Page 1

Forecourt Controller

Forecourt Controller Interface

Interface

Installation Guide

Date: August 11, 2016

Page 2

Page 3

Forecourt Controller Interface Installation Guide

August 11, 2016

Verifone

88 West Plumeria Drive

San Jose, CA

Telephone: 408-232-7800

http://www.verifone.com

Printed in the United States of America.

© 2016 Verifone, Inc. All rights reserved.

No part of this publication covered by the copyrights hereon may be reproduced or copied in

any form or by any means - graphic, electronic, or mechanical, including photocopying, taping,

or information storage and retrieval systems - without written permission of the publisher.

The content of this document is subject to change without notice. The information contained

herein does not represent a commitment on the part of Verifone. All features and

specifications are subject to change without notice.

Verifone, Ruby SuperSystem, and Secure PumpPAY are registered trademarks of Verifone, Inc.

Ruby Card, iOrder, and Commander Site Controller are trademarks of Verifone. All other brand

names and trademarks mentioned in this document are the properties of their respective

holders.

®

, Inc.

95134

Page 4

Forecourt Controller Interface Installation Guide

Revision History

Date Description

June 25, 2012

November 2, 2012

May 1, 2014

June 19, 2014

September 19, 2014

March 25, 2015

August 11, 2016

Initial documentation release.

Added Warning below. Also, added new part numbers

for the FCI kit and manual.

Added references to Commander Site Controller and

current loop board changes.

Added Tokheim and Bennett

Added information regarding Tokheim and Bennett

RS485 board connections and added Current Loop

Jumper Settings.

Added SFC section.

Updated the Determing a Location section, Tokheim

TED, added a Megger Test note to the Connecting the

Dispenser Control Cables section, and added Product

Warranty information to the Introduction.

Page 5

WARNING!

1. This equipment is not intended to be repaired by the user. All

repairs must be performed by an Authorized Service Technician or

a Verifone VASC.

2. The AC Outlet must be within six feet of the Forecourt Controller

Interface unit.

3. The power supply cord must not be attached to the building

surface nor through wall, ceilings, floors, or similar openings in

the building structure.

4. Installation measures must be taken to prevent physical damage

to the power supply cord, including proper routing of the power

supply cord.

5. When replacing the cover on the Forecourt Controller Interface,

tighten the thumbscrews securely with a screwdriver.

Page 6

Page 7

Forecourt Controller Interface Installation Guide i

Contents

1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Before You Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Installing the Forecourt Controller Interface Box 7

Determining a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Existing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sites required to use the Smart Fuel Controller (SFC) . . . . . . . 8

Gilbarco Sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wayne Sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tokheim Sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bennett Sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preparing to Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the Forecourt Controller Interface Box. . . . . . . . . . . . 14

Installing the Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting the Dispenser Control Cables. . . . . . . . . . . . . . . . . 22

Connecting to Current Loop Boards . . . . . . . . . . . . . . . . . . 23

Connecting to RS485 Boards . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting to a Tokheim TED . . . . . . . . . . . . . . . . . . . . . . . . 29

Completing the Installation. . . . . . . . . . . . . . . . . . . . . . . . . . 30

August 11, 2016

Page 8

ii Forecourt Controller Interface Installation Guide

August 11, 2016

Page 9

1 INTRODUCTION

Forecourt Controller Interface Box

This guide provides instructions for installing the Verifone® Forecourt Controller

Interface (FCI) Box.

Product Warranty

For Product warranty information, go to

http://global.verifone.com/company/terms-and-conditions/

Description

The Forecourt Controller Interface allows fuel and DCR communications

between the dispensers and the Commander Site Controller.

Note: The Forecourt Controller Interface is not used for fuel communication

for Tokheim, Bennett, and sites required to use the Smart Fuel

Controller (SFC).

.

August 11, 2016

Page 10

2 Forecourt Controller Interface Installation Guide

The FCI box can hold up to four current loop or RS485 boards (or a combination

of both). Each board can support up to 16 fueling positions. The FCI box comes

with one current loop board installed. Additional boards must be ordered

separately.

• Current Loop Board (Kit # 29721-01) — Supports both current loop and

RS232 communications.

• RS485 Board (Kit # 29376-01) — Supports RS485 communications and must

be used for Dresser Wayne CAT/Ovation, Tokheim DPT, Bennett Secure

Payment Module (SPM), and Verifone Secure PumpPAY installations.

Before You Install

This section describes the components supplied with the Forecourt Controller

Interface box.

Unpacking

Carefully inspect the shipping carton and its contents for any damage that might

have occurred during shipment. If anything appears damaged, immediately file

a claim with the shipping company or carrier and notify your Verifone

representative.

Never use damaged equipment. A shock or fire hazard may exist if equipment is

energized in a damaged condition.

