Page 1

Introduction

2010

ESF

CSU

®

TRANSPORT

Reference Manual

34-00204

1st Edition, Rev 1.02

Page 2

Table of Contents

General

Introduction ................................................................. 1- 1

Specifications .............................................................. 1-1

FCC Requirements ...................................................... 1 - 2

Canadian Emissions Requirements ............................. 1-3

Warranty ...................................................................... 1 - 3

TxPORT Customer Service ......................................... 1-3

Ordering Numbers ....................................................... 1-4

Installation

Introduction ................................................................. 2- 1

Safety Summary ............................... ........................... 2-1

Unpacking and Inspection ........................................... 2-1

Supplied Material ........................................................ 2-1

Operation

Introduction ................................................................. 3 -1

Front Panel Descriptions ........................................... 3 -1

General Status Indicators ..................................... 3-1

Alarm Controls and Indicators ............................ 3-1

Test Controls and Indicators ................................ 3-2

Front Panel Testing ..................................................... 3-2

Test Switch .......................................................... 3-2

Test Access Jacks ................................................ 3-2

Terminal Operation .................................................... 3- 2

Mounting ..................................................................... 2-1

Unit Configuration ..................................................... 2-1

Configuration Switch S1 ...................................... 2-2

Configuration Switch S2 ...................................... 2-2

Configuration Switch S3 ...................................... 2-3

Alarm/ACO Card (Option) .................................. 2-3

DTE Connection ......................................................... 2 - 4

Network Connection ................................................... 2-4

Alarm Connection ....................................................... 2-4

Power Connection ....................................................... 2-4

Page 3

Copyright/liability

Copyright

© 1995 TxPOR T, All rights reserved. No part of this pub licatio n may be reproduced , transmitted, transcribed, stored in a retrieval system, or translated into any language in any form

by any means without the written permission of TxPORT.

Reorder # 34-00204

1st Edition, February 1995

TxPORT shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material. TxPORT

reserves the right to revise this publication from time to time and make changes in content

without obligation to notify any person of such revision changes.

Contents of this pu blication m ay be prelimin ary and/or may be changed at an y time with out

notice and shall not be regarded as a warranty.

Documentation Disclaimer

TxPOR T makes no representation or war ranties of any kind whatsoe ver with respect to the

