Page 1

ATINA 500 / VERTEX 700

MODEL NUMBERS: NABG50RN, NABG50RP/ NVBG70RN, NVBG70RP.

THIS IS NOT

A `DO-IT-YOURSELF` PRODUCT

THE APPLIANCE MUST BE INSTALLED BY

A GAS SAFE REGISTERED PERSON

INSTALLATION, SERVICING AND USERS

INSTRUCTIONS

THESE PRODUCTS ARE APPROVED TO THE EUROPEAN GAS DIRECTIVE

PLEASE LEAVE THESE INSTRUCTIONS WITH

THE USER FOR FUTURE REFERENCE

Page 2

2

Important Notes – Please read before undertaking the installation

1. The chimney must be swept before the appliance is fitted.

2. The Installation Instructions must be adhered to without exception.

LIST OF COMPONENTS

a) Firebox complete with burner and controls.

b) Installation, Servicing & Users Instructions

c) Packet of burner fill; either black granules or limestone pebbles

d) 1 Handset Control unit, 1 off 9 volt battery, 4 off Lithium AA batteries.

e) Pack containing – 4 magnets, sealing tape, and 8 self-tapping screws for joining the

upper and lower fireboxes.

f) Fuel pack if ordered.

g) Trim (as ordered – either XL trim for Atina & Vertex or Portrait for Atina only). The box

containing the trim will include 4 off mounting screws and a pair of disposable gloves.

h) Four Sided Trim (Optional).

APPLIANCE DATA

NABG50RN

NVBG70RN

NABG50RP

NVBG70RP

GAS TYPE

NATURAL GAS

PROPANE

SUPPLY

PRESSURE

20mb

37mb

HEAT INPUT

6.2 kW Net

8.5kW Net

6.4 kW Net

8.1 kW Net

INJECTOR SIZE

Ø 1.9mm

Ø 2.3mm

Ø 1.31mm

Ø 1.46 mm

GAS CONNECTION

8 mm Compression

WEIGHT

16kg

23kg

16kg

23kg

GENERAL INSTALLATION REQUIREMENTS

Fitting the Appliance

1 The law demands that all gas appliances are installed by a qualified installer in

accordance with the current GAS SAFETY (INSTALLATION AND USE) REGULATIONS.

The installation must comply with these installation instructions and all relevant parts

of Local and National Building Regulations or Building Standards (Scotland)

(Consolidation) Regulations and those relevant recommendations of the following

British Standards.

