Page 1

1558D APS

TRANSPORT

CSU/DSU

®

34-00255

st

Edition

1

i

Page 2

Copyright

1996 TxPORT, All rights reserved. No part of this publication may be reproduced, transmitted, transcribed , stored in a

retrieval system, or translated into any language in any form by any means without the written permission of TxPORT.

Reorder # 34-00255

st

1

Edition, August 1996

TxPORT shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material. TxPORT reserves the right to revise this publication from time to time and make

changes in content without obligation to notify any person of such revision changes.

Contents of this publication may be prelimin ary and/or may be ch anged at any time with out notice and s hall not be regarded

as a warranty.

Documentation Disclaimer

TxPORT makes no representation or warranties of any kind whatsoever with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability or fitness for any particular purpose.

ii

Page 3

Table of Contents

General...................................... 1-1

Specifications .....................................................1-1

T1 Network Interface ................................1-1

V.35 CPE (Equipment Interface) ..............1-1

Diagnostics..................................................1-1

Test Jacks .................................................... 1-1

Alarms.........................................................1-1

Power...........................................................1-2

Mechanical ..................................................1-2

Environmental.............................................1-2

Compatibility...............................................1-2

Industry Listings.........................................1-2

FCC Requirements............................................1-2

Canadian Emissions Requirements....................1-2

Warranty ............................................................1-3

Ordering Numbers ............................................1-3

TxPORT Customer Service .............................1-3

Installation ................................ 2-1

Site Preparations......................................... ......2-1

Unpacking and Inspection................................2-1

Mounting...................................................... ......2-1

Wiring & Connections.....................................2-1

Chassis Ground Connection ......................2-1

Alarm Connections.....................................2-2

T1 Connections...........................................2-2

COM Bus Connections..............................2-2

V.35 Interface..............................................2-2

AC Power ....................................................2-3

Configuration Modes ........................................2-3

Switch Configuration .................................2-3

Option Switch S1................................2-3

Option Switch S2..................................2-3

Option Switch S3................................2-4

Option Switch S4..................................2-4

ROM Configuration ...................................2-5

RAM Configuration ...................................2-5

Manager Configuration..............................2-5

Pre-service Testing............................................2-5

Path A Pre-service Testing ........................2-6

Path B Pre-service Testing ........................ 2-6

End - to - End Pre-Service Testing .............. 2-7

Operation ....... ..................... ...... 3-1

Applications ....................................................... 3-1

General Operation..............................................3-1

Revertive and Non-Revertive Switching.3-1

Default Power-Up Path.............................3-1

Loss of Signal / Loss of Frame..................3-1

Bipolar Violations ......................................3-1

CSU Loopbacks..........................................3-1

Forced/Locked Capability .........................3-2

APS Switching Time.................................3-2

APS Switching Parameters.......................3-3

Line Availability Timer ............................ 3-3

Status and Performance Information........3-3

Configuration Modes ................................. 3-4

Front Panel Functions...................................... 3-4

Supervisor Port............................................3-4

Power Indicators ........................................3-4

Locked Indicator........................................ 3-4

Status Indicators......................................... 3-4

Manual Path Selector Switch...................... 3-4

Path Status Alarm Indicators.................... 3-5

Path Status LOS Indicators...................... 3-5

Path Status Loop Indicators.....................3-5

Bantam Test Access Jacks ....................... 3-5

DTE Status Indicators............................... 3-5

DTE SD LED.............................................. 3-5

DTE RD LED..............................................3-5

TEST LED ..................................................3-6

Loopbacks..........................................................3-6

Local Manual Loop/Unloop........................3-6

Manual Remote Loop/Unloop ....................3-6

Inband CSU Loop/Unloop.......................... 3-6

ESF CSU Loop/Unloop ..............................3-7

Local/Remote Soft Testing......................... 3-7

Rear Panel Connections...................................3-7

Alarm Terminal Strip..................................3-7

Power ..........................................................3-7

Option Switches SW1 - SW4...................... 3-7

Option Switch 1 .................................... 3-7

Options Switch SW2............................3-8

Option Switch SW3 .............................. 3-8

Option Switch SW4 .............................. 3-8

V.35 Female Interface Connector (DCE) ... 3-8

DTE Control Lines......................................3-9

COM Bus Connections.............................3-9

Network T1 Connections.......................... 3-9

LAPS Operation....................... 4-1

LAPS Installation ..............................................4-1

Screens And Menus......................................... 4-1

Common Screen Elements........................ 4-1

Cursor Controls..........................................4-2

User Log On......................................... 4-3

Main Menu Screen........................................... 4-3

Circuit List Screens .........................................4-3

Circuits in Alarm......................................... 4-3

Circuits in Test ............................................ 4-3

Circuit List.................................................. 4-3

Circuit List Screen Manipulation................ 4-3

Performance Screen....................................4-5

Maintenance Screen...........................................4-6

Configuration Screen......................................... 4-7

Utilities Screen ..................................................4-9

Loopback Operations........................................ 4-9

iii

Page 4

Near Payload Loop..................................4-10

Near Line Loop ........................................4-11

Near Facility Loop ..................................4-11

Near Equipment Loop.............................4-11

Far Payload...............................................4-11

Far Line....................................................4-12

CSU Loop.................................................4-12

NET Loop.................................................4-12

NPC Payload Loop..................................4-13

BERT Testing.................................................4-13

iv

Page 5

1. General

The TxPORT 1558D APS CSU/DSU (Automatic Protection

Switch with integral V.35 DSU/CSU) provides the ideal

solution for mission-critical high speed data applications

requiring redundant path T1 access. The 1558D supports

both T1 and FT1 high speed applications and can automatically restore your applicat ion when a problem arises on

either the primary or standby T1 facility. See the ‘Operation’

chapter for a typical APS application. Switching from the

failed T1 line (Path A or Path B) to the standby (Path A or

Path B) is based upon user definable switching alarm thresholds (errored seconds, consecutively severely errored seconds, loss of signal, loss of frame). The 1558D APS CSU/

DSU is fully compatible with AT&T 54017 T1 protection

standards, AT&T 54016 ESF performance standards and TR

62411 T1 standards.

Features

The APS CSU/DSU unit is designed s o that it can be configured to support a wide variety of user applications and

speeds. The key features and functions are:

• Mission-Critical Automatic Protection Switching from a Fail

or Impaired T1 F acili ty to a St an dby T1 F a cili ty

• AMI or B8ZS Line Coding

• Integral ESF CSUs (TR 54016 compl iant)

• 24 Hour Performance History

• Revertiv e and Non-rev erti v e Operation

• User-Definable Alarm Switching Thresholds

Specifications

T1 Network Interface

Line Rate: 1.544 Mbps

Framing: ESF

Line Code: AMI or B8ZS

DS1 Interface: +1 to -27 dB ALBO, 100 Ω (± 5%)

Connector: RJ-48 modular jack

Overvoltage Primary and Secondary lightning

Protection:fusing for line cross

V.35 CPE (Equipment Interface)

Standards: Complies with CCITT V.35

Data Rates: 56Kb to 1.536 Mbps (n x 56/64)

Clocking: Internal, External, Network

Looping: Local and Remo te (per V.54)

Data Invert: Enable/Disable

Connector: Female, 34-pin

Diagnostics

Line Loop: Signal regeneration only (bidirectional)

Payload Loop: Signal regenerated with new frame syn-

chronization, CRC6, and data.

Loop Activation Industry standard formats and De-acti-

vation:(54016, 62411, T1-403)

Performance: Per AT&T TR54016, TR54017

SUPV Port: Local diagnostics and configuration in-

terface (RS-232/RJ-11)

• Proactive Call-on-Alarm Reporting (requires manager)

• V.35 high speed interface (N x 56/64)

• Desk T op or Rack Mount

• Bantam T est Access Jacks

• Complies with AT&T 54017 Automatic Protection Switching, 1991

• FCC, IC, UL, and CSA Compliant

SUPV

PWR

STATUS

ALOCKED B

SELECT

AUTO

A

PATH

PATH

STATUS

ALM LOS LP

B

A

B

Figure 1-1 1558D Automatic Protection Switch CSU/DSU

Test Jacks

Network Side Bantam jacks Tx, Rx, and Bridging for

sides A and Side B

Alarms

Contacts: Normally Opened (NO) and Normally

Closed (NC)

Rating: 0.6A @ 125 VAC

2.0A @ 30 VDC

RX BRDG

N

E

T

A

TX BRDG

RX BRDG

N

E

T

B

TX BRDG

PATH

STATUS

SD RD TEST

RL

LOOP

NORM

LL

TxPORT

1558D

APS CSU/DSU

General 1-11558D APS CSU/DSU

Page 6

Power

Unit: 115 VAC, ≤75 mA, 35 BTU maximum

Mechanical

Mounting: Desk, wall, or rack installation (comes

with 19” rack mount hardware)

Dimensions: 17.25" W, 1.75" H, 12" D

Weight: 5 lbs.

Environmental

Operating Temp: 0° to 50° C(32° to 122°F)

Storage Temp: -20° to 85° C(-4° to 185°F)

Humidity: 95% maximum (non-condensing)

Compatibility

PUB 54017: Automatic Protection Switching Equip-

ment, 1991

TR 62411: T1 interface and CSU specifications

PUB 54016: ESF requirements

CCITT: V.35

Industry Listings

FCC Compliance: Part 15 Subpart B, Clas s A

FCC Part 68 Registration:

UL Listed:

CSA Certified:

IC/CS03:

FCC Requirements

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and

if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user is

required to correct the interference at his own expense.

Shielded cables must be used to ensure compliance with

the Class A FCC limits.