contents hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

Page 4

General

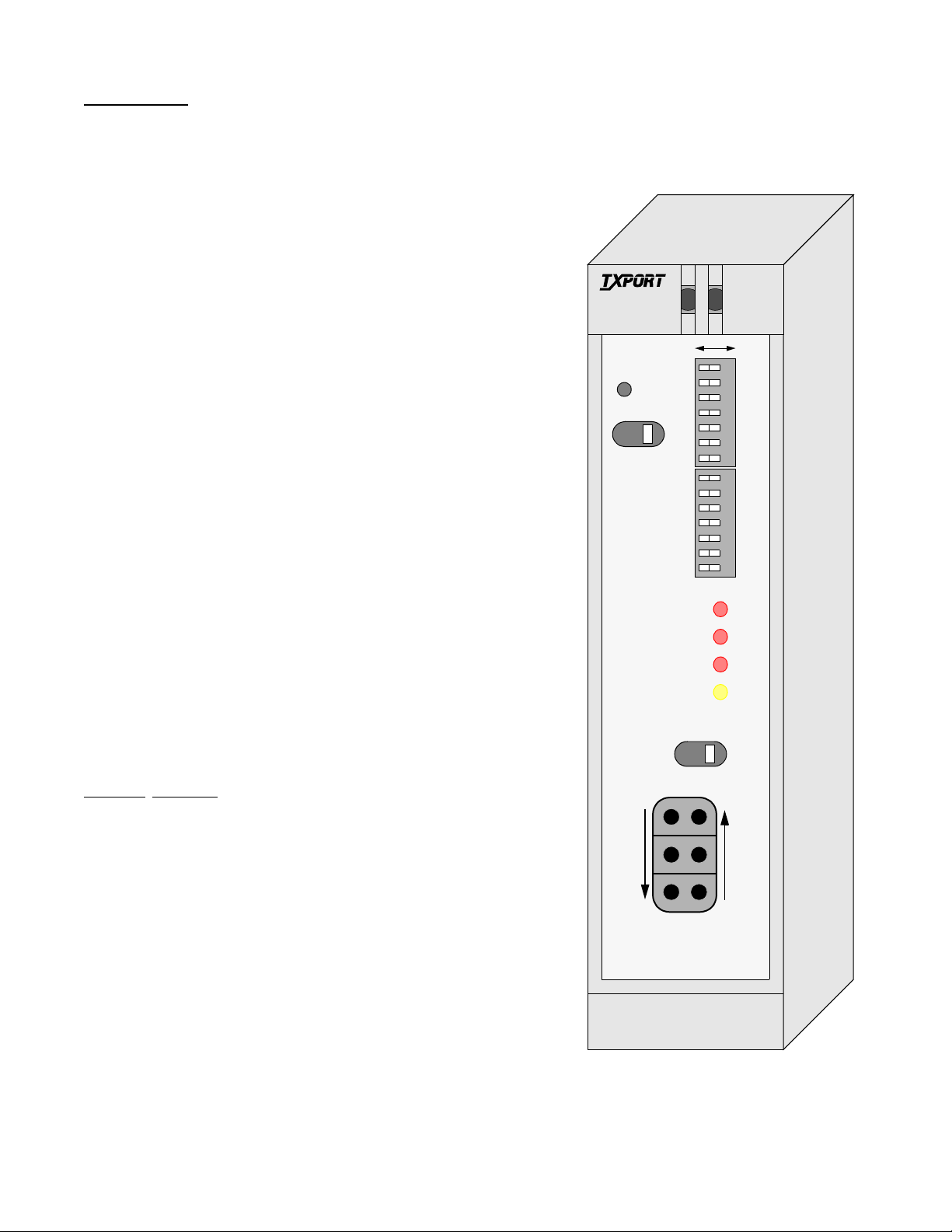

1.0 Introduction

The TxPORT 2010 ESF CSU provides an economical solution for interfacing a metallic T1 facility to customer provided T1 equipment. The 2010 supports ANSI T1.403 or

AT&T 54016 ESF CSU requirements.

The 2010 may be ordered as a stand -alone unit or as a modular card for mounting in a chassis. When the 2010 is paired

with a TxPORT 2000 CSU at the far end, the 2010 can be

managed over the TxPORT EM8000 element manager network.

For applications requiring the use of alarm contacts, the unit

may be ordered with an ACO and alarm card. The 2010 has

primary and secondary surge protection on both the network

and DTE side (meeting UL 1459 requirements).

The unit provides ALBO circuitry on the network path and

DSX circuitry on the DTE receive paths. The network

ALBO supports a receive range of +1 dB to -30 dB. The

DTE supports DSX1 signal ranges up to 655 feet.

The unit also provides LBO circuitry on both network and

DTE. The network transmit LBO is user selectable (0, -7.5,

-15, and -22.5 dB). The DTE transmit LBO is user selectable in four incremental ranges from 0 to 655 feet.

TxPORT 2010 CSU

®

TRANSPORT

2010

ESF CSU

AB

7654321

ACO

S1

ACO SW

7654321

S2

NET ERROR

FAR ERROR

DTE ERROR

LOOP

1.1 Specifications

Network Interface

Line Rate: 1.544 Mb/s (±50 bps)

Line Framing: D4 or ESF

Line Code: AMI or B8ZS

Line Impedance: balanced 100 Ω (±5%)

Input Signal: DS1, +1 to -30 dB (ALBO)

Output Signal: 3.0 V (±15%) base-peak into 100 ¾

Line Build Ou t: 0, -7.5, -15, a nd -22.5 dB attenuation

Line Protection: 1000 V lightning, fused input/output

Jitter Control: per TR62411 and T1.403

Pulse Density: per TR62411

FRM

NET

MON

TO

DTE

LOOP

NRM

TO

NET

MON

FRM

DTE

General 1-12010 CSU

Page 5

Equipment Interface

!

Line Rate: 1.544 Mb/s (±50 bps)

1.2 FCC Requirements

Line Framing: D4 or ESF

Line Code: AMI or B8ZS

Line Impedance: balanced 100 Ω (±5%)

Input Signal: DSX1 to -6 dB

Output Signal: Selectable DSX1 level from 0 to 655

feet in 4 incremental levels

Line Protection: 1000 V lightning, fused input/output

Mechanical

Stand-alone Unit:

Mounting: desktop, wall, horizontal rack, or

vertical rack

Dimensions: 1.72" W, 6.8" H, 10.5" D

Weight: 2 lbs.

12-slot Chassi s

Mounting: 19" rack (23" available)

Dimensions: 19" W, 7" H, 10.5" D

Weight: 9.5 lbs.

Environmental

Operating Temp: 0° to 50° C (32° to 122°F)

Storage Temp: -20° to 85° C (-4° to 185°F)

Humidity: 95% max (non-condensing)

:

WARNING: Changes or modifications to

this unit not expressly approved by the party

responsible for compliance could void the user’s

authority to operate the equipment.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditi ons:

1) This device may not cause harmful interference.

2) This device must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and

if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference. The user will be

required to correct the interference at his own expense.

Shielded cables must be used with th is unit to ensure compliance with the Class A FCC limits.

Notice to Users of 1.544 Mb/s Service: The following

instructions are provided to ensure compliance with FCC

Rules, Part 68:

1) All di rect connections to T1 lines must be made using

standard plugs and jacks.

