Page 1

PRISM 2100

T1

CSU

®

TRANSPORT

34-00187

th

Edition

6

i

Page 2

Copyright

©1997 TxPORT. All rights reserved. No part of this publication may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any language in any form by any means without the written permission of TxPORT.

Reorder # 34-00187

th

Edition, March 1997

6

TxPORT shall not be liable for e rrors co ntained here in or for inci dental or co nsequent ial da mages in conne c-

tion with the furnishing, performance, or use of this material. TxPORT reserves the right to revise this publication from tim e to time and make changes in content without obligation to notify any person of such revision

changes.

Contents of this publication may be preliminary and/or may be changed at any time without notice and shall

not be regarded as a warranty.

Documentation Disclaimer

TxPORT makes no representation or warranties of any kind whatsoever with respect to the contents hereof

and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

ii

Page 3

Table of Contents

General 1-1

Introduction 1-1

Features 1-1

Specifications 1-2

Network Interface 1-2

Equipment Interface 1-2

Diagnostics 1-2

Alarms 1-2

Power 1-2

Mechanical 1-2

Environmen t al 1-2

Industry Listings 1-2

FCC Requirements 1-2

Canadian Emissions Requirements 1-3

Warranty 1-3

Ordering Numbers 1-3

TxPORT Customer Service 1-4

Technical Support 1-4

Returns/RMA 1-4

Installation 2-1

Introduction 2-1

Safety Summary 2-1

Unpacking and Inspection 2-1

Supplied Materials 2-1

Mounting 2-1

Standalone Unit 2-1

Chassis Assembly 2-2

Unit Configuration 2-2

Configuration Switch S2 2-2

Sealing Current 2-2

Zero Suppression 2-2

Test Pattern 2 -2

Line Coding 2-2

Test Mode 2-2

Keep Alive 2-3

Configuration Switch S3 2-3

Network LBO 2-3

DSX Level 2-3

Line Code 2-3

Remote Loop 2-3

ACO/Alarm Card (Optional) 2-3

DTE Connection 2-4

DB-15 Connec tion 2-4

Network Connection 2-6

Alarm Connection (Optional) 2-6

Standalone Unit 2-6

Chassis Unit 2-6

Power Connection 2-7

Standalone Unit 2-7

Chassis Unit 2-7

Redundant Power Source 2-7

Single Power Source 2-7

Dual Power Source 2-7

Operation 3-1

Introduction 3-1

Front Panel Descriptions 3-1

General Status Indicators 3-1

Alarm Controls and Indicators 3-1

Test Controls and Indicators 3-1

Front Panel Testing 3-2

Test Switch 3-2

Test Access Jacks 3-2

NET 3-2

MON 3-2

DTE 3-2

iii

Page 4

iv

Page 5

1. General

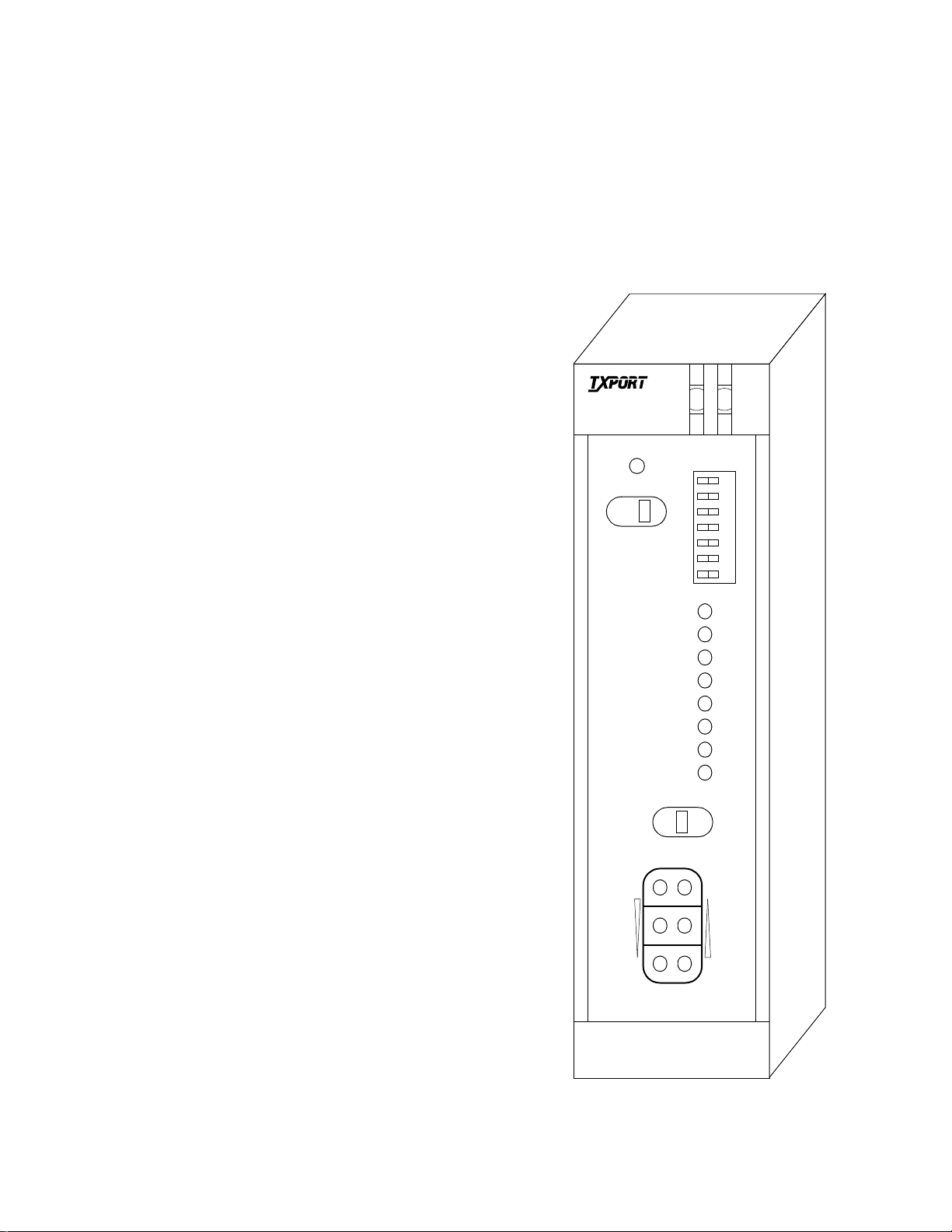

Figure 1-1 TxPORT 2100 CSU

Introduction

TxPORT’s 2100 CSU (channel service unit) is an advanced

frame transparent unit providing an interface between the

customer premises equipment (CPE) and the carrier T1

facilities. The unit is compatible with all T1 carrier transmission equipment and is designed to comply with all

industry standard CSU specifications. The 2100 CSU is

responsible for providing the proper electrical interface to

the T1 circuit and for shaping and regenerating the 1.544

Mbps signal.

The CSU works with any T1 line format and is line code

transparent to unframed, D4, and ESF framing formats.

Optionally, the CSU provides AMI /B8ZS conversion from

the DTE to the facility and B8ZS/AMI conversion from the