Contents

Remove the components from the packaging and place them on a table or

counter top. Make certain you have all the parts listed in Table 1 before you

begin. Contact the Verifone Technical Support Center if you are missing

anything.

Note: Keep the shipping carton and any packing material in case it is necessary

to move components from one location to another or to return the

equipment for service.

Note: One FCI box supports up to 32 fueling positions.

August 11, 2016

Page 11

Forecourt Controller Interface Installation Guide 3

Table 1: Forecourt Controller Interface Box (P/N M149-901-01-R)

Quantity Item Verifone Part Number

(1) unit Forecourt Controller Interface

Box

Includes:

- Locking ribbon cables (4)

- AC Power Cable

- Current Loop Board

(1) per unit Forecourt Controller Interface

Installation Guide

Table 2: Materials Provided by Installer

Quantity Item

Various lengths 18 AWG plenum rated twisted-pair cable (for example,

Belden P/N 88760). Lengths depend on configuration.

(20) per unit Wire nuts for splicing 18 AWG wires

(3) per unit 1-inch metallic conduit fittings

M149-901-01-R

DOC149-901-01-R,

Revision C00

(1) per unit 1/2-inch Romex cable clamp

(4) per unit #8, 1-1/2 inch wood screws

(4) per unit 1/8 inch toggle bolts. 3 inches long

General Requirements

August 11, 2016

Before you start, read the following important information:

1. Changes or modifications not expressly approved by Verifone, Inc., could

void the user’s authority to operate this equipment.

2. This equipment is not intended to be repaired by the user. All repairs

must be performed by an Authorized Service Technician or a Verifone

VASC .

3. All installations must comply with the requirements of the National

Electrical Code (NFPA 70), the Code for Fuel Dispensing Facilities and

Repair Garages (NFPA 30 and 30A), OSHA regulations, including Standard

29 CFR 1910.147, and all other applicable national and local codes.

Page 12

4 Forecourt Controller Interface Installation Guide

4. The circuit providing power to the Forecourt Controller Interface unit

must not power other devices. The AC outlet must be within six feet of

the Forecourt Controller Interface unit. Do not use extension cords.

5. The power supply cord must not be attached to the building surface nor

through walls, ceilings, floors, or similar openings in the building

structure.

6. Installation measures must be taken to prevent physical damage to the

power supply cord, including proper routing of the power supply cord.

7. Do not connect the Forecourt Controller Interface unit to the AC power

until the installation is complete.

8. Always wear an electrostatic wrist strap. Working on console electronics

without connecting to a ground or discharging static can damage

electronic parts.

9. When replacing the cover on the Forecourt Controller Interface

enclosure, tighten the screws securely with a Phillips screwdriver.

Safety Instructions

For safe disassembly and installation of this equipment, read and understand all

safety notices.

WARNING: You must be a Verifone Authorized Service Contractor

DANGER means: If you do not follow the instructions, severe injury or

WARNING means: If you do not follow the instructions, severe injury or

CAUTION means: If you do not follow the instructions, damage to the

CAUTION: High voltage. To be serviced by authorized service

(VASC) with training in the installation, service, or

maintenance of this equipment before working on it.

death will occur.

death can occur.

equipment can occur.

personnel only.

CAUTION: There is a risk of explosion if the battery is replaced by

an incorrect type. Dispose of used batteries according to

the instructions.

August 11, 2016

Page 13

Forecourt Controller Interface Installation Guide 5

DANGER: Disconnect all power to this equipment during

installation, service, or maintenace. Tag breakers to

prevent others from reconnecting power.

DANGER: This equipment is to be installed in an indoor location

only. Do not install this equipment in a hazardous

location.

WARNING: Make sure this equipment is correctly grounded. Failure

to do so can cause injury or damage to the equipment.

August 11, 2016

Page 14

6 Forecourt Controller Interface Installation Guide

August 11, 2016

Page 15

2 INSTALLING THE FORECOURT

C

ONTROLLER INTERFACE BOX

This chapter provides instructions for installing the Forecourt Controller

Interface (FCI) box.

You can install the FCI box with

• Up to four current loop boards

• Up to four RS485 boards

• Any combination of current loop boards and RS485 boards (up to four

boards)

Warning:Before you begin to install the Forecourt Controller Interface box,

be sure all power to the existing distribution box and PAM or

Electronics Cabinet is disconnected at the main panel. Multiple

disconnects may be required to de-energize these devices. (Refer to

the General Requirements section in Chapter 1.)

Determining a Location

August 11, 2016

The Forecourt Controller Interface box must be mounted in an indoor location.

Locate the box at least 18 inches above the floor in an area where liquids will

not be spilled onto it.

Note: The Forecourt Controller Interface box is to be mounted in an indoor

location only. The box is not to be used in a hazardous location. Do not

mount the Forecourt Controller Interface in a fuel dispenser.

