Page 1

TRANSPORT

®

®

USTOMERSERVICE

TRANSPORT

TxPORT

127 Jetplex Circle

Madison, Alabama 35758

C

T e le ph one Number : 800-926-0085 or

205-772-3770

Sales /Administration FAX: 205-772-3388

Customer Service Returns: 800-926-0085, ext. 227

Product Technical Support

Normal Hours:

8 a.m. to 5 p.m. Central Time, Monday – Friday

T e le ph one Number : 800-285-2755

205- 772-3770, ext. 255

or ext. 252 (manager)

Emergency Hours (Nights / Weekends / Holidays):

800- 285-2755

205-603-2194 (Manager)

P

RODUCTIVITY

S

200 CSU

210 CSU

R

EFERENCE

34-00196

1

ST

ERIES

M

E

DITION

ANUAL

1 16

Page 2

OPYRIGHT/LIABILITY

DTE

NET

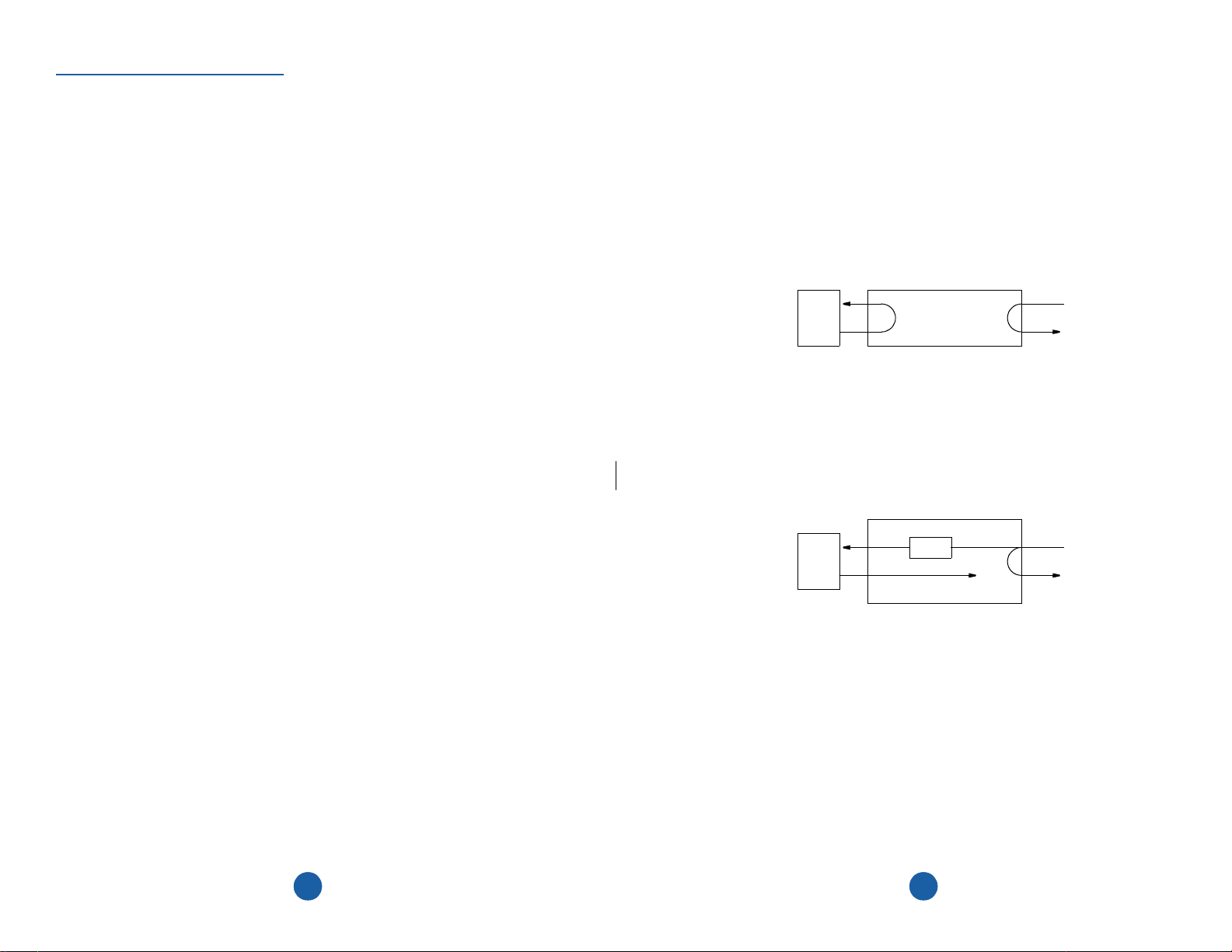

Local Loopback

DTE

NET

AIS

Remote Loopback

C

© 1995 TxPORT, All rights reserved. No part o f this publica tion may be rep roduced,