facility to the DTE. The unit monitors transmission for bipolar violations and maintains the pulse density of the

transmitted signal.

The CSU’s front panel has features which aid in quick fault

isolation. Eleven LED indicators display status, alarm, and

test conditions. A DIP switch allows for the quick configuration of operation and test parameters. Test jacks allow

bridged monitoring of th e passed si gnal and sign al insertion

toward the network or the DTE. A test switch activates local

and remote loops and controls the internal BERT generator

and comparator.

Power options for the CSU include line or local -24/-48

VDC power. Sealing current can be provided for dry spans.

Network and DTE connections are made through RJ-48C

jacks.

The CSU is available as a stand - alone unit or for use in a

multi -u nit chassis holding up to 12 CSUs. The chassis can

consolidate the CSU requirements of an entire network

node. Power supplies are available from TxPORT to meet

any requirement, including full redundancy.

• Selectable alarms with alarm indicators and optional alarm

relay contacts

• Selectable facility ALBO levels and DTE DSX levels

• Selectable sealing current source

• Line or local -48 VDC powering

2100

CSU

ACO SW

FAR

®

ACO

BPV

LOS

AIS

LOOP

DENSITY

SET

RESET

ERR

S2

7654321

LOC

TRANSPORT

Features

• Available as a stand-alone unit or a nest mounted unit

• Transparent to framing; supports ESF or D4 framing

• AMI or B8ZS line coding; B8ZS transparency

• Front panel test access jacks and test switch

• Complete diagnostic capabilities including loopbacks and

built-in BERT

FRM

NET

MON

TO

DTE

TO

NET

MON

FRM

DTE

General 1-12100 CSU

Page 6

Specifications

Network Interface

Line Rate: 1.544 Mbps, ±50 ppm for internal

clock, ±200 bps in through mode

Line Framing: D4 or ESF (transparent)

Line Code: AMI or B8ZS

Input Signal: DS1, 0 to -30 dB ALBO

Connection: RJ-48C jack, 100 Ω (± 5%)

Output Signal: 3.0 V (±15%) base-peak into 100 Ω

Line Build Out: 0, -7.5, -15, and -22.5 dB attenuation

Line Protection: 1000 V lightning, fused input/output

Sealing Current: 14 mA, switch selectable, 3500 Ω in

series with -48 VDC

Keep Alive: Line loopback or all ones (framed or

unframed)

Jitter Control: per TR62411 and T1.403

Pulse Density: 15 or 175 zeros

Equipment Interface

Line Rate: 1.544 Mbps, ± 50 ppm for internal

clock, ± 200 bps in through mode

Line Framing: D4 or ESF (transparent)

Line Code: AMI or B8ZS

Input Signal: DSX1 to - 6 dB

Connection: RJ-48C jack, 100 Ω (± 5%)

Output Signal: Selectable DSX1 level from 0 to 655

feet in six incremental levels

Line Protection: 1000 V lightning

Diagnostics

Loopbacks: Line loopback on network and DTE

interface

Network BERT: 1 in 8 (B8ZS), 3 in 24 (AMI), Clear,

selectable framed or unframed pattern

Alarms

Network Activation:BPVs, all zeros, AIS

DTE Activation: Low density (>15 or > 175 zeros)

Reporting: Front panel LEDs and alarm contacts

Contact Ratings: UL 120 mA @ 110 VAC or 110 VDC

Connection: Terminal strip

Power

Line Power: 60 or 140 mA, 33 V max

Local Power: 19 VDC to 60 VDC, 4.3 W, 15 BTU

Connection: Terminal strip

Mechanical

Mounting: desktop, wall, horizontal rack,

vertical rack

Dimensions: 1.72" W, 6.8" H, 10.5" D

Weight: 2 lbs.