Compatibility

TR54016 September 1989

TR62411

ANSI T1.403

Industry

FCC Compliance: Part 15, Subpart B, Class A

FCC Part 68 Reg: FXKUSA- 75690-DE-N

UL Approved

CSA Certified: LR 62298

DOC/CSO3: 1653 5649 A

1-2 General 2010 CSU

Standards

2) Before connecting yo ur unit, you must inform the local

telephone company of the following information:

Port ID: P/N/12 - 00635

REN/SOC: 6.0 N

FIC (Facility Interface Code):

04DU9-BN 04DU9-DN

04DU9-1KN 04DU9-1SN

04DU9-1ZN

USOC jack: RJ48C (stand-alone version)

RJ48H (chassis version)

3) If the unit appears to be malfunctioning, it should be

disconnected from the telephone lines until you learn

whether the source of trouble is your equipment or the tele-

Page 6

phone line. If your equipment needs repair, it should not be

reconnected until it is repaired.

4) The unit has been designed to prevent harm to the T1

network. If the telephone company finds that the equipment

is exceeding tolerable parameters, they can temporarily disconnect service. In this case, the telephone company will

give you advance notice, if possible.

5) Under FCC rules, no customer is authorized to repair

this equipment. This restriction applies regardless of

whether the equipment is in or out of warranty.

6) If the telephone company alters their equipment in a

manner that will affect the use of this device, they must give

you advance warning so that you can have the opportunity

for uninterrupted service. You will be advised of your right

to file a complaint with the FCC.

7) The attached affidavit must be completed by the

installer.

8) In the event of equipment malfunction, all repairs

should be performed by our company or an authorized

agent. It is the responsibility of users requiring service to

report the need for service to our company or to one of our

authorized agents.

1.3 Canadian Emissions Requirements

return the unit to the factory, shipping prepaid and packaged

to the best commercial standard for electronic equipment.

TxPORT will pay shipping charges for delivery on return.

The customer is responsible for mode and cost of shipment

to TxPORT. This warranty does not apply if the unit has

been damaged by accident, misuse or as a result of service

or modification by othe r than TxPORT personnel.

When returning the unit for warranty work, a Return Material Authorization (RMA) number must be obtained from customer service (refer to Section 1.5 for the phone numbers).

When calling TxPORT to obtain a Return Material Authorization number or to arrange service, please have the following information available:

• Model number(s) and serial number(s) for the unit(s).

• Reason for return and symptoms of problem.

• Warranty status (if known).

• Purchase order number to cover charges for out-ofwarranty items.

• Name and phone number of person we can contact if

we have questions about the unit(s).

• Mode of shipment required (second day air is the normal mode of shipment for all retu rned material unless

otherwise specified).

As soon as TxPORT has the above information, the RMA

that must accompany the item(s) returned can be issued.

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department

of Communications.

Note: End users should use existing 48 VDC battery

sources or a CSA certified power supply.

Le present appareil numerique n’emet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques (de la class A) prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communication s du Canada .

1.4 W arr anty

TxPORT warrants each unit against defects in material and

workmanship for a period of five years from the date the

unit was shipped to the customer. If the unit malfunctions at

any time during the warranty period, TxPORT will repair, or

at TxPORT’s option, replace the unit free of charge.

The remedies listed herein are the users sole and exclusive

remedies. TxPORT shall not be liable for any indirect, direct, incidental or consequential damages. The owner must

1.5 TxPORT Customer Service

TxPORT

127 Jetplex Circle

Madison, Alabama 35758

T e le ph one Number: 800-926-0085 or

205-772-3770

Sales /Administration FAX: 205-772 -3388

Manufacturing FAX: 205 -772 - 8280

Customer Service Returns: 800-926-0085, ext. 227

Product Support

Normal Hours (8 a.m. to 5 p.m. Central Time, Mon. – Fri.)

Telephone Number: 800- 285-2755, ext. 255 or

205- 772-3770, ext. 255

Emergency (Nights / Weekends / Holidays):

800 -285-2755

205-603-2194 (Manager)

General 1-32010 CSU

Page 7

1.6 Ordering Numbers

The unit is shipped from the factory with the 2010 CSU

reference manual. Refer to Table 1 - 2 on page 4 for the op-

tional equipment part numbers.

The part numbers for the stand- alone unit and the modular

chassis unit are shown in the following table:

The following accessories may also be needed for the installation and operation of the 2010 CSU.