Modifications to this unit not

expressly approved by the party

responsible for compliance could void the

user ’s authority to operate the equipment.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received,

including interference that may cause undesired operation.

Notice to Users of 1.544 Mb/s Service:

instructions are provided to ensure compliance with FCC

Rules, Part 68:

1. All direct connections to T1 lines must be made using

standard plugs and jacks.

2. The following information may be required by the local

telephone company when applying for leased line facilities:

Table 1-A. Leased Line Information

Port ID REN / SOC FIC USOC

P/N/12 - 00635 6.0 N 04DU9-BN

04DU9-DN

04DU9-IKN

04DU9-ISN

3. If the unit appears to be mal functioning , it should be disconnected from the telephone lines until you learn

whether the source of trouble is your equipment or the

telephone line. If your equipment needs repair, it should

not be reconnected until it is repaired.

4. The unit has been designed to prevent harm to the T1

network. If the telephone company finds that the equipment is exceeding tolerable parameters, they can temporarily disconnect service. In this case, the telephone

company will give you advance notice, if possible.

5. Under FCC rul es, no cus tomer is autho rized to repair thi s

equipment. This restriction applies regardless of whether

the equipment is in or out of warranty.

6. If the telephone company alters their equipment in a

manner that will affect the use of this device, they must

give you advance warning so that you can have the

opportunity for uninterrupted service. You will be

advised of your right to file a complaint with the FCC .

7. The attached affidavit must be completed by the installer.

8. In the event of equipment malfunction , all repairs sh ould

be performed by our company or an authorized agent. It

is the responsibility of users requiring service to report

the need for service to our company or to one of our

authorized agents.

The following

RJ-48C

Canadian Emissions Requirements

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department

of Communications.

General 1-2

1558D APS CSU/DSU

Page 7

End users should use existing 48 VDC battery

sources or a CSA certified power supply.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites applicables aux appareils

numeriques (de la class A) prescrites dans le Reglement sur

le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

• One PC to 1558D user interface cable

• AC Pow er Cord

• T wo 10' RJ-48 modular T1 cables

The following is a list of the standard and optional equipment which may also be needed.

Table 1-B. Available Equipment and Part Numbers

Warranty

TxPORT warrants each unit against defects in material and

workmanship for a period of five years from the date the

unit was shipped to the customer. If the unit malfunctions at

any time during the warranty period, TxPORT will repair, or

at TxPORT’s option, replace the unit free of charge.

The remedies listed herein are the users sole and exclusive

remedies. TxPORT shall not be liable for any indirect,

direct, incidental or consequential damages. The owner must

return the unit to the factory, shipping prepaid and packaged

to the best commercial standard for electronic equipment.

TxPORT will pay shipping charges for delivery on return.

The customer is responsible for mode and cost of shipment

to TxPORT. This warranty does not apply if the unit has

been damaged by accident, misuse or as a result of service

or modification by other than TxPORT personnel.

When returning the unit for warranty work, a Return Material Authorization (RMA) number must be obtained from

customer service at the address/ phone number given at the

end of this chapter. When calling TxPORT to obtain a

Return Material Authorization number or to arrange service,

please have the following information available:

• Model number(s) and serial number(s) for the unit(s).

• Reason for return and symptoms of problem.

• Warranty status (if known).

• Purchase order number to cover charges for out-of-warranty

items.

• Name and phone number of person we can contact if we

have questions about the unit(s).

• Mode of shipment required (second day air is the normal

mode of shipment for all returned material unless otherwise

specified).

As soon as TxPORT has the above information, the RMA

that must accompany the item(s) returned can be issued.

Ordering Numbers

The 1558D is shipped from the factory with the following

standard items:

• The 1558D reference manual

• 19" rack mount hardware

• Local Access PC software

Part Number Equipment

F-1558-001D-1111

6-3030-035-1

6-3030-036-1

9-1558D-003-1 PC DOS Local Access software on 3.5”

9-1001-029-2

9-1001-004-0 10

1558D unit with integral ESF CSUs

and V.35 DSU, 110 VAC operation.

19" Rack Mount Hardware for

1558D. Standard with 1558D unit.

23" Rack Mount Hardware for

1558D. Ordered as an option to the

1558D.

Disk. Allows the user to access unit performance, status, and configurati on

information and to perform loca l loo p

testing.

PC to 1558D data cable, 10' DB-9 to

6-pin modular. Standard with 1558D

unit.

RJ-48 8-pi n modular 10' c able Contact the factory for additional cable

lengths and types.

TxPORT Customer Service

Address: TxPORT

127 Jetplex Circle

Madison, Alabama 35758

Telephone: 888-4TxPORT

800-926-0085 or

205-772-3770

Customer Service Returns: 800-926-0085, ext. 2227

Product Technical Support

Normal Hours - 8 a.m. to 5 p.m. Central, Monday – Friday

Telephone: 888-4TxPORT

800-285-2755 or

205-772-3770

Emergency - Nights / Weekends / Holidays:

Telephone: 800-285-2755

E-Mail (Internet address): support@txport.com

General 1-31558D APS CSU/DSU

Page 8

General 1-41558D APS CSU/DSU

Page 9

2. Installation

Proper installation of the 1558D unit involves the following

key steps:

• Site Survey and Preparation

• Unpacking and Inspecting Equipment

• Equipment Mounting

• T1, Alarm, and Power Connections

• Setting Equipment Options

• Preservice Testing

The following paragraphs contain information and instructions to assist the user in preparing the 1558D for operation.

A tear-out configuration guide (P/N 45-00083) is included

in the back of this manual. It is recommended that the user

sequentially follow the site preparation and unit installation

steps described.

Site Preparations

The following site preparations should be performed before

starting installation of the 1 558D A PS C SU/ DSU un it. F irst,

determine the physical location of 1558D unit and perform

the following:

1. Determine the distance from the APS unit to the AC

power outlet. The 1558D is shipped from the factory

with a industry standard 3-prong, 5.5 ft. AC power cord.

The maximum current draw of the 1558D is ≤75 milliamps.

2. Determine t he distance from the T1 facility demark and

the actual location of the 1558D. After determining distance, verify that the proper cable lengths and types have

been ordered to connect from the T1 demark to the

1558D unit. The 1558D is shipped with three RJ-48

modular T1 cable, 10 feet in length.

3. Normally, the provider of the T1 facility will provide the

required LBO setting (transmit signal level) required for

connection to the T1 facilities. This value should be used

when setting the 1558D LBO transmit values (0, 7.5, 15,

or 22 dB) in the 1558D unit. If the value cannot be

obtained from the provider, the LBO transmit values for

Path A and Path B should be set to 0 dB.

4. Verify that the T1 line is operating properly before you

attempt to install the 1558D unit. Both of the T1 lines

should be checked for error free operation for at least one

hour to ensure that they are performing error free.

5. If the unit is to be in stalled in a 19’ equipment be rack,

verify that there is enough rack space available in the

rack (requires 1.75 inches per 1558D unit). Four pan

head (type 12-24 x 1/2 inch) screws are provided for

mounting the unit. An optional 23” rack mount kit is

available for applications using this size rack.

6. Verify that no external CSUs (channel service units) preexist at the location where the 1558D is being installed.

The 1558D unit provides internal ESF CSU functions and cannot operate properly if another

CSU is also co-located with the 1558D.

Unpacking and Inspection

This unit is carefully packaged to prevent damage in shipment. Upon receipt, inspect the shipping container for damage. If the shipping container or cushioning material is

damaged, notify the carrier immediately and make a notation on the delivery receipt that the container was damaged

(if possible, obtain the signature and name of the person

making delivery). Retain the packaging material until the

contents of the shipment have been checked for completeness and the instrument has been checked both mechanically

and electrically.

If the contents of the shipment are incomplete or, if there is

mechanical damage or defect, notify TxPORT. If the shipping container is also damaged, or the cushioning material

shows signs of stress, notify the carrier of the damage as

well as TxPORT. Keep the shipping materials for carrier’s

inspection. TxPORT will arrange for repair or replacement

without waiting for claim settlement.

Mounting

If the 1558D is to be installed in an equipment rack, simply

mount the 1558D in the equipment rack using the provided

mounting screws and rack mount adapters. If the equipment

is to be located on a desktop, remove the rack mount adapters and set the unit on any flat surface. Once the equipment

has been physically located, the following rear panel wiring

connections should be performed.

Wiring & Connections

There are several wiring connections that must be performed

to install the 1558D. The following paragraphs describe how

to attach the APS unit to the associated T1 lines, power connections, alarm connections, and COM BUS connections.

