Page 1

TRANSPORT

®

2010 ESF CSU

Configuration Guide

Part Number 45-00055

Rev 1.01

(chassis version)

®

TRANSPORT

2010

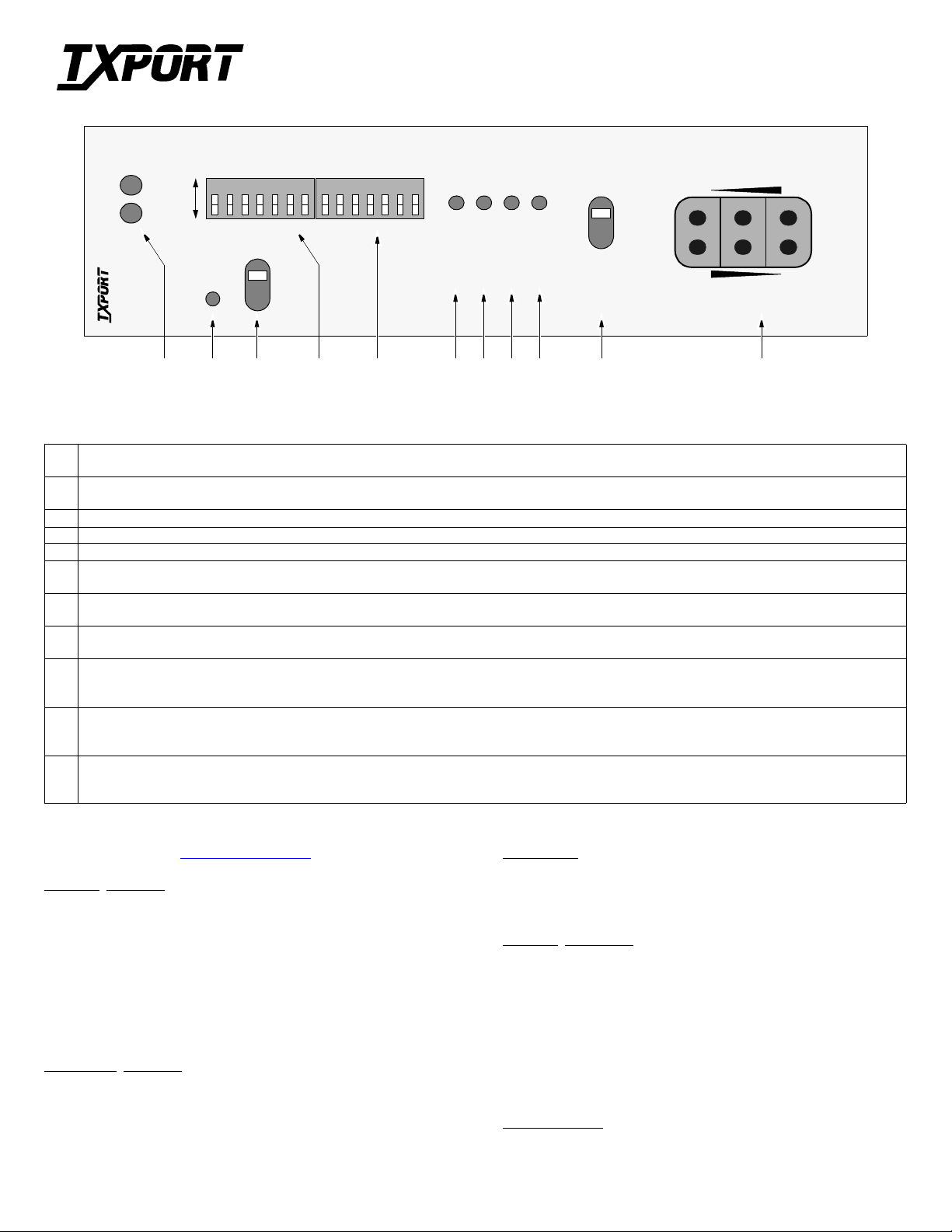

STATUS

ESF CSU

1

7654321

AB

ACO

S1

ACO SW

32 4 7 8 9

7654321

S2

NRM

LOOP

FAR ERR

NET ERR

5

6 10

DTE ERR

LOOP

TO

NET

NET

FRM

DTE

FRM

MON

TO

MON

DTE

11

Front Panel Description

1 Status: This green LED light s wh en t he unit is powered and operating norm a ll y. The red LED lights if the alarm card circuitry detec ts an alarm condition from the

FAR, NET, or DTE indicators or if an alarm threshold ha s bee n exceeded (if equipped with optional alarm card).