Table 1-2 Optional Equipment

Part Number Description

Cables

Table 1-1 2010 Ordering Numbers

Part Number Description

F-2010-100-11

9- 2000-001-1

9-2000-001-2

9-2000-002-1

9-2000-002-2

F-2010-101-11

CD

2010 ESF CSU Stand - alon e Unit

C

Backplane

1

RJ48C NET / RJ48C DTE

2

RJ48C NET / DB15 DTE

3

DB15 NET / DB15 DTE

D

ACO Option

0

without ACO

1

with ACO

19" single unit rack mount bracket

19" dual rack mount bracket

23" single unit rack mount bracket

23" dual rack mount bracket

C

0

2010 ESF CSU Module (chassis)

C

ACO

1

1051 chassis without ACO

2

1051 chassis with ACO

3

K-type chassis without ACO

4

K-type chassis with ACO

Option

Option

For example, the default part number for the stand-alone

unit is ‘F-2010-100--1110’. This is a unit with RJ48C

backplane connectors for both the network and DTE and

without ACO.

9-1001-042-1

9-1001-042-2

33-00085

33-00086

F - 1051 - 000 - - 112 1051 1 2 - slot chassis (RJ48C)

9-2000-036--1 Stand-alone to rack mount conversion

30-00087 200 mA stand-alone wall mount

F-1040-000--111

F-1040-000--112

F-1041-000--110

9-1000-48V-1

F-1200-000--11 1200 power supply with redundant

9-8000-001-1

9-8000-001-2

Dual 6-pin modular to DB25 male

Dual 6-pin modular to DB25 female

Bantam to bantam test cord - red

Bantam to bantam test cord - black

Mounting

module with DB25 to 6-pin adapter

Power Supplies

-48 V power supply

Single 2 A, -48 VDC power supply

Redundant 2 A, -48 VDC power supplies

1041 redundant power shelf (w/o supplies)

Spare -48 VDC power supply (holds 2)

-48 VDC, 5 A with fuse panel

Misc.

EM8000 with manual on 3-1/2 inch disk

(DOS and UNIX version, respectively)

1-4 General 2010 CSU

Page 8

Installation

2.0 Introduction

This chapter contains information and instructions required

to prepare the TxPORT 2010 ESF CSU for use. Included

are initial inspection procedures, mounting instructions,

configuration guidelines, connection instructions, and powering information.

NOTE: Throughout this manual, all factory default

settings will be underlined

2.1 Safety Summary

This manual contains information and warnings which must

be followed by the user to ensure safe operation and to

retain the equipment in a safe condition.

!

The WARNING sign denotes a hazard to the

operator. It calls attention to a procedure or practice

which, if not correctly performed or adhered to,

could result in injury or loss of life. Do not proceed

beyond a WARNING sign until the indicated conditions are fully understood and met.

.

2.3 Supplied Materials

The TxPORT 2010 CSU is shipped from the factory with

the 2010 CSU reference manual. The user may also require

the following additional materials for the installation and

operation of the 2010 CSU.

• -48 VDC power source

• Network and DTE interface cables

• Bantam test cables

• 20-gauge stranded wire (or similar) for DC power

and alarm connection

The interface requirements of any application may be met

by using the appropriate cable. Standard cables and ordering

numbers are listed in Table 1-1 on page 1-4. Contact

TxPORT for any needed assistance in cable selection.

2.4 Mounting

The TxPORT 2010 CSU is a modular unit that plugs into

either a single unit housing or into a chassis that holds up to

12 units. Single units are designed for stand- alone desktop

use, wall mounting, or chassis mounting (in either a vertical

or horizontal orientation). The unit uses an interchangeable

front panel to accommodate the chassis card cage.

Up to 12 units may be inserted into a chassis and the chassis

may be installed in a 19" or 23" rack using four screws.

Connections are made from the rear of the chassis.

2.2 Unpacking and Inspection

This unit is carefully packaged to prevent damage in shipment. Upon r eceipt, ins pect th e shipping contai ner for damage. If the shipping container or cushioning material is

damaged, notify the carrier immediately and make a notation on the delivery receipt that the container was damaged

(if possible, obtain the signature and name of the person

making deliver y).

Retain the packaging material until the contents of the shipment have been checked for completeness and the instrument has been checked both mechanically and electrically.

If the contents of the shipment are incomplete or, if there is

mechanical damage or defect, notify TxPORT. If the shipping container is also damaged, or the cushioning material

shows signs of stress, notify the carrier of the damage as

well as TxPORT. Keep the shipping materials for carrier’s

inspection. TxPORT will arrange for repair or replacement

without waiting for claim settlement.

2.5 Unit Configuration

The following sections describe the configuration of the

2010 CSU. The unit was designed to be operated from manual switch control.

On power up, the unit is configured to the hardware settings

of the DIP configuration switches. Changes to these settings

will not take effect until the unit has been reset. This may be

accomplished either by removing and then reapplying power

or by quickly placing the test switch in the ‘Loop’ position

and then back to ‘Normal’.