transmitted, transcribed, stored in a retrieval system, or translated into any language in

any form by any means without the written permission of TxPORT.

Reorder # 34-00196

1st Edition, March 1995

TxPORT shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

TxPORT reserves the right to revise this publication from time to time and make

changes in content without obligation to notify any person of such revision changes.

Contents of this publication may be pre liminary and/or may be c hanged at any time

without notice and shall not be regarded as a warranty.

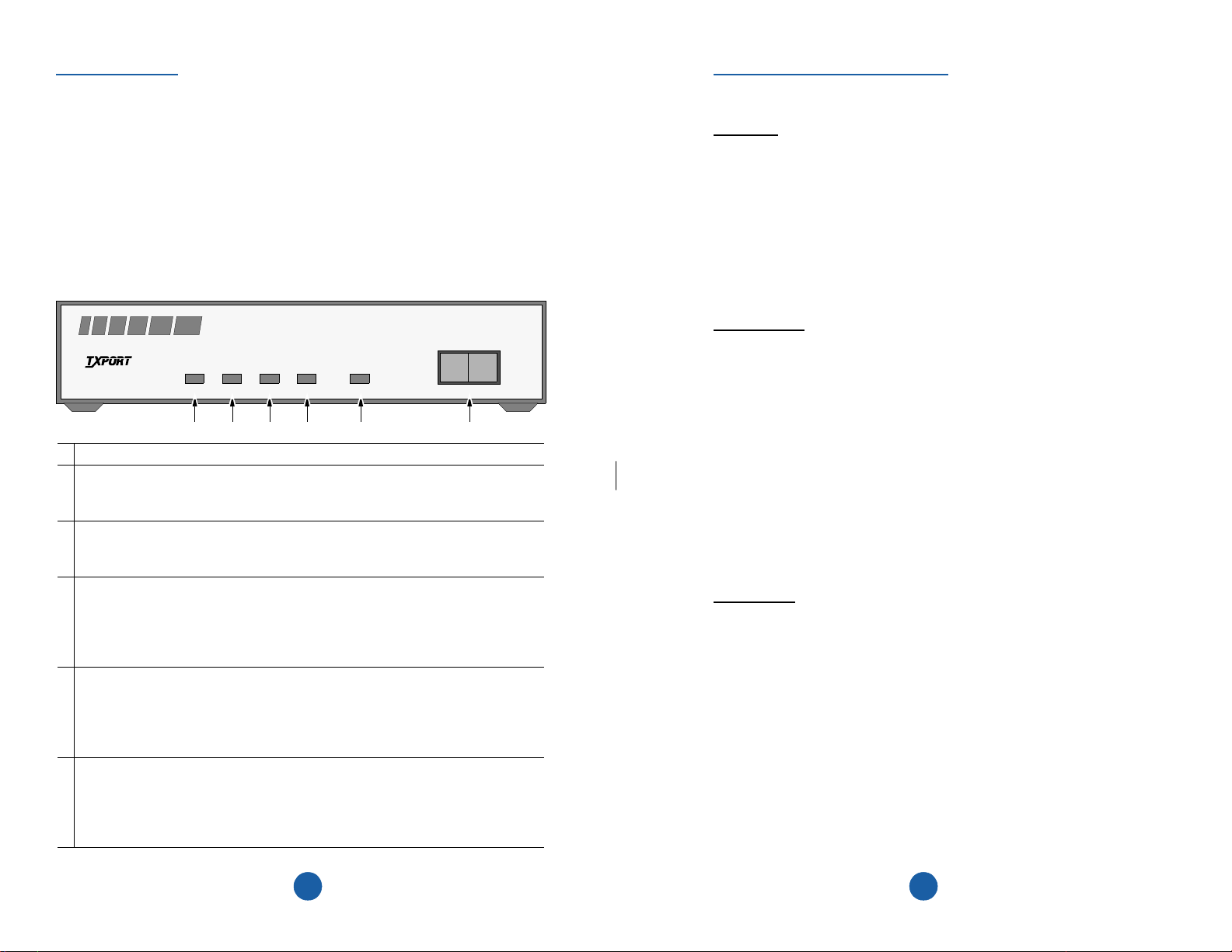

The controls, indicators and test features are identical for both units except for the front