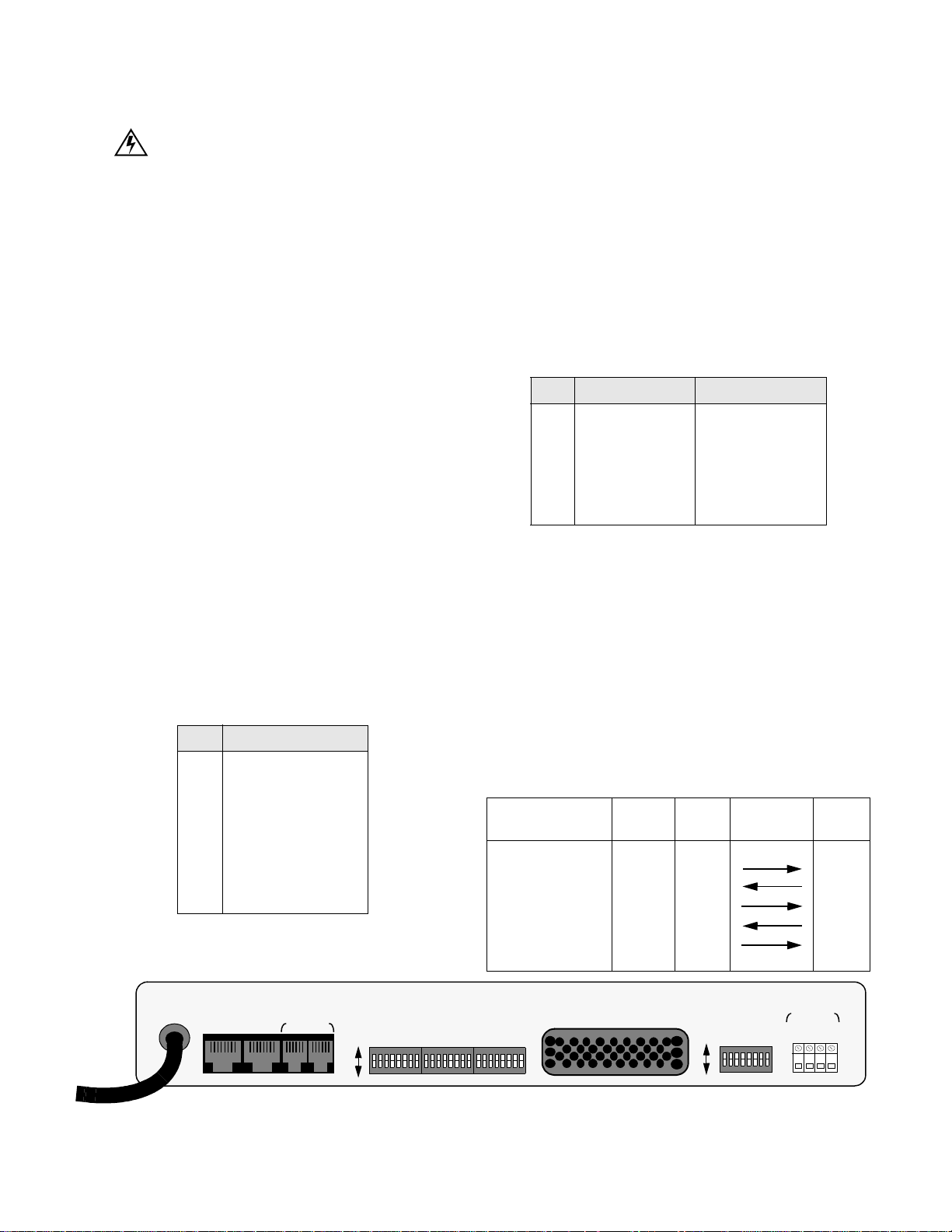

Figure 2 -1 should be used as a reference for the following

paragraphs concerning installation of the 1558D APS unit.

Chassis Ground Connection

The 1558D unit should be connected to a good earth ground.

To connect ground to the unit, attach a 26 gauge or larger

Installation 2-11558D APS CSU/DSU

Page 10

wire from the rear panel screw terminal labeled ‘GND’ to a

good earth ground.

Voltages in excess of 100 VDC may be

present on the T1 telecommunications

lines. Before connecting the APS unit to telecommunication lines, ensure that the rear

panel screw terminal labeled ‘GND’ has been

connected to a good earth ground.

Alarm Connections

The 1558D has alarm contacts provided at the rear panel

screw terminals labeled ‘COMMON’, ‘NC’, and ‘NO’. The

alarm relay is operated when power is present to the 1558D.

To connect the APS alarm relay to an external customer

alarm surveillance system, perform the following:

• Connect a 26-gauge wire to the rear panel screw terminal

labeled ‘COMMON’ to the external alarm system.

• Connect a 26 -gauge wire to the rear panel screw terminal

labeled ‘ALARM NO’ (normally open) or to ‘ALARM NC

(normally closed) to the external alarm system. The alarm

relay is normally operated when power is connected to the

unit.

COM Bus Connections

The rear panel COM BUS connectors (IN/OUT) are used to

communicate to/from the optional APS 15 59 site manager.

These connections are only used when a 1559 Network

manager is co-located with the 1558D(s). Bus connections

from the manager to one or more 1558D units is done in a

daisy chain fashion. That is, the COM BUS Out from the

1559 is connected to the COM BUS IN of the 1558D and

the COM BUS OUT of the 1558D is connected to the COM

BUS IN of the 1559. Physically, the connections to the

COM Bus IN/OUT are RJ-11, 6-pin miniature modular

jacks. The function of the six pins associated with the jacks

are shown below in Table 2-D.

Table 2-D RJ-11 Pinouts

PIN CO M BUS IN COM BUS OUT

1 Not Used Not Used

2 Signal Ground Signal Ground

3 Data, output Data, Output

4 Data, input Not Used

5 Signal Ground Signal Ground

6 Not Used Not Used

T1 Connections

All T1 lines are connected to the 1558D unit usin g modular

8-pin RJ-48 cables (two 10' RJ-48 cables come with the

unit). Insert the RJ48 connectors into the rear panel receptacles labeled NET A, and NET B. Connect the other ends of

the cable to the appropriate external T1 A and B facility

equipment. The modular RJ-48 Pinouts and their functions

are shown in Table 2-C.

Table 2-C RJ-48 Pinouts

Pin NET A & B, RJ-48

1 Data In, Tip

2 Data In, Ring

3 Not Used

4 Data Out, Tip

5 Data Out, Ring

6 Not Used

7 Not Used

8 Not Used

V.35 Interface

The 1558D high speed DTE port is a 34-pin female connection. The interface is fully compatible with CCITT V.35

standards. To connect external CPE equipment to the

1558D, simply attach a male V.35 cable to the V.35 DTE

port found at the rear of the 1558D. Be sure to mechanically

secure the cable in place by tightening the provided thumb

screws. The operating speed and clocking arrangements are

described in the section entitled Configuration Modes on

page 2 -3. The pinouts for the V.35 interface are shown in

Table 2-E.

Table 2-E V.35 Pinouts

Function CCITT Name

Frame Ground 101 FG A

Signal Ground 102 SG B

Send Data 103 SD P, S

Receive Data 104 RD R, T

Request to Send 105 RTS C

Clear to Send 106 CTS D

Data Set Ready 107 DSR E

Direction

DTE/DCE

1558D

V.3 5

Installation 2-2

NET BNET A

COM BUS

ON

S1 S2 S3

IN OUT

OFF

V.35

ON

OFF

S4

ALARM

GND

N.O.

COM

N.C.

Figure 2-1 1558D Rear View

1558D APS CSU/DSU

Page 11

Table 2-E V.35 Pinouts

Function CCITT Name

Data Terminal Ready 108 DTR H

Data Carrier Detect 109 DCD F

Transmit Clock 113,114 TC Y , AA

Receive Clock 115 RC V, X

External Clock 113 ext.TC U, W

Test Mode 142 TM K

Direction

DTE/DCE

1558D

AC Power

V.3 5

• Master or Slave Card Operation

• Boot general parameters from Switches, ROM, RAM, or

Manager

• Boot alarm parameters from ROM or RAM

• Enable/Disable Framing Error Alarm

• Enable/Disable Loss of Signal Alarm

• AMI/B8ZS Line Encoding, NET A, NET B

The following table describes the DIP switch settings co ntrolled by Switch S1.

The 1558D unit operate from 115 VAC, 75 mA maximum.

The unit is shipped with a 5.5 foot 3-prong industry standard

AC power cord. After all wiring connections have been

completed, attach the unit to the AC wall receptacle. The

unit responds by turning on the front panel (green) LED

power indicator. The user is now ready to configure the

1558D. The following sections describe how to quickly configure the 1558D unit.

Configuration Modes

Any time that the 1558D unit is initi alized (power removed,

then reapplied), all key configuration data is read by the

1558D CPU and implemented based upon the particular

configuration boot mode options selected by the user. There

are four possible configuration boot modes:

• Configure/Boot from Switches

• Configure/Boot from ROM.

• Configure/Boot from RAM.

• Configure/Boot from Manager. This requires the optional

1559 manager.

All factory default settings in this manual are

shown underlined.

Switch Configuration

After the equipment has been unpacked and inspected and

mounted, the next step is to configure the unit. All unit

options are set by the manual DIP s witch positions located

on the four rear panel option switches (S1, S2, S3, and S4).

The 1558D is shipped from the factory with all option

switches in the OFF (factory default) positions. The following paragraphs briefly describe the 1558D option switches

and there functions.

After the option switches have been set to the

desired operating mode, recycle the power to the

unit. At power up, the C PU will read and implement the switch settings.

O

PTIONSWITCH

Switch S1 is an eight position DIP switch used to set the

following unit options.

S1

.

Table 2-F Switch S1

Position Selection Switch S1 Description

1Off

2,3 Off, Off

4Off

5Off

6Off

7Off

8Off

O

PTION SWITCH

On

Off, On

On, Off

On, On

On

On

On

On

On

Card Function, Slave

Card Function, Master

Boot from Switches

Boot from Manager

Boot from RAM

Boot from ROM

ARM from ROM

ARM from RAM

Enable Frame Error Alarm

Disable Frame Error Alarm

LOS, Enabled

LOS, Disabled

NET/A, B8ZS

NET/A, AMI

NET/B, B8ZS

NET/B, AMI

S2

Switch S2 is an eight position DIP switch used to set the

following unit options.

• CSU Mode, Enable/Disable

• Path Revert, Enable/Disable

• NET A, LBO V alue

• NET B, LBO V alue

• Clocking Mode, Internal, External, Network

Table 2-G describes the DIP switch settings controlled by

Switch S2.