BS 5871: Parts 2 & 3, BS 8303, BS 5440: Parts 1 & 2, BS 1251, BS 6891

Page 3

3

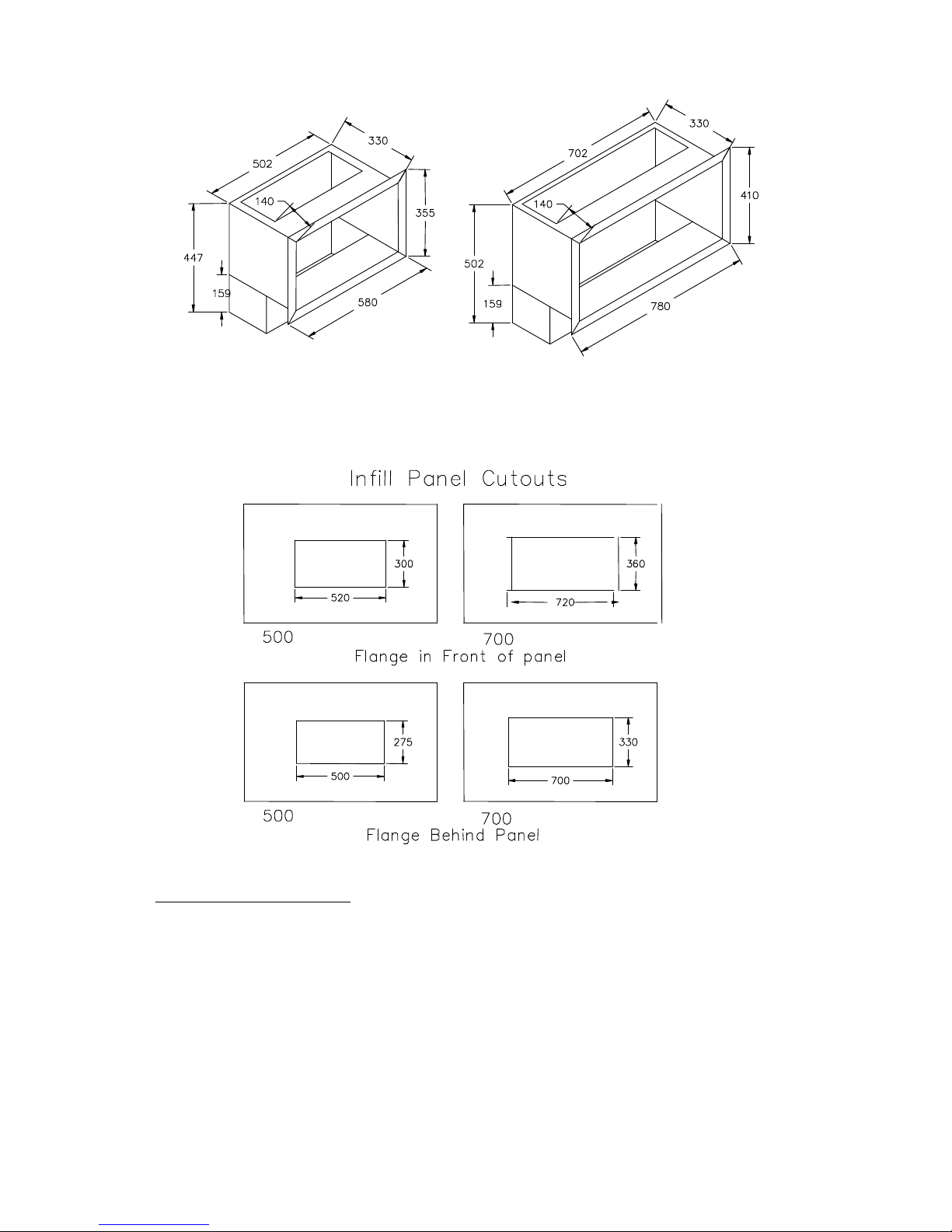

2 The 500 & 700 Fireboxes can be fitted into fireplaces which are large enough or can be

altered to accept these boxes. Their dimensions are shown in Figure 1. If the fireplace

has to be altered a lintel may be required to support the masonry over the opening.

3 Decorative Infill Panels

These appliances can be installed either with a decorative infill panel or directly against

a wall finished with a non combustible material. If an infill panel is to be used the

firebox flange can either be on the outside of the panel and finished with a decorative

trim or the flange can be set on the inside of the infill panel where a trim will not be

required. The size of the hole in the infill panel will vary depending on whether the

flange is inside or outside. The hole sizes required are shown in Figure 2. A trim will be

required if the appliance is to be installed directly against a wall. The depth of the

fireplace opening must be checked against the firebox dimensions given in Figure 1 to

make sure there is space available.

FIGURE 1

FIGURE 2

500

700

Page 4

4

4 The Hearth (Appliances in floor level fireplaces)

Where the appliance is fitted in a floor level builders opening, floor level fireplace recess

or floor level flue box, the hearth shall:

a) Extend through the whole base of the builders opening, fireplace recess or

beneath the flue box.

b) Project at least 300mm in front of any naked flame or incandescent part of

the fire bed.

c) Project at least 150mm beyond each side of any naked flame or incandescent

part of the fire bed, or if there is a non-combustible wall within 150mm of any

naked flame or incandescent part of the fire bed, up to that wall.

d) Have a thickness of not less than 12mm and a minimum height of 50mm

along its front and side edges.

Hole-in-the-wall installations

Where the appliance is installed in a hole-in-the-wall fireplace, a hearth as previously

detailed for floor level fireplaces shall be fitted on the floor beneath the hole so as to

protect combustible material from radiant heat.

a) If a hearth is not to be used, so as to maintain a minimal and contemporary

styling, the appliance must be installed so that every part of any naked flame

or incandescent part of the fire bed is at least 225mm vertically above any

carpet or floor covering.

b) Where no hearth is to be fitted consideration should be given to fixing a

tactile separator to protect young children, the elderly and the infirm. A

tactile separator can be in the form of a fender, kerb, hearth, shelf or

horizontal bar all made from non combustible material and fixed not less

than 50mm & not more than 1000mm above the floor level. They should be

positioned not less than 300mm in front of and 150mm beyond the edge of

any naked flame or incandescent part of the fire bed.

5 The Chimney Flue

Both Appliances The chimney should be of the open-flue type and have a minimum

cross sectional dimension of not less than 175mm.