panel ‘FAR’ indicator, which is found only on the 200 CS U. Each unit uses LED in dicators to convey major alarm conditions and looping status. Loop s are initiated using

the network test switch.

3.1 Testing

The front panel test switch is used for local testing. When placed in the local loop

mode (LOOP), the unit loops the signal from the customer equipment (DTE IN) back

to the customer equipment (DTE OUT). It also loops the received signal from the T1

facility (NET IN) back to the T1 facility (NET OUT). When moved back to ‘NORM’,

the local loopback is removed.

The unit can also be looped remotely by generating towards it a standard CSU line

loopback code (000 01 repeating for Š 5 se conds, framed or unframe d). Once looped,

the received signal from the T1 facility (NET IN) is regenerated and transmitted back

to the T1 facility (NET OUT). The unit can be unlooped remotely by generating

towards it a standard CSU line unloop code (001 repeating for Š 5 seconds, framed or

unframed).

Documentation Disclaimer

TxPORT makes no representation or warranties of any kind what soever with respect to

the contents hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

2

DIP switch S1-6 configures the unit to either generate an unframed all ones (AIS) signal to the DTE or to pass the received data from the network to the DTE. The 200 unit

responds to the facility data link (FDL) loop (PLB, 0000111011111111) and unloop

command messages (0011100011111111) .

15

Page 3

O

PERATION

T

ABLE OFCONTENTS

3.0 Introduction

This chapter describ es the front panel operat ion and test features of the TxPORT 200

and 210 CSUs. Both units are controlled manually using a front panel test switch and

rear panel DIP switches (the DIP switches are discussed in the ‘Installation’ chapter).

The front panel switch and the LED indicators are described below.

200 CSU Front Panel

PRODUCTIVITY SERIES 200

®

TRANSPORT

CSU

POWER

1

DTE T1 Status:

2

of signal condition for Š 175 bit times from the DTE. The LED stays lit until the

unit detects Š 4 pulses in 32 bit times.

Network T1 Status:

3

loss of signal condition for Š 175 bit times from the network. The LED stays lit

until the unit detects Š 4 pulses in 32 bit times.

Far end T1 status

4

cuitry detects a yellow alarm signal from the far end terminal equipment. This condition occurs if the far end terminal is out of sync with the T1 signal from the

network. The format for a yellow alarm is bit 2 set to 0 in each DS0 (D4 mode) or

8 ones/8 zeros in the facility data link (ESF mode).

Loop:

5

switch is placed in the ‘LOOP’ position or the unit receives an inband loop code

for > 5 seconds, or (for the 200 only) the unit re ceives an FDL loop message (PLB

or LLB). The LED does not light if the test switch is placed in the ‘NORM’ position or if an inband or FDL unloop code is received for >5 seconds.

Te st Swi tch:

6

local loop mode (LOOP), the unit loops the signal from the customer equipment

(DTE IN) back to the customer equipment (DTE OUT). It also loops the received

signal from the T1 facility (NET IN) back to the T1 facility (NET OUT). When

moved back to ‘NORM’, the local loopback is removed.

: This green LED lights when power is applied to the unit.

