Page 1

P

RODUCTIVITY SERIES

DSU/CSU

®

TRANSPORT

400

DDS

34-00222

October 1997

1 16

Page 2

C

OPYRIGHT/LIABILITY

4. Customer Service

TxPORT provides easy access to customer support information 24 hours a day,

seven days a week through a variety of services including telephone, e-mail,

and the world wide web.

© 1997 TxPORT, All rights reserved. No part of this publication m ay

be reproduced, transmitted, transcribed, stored in a retrieval system, or

translated into any language in any form by any means without the

written permission of TxPORT.

Reorder # 34-00222

nd

Edition, October 1997

2

TxPORT shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing, performance, or use of this material. TxPORT reserves the right to revise this

publication from time to time and make changes in content without

obligation to notify any person of such revision changes.

Contents of this publication may be preliminary and/or may be changed

at any time without notice and shall not be regarded as a warranty.

Telephone

To speak directly wit h a TxPORT customer service representative or send a facsimile you may dial any one of the following numbers.

Toll Free: 800-926-0085 or 888-4TxPORT

Local: 205-772-3770

FAX: 205-772-3388

E-mail

You can request sales and marketing information or pose a technical support

question about your TxPORT product with direct e-mail access.

Sales & Marketing:info@txport.com

Technical Support: support@txport.com

World Wide Web

You can access product informatio n, technical support, news releases and mo re

from our world wide web site by entering our URL into your internet browser.

http://www.txport.com

Documentation Disclaimer

TxPORT makes no representation or warranties of any kind whatsoever

with respect to the contents hereof and specifically disclaims any

implied warranties of merchantability or fitness for any particular purpose.

2

15

Page 3

V.54 Channel Loop:

mand. This loop is unidirectional and returns the DSU receive data to the DSU transmit data, and subsequently the DDS transmit data. Receive data is unaffected and

DSR and RLSD are forced Off.

Remote Channel Loop:

the RL position. This starts an internal test by replacing the DSU’s transmitted data

with the V.35 activate code to the far end DSU equipment for the proper time period.

Then a test pattern is sent to verify the looped DDS DSU’s integrity. If the transmitted pattern is received error free, the test lamp turns green . If errors are det ected, the

test lamp turns red. Normal DSU operation may resume for DCE BERT testing.

Placing the switch in the NORM position transmits the V.54 deactivate code.