Installation 2-12010 CSU

Page 9

Figure 2-1 Circuit Board View

TX KX

Optional Alarm Card

Factory set -

do not change

2.5.1 Configuration Switch S1

Front panel Switch S1 provides the following configuration

parameters.

Density - Enabled

Not used

DTE framing - ESF

NET framing - ESF

DTE code - AMI

NET code - AMI

Op Mode - 54016

Density - Disabled

Not used

54321 6 7

DTE framing - D4

NET framing - D4

DTE code - B8ZS

NET code - B8ZS

Op Mode - T1.403

BA

S1 - 1: This switch position sets the ESF operating mode

for the unit. In the 54016

mode, the unit responds only to

54016 CSU messages. In the T1.403 mode, the unit

responds to ANSI loop /un loop commands and generate s a

PRM every second, but will not respond to 54016 messages.

The two modes are exclusive of each other.

Alarm Relay

Contacts

S1-7: This position controls the zero suppression mode.

Enabled

allows ones density control after 15 successive

zeros from the DTE per TR62411. Disabled ignores density

control and allows 175 zeros to pass towards the network.

A

- Enabled B - Disabled

2.5.2 Configuration Switch S2

Front panel Switch S2 provides the following configuration

parameters.

PRM enable

AIS generation

DTE LBO

DTE LBO

DTE LBO

NET LBO

NET LBO

PRM disable

Pass received data

DTE LBO

54321 6 7

DTE LBO

DTE LBO

NET LBO

NET LBO

BA

A

- 54016 B - T1.403

S2 - 1, S2-2 : These two positions set the network l ine build

S1-2: This position sets the network line coding, includ-

ing conversion.

A

- AMI B - B8ZS

S1-3: This position sets the DTE line coding, including

out signal level of data transmitted towards the T1 facility.

The output level is factory set at 0 dB

. It may be attenuated

by -7.5 dB, -15 dB, or -22.5 dB if operating conditions

require a change. The telco should provide the proper se tting

to the user.

If unsure, then leave it at the default setting of 0

dB.

conversion.

A

- AMI B - B8ZS

S1-4: This position sets the CSU to the framing of the

network line. In the ESF

mode, the unit responds to all

T1.403 or 54016 messages.

S2-1 S2-2 Network LBO Level

A

A B -7.5 dB

B A -15.0 dB

B B -22.5 dB

A 0 dB

A - ESF B - D4

S1-5: This position sets the CSU to the framing of the

DTE line.

A

- ESF B - D4

S2 -3, S2 - 4, S2 -5: These three positions set the DTE line

build out transmit signal value towards the customer equipment. The value should match the cable length from the

CSU DTE port to the attached equipment.

2-2 Installation 2010 CSU

Page 10

S2 - 3 S2 - 4 S2 - 5 DTE ALBO Level

A

B B B 134-266 feet

A B B 267-399 feet

B A B 400-533 feet

A A B 534-655 feet

A A 0-133 feet

S2-6: This position enables the sendin g of an alarm indication signal (AIS) during an active payload loopback. The

unit can be optioned to generate an alarm indication signal

(unframed all ones) to the DTE during remote loop or to

pass the received network signal to the DTE on remote loop.

A

- Generate AIS to DTE B - Pass signal to DTE

S2-7: This position enables the sending of a PRM (performance report message) during an alarm indication signal

(AIS). If the unit detects a loss of sync from the DTE, an

unframed all ones signal is generated to the T1 facility. If

Switch S2 - 6 is set to generate AIS and S witch S1 -1 i s set

for T1.403 operation, the unit interru pts the AIS s ignal with

a PRM once a second.

A

- PRM enabled B - PRM disabled

2.5.3 Configuration Switch S3

shown below. This 3 -pin jumper straps the ACO alarm contact. Position jumper over pins 1 & 2 for normally open

operation (closes on alarm) or over pins 2 & 3 for normally

closed operation (opens on alarm).

Alarm

Relay

NO

NC

1

2

3

Figure 2-2 2010 CSU Rear Panel

8

1

2100 Rear Panel

DTE

DB15

Option

Available

Switch S3 is a 2 -position slid e switch (refer to Figure 2-1).

It selects the DTE side transmit and receive pair configuration for either a TxPORT (TX) shelf or any other manufacturer’s shelf (KX). This switch is factory set and should not

be changed.

2.5.4 ACO/Alarm Card (Option)

The optional ACO/ alarm card monitors the ‘NET’, ‘FAR’,

and ‘DTE’ alarm indicators for either an ‘alarm active’ or an

‘alarm clear’ condition and provides closure contact points

on the rear panel. The corresponding front panel LED lights

when an alarm condition is detected.

The alarm card circuitry scans the status (on/off) of the

NET, FAR, and DTE indicators 10 times a second (100 ms

windows). The card declares an alarm if one or more indicators are on for 100 consecutive 0.1 second samplings (10

seconds). When this happens, the red ‘Status’ indicator turns

on until no alarm conditions are detected for more than 100

consecutive 0.1 second samplings (another 10 seconds).