Environmental

Operating Temp: 0° to 50° C(32° to 122°F)

Storage Temp: -20° to 85° C(-4° to 185°F)

Humidity: 95% max (non-condensing)

Industry Listings

FCC Compliance: Part 15 Subpart B, Class A

FCC Part 68 Reg: FXKUSA-74937-DE-N

UL Approved: E 110448

CSA Certified: LR 98859

DOC/CSO3: 1653 5331 A

FCC Requirements

WARNING: Changes or modifications

!

to this unit not expressly appr oved by the

party responsible for compliance could void

the user’ s authority to o perate the equipment.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursu ant to Part 15 o f

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and

if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a resid ential area is

likely to cause harmful interference. The user will be

required to correct the interference at his own expense.

Notice to Users of 1.544 Mbps Service: The following

instructions are provided to ensure compliance with FCC

Rules, Part 68:

1. All direct connections to T1 lines must be made using

standard plugs and jacks.

2. Before connecting yo ur unit, you must inform the local

telephone company of the following information:

Port ID: SS-650810-A-NF

REN/SOC (Service Order Code): 6.0 N

1-2 General

2100 CSU

Page 7

FIC (Facility Interface Code):

04DU9-BN

04DU9-DN

04DU9-IZN

04DU9-IKN

04DU9-ISN

USOC jack: RJ-48C

RJ-48H

3. If the unit appears to be malfunctioning, it should be disconnected from the telephone lines until you learn

whether the source of trouble is your equipment or the

telephone line. If your equipment needs repair, it should

not be reconnected until it is repaired.

4. The unit has been designed to prevent harm to the T1

network. If the telephone company finds that the equipment is exceeding tolerable parameters, they can

temporarily disconnect service. In this case, the telephone company will give you advance notice, if possible.

5. Under FCC rules, no customer is authorized to repair this

equipment. This restriction applies regardle ss of whether

the equipment is in or out of warranty.

6. If the telephone company alters their equipment in a

manner that will affect the use of this device, they must

give you advance warning so that you can have the

opportunity for uninterrupted service. You will be

advised of your right to file a complaint with the FC C.

7. The attached affida vit must be completed by the installer.

8. In the event of equipment malfunctio n, all repairs shoul d

be performed by our company or an authorized agent. It

is the responsibility of users requiring service to report

the need for service to our company or to one of our

authorized agents.

Canadian Emissions

Warranty

TxPORT warrants each unit against defects in material and

workmanship for a period of five years from the date the

unit was shipped to the customer. If the unit malfunctions at

any time during the warranty period, TxPORT will repair, or

at TxPORT’s option, replace the unit free of charge.

The remedies listed herein are the user’s sole and exclusive

remedies. TxPORT shall not be liable for any indirect, direct, incidental or consequential damages. The owner must

return the unit to the factory, shipping prepaid and packaged

to the best commercial standard for electronic equipment.

TxPORT will pay shipping charges for delivery on return.

The customer is responsible for mode and cost of shipment

to TxPORT. This warranty does not apply if the unit has

been damaged by accident, misuse or as a result of service

or modification by other than TxPORT personnel.

When returning the unit for warranty work, a Return Material Authorization (RMA) number must be obtained from customer service at the address/phone number given below.

When calling TxPORT to obtain a Return Material Authorization number or to arrange service, please have the following information available:

• Model number(s) and serial number(s) for the unit(s).

• Reason for return and symptoms of problem.

• Warranty status (if known).

• Purc hase order number to c over charges for out -of-warranty

items.

• Name and phone number of person we can contact if we

have questions about the unit(s).

• Mode of shipment required (second day air is the normal

mode of shipment for all returned material unless otherwise

specified).

As soon as TxPORT has the above information, the RMA

that must accompany the item(s) returned can be issued.

Requirements

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department

of Communications.

End users should use existing 48-VDC battery

sources or a CSA certified power supply.

Le présent appareil numérique n’émet pas de bruits

radioélectriques dépassant les limites applicables aux appareils numériques (de la class A) prescrites dans le Règlement

sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

Ordering Numbers

The part numbers for the stand- alone unit and the modular

chassis unit are shown in Table 1-A on page 1-4 :

The unit is shipped from the factory with the 2100 CSU

reference manual. Refer to Table 2-B on page 1 -4 for the

optional equi pment part numbers.

General 1-32100 CSU

Page 8

Table 1-A 2100 CSU Part Numbers

Part Number Description

BCD

F-2100-100-1

F-2100-101-11

2100 D4 CSU stand - alone unit

B

Special option

1

Standard unit

2

Ones-density disable

C

Backplane option

1

RJ-48C NET / RJ-48C DTE

2

RJ-48C NET / DB-15 DTE

3

DB-15 NET / DB-15 DTE

D

ACO (alarm cut off) option

0

Without A C O

1

With ACO

C

0

2100 D4 CSU module (chassis)

C

Panel / ACO option

0

1051 chassis without ACO

1

1051 chassis with ACO

2

K - type without ACO

3

K - type with ACO

The following accessories may also be needed for the installation and operation of the 2100 CSU.