The flue must have a minimum effective height of 3 metres.

No restrictor plate or flue damper is permitted. Where a variable damper is fitted, this

must be removed.

The chimney must be swept before the appliance is fitted.

500 Model This model may also be connected to 125mm diameter flue liner or twin wall

gas flue using the optional gather and the 125mm adaptor.

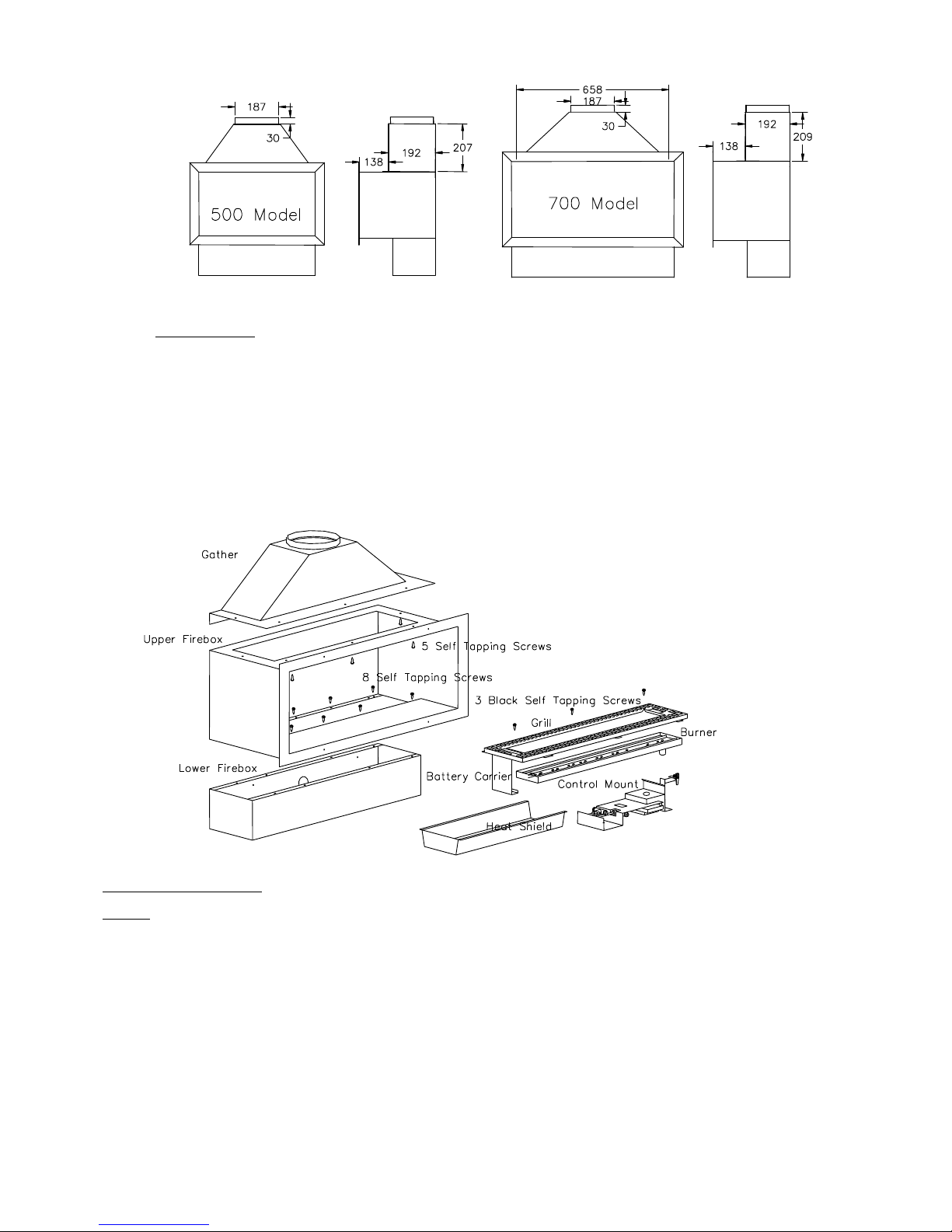

6 Optional Gather

An optional gather is available for both appliances to connect to a flue liner or a twin

wall metal chimney. The dimensions of the gathers are given in Figure 3. Check the

thickness of any masonry plus the decorative infill panel, if used, against the distance

shown between the rear of the flange and the front of the gather. The gather should be

installed before the firebox is finally placed in position and temporarily lodged in

position. After the firebox is properly positioned the gather can be drawn down to the

firebox by gripping the handles provided inside the gather and secured with five self

tapping screws which pass through the top of the firebox into the gather. Please note

that the gather and firebox are not structural items and the flue connected should be

supported and not rest entirely on the gather.

