Page 1

Introduction

2048

PMU/NTU

®

TRANSPORT

Reference Manual

34-00179

2nd Edition

Page 2

Table of Contents

Operation

Introduction .................................................................3-1

Front Panel Descriptions .............................................3-1

General

Introduction ................................................................. 1 -1

Design Highlights ....................................................... 1 - 2

Specifications .............................................................. 1-2

FCC /European Requirements .................................... 1 -3

Warranty ...................................................................... 1 - 3

Ordering Numbers ...................................................... 1 - 4

TxPORT Customer Service ....................................... 1 - 4

Installation

Introduction ................................................................. 2 -1

Safety Summary ......................................................... 2-1

Unpacking And Inspection ........................................ 2 - 1

Supplied Materials ...................................................... 2-1

Mounting ..................................................................... 2 -1

Stand - alone Unit ................................................. 2 - 1

Chassis Assembly ............................................... 2-2

Unit Configuration ..................................................... 2- 2

Switch SW1 (BERT Pattern) ............................... 2-2

Switch SW2 (National Bit) ................................. 2-2

Switch S1 (Network LBO) .................................. 2-2

Switch S2 (Chassis Operation) ........................... 2-3

Switch S4 (Configuration) ................................... 2-3

Switch S5 (Configuration) ................................... 2-3

Switch S6 (Bit Rate Selection) ............................. 2-4

Switch S7 (Address) ............................................ 2-4

Equipment Connection ................................................ 2-5

Network Connection ................................................... 2-5

Network Management ................................................ 2 -5

Supervisory Port ................................................... 2-5

PTT Port .............................................................. 2 - 6

User Port ............................................................. 2-7

Chassis Network Management ............................. 2-7

Alarm Connection ....................................................... 2-8

Stand - alone Unit ................................................. 2 - 8

Chassis Assembly ............................................... 2-8

Power Connection ...................................................... 2 -8

Stand - alone Unit ................................................. 2 - 8

Chassis Assembly ............................................... 2-8

General Status Indicators ................................... 3 - 1

Alarm Controls & Indicators ..............................3 -1

Test Controls & Indicators .................................3-2

Front Panel Testing .....................................................3-2

Test Switch ......................................................... 3-2

Test Access Jacks ..............................................3-2

Supervisory Port ................................................. 3-2

BERT Pattern Select ............................................3-2

Terminal Operation

Introduction ................................................................. 4 -1

System Description ..................................................... 4-1

Modem Compatibility .......................................... 4-1

Screen Components ............................................. 4-1

Interface Start Up ................................................. 4-2

Daisy-Chain Menu Operation ............................. 4-2

Cursor Controls .................................................... 4-2

Field Types .......................................................... 4-3

Main Menu Screen ...................................................... 4-3

Alarms Screen ............................................................. 4-4

Performance Screens ................................................... 4-5

Maintenance Screen .................................................... 4-7

Test Loops ........................................................... 4-8

BERT ................................................................... 4- 8

Line Fault and Loop Status .................................. 4-8

Configuration Screens ................................................. 4-9

Line Configuration .............................................. 4-9

Alarm Configuration ............................... ...... ...... . 4-10

Utilities Screen ............................................................ 4-10

General Functions ................................................ 4-11

COA Parameters .................................................. 4 - 11

Index

Configuration Guide

Page 3

Copyright / Liability

Copyright

© 1995 TxPOR T, All rights re served. No part of this pub licatio n may be repro duced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any form

by any means without the written permission of TxPORT.

Reorder # 34-00179

2nd Edition, July 1995

TxPORT shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material. TxPORT

reserves the right to revise this publication from time to time and make changes in content

without obligation to notify any person of such revision changes.

Contents of this pu blication m ay be prelimin ary and/or may be changed at an y time with out

notice and shall not be regarded as a warranty.

Documentation Disclaimer

TxPOR T makes no representation or war ranties of any kind whatsoe ver with respect to the

contents hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

Page 4

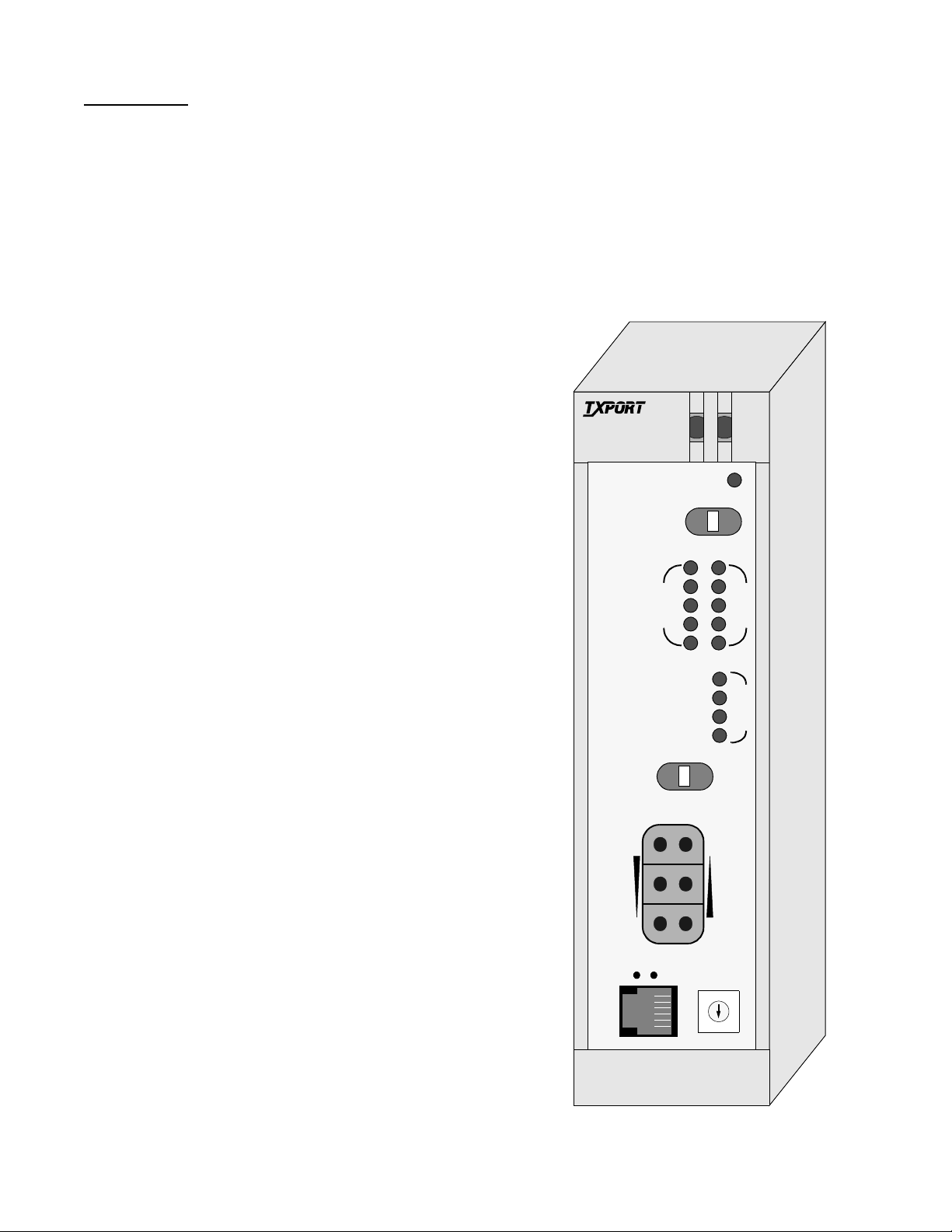

General

1.0 Introduction

The TxPORT International 2048 PMU /NTU (Performance

Monitoring Unit /Network Terminating Unit) is an advanced

network device capable of operating in framed or multi-

framed (G.704) modes, using AMI or HDB3 line coding.

The 2048 is designed for CEPT E1 (2.048 Mb/s) connection

to the PTT (the national Postal, Telephone, and Telegraph

authority) by the user. The unit provides end -to-end inband

protocol via a selectable national bit. This allows one PMU

to interrogate and control the remote far end PMU.

The 2048 is equipped with a dual set of performance data

registers that hold line statistics for both the PTT and the

user. Each register set provides detailed status and performance history for the network and equipment interfaces.

front panel test switch activates local/remote loops and controls the internal BERT generator and comparator.

The optional EM8000 Element Manager is available for

applications requiring multiple PMUs. The EM8000 provides access, control, testing, alarm reporting, and database

management functions.

TxPORT 2048 PMU/NTU

TRANSPORT

PMU/NTU

®

2048

ACO

The PTT performance data registers may be accessed, read,

and cleared by the PTT. User registers can only be accessed

by the user. Both registers contain identical core performance information, but the user registers also contain additional fields relating to unit configuration and status.

Performance data (per TR54016 and G.821/ X) is collected

in 15- minute increments for the preceding 24- hour period

and in 24 - hour increments for the preceding 30 -day period.

The unit enables downloading of remote site performance

data from the far end PMU, in all modes of operation, using

the facility data link (user selectable national bits).

The PMU provides access to the data registers through one

front and two rear management ports. These ports provide

test, diagnostics, and control over the CEPT E1 network.

Program upgrades may be downloaded into electrically erasable memory (EPROM) in the field via the supervisory port

on the front panel.

Access can also be obtained through a data link using an

assigned national bit. The national bit data link uses the

54016 U.S. FDL TABS protocol and message set. Additional request/response FDL messages have also been added

to enhance the PMU’s operation. The TxPORT EM8000

network manage r uses these messages to provid e complete

end-to-end control and performance monitoring.

The 2048 also provides features to aid in quick fault isolation. Front panel indicators display alarm and test conditions. Test jacks allow bridged monitoring of the passed

signal and signal insertion toward the PTT or the user. A

ACO SW

BV/CR /FE

LOS/LOF

AIS

REM ALM

LOC ALM

FAR

FRM

NET

MON

TO

DTE

S

U

P

V

N

E

T

LLB

PLB

TST

ERR

4

3

2

1

MON

FRM

SW1

5

0

LOC

TO

NET

DTE

6

9

7

8

D

T

E

T

S

T

General 1-12048 PMU/NTU

Page 5

1.1 Design Highlights

• End-to-end user control and access to

extensive unit performance data

unit configuration

unit status (normal, looped, alarm)

DTE Input Signal: 75 ¾ mark 2.37 V, space 0 ± 0.237 V

(per G.703) 120 ¾ mark 3 V, space 0 ± 0.3 V

attenuated by 0 to -6 dB at

1024 kHz (0 dB = 2.4 V)

Connection: 120 ¾ balanced or 75 ¾ unbalanced

• AMI or HDB3 coding

• User and PTT access via FDL link

• Dual performance registers - User and PTT/carrier

• Jitter control of network signal (per G.823)

• Complete diagnostic capabilities, including multiple

loopbacks and buil t-in BERT

• Front panel test jacks, alarm indicators, and test switch

1.2 Specifications

Network Interface

Line Rate: 2.048 Mb/s, ± 50 ppm, PCM-30

Multi-frame Type: CAS and/or CRC4, or none

Line Code: AMI or HDB3

Connection: 120 ¾ balanced or 75 ¾ unbalanced

Backplane: DB15, Twin-axial, and BNC options

Output Signal: 75 ¾ mark 2.37 V, space 0 ± 0.237 V

(per G.703) 120 ¾ mark 3 V, space 0 ± 0.3 V

Line Build Out: 0, -7.5, -1 5 dB switch settings

Input Signal: 75 ¾ mark 2.37 V, space 0 ± 0.237 V

(per G.703) 120 ¾ mark 3 V, space 0 ± 0.3 V

attenuated by 0 to -27 dB (ALBO)

Backplane: DB15, Twin- axial, and BNC options

AIS: Unframed or framed all ones, or

line loopback

Overvoltage: 1000 V minimum protection

Diagnostics

Line Loopback: Signal regeneration only

Payload Loopback: Signal regenerated with new frame

synchronization and CRC4

BERT: 63, 511, 2047, 2

BERT Activation: Front panel switch for test. User

Loopback Control: Inband loop up, 00001 for Ý 5 sec

PTT and EM8000 Full ESF performance monitoring

23

2

, QRW, and ALT

selection of BERT patterns via

command. Pattern sync and bit

errors reported via command.