Table 2-B Optional Equipment

Part Numb er Description

9 - 1544N- 075 --X

9 - 1544N-07 6 - -X

9-1001-006--X 8-pin jack to 15-pin adapte r w/ screw

9-1001-009--010 8-pin to 8-pin twisted pai r

9-1001-011--025

9-1001-012--025

9-1001-036--010

9-1001-037--010

9-1001-048-1 Y male adapter/cable (splits EM8000

33-00085

33-00086

9-2000-036--1 Stand-alone to rack mount conversion

F-1051-000--111

F-1051-000--112

9-2000-001--1

9-2000-001--2

9-2000-002--1

9-2000-002--2

F-1040-000--111

F-1040-000--112

F-1200-000--11 1200 power supply with redundant

9-8000-001-1

9-8000-001-2

Va riable X in the part number as follows: 1 = male, 2 = female.

8-pin jack to 15-pin adapter w/ post

8-pin jack to 15-pin adapter w/ nuts

50-pin male-male twisted pair

50-pin male-female twisted pair

50-pin to 8-pin modular (DTE)

50-pin to 8-pin modular (NET)

In/Out), DB-25 to two 6-pin NMS ports

Bantam to bantam test cord - red

Bantam to bantam test cord - black

module with DB-25 to 6-pin adapter

1051-1 chassis (RJ-48H)

1051-2 chassis (RJ-48C)

19" single unit rack mount adapter

19" dual rack mount adapter

23" single unit rack mount adapter

23" dual rack mount adapter

Power shelf with single 48 VDC, 2 A supply

Shelf with redundant 48 VDC, 2 A supply

-48 VDC, 5 A with fuse panel

EM8000 with manual on 3-1/2 inch disk

(DOS and UNIX version, respectively)

TxPORT Customer Service

TxPORT office hours are Monday through Friday from 8

a.m. to 5 p.m. Central Time. For general, sales, and marketing information, contact TxPORT at:

Toll Free: 888-4TxPORT

Toll Free: 800-926-0085

Local: 205-772-3770

International: 205-772-3770

e-mail: info@txport.com

Technical Support

Technical supprt is available 24 hours a day, seven days a

week. You may contact a support representative by telephone or e-mail.

Toll Free: 1-800-285-2755

Local: 205-772-3770

International: 205-772-3770

e-mail: support@txport.com

Returns/RMA

If for any reason you need to return a TxPORT unit, you

must have a Return Material Authorization (RMA) number

marked on the shipping package. You may obtain an RMA

number from customer service at 888-4TxPORT; 8000-9260085, ext. 2227; or for local or international customers 205772-3770.

When calling TxPORT for an RMA; please have the following information available:

• Model number and serial number for each unit.

• Reason for return and symptoms of the problem.

• Warranty status (if known).

• Purc hase order number to cover charges for out-of-warranty

items.

• Name and telephone number of a person we can contact if

we have questions about the unit(s).

• Mode of shipment required (second-day air is the normal

mode of shipment for all returned material unless otherwise

specified).

Units being returned to TxPORT should be sent to the following address:

TxPORT, Inc.

127 Jetplex Circle

Madison, Alabama 35758

1-4 General

2100 CSU

Page 9

2. Installation

Introduction

This chapter contains information and instructions required to

prepare the TxPORt 2100 CSU for use, Included are initial

inspection procedures, mounting instructions, configuration

guidelines, connection instructions, and powering information.

Throughout this manual, all factory default settings are

underlined.

Safety Summary

This manual contains information and warnings that must be

followed to ensure safe operation and to retain the equipment in a safe condition.

The WARNING sign denotes a hazard

to the operator. It calls attention to a

procedure or practice which if not correct performed or adhered t o, cou l d r esu l t in in ju r y or

loss of life. Do not proceed beyond a WARNING sign until the indicated conditions are

fully understood and met.

Follow proper ESD (electrostatic discharge) procedures while handling the circuit boards.

Unpacking and Inspection

Supplied Materials

The TxPORT 2100 CSU is shipped from the factory with the

2100 CSU reference guide.

The following additional material may be required for the

installation and operation of the un it:

• -48 VDC power source

• Network and DTE interface cables

• Bantam test cables

• 2 0-gauge stranded wire (or sim ilar) for DC power and alarm

connection

For specific applications, additional adapters and cables may

be required. The interface requirements of any application

may be met by using the appropriate cable. Standard cables

and ordering numbers are listed in Optional Equipment on

page 1-4. Contact TxPORT for any needed assistance in

cable selection.

Mounting

The TxPORT 2100 CSU is a modular unit that plugs into

either single unit housing or into a chassis that holds up to

12 CSUs. Single units are designed for standalone desktop

use, wall mounting, or rack mounting (in either a vertical or

horizontal orientation). The CSU utilizes an interchangeable front panel to accommodate the chassis card cage.

This unit is carefully packaged to prevent damage in shipment. Upon receipt, inspect the shipping container for

damage. If the shipping container or cushioning material is

damaged, notify the carrier immediately and make a notation on the delivery receipt that the container was damaged

(if possible, obtain the signature and name of the person

making delivery). Retain the packaging material until the

contents of the shipment have been checked for completeness and the instrument ha been checked both mechanically

and electrically.