FIGURE 3

Page 5

5

7 Ventilation.

500 Model

Subject to a satisfactory spillage test, there is no requirement for purpose made

ventilation with these models.

700 Model

The room containing the appliance must have a permanent air vent with an effective

open area of at least 100 cm2. The vent must be either direct to outside air or to an

adjacent room having a permanent vent of the same area.

Fitting the Firebox

NOTE

As LPG (Propane Gas) is heavier than air any large voids below an LPG appliance must be back filled

with a suitable material or low level venting must be installed. If low level venting is installed this must

not be connected to the main flueway as this will cause dilution and may well result in lack of flue pull

through the appliance.

1 Check that the fireplace is of the correct size or has been modified to accept the

selected firebox. (See Figure 1).

2 It is recommended that, before proceeding further, a simple smoke test be performed to

check the condition of the chimney. Light a smoke match or a twist of rolled paper,

hold it within the fireplace opening and observe the behaviour of the smoke. If it is

being drawn into the chimney proceed with the installation. If not, pre-heat the

FIGURE 4

Page 6

6

chimney over the period of a few minutes and recheck. If there is any doubt about the

soundness of the chimney a smoke pellet should be used after preheating the flue and

if smoke still fails to clear, further investigation of the chimney is required and the

appliance MUST NOT be fitted until any fault has been rectified.

3 Clear the recess of any loose material. Ensure that the base on which the lower firebox

will stand is level and that the base of the recess and the hearth are horizontal and

non-combustible. If the fire opening is to be elevated the base under the firebox will

have to be raised to suit and the gather built into the fire opening may have to be reformed at a higher level.

4 The gas supply should be routed from the meter or cylinder to a point convenient to the

fireplace.

5 The firebox is made in two sections, the lower part which houses the gas control and

the upper part which is the actual firebox and provides containment of the flame and

products of combustion. See Figure 4.

6 Before starting to install the firebox remove all assembled items from the lower firebox.

The heat shield is retained during transit by self-taper screws these need not be

replaced. Temporarily secure the lower firebox to the upper firebox with four plain selftapping screws. Grommetted gas entry holes are set into the rear and bottom of the

lower firebox.

7 Slide the firebox into the opening. If a decorative infill panel is going to be used and is

not yet in place make sure that the firebox flange clears the front face of the fire

opening by the thickness of the infill panel. Ensure that the flue opening is

unobstructed and gives a clear passage for the products of combustion to the flue. The

firebox may, if required, be fixed in position by making holes in appropriate positions;

the firebox should then be secured with screws and wall plugs to the hearth and/or

rear wall of the fire opening. Do not fully tighten these screws at this time.

8 At this point the installation may be easier if the top part of the firebox is removed from

the bottom to give better access to install the gas supply.

9 Temporarily place the control mount in the lower part of the firebox and run the gas

supply through one of the grommeted holes at the rear or bottom of the lower firebox

and connect it to the gas inlet fitting. IMPORTANT; Ensure both grommets are fitted

correctly in the gas input holes, failure to seal the lower box can allow hot

product to be drawn down past sensitive electronics causing serious damage. This

fitting accepts 8mm diameter tubing. Prior to connecting the gas supply to the

appliance it is important to blow out the supply pipe to clear any of the debris that may

be present and which could cause a blockage in the control valve or pilot. Provision will

have to be made to pass the pipe through the masonry of the fireplace. Care must be

taken to sleeve the supply pipe when passing through the masonry. Exposed pipe

within the fire opening should be wrapped, painted with bituminous paint or factory

sheathed. Disconnect the gas supply and remove the control mount.

10 The space in front of the lower part of the firebox can be filled with masonry and made

good or an infill panel fitted. Slide the upper part of the firebox into position and fix to

the lower part with eight plain self tapping screws. Apply the sealing tape to the inside

of the upper firebox flange, or seal the firebox to the wall or infill panel with a waterbased mastic. Before tightening the fixing screws to the hearth and/or the rear of the

fireplace, the whole box should be pushed firmly back to make a good seal to the wall

or infill panel. THE AREA WITHIN THE FIREPLACE AROUND THE BACK AND SIDES

OF THE FIREBOX SHOULD BE BACKFILLED WITH MINERAL INSULATION MATERIAL

UP TO THE LEVEL OF THE TOP OF THE FIREBOX. This need not be done if the

appliance is sealed into the flue via the optional gather.