This loop is activated by the receipt of the V.54 loop com-

This loop is activated by pressing the front panel switch to

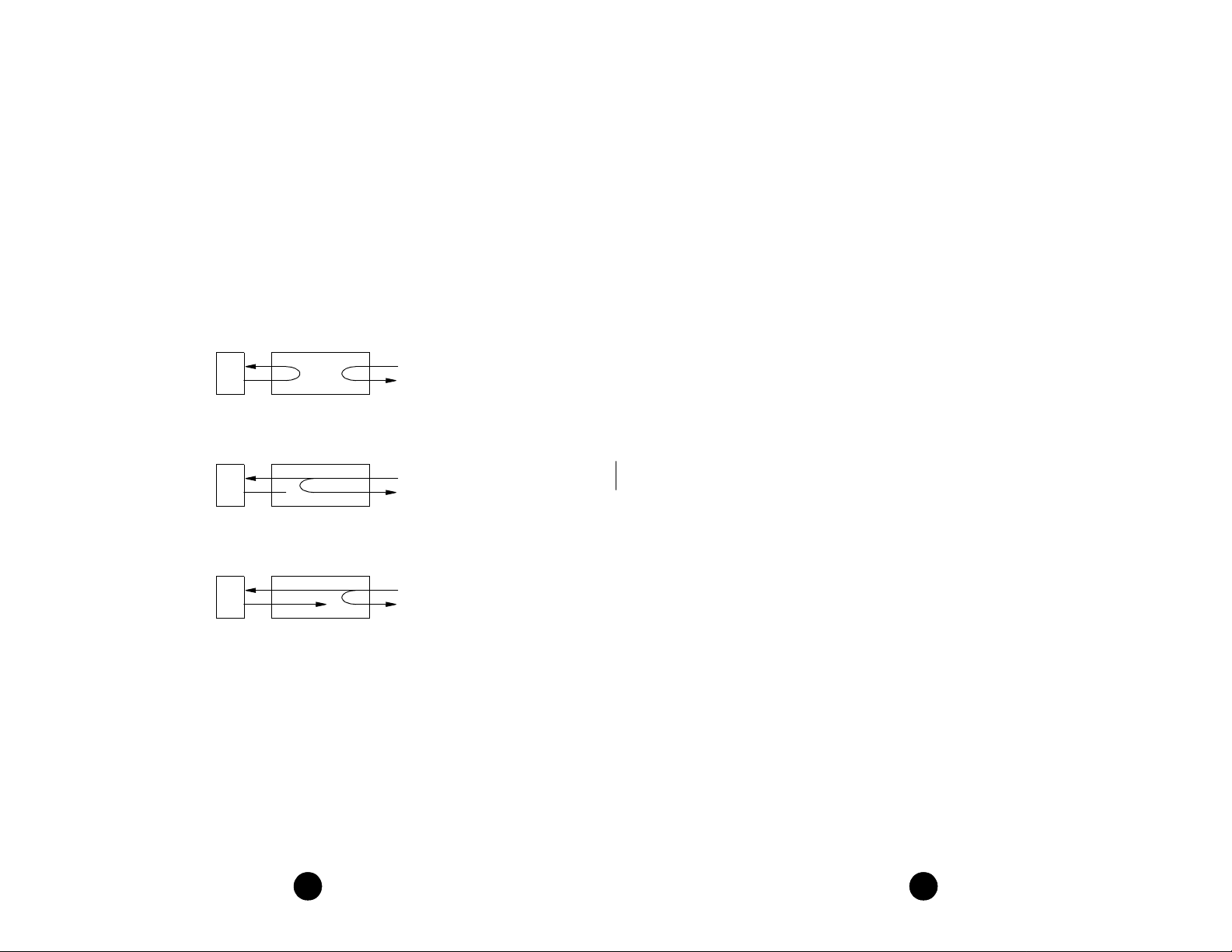

Looping Diagrams

T

ABLE OF

1. Introduction

Specifications ............................................................................................. 4

FCC Requirements .................................................................................... 5

Warranty .................................................................................................... 6

Ordering Information ................................................................................. 7

2. Installati on

.......................................................................... 4

............................................................................ 8

C

ONTENTS

Local Loopback

DTE

Remote Channel Loop

(V.54) and Data Set Loop

DTE

Channel Loop (Mandatory Loop)

DTE

NET

NET

NET

Supplied Materials ..................................................................................... 8

Unit Configuration ..................................................................................... 8

Connections...............................................................................................10

DDS Network Connection .............................................................. 10

V.35 and RS-232 Port Connection .................................................. 10

3. Operation

Testing ...................................................................................................... 13

4. Customer Service

Telephone...................................................................................................15

E-mail........................................................................................................15

World Wide Web........................................................................................15

............................................................................13

........................................................ 15

314

Page 4

1. Introduction

The TxPORT Productivity Series DDS 400 provides an economical solution to

access Digital Data Se rvice. The 400 u nit is ful ly com patible with AT&T TR62 310,

the industry specification standard for DDS. This unit is designed for standalone

(table top) use, but may be rack mounted using the optional rack mount kit. See page

page 7 for ordering information.

The 400 rear panel has three interface connectors. An RJ-48C (8 -pin) interface

allows connection to th e net work. The V.35 (34 -pin) high spe ed por t conn ector supports data rates of 2.4, 4.8, 9.6, and 56 kbps. An RS-232 (25-pi n) interface is also

provided as a substitute for the V.35 interface.

The 400 unit is configur ed through a rear panel DIP switch. LED indicator s on the

front panel alert local personnel of the unit’s line, DTE, and test status. A test switch

activates a local loopback or initiates a remote loopback and pattern test.

A power cord on each unit provides 115 VAC operation. Primary and secondary

surge protection is provided on the network side (meeting UL 1459 requirements).

Each unit provides network ALBO circuitry. This network ALBO supports a receive

range of +1 dB down to -40 d B.

Specifications

Network Interface

Line Rate: 2.4, 4.8, 9.6, 19.2, 28, 38.4, 56, and 64 kbps

Line Code: AMI

Line Impedance: Balanced 135 Ω

Input Signal: +1 to -40 dB (ALBO)

Output Signal: 3.0 V (±15%) base-peak into 135 Ω,

1.5 V (±15%) at the 9.6 kbps line rate

Line Protection: 1000 V lightning, input/output

PRODUCTIVITY SERIES 400

NORM

RL LL

TRANSPORT

DSU/CSU

®

SD RD RTS CTS RLSD LOOP

OOS

(BA) (BB) (CA) (CB) (CF) TEST

Productivity 400 DDS DSU/CSU

the V.54 code). If errors are detected, the TEST LED will be red. The NORM position deactivates the loop codes for normal op eration. Refer to the Testing section on

page 4 for further information.