2 ACO: Th is red LED (only on units equipped with the optional alarm car d) lights if the ‘alarm cut off’ switch is pl aced in the left ‘ON’ position. This indicates that

the alarm relay cont acts are disabled.

3 ACO SW: The alarm cut off switch controls the alarm relay circuitry. It is disabled in the left ‘ON’ position. The right ‘OFF’ position enables alarm reporting.

4 Switch S1: This 7-position DIP configuration switch is de scribed on the reverse side.

5 Switch S2: This 7-position DIP configuration switc h is de scribed on the reverse side.

6 Net Error: This LED lights a minimum of 0.1 second if the internal alarm circuitry detects any of the following conditions from the inc oming T1 signal – one or

more bipolar violations (BPV), frame bit errors (FBE), cyclic re dundancy check errors (CRC), or a loss of signal/out of frame (LOS/OOF) condition.

7 Far Error: Thi s LE D li ghts a minimum of 0.1 second if the internal alarm circuit ry de tects a yellow alarm signal from the far end terminal equipment. This

condition occurs i f the far end terminal is out of sync with the T1 signal from the network.

8 DTE Error: This LED lights a mini mum of 0.1 second if the inte rnal alarm circuitry detect s any one of the following conditions from t he DTE – one or more

bipolar violations (BPV), fram e bit errors (FBE), cyclic redundancy check erro rs (CRC), yellow alarm, low one’s density, or a loss of signal/out of frame condition.

9 Loop: This LED lights under the following conditions – the manual loop switch is in the ‘LOOP’ position, the unit receives an inband loop code for more than 5

seconds, or the unit receives an FDL loop message (PLB or LLB). The LED does not light if the te st swit ch is placed in the ‘NRM’ position or if an inband or FDL

unloop code is received.

10 Test Switch: This switch is used for loca l testing. In the local loop mo de (LOOP), the unit loops the signal from the customer equipment (DTE in) back to the

customer equipment (DTE out). It also loops the received signal fr om the T1 fac il it y (NE T IN) ba ck to the T1 facility (NET OUT). W hen moved back to ‘NRM’,

the local loopbac k is re moved.

11 Test Jacks: These bantam jacks provide access to the T1 line on the DTE side as follows – the top 2 jacks break connect ion to the DTE and make connection to the

unit in the directio n of the network, the middle 2 por ts are used for monitoring the signals passing through the unit (bet ween the DTE and the network), and the

bottom 2 ports break connection to the unit and m ake connection to the DTE.

SPECIFICATIONS

Network

Line Rate: 1.544 Mb/s (±50 bps)

Line Framing/Coding: D4 or ESF / AMI or B8ZS

Line Impedance: balanced 100 Ω (±5%)

Input Signal: DS1, +1 to -30 dB (ALBO)

Output Signal: 3.0 V (±15%) base-peak into 100 ¾

Line Protection: 1000 V lightning, fused input/outp ut

Jitter Control: per TR62411 and T1.403

Pulse Density: per TR62411

Interface

Equipment Interface

Line Rate: 1.544 Mb/s (±50 bps)

Line Framing/Coding: D4 or ESF / AMI or B8ZS

Line Impedance: balanced 100 Ω (±5%)

Input Signal: DSX1 to -6 dB

Output Signal: Selectable DSX1 level from 0 to 655 feet

Line Protection: 1000 V lightning

Mechanical

Mounting: 19" rack (23" available)

Dimensions: 19" W, 7" H, 10.5" D

Weight: 9.5 lbs.