11 Inspect the High Tension lead on the control mount, this may have moved during

handling, ensure that it has not come into contact with the sensor or switch leads.

Replace the control mount in position making sure that the holes locate over the studs

Page 7

7

in the base of the firebox. Re-connect the gas supply. Inset four AA batteries into the

battery holder and return it and its carrier to its position at the end of the burner.

(Note; the tab at the front of the battery carrier top should be inserted into its slot and

the whole carrier drawn forward to allow it to seat correctly). Ensure the power lead

from the battery pack is plugged into the power socket at the end of the electronic

control box making sure that any excess wire cannot come into contact with any hot

surfaces. Place the burner heat shield in position. Place the burner in position

ensuring that the mixing tube locates in its hole in the burner mount over the injector.

Carefully place the infill grille in position with the locating tabs engaging with the slots

in the front lower part of the firebox and fix in place at the back of the box with the

three black self tapping screws provided. Since the infill grille locates and secures the

main burner, the burner position may have to be adjusted slightly before the grille will

lay flat. If a decorative outer trim is to be used it can be fixed into position on the frame

of the firebox using the four magnets provided or as directed with the fixing instruction

supplied with the trim.

12 Gas Soundness Check

Once the gas supply is connected, all joints must be checked for gas soundness. Note:

It is permissible to light the fire FOR SHORT PERIODS ONLY when the burner has not

been filled with the loose infill. It is easier to perform these checks if the burner is

placed in position without re-placing the grille as the tube from the manometer can

pass in front of the burner. Please note that the flames from the burner ports will not

all be of equal length.

FILLING THE BURNER.

Fill the burner tray level to the top with either the glass gravel, black ceramic granules

or limestone pebbles provided.

PLACING OF DECORATIVE REFRACTORY SHAPES.

1 Decorative items made from refractory material may be placed on top of the gravel,

granules or pebbles to increase the decorative effect. These items must not reach more

than 100mm (4 inches) above the gravel, etc. and must not be in more than two layers.

If pebbles or coals are selected no more than 17 may be used on the Atina 500.

2 When a fuel pack is used no part of the pebble, coal or log must touch the access plate

above the battery compartment, this would cause the battery pack to over heat and

damage may occur.

3 If the objects on the fire bed become excessively covered in soot they should be removed

from the fire or placed in another position.

FIREJACKS.

Contents of Firejack Pack

3 Small Spheres

2 Large Spheres

7 Small Jacks

6 Medium Jacks

3 Large Jacks

Placing the Jacks and Spheres.

Arrange the objects as desired on top of the granules. Ensure that they are placed so

that air gaps are left between the pieces to allow air to the flames. The height of the

arrangement must not exceed 100mm above the granules. The area around the pilot

flame must be left clear to allow for cross lighting.

Soot Formation.

Some soot will form on pieces placed in the flames but this is generally harmless unless

an excessive amount is deposited. When the fire is cold the pieces can be removed from

the fire and cleaned with a soft brush.

Page 8

8

NOTE:

Sometimes a ‘popping’ noise is produced by the burner at Maximum. This is caused by

a flame repeatedly lighting and then going out. To correct this, carefully examine the

fire and try to identify the flame responsible for the noise. Turn the fire out and with a

screwdriver or similar move either a ceramic piece or some granules in the area of the

flame a small amount. Turn the fire back on and listen for any noise. This process may

have to be repeated several times to cure the problem. At low fire the noise may reappear. This can be reduced by turning the gas control towards Maximum. This is not

harmful to the fire or at all dangerous.

FITTING THE TRIM (IF ORDERED)

Note: When handling the trim it is important that your hands are clean and are

free of oil / grease. We supply disposable gloves & we recommend that they are

worn to avoid unsightly marks.