This amber LED lights under the following conditions: the manual loop

PWR DTE NET LOOPFAR

This red LED lights if the internal alarm circuitry detects a loss

This red LED lights if the internal alarm circuitry detects a

(200 CSU only): This red LED lights if the internal alarm cir-

This 2-position switch is used for local testing. When placed in the

LOOP NORM

654321

General

Introduction ................................................................................... 4

Specifications ................................................................................ 5

FCC Requirements ........................................................................ 6

Warranty ........................................................................................ 7

Ordering Numbers .................................................... ..................... 8

Installation

Introduction ................................................................................... 9

Supplied Materials ........................................................................ 9

Unit Configuration ........................................................................ 9

Configuration Switch S1 ........................................................ 10

Configuration Switch S2 ........................................................ 11

Connections ................................................................................... 12

DTE and Network Connections ............................................. 13

Power Connection .................................................................. 13

Operation

Introduction ................................................................................... 14

Testing ........................................................................................... 15

TxPORT Customer Service .......................................................... 16

314

Page 4

ENERAL

G

1.0 Introduction

The TxPORT Productivity Series 20 0 ESF CSU and 210 CSU provide an eco nomical

solution for providing the T1 interface between customer premise equipment and T1

facilities (telco or private). Each unit is compatible with all T1 carrier transmission

equipment and is designed to comply with all industry standard specifications. Both the

transmitted and received 1.544 Mbps signals are conditioned.

The 200 unit is an industry standard, ESF T1 channel service unit which supports ESF

performance monitoring, testing, and performance reporting per AT&T 54016 and

ANSI T1.403.

The 210 unit is an industry standard, frame transparent T1 channel service unit. It

detects and activates network initiated loopbacks, monitors bipolar violations, and

maintains pulse density of the transmitted signal. The unit works with any T1 line format and is transparent to framed (D4 or ESF) or unframed T1 signals. The 210 unit is

transparent to line coding an d may operate with either AMI or B8ZS.

2.3 Connections

Both 200 and 210 CSU rear panels have RJ48C connections for the net work and DTE

interface and a terminal strip for the power connection. The fol lowing paragraphs describe these connections.

2.3.1 DTE and Network Connections

The equipment and network physical interfaces are standard RJ48C 8-pin modular

jacks with the following pinout.

Pin NET Interface DTE Interface

1 Data In Data Out

2 Data In Data Out

3 Not Used Not Used

4 Data Out Data In

Both units are constructed for stand- alone (tabletop) use but may be installed in an

equipment rack or cabinet (requiring optional rack m ount hardware). The front and rear

panels of the two units are sim ilar. Any differences will b e noted in the appropriate

places throughout this manual.

Each unit provides ALBO circuitry on the network receive path. The network ALBO

supports a receive range of +1 dB to -30 dB . Th e DTE supp ort s DSX 1 signa l ran ges up

to 655 feet. The units also provide LBO circuitry on both network and DTE. The network transmit LBO is user selectable (from 0 dB to -22.5 dB). The DTE transmit LBO

is user selectable in five incremental ranges from 0 to 655 feet.

Both CSU units operate from an externally provided -24 or -48 VDC power source.

Network and DTE connections are made through RJ48C type connectors. The u nits

have primary and secondary surge prote cti on on b oth th e net work a nd DTE side (m eet ing the UL 1459 requirements ).

TxPORT 200 CSU

PRODUCTIVITY SERIES 200

TRANSPORT

CSU

®

PWR DTE NET LOOPFAR

LOOP NORM

5 Data Out Data In

6 Not Used Not Used

7/8 Chassis Ground Chassis Ground

2.3.2 Power Connection

The 200 and 210 CS U units operat e from -48 Volts DC. Connections are made on th e

following power terminals using 20-gauge stranded (or similar) wire:

GND Ground

PWR- -48 VDC (± 6 V, 45 mA)

PWR+ Return

134

Page 5

DTE Line Coding: Position S2-3 sets the DTE line coding, including conver sio n.

- AMI B - B8ZS

A

Network Line Framing: Position S2 - 4 sets the CSU to the framing of the network

line. In the ESF mode, the unit responds to all T1.403 or 54016 messages.

- ESF B - D4

A

DTE Line Framing: Position S2-5 sets the CSU to the framing of the DTE line.

A - ESF B - D4

PRM: Position S2 -7 en ables /d isables sending a PRM (performance re port message)

during AIS. If the unit detects a loss of sync from the DTE, an unframed all ones signal

is generated to the T1 facility. If Switch S2-1 is set for T1.403 operation, the unit interrupts the AIS signal with a PRM once a second.

- PRM enabled B - PRM disabled

A

The differences between the 200 and 210 CSU units are summarized as follows:

• Configuration switch S2 is found only on the 200 CSU.

• Position S1 -7 ( switch S1, position 7) is a spare on the 200 CSU.