If the contents of the shipment are incomplete or, if there is

mechanical damage or defect, notify TxPORT. If the shipping container is also damaged, or the cushioning material

shows signs of stress, notify the carrier of the damage as

well as TxPORT. Keep the shipping materials for carrier’s

inspection. TxPORT will arrange for repair or replacement

without waiting for claim settlement.

Standalone Unit

To access the circuit boards and configuration switches, perform the following steps:

1. Remove the front panel cover by opening the front panel

access door and gently spreading the plastic from the

middle using both hands.

2. Pull the two sides o f the plastic cover from the middle

outwards until the four stops are clear of the front panel.

Pull the cover off the front panel.

3. Remove the two Phillips-head screws from the front

panel and pull the front panel and circuit boards out of

the housing. Observe the proper electrostatic discharge

procedures while handling the circuit boards.

The standalone unit may be used in a chassis installation

with the following modifications:

1. Remove the housing as described in the procedure above

and then remove the four screws holding the front panel

to the circuit boards

Installation 2-12100 CSU

Page 10

Alarm Relay

Optional Alarm Card

Switch S3

12 76543

Figure 2- 1 Bottom-Edge View of the 2100 CSU

2. Replace the standalone front panel with a front panel

module. The unit can now slid e into one of the 12 C SU

slots on the chassis fron t.

Chassis Assembly

Up to 12 modular units may be inserted into a chassis and

the chassis may be installed in a 19-inch or 23-inch rack

using four screws. Connections are made from the rear of

the chassis. Refer to Figure 2-6 on page 2-5.

Unit Configuration

The TxPORT 2100 CSU is hardware configured using two

DIP switches and a jumper located on the side of the circuit

boards. These are shown in Figure 2-1 except for Switch S2

which is located on the front panel (see Figure 2- 2). The

numbering system used for each switch position is as follows: Position 2 of Switch S3 is referred to as Switch S3-2,

and so on.

Before installation, verify each configuration switch setting.

Differences in the switch settings between the chassismount and standalone units are shown on their respective

configuration guides.

Configuration Switch S2

Front panel Switch S2 (Figure 2-2) is used to set the con figuration parameters listed in the following paragraphs.

Keep Alive - All Ones

Keep Alive - Unframed

Test Mode - BERT

Line Mode - B8ZS

Test Pattern - Framed

Zeros - 15

Sealing Current - Off

Left Right

Figure 2-2 Switch S2

Sealing Current

Position S2-1 is used to apply a sealing cu rrent of 20 mA to

the network interface for applications where the telco provides a dry (no power interface and sealing current is

needed. For most applications (where the telco provides line

power or where sealing current is not required), this switch

should be left in the Off position.

Keep Alive - Loopback

Keep Alive - Framed

Test Mode - Clear

Line Mode - AMI

Test Pattern - Unframed

Zeros - 175

Sealing Current - On

12 76543

Up

Down

Switch S4 is set

at the factory—

do not change.

Switch S4

KX TX

Sealing current is any low-level current passing through a

splice, joint, or wire-wrap connection. It seals the joints on a

span line. The action of the current flow prevents the joint

from becoming a source of high impedance.

Prior to divestiture, th e CSUs were owned and powered by

the telephone company, ensuring sealing current on all joints

up to the CSU. Since divestiture, the telephone company

may sometimes loop the power back at the last repeater or at

the network interface. This removes power from the final

section, which in turn removes sealing current from those

joints. The dry spans can cause mechanical contacts to eventually fail. Providing sealing current to a span reduces this

corrosion.

Left: sealing current is Off.Right: sealing current is On.

WARNING: Enabling sealing current

with telco line power present could dam-

age the unit and/or cause improper operation.

Zero Suppression

Position S2-2 implements ones-density insertion after the

preset number of zeros has been received from the DTE and

the Keep Alive mode is activated.

Left: 15 zeros Right: 175 zeros

Test Pattern

Position S2-3 sets the framing of the SET, RESET, and

BERT test signals.

Left: Framed Right Unframed

Line Coding

Position S2-4 sets the network line coding. If set to AMI, the

unit indicates a BPV error for each event. The B8ZS code

coming from the network and sets the test signals to B8ZS.

Left: B8ZS Right: AMI

Test Mode

Position S2-5 either sets or clears the test pattern. The BERT

position allows the CSU to send a BERT pattern after the set

signal (LOOP) is sent. Clear passes the traffic from the DTE

through the network and allows network access via test

jacks to run bit error tests (affects network tests only).

Left: BERT Right: Clear

2-2 Installation

2100 CSU

Page 11

Keep Alive

Positions S2-6 and S2-7 are used to select the action that

occurs upon loss of DTE signal, when the unit switches to

the Keep Alive mode on the network line. The choices are

shown in Table 2-C.

Table 2-C Keep Alive Settings

Table 2-E DSX Level

DTE LBO S3-3 S3-4 S3-5

267-399 ft Up Down Up

400-533 ft Down Up Up

534-655 ft Up Up Up

Function S2-6 S2-7

Keep Alive is unfram ed all ones Left Left

Keep Alive is framed all ones Left Right

The Keep Alive signal is the acti-

vation of the line loopback.

Right Left

Right Right

Configuration Switch S3

Switch S3 is used to set the configuratio n parameters listed

in the following paragraphs.

NET LBO

NET LBO

DTE Level

DTE Level

DTE Level

Line Code

Remote Loop

Up

12 76543

Figure 2-3 Switch S3

Network LBO

Positions S3-1 and S3-2 set the output signal level to the

transmit data (TXD) from the CSU to the network to the

proper line build out. These values are shown in Table 2-D.