Industry Standards

FCC Compliance: Part 15, Subpart B, Class A

FCC Part 68 Reg: FXKUSA- 75690-DE-N

NRTL UL 1459

CSA Certified: LR62298

DOC /CSO 3: 165 3 5649 A

TR54016 September 1989

TR62411

ANSI T1.403

Environmental

Operating Temp: 0° to 50° C (32° to 122°F)

Storage Temp: -20° to 85° C (-4° to 185°F)

Humidity: 95% max (non-condensing)

Page 2

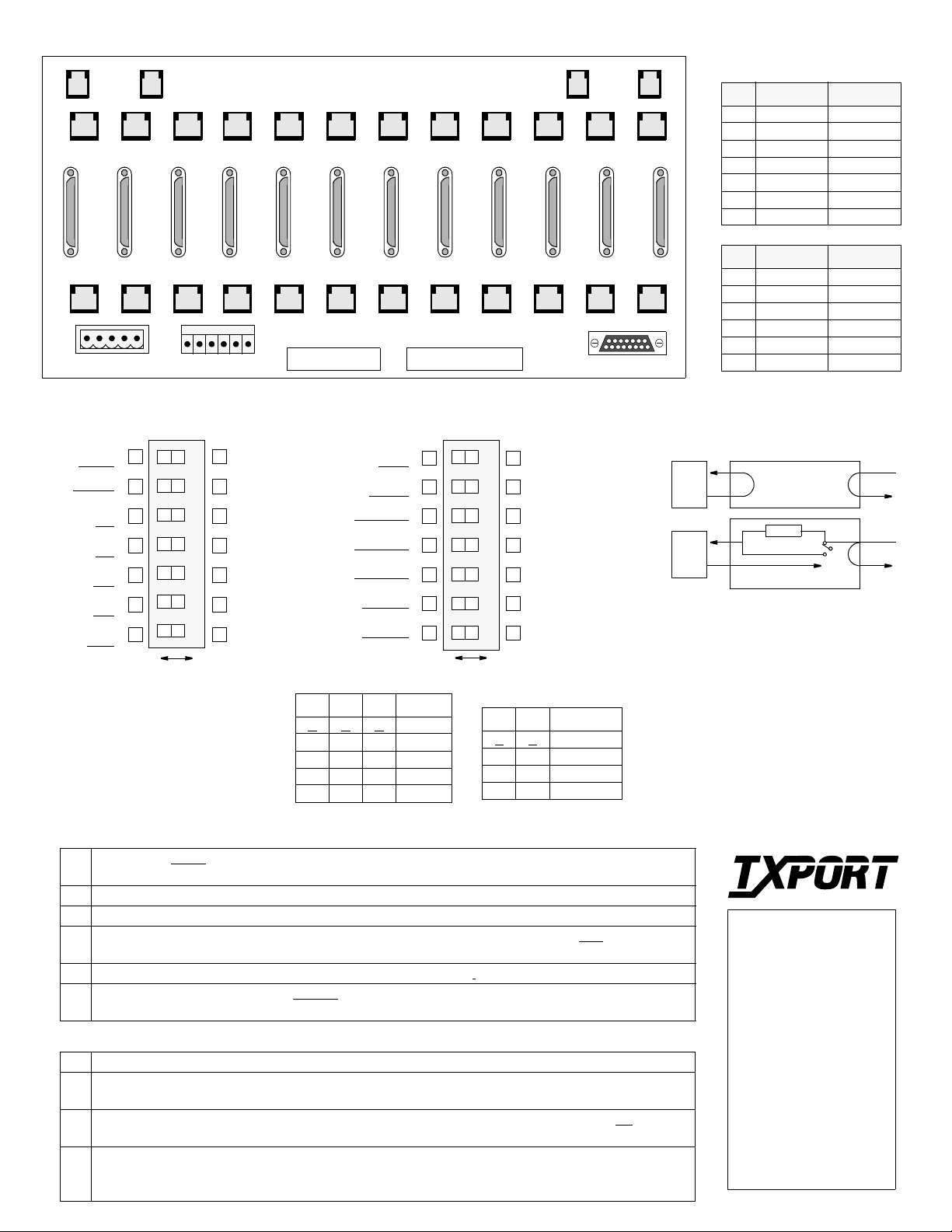

TxPORT 1051-2 Chassis Rear View

( B )

NMS

IN

12

11 10 9 8 7 6 5 4 3 2 1

TB1 TB2

( B )

NMS

OUT

T1 DTE

High Speed DTE

T1 NET

TB1 TB2

( A )

NMS

IN

( A )