Insert two of the screws provided into the top two hole in the firebox frame, these

should be screwed in so that there is a gap between the screw head and firebox frame

of approximately 1.5 - 2.0mm, take the remaining two screws and insert them into the

bottom set of holes in the lower firebox frame, these should have a 1.5 – 2.0mm gap as

above. Using the gloves, lift the frame in front of the fire, looking at the rear of the

frame check that it is the correct way up, this is done by looking at the key hole slots,

the smallest slot part of the key hole should be at the top, now lift into position, this is

done by looking through the aperture of the frame and aligning it with the fire box, it is

important that the frame is offered up so that it is central to the opening but

approximately 25mm higher, push the frame back and then lower it gently so that the

frame locates on the four mounting screws, if the frame does not locate onto the screws

remove the frame and very slightly increase the gap between the screw head and fire

frame, a large gap must be avoided as this will result in the frame being loose on the

fire.

COMMISSIONING

Before attempting to light the appliance the gas supply must be turned on by removing

the cap from the isolator fitting and unscrewing the plug all the way out. (This has to be

done before the burner is placed into position and the infill grille fixed down). Replace

the cap making sure that the tab engages with the slot in the top of the plug. Tighten

the cap securely. Inset four AA batteries into battery case located in the battery carrier

at the left hand end of the main burner. Light the appliance in accordance with the

instructions in the Users Guide.

Check for spillage

1 Before briefing the customer on how to use the appliance, a spillage test must be

carried out. The following procedure must be followed.

2 Close all doors and windows in the room or space containing the appliance. Light the

appliance and turn to the maximum rate as detailed in the lighting section of the users

instructions.

3 Light a smoke match and pass completely along and just inside the inner flange that is

just forward of the opening to the chimney. A visual check should ascertain that all the

smoke generated is drawn into the firebox and up the flue.

4 If there is evidence of spillage, the flue should be heated for a period of 5 to 10 minutes

and the test repeated.

5 If there is still evidence of spillage the appliance should turned be off and the chimney

and ventilation investigated. The appliance must not be left in an operational state until

the faults have been identified and corrected.

Page 9

9

Briefing the User

1 Demonstrate the full operation of the appliance to the customer, referring them

specifically to the glass gravel, black ceramic granules or limestone pebbles, any

decorative ceramic shapes and the removal of soot as described in these instructions.

2 Inform the customer that all cleaning procedures should be carried out only when the

appliance is cold.

3 Leave these instructions with the customer.

4 Advise the importance of having the appliance serviced and the chimney checked for

clearance of combustion products on an annual basis.

Page 10

10

USERS GUIDE

Useful tips & recommendations

Once your fire has been fitted, the following recommendations are made to ensure you

enjoy the best results from your purchase;

1 The installation of this appliance must have been carried out by a qualified installer

and in accordance with the requirements of the Gas Safety (Installation & Use)

Regulations

2 The chimney must be swept before the appliance is installed and checked annually to

ensure continued clearance of combustion products and that there is no excessive

build-up of soot.

3 As with any fire, certain components will become hot in use. Care should be exercised

when approaching the appliance when it is hot. We also recommend that a fireguard,

conforming to BS 6539 or BS 6778, be fitted for the protection of young children, the

elderly or infirm.

4 When new any ceramic components may produce a slight odour, but this will

completely vanish after a few hours of use.

5 Handle any ceramic components gently. They are fragile. A soft brush can be used to

clean them of any excess soot. UNDER NO CIRCUMSTANCES should they be washed.

6 Never throw cigarette ends or other foreign matter onto the fire.

7 Never leave the house unattended, with the fire alight, for long periods.

8 Check periodically that any purpose-made ventilation is free from obstruction.

9 To obtain the best results from your fire we recommend that it be serviced annually.

10 These instructions are provided to assist you to operate the fire correctly and should be

kept in a safe place.

11 This appliance is intended for decorative purposes.

12 This appliance is fitted with a flue blockage device that will shut off the appliance in the

event of abnormal flue conditions. This device is NOT a substitute for an independently

mounted carbon monoxide detector.

Operation of the fire

1 It should be noted that your fire is fitted with a Flame Supervision Device, which cuts

off the gas supply to your fire if, for any reason the pilot light is extinguished. It also

monitors constantly the oxygen in the room. The pilot flame heats the thermocouple

probe and allows gas to flow to the burners. If due to pilot failure, the thermocouple

cools, no gas will flow to the main burner. If the fire is turned off or the flames go out,

wait for AT LEAST 3 MINUTES before attempting to relight the fire.

Page 11

11

Lighting the Appliance

1 Fitting the Battery to the Handset

Before using the appliance remove the access cover in the rear of the handset and

insert a 9 volt PP3 size battery. Connect the battery by pushing the connector on to the

terminals. Make sure the battery is connected correctly. Replace the access cover.