Inband loop down, 001 for Ý 5 sec

User enable/disable

Manual loopback switch

FDL loopback command

through a terminal port (6-pin RJ11),

and via FDL in selected national bit

15

(default), 220,

Jitter Attenuation: per CCITT G.823

AIS: Unframed or framed all ones, or

(user selectable) line loopback

Overvoltage: 1000 V minimum protection

Equipment

Line Rate: 2.048 Mb/s, ± 50 ppm, PCM-30

Multi-frame Type: CAS and/or CRC4, or none

Line Code: AMI or HDB3

Output Signal: 75 ¾ mark 2.37 V, space 0 ± 0.237 V

(per G.703) 120 ¾ mark 3 V, space 0 ± 0.3 V

Pulse Width: 244 ns, nominal

1-2 General 2048 PMU/NTU

Interface

Access

Jack

Toward Network: Bantam jacks (In, Out, and Monitor)

Toward DTE: Bantam jacks (In, Out, and Monitor)

Access

User Net Manager: Asynchronous, RS232

Telco Net Manager: Asynchronous, RS232

Local Access: Asynchronous, RS232

Bit Rates: 1200, 2400, 9600 or 19200 b/s

(all ports) (switch selectable)

Formats: 8 data bits, 1 stop bit, no parity

Ports

Page 6

Protocol: TxPORT COMVIEW (pro prietary)

!

ASCII VT100

Connection: All ports, 4-pin modular

G.732 primary PCM multiplex @ 2.048

G.821 error performance criteria

G.823 co ntrol of jitter and wander

Alarms

Contacts: Normally Open or Normally Closed

(screw terminal connection)

Activation: Programmable

Reporting: Through TxPORT EM8000 manager

Cut Off: Manual, 2-position switch

Mechanical

Mounting: Wall, vertical, or horizontal rack

Width: 1.75"

Height: 6"

Depth: 11.75"

Weight: 1 pound

Power

Local Power: -48 VDC (± 10%)

75 mA maximum

(screw terminal connection)

G.832 framing requirements

TR54016 performance data

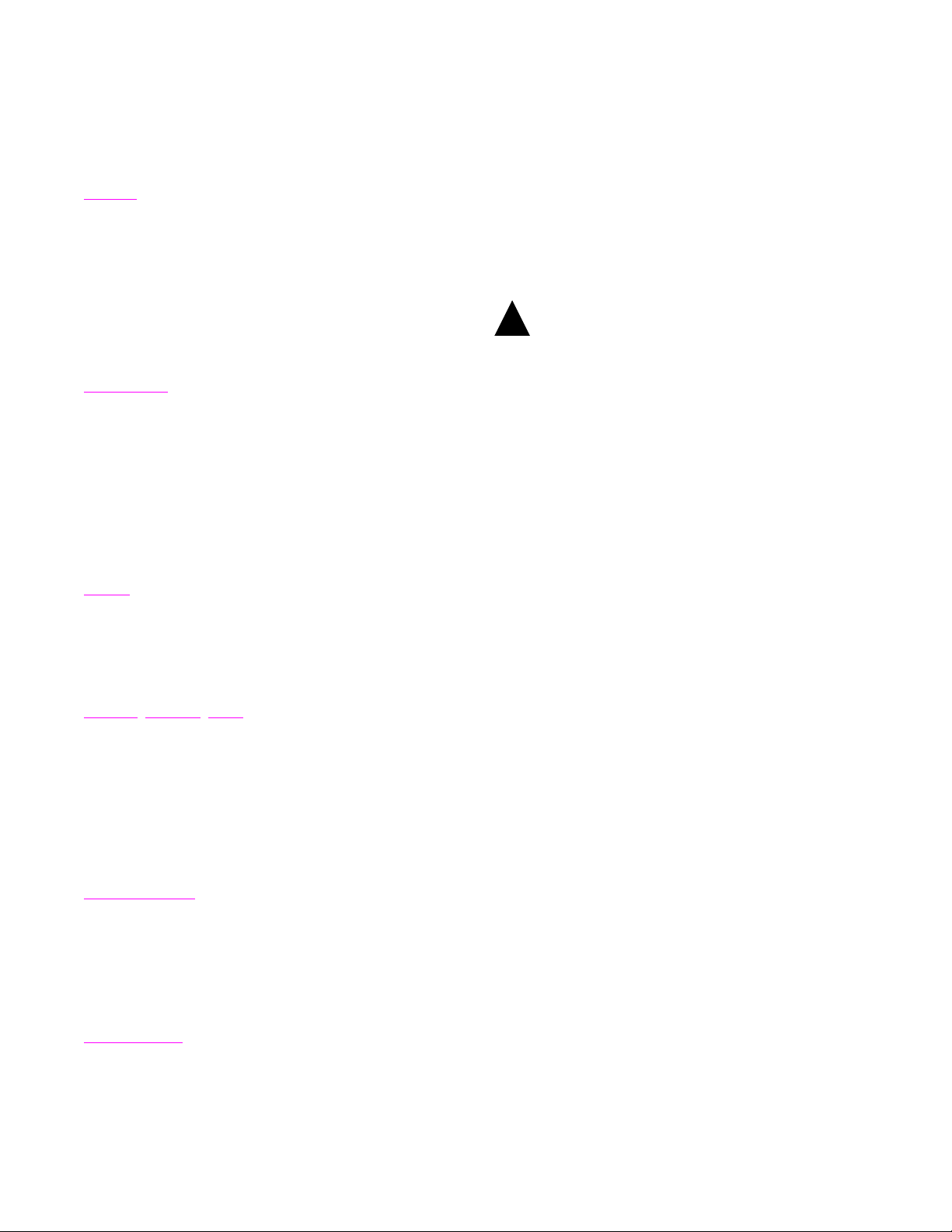

1.3 FCC/European Requirements

WARNING: Changes or modifications to this

unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the

equipment.

FCC and European homologation pending.

This equipment generates, uses, and can radiate radio fre-

quency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Shielded cables must be used with th is unit to ensure compliance.

Battery

The unit’s configuration and operating parameters are stored

in nonvolatile RAM memory. In case of a power outage and

if the DIP switches are set to boot from RAM, then the

unit’s memory is checked upon power- up conditions. If the

RAM has been compromised, the unit’s configuration will

revert to the options set with the remaining DIP switches.

Environmental

Operating Temp: 0° to 50° C (32° to 122°F)

Storage Temp: -20° to 85° C (-4° to 185°F)

Humidity: 95% max (non-condensing)

Compatibility

G.703 signal waveform

G.704 synchronous frame structures

Backed RAM

1.4 Warranty

TxPORT warrants each unit against defects in material and

workmanship for a period of five years from the date the

unit was shipped to the customer. If the unit malfunctions at

any time during the warranty period, TxPORT will repair, or

at TxPORT’s option, replace the unit free of charge.

The remedies listed herein are the user’s sole and exclusive

remedies. TxPORT shall not be liable for any indirect,

direct, incidental or consequential damages. The owner must

return the unit to the factory, shipping prepaid and packaged

to the best commercial standard for electronic equipment.

TxPORT will pay shipping charges for delivery on return.

The customer is responsible for mode and cost of shipment

to TxPORT. This warranty does not apply if the unit has

been damaged by accident, misuse or as a result of service

or modification by othe r than TxPORT personnel.

When returning the unit for warranty work, a Return Material Authorization (RMA) number must be obtained from

customer service at the address/phone number shown in

Section 1.6. When calling TxPORT to obtain a Return Mate-

General 1-32048 PMU/NTU

Page 7

rial Authorization number or to arrange service, please have

the following information available:

• Model number(s) and serial number(s) for the unit(s).

• Reason for return and symptoms of problem.

• Warranty status (if known).

• Purchase order number to cover charges for out-ofwarranty items.

• Name and phone number of person we can contact if

we have questions about the unit(s).

• Mode of shipment required (second day air is the normal mode of shipment for all returned material unless

otherwise specified).

As soon as TxPORT has the above information, the RMA

that must accompany the item(s) returned can be issued.

1.5 Ordering Numbers

The unit is shipped from the factory with the 2048 PMU/

NTU reference manual. Refer to Table 1 -1 for optional

equipment part numbers.

The part numbers for the stand- alone unit and the modular

chassis unit are shown in the following table:

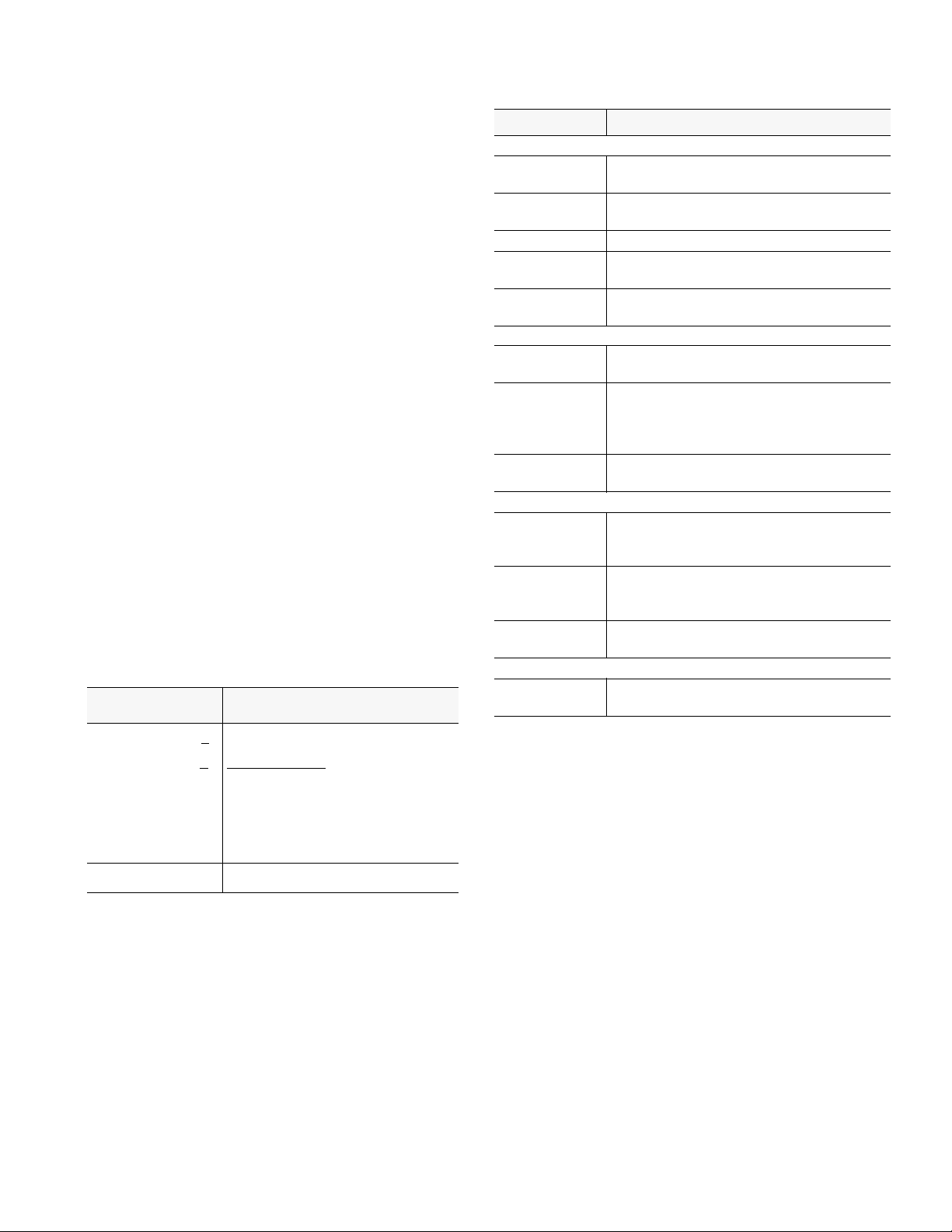

Part Number Description

Table 1-1 Optional Equipment

Part Number Description

Cables

9 - 1001 - 027- 1

9 - 1001 - 027- 2

9-1001-028-1

9-1001-028-2

9-1001-029-2 DB9 female to 6-pin RJ11 (terminal to SUPV)

9-1001-048-1

9-1001-048-2

33-00085

33-00086

F-1051-000--112 Twelve-slot 1051 chassis with RJ48C and DB25

9-2000-001--1

9-2000-001--2

9-2000-002--1

9-2000-002--2

9-2000-036--1 Stand-alone to rack mount conversion module

F-1040-000--110

9-1000-48V-1

F-1041-000--110

9-1000-48V-2

30-00087 Stand-alone wall mount power supply

9-8000-001-1

9-8000-001-2

DB25 male to 6-pin RJ11 (modem to SUPV)

DB25 female to 6-pin RJ11 (modem to SUPV)

DB25 male to 6-pin RJ11 (terminal to SUPV)

DB25 female to 6-pin RJ11 (terminal to SU PV )

DB25 male to two 6-pin RJ11 (terminal to NMS)

DB25 female to two 6-pin (terminal to NMS)

Bantam to bantam test cord - red

Bantam to bantam test cord - black

Mounting

backplane connectors

19" single unit rack mount bracket

19" dual rack mount bracket

23" single unit rack mount bracket

23" dual rack mount bracket

with DB25 to 6-pin adapter

Power

1040 power shelf (type 400 mechanics)

w/o power supplies

One -48V/2A power supply (1040 holds 2)

Redundant 1041 power shelf (type 400

mechanics) w/o power supplies

One -48V/2A power supply (1041 holds 2)

(- 4 8VDC/200mA)

Misc.

EM8000 with manua l on 3-1/2 inch disk (DOS

and UNIX version, respectively)

F-2048-100-11

C

2048 PMU/NTU stand-alone unit

C

=

Backplane option

1

with BNC connector

2

with Tri-axial connector

3

with Twin-axial connector

4

with DB15 connector

5

with BNC and DB15

1.6 TxPORT Customer Service

TxPORT

127 Jetplex Circle

Madison, Alabama 35758

T e l eph one Nu mber: 800-926-0085 or

F-2048-101-111

2048 PMU / NTU module (chassis)

205-772-3770

Sales /Administration FAX: 205-772-3388

Manufacturing FAX: 205 -772 - 8280

For example, the default part number for the stand-alone

Customer Service Returns: 800-926-0085, ext. 227

unit is ‘F – 2048– 100 – – 111’. This is a unit equipped

with BNC connectors on the backplane.

Product Technical Support (Normal Hours)

8 a.m. to 5 p.m. Central Time, Monday – Friday)

T e l eph one Nu mber: 800-285-2755 or

205-772-3770

Emergency (Nights / Weekends / Holidays)

The following accessories may also be needed for the installation and operation of the TxPORT 2048 PMU/NTU.

T e l eph one Nu mber: 800-285-2755

Internet Address: support@txport.com

1-4 General 2048 PMU/NTU

Page 8

Installation

2.0 Introduction

This section contains information and instructions required

to prepare the 2048 PMU for use. Included are initial

inspection procedures, mounting instructions, configuration

guidelines, connection instructions, and powering information.

NOTE: Throughout this manual, all factory default

settings will be underlined

.

2.3 Supplied Materials

The TxPORT 2048 PMU /NTU is shipped from the factory

with the following equipment:

• 2048 PMU with 19" mounting brackets attached

• 2048 PMU Reference Manual

The user may also require the following additional materials

for the installation and operation of the 2048 PMU.

• -48 VDC power source

• A wall transformer to provide 110 VAC to -48 VDC

local power

• Network and DTE interface cables

2.1 Safety Summary

This manual contains information and warnings which must

be followed by the user to ensure safe operation and to

retain the equipment in a safe condition.

!

The WARNING sign denotes a hazard to the

operator. It calls attention to a procedure or practice

which, if not correctly performed or adhered to, could

result in injury or loss of life. Do not proceed beyond a

WARNING sign until the indicated conditions are fully

understood and met.

NOTE: Follow the proper ESD (electrostatic device)

procedures while handling the circuit boards.

2.2 Unpacking and Inspection

This unit is carefully packaged to prevent damage in shipment. Upon r eceipt, ins pect th e shipping contai ner for damage. If the shipping container or cushioning material is

damaged, notify the carrier immediately and make a notation on the delivery receipt that the container was damaged

(if possible, obtain the signature and name of the person

making delivery). Retain the packaging material until the

contents of the shipment have been checked for completeness and the instrument has been checked both mechanically

and electrically.

If the contents of the shipment are incomplete or, if there is

mechanical damage or defect, notify TxPORT. If the shipping container is also damaged, or the cushioning material

shows signs of stress, notify the carrier of the damage as

well as TxPORT. Keep the shipping materials for carrier’s

inspection. TxPORT will arrange for repair or replacement

without waiting for claim settlement.

• 20-gauge stranded wire (or similar) for DC power

and alarm connection

For specific applications, the user may require additional

cables and adapters. The interface requirements of any

application may be met by using the appropriate cable. Standard cables an d ord ering n umber s are lis ted in Table 1 -1 on

page 1-4. Contact TxPORT for any needed assistance in

cable selection.

2.4 Mounting

The 2048 PMU is a modular unit that plugs in to eith er a single unit housing or into a chassis that holds up to 12 units.

Single units are designed for stand - alone desktop use, wall

mounting, or chassis mounting (in either a vertical or horizontal orientation). The unit uses an interchangeable front

panel to accommodate the chassis card cage.

The unit utilizes an interchangeable backplane to accommodate the nest mount card cage and, when used in the single

unit housing, to provide various connector types for differing application requirements. Backplane options for the

2048 include DB15, Twin-axial, and BNC connectors.

2.4.1 Stand-alone Unit

To access the circuit boards and configuration switches, perform the following steps: Open the front panel access door

and remove it by gently bending the plastic from th e middle

using both hands. Then pull the two side strips of plastic

from the middle outwards until the four stops are clear of

the front panel. Pull the cover off the front panel. Then

remove the 2 screws and pull the front panel and circuit

boards out of the housing. Observe proper electrostatic

device handling procedures while holding the circuit boards.

Installation 2-12048 PMU/NTU

Page 9

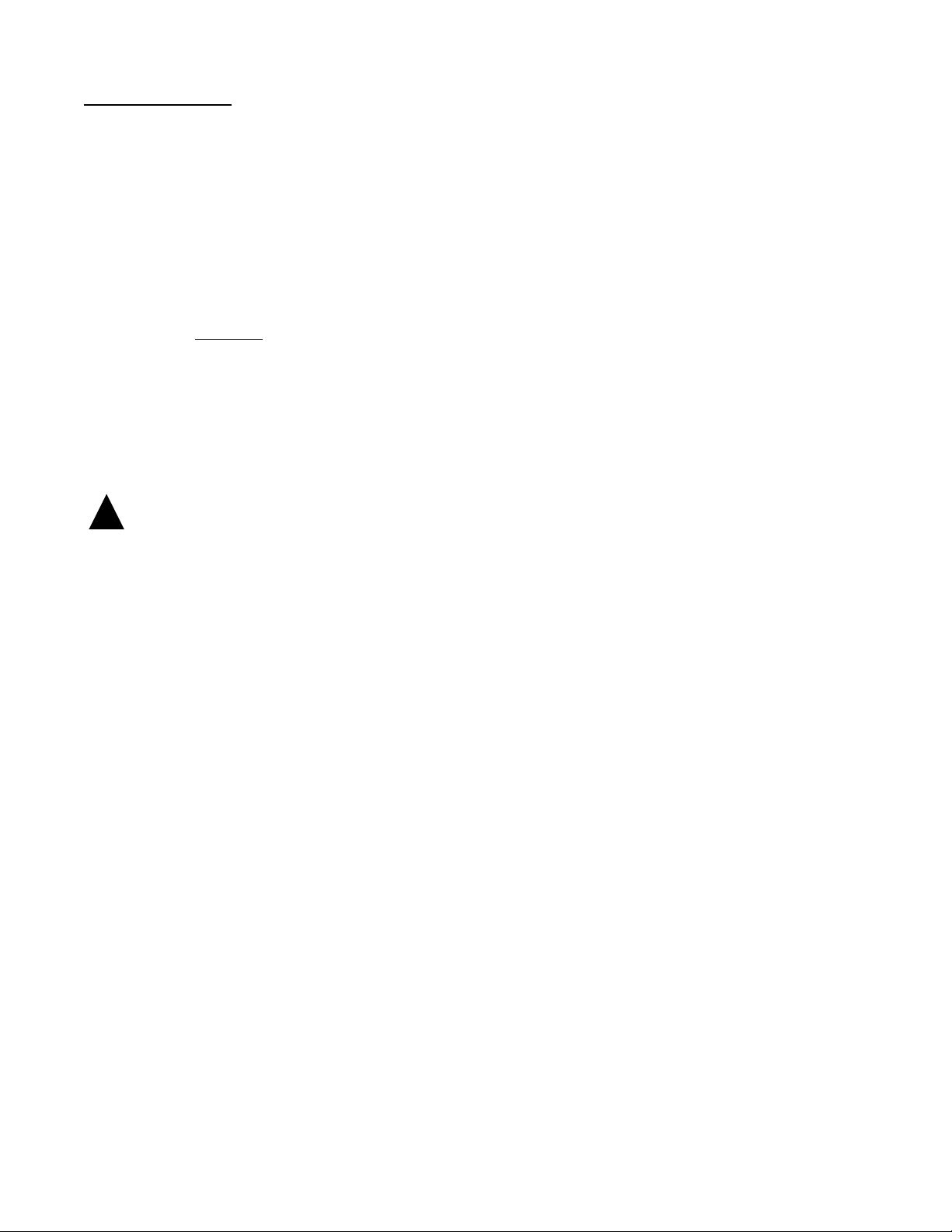

Figure 2-1 Circuit Board Views

0

1

9

2

8

3

7

6

4

5

2048

rear

Switch S1

-15 -7.5 0

The stand -alone unit may be used in a chassis installation

with the following modifications: Remove the housing as

described above and then remove the four screws holding

the front panel to the circuit boards. Replace the stand -alone

front panel with a module type front panel. The unit will

now slide into one of the 12 slots in the chassis.