Testing

The front panel test switch is used as described in the following paragraphs. Three

types of loops are shown in the diagrams on page 14.

Local Loop

LOC position. The unit loops the signal from the customer equipment (DTE IN)

back to the customer equipment (DTE OUT). It also transmits the DTE data towards

the network.

Remote Channel Loop

placing the test switch in the RL position. The unit sends a V.35 loop code in the

assigned channels to the far end for two seconds followed by two seconds of all

ones, followed by DTE data. After four seconds, the far end should be looped.

In other words, this function starts an internal test by replacing the DSU’s transmitted data with the V.54 activate code to the far end DSU e quipment for the proper

time period. Then a test pattern is sent to verify the looped channel’s integrity. If the

transmitted pattern is received error free, the LED illuminates green. If any errors are

detected, the LED illuminates red. Normal DSU operation may resume at this time

for DCE BERT testing. Returning the test switch to NORM transmits the V.54 deactivate code.

Normal (Unloop)

local loopback is removed. When the test switch is moved from REM back to

NORM, the unit sends unloop messages to the far end unit for six seconds and the

remote loopback is removed.

The following paragraphs describe other loops that may b e initiated on th e 400 unit:

Channel Loop:

current. This is a unidirectional loop that ignores the DSU transmit data and retransmits the received DDS data. Receive data is un affected and circuits CC and CF a re

forced Off.

Data Set Loop:

loop commands an d remains looped as long as each third pattern byte is the loop

command. It returns to normal operation after at least four pattern bytes that are not

the loop command. This is a unidirectional loop that retransmits the DSU received

data on the DSU transmit d ata. Receive data is unaffected and circuits CC and CF

are Off.

Local Loop:

position. This loop is bidirectional and returns the DDS receive data to the DDS

transmit line and the DSU transmit data to the DSU receive data output.

: Each unit can initiate a local loop by placing the test switch in the

: Each unit can g enerate a far end re mote channel loop by

: When the test switch is moved from LOC back to NORM, the

This loop is activated by the reversal of the simplex, 20 mA sealing

This loop is activated by the receipt of at least four consecutive

This loop is activated by pressing the front panel switch to the LL

134

Page 5

3. Operation

This chapter describes the front panel operation and test features of the TxPORT 400

DDS DSU/ CSU. The unit is controlled manually using a front panel test switch and

rear panel DIP switches. Refer to page 8 for specific information concerning DIP

switch settings.

OOS:

1)

operating status. Green indicat es DDS signal at the receiver (either customer data or

zero suppression). Amber indicates DDS signal is still present, but received data is

idle or out of service. Red indicates an insufficient signal for the DDS receiver to

operate properly.

2)

off when the data lead is a space. Therefore, the LED will vary from full intensity to

off depending on the relative number of marks and spaces.

3)

is off when the data lead is a space. Therefore, the LED will vary from full intensity to

off depending on the relative number of marks and spaces.

4)

On state at the DSU interface.

5)

state at the DSU interface.

6)

CF is in the On state at the DSU interface.

7)

either by manually depressing the loop switch or by receipt of a test command from the

facility. The LED turns red or green at the end of a V.54 test indicating the pass or fail

state of the BERT. Refer to the Testing section on page 4 for specific information.

8)

the unit in a local loop mode. Data from the DTE is looped back to the DTE. Data from

the network is looped back to the network. The RL position initiates an automated V.54

remote loop and BERT sequence of assigned data channels. The TEST LED will be

green if the test is succes sful (t he fa r end u nit l oops an d returns the data error free with

This three color Out Of Service LED indicates the DDS loop receiver’s

SD:

This green Send Data LED illuminates when the data lead is a mark and is

RD:

This green Receive Data LED illu minates wh en the d ata le ad is a m ark and

RTS:

This green Request To Send’ LED illuminates when circuit CA is in the

CTS:

This green Clear To Send LED illuminates when circuit CB is in the On

RLSD:

LOOP/TEST:

Te s t S w it c h:

This green Receive Line Signal Detector LED illuminates when circuit

This amber LED remains illuminated if the unit is in a test mode,

This 3 - position switch is used as follows: The LL position places

Power

AC Power: 115 VAC (± 10%), 150 mA maximum,

20 Watts, 73 BTU maximum

Connection: 5-foot power cord

Mechanical

Mounting: Desktop, wall, or rack m ount

Dimensions: Height: 1.75 inches (4.45 cm)

Width: 6.8 inches (17.27 cm)

Depth: 10.5 inches (26.67 cm)

Weight: 2 pounds (0.91 kg)

Industry

Standards

FCC Compliance: Part 15 Subpart B, Class A, Part 68

U.S. Safety: UL 1459

Canadian Safety: CSA C22.2 No. 225-M90

IC: CS03

Environmental

Operating Temp: 0° to 50° C (32° to 122 °F)

Storage Temp: -20° to 85° C (-4° to 185°F)

Humidity: 95% max (non-condensing)

FCC Requirements

Changes or modifications to t his unit not expressly a pproved by the party

responsible for compliance could void the user ’s authority to operate the

equipment.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

This device may not cause harmful interference.

2) This device must accept any interference received, including interference t hat may

cause undesired operat ion.

TRANSPORT

DSU /CSU

PRODUCTIVITY SERIES 400

®

OOS

SD RD RTS CTS RLSD LOOP

(BA) (BB) (CA) (CB) (CF) TEST

NORM

RL LL

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipm ent generates, uses, and can radiate radio frequency energy and if not installed and us ed in accordance with the instructio n manual,

may cause harmful interfere nce to ra dio com munication s. Opera tion of this equ ipment

754321 6 8

400 DDS Front Panel

12

in a residential area is likely to cause harmful interference. The user will be required to

correct the interference at his own expense.

5

Page 6

Notice to Users of DDS service: The following instructions are provided to ensure

compliance with FCC Rules, Part 68:

1) All direct connecti ons to DDS lines must be made using standard plugs and jacks.

2) Before connecting your unit, you must inform the local telephone company of the

following information:

Port ID REN / SOC kbps FIC USOC

12 - 00492 6.0 N 2.4

4.8

9.6

38.4

56

64

04DU5-24

04DU5-48

04DU5-96

04DU5-38

04DU5-56

04DU5-64

RJ-48C jack

3) If the unit appear s to be malfunctio ning, it should be disconnected fr om the telephone lines until you learn whether the source of trouble is your equipment or the telephone line. If your equipment needs repair, it should not be reconnected until it is

repaired.

4) The unit has been de signed to pr event harm to the DDS net work. If the te lephone

company finds that th e equipment is exceeding tolera ble parameters, they can temporarily discon nect service. In this case, the telephone company will give you advance

notice, if possible.

5) Under FCC rules, no customer is authorized to repair this equipment. This restriction applies regardless of whether the equipment is in or out of warrant y.

6) If the telephone company alters their eq uipment in a manner that will affect the

use of this device, they must give you advance warning so tha t you can have the oppor tunity for uninterrupted service. Yo u will be advised of your right to file a complaint

with the FC C.

7) The attached affidavit must be completed by the installer.

8) In the event of equipment malfunction, all repairs should be performed by our

company or an authorized agent. It is the responsibility of users requiring service to

report the need for service to our company or to one of our authorized agents.

Warranty

If for any reason you must return your TxPORT product, it must be returned to the factory, shipping prepaid and packaged to the best commercial standard for electronic

equipment. TxPORT will pay shi pping c harges for d elivery on return. You are responsible for mode and cost of shi pment to TxPORT.

You must have a Return Material Authorization (RMA) number marked on the shipping package. Products sent to TxPORT without RMA numbers will be returned to the

sender unopened, at the sender’s expense. A product sent directly to TxPORT for repair

must first be assigned a Return Materials Authorization (RMA) number.

Circuit V.35 RS-232

101 A 1 Frame G round - This circuit is used to term i nate

102 B 7 Signal Ground - This circ uit is use d as the return

103 P/S 2 Transmit Data - This input is used for synchronous TD

104 R/T 3 Receive Data - This output is the da ta dec oded from

105 C 4 Request To Send - This input is a control line from the

106 D 5 Clea r To Send - This output is a DCE re sponse,

107 E 6 Data S et Ready - This outpu t is O n w hen the unit is

109 F 8 Data Carrier Detect - This output is On when the

113 U/W 24 External Transmit Cloc k - This is the synchronous

114 Y/AA 15 Transmit Clock - This output is supplied by the DCE

115 V/X 17 Receive Clock - This clock output is the timing for the

142 K 25 Test Mode - This output is On when the unit is in the

Signal Function

shields.

reference for unbalanced signals.

from the DTE. It is transmitted on the DDS side.

the incoming DDS receive data.