The output level is factory set at 0 dB . It may be attenuated

by 7.5 dB, -15 dB, or -22.5 dB if operating conditions

require that it be changed. The telco should provide the

proper seting to the user. If unsure of the exact setting, then

leave it at 0 dB.

Table 2-D Network Line Build Out

Down

Line Code

Position S3-6 is used to provide AMI/B8ZS conversion from

the DTE to the facility and B8ZS/AMI conversion from the

facility to the DTE or set the line code to be transparent.

Up: Transparent Down: Conversion

Remote Loop

Position S3-7 is used to select the signal sent to the DTE

during a remote loop.

Up

: AIS to DTE Down:Network data to DTE

ACO/Alarm Card (Optional)

The optional; ACO/alarm card monitors the alarm indicators for an alarm active or an alarm clear condition and

provides closure contact points on the rear panel. The corresponding front panel LED lights when an alarm condition is

detected on four different conditions:

• Network AIS (all ones)

• Network LOS (all zeros)

•Network BPVs

• DTE ones density)

The alarm card circuitry scans the status (on or off) of the

alarm indicators ten times a second (100-ms windows). The

card declares an alarm if one or more indicators are on for

100 consecutive 0.1-second samplings (10 seconds). When

this happens, the red Status indicator turns on until no alarm

conditions are detected for more than 100 consecutive 0.1second samplings (another 10 seconds).

Network LBO S3-1 S3-2

0 dB Down Down

-7.5 dB Down Up

-15.0 dB Up Down

-22.5 dB Up Up

DSX Level

Positions S3-3, S3-4, and S3-5 set the DTE line interface

DSX level to one of the values shown in Table 2-E. The setting should match the cable length from the C SU DTE port

to the attached equipment (cross-connect).

Table 2-E DSX Level

DTE LBO S3-3 S3-4 S3-5

0-133 ft Up Up Down

134-266 ft Down Down Up

Installation 2-32100 CSU

Page 12

DTE Connection

The DTE interface of the CSU is a DSX interface. The DTE

output level should be set as described in DSX Level on

page 2- 3. The DTE physical interface for both the standalone unit (Figure 2 -4) and the chassis unit (Figure 2- 5 and

Figure 2- 6) is a standard RJ-48C, 8-pin modular jack with

the pinout shown in Table 2-F.

Table 2-F DTE Interface Pinout

Pin DTE Interface

1 Data Out

2 Data Out

3Not Used

4 Data In

5 Data In

6Not Used

7, 8 Chassis Ground

DB-15 Connection

DB-15 connectors are optional for the DTE and network

interfaces. Refer to Optional Equipment on page 1-4 for

ordering information. The DB-15 pinout is shown in Table

2-G.

Table 2-G DB-15 DTE and Network Interface

Pinouts

Pin DTE NET

1 Data In Data Out

2 Frame Ground Frame Groun d

3 Data Out Data In

4 Frame Ground Frame Groun d

9 Data In Data Out

11 Data Out Data In

8

1

DTE

1+V

2GND

3-V

4FRM GND

5ALM

6ALM COM

1

8

1

6

DB-15

(optional)

DB-15

(optional)

NET

Figure 2-4 2100 CSU Standalone Rear Panel

2-4 Installation

2100 CSU

Page 13

Unit 1 Unit 2 Unit 3 Unit 4 Unit 5 Unit 6 Unit 7 Unit 8 Unit 9 Unit 10 Unit 11 Unit 12

T1

DTE

12

14

High

Speed

DTE

12

25

T1

NET

12

TB1 - 23451

( B )

NMS

16

81

1

13

81

IN

DTE

High

Speed

DTE

NET

Line Chassis Mounting Hardw are

Rack and19" or 23" Multiple

Figure 2-5 Model 1051-2 Chassis, Front View

( B )

NMS

OUT

T1

11

11

T1

11

T1

DTE

10

High

Speed

DTE

10

T1

NET

10

Redundant

Power

Board

T1

DTE

9

High

Speed

DTE

9

T1

NET

9

TB2 - 23456

DTE

High

Speed

DTE

NET

1

T1

8

8

T1

8

T1

DTE

7

High

Speed

DTE

7

T1

NET

7

1 - EXT CLK

2 - EXT CLK

3 - ALARM RING

T1

DTE

6

High

Speed

DTE

6

T1

NET

6

TB1

4 - ALARM TIP

5 - SIG GND

T1

DTE

5

High

Speed

DTE

5

T1

NET

5

T1

DTE

4

High

Speed

DTE

4

T1

NET

4

1 - +48V RTN (B)

2 - FRAME GND

3 - -48V IN (B)

TB2

T1

DTE

3

High

Speed

DTE

3

T1

NET

3

4 - -48V IN (A)

5 - SIG GND

6 - +48V RTN (A)

( A )

NMS

IN

T1

DTE

2

High

Speed

DTE

2

T1

NET

2

( A )

NMS

OUT

T1

DTE

1

High

Speed

DTE

1

T1

NET

1

ENET

Figure 2-6 Model 1051-2 Chassis, Rear View

Installation 2-52100 CSU

Page 14

Network Conn ectio n

Figure 2-7 Alarm Relay Jumpers and Strap

NO

NC

The network side of the CSU is referred to as the network

interface. This interface is located on the contains an ALBO

to allow the unit to be located a substantial distance away

from the telco network interface (receive signal level down

to -30 dB).