2.4.2 Chassis Assembly

Up to 12 units may be inserted in to a chass is and the ch assis

may be installed in a 19" or 23" rack using four screws.

Connections are made from the rear of the chassis. Refer to

the figures on page 2-10 for these illustrations.

Switch S6Switch S5Switch S4Switch SW2

NORM RACK

Switch S7

1234567

Switch S2

8123456781234567812345678

2048

rear

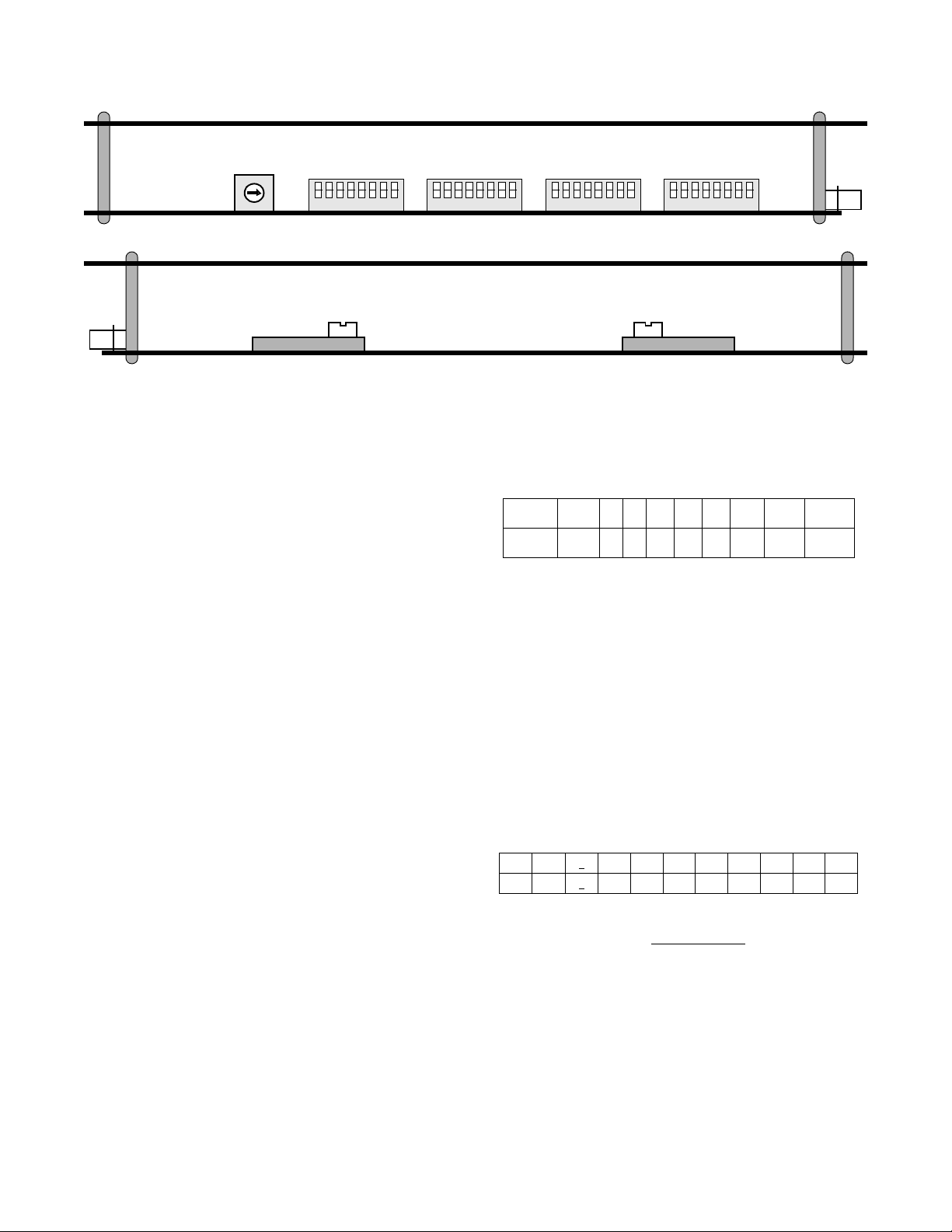

tern as determined by rotary switch SW1 (refer to the following table). This switch is located on the front panel

(shown on page 3-1).

Pos

Pattern

PROM Downloading Procedures:

0 12345 6 7 9

QRW 2

729215220223

1:8 3:24 PROM

Rotary switch SW1,

position 9 is used to download new PMU operating firmware into the flash memory. This operation requires a PC

and a diskette which contains TxPORT’s downloading program (

download.exe

) and the hex file to be downloaded.

Downloading procedures are described in the 2048 Download Procedures document sent with the software.

2.5 Unit Configuration

2.5.2 Switch SW2 (National Bit)

The 2048 PMU model is designed as a two card set. The

two cards roughly divide into analog and digital functions.

The unit provides an interface to the network in compliance

with established standards. It has been designed to operate

either manually or through the use of a console/terminal.

Therefore, the unit has both hardware and software configuration settings.

This following paragraphs explain the various hardware

configurations that may be adjusted for unique applications.

Software controlled settings are discussed i n the Operations

section of this manual.

2.5.1 Switch SW1 (BERT Pattern)

When the PMU is instructed to send a test pattern by the test

switch (FAR/LOC) on the front panel, it will send 5 seconds

of inband loop code (10000) and then transm it the test pat-

2-2 Installation 2048 PMU/NTU

Rotary switch SW2 is used to select th e National Bit. The

following table shows the switch positions. The factory

default is position 1.

Pos

NB

01

N/A 1

2345678 9

23454 4 4 4

Switch S6 has two positions affecting the optio ns fo r Switch

SW2. For position S6- 7, Down = ‘Pass’

and Up = ‘Select’.

For position S6 -8, select eith er ‘Down’ (0) or ‘Up’ (1) for

National Bit data (applies only if position S6-7 is set for

‘Select’). Switch S6 is cov ered in Sectio n 2.5.7 on pag e 2-4.

2.5.3 Switch S1 (Network LBO)

The output signal level of the transmit data (TXD) from the

2048 PMU to the network must be set by the LBO switch

Page 10

located on the bottom of the PC board (refer to the bottom

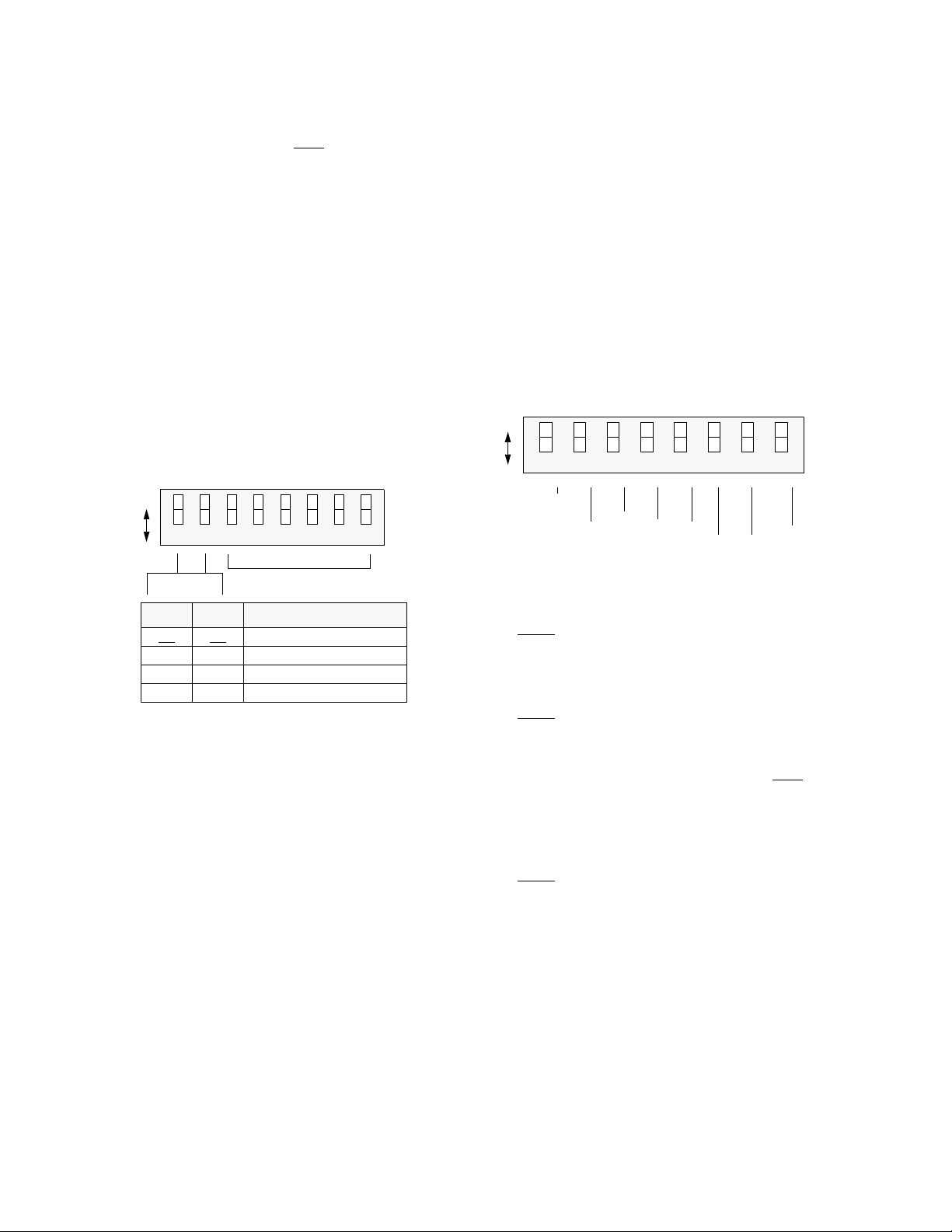

7654321 8

Dn Up

Ones Polarity

1

IBLC

Enable

Signal

CAS

Code

HDB3

CRC4

Enable

AIS / KA

AIS / KA

Insert CRC

Disable

Ones Polarity0IBLC

Disable

Signal

CCS

Code

AMI

CRC4

Disable

AIS / KA

AIS / KA

Insert CRC

Enable

Switch

S5

circuit board view in Figure 2-1).