Alarm Relay: The rear panel alarm relay contacts may be

configured as normally open (NO) or normally closed (NC)

depending on the setting of the optional alarm card jumper

1+ V

2GND

3– V

4FRMGND

5ALM

6ALMCOM

1

6

8

1

NET

DB15

Option

Available

Installation 2-32010 CSU

Page 11

2.6 DTE Connection

Pin RJ48 Interface

1 Data In

2 Data In

3/6 Not Used

4 Data Out

5 Data Out

7/8 Chassis Ground

Pin DB15 Interface

1 Data Out

2 Not Used

3 Data In

4 Not Used

9 Data Out

11 Data In

The DTE connection is provided on the rear panel (refer to

Figure 2-2 on page 2 -3). The equipment side DTE interface

of the CSU is a DSX interface. The DTE line build out level

should be set as instructed in Section 2.5.2 on page 2-2.

The DTE physical interface for both the stand-alone unit

and the chassis mounted unit is a standard RJ48C 8-pin

modular jack. A DB15 backplane is also an option for the

network and DTE interfaces. The pinout assignments are

shown in the following table:

Pin RJ48 Interface

1 Data Out

2 Data Out

3/6 Not Used

4 Data In

5 Data In

7/8 Chassis Ground

Pin DB15 Interface

1 Data In

2 Frame Ground

3 Data Out

4 Frame Ground

9 Data In

11 Data Out

2.7 Network Connection

The network side of the CSU is referred to as the net work

interface. This interface contains an ALBO to allow the unit

to be located a substantial distance away from the telco network interface (receive signal level down to -27 dB).

The network interface line build out (LBO) levels should be

adjusted as instructed in Section 2.5.2 on page 2-2. The

maximum suggested cable lengths for units connected to the

network are listed in the following table.

Network Disconnection

: In accordance with FCC Part

68.218(b), the user must notify the telephone company prior

to disconnecting the CSU.

2.8 Alarm Connection

A rear panel terminal strip provides connections for the

alarm leads. Alarm relay contacts are provided (with the

optional alarm card) to permit connection to a remote indicating device. The connection is made on pins 5 and 6 as

shown below in Ta ble 2 - 3. Pin 5 is configured to operate in

a ‘normally

the setting of the alarm relay jumper.

open’ or ‘normally closed’ mode, depending on

Table 2-3 Power & Alarm Connector

Pin Description

1 48 VDC return

2 Signal Ground

3 -48 VDC

4 Frame Ground

5 Alarm Contact

6 Alarm Common

Cable Type Loss per 1000' Max. Length

26 gauge PIC 6.8 dB 4,400 ft

24 gauge PIC 5.4 dB 5,500 ft

22 gauge PIC 4.2 dB 7,100 ft

19 gauge PIC 3.0 dB 10,000 ft

Calculations are based on a cable temperature of 70°F, 0.083

uF/mile capacitance, a 27 dB loss, and a 100 Ω, non-loaded,

twisted pair cable; PIC refers to Plastic Insulated Cable.

The network physical interface for both the stand -alone unit

and the chassis mounted unit is a standard RJ48C, 8-pin

modular jack. A DB15 backplane is also an option for the

network and DTE interfaces. The pinout assignments are

shown in the following table:

2-4 Installation 2010 CSU

2.9 Power Connection

The 2010 is designed to operate from either a -24 VDC

source (± 3 V, 80 mA) or from a -48 VDC source (± 6 V, 45

mA). The unit will operate over a voltage input range of - 20

to -55 VDC. The chassis module of the 2010 unit obtains it s

power from the 12-position shelf wiring connections.

Connections are made on the rear panel power and alarm

terminal strip. All terminal strip connectio ns are made with

20 - gauge stranded (or similar) wire. The contacts are rated

at 0.6 Amp AC or 2.0 Amp DC.

Page 12

Operation

3.0 Introduction

This chapter describes the front panel operation and test features of the TxPORT 2010 ESF CSU. These controls and

indicators are described below. A section is also included

describing the performance statistics which are collected

when the 2010 is on the far end of a TxPORT product with

an embedded terminal interface.

Described in

‘Installation’

chapter

Figure 3-1 2010 CSU Front Panel

2010

®

ACO

AB

7654321

TRANSPORT

1

ESF CSU

2

3

ACO SW

S1

7654321

3.1 Front Panel Descriptions

This section describes the controls and indicators found on

the 2010 CSU front panel. The unit uses LEDs to convey

major alarm conditions and looping status, a network test

switch, and test jacks. The two DIP configuration switches

are described in Section 2.5 on page 2-1. The following

descriptions are indexed to Figure 3-1.