Table 2-G Switch S2

Position Selection Switch S2 Description

1Off

On

2Off

On

3,4

Off

, Off

Off, On

On, Off

On, On

CSU Mode, Enabled

CSU Mode, Disabled

Path Revert, Disabled

ON = Path Revert, E nabl ed

NET A LBO Value

0.0 dB

7.5 dB

15.0 dB

22.5 dB

Installation 2-31558D APS CSU/DSU

Page 12

Table 2-G Switch S2

Position Selection Switch S2 Description

5,6

7,8 Off

O

PTIONSWITCH

Off

, Off

Off, On

On, Off

On, On

, Off

Off, On

On, On

On, Off

S3

NET A LBO Value

0.0 dB

7.5 dB

15.0 dB

22.5 dB

Network Clock ing

Network Clock ing

Internal Clocking

External DTE Clocking

Switch S3 is an eight positio n DIP switch used to configure

the 1558D unit address ID for the NET A hardware and the

NET B hardware. Unique addresses must be optioned for

each 1558D unit when multiple units are co-located and a

1559 Site Manager is being used. If no manager is being

used, the user should leave the DIP switches in the factory

default positions (all in the OFF or DOWN position). This

configures the unit for NET A address 1 and NET B address

2. Table 2-H indicates how to configure the address settin gs

for the first six 1558D units.

Table 2-H Address Settings

*APS Mgr .

Unit Pos.

1.01 1/2

1.02 3/4 On On Off Off Off

1.03 5/6 On Off On Off Off

1.04 7/8 On On On Off Off

1.05 9/10 On Off Off On Off

1.06 11/12 On On Off On Off

NET A/B

Address

Pos1Pos2Pos3Pos4Pos

5 - 8

Off Off Off Off

Off

When connecting to the SUPV port using the

APS local access software, the 1558D NET A

and NET B addresses are viewed as a single unit

address and are displayed as 1.01 for addresses

1 and 2, 1.02 for addresses 3 and 4, etc.

O

PTION SWITCH

S4

Switch S4 is a ten position DIP sw itch used t o configure the

following DTE interface options.

• Set DSU Operating Speed (56kb - 1.536 Mbps)

• Set Rate Multiple, 56kb or 64kb

• Set DS0 Assignment Mode, Contiguous/Alternate

• Set Flow Control, On/OFF

• Set Data Invert, Yes/No

Switch 4, (Pos. 1 - 6) - These six DIP switches allow the

user to select the operating speed of the 1558D DTE port

and whether or not the DS0s are assigned sequentially,

beginning with DS0#1 or Alternately, beginning with

DS0#1, 3, 5, etc. The table below shows the option position

settings for the various combinations of speed and DS0

channel assignments. The 1558D can be configured to operate from 56 kb to 1.536 Mbps.

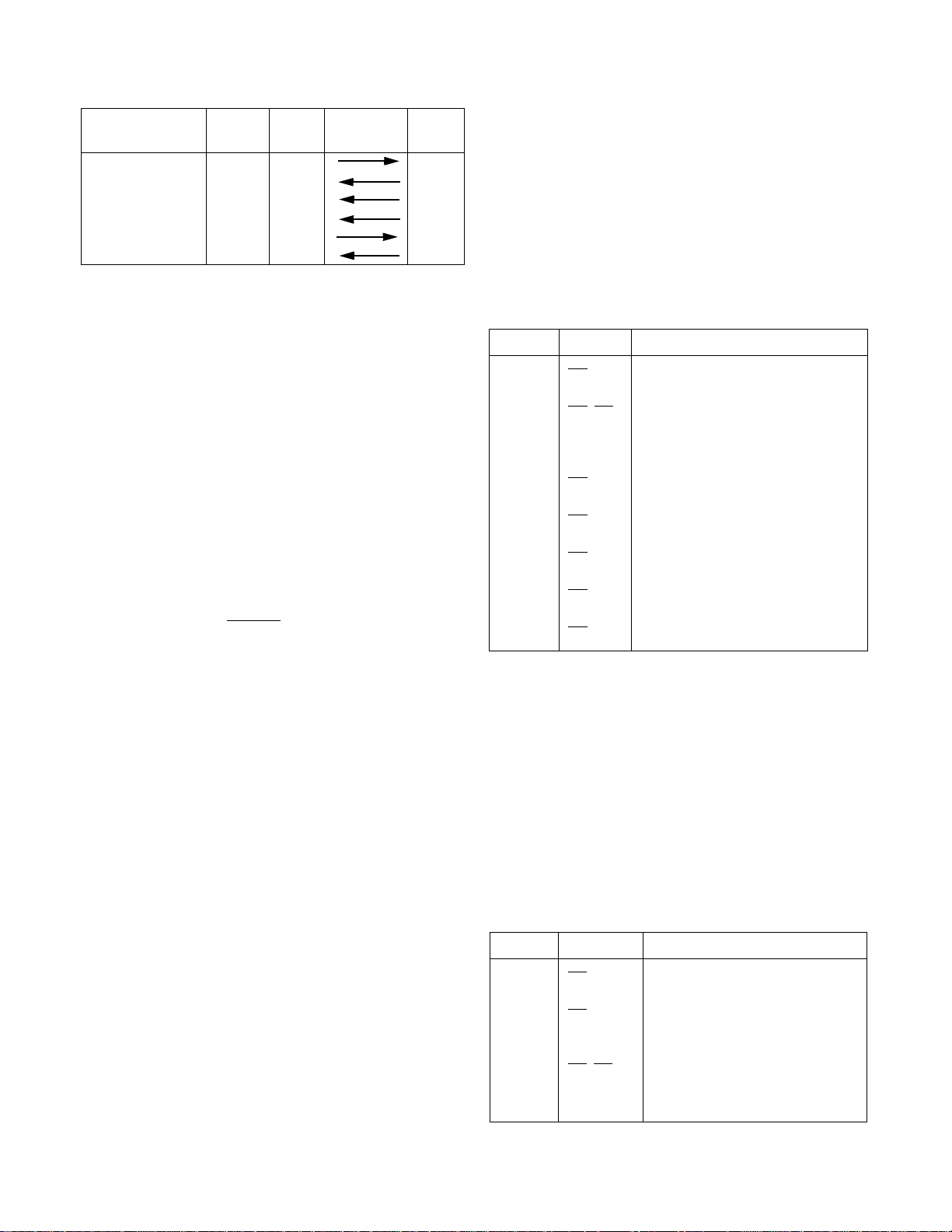

Table 2-I Speed Settings

Pos1Pos2Pos3Pos4Pos5 Pos 6

Off

(64Kb)

Off

Off Off Off Off 1536 1 344 24

Off Off Off On Off 1472 1288 23

On Off Off On Off 1408 1232 22

Off On Off On Off 1344 1176 21

On On Off On Off 1280 1120 20

Off Off On On Off 1216 1064 19

On Off On On Off 1152 1008 18

Off On On On Off 1088 952 17

On On On On Off 1024 896 16

Off Off Off Off On 960 840 15

On Off Off Off On 896 784 14

Off On Off Off On 832 728 13

On On Off Off On 768 672 12

Off Off On Off On 704 616 11

On Off On Off On 640 5 60 10

Off On On Off On 576 504 9

On On On Of On 512 448 8

Off Off Off On On 448 392 7

On Off Off On On 384 336 6

Off On Off On On 320 280 5

On On Off On On 256 224 4

Off Off On On On 192 168 3

On Off On On On 128 112 2

On On On On On 64 56 1

Pos 6

On

(56Kb)

DS0

Switch 4 (Pos. 7 - 10) - These option switches are used to

set the following:

• Contiguous or Alternate DS0 assignment

• Set control lines to either ON or OFF

• Enable or disable data invert feature

Table 2-J displays the various options/positions controlled

by SW4, positions 7 - 10.

Table 2-J Switch SW4-7 thru SW4-10

Position Selection Switch S4 Description

7OffOnContiguous DS0s

Alternate DS0s

8OffOnControl Lines (CTS, DSR,CD) are set

On

to

Control Lines follow (DSR follows T1

sync, CTS follows RTS, and CD follows T1 density status)

9OffOnData Invert Disabled

Data Invert Enabled

10 — Not Used

Installation 2-4

1558D APS CSU/DSU

Page 13

DS0 channel speed assignments are sequentially

assigned beginning with DS0 #1 if SW4, Position

7 is set to the OFF positi on (contiguous channel

assignment). When SW4, Position 7 is set to ON,

the channels will be assigned in alternate DS0s,

beginning with DS0#1, DS0#3, etc.

ROM Configuration

The 1558D may be configured to boot operational parameters from the internal ROM (read only memory). To configure the 1558D to boot from ROM, set SW1, Position 2 and

SW1, Position 3 to the ON pos ition and SW1, Positio n 6 to

the OFF position. With these settings, the 1558D will

always boot (at power up) the unit configuration parameters

from the internal ROM settings. The ROM unit parameters

set when the user selects ‘boot from ROM’ are listed below:

• Slave Unit Operation

• B8ZS line coding, Path A and Path B

• ESF framing, Path A and Path B

• Revert mode, Disabled

• A v ailability timer set to 60 seconds

• Errored seconds set to 20

• Consecutively errored seconds set to 2

• Loss of frame set to Enabled

• Loss of signal set to Enabled

When the 1558D is being configured to boot from ROM the

user must still review and set the manually selected operating parameters listed below.