The output level is factory set at 0 dB

. It may be attenuated

by -7.5 dB or by - 15 dB if operating conditions require that

it be changed. The PTT should provide the proper setting to

the user.

If unsure of the exact setting, then slide to 0 dB.

AIS: Unframed all ones

Keep Alive: AIS

BERT Ones polarity: 1 (normal)

National Bit Position: 4

National Bits: Pass

BERT Polarity: Normal

2.5.4 Switch S2 (Chassis Operation)

Switch S2 is used to swap the DTE transmit and receive pair

(Tx/Rx) for either normal stand-alone use or for rack mount

2.5.6 Switch S5 (Configuration)

DIP Switch S5 is used to set the following configuration

parameters on the 2048 unit.

use. It is located on the bottom of the PC board (refer to the

bottom circuit board view in Figure 2-1).

2.5.5 Switch S4 (Configuration)

During initial power up, four modes of configuring the 2048

are available using the first two positions of DIP Switch S4.

Switch

7654321 8

Dn Up

Spares

Pos 1 Pos 2 Power Up (Boot) Mode

Dn

Dn Up Boot from Manager

Up Dn Boot from RAM

Up Up Boot from ROM

Dn Boot from Switches

S4

One’s Polarity: Position S5-1 sets the bit error rate test

(BERT) data ones polarity to either a 1 or 0.

: ‘1’ Up: ‘0’ (Inverted)

Down

IBLC: P osition S5-2 enables inband 5-b it (10000) loop up

code and 3-bit (100) loop down code detection.

:Enabled Up:Disabled

Down

1) Boot from switch settings: Upon reset, the unit reads

its configuration from the hardware switch settings

described in this chapter.

Line Framing: Position S5- 3 is used to m atch th e PM U to

the framing format used. The options are CAS

(Channel

Associated Signalling) or CCS (Common Channel Signal-

2) Boot from manager: Upon reset, the unit requests configuration information from the EM8000 element manager.

If the manager is not on-line, the unit will boot from RAM.

3) Boot from RAM: Up on reset, the unit reads its configuration from the internal, battery-backed RAM.

4) Boot from ROM: Upon reset, the unit reads its configuration from the internal ROM. The ROM factory default settings are as follows:

ling). CAS is also referred to as PCM30, (or CAS Multiframe). CAS framing also includes an additional FAS sync

word in time slot 16, frame 0.

Down

: CAS Up: CCS

CCS is also referred to as PCM31 (or no Multiframe). It

contains alternating aligned frames and non-aligned frames.

If the PMU is configured for CCS, it will pass both CCS and

CAS framing data. In this case, the additional FAS sync

word in the CAS mode is passed as data and the PMU does

Signalling: CAS

Network CRC4: Enabled

DTE CRC4: Enabled

Line Code: HDB3

Inband Loop Code: Enabled

not try to sync on the additional sync word.

If CAS framing is used, then a more rigid sync and error

detection is used by the PMU. If CAS is selected, the PMU

expects CAS framing. If CCS framing is used, the PMU

declares an out of sync condition and transmits the Keep

Installation 2-32048 PMU/NTU

Page 11

Alive (KA) option. The PMU expects the framing format to

be the same on the equipment and network sides.

Network Line Code: Position S5 - 4 sets the network line

code for the E1 signal.

: HDB3 Up: AMI

Down

2.5.7 Switch S6 (Bit Rate Selection)

DIP Switch S6 is used to select the bit rates for the USER,

PTT, and the Supervisory ports. The national bit ‘Pass’ or

‘Select’ option is also included on this switch.

CRC4: Position S5 -5 enables

or disables the CRC4 fram-

ing mode. If enabled, the PMU will transmit the CEPT

CRC4 multiframe format and also expects to receive the

same format. The CRC4 checksum is the bases for obtaining

the performance monitoring data, so it important that this

position is enabled.

The PMU also expects to receive a CRC4 formatted input. If

the PMU is configured for CRC4 and a non -CRC4 format

signal is received, the PMU will indicate alarm conditions.

If the PMU is not configured for CRC4 and a CRC4 signal

is received, the PMU will ignore the CRC4 code. However,

the PMU will reframe the signal and the CRC4 code will not

be passed through the PMU.

The PMU always regenerates the CRC4 code, from the

equipment to the network. If both network and equipment

are configured the same, the PMU passes data from the network to the equipment with regeneration only. In this mode,

the BPV, FBE, and CRC errors are passed through the PMU.

Insert CRC: Positio n S5-8 enables or disables

the PMU to

insert CRC4 data on the network side of the PMU. If

enabled, the PMU will transmit and receive the CRC4 format on the network side only. Through the EM8000 network

manager, the PMU may be configured to enable/disable

CRC4 on either the network or equipment side.

Supervisory

Supervisory

USER NMS

USER NMS

PTT NMS

PTT NMS

Nat’l Bit

Nat’l Bit

Switch

Dn Up

SUPV

USER

NMS

PTT

NMS

Pos 1.2 kb/s 2.4 kb/s 9.6 kb/s 19.2 kb/s

1DnDnUp Up

2DnUpDn Up

3DnDnUp Up

4DnUpDn Up

5DnDnUp Up

6DnUpDn Up

7654321 8

Position S6-7: National bit, Dn = Pass

, Up = Select.

S6

Posit io n S6- 8: Select ‘Dn’ (0 ) or ‘Up’ (1 ) for Nati onal Bit

data (only if position S6-7 is set for ‘Select’).

2.5.8 Switch S7 (Address)

S5-5 S5-8 CRC4 Configuration NET

Dn CRC ON, Insert CRC OFF ON O N

Dn

Dn Up CRC ON, Insert CRC ON ON ON

Up Dn CRC OFF, Insert CRC OFF OFF OFF

Up Up CRC OFF, Insert CRC ON ON OFF

CRC

DTE

CRC

DIP switch S7 is used to provide up to 250 unique unit

addresses. TxPORT’s EM8000 element manager recognizes

addresses from 1 to 250.

LSB MSBBinary values

1

2

4

8

16

32

64

128

AIS / Keep Alive Selection: Positions S5- 6 and S5 -7 con -

figure the PMU for the following options:

S5-6 S5-7 AIS / Keep Alive

Dn Dn AIS is unframed all ones

Dn Up AIS is framed all ones

(only active toward network)

Up Dn Line Loop Back (LLB)

Up Up N / A

Dn Up

7654321 8

Switch S7 is an 8 - position switch with po sitions labeled 1

through 8. The #1 position represents the least significant

bit (LSB) and the # 8 position represents the most significant

bit (MSB) of the binary code. The eight switches are set to a

binary address code in the range of 1 to 250.

Switch

S7

2-4 Installation 2048 PMU/NTU

Page 12

2.6 Equipment Connection

2.8 Network Management

The equipment physical interface for both the stand- alone

unit and the chassis mounted unit is a standard RJ48C 8-pin

modular jack. A DB15 backplane is also an option for the

equipment interface. The pinout assignments are as follows:

Pin RJ48 Interface Pin DB15 Interface

1 Data Out 1 Data In

2 Data Out 2 Frame Ground

3/6 Not Used 3 D ata Out

4 Data In 4 Frame Ground

5 Data In 9 Data In

7/8 Chassis Ground 11 Data Out

NOTE: For 75 ¾ DB15 operation, the following pins

must be connected together: pins 2 & 9; pins 4 & 11.

For 120 ¾, leave as specified.

2.7 Network Connection

The network physical interface for both the stand -alone unit

and the chassis mounted unit is a standard RJ48C 8-pin

modular jack. A DB15 backplane is also an option for the

network interface. The pinout assignments are shown in the

following table.

Pin RJ48 Interface Pin DB15 Interface

1 Data In 1 Data Out

2 Data In 2 Not Used

3/6 Not Used 3 Data In

4 Data Out 4 Not Used

5 Dat a Out 9 Data Out

7/8 Chassis Ground 11 Data In

The 2048 PMU provides several means for user interface.

Using the configuration switch s ettings describ ed in Section

2.5, the PMU may be configured and operated without further interface. However, this mode does not allow access to

many of the capabilities of the unit.

For full software control and access to information, the

PMU has 3 ports which provide management functions

(SUPV, USER, and PTT ports). These ports may be used

for a VT100 terminal interface or for an EM8000 network

manager interface.

An element may be accessed by using an RS232 connection

from the serial port of the computer running the EM8000

program to the element’s SUPV, USER, or PTT ports.

These ports are described in the following paragraphs.

2.8.1 Supervisory Port

The front panel ‘SUPV’ port serves several functions. A

modem may be connected to this port for remote access or

use of the COA (call on alarm) feature. A computer connected to the SUPV port can access the embedded ‘terminal

interface’ firmware for PMU software control (refer to the

‘Terminal Operations’ chapter).

For cabling convenience, the EM8000 element manager

may be directly connected to the ‘SUPV’ port. When a

group of elements is connected in an NMS chain, the

EM8000 may be connected to the supervisory port of any

one of the elements. This element can then route messages

onto the NMS chain to reach the other elements. Refer to

Section 2.8.2 for more information on the EM8000.

The SUPV port is an independent serial interface into the

unit and connecting to it does not interrupt NMS port traffic.

Figure 2-2 2048 Rear Panel with DB15 Connector

NET

1

6

IN

1

OUT

8

EQPT

15

1

9

USER

IN

6

PTT

1

OUT

9

Power/Alarm

123456

8

15

Installation 2-52048 PMU/NTU

Page 13

Note that the unit’s call on alarm (COA) feature works

through the ‘SUPV’ port only.

The supervisory port bit rate must be set as described in

Section 2.5.5 on page 2- 3 (Switch S4-5 and S4- 6). The

physical connection is a 6- pin modular connector with the

following pinout assignments. This is a serial RS232 DCE

port configured for 8 bits, no parity, and 1 stop bit.

Pin SUPV Port Interf ace

1RTS

2 Signal Ground

3 Data Out

4 Data In

5 Signal Ground

6 Mod - CD/CTS

2.8.2 PTT Port

The 2048 PMU is fully compatible with the TxPORT

EM8000 element manager. The EM8000 software system is

used to manage small to large networks of TxPORT network

access products. The different connection methods are

described in the following paragraphs.

PTT IN/OUT: The two 6 - pin modular connectors labeled

‘PTT IN’ and ‘PTT OUT’ on the rear panel may be used

for connection to the EM8000 manager. This port is configured in this manner to allow the connection of multiple collocated units in a daisy chain IN/ OUT bus arrangement as

shown in the following figure.