The network interface line build out (LBO) levels should be

adjusted as in Table 2-D on page 2 -3. The maximum suggested cable lengths for connection of the CSU to the

network are shown in Ta ble 2-H. Calculations are based on a

70°F cable temperature; a 0.083 µF capacitance; a 30-dB

loss; and a 100-Ω, non-loaded, twisted pair cable. PIC refers

to Plastic Insulated Cable.

Table 2-H Line Loss versus Cable Gauge

Cable Type Loss per 1000' Max Length

26-gauge PIC 6.8 dB 4,400 ft

24-gauge PIC 5.4 dB 5,500 ft

22-gauge PIC 4.2 dB 7,100 ft

19-gauge PIC 3.0 dB 10,000 ft

Standalone Unit

The connection for the standalone unit is made on pins 5 and

6 of the Alarm/Power connector as shown in Table 2-J.

Table 2-J Power and Alarm Connector Pinout

Pin Function

1 48 VDC Return

2 Signal Ground

3-48 VDC

4 Frame Grou nd

5 Alarm Contact

6 Alarm Common

Pin 5 is configured to operate in either a normally open

(NO) or normally closed (NC) mode as determined by the

setting of the alarm relay jum per shown in Figure 2-7. This

jumper is located on the circuit board.

The network physical interface for both the standalone unit

and chassis unit is a standard RJ-48C 8-pin modular jack

with the pino ut shown in Table 2-I.

Table 2-I Network Interface Pinout

Pin NET Interface

1 Data In

2 Data In

3 Not Used

4 Data Out

5 Data Out

6 Not Used

7, 8 Chassis Ground

In accordance with FCC rules, Part 68.218(b),

notify the telephone company before disconnecting the CSU.

Alarm Connection (Optional)

The standalone unit and the chassis modular unit provide

rear panel alarm relay contacts as an option. These dry (isolated) alarm contacts permit connection to a remote

indicating device.

The unit allows normally open (NO) or normally closed

(NC) alarm relay contacts. Using NO contacts, a nest of

CSUs and any other equipment may use a common bused

alarm line. Using a NC contact set allows a serial daisy

chain from unit to unit. Any unit going into alarm then

breaks the alarm loop.

NO and NC refer to the contact’s relationship to the common contact under a no alarms conditio n. Move the jumper

to NC for normally closed operation (opens on alarm) or to

NO for normally open operation (closes on alarm).

Make connections to the alarm contacts using 20-gauge

stranded (or similar) wire. The contacts are rated at 120 mA

AC or 120 mA DC.

Chassis Unit

Alarm conditions from all modules in the chassis are bused

together in parallel and are presented on a sin gle set of alarm

relay contacts which permit connection to a remote indicating device. When connected, pins 3 and 4 on terminal strip

TB1 operate in normally open mode. Refer to the 1051-2

Chassis Configuration Guide for further information.

All PRISM 3001 modules in a common chassis

must use the normally open contact mode.

Make connections to the alarm contacts using 20-gauge

stranded wire (or similar). The contacts are rated at 120 mA

AC or 120 mA DC.

2-6 Installation

2100 CSU

Page 15

Power Connection

The standalone unit and the modular chassis unit require a 19- to 60-VDC power supply capable of delivering 4.3 watts

per unit. Power supplies are available from TxPORT and are

listed in Optional Equipment on page 1-4.

Connect the ground lead before applying power to the unit.

Standalone Unit

The power source is connected to pins 1 and 3 of the Power

and Alarm terminal as shown in Table 2-J on page 2-6.

Connect a chassis ground lead (18- to 20-gauge is recommended) to the Frame Ground terminal (pin 4). Connect the

other end of this lead to an appropriate facility ground.

Often, the 48 DC return is also ground. In that case, both

return and ground leads should be connected to ground.

Connect the lead of the -48VDC source to the -V terminal

(18- to 20-gauge wire is recommended). Connect the return

lead of the 48-volt source to the +V terminal. When powered

up, the STATUS indicator on the front panel lights and the

unit goes through the normal LED sequencing.

Chassis Unit

the chassis is designed with two power buses. The A bus

feeds the odd slots while the B bus feeds the even slots.

Refer to Figure 2-6 on page 2 -5 for an illustration of the

1051-2 rear panel and to the appropriate 1051 chassis configuration guide for further information.

Three modes of powering the chassis are available:

Redundant Power Source

A redundant power board is factory installed on power connector TB2 which allows connection of two independent -48

VDC supplies operated in a redundant mode. All slots are

powered from the combi ned inpu t of t h e A and B power supplies. If either supply fails, the other powers the entire

chassis.

Single Power Source

Using a single power source is essentially th e same as the

redundant configuration with power supply B not operational. If the redundant power board is not used, the A bus

and the B bus must be connected together with a jumper.

Dual Power Source

When using a dual independent power supply, one -48 VDC

source feeds the A bus while another -48 VDC source feeds

the B bus.

Each 2100 CSU requires a 19- to 60- VD C pow er

supply capable of delivering 4.3 watts. Ensure

the proper fuse size is used. Refer to the 1040

Power Shelf configuration guide.