3.1.1 General Status Indicators

1) STATUS: The CSU has two LED indicators on the

front panel bezel that are exposed whether the access door is

open or closed. These general status LEDs provide a quick

check of the CSU’s operating condition (Go or No Go).

The green LED lights when the unit is powered and operating normally. The red LED lights if the alarm card circuitry

detects an alarm condition from the FAR, NET, or DTE

indicators or if an alarm threshold has been exceeded (if

equipped with optional alarm card). The green LED shuts

off if the red LED is on.

S2

FRM

NET

MON

NET ERR

FAR ERR

DTE ERR

LOOP

LOOP

NRM

TO

NET

MON

4

5

6

7

8

9

TO

DTE

FRM

DTE

3.1.2 Alarm C ontrols and Indicators

2) ACO: This r ed LED (only on units equippe d with the

optional alarm card) lights if the ‘alarm cut off’ switch is

placed in the left ‘on’ position. It indicates that the alarm

relay contacts are disabled.

3) ACO SW: This switch controls the alarm relay circuitry. This circuitry is deactivated in the left ‘on’ position.

The right ‘off’ position enables alarm reporting.

4) NET ERROR: This LED lights a minimum of 0.1

second if the internal alarm circuitry detects any of the following conditions from the incoming T1 signal: one or

more BPVs, FBEs, CRCs, or loss of signal/loss of sync.

5) FA R ER R O R : This LED lights a minimum of 0.1 second if the internal alarm circuitry detects a remote (yellow)

alarm signal from the far end terminal equipment. This condition occurs if the far end terminal is out of sync with the

T1 signal from the network. The format for a remote alarm

is bit 2 set to 1 in each DS0 (D4 mode) or 8 ones /8 zeros in

the facility data link (ESF mode).

6) DTE ERROR: This LED lights a minimum of 0.1

second if the internal alarm circuitry detects any one of the

Operation 3-12010 CSU

Page 13

following conditions from the DTE: one or more BPVs,

Receive signal

from the DTE

Transmit signal

to the network

Transmit signal

to the DTE

Receive signal

from the network

Monitor signal

from the network

Monitor signal

from the DTE

FBEs, CRCs, a yellow alarm, low ones density, or loss of

signal/loss of sync.

towards it a standard CSU line unloop code (001 repeating

for Š 5 seconds, framed or unframed).

AIS

3.1.3 Test Controls and Indicators

7) Loop: This yellow LED lights under the following

conditions: if the manual loop switch is placed in the

‘LOOP’ position, if the unit receives an inband loop code

for > 5 seconds, or if the unit receives an FDL loop message

(PLB or LLB). The LED does not light if the test switch is

placed in the ‘NRM’ position or if an inband or FDL unloop

code is received.

8) Test Switch: This switch is used for local testing.

Refer to Section 3.2.1 for further information.

9) Te st Jac ks: Bantam jacks are provided for access to

the T1 line on the DTE side of the CSU. Refer to Section

3.2.2 for further information.

3.2 Front Panel Testing

The previous section gave a brief description of each front

panel control and LED indicator. This section explains the

front panel test functions. Refer to Figure 3- 1 on page 3 - 1

for locations.

DTE

Remote Loopback

NET

DIP switch S2 configures the unit to either generate an

alarm indication signal (unframed all ones) to the DTE or to

pass the received data from the network to the DTE. The

unit responds to FDL loop (PLB, 0000111011111111) and

unloop command messages (0011100011111111).

3.2.2 Test Access Jacks

Six bantam test jacks are provided for access to the T1 line

on the DTE side of the CSU. Jacks allow transmit and

receive toward the network, toward the DTE, or monitoring

of traffic between DTE and network. These are customarily

used to inject and receive T1 signals using a T1 test set.

3.2.1 Test Switch

Local Loop: In the local loop mode (LOOP), the unit loops

the signal from the customer equipment (DTE IN) back to

the customer equipment (DTE OUT). It also loops the

received signal from the T1 facility (NET IN) back to the

T1 facility (NET OUT). When moved back to ‘NRM’, the

local loopback is removed.

Remote Loop: The unit can be looped remotely by generating towards it a standard CSU line loopback code (00001

repeating for Š 5 seconds, framed or unframed). Once it is

looped, the received signal from the T1 facility (NET IN) is

regenerated and transmitted back to the T1 facility (NET

OUT). The unit can be unlooped remotely by generating

3-2 Operation 2010 CSU

DTE

Local Loopback

NET: The top 2 ports are used to insert into the line in both

directions. They break connection to the DTE and make

connection to the CSU in the direction of the network.

MON: The middle 2 ports are used for non-intrusive

bridge monitoring of the line in both directions. They monitor the signals passing through the CSU (between the DTE

and the network).

DTE: The bottom 2 ports are used to drop the line, to break

connection to the CSU and make connection to the DTE.