The OUT port of one element is connected to the IN port of

the next element, and so on, to form a complete chain

among the group of elements.

EM8000

Element #1

Element #2

Last Element

PTT

PTT

PTT

OUT IN/OUTNMS

IN OUT

IN OUT

IN OUT

NOTE: All units on the sa me NMS chain must use the

same NMS bit rate whether in a chassis or stand-alone

housing.

PTT IN Only: The ‘PTT IN’ connector provides both the

transmit and receive signal pair. This port may be used for a

modem connection or as a VT100 terminal interface

(explained in the ‘Terminal Operation’ chapter).

NMS Split Cable: The EM8000 may be connected directly

into the NMS chain between two elements if connection to

the ‘SUPV’ port is not desirable. A ‘Y’ cable is used from

the EM8000 serial port which splits the transmit and receive

signals into two 6- pin modular connectors for the ‘USER’

or ‘PTT’ ports. Ordering information for this cable is found

in Table 1-1 on page 1-4.

The NMS address, port bit rate, and power up configuration

mode may be set by either the configuration switches or

through software control. The physical connection is a 6-pin

modular connector with the following pinout assignments.

Figure 2-3 2048 Rear Panel with BNC Connector

IN

NET

OUT

6

OUT

IN

1

OUT

IN

EQPT

USER

IN

6

1

OUT

Power/Alarm

123456

PTT

2-6 Installation 2048 PMU/NTU

Page 14

This port is a serial RS232 DCE port configured for 8 bits,

no parity, and 1 stop bit.

Pin PTT In PTT Out

1 Not Used Not Used

2 Signal Ground Signal Ground

3 Data Out Data Out

4 Data In Not Used

5 Signal Ground Signal Ground

6 Not Used Not Used

2.8.3 User Port

The USER port (labeled ‘USER – IN/ OUT’) is located on

the rear panel. The function of this port is identical to that of

the PTT port with the following exception. The USER port

does not allow the clearing of PTT data and the PTT port

does not allow clearing the USER data. This is explained

further in Section 4.4 on page 4-5. The physical connection

is a 6-pin modular connector with the following pinout

assignments.

Pin USER In USER Out

1 Not Used Not Used

2 Signal Ground Signal Ground

3 Data Out Data Out

4 Data In Not Used

5 Signal Ground Signal Ground

6 Not Used Not Used

2.8.4 Chassis Network Management

The operation of the EM8000 in the 12-slot chassis is similar to the stand-alone operation. Within the chassis, each

element is physically connected to the next element in a

daisy chain fashion. Signals from all modules are gathered

and presented on consolidated 6-pin modular connectors on

the rear panel, labeled ‘NMS IN’ and ‘NMS OUT’. The

front panel ‘SUPV’ port operates in the same fashion as in

the stand-alone unit.

When used in the chassis, the communications bus is automatically tied into each unit, allowing single point interfacing to the chassis. Cards may be inserted and removed from

Figure 2-4 75 ¾ Jumper Configuration

Front

J5

J6

J7

J8

J18

Equipment

J14

J15

J16

J12

J4

J13

Network

NO NC

Rear Rear

Front

J18

NO NC

Network

J5

J6

J7

J8

Equipment

J14

J15

J16

J12

J4

J13

Installation 2-72048 PMU/NTU

Page 15

the chassis without rewiring the communications bus. Com-

!

munications are restored by shorting contacts on the backplane when a slot is vacant.

NOTE: Ensure that Switch S2 is set to the ‘RACK’ position (refer to Section 2.5.4 on page 2-3).

2.9 Alarm Connection

The stand -alone unit and the chassis modular unit provide

rear panel alarm relay contacts. These dry (isolated) alarm

contacts permit connection to a remote indicating device.

2.9.1 Stand-alone Unit

The connection for the stand -alone unit is made on pins 5

and 6 of the Alarm/Power connector as shown in Table 2-1.

strip TB1 operate in a normally open mode. Refer to the

1051-2 Chassis Configuration Guide for more information.

NOTE: All modules in a common chassis must use the

normally open contact mode.

Make connections to the alarm contacts using 20-gauge

stranded wire (or similar). The contacts are rated at 120 mA

AC or 120 mA DC.

2.10 Power Connection

The stand-alone unit and the modular chassis unit require a

- 48 VDC power source that is capable of supplying 75 mA

current. Power supplies are available from TxPORT and are

listed in Table 1-1 on page 1-4.

Table 2-1 Alarm/Power Connection

Pin Function

1 48 VDC return

2 Signal Ground

3 -48 VDC

4 Frame Ground

5 Alarm Contact

6 Alarm Common

Pin 5 is configured to operate in either a normally open

(NO) or normally closed (NC) mode as determined by the

setting of the alarm relay jumper sh own below. Jumper J 18

is located on the circuit board.

NO

J18

ALM

‘NO’ and ‘NC’ refer to the contact’s relationship to the

common contact under a ‘no alarms’ condition. Move the

jumper to NC for normally closed operation (opens on

alarm) or to NO for normally open operation (closes on

alarm). Make connections to the contacts using 20-gauge

stranded wire (or similar). Contacts are rated at 0.3 Amp

AC or 1.0 Amp DC.

NC

Connect the ground lead before applying power

to the unit.

2.10.1 Stand-alone Unit

The power source is connected to pins 1 and 3 of the Power

and Alarm terminal as shown in Table 2-1.

Connect a chassis ground lead (18 - to 20- gauge is recommended) to the ‘Frame Ground’ terminal (pin 4). Connect

the other end of this lead to an appropriate facility grou nd.

Often, the 48 VDC return is also g round. In that case, both

return and ground leads should be connected to ground.

Connect the - 48 VDC lead to the ‘- 48 VDC’ terminal (18 to 20 -gauge recommended). Connect the return lead to the

‘48 VDC return’ terminal.

When power is applied to the unit, the front panel indicators

flash for approximately 10 seconds as the unit executes a

self-test function. If an ambiguous configuration has been

programmed, the front panel indicators will continue to

flash after the self - test is completed. If the unit is correctly

configured, the green ‘STATUS’ indicator on the front panel

should light.

2.10.2 Chassis Assembly

2.9.2 Chassis Assembly

Alarm conditions from all modules in the chassis are bused

together in parallel and are presented on a single set of

alarm relay contacts which permit connection to a remote

indicating device. When connected, Pins 3 and 4 on terminal

2-8 Installation 2048 PMU/NTU

When operating the 2048 in the 12-slot chassis , all units are

powered by -48 VDC sources which are connected to the 6-

position terminal strip TB2 on the rear of the chassis. The

chassis is designed with two power buses. The ‘A’ bus feeds

the odd slots (1, 3, 5, 7, 9, and 11). The ‘B’ bus feeds the

even slots (2, 4, 6, 8, 10, and 12).

Page 16

Figure 2-5 120 ¾ Jumper Configuration

Unit 1 Unit 2 Unit 3 Unit 4 Unit 5 Unit 6 Unit 7 Unit 8 Unit 9 Unit 10 Unit 11 Unit 12

T1

DTE

12

High

Speed

DTE

12

T1

NET

12

TB1 - 23451

81

14

25

81

Line Chassis Mounting Hardware

Rack and19" or 23" Multiple

Figure 2-6 Model 1051-2 Chassis, Front View

( B )

NMS

IN

16

T1

DTE

11

1

High

Speed

DTE

11

13

T1

NET

11

( B )

NMS

OUT

T1

DTE

10

High

Speed

DTE

10

T1

NET

10

Redundant

Power

Board

T1

DTE

9

High

Speed

DTE

9

T1

NET

9

TB2 - 23456

DTE

High

Speed

DTE

NET

1

( A )

NMS

IN

T1

8

8

T1

8

T1

DTE

7

High

Speed

DTE

7

T1

NET

7

1 - EXT CLK

2 - EXT CLK

3 - ALARM RING

T1

DTE

6

High

Speed

DTE

6

T1

NET

6

TB1

4 - ALARM TIP

5 - SIG GND

T1

DTE

5

High

Speed

DTE

5

T1

NET

5

T1

DTE

4

High

Speed

DTE

4

T1

NET

4

1 - +48 V RTN (B)

2 - FRAME GND

3 - -48V IN (B)

T1

DTE

3

High

Speed

DTE

3

T1

NET

3

TB2

4 - -48V IN (A)

5 - SIG GND

6 - +48 V RTN (A)

T1

DTE

2

High

Speed

DTE

2

T1

NET

2

( A )

NMS

OUT

T1

DTE

1

High

Speed

DTE

1

T1

NET

1

ENET

Installation 2-92048 PMU/NTU

Page 17

Figure 2-7 Model 1051-2 Chassis, Rear View

2-10 Installation 2048 PMU/NTU

Page 18

Connect a ground lead (18- to 20-gauge) to the terminal

marked ‘Frame Ground’ on TB2, pin 2. Connect the other

end of this lead to an appropriate facility ground.

The following three modes of powering the chassis are

available:

Redundant Power Source: The chassis is shipped with a

redundant power board installed on power connector TB2.

This board allows the connection of two independent - 48

VDC supplies operated in a redundant mode. All slots in the

chassis are powered from the combined input of the A and B

power supplies. If either supply fails, the other will power

the entire chassis.

To operate in the redundant power mode, connect the A bus

“-48 V IN (A)” and “+48 V RTN (A)” terminals on the

redundant power board to the corresponding terminals of

power supply A. Connect the B bus “-48 V IN (B)” and

“ + 48 V RTN (B)” terminals to the corresponding terminals

of power supply B.

Single Power Source: When using a single power source,

simply connect the A bus “-48 V IN (A)” and “ +48 V RTN

(A)” terminals on the redundant power board to the corresponding terminals of power supply A. This is essentially

the same as the redundant configuration w ith power supply

B not operational.

If not using the redundant power board, the A bus and the B

bus must be connected together on the rear of the chassis

with a jumper (pin 3 to pin 4 and pin 1 to pin 6).

Dual Power Source: When using a dual independent power

supply, one - 4 8 VDC source feeds the A bus while another -

48 VDC source feeds the B bus. First, remove the redundant

power board. Connect the A bus “48 V Return” and “- 48

VDC” terminals to the corresponding terminals of power

supply A (to power the odd numbered slots). Connect the B

bus “48 V Return” and “- 48 VDC” terminals to the corresponding terminals of power supply B (to power the even

numbered slots).

NOTE: Each PMU requires a 75 mA current. Ensure

that the proper fuse size is used. Refer to the 1040

Power Shelf configuration guide.

Installation 2-112048 PMU/NTU

Page 19

Operation

3.0 Introduction

This chapter contains the general operation instructions for

the TxPORT 2048 front panel. The unit is operated either

manually or through software control. Manual operation

consists of using the front panel (described in this chapter)

and the circuit board configuration switches (described in

the Installation chapter).

The Terminal Operation chapter covers the firmware controlled Terminal Interface program, which gives the user the

maximum amount of control. The unit may also be controlled using the TxPORT EM8000 element manager (refer

to the EM8000 reference manual).