On the 210 CSU, position S1 -7 is used to enable the ‘Transparent’ mode.

• The front panel ‘FAR’ LED indicator is installed only on the 200 CSU.

1.1 Specifications

Network Interface

Line Rate: 1.544 Mb/s (± 50 bps)

Line Framing: D4 or ESF

Line Code: AMI or B8ZS

Line Impedance: balanced 100 Ω (± 5%)

Input Signal: DS1, +1 to -30 dB (ALBO)

Output Signal: 3.0 V, ±15%, base-peak into 100 ¾

Line Build Out: 0, -7.5, -15, and -22.5 dB attenuation

Line Protection: 1000 V lightning, fused input/output

Jitter Control: per TR62411 and T1.403

Pulse Density: per TR62411

Equipment

Interface

Line Rate: 1.544 Mb/s (± 50 bps)

Configuration Switch S2

Line Framing: D4 or ESF

Line Code: AMI or B8ZS

Mode

NET

DTE

NET

54016

AMI

B8ZS

AMI

DTE

B8ZS

A

B

NET

Mode

T1.403

ESF

D4

NET

DTE

54321 6 7

DTE

Spare

ESF

D4

PRM

Enable

Note: This switch

is provided only on

the 200 CSU

PRM

Spare

Disable

Line Impedance: balanced 100 Ω (± 5%)

Input Signal: DSX1 to 655 feet

Output Signal: Selectable DSX1 signal level from 0 to 655 feet

Line Protection: 1000 V lightning, input/output

TxPORT 210 CSU

PRODUCTIVIT Y SERIES 210

12

TRANSPORT

CSU

®

PWR DTE NET LOOP

5

LOOP NORM

Page 6

Mechanical

Mounting: desktop or wall

Dimensions: 1.75" H, 6.8" W, 10.5" D

Weight: 2 lbs.

Industry

FCC Compliance: Part 15 Subpart B, Class A

FCC Part 68 Reg: FXKUSA- 75742-DE-N

NRTL: UL 1459

CSA Certified: LR62298

DOC/CSO3: 1653 5663 A

TR54016: September 1989

TR62411

ANSI T1.403

Environmental

Operating Temp: 0° to 50° C (32° to 122°F)

Storage Temp: -20° to 85° C (-4° to 185°F )

Humidity: 95% max (non-condensing)

Standards

Network LBO: Positions S1 -1 and S1-2 set the network line build out signal level of

data transmitted towards the T1 facility. The output level is factory set at 0 dB

be attenuated by -7.5 dB, - 15 dB, or -22.5 dB if operating conditions require a change.

The telco should provide the proper setting to the user. If unsure of the exact setting,

then leave it at 0 dB.

DTE LBO: Positions S1-3, S1-4, and S1-5 set the DTE line build out transmit signal

value towards the customer equipment. The value should match the cable length from

the CSU DTE port to the attached equipment.

Loop Mode: Positi on S1-6 selects the op erating mode du ring an active payload loo pback. The unit can be optioned to ‘generate’ un framed all ones (Alarm Indicati on Signal) to the DTE during a remote loop or to ‘pass’ the received network signal to the

DTE on a remote loop.

- Generate AIS B - Pass network data

A

AMI /B8ZS: Position S1-7 is used only on the 210 CSU as follows: In the ‘Transparent’ mode, the unit is transparent to line code information. In the ‘Conversion’ mode,

AMI signals from the DTE are converted to B8ZS and B8ZS signals from the network

to the DTE are converted to AMI. This mode provides clear channel capability across

the network witho ut viola tin g ones density requirements.

- Transparent B - Conversion

A

. It may

1.2 FCC Requirements

!

WARNING: Changes or modifications to this unit not expressly

approved by the party responsible for compliance coul d void the user’s authority

to operate the equipment.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

1) This device may not cause harmful interference.

2) This device must accept any interference received, including interference that may

cause undesired operat ion.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection agains t harmful interference when the equipment is operated in a

commercial environment. This equipm ent generates, uses, and can radiate radio frequency energy and if not installed and us ed in accordance with the instructio n manual,

may cause harmful interfere nce to ra dio com munication s. Opera tion of this equ ipment

in a residential area is likely to cause harmful interference. The user will be required to

correct the interference at his own expense.