• LBO transmit level setting for both NET A and NET B

• 1558D unit address (if optional 1559 manager is installed)

• DSU Operating Speed (56kb - 1.536 Mbps)

• Rate Multiple, 56kb or 64kb

• DS0 Assignment Mode, Contiguous/Alternate

• Flow Control, O n/O FF

• Data Invert, Ye s/ No

RAM Configuration

The 1558D can be optioned to boot all alarm and operating

parameters from the battery backed RAM at power up. To

configure the 1558D for this mode of operation, simply set

SW1 , P osition 7 to ON, and S W1, Pos ition 8 to OFF. Keep

in mind that the user must still manually configure the following unit operating features:

• LBO transmit level setting for both NET A and NET B

• 1558D unit address (if optional 1559 manager is installed)

• DSU Operating Speed (56kb - 1.536 Mbps)

• Rate Multiple, 56kb or 64kb

• DS0 Assignment Mode, Contiguous/Alternate

• Flow Control, O n/O FF

• Data Invert, Yes/No

Manager Configuration

The 1558D may be configured and controlled using the

optional 1559 APSM site manager. The manager, co-located

with one or more 1558D units (up to 56), provides both

local and remote access and control/ alarm reporting to one

or more remote locations. When the 1558D has been configured to ‘Boot from Manager’, the 1559 can access and

change all options except the following:

• LBO transmit level setting for both NET A and NET B

• 1558D unit address (if optional 1559 manager is installed)

• DSU Operating Speed (56kb - 1.536 Mbps)

• Rate Multiple, 56kb or 64kb

• DS0 Assignment Mode, Contiguous/Alternate

• Flow Control, O n/O FF

• Data Invert, Yes/No

• Boot Mode (Switches, RAM, ROM, Manager)

To configure the 1558D to ‘Boot from Manager’, set S1- 7

to OFF and S1-8 to ON. For additional information concerning the use and operation of the 1559 manager, refer to

the TxPORT 1559 APSM reference manual.

Unit configuration of the 1558D APS is now complete. The

final steps to complete installation is to perform the 1 558D

preservice testing steps describe in th e following sections.

Pre-service Testing

The pre-service test checks the operational integrity of the

1558D unit and the T1 facilities (Net A and Net B). The

local pre-service testing is made independen tly of any DTE

or T1 connections. The end-to-end testing requires that the

T1 facilities be connected to the 1558D unit.

Local 1558D Test Diagram, Path A and Path B on page 2 -

8 illustrates the testing described in the following pre-ser-

vice steps. Pre-service Testing verifies the following:

• Path Integrity for Path A and Path B (local)

• Path Integrity for Path A and Path B (end-to-end)

The following T1 test equipment and miscellaneous cables

will be required to perform the 1558D pre-service tests :

• A Data BERT Test Set with a V.35 Interface

• One V.35 cable (1558 to T est Set)

Before proceeding, the user should read and understand the

background information presented in the following paragraphs concerning the basic operation theory of an APS service (also refer to Figure 3- 1 on page 3- 2 and Figure 3 -4

on page 3-10).

Installation 2-51558D APS CSU/DSU

Page 14

APS service is different from “normal” point- to- point T1

service. The 1558D APS unit accepts a single source signal

from the attached DTE equipment, verifies signal density,

duplicates the signal, and then transmits it on two T1 lines

(Path A, Transmit and Path B, Transmit). This duplication

and dual transmission is also done at the far-end APS equipment.

In addition to the un iqu e transm itting functi on p erform ed by

the APS, the unit also performs a unique receiving function.

There are two identical signals being received from two T1

lines by the APS equipment (Path A, Receive and Path B,

Receive). The 1558D constantly monitors both of these lines

for satisfactory signal performance. In the event that the

present active receive line exceeds an alarm value, the APS

will automatically switch the service from the failed receive

path to the standby receive path. The active receive signal is

the path connected to the DTE equipment.

Once a path has declared an alarm condition from Errored

Seconds, Consecutively Severely Errored Seconds, Loss of

Frame, or Loss Of Signal, it will not be available for service

until the Line Availability Timer has determined that the line

is available for service (line has run error free for the user

defined time period, 0 to 900 seconds, user definable). At

that time, the path alarm circuitry will be reset and then the

path will be ready to accept service.

Path A Pre-service Testing

Perform the following test steps to verify that the 1558D can

run error free data from the DTE V.35 port to the NET A

port and back (local loop test). The test setup for performing

this test is depicted in Local 1558D Test Diagram, Path A

and Path B on page 2-8.

4. Manually operate the front panel Path Select Switch to

the (A) position. This forces and locks the unit to Path A.

The following unit status LEDs associated with Path A

testing should be illuminated on the unit:

• Power A or B LED ON (green)

• Status ‘Locked’ LED ON (yellow)

• Status Path Active ‘A’ ON (green)

• The Path Status, Alarm A (red) LED may be ON or OFF

depending on the alarm timer setting (0 to 900 seconds)

configured in the 1558D.

5. The 1558D unit is now looped back to the V.35 DTE port

and the BERT test set should be running in sync and

error free. If not, verify that the test set speed and clocking settings are set to work with t he speed and clocking

options configured for the 1558D.

Path B Pre-service Testing

Perform the following test steps to verify that the 1558D can

run error free data from the DTE port to the NET B Port and

back (local loop test). The test setup for performing this test

is depicted in Figure 2-2.

1. Connect a data BERT test set to the DTE V.35 port at the

rear of the 1558D unit. The test set should be configured

to generate a BERT pattern (511, 2047, etc.) at the data

rate set previously by the user (56kb - 1.536Mbps). Also,

the test set clocking should be configured to operate per

the clocking options set in the 1558D (Internal, External). Typically, the 1558D will supply clocking to the

DTE equipment.

1. Connect a data BERT test set to the DTE V.35 port at the

rear of the 1558D unit. The test set should be configured

to generate a BERT pattern (511, 2047, etc.) at the data

rate set previously by the user (56kb - 1.536Mbps). Also,

the test set clocking should be configured to operate per

the clocking options set in the 1558D (Internal, External). Typically, the 1558D will supply clocking to the

DTE equipment.

2. Manually operate the DTE Loop Switch from the AUTO

position to the LL (L ocal Loop) positio n. This manually

loops the data coming from the DTE port back to the

DTE port.

3. Optionally, the user can insert a bantam test cord into the

NET A Bridge jacks (transmit and receive). This places a

metallic loop of the transmit signal of the 1558 D back to

the receive of the 1558D.

Verify that there is no connection at the NET A

jack when looping the 1558D at the Tx and Rx

bridge bantam jacks.

Installation 2-6

2. Manually operate the DTE Loop Switch from the AUTO

position to the LL (Local Loop) position. This manually

loops the data coming from the DTE port back to the

DTE port.

3. Optionall y, the user can insert a bantam test cord into the

NET B bantam Bridge jacks (transmit and receive). This

places a metallic loop of the transmit signal of the 1558D

back to the receive of the 1558D.

Verify that there is no connection at the NET B

jack when looping the 1558D at the Tx and Rx

bridge bantam jacks.

4. Manually operate the front panel Path Select Switch to

the (B) position. This forces and locks the unit to Path B.

The following unit status LEDs associated with Path B

testing should be illuminated on the unit:

• Power A or B LED ON (green)

• Status ‘Locked’ LED ON (yellow)

• Status Path Active ‘B’ ON (green)

1558D APS CSU/DSU

Page 15

• The Path Status, Alarm B (red) LED may be ON or OFF

depending on the alarm timer setting (0 to 900 seconds)

configured in the 1558D.

5. The 1558D unit is now looped back to the V.35 DTE port

and the BERT test set should be running in sync and

error free. If not, verify that the test set speed and clocking settings are set to work with t he speed and clocking

options configured for the 1558D.

Standalone pre-service testing verifies the operational

integrity of the 1558D using both the A and B p ath circuitry.

If either Path A or Path B fails, but not both, and the options

have been verified, contact the TxPORT Customer Service

for additional assistance.

End-to-End Pre-Service Testing

The following paragraphs describe pre-service APS testing

of the 1558D when it is initially connected to the T1 facilities (Path A and Path B) and is configured with another

1558D APS at the far-end.

After completing the stand-alone pre-service test procedures, the 1558D is ready to be connected to the Path A and

Path B T1 facilities for verification of end-to -end operation. These test procedures will verify the following:

• End-t o-End Performance of Path A

• End-t o-End Performance of Path B

• Ability to generate remote V.54 loop of 1558D port

The following steps assume that there is a near end unit and

a far-end unit and a technician with a BERT test is at both

locations (near and far).

1. Attach the Path A and Path B T1 facilities to the respective NET A and NET B modular jacks at the rear of the

unit (both near and far locations).

should be error free

repeat test for another 15 minutes. If errors are still

detected, a problem exists in the T1 facility. Refer problem to appropriate channels for resolution.

After completing the end-to-end BERT testing of both Path

A and Path B facilities, verify that the remote V.54 loop

operates properly by performing the following steps.

1. To verify that the loop operates, simply move the DTE

manual loop switch from the AUTO to the RL (remote

loop position). The unit responds by:

2. TEST LED indicator turns On (amber) and the 1558D

internally generates a V.54 loop code to the far-end for ≥

five seconds.

3. After approximately five seconds, the TEST LED indicator will change from amber to green if the V.54 loop

operated at the far-end. If the loop did not operate, the

TEST LED will turn from amber to red which indicat es

that the far-end unit did not respond to the reques ted V.54

DTE loop.

The remote V.54 lo op will rema in active until the DTE manual loop switch is moved from the RL position back to the

AUTO position. When this is done, the 1558D will generate

an UNLOOP command to the far unit. After approximately

≤ five seconds the front panel TEST LED indicator will

change from green to off.

This completes the end-to-end operational check for the

1558D. Remove all test equipment and verify that both units

are attached to the T1 facilities (NET A and B) and verify

that the DTE high speed data application is attached. After

performing these checks, the 1558D unit is now ready to

fully support proactive automatic protection switching and

performance monitoring.

at both ends. If errors are detected,

2. At both locations attach the data BERT test sets to the

1558D DTE port making sure that the speed and clocking settings match those configured in the 1558D unit.