2 Using the Handset

When using the handset make sure that it is pointed at the infrared signal receiver

located just in front of the pilot burner at the right hand end of the main burner (the

small black pad )See Figure 5. Unlike a TV control the fire does not react to a quick

press on the button on the handset control. The buttons must be pressed and held

until the control box under the burner acknowledges the signal by emitting a 'beep'

sound (this can take two or three seconds). When the handset is emitting a signal the

red LED at the top of the control will light.

2 Lighting the Fire

MAKE SURE THE ON / OFF SWITCH LOCATED NEAR THE PILOT BURNER HAS BEEN

TURNED TO THE ON POSITION. (Indicated with the symbol 1 ).

To light the fire press the SMALL BUTTON and the UP BUTTON buttons together on the

handset until the fire control box answers with a 'beep'. The fire will go through its start

- up procedure by lighting first the pilot burner and then the main burner on high fire.

This procedure takes about 30 seconds. During this process the fire will emit a regular

series of ‘beeps’. If the fire does not light or there is no reaction when the two buttons

are pressed, press the OFF button to 're-set' the control and try again.

4 Adjusting the Flame Height

To lower the flame height press and hold the DOWN BUTTON until the flame is at the

desired height. To turn the main burner off and just leave the pilot burner alight

continue to press and hold the down button until the main burner goes out. To re-light

the main burner press and hold the SMALL BUTTON and UP BUTTON together until

the flame is at the desired height.

5 Turning the Fire OFF

To turn the fire off but leave the pilot burner alight press the DOWN BUTTON until the

main burner does out. To turn the fire completely off press the OFF button.

Manual Off Facility

If, whilst the fire is alight, the handset control is lost or its battery becomes discharged

the fire can be turned off by switching the appliance ON/OFF switch (located just

behind the signal receiver which is situated just in front of the pilot burner) to the OFF

FIGURE 5

Page 12

12

position which is indicated by the symbol O. Caution should be exercised as this switch

is situated quite close to the pilot flame. Switch back to the ON position to allow the

appliance to be re-lit when required.

Cleaning the fire

1 Ensure that the fire is cold before undertaking any cleaning. Remember that heat is

retained for some time after the fire is switched off. In normal use your fire requires

only minimal cleaning. Some soot may form on any ceramic pieces placed in the flames

but this is generally harmless unless an excessive amount is deposited.

2 If large pieces of debris are found in the fire, sufficient to alter the appearance or

operation of the appliance, the chimney / flue should be inspected and the appliance

serviced before further use.

3 In any event, the chimney should be checked annually to ensure continued clearance of

the combustion products and that there is no excessive build-up of soot.

SERVICE AND MAINTENANCE

The appliance should be serviced at least once a year by a GAS SAFE registered

engineer, and MUST include changing the oxy-pilot.

1 Any refractory shapes should be taken off the fire and shaken to remove any debris but

should only be cleaned if absolutely necessary. This should be done by gently brushing

with a soft brush in a direction away from the person and any persons nearby. This

operation should be performed outside facing downwind. A vacuum cleaner must not

be used for this purpose.

2 Undo the three screws holding the infill grille in position a lift it out of the firebox. Lift

the main burner out of the firebox. The gas supply should be turned off at the

combination pressure test point and isolator fitting. Disconnect the control mount from

the gas supply and lift it out of the lower firebox.

3 Empty the glass gravel from the burner on to a clean surface and thoroughly clean the

burner ports.

4 The pilot burner fitted is an oxygen depletion pilot burner and is the primary safety

device on the appliance. It must therefore be replaced annually. After changing the pilot

burner operate the spark generator and observe that the spark is satisfactory.

5 Lay the control mount assembly on a flat surface and remove, clean and replace the

main injector.

6 Any soot or debris should be removed from the fireplace and flue. The flue should be

inspected for soundness and a smoke test performed as described in the fitting section

to check the condition of the flue.

7 Replace the control mount in position making sure that the holes locate over the studs

in the base of the firebox. Re-connect the gas supply. Place the burner in position

ensuring that the mixing tube locates in its hole in the burner mount over the injector.

Carefully place the infill grille in position with locating tabs engaging with the slots in

the front lower part of the firebox and fix in place with the three screws removed in

paragraph 2. Refill the burner with the glass gravel. Replace any refractory shapes that

were in place on the burner.