Installation 2-72100 CSU

Page 16

2-8 Installation

2100 CSU

Page 17

3. Operation

Figure 3-1 2100 CSU Front Panel

LOC

FAR

ACO SW

ACO

LOOP

BPV

LOS

AIS

DENSITY

SET

RESET

ERR

7654321

S2

FRM

NET

MON

TO

DTE

TO

NET

MON

FRM

DTE

3

2

4

1

5

6

8

7

9

10

11

12

13

2100

CSU

Introduction

This chapter contains the general operation instructions for

the TxPORT 2100 CSU. The unit is operated manually by

using the front panel controls and indicators (described in

this chapter) and configuration Switch S2 (described in the

Installation chapter).

Front Panel Descriptions

The 2100 CSU uses LED indicators to convey major alarm

conditions and looping status. The front panel contains 11

LED indicators, a test switch, and a set of bantam test jacks.

The following paragraphs describe these controls and indicators and are referenced to the illustration on this page.

General Status Indicators

1. STATUS: The CSU has two LED indicators on the

front panel bezel that are exposed whether the access

door is open or closed. These general status LEDs provide a quick check of the CSU’s operating condition

(Go or No Go).

If neither LED is lit, the unit is not powered. If the

green LED is lit, the unit is powered and functioning

normally. If the red LED is lit, there is a lin e fault wh ich

exceeds alarm thresholds or another type of unit failure.

The problem can be isolated by further examinat ion of

the other front panel LEDs as described below.

Alarm Controls and Indicators

2. ACO: This red LED lights whenever the alarm cut off

switch is in the right (On) position (when the alarm

relay contacts are disabled).

3. ACO SW: The alarm cut off switch controls the alarm

relay circuitry. If the switch is placed in the right On

position, this circuitry is deactivated. The left Off position enables the contacts to report alarm conditions.

4. BPV: This red LED lights (0.1 second minimum) for

each occurrence of bipolar violations from the network.

5. LOS: This red LED lights constantly when a loss of

signal condition is detected from the network.

6. AIS: This red alarm indication signal LED lights con-

stantly if an unframed all-ones condition is detected

from the network.

TRANSPORT

®

7. DENSITY: This red LED lights co nstantly if the ones

density from the equipment is less than 12 .5 percent or

if there is a loss of signal.

Test Controls and Indicators

8. LOOP: This yellow LED lights constantly when the

network interface is in a line loopback.

Operation 3-12100 CSU

Page 18

9. SET: This yellow LED flashes if the set code is trans-

Receive signal

from the DTE

Transmit signal

to the network

Transmit signal

to the DTE

Receive signal

from the network

Monitor signal

from the network

Monitor signal

from the DTE

Figure 3-3 Test Jacks

mitted. It lights constantly if the set code is received.

10. RESET: This yellow LED flashes if the reset co de is

transmitted. It lights constantly for five seconds if the

reset code is received.

11. ERR: This red LED lights 0.1 second if an error is

received during a network test.

12. Test Switch: This switch (FAR/ LOC) is used for local

testing. Refer to T est Switch below for more informa tion.

13. Test Access Jacks: These six bantam test jacks are

provided for access to the T1 line on the DTE side of

the CSU. Refer to Test Access Jacks below for more

information.

Front Panel Testing

The previous section gave a brief description of each front

panel control and LED indicator. This section explains the

front panel test functions. Testing may also be performed

using software control from the TxPORT EM8000 element

manager (refer to the EM8000 reference manual).

Test Switch

This switch is used for local testing. When in the Far posi tion (FAR), the unit sends five seconds of IBLC (in-band

loop codes), then switches to Clear Test or BERT When

transmitting IBLC or the t est pattern, the test LED blinks.

The ERR LED lights for 0.1 second when a bit error or sync

loss is detected.

When this switch is returned to the normal center positio n,

the unit sends five seconds of loop down code (100) and

then returns to its normal operating mode.

When the Test switch is in the local position (LOC), the unit

performs a bidirectional loopback as shown in the following

diagram and the LLB indicator lights.

Test Access Jacks

Six bantam test jacks are provided for access to the T1 line

on the DTE side of the CSU. Jacks allow transmit and

receive toward the network, toward the DTE, or monitoring

traffic between DTE and network. Jacks are customarily

used to inject and receive T1 signals using a T1 test set.

NET

The top two ports are used to insert into the line in both

directions. They break connection to the DTE and make

connection to the CSU in the direction of the network.

MON

The middle two ports are used for non-intrusive bridge

monitoring of the line in both directions. They monitor the

signals passing through the CSU (between the DTE and the

network).

DTE

The bottom two ports are used to drop the line. They break

connection to the CSU and make connection to the DTE.

3-2 Operation

Equipment Network

Figure 3-2 Local Loop

CSU

2100 CSU

Page 19

®

TRANSPORT

Document:

Date:

PRISM 2100 T1 CSU Reference Manual, 6th Edition, March 1997

September 30, 1997

Addendum

Sealing Current and Line

Power Are Not Applicable

The following no longer applies:

Page 1-1: The second sentence of the fourth paragraph of

the section Introduction

Selectable sealing current source under Design

Highlights

34-00187-A6.01

Page 1-2: Sealing Current under Network Interface of

Specifications

Line Power under Power of Specifications

Page 2-2: Figure 2-2 Switch S2, position 1 and section

Sealing Curre nt

Loading...

Loading...