1

3

4

5

6

7

8

9

2048 PM U/NTU Front Panel

TRANSPORT

PMU/NTU

®

2048

ACO SW

BV/CR/FE

LOS/LOF

AIS

REM ALM

LOC ALM

ACO

N

E

T

D

T

E

3.1 Front Panel Descriptions

The 2048 PMU uses LED indicators to convey major alarm

conditions and looping status. The front panel contains 19

LED indicators, 2 test switches, a set of bantam test jacks,

and a supervisory port connector. The following paragraphs

describe these controls and indicators and are referenced to

the illustration on this page.

3.1.1 General Status Indicators

STATUS:

1)

front panel bezel that are exposed whether the access door is

open or closed. These general status LEDs provide a quick

check of the unit’s operating condition (Go or No Go).

If neither LED is lit, the unit is not powered. If the green

LED is lit, the unit is powered and functioning no rmally. If

the red LED is lit, there is a line fault which exceeds alarm

thresholds or another type of unit failure. The problem can

be isolated by further examination of the other front panel

LEDs as described below.

Activity Indicators:

2)

are provided to indicate supervisory and network manager

port activity.

The unit has two LED indicators on the

These two small, recessed LEDs

10

11

12

13

14

15

16

17

LLB

PLB

TST

ERR

FAR

FRM

NET

MON

TO

DTE

2

S

U

P

V

1

6

LOC

TO

NET

MON

FRM

DTE

SW1

5

4

3

2

1

0

T

S

T

6

7

8

9

3.1.2 Alarm Controls and Indicators

ACO

3)

: This red LED lights whenever the ‘alarm cut

off’ switch is placed in the left ‘ON’ position. It indicates

that the alarm relay contacts are disabled.

ACO SW

4)

: The ‘alarm cut off’ switch controls the

alarm relay circuitry. If the switch is placed in the left ‘ON’

position, this circuitry is deactivated. The right ‘OFF’ position enables the contacts to report alarm conditions.

BV/CR / FE:

5)

This LED lights 1 second for each second with an occurrence of bipolar violations (BPV), cyclic

redundancy check (CRC) errors, or frame bit errors (FBE).

LOS/OOF:

6)

This red LED blinks with loss of signal

(LOS) from the network or DTE. It lights constantly when

an Out of Frame (OOF) condition is detected.

Operation 3-12048 PMU/NTU

Page 20

7) AIS: This red ‘alarm indication signal’ lights if the

Receive signal

from the DTE

Transmit signal

to the network

Transmit signal

to the DTE

Receive signal

from the network

Monitor signa l

from the network

Monitor signal

from the DTE

selected AIS condition is detected from the network or

equipment. Refer to Section 2.5.6 on page 2-3.

8) REM ALM: This LED lights constantly when a

remote (yellow) alarm signal is received.

9) LOC ALM: This LED lights when a local alarm

exceeding alarm thresholds exists.

Refer to Section 4.6.2 on page 4 -10 for more information

on alarm thresholds.

pattern, it lights continuously. The ‘ERR’ LED lights for 1

second when a bit error or sync loss is detected.

When the test switch is returned to the ‘normal’ cent er position, the unit sends 5 se conds of loop down code (100 ) and

then returns to its normal operating mode.

When the Test switch is in the ‘Local’ position, the unit performs a bidirectional loop as shown below. The ‘LLB’ and

‘Test’ LEDs should be lit.

3.1.3 Test Controls and Indicators

10) LLB: This red LED lights to indicate that t he unit is in

a line loopback condition.

11) PLB: This red LED lig hts to indicate that the unit is in

a payload loopback condition.

12) TST: This red LED lights constantly if the PMU has

been placed in a local or remote test loop. It blinks while a

loop or unloop code is being sent.

13) ERR: This red LED lights 1 second when BERT error

or sync loss is detected. It lights continuously to indicate

high bit error rates or loss of pattern sync. A loss of pattern

sync may be due to the far end not responding to the IBLC.

14) Test S witch : This switch (FAR / LOC) is used for local

testing. Refer to Section 3.2.1 for more information.

15) Test Access Jacks: These bantam jacks are provided

for access to the E1 line on the DTE side of the PMU. Refer

to Section 3.2.2.

16) Supervisory Port: The supervisory jack provides

direct terminal access to control the unit and gather status /

facility performance data. Refer to Section 3.2.3.

17) Pattern Select: This rotary switch determines the

BERT pattern sent by the unit when the test switch is in the

‘FAR’ or ‘LOC’ position. Refer to Section 3.2.4.

Equipment Network

PMU

3.2.2 Test Access Jacks

Six bantam test jacks are provided for access to the E1 line

on the DTE side of the PMU. Two are used for non-intrusive

bridge monitoring of the line in both directions (MON). Two

are used to drop the line (DTE) and two are used to insert

into the line in both directions (NET). Jacks are customarily

used to inject and receive E1 signals using an E1 test set.

3.2.3 Supervisory Port

This 6-pin modular RS232 supervisory jack provides direct

terminal access for controlling the unit and gath ering status

and performance data. A terminal may be connected to this

port for external software control. A modem may be connected for remote access.

3.2 Front Panel Testing

The previous section gave a brief description of each front

panel control and LED indicator. This section explains the

front panel test functions. Testing may also be performed

using software control from the EM8000 element manager

or the Terminal Interface program.

3.2.1 Test Switch

This switch (labeled ‘Far/Loc’) is used for local testing.

When in the ‘Far’ position, the unit sends 5 seconds of

IBLC (inband loop codes), then switches to t he test pattern

selected by rotary switch SW1 (Pattern Select). When transmitting IBLC, the test LED blinks. When transmittin g a test

3-2 Operation 2048 PMU/NTU

3.2.4 BERT Pattern Select

Rotary Switch SW1 determines the BERT pattern sent when

the Test switch is in the ‘Far’ position. The following table

shows the corresponding BERT test pattern sent when the

rotary switch is set to positions ‘0’ through ‘7’.

Pos

Pattern

0 12345 6 7 9

QRW 2

729215220223

1:8 3:24 PROM

Dnload

Firmware Upgrades: F ield software upgrades are accomplished using p ositi on 9 a nd t he ‘Sup ervis ory’ por t. Refe r to

Section 2.5.1 on page 2-2 for more information.

Page 21

Terminal Operation

serial RS232 ports. The modem should be optioned to

ignore DTR, enable auto answer, inhibit command echo,

and return verbal result codes.

4.0 Introduction

This chapter describes the screens and menus associated

with the TxPORT 2048 PMU Terminal Interface, which is a

firmware application program embedded inside the unit. The

interface allows control and monitoring of the unit through a

serial terminal, using any of the serial ports located on the

front and rear panels.

4.1 System Description

The Terminal Interface requires an ANSI compatible VT100

terminal (ASCII), or a computer running an ANSI terminal

emulation program. The Terminal Interface utilizes the

ASCII ‘Break’ and ‘Escape’ functions, which are implemented differently with various terminal emulation programs. The documentation supplied with the emulation

program should be consulted for further reference.

The unit has three serial interface RS232 ports. Any of these

ports may be used for the Terminal Interface or as a connection to the EM8000 network manager. Two of these ports are

pairs of daisy chain type rear panel connectors labeled ‘PTT

IN/OUT’, ‘PTT OUT’ and ‘USER IN/OUT’, ‘USER OUT’.

The other port is located on the front panel and is labeled

‘SUPV’. Serial bit rates of 1200, 2400, 9600, or 19200 may

be selected using option switches (refer to Section 2.5.7 on

page 2-4).

NOTE: If the user calls the 2048 PMU and sends the

‘

BREAK

’ command before receiving the ‘

message, the modem will hang up.

4.1.2 Screen Components

Terminal Interface screens have several components common to all screens and will be discussed in dividually in the

following paragraphs. These common screen elements are

shown on the ‘Password Screen’ (see Screen 4-1 below).

Device Type and Revision: The device type (2048 PMU)

and the revision control numbers are shown in the upper left

corner. The first number is the hardware revision and the

second number is the software revision. Information is displayed for the near end unit (connected directly to the terminal) on the top line, and for the far end unit (connected to

the network E1 interface) on the second line. Refer to this

information when contacting the factory w ith inquiries.

The far end information is available only for TxPORT products that support a proprietary message set. If the far end

does not support these messages but does support standard

54016 protocol, then the far end information is displayed as

‘GENERIC 54016 FAR END’. If the far end does not

respond to either proprietary or 54016 messages, then ‘NO

FAR END RESPONSE’ will be d isplayed. If the far end ech-

oes the FDL messages transmitted by the near en d un it, then

‘FAR END LINE LOOP’ is displayed.

CONNECT

’

4.1.1 Modem Compatibility

The 2048 PMU Terminal Interface supports the use of an

‘AT’ command set compatible modem on any of the unit’s

Screen 4-1 Password

2048 PMU x.xx/x.xx 2048 PMU Date MM/DD/YY

2048 PMU x.xx/x.xx (Unit Address: xxx) Time HH:MM:SS

------------------------------- PASSWORD SCREEN --------------------------------

Enter Password: (**********)

Start Date: MM/DD/YY

Start Time: HH:MM:SS

----------------------------------- Messages -----------------------------------

Date /Time: The top right corner of the terminal screen displays the current date and time. The setting of these functions is described in Section 4.7 on page 4-10.

Terminal Operation 4-12048 PMU/NTU

Page 22

Unit Address: Below the unit header (2048 PMU), the cur-

Unit #1

IN /OUT OUTPTT

IN/OUT OUTPTT

IN/OUT OUTPTT

Unit #2

Last Unit

Split

Cable

rent unit address is displayed along with any information

entered in the ‘Element ID’ field of the ‘Utilities’ screen.

must enter the correct password to obtain access to any other

menu.

Menu Title: The third line displays the general classification of functions currently accessible by the user (such as

‘Alarms’ or ‘Performance’).

Messages: This line may display the following messages:

NET ALARM: An error condition has exceeded the specified alarm threshold on the network interface.

DTE ALARM: An error condition has exceeded the specified alarm threshold on the DTE interface.

NET LOOP: A payload or line loopback is active on the

network interface.

DTE LOOP: A payload or line loopback is active on the

DTE interface.

TEST ACTIVE: BERT has been activated by the Terminal

Interface or the EM8000 system. While this is being displayed, alarm detection and reporting is inhibited.

FAR END ALARM: The far end has an alarm condition

(detectable only with TxPORT proprietary devices).

FAR END LOOP: A payload or line loopback is active at

the far end device.

4.1.4 Daisy-Chain Menu Operation

Multiple units may be connected to a single terminal by

using the PTT or USER daisy - chain bus. This terminal can

access the firmware embedded interface software within any

unit without having to move the connecting cables. The terminal must be connected to the first unit’s PTT interface in a

daisy chain fashion usin g a s pli t cable (refer to Table 1 -1 on

page 1-4 for ordering information).

Each unit must then be connected to the next unit’s PTT port

in a daisy chain fashion (as required for the EM8000 manager). The last unit is then connected to the other end of the

split cable. Refer to Figure 4-1.

Figure 4 -1 Daisy-Chain Arrangement

FAR END TEST ACTIVE: The far end device has a test

active (this is detectable only with TxPORT proprietary

devices).