3. Operate the Service Select switch on the 1558D to the

Path A position at both the near and far 1558D units.

This forces both units to use Path A as the receive signal

source. Once this is done, both t est sets should indicate

pattern sync at both the near and far locations. Run test

for a minimum of 15 minutes. The test results should be

error free

for another 15 minutes. If errors are still detected, a problem exists in the T1 facility. Refer problem to appropriate

channels for resolution.

4. Operate the Service Select switch on the 1558D unit to

the Path B position at both the near and far 1558D units.

This forces both units to use Path B as the receive signal

source. Run tes t for a minimum of 15 mi nutes. The test

at both ends. If errors are detected, repeat test

Installation 2-71558D APS CSU/DSU

Page 16

SUPV

SUPV

PWR

PWR

STATUS

STATUS

ALOCKED B

ALOCKED B

A

SELECT

A

PATH

SELECT

AUTO

PATH

AUTO

PATH

STATUS

ALM LOS LP

B

A

B

PATH

STATUS

ALM LOS LP

B

A

B

N

E

T

A

N

E

T

A

RX BRDG

TX BRDG

RX BRDG

TX BRDG

N

E

T

B

N

E

T

B

Bantam Patch Cord

Path NET A

RX BRDG

SD RD TEST

TX BRDG

RX BRDG

SD RD TEST

TX BRDG

PATH

STATUS

LOOP

NORM

RL

Bantam Patch Cord

Path NET B

PATH

STATUS

LOOP

NORM

RL

LL

LL

BERT Test Set

NET BNET A

COM BUS

IN OUT

1558A (near)

ON

S1 S2 S3

OFF

V.54 Loop Testing

Active Path (A or B)

V.35

DCE/V.35

DTE/V.35

Data Communications

BERT Test Set

Speed - 1.536 Mbps

Clocking - DCE

Pattern - QRSS

ON

OFF

1558A (Far)

ALARM

GND

N.O.

COM

S4

N.C.

DTE Port

Installation 2-8

V.54 Loop

Figure 2-2 Local 1558D Test Diagram, Path A and Path B

1558D APS CSU/DSU

Page 17

3. Operation

The 1558D automatically switches a customer high speed

data application from a “defective” T1 service to a standby

facility. This capability minimizes any actual service ou tage

to the customer. Typically, switching from the active to the

standby path is transparent to the customer with minimal

impact on data services. The 1558D Automatic Protection

Switch (APS) equipment is compatible with AT&T TR

54017, Addendum, February, 1991. When the 1558D is configured for internal ESF CSU operation, it is fully compatible with AT&T TR 54016 ESF CSU requirements.

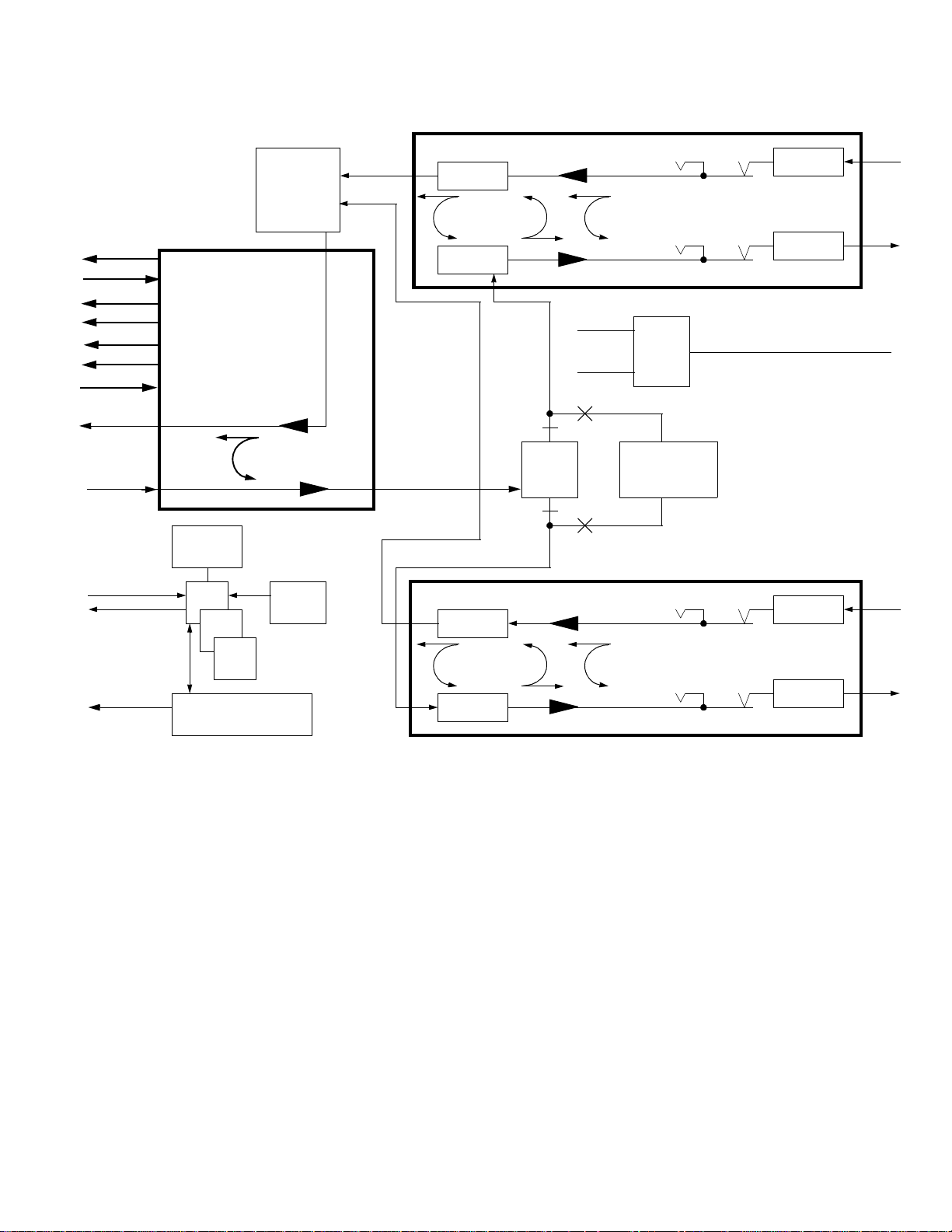

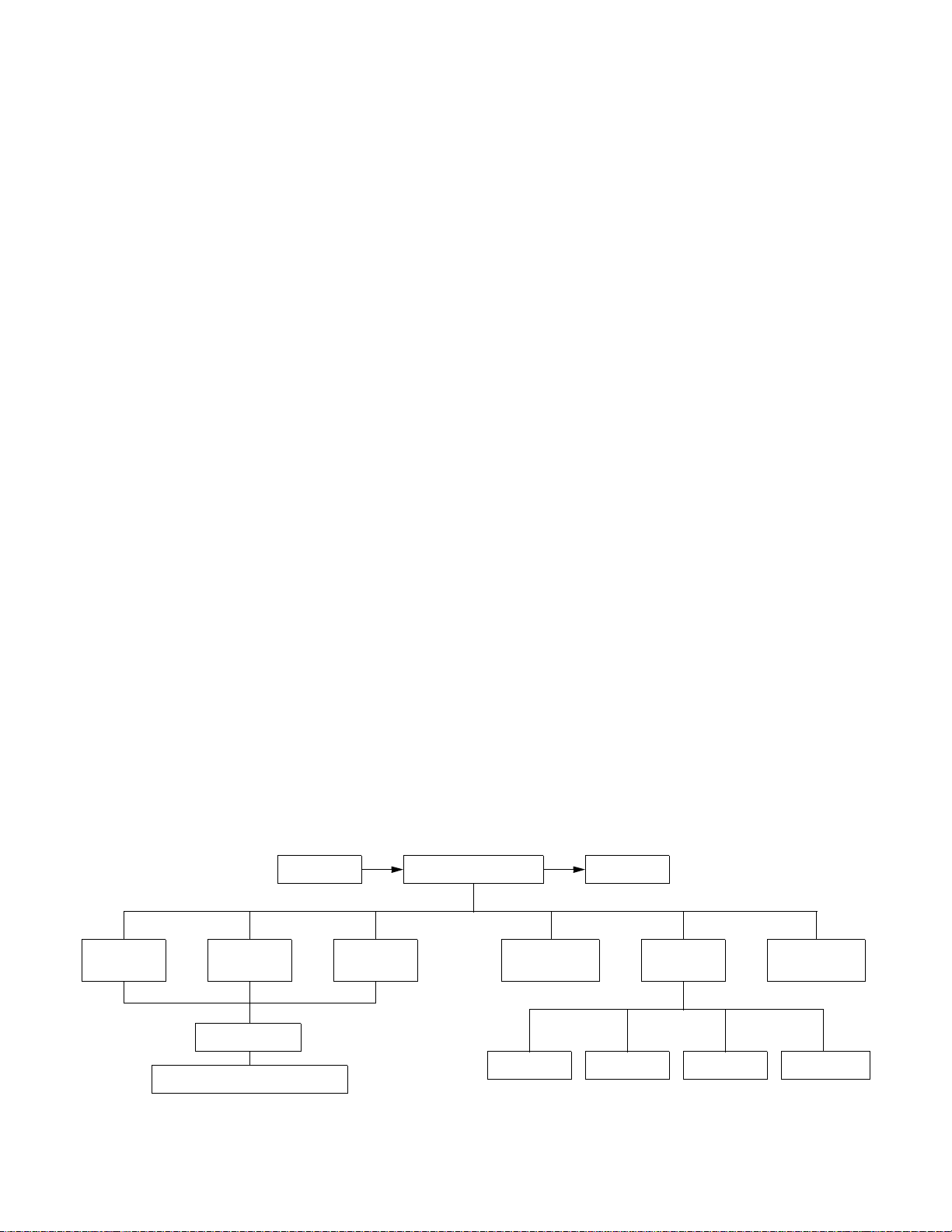

Applications

APS T1 protection service (per TR 54017) is either provided

by a Common Carrier (AT&T or MCI, etc.) or by the customer. When a Common Carrier provides the service, APS

equipment is installed in the central office and at the customer premise location(s). In the case of customer provided

APS, the customer installs a 1558D at both ends of the mission-critical service. Figure 3 -1 on page 3 - 2 depicts some

of the more common APS applications.