6 11

Density: Position S1-8 enables ones density insertion per AT&T 62411. The

‘Enabled

abled’ mode ignor e s density control and allows up to 175 zeros to pass towards the network before a loss of signal is declared.

’ mode allows insertion after 15 successive zeros from the DTE. The ‘Dis-

A

- Enabled B - Disabled

2.2.2 Configuration Switch S2

Switch S2 is located only on the 200 CSU. This switch provides the following configuration parameters:

Operating Mode: Position S2 -1 sets the operating mode of the unit. In the 54016

mode, the unit resp onds only to 54016 CS U messages. In the T1.403 mode, the unit

responds to ANSI loop/unloop commands and generates a PRM every second, but will

not respond to 54016 messages. The two modes are exclusive of each other.

- 54016 B - T1.403

A

Network Line Coding : Position S2- 2 sets the network line coding, including conversion.

A

- AMI B - B8ZS

Page 7

2.1 Supplied Materials

The TxPORT 200 and 210 CSUs are shipped from the factory with the 200/210 CSU

reference manual. The user may require ad diti onal ite ms for the in stalla tion and ope ra-

tion of the units. Refer to Section 1.4 for complete ordering information.

2.2 Unit Configuration

The following sections describe the configuration of the 200/ 210 CSU. These units

were designed to be operated from manual DIP switch control. Refer to the diagrams in

this chapter for switch locations. The 210 unit is transparent to framed (D4 or ESF) or

unframed T1 signals. It is also transpa rent to line codin g and may operate with either

AMI or B8ZS.

On power up, each unit is configured to the hardware settings of the option switches.

Subsequent changes to these settings will not take effect until the unit has been reset.

This may be acc omplished e ither by removing and then reapplying power or by pushing the test switch toward ‘LOOP’ and then quickly back to ‘NORM’. The unit will

then recycle through its LEDs and read the new configuration.

2.2.1 Configuration Switch S1

Switch S1 is located on the CSU rear panel. This switch provides the following configuration parameters:

position 7

Note:

is used only on

the 210 CSU

Line Code

Loop

Transparent

AIS

Ones Density

15 Zeros

-7.5

-15

-22.5

A

Configuration Switch S1

A

A

B

B B

A

Network

B

A

0

LBO

(dB)

Notice to Users of 1.544 Mb/s Service: The following instructions are provided to

ensure compliance with FCC Rules, Part 68:

1) All direct connections to T1 lines must be made using standard plugs and jacks.

2) Before connecting you r unit , you m ust i nform the lo cal te lepho ne com pany of th e

following information:

Port ID: P/N/12 - 00492

REN/SOC (Service Order Code): 6.0 N

FIC (Facility Interface Code):

04DU9-BN 04DU9-DN 04DU9-1ZN

04DU9-1KN 04DU9-1SN

USOC jack: RJ48C

3) If the unit appears to be malfun ctioning, it sh ould be disconne cted from the tel ephone lines until you learn whether the source of trouble is your equipment or the telephone line. If your equipment needs repair, it should not be reconnected until it is

repaired.

4) The unit has been designed to prevent harm to the T1 network. If the telephone

company finds that the equ ipment is exceeding tolerab le parameters, they can temporarily disconnect service. In this case, the tel ephone company will give you advance

notice, if possible.

5) Under FCC rules, no customer is authorized to repair this equipment. This restriction applies regardless of wh ether the equipment is in or out of warranty.

6) If the telephone company alters their equipment in a mann er that will affect the

use of this device, they must give you advance warning so th at you can have the opportunity for uninterrupted service. You will be advised of your right to file a complaint

with the FCC.

7) The attached affidavit must be completed by the installer.

8) In the event of equipment malfunction, all repairs should be performed by our

company or an authorized agent. It is the responsibility of users requiring service to

report the need for service to our company or to one of our authorized agents.

1.3 Warranty

B

DTE LBO

0 - 133 FT.

134 - 266 FT.

267 - 399 FT.

400 - 533 FT.

534 - 655 FT.

54321 6 8

7

of five years from the date the unit was shipped to the customer. If the unit malfunctions at any time during the warranty period, TxPORT will repair, or at TxPORT’s

TxPORT warrants each unit against defects in material and workmanship for a period

A

A

B

B

A

B

B

A

A

A

Loop

A

B

B

B

B

Network Data

DTE AMI to

NET B8ZS

175 Zeros

Ones Density

option, replace t he unit free of charge.