4.1.3 Interface Start Up

Once a compatible terminal is properly connected to the

PMU, a Terminal Interface session is started by sending a

‘BREAK’ to the unit. If the PTT or USER port is used, the

unit then responds with the prompt “Enter Unit

Address”. To activate the first (or only) unit, simply press

<return>. To select a specific unit, enter the address number

of the desired unit and press <return>.

The “Enter Unit Address” prompt will time out after

10 seconds. If this happens, send another ‘BREAK’. To

select another unit, exit the current Terminal Interface, send

a ‘BREAK’, and repeat the process.

If an invalid address is entered, that address is echoed back

to the terminal. Send a ‘BREAK’ to start a new session.

The ‘Main Menu’ screen (Screen 4-2) is displayed if no

password has been specified in the ‘Utilities’ menu. Refer to

Section 4.7 on page 4-10 for information on setting the

password. In the ‘Password’ screen (Screen 4- 1) the user

The firmware revision number of all units in the NMS daisy

chain must be as follows:

2000 CSU Revision 2.09 or later

2048 PMU Revision 2.29 or later

4.1.5 Cursor Controls

The Terminal Interface utilizes a highlighted cursor to make

selections from menus and to select fields within screens.

The cursor can be moved using the standard keyboard arrow

keys (left, right, up, and down). Once a field is highlighted,

it is manipulated as described in Section 4.1.6.

For keyboards which do not have these standard keys or

have only some of them, an alternate set of cursor control

commands is provided. Each of these is performed by press-

4-2 Terminal Operation 2048 PMU/NTU

Page 23

ing a letter key while holding down the <Ctrl> key. Alternate commands may be freely mixed with the keyboard

commands at the user’s discretion. The alternate command

keys are listed in the following table.

Keyboard Command Alternate Command

< left arrow > < Ctrl - S >

< right arrow > < Ctrl - D >

< up arrow > < Ctrl - E >

< down arrow > < Ctrl - X >

< backspace > < Ctrl - H >

< delete > < Ctrl - Z >

4.1.6 Field Types

Each screen is made up of fields. The two basic types are

‘user selectable’ and ‘display only’. If the highlighted cursor

can be moved to a field, it is a ‘user selectable’ field. All

other fields are ‘display only’. User selectable fields allow

for changes to be made or commands to be executed.

1) Pressing <return> on such fields as (Reset) and

(Start Test) simply execute the function.

2) The most common type of field in parenthesis accepts

typed input in the form of letters and /or numbers. Typing

characters when the field is highlighted causes the current

entry to be replaced with the new characters. To edit an

existing entry rather than replace it, press the <right arrow>

key to move the cursor to the point that needs editing. Characters may then be inserted or deleted. Typed data is always

inserted rather than typed over. If the field is full, though, at

least one character must be deleted to add another.

Many fields of this type may also be toggled by pressing the

<spacebar>. Other fields are range checked, where the user

is not allowed to exit with an illegal value set.

NOTE: Any changes to fields on a screen that have not

been activated by pressing <return> will be discarded.

NOTE: Any screen may be redisplayed (or refreshed)

by pressing <Ctrl - U>.

Fields without brackets or parenthesis are ‘display only’

fields. They cannot be changed on the screen. Most ‘user

selectable’ fields are enclosed in brackets or parenthesis and

are described in the following paragraphs. Any exceptions

are noted in the appropriate section of this manual.

Fields enclosed in brackets [ ] offer the user a list of selections from which to choose. The selections may be toggled

by pressing the spacebar. Each time the spacebar is pressed,

a new item appears. When the appropriate choice is displayed, press <return> to select it.

Fields enclosed in parenthesis ( ) are manipulated by one

of the following two methods:

Screen 4-2 Main Menu

2048 PMU x.xx/x.xx 2048 PMU Date MM/DD/YY

2048 PMU x.xx/x.xx (Unit Address: xxx) Time HH:MM:SS

------------------------------------- MAIN -------------------------------------

Alarms

Performance

Maintenance

Configuration

Utilities

4.2 Main Menu Screen

The ‘Main Menu’ screen (refer to Screen 4 -2) lists the functional menus accessible by the user. To activate any menu,

highlight the desired selection and press <return>. This

menu and any subsequent menu may be exited by pressing

<esc>. If the ‘Main Menu’ is exited, the Terminal Interface

program terminates. This is a valid way to end a user session. If any other menu is exited, the user is returned to the

previous screen.

NOTE: If the keyboard is inactive for a 10-minute

period, the Terminal Interface logs off automatically. To

manually log off, press <esc> from the ‘Main Menu’.

----------------------------------- Messages -----------------------------------

Terminal Operation 4-32048 PMU/NTU

Page 24

The menu structure (Figure 4-2) shows all the screens

accessible from the ‘Main Menu’.

Figure 4-2 Menu Structure

Alarms

Log

On

Standard 24-Hour

Enhanced 24-Hour

Performance

Standard 30-Day

MAIN

MENU

Maintenance

Configuration

Enhanced 30-Day

Line Parameters

Log

Off

Utilities

Alarm Parameters

NET / DTE Alarms: These status lines display t he selected

element’s current network /DTE signal alarm state. Alarms

are determined by the following user selectable thresholds.

Table 4-1 Alarm Indications

Alarm Description

------- No status is available

None No alarm threshold has been exceeded, although

errors may exist which do not exceed thresholds.

ERRS Errored Seconds, Severely Errored Seconds, or

Bipolar Errored Seconds threshold is exceeded.

LOSS Loss Of Signal Seconds threshold is exceeded.

OOFS Out Of Frame Second s th reshold is exceeded.

RAIS Remote Alarm Seconds threshold is exceed ed.

AISS Alarm Indication Seco nds threshold is exceeded.

UAS Unavailable Seconds threshold is exceeded.

(alarm status): The main body of the ‘Alarms’ screen displays the current count for parameters that may be used to

trigger an alarm.

4.3 Alarms Screen

The ‘Alarms’ screen (Screen 4 -3) is used to view the current

alarm status of the network and DTE lines. The fields are

described as follows:

Element: Pressing the <spacebar> toggles this field for

selection of either the ‘NEAR’ or ‘FAR’ unit. ‘NEAR’ refers

to the unit to which t he terminal is connected. ‘FAR’ refers

to the unit at the other end of the network E1 span.

Screen 4-3 Alarms

2048 PMU x.xx/x.xx 2048 PMU Date MM/DD/YY

2048 PMU x.xx/x.xx (Unit Address: xxx) Time HH:MM:SS

------------------------------------ ALARMS -----------------------------------Element: [NEAR]

NET Alarms: NONE

DTE Alarms: NONE

Loss Of Signal Seconds (LOSS): 0 5

Errored Seconds (ES): 2 45

Severely Errored Seconds (SES): 2 5

Unavailable Seconds (UAS): 0 0

Out Of Frame Seconds (OOFS): 0 0

Remote Alarm Seconds (RAS): 0 0

AIS Seconds (AISS): 0 0

BPV Seconds (BPVS): 0 0

DTE LOS/OOF Seconds (LOSS): 0 5

Power Loss Seconds (PLS): 0

Reset Alarm Registers: (RESET)

The ‘Current’ column shows the total of the preceding 15

one -minute intervals. At the end of each one -minute interval, the o ldes t mi nute of the 15-minute interval is discarded.

The ‘Threshold’ column shows the values set in the

‘Alarm Configuration’ screen (Screen 4-7 on page 4-10).

Any parameter that has a current value equal to or greater

than its non-zero threshold will generate an alarm. Any

parameter with a threshold value of ‘0’ is disabled from

generating alarms.

Current Threshold

4-4 Terminal Operation 2048 PMU/NTU

Page 25

NOTE: The parameters shown on the Alarms Screen

are updated at five second in tervals.

the USER or SUPV port. Both registers contain identical

core performance information.

Power Loss Seconds: This field displays the number of

seconds that the PMU has been without power since this

value was last cleared.

Reset Alarm Registers: Pressing <return> on (RESET)

zeros the value of all ‘Current’ alarm parameters, but

does not affect 24-hour or 30-day performance registers.

4.4 Performance Screens

The ‘Performance’ screens display a detailed history of the

error parameters that are continuously monitored. The Terminal Interface provides display of near end or far end performance data using the facility data link.

The PMU is equipped with a dual set of performance data

registers with individual resets that hold line statistics for

both the PTT and user. Each register set provides detailed

status and performance history for the network and DTE

interfaces. Access to the data registers is provided through

one front and two rear management ports, which provide

test, diagnostics, and control over the CEPT E1 network.

Access can also be obtained through a data link using an

assigned spare national bit.

Both register sets may be viewed from any serial port. The

PTT performance data registers can be cleared only through

the PTT port. USER registers can only be cleared through

The unit enables downloading of remote site performance

data from the far end unit, in all modes of operation, using

the facility data link (user selectable national bits).

The system has four ‘Performance’ screens. The ‘STANDARD 24 HOUR’ and the ‘ENHANCED 24 HOUR’ screens

allow the user to view the 24-hour detailed performance history of the E1 circuit. The only difference in the two screens

is in the type of performance data displayed. The ‘STANDARD 24 HOUR’ screen is shown in Screen 4-4.

The ‘STANDARD 30 DAY’ and the ‘ENHANCED 30 DAY’

screens allow the user to view a 30-day history of a particular element’s performance. These screens reference intervals

by date rather than by time. To reach each of the four screen

types, use the <spacebar> to toggle the ‘STANDARD 24

HOUR’ field. The other fields are described as follows:

Element: Pressing the <spacebar> toggles this field for

selection of either the ‘NEAR’ or ‘FAR’ unit as the source of

performance data or the target of commands. ‘NEAR’ refers

to the unit to which t he terminal is connected. ‘FAR’ refers

to the unit at the other end of the network E1 span.

Target: This two-part field determines whi ch sect ion o f the

circuit is presently displayed. Pressing the <spacebar> toggles the following options:

[USER] [NET] – Display the Near or Far PMU user performance registers for the network.

Screen 4-4 Performance

2048 PMU x.xx/x.xx 2048 PMU Date MM/DD/YY

2048 PMU x.xx/x.xx (Unit Address: xxx) Time HH:MM:SS

--------------------------------- PERFORMANCE ----------------------------------

Element: [NEAR] Status: OK

Target: [USER][NET] Completed Days: 30

Error Events: 65535 (RESET) Completed Intervals: 96

(RESET PERFORMANCE REGS) 24 Hr.% Error Free: 98.2

[STANDARD 24 HOUR]

411 0 0 0 2 3 3

24 Hour 10 0 0 2 3 0

30 Day 30 10 20 12 2 13

PAGE-UP-------------------------------------------------------------------

PAGE-DN-------------------------------------------------------------------

Time Interval ES UAS BES SES LOFC CSS

13:45 6 1 0 0 0 1 0

13:30 7 2 0 0 0 2 0

13:15 8 4 0 0 0 2 0

Terminal Operation 4-52048 PMU/NTU

Page 26

[USER] [DTE] – Display the Near or Far PMU user per-

formance registers for the DTE.