NMS

OUT

ENET

123456789101112

123456789101112

Chassis Connections

Pin T1 DTE T1 NET

1 Data Out Data In

2 Data Out Data In

3 Not used Not used

4 Data In Data Out

5 Data In Data Out

6 Not used Not used

7, 8 Signal Gnd Signal Gnd

Pin NMS In NMS Out

1 Not Used Not Used

2 Signal Gnd Signal Gnd

3 Data Out Data Out

4 Data In Not Used

5 Signal Gnd Signal Gnd

6 Not Used Not Used

Switch S1 (front panel)

Density

Enabled

Not Used

DTE framing

ESF

NET framing

ESF

DTE code

AMI

NET code

AMI

Op Mode

54016

7654321

BA

NOTE: The ‘A’ position is the factory default for all switch settings.

If a particular user configuration

requires that a switch be plac ed in

the ‘B’ direction, then mark this

sheet for future re ference.

Density

Disabled

Not Used

DTE framing

D4

NET framing

D4

DTE code

B8ZS

NET code

B8ZS

Op Mode

T1.403

DTE ALBO

S2-3 S2-4 S2-5 Distance

A

A A 0 -133

B B B 134 -266

A B B 267-399

B A B 400- 533

A A B 534-655

Switch S2 (front panel)

PRM

Enable

AIS AIS

Generate

DTE ALBO

DTE ALBO

DTE ALBO

NET LBO

NET LBO

PRM

7654321

Disable

Pass Data

DTE ALBO

DTE ALBO

DTE ALBO

NET LBO

NET LBO

BA

Network LBO

S2 -1 S2 -2 Attenuation

A

A 0 dB

A B -7.5 dB

B A -15.0 dB

B B -22.5 dB

Switch S1

ESF Mode:

1

54016 - the unit responds only to 54016 CSU messages . T1.403 mode - th e unit respond s to

ANSI loop/unloop commands and generates a PRM every second, but will not respond to 54016 messages.

Network Line Coding:

2

DTE Line Coding:

3

Network Line Framing:

4

Sets the NET line coding (including conversion).

Sets DTE line coding (including conversion)

Sets the CSU to the framing of the network line. In the ESF

mode, the unit

responds to all T1.403 or 54016 messages.

DTE Line Framing:

5

7

Density

(zero suppression mode): Enabled allows ones density control after 15 successive zeros from the

Sets the CSU to the framing of the DTE line.

DTE (per TR62411). Disabled ignores density control and allows 175 zeros to pass towards the network.

Switch S2

Network LBO:

1-2

DTE ALBO:

3-5

Sets the network signal l e v el of da ta tran smitted towards the T1 facility. Refer to the ta ble.

Sets the DTE line build out transmit value towards the customer equipment. The value

should match the cable length from the CSU DTE port to the attached equipment. Refer to the table above.

AIS Enable:

6

Enables sending a n a la rm ind i cati on si gnal du ri ng an a ct ive payload loo pba ck. A

AIS to DTE during remote loop; B - Pass received network signal to DTE.

PRM Enable :

7

Enables sending a PRM during an AIS. If the unit detects loss of sync from the DTE, an

unframed all ones signal is generated to the T1 facility. If Switch S2- 6 is set to generate AIS and Switch

S1-1 is set for T1.403 operation, the unit interrupts the AIS signal with a PRM once a second.

Loopbacks

DTE

Local Loopback

AIS

DTE

Remote Loopback

The 2010 can be looped remotely by generating

towards it a standard CSU line loopba ck code

(00001 repeating for Š 5 seconds, framed or unframed). Once looped, t he rec eived signal from

the T1 facility (NET IN) is regenerated and

transmitted ba ck to the T 1 faci lity ( NET OUT).

The 2010 can be unlooped remotely by generating towards it a standard CSU line unloop code

(001 repeating for Š 5 seconds, framed o r unframed). The 2010 respon ds to FDL loop and

unloop command messages.

TRANSPORT

TxPORT Custo mer Service

127 Jetplex Circle

Madison, Alab ama 35758

Customer Service Returns:

800-926-0085, ext. 227

Product Technical Supp or t

(8 a.m. to 5 p.m. Central)

800-285-2755 or

205-772-3770, ext. 255

- generate

Emergency After Hours:

800-285-2755

Manager: 205-603- 2194

NET

NET

®

Loading...

Loading...