TxPORT APS equipment must be installed in pairs (one

TxPORT unit at one end of the service and another unit at

the other end of the service). One unit of the pair must be

configured for Master mode and the other as Slave mode.

Revertive and Non-Revertive Switching

The default configuration of the 1558D APS provides nonrevertive protection. Specifically, this means that service,

when transferred to the standby path, remains on the new

path until its performance degrades past the threshold settings. This is in contrast to the optional revertive mode

which returns service to the default path when it has

returned to a minimal level of error free performance.

Default Power-Up Path

The desire for geographically diverse routing may also

result in diversity in the medium of transmission (copper,

fiber, microwave, etc.). Certain media have higher intrinsic

performance criteria and are therefore the service of preference. To accommodate this preference, on power up, the

1558D APS unit forces the Path A as the active path.

Loss of Signal / Loss of Frame

When a LOS (Loss Of Signal) is detected on the active path

from the facility side of the APS, the 1558D will immediately switch the service to the standby facility (assuming

that the standby path is not in an alarm or a maintenance

state and the LOS alarm is enabled). If the standby path is in

an alarm state, the service will remain on the failed path

until the alarm condition clears on the standby path.

General Operation

The 1558D constantly moni tors the status and q uality of the

path signal (A and B) received on both the active access

path and standby access path. In general, the status and quality of the signal is based on the ESF parameters described in

Section 3.1 of TR 54016 and additional parameters

described in this document and in TR 54017, 1991. If the

performance of the active path is determined to be impaired,

the protection switching equip ment will au tomatically s elect

the standby access path if that path is ready for service (not

in an alarm or a maintenance state). The level of impairment

at which a transfer is accomplished is dependent upon the

alarm threshold values set in the equipment.

Following a switch, the former standby access path becomes

the active path. The 1558D continues to monitor both of the

incoming data streams after a switch has occurred. If both

active and standby access paths exceed their specified

thresholds, service will be maintained on the currently

active access path.

The switch from the active to the standby path is completely

independent of any external equipment. Switching from an

active path to a standby path only involves the receive paths

(Path A and Path B), not the transmit paths.

Optionally, in the event that there is a signal present but it is

so impaired that it results in a LOF (Loss Of Frame), the

1558D shall immediately switch after detecting 32 consecutive framing errors (approximately 93 milliseconds) to the

standby path (assuming that it is not in an alarm or a maintenance state and the LOF alarm is enabled).

Bipolar Violations

The 1558D APS units will not allow BPV

(Bipolar Violations) in the DS-1 data stream unless they are

used for B8ZS (Bipolar 8 Zero Substitution) encoding for

clear channel capability. Where used, the B8ZS code will be

employed to prevent the generation of an all zero octet.

CSU Loopbacks

Two ESF CSU loopbacks are provided in the 1558D unit

(CSU Line Loop and CSU Payload Loop). These loops can

be activated and deactivated by TR 54016 ESF messages, or

Inband per TR 62411. To insure maximum service availability, the following special conditions shall be applied to CSU

loopback actuation via the ESF data link messages:

• A CSU Line Loop or Payload can’t be activated on the

active path.

Operation 3-11558D APS CSU/DSU

Page 18

• If the CSU Line Loop or Payload Loop activate signal is

received by both paths simultaneously, no change of LB state

shall occur, regardless of their current states.

The “one-way” protection characteristic of the APS can

result in split-service operation. That is, service from the

1558D near APS to the 1558D far APS via one access path

while the 1558D far APS to the 1558D near APS service is

on the other access path. This is desirable to minimize service disruptions. However, normal maintenance and fault

isolation techniques can’t be carried out while service is

being delivered in the split mode. Service to and from the

APS must be forced to a common access, either manually or

via maintenance message, before the standby path LB can

be activated.

Forced/Locked Capability

A manual path select control is provided on the APS which

selectively forces service to either Path A or Path B and

effectively inhibits the other path from accepting service.

The manual service select control supersedes all automatic

transfers and forces the path not inhibited to carry the service, regardless of its status or condition.

APS Switching Time

Two times are of significance in specification of the APS

protection switching function. Th e first is the latency period

between the point when the switching criteria is satisfied on

the active access path and the point at which restoration

occurs on the standby access path. This time is less than 50

milliseconds.

The second is the duration of the switching transient event

associated with physically moving service from the active to

the standby access path. The 1558D APS can complete the

transition from active to standby path within 1 bit time.

The decision to transfer service from the active path to the

standby path, and vice-versa, is based on a priority system,

where the highest priority condition that sat isfies a transfer

controls, regardless of the conditions in lower priorities.

• Priority 1 – LB Status:

If the standby path’s LB is activated, then service shall

remain on the active path.

• Priority 2 – Failed Status:

If the standby path is in a failed state then service shall

remain on the active path. A failed state could be a result of

excess ES, CSES, LOS, or LOF.

• Priority 3 – Error Event Threshold Criteria:

This level of transfer is based on the occurrence of 1 second

events within the current 15 minute interval as described in

the TR 54017 Addendum.

Each error event requires storage for the following values:

threshold setting, current count, and a service transfer flag.

The threshold setting for the events (ES and CSES) may

range from 1 to 900 seconds. Transfer of service is based

only on these events.

If the threshold of an event is 0, that event is inactive and is

not a criterion for transfer of service. The current count tallies the total number of error event seconds within the current 15 minute interval. This count is reset at the beginning

of a new 15 minute interval.

The service transfer flag is set for the event that causes a

transfer of service. It allows the cause of the service transfer

to be determined even after the current count has been reset

at the beginning of a new interval. This flag is reset when a

service transfer acknowledgment message is received, which

is described in the next section.

DTE

Slave Slave

1

5

5

8

Master

Operation 3-2

T1, A

1

5

5

8

T1, B

1

5

5

7

Master

IXC Network

CO #1 CO #2

1

5

5

7

Master

T1, A

T1, B

1

5

5

DTE

8

IXC Local Loop APS application, both ends

T1, A

T1, A

1

Telco and/or IXC Network

5

5

DTEDTE

8

T1, B

Customer Provided end-to-end APS Application

T1, B

Slave

Figure 3-1 Typical APS Applications

1558D APS CSU/DSU

Page 19

APS Switching Parameters

Line Availability Timer

The 1558D unit switches from the active line to the standby

line based upon user definable alarm parameters. The alarm

performance parameters that can configured by the user are

Errored Seconds, Consecutively Severely Seconds, Loss of

Signal, and Loss of Framing. These alarm parameters and

their definition are described below.

Errored Sec onds (ES) - The user can define that the 1558D

switches from the active line to the s tandby line wh en a cer tain number of errored seconds have been detected during

the current 15 minute performance interval (900 seconds).

The ES threshold can be set from 0 (setting this p a rameter to

a zero value disables ES switching) to 900 seconds. The

1558D is configured at the factory with 20 errored seconds

as the default errored second value. The definition of an ES

is a second containing one or more CRC errors.

Consecutive Severely Errored Seconds (CSES) - Customers can define the 1558D switches from the active line to the

standby line when a certain number of Consecutive Severely

Errored Seconds have been detected during the current 15

minute performance interval (900 seconds). The CSES

threshold can be set from 0 (setting this pa rameter to a zero

value disables CSES switching) to 900 seconds. The 1558D

is configured at the factory with 2 consecutive severely

errored seconds as the default CSES value. The definition of

a CSES is when two or more consecutive SES have been

detected (note that CSES are transparent to the boundary

between 15 minute intervals). A severely errored second is

defined as a second containing 320 or more ESF errors.

Loss of Signal (LOS) - The user can define that the 1558D

switches from the active line to the s tandby line wh en a loss

of signal state has been detected. The 1558D is shipped

from the factory with loss of signal parameter enabled. The

definition of a loss of signal is when the receive signal from

the network contains ≥175 consecutive bit intervals containing all zeros (no pulses). The condition will be cleared when

one or more intervals contain a one.

Loss of Frame (LOF) - The user can define that the 1558D

switches from the active line to the s tandby line wh en a loss

of frame error state has been detected. The 1558D is shipped

from the factory with the loss of frame parameter enabled.

An LOF alarm condition occurs when 32 or more consecutive ESF frames contain frame bit errors.

When the current count of either ES or CSES is greater than

or equal to the threshold setting or when a LOS or LOF (if

enabled) is detected, the service shall be transferred from

the active path to the standby path as long as the standby

path is available (not in an alarm state or in a looped state).

A requirement for th e stan dby p ath to be available is tha t the

timer circuitry, described below, is not active and a LOS or

LOF condition does not exist.

The line availability timer is used to quantify when a path is

eligible to accept service.Line availability is determined by

the APS by observing a defined win dow of time in which no

active error events have occurred. The APS line availability

timer can be set to any value from 0-900 seconds. This

value represents the minimum amount of time, free of active

error events, that must expire before this path is declared as

ready to accept service. The factory default setting for the

line availability timer is 60 seconds.