DTE indicati ng da ta is to be t ran smitte d . Whe n RTS is

On (space), the data transmitter, the zero suppression

circuitry, and the CTS are enabled. Whe n RTS is Off,

the transmitter sends idle code and the CTS is forced

Off.

indicating that either RTS is On or S1-8, position B, is

forcing RTS On. When S1-7 is in position B, RTS and

RLSD must be On for CTS to be On.

not in a test mode (othe r than a V.54 test).

correct data or zero suppression code is being received

and DSR is On. It is Off when either DSR is Off, the

DDS receiver has lost suffic ient signal to operate for at

least one second, or the receiver has received OOS,

OOF, idle, or loop cod es for a bout 20 U.I.

transmit clock input from the DTE. When both S1-3

and S1-4 are in the B position, this clock controls t he

frequency of the DDS transmit clock and clocks

circuit 103 (TD). When either S1-3 or S1-4 is in the

A position, this input has no effect on DDS operation.

as an external DTE timing source. It is generated from

the internal data clock or the far end transmit data. Not

available when S1-3 and S1-4 are in the B position.

RD and is always use d to time the receive data. This

clock is always derived from the DDS receive data.

Test/Loop mode.

(Note: all other pins are open)

DCE

Gnd

Gnd

In

Out

In

Out

Out

Out

In

Out

Out

Out

6 11

Page 7

Connections

The 400 DDS rear panel has thre e interface connectors: an RJ-48C DDS ne twork

connector, a V.3 5 high speed port connector, and an RS-232 connector. Each unit

comes equipped with a power cor d for 115 VAC operation (±10%).

115 VAC

V.3 5

TxPORT 400 DDS Rear Panel

13 1

RS-232

A

B

8654321 7

S1

DDS

1425

9

10

NET

81

You may obtain an RMA number from customer service at 800 -926 - 0085 extension

2282. When calling TxPORT for an RMA, please have the following information available.

• Model number and serial number for each unit.

• Reason for return and symptoms of problem.

• Warranty status (if known).

• Purchase order number to cover charges for out-of-warranty items.

• Name and phone numbe r of pe rson we can co ntact if we have questions about t he

unit(s).

• Mode of shipment required (second-day air is the normal mode o f shipment for all

returned material unless otherwise specified).

Units being returned to TxPORT should be sent to the following address.

DDS Network Connection

The network DDS facility interface is a standard RJ-48C (8-pin) modular jack with

the following pinout:

Pin Assignment

1 Network Transmit Out

2 Network Transmit Out

3 Not Used

7 Network Data In

8 Network Data In

V.35 and RS-232 Port Connection

The V.35 or the RS-232 port is automatically selected when you physically conne ct

the cable to the port. Conn ection to only one of these two co nnectors is allowed at

any one time because the internal circuitry selects the proper interface depending on

which connector has TXD applied. These ports meet all the general physical and

electrical requirements. T he V. 35 connector is a standard 34- pin female. The RS232 connector is a standard DB-25 female.

The V. 35 and RS-232 pin assignments are shown in the previous table. Only circuits serviced by the unit are listed. When two pins are listed, the first is the A differential pin and the second is the B differential pin. All balanced bipolar inputs and

outputs meet the physical and electrical speci fications at ITU V. 35. All unbal anced

bipolar inputs and outputs meet the physical and electrical specifications of ITU

V. 28.

TxPORT

127 Jetplex Circle

Madison, Alabama 35758

Ordering Information

You may require additional items to install and operate each unit. Use the following

numbers to order the bas ic unit or op tio na l eq uip m en t.

Part Number Description

F-400-00 1--111 Produc t ivity Serie s Mult irate 400 DSU/CSU unit

9-20 00-001-1 Single unit horizontal rack mount ha rdware for 19-inch equipment rac k

9-20 00-001-2 Dual unit horizontal rack moun t ha rdware for 19-inch equipment rack

9-20 00-002-1 Single unit horizontal rack mount ha rdware for 23-inch equipment rac k

9-20 00-002-2 Dual unit horizontal rack moun t ha rdware for 23-inch equipment rack

9-20 00-001-8 19-inch multi-unit rack mounting for eight units.

