soot particles but should only be cleaned if absolutely necessary. This should be

done by gently brushing with a soft brush in a direction away from the person and

any persons nearby. This operation should be performed outside facing downwind. A

vacuum cleaner must not be used for this purpose. Badly damaged logs should be

replaced. Replacement logs and ceramic pieces are available via our stockists.

2 The gas supply should be turned off at the combination pressure test point and

isolator fitting. Disconnect the burner from the gas supply, remove any burner fixings

and lift away the burner.

3 Remove all debris and soot from the burner and thoroughly clean the burner ports.

4 The pilot burner fitted is an oxygen depletion pilot burner and is the primary safety

device on the appliance. It must therefore be replaced annually. After changing the

pilot burner operate the spark generator and observe that the spark is satisfactory.

5 Lay the burner on a flat surface and remove, clean and replace the main injector.

6 Any soot or debris should be removed from the fireplace and flue. The flue should be

inspected for soundness and a smoke test performed as described in the fitting

section to check the condition of the flue.

7 Replace and fix the burner in position. Re-connect to the gas supply. Check all joints

for gas soundness.

8 Light the burner and check that it functions correctly. Re-light the pilot burner. Check

that the pilot flame is satisfactory. Check correct functioning of the thermocouple and

magnet valve (housed within the control valve). This is done by turning the control

knob to the pilot position and then blowing out the pilot burner. Time the period

between the blowing out of the pilot burner and hearing the 'click' of the magnet

valve closing. If this period exceeds 60 seconds the magnet valve will also have to

be replaced.

9 Replace the burner ceramics and rebuild the fuel lay as described in the installation

section. Light the fire and, after allowing it a few minutes to warm up, make final

adjustments to the logs to obtain a satisfactory visual affect.

AFTER REFITTING THE APPLIANCE CHECK FOR GAS SOUNDNESS AT ALL

GAS JOINTS AND TEST FOR SPILLAGE.

10 The service record sheet is enclosed with these instructions and should be

completed to maintain the validity of the five year warranty

Page 16

16

SPARE PARTS LIST

In the event of a part requiring replacement the parts list is as follows

DESCRIPTION

VERINE PART

NUMBER

OXYGEN DEPLETION PILOT ASSEMBLY (NATURAL GAS ONLY).

P47

OXYGEN DEPLETION PILOT ASSEMBLY (L.P.G. PROPANE ONLY).

P48

GAS CONTROL BM VALVE (NATURAL GAS MANUAL) INC. PIEZO & HT LEAD

P12

SPECIAL ORDER

GAS CONTROL BM VALVE (L.P.G. MANUAL) INC. PIEZO & HT LEAD

P12

SPECIAL ORDER

GAS CONTROL BM VALVE (NATURAL GAS & L.P.G S/C) INC. PIEZO & HT LEAD

P12

SPECIAL ORDER

SIT TANDEM 830 SOLENOID VALVE (NATURAL GAS & L.P.G. S/C ONLY)

P97(22NG)

EXTERNAL SWITCH LEAD.

SC13

BRASS WALL SWITCHPLATE.

SC2

WHITE WALL SWITCHPLATE.

SC3

LOG/CERAMIC SET – BURNER TRAY.

VO28

FIREBOX CERAMIC LINING.

H63

HIGH TEMPERATURE FIREBOX/STOVE PAINT SATIN BLACK – CAN.

P55

BLACK MAGIC COAL/CERAMIC RESTORER – CAN.

P56

SENSOR DOUBLE SOLENOID VALVE

SC10

SENSOR HAND HELD UNIT

SC10H

SENSOR RECEIVER UNIT

SC10R

Page 17

17

GUARANTEE.

1. The appliance is guaranteed for one year from the date of purchase.

2. This guarantee is given subject to the following provisions:-

a) The installation is carried out by a CORGI registered person.

b) That the fireplace conforms to the requirements given in the Installation

Instructions for this appliance.

c) That our instructions covering cleaning and handling are adhered to.

This guarantee does not cover mishandling.

d) That the guarantee card supplied with every purchase is returned to us

for registration within four weeks of the date of purchase with the details

correctly filled in.

e) That any part or parts on which a claim is made are returned to us

postage paid for inspection.

f) That our liability is limited to free replacement of the parts affected.

g) The guarantee does not cover (1) Normal wear and tear. (2) Possible

discolouration of polished parts. (3) Replacement of batteries.

h) The remote battery pack, if fitted, is guaranteed against faults but battery

life is not guaranteed as this is dependant on usage, the battery is also

not guaranteed if it is damaged due to heat if the instructions on

placement are not followed.

Page 18

18

Installation & Service Record

Please ensure that installer completes the installation record below

INSTALLATION RECORD

Appliance Supplied by: …………………………....

Installation Date: ……………Serial No.: ….……...

Installed By: …………..…...CORGI No.: …..……

Signed by Installer: ……………………………..…

RECORD OF 1st SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

……………………………………………………………

……………………………………………………………..

RECORD OF 2nd SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

………………………………………………………………

…………………………………………………………..

RECORD OF 3rd SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

……………………………………………………………

……………………………………………………………..

RECORD OF 4th SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

………………………………………………………………

…………………………………………………………..

RECORD OF 5th SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

……………………………………………………………

……………………………………………………………..

RECORD OF 6th SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

………………………………………………………………

…………………………………………………………..

RECORD OF 7th SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

……………………………………………………………

……………………………………………………………..

RECORD OF 8th SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

………………………………………………………………

…………………………………………………………..

RECORD OF 9th SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

……………………………………………………………

……………………………………………………………..

RECORD OF 10th SERVICE

Serviced by: ………… CORGI No.:…………....

Service Date: …………… Signed: ….…….…...

Comments: ……………………………………………

………………………………………………………………

…………………………………………………………..

Page 19

19

Page 20

20

Verine Limited

52 Broton Drive Trading Estate

Halstead, Essex CO9 1HB

Tel: (01787) 472551 Fax: (01787) 476589

Email: sales@verine.co.uk

Website: www.verine.co.uk

LOG/1006/II&UI THIS BOOKLET CONTAINS 20 PAGES

Loading...

Loading...