The remedies listed herein are the users sole and exclusive remedies. TxPORT shall not

be liable for any indirec t, direc t, incident al or conseq uentia l damages. Th e owner must

return the unit to the factory, shipping prepaid a nd packaged to the best commercial

10 7

Page 8

standard for electronic equipment. TxPORT will pay shipping charges for delivery on

return. The customer is responsible for mode and cost of shipment to TxPORT. This

warranty does not appl y i f the un it has b een da mage d by ac ciden t, m is use or as a re sult

of service or modification by other than Tx PORT personnel.

When returning the unit for warranty work, a Return Material Authorization (RMA)

number must be obtained from customer service (refer to the last page of this manual

for phone numbers). When calling TxPORT to obtain a Return Material Authorization

number or to arrange service, please hav e the following information available:

• Model number(s) and serial number(s) for the unit(s).

• Reason for return and symptoms of problem.

• Warranty status (if known).

• Purchase order number to cover charges for out-of-warranty items.

• Name and phone number of person we can co ntact if we have question s abou t the

unit(s).

• Mode of shipment required (second da y air is the no rmal mode of ship men t for al l

returned material unless otherwise specified).

As soon as TxPORT has the above information, the RMA that must accompany the item(s) returned can be issued.

NSTALLATION

I

2.0 Introduction

This chapter contains information and instructions required to prepare the TxPORT

200 and 210 CSUs for use. Included are initia l inspection procedures, configurati on

guidelines, connection instructions, and powering information.

The differences between the 200 and 210 CSU units (which are covered in this chapter)

are summarized below:

• DIP Switch S2 is found only on the 200 CSU.

• Position S1-7 (switch S1, posi tion 7) is a spare on the 200 CSU. On the 210 CSU,

position S1-7 is used to enable the ‘Transparent’ mode.

NOTE: Th roughout this manual, all factory default settings are shown underlined

(the ‘A’ position is the default setting for all switches).

TxPORT Model 200 Rear Panel

1.4 Ordering Numbers

Both the TxPORT 200 and 210 units are shipped from the factory with the 200/ 210

CSU reference manual. The user may require additional item s for the installation and

operation of each unit. Use the following numbers to order the basic unit or optional

equipment.

Part Number Description

F-200-001--111 200 ESF CSU unit

F-210-001--111 210 CSU unit

30 -00087 200 mA, wall mount power transformer, 115 VAC to -48 VDC

9 -2000-001 -1 Single unit horizontal rack mount hardware for 19" equipment rack

9-2000-001-2 Dual unit horizontal rack mount hardware for 19" equipment rack

9 -2000-002 -1 Single unit horizontal rack mount hardware for 23" equipment rack

9 -2000-002 -2 Single unit horizontal rack mount hardware for 23" equipment rack

8 9

-20to-56VDC

MAX CURRENT, 100 MA

PWR

PWR

(+) GND

(-) GND

-20to-56VDC

MAX CURRENT, 100 MA

PWR

PWR

(+) GND

(-) GND

A

B

S1 S2

76543218654321 7

TxPORT Model 210 R ea r Panel

A

B

S1

8654321 7

NET

NET

DTE

81

81

DTE

81

81

Page 9

®

TRANSPORT

Addendum

34-00196-A1.01

Subject: 200 ESF CSU Reference Manual, 1st Edition, March 1995

Date: March 4, 1996

Re: Test Jacks

This addendum provides additional information and/or corrections to the present manual.

The information will be incorporated into the next printing of this manual.

Test Jacks

TxPORT 200 Front Panel

TRANSPORT

T

O

D

T

E

®

PRODUCTIVITY SERIES

T

O

N

E

T

NETMONDTE

MODEL þ200 þESF / CSU

PWR DTE NET LOOPFAR

LOOP NORM

Test Access Jacks: These bantam jacks provide access to the T1 line on the DTE side as fol-

lows: the left 2 ports break connection to the unit and make connection to the DTE, the middle 2

ports are used for monitoring the signals passing through the unit (between the DTE and the network), and the right 2 ports break connection to the DTE and make connection to the unit in the

direction of the network.

Loading...

Loading...