9-20 00-002-8 23-inch multi-unit rack mounting for ten units.

10 7

Page 8

2. Installation

This chapter contains information and instructions required to prepare the TxPORT

400 DSU/CSU for use. Included are configuration guidelines and connection

instructions.

Supplied Materials

Each 400 unit i s shippe d with th e TxPORT 400 DD S DSU/ CSU reference manual.

Yo u may require additional items for the installation and operation of the unit. Refer

to page 7 for complete ordering information.

Channel Bit Rate Select:

Positions S1- 1, S1- 2, and S1 -3 select the channel bit

rate. Refer to the table in the above diagram to determine the switch settings for a

particular bit rate. The RTS to CTS delays are multiplied by two when position S110 is in the B position.

Line Clock:

Position S1-4 selects either an internal clocking source or a loop tim-

ing source from the received data.

A - Loop timing source B - Internal line clock

Internal Clock:

Position S1- 5 selects either the DSU external clock input or the

crystal oscillator as the clocking source. This function is applicable only if position

S1 -4 is in the B position.

A - Internal master clock B - DSU external clock input

Unit Configuration

On power up, each unit is configured to the hardware settings of the option switches

(S1). Subsequent changes to these settings will not take effect until the unit has been

reset. This may be acc omplished either by removing a nd then reapplying p ower or

by pushing the test switch toward local loop LL and then quickly back to center or

NORM. The unit then recycles through its LE Ds and reads the new configuration.

S1 is a 10-position DIP switch located on the unit’s rear panel. This switch provides

the following configuration parameters.

The symbol ‘ ’ indicates that the switch pointed to is not functional unless

✍

the opposite end of the arrow is in the position shown. For example, S1-5 is

not functional unless S1-4 is in the B position.

Rate

S1-1 S1-2 S1-3

(kbps)

2.4 B B B 8 ms

4.8 A B B 4 ms

9.6 B A B 2 ms

19.2 A A B 1 ms

28 B B A .8 ms

38.4 A B A .5 ms

56 B A A .4 ms

64 A A A .3 ms

A

B

Channel

Bit Rate

RTS

to CTS

Delay

n/a

BAA

BBExternal

V.54 Loop

Inhibited

65431 7 982

Enabled

Line Clock

V.54 Loop

Internal Clock

Network

Master

Data Polarity

Normal

Inverted

Data Polarity

Circuit Assurance

Circuit Assurance

Off

On

RTS/CTS Control

RTS/CTS Control

RTS Normal Delay

10

RTS Control On

RTS -> CTS Delay

Normal

X 2

RTS -> CTS Delay

V.54 Loop Operation:

Position S1-6 enables or disables V.54 loop operation.

A - Disabled B - Enabled

Data Polarity:

Position S1- 7 determines whether data bits are inverted. In the A

position, marks equal pulse s. In the B pos itio n, spac es equ al pu lses. Receip t of OOF,

OOS, idle, or loop codes forces the DS U data to all ma rks (A position) o r spaces (B

position).

A - Normal B - Inverted

Circuit Assurance:

When position S1-8 is On, the st atus of CF (receive line signal

detector) and CA (request to send) controls the output CB (clear to send). If either

CA or CF is Off (position A), CB is Off. If CA and CF are On (position B), CB is

On.

A - Off B - On

RTS/ CTS Control:

When position S1- 9 is in the B position, CTS is forced On

regardless of the RTS input status. In the A position, the delays are determined by

S1 - 10.

A - Normal Delay B - Control On

RTS -> CTS Delay:

When position S1- 10 is in the A position, the RTS to CTS

delay is as shown in the S1- 1 , S1- 2, and S1 - 3 bit rate table. In the B position, the

delays shown are multiplied by two.

A - Normal Delay B - Delay multiplied by two

8 9

Page 9

®

TRANSPORT

Document:

Date:

Pow er

34-00222-A2.01

Addendum

Productivity Series 400 Reference Manual

June 12, 1998

The power rating, as listed on page 5 of the manual, has been revised as follows.

AC: 115 VAC, 120 mA, 7 W maximum, 23 BTU maximum

Productivity Series 400 Page 1 of 1

Loading...

Loading...