NET

3.3 Terminal Operation

When the 2010 CSU is located at the far end of a TxPORT

product which has an embedded terminal interface, 2010

performance information may be accessed. The terminal

interface is a firmware application program embedded

inside units such as the 2000 CSU. Since the 2010 was primarily developed for placement at the far end of a 2000

CSU, the 2000 example will be used in the following para-

Page 14

graphs. The reference manual supplied with the TxPORT

product should be consulted for the interface system

description.

The ‘Performance’ screen (see Screen 3- 1 below) displays

the 24 -hour performance history of the T1 circuit. The error

parameters are continuously monitored. The Terminal Interface provides display of near end or far end performance

data using the facility data link.

Reset Performance Registers: This field allows the element registers to be reset and may only be used when

‘Target’ is set to [USER]. If <return> is pressed, the fol-

lowing warning appears: DELETE ALL PERFORMANCE

DATA? To exit this screen without performing the reset

function, press <return> with (NO) selected. To proceed

with the reset function, press <return> on (YES). All values for the chosen register set (NET or DTE) are then reset

to zero.

The near end unit is equipped with a dual set of performance

data registers that hold line statisti cs for both the telco and

user. Each register set provides detailed status and performance history for the network and DTE interfaces. For

generic 54016 far end devices, such as the 2010, only the

standard telco 24- hour performance data is displayed. The

30-day data is not available.

The fields in this screen are described as follows:

Element: Pressing the <spacebar> toggles this field for

selection of either the ‘NEAR’ or ‘FAR’ unit as the source of

performance data or the targ et of commands. ‘NEAR’ refers

to the unit to which the terminal is connected (the 2000).

‘FAR’ refers to the unit at the other end of the network T1

span (the 2010).

Error Events: This field displays the running total of ESF

error events for the circuit selected in ‘Element’ and is

applicable only when ‘Target’ is set to [USER]. This

count accumulates until it reaches 65535 or is reset by

pressing <return> with the (RESET) field highlighted.

The remainder of the fields in the ‘Performance’ screen are

for display o nly. They are defined as follows:

Status: This field displays the selected T1 line status

derived from the type (or absence) of errors in the received

data. The status represents the immediate state of the

received T1 signal and is not related to the alarm thresholds.

Completed Intervals: This field displays the number of

15 -minute intervals in the last 24 -hour period since the registers were last cleared (a 24- hour period may contain up to

96 intervals).

24 Hr. % Error Free: This field displays the percentage of

error free seconds within the last 24 hours or since the event

registers were last cleared. It is based only on the ES and

UAS pa rameters.

(performance data): The main body of display data consists of error events for two different periods: The first display line shows the data accumulating for the current

interval (from 0 to 900 seconds). The second line shows the

Screen 3-1 Performance

2000 CSU x.xx/x.xx 2010 CSU Date MM/DD/YY

2010 CSU x.xx/x.xx (Unit Address: xxx) Time HH:MM:SS

--------------------------------- PERFORMANCE ----------------------------------

Element: [FAR ] Status: OK

Error Events: 65535 (RESET) Completed Intervals: 96

[STANDARD 24 HOUR]

411 0 0 0 2 3 3

24 Hour 10 0 0 2 3 0

PAGE-UP-------------------------------------------------------------------

Time Interval ES UAS BES SES LOFC CSS

PAGE-DN-------------------------------------------------------------------

13:45 6 1 0 0 0 1 0

13:30 7 2 0 0 0 2 0

13:15 8 4 0 0 0 2 0

24 Hr.% Error Free: 98.2

Operation 3-32010 CSU

Page 15

totals for the last 24-hour period (or the last 96 fifteen-

minute intervals).

The remaining lines of this screen s how the data for any of

the intervals that contained errors. Interval 1 is the most

recently stored interval and interval 96 is the oldest 24-hour

interval. The real time of the interval beginning is shown in

the first column.

If more than five errored intervals have elapsed, [PAGE-

DN] appears to the left of the performance data. Pressing

<return> on th is field displays the next five errored intervals.

[PAGE-UP] appears once [PAGE -DN] is used. Pressing

<return> on [PAGE -UP] displays the previous five errored

intervals. Only intervals that contained errors are displayed,

which eliminates rows of zeroes. If an interval is not displayed, no errors were detected during that time period.

NOTE: The parameters shown on the ‘Performance’

screens are updated at 5 second intervals.

Per AT&T Technical Reference TR54016, the ‘Standard 24 Hour’ performance data consists of Errored Sec-

onds (ES), Bursty Errored Seconds (BES), Severely Errored

Seconds (SES), Unavailable Seconds (UAS), Loss of Frame

Count (LOFC), and Controlled Slip Seconds (CSS).

3-4 Operation 2010 CSU

Loading...

Loading...