8 AFTER REFITTING THE APPLIANCE CHECK FOR GAS SOUNDNESS AT ALL GAS

JOINTS AND TEST FOR SPILLAGE.

Battery Replacement

9 HANDSET; The handset is powered by one Alkaline 9volt PP3 size battery. If the fire

fails to respond to the handset control check that the red LED on the handset lights

whilst pressing the SMALL BUTTON and the UP BUTTON buttons at the same time. If

the LED does not light, the battery in the handset requires renewing. To change the

battery in the handset, remove the battery cover on the underside of the handset,

Page 13

13

unclip the battery from its connector and put a new one put in its place. Replace the

cover.

10 BURNER: (see figure 4) Wait until the fire is cold before attempting to change these

batteries which are in a carrier at the left hand side of the burner. Grip the separate

piece of grille at the left hand side of the burner by inserting two fingers into the holes

provided, tip forwards and lift the battery carrier out of the firebox. Remove the battery

case from the carrier. Open the case by unscrewing the locking screw and remove the

used batteries. Insert four new Lithium AA batteries observing the correct polarity.

Close the case and replace the screw. Place the battery case in the battery carrier and

replace the whole assembly back into the appliance.

Note; Replacement AA Lithium batteries are available from Verine Ltd. Alkaline batteries

are not recommended for this application.

Spare Parts List

In the event of a part requiring replacement the parts list is as follows

Part Description

Part Number

Electronic Control Box and

Remote hand control

G6R - P4S1A5

GV60 Motorised valve

GV60M1- C5D1H1L

Oxypilot (NG models)

OP9037

Oxypilot (LPG models)

OP9223

Burner Control Battery

Energiser 1.5 volt AA Size Lithium L91

Page 14

14

Installation & Service Record

Please ensure that installer completes the installation record below

INSTALLATION RECORD

Appliance Supplied by: …………………………....

Installation Date: ……………Serial No.: ….……...

Installed By: …………..…...GAS SAFE No.: …..……

Signed by Installer: ………………………..…

RECORD OF 1st SERVICE

Serviced by: ………..…….. GAS SAFE

No.:……………....

Service Date: ……………… Signed: .………….….…...

Comments: ……………………………………..…….……

…………………………………………………………………

…………………………………………………………………

RECORD OF 2nd SERVICE

Serviced by: ………..…….. GAS SAFE

No.:……………....

Service Date: ……………… Signed: .………….….…...

Comments: ……………………………………..…….……

…………………………………………………………………

…………………………………………………………………

RECORD OF 3rd SERVICE

Serviced by: ………..…….. GAS SAFE

No.:……………....

Service Date: ……………… Signed: .………….….…...

Comments: ……………………………………..…….……

…………………………………………………………………

…………………………………………………………………

RECORD OF 4th SERVICE

Serviced by: ………..…….. GAS SAFE

No.:……………....

Service Date: ……………… Signed: .………….….…...

Comments: ……………………………………..…….……

…………………………………………………………………

…………………………………………………………………

RECORD OF 5th SERVICE

Serviced by: ………..…….. GAS SAFE

No.:……………....

Service Date: ……………… Signed: .………….….…...

Comments: ……………………………………..…….……

…………………………………………………………………

…………………………………………………………………

RECORD OF 6th SERVICE

Serviced by: ………..…….. GAS SAFE

No.:……………....

Service Date: ……………… Signed: .………….….…...

Comments: ……………………………………..…….……

…………………………………………………………………

…………………………………………………………………

RECORD OF 7th SERVICE

Serviced by: ………..…….. GAS SAFE

No.:……………....

Service Date: ……………… Signed: .………….….…...

Comments: ……………………………………..…….……

…………………………………………………………………

…………………………………………………………………

RECORD OF 8th SERVICE

Serviced by: ………..…….. GAS SAFE

No.:……………....

Service Date: ……………… Signed: .………….….…...

Comments: ……………………………………..…….……

…………………………………………………………………

…………………………………………………………………

Page 15

15

B-111620

Issue 3

BFM Europe Limited

Trentham Lakes

Stoke on Trent, Staffordshire ST4 4TJ

Tel: (01782) 339000 Fax: (01782) 339009

Email: info@bfm-europe.com

www.bfm-europe.com

THIS BOOKLET CONTAINS 15 PAGES.

ATINA/VERTEX/1007/II/UI

Loading...

Loading...