The line availability timer requires storage for the timer setting and the active timer count. If the timer setting is 0, the

timer circuitry is disabled and the path is always available

for service, assuming that there are no active alarm conditions present. If the timer setting is set to a value ranging

from 1 to 900 seconds and a service transfer takes place, the

standby unit initializes the active timer count to the timer

setting. When the timer expires, thi s standby path becomes

available for a service transfer. This timed period must be

free of errors for all active events. If an error occurs, the

active timer count is reset.

When operated in the optional revertive mode, the path

availability timer serves to force restoration of service back

to the default access, Path A. That is, when service is

switched from Path A, it will remain on the standby path

(Path B) only until Path A’s availability timer expires. The

factory default is Revert set to OFF.

Status and Performance Information

The current status and performance parameters are stored in

the internal registers of the 1558D. Access to this information is via the 1559 APSM site manager (optional) or the

LAPS (local access protection switch) PC software. The

LAPS software is shipped with each 1558D unit.

The following information can be viewed by the user using

either the 1559 APS Site Manager or the provided APS

Local Access DOS Software.

• This path is currently carrying the service.

• This path is currently in a failed state.

• This path is currently in an inhibit state.

• The LB of this path is currently activated.

• The other path is currently in a failed state.

• The other path is currently in an inhibit state.

• The LB of the other path is activated.

• The manual locked control state.

• Current status

• Current interval Occurrences

• Current interval Duration

• Current Interval Timer

Operation 3-31558D APS CSU/DSU

Page 20

• Occurrences - Intervals, 1 through 96

• Duration - Intervals, 1 through 96

• Valid Intervals Total

• Occurrences, 24-hour value

• Duration, 24-hour total

• 30-day switch occurrence history

Configuration Modes

Any time that the 1558D unit is initi alized (power removed,

then reapplied), all key configuration data is read by the

1558D CPU and implemented based upon the particular

boot mode options selected by the user (see Installation on

page 2-1 for additional information). The four possible

BOOT mode configurations are described below:

1. Boot from Switches - At power up, the 1558D CPU

reads the values set at the rear panel option switches and

configures the unit per those switch settings.

2. Boot from Manager - At power up the CPU sends a

message to the 1559 APS manager for a download of

1558D unit configuration information. Note that this

mode requires that a 1559 site manager be installed.

3. Boot from RAM - At power up, the 1558D CPU reads

the unit configuration from the battery backed RAM

data.

4. Boot from ROM - At power up, the 1558D CPU reads

the factory firmware default values from ROM. The factory default ROM configuration option settings are:

• Slave operation

• Net A/B B8ZS line coding

• Net A/B ESF framing

• Revert mode, disabled

• Av ai lability ti mer set to 60 seconds

• Errored seconds set to 20

• Consecutively errored seconds set to 2

• Loss of frame set to enabled

• Loss of signal set to enabled

Front Panel Functions

The front panel of the APS unit contains several LED indicators, a SUPV access port, a path select switch, and several

bantam test access jacks. The following paragraphs briefly

describe the operation of these items (refer to Figure 3- 2

and the 1558D Configuration at the end of this manual).

Access protection software) application. This user interface

software allows the user to gain access to the unit configuration data, unit status, unit performance, and perform local

and remote loopback testing.

Electrically, the SUPV port is RS232 and the data format is

19.2 Kb, asynchronous. The cable used to connect the PC to

the SUPV port is a DB9 (female) to 6-pin modular cable.

This cable is provided with the 1558D unit. The pin functions for the SUPV port are shown in the following table.

Table 3-A SUPV Pinouts

Pin SUPV Port Wiring

1 Not Used

2 Ground

3Data Out

4 Data In

5 Ground

6 Not Used

Power Indicators

The 1558D has a green power LED indicator located on the

front panel. This indicator will be ON when the unit is connected to a nominal power source of 115 volts, AC. The

1558D draws approximately 75 milliamps. The AC power

cord is approximately 6 feet long and the plug end is an

industry standard 3-prong male connector.

Locked Indicator

The user can manually force and lock either the A or B T1

path as the active path by moving the PATH SELECT switch

from the AUTO position to either the A or B Path Select

positions. This action will force the 1558D to use the

selected path. Also, the 1558D is now manually locked to

this path and will not switch from it, even if the selected

path is in a failed state or subsequently fails. When the

1558D has been manually forced to either the A or B PATH,

the amber LOCKED LED indicator will be on. Moving the

PATH SELECT switch back to the AUTO position will turn

off the LOCKED LED and restore normal APS operation.

Placing the 1558D in a manually

locked mode prevents the unit from

performing automatic protection switching.

Status Indicators

The 1558D front panel STATUS A and B LEDs (green)

indicate which of the two T1 receive paths (A or B) is presently being utilized to provide service to the CPE equipment.

Supervisor Port

The front panel SUPV port allows the user to connect to the

1558D via a PC running the supplied APS LAPS (Local

Operation 3-4

Manual Path Selector Switch

The front panel manual PATH SELECT switch is used to

force the 1558D to use either the A or B path as the active

1558D APS CSU/DSU

Page 21

line. If the user momentarily moves the switch to either th e

A or B position and then returns the switch to the Auto position, the 1558D will force s ervice to the s elected path (A or

B). If the user leaves the switch in the manual A or B p osition, the 1558D will LOCK the service t o this path and turn

on the LOCKED LED.

Placing the 1558D in a manually

locked mode prevents the unit from

performing automatic protection switching.

Path Status Alarm Indicators

The 1558D alarm circuitry is driven by the alarm parameters

defined by the user at time of installation. The user definable alarm parameters are ES (errored seconds), CSES (consecutive severely errored seconds), LOS (loss of signal),

LOF (consecutive ESF errored frames). When any of these

alarm thresholds are met or exceeded, the ALARM LED

indicator (red) will be on for the path (A or B) that has

“failed”.

Path Status LOS Indicators

The 1558D LOS (loss of signal) Path A and B indicators

(red) will be ON when no T1 pulses are being detected on

the receive signal paths from the network. The definition of

loss of signal is no pulses for 175 bit times. The loss of signal state will be cleared when one or more data pulses are

detected on the receive path. After the pulses are detected,

the respective LOS indicator will be turned OFF.

Path Status Loop Indicators

The 1558D can respond to CSU loop/unloop commands

(both inband and FDL) and local or remote APS loop/

unloop commands. When a loop has been activated (Path A,

B, or DTE) the respective front panel LP LED indicator

(amber) will be ON. If no loop is active, the LP indicator

will be OFF.

Bantam Test Access Jacks

Bantam test access jacks and bridge/monitor jacks are provided to gain physical access to the T1 Path A (NET A), and

T1 Path B (NET B) facilities. The placement of the jacks is

depicted in Figure 4-10 on page 4 -10. The function of these

jacks is described in the following table.

Table 3-B. Bantam Jack Functions

Path A/B J a cks Function

Transmit (Tx) to

T1 facility (lower

left jack)

Receive (Rx) from

T1 facility (upper

left jack)

Transmit Bridge

(BRDG) to T1

facility (lower

right jack)

Receive Bridge

(BRDG) from T1

facility (upper

right jack)

Allows the user to gain access to the

transmit T1 path towa rd s the T1 f acil ity.

Inserting a test cord into this jacks disconnects the 1558D from the T1 facility

Allows the user to gain access to the

receiv e T1 path from the T1 fac ility.

Inserting a test cord into this jacks disconnects the 1558D from the T1 facility

Allows the user to bridge/monitor the

transmit T1 signal towards the T1 facility. Note, test set must be set to the

bridge termination mode.

Allows the user to bridge/monitor the

receiv e T1 sign al from the T1 fa c ility.

Test set must be set to the bridge termination mode.

DTE Status Indicators

Three DTE port status LED indicators provide a visual indication of the present state of the SD (send data), and RD

(receive data) signals. Also, the TEST LED indicates if a

manual or soft loop has been initiated by the user. A brief

description of these items is described in the paragraphs

below.

DTE SD LED

This LED (green) will indicate that data transitions are

present on the TD lead (from the DTE equipment). The

LED will be on for a mark and off for a space condition.

The LED will vary in intensity depending upon the relative

number of marks or spaces present at any given time.

DTE RD LED

This LED (green) will indicate that data transitions are

present on the RD lead (to the DTE equipment). The LED

will be on for a mark and off for a space condition. The

LED will vary in intensity de pending upon the relative number of marks or spaces present at any given time.

SUPV

PWR

STATUS

ALOCKED B

PATH

SELECT

AUTO

A

PATH

STATUS

ALM LOS LP

B

A

B

RX BRDG

N

E

T

A

TX BRDG

N

E

T

B

Figure 3-2 1558D Front View

RX BRDG

TX BRDG

PATH

STATUS

SD RD TEST

RL

LOOP

NORM

TxPORT

1558D

APS CSU/DSU

LL

Operation 3-51558D APS CSU/DSU

Page 22

TEST LED

This LED (tri-color amber, red, green) will indicate when

the DSU portion of the 1558D has been placed in a TEST

state either via remote loop command (V.54, Lp DTE Fac or

DTE Eq) or by placing the front panel manual loop switch

to either the RL or LL positions. The LED will be off when

the unit is not in a test state (no active loops either locally or

remotely). The LED will be ON (yellow when the manual

loop switch is in the LL position). The LED will be On

(yellow) when the manual loop switch is placed in the RL

(remote loop) position. In ð5 seconds, the yellow LED will

change to green if the far-end looped (V.54) or RED if th e

far-end did not loop.

Loopbacks

The 1558A unit supports several local and remote loopback

diagnostic capabilities allowing the user to quickly determine both facility and equipment problems. The types of