Avoid the following locations:

• DO NOT install less than six inches near or inside electrical panels

• DO NOT install less than six inches near submersible pump controllers or

along side wiring to these devices

• DO NOT install less than six inches near submersible pump relays

Page 16

8 Forecourt Controller Interface Installation Guide

Distribution Box

Dispenser Communications Cables

Existing Equipment

Note: Dispose of all removed components in an appropriate manner as

approved by the site owner.

Sites required to use the Smart Fuel Controller (SFC)

Note: The Commander Site Controller application must be at base 32 or higher

OR supports POP Discounts and loyalty using the Smart Fuel Controller.

If the site is required to use the Smart Fuel Controller for fuel, then the Current

Loop boards are not needed in the FCI box. The FCI box and RS-485 boards are

still needed for the DCRs. A RS-232 cable is required from the Commander Site

Controller to the SFC box. See the Smart Fuel Controller Installation Guide on

the Verifone Premier Portal at Petro Downloads > Verifone Fuel Controllers >

Smart Fuel Controller for more information.

Gilbarco Sites

If there is an existing distribution box at the site, disconnect the cables from the

box and remove it. It is not used with the Forecourt Controller Interface. The

Forecourt Controller Interface box can be mounted in the same location.

The dispenser control cables will be reconnected to the Forecourt Controller

Interface.

Also, disconnect and remove the PAM. It is not used with the FCI box.

August 11, 2016

Page 17

Forecourt Controller Interface Installation Guide 9

PAM

Dispenser Control Cables

Cables to Electronics

Cabinet

Outside of Distribution Box

Wayne Sites

If there is a Wayne distribution box, disconnect all the dispenser control cables.

The terminals on the distribution box are marked (

+) wires. The dispenser control cables will be reconnected to the FCI. Also,

(

disconnect the cables that go to the Electronics Cabinet.

+) and (–); mark the positive

Remove the distribution box. It is not used with the FCI. The FCI box can be

mounted in the same location.

Remove the Electronics Cabinet and all the cables connected to it. It is not

reused.

August 11, 2016

Page 18

10 Forecourt Controller Interface Installation Guide

Wayne Electronics Cabinet

August 11, 2016

Page 19

Forecourt Controller Interface Installation Guide 11

Tokheim DHC/VXDHC

To k he i m S i t e s

The FCI Box does not control Tokheim fuel communications. Tokheim sites

require a VXDHC or DHC box. Use a RS-232 cable (P/N 13836-XX) and red null

modem connector (P/N 13581-01) to connect the Commander Site Controller to

the VXDHC or DHC.

Note: If the Verifone Site Controller is being replaced rather than a new

installation, use the existing VXDHC/DHC box, cable and connector as

described above.

August 11, 2016

Page 20

12 Forecourt Controller Interface Installation Guide

Bennett 515 Box

Bennett Sites

The FCI Box does not control Bennett fuel communications. Bennett sites

require a 515 Box. Use a RS-232 cable (P/N 13836-XX) and black straight through

connector (P/N 13641-01) to connect the Commander Site Controller to the 515

Box.

Note: If the Verifone Site Controller is being replaced rather than a new

installation, use the existing 515 box, cable and connector as described

above.

August 11, 2016

Page 21

Forecourt Controller Interface Installation Guide 13

Thumbscrews (2)

Preparing to Install

Before you begin the installation, loosen the two thumbscrews that attach the

cover of the FCI enclosure. Push the cover forward 1/2- inch and lift.

August 11, 2016

Page 22

14 Forecourt Controller Interface Installation Guide

Ribbon Cable

Connector

Power

Connector

Loop Cable Connectors

Installing the Forecourt Controller Interface Box

This section describes how to install the distribution boards and mount the FCI

box on the wall.

Installing the Boards

Note: The Forecourt Controller Interface box come with one current loop

board installed. Additional boards must be ordered separately.

Installing the Current Loop Boards

The current loop boards (Kit # 29721-01) support both current loop and RS232

communications. (For RS485 communications, go to the section Installing the

RS485 Boards.)

To install the current loop boards:

1. Locate the current loop board (P/N 29521-01-R) provided with the

Current Loop Board kit.

August 11, 2016

Page 23

Forecourt Controller Interface Installation Guide 15

Mounting Post Locations

1

2

3

4

2. Locate the mounting posts on the FCI box.

August 11, 2016

Page 24

16 Forecourt Controller Interface Installation Guide

Screw Locations (4)

COM Ports

3. Position the first current loop board over the mounting posts in

location 1 above, and secure the board to the posts using the four screws

(P/N SCR-0001) provided with the Current Loop Board kit.

August 11, 2016

Page 25

Forecourt Controller Interface Installation Guide 17

Connector Blocks (8)

Ribbon Cable

Connector

Power

Connector

4. Repeat these steps to install additional boards, installing the boards in

locations 2, 3, and 4 as shown in the picture in step 2 above.

Jumper Settings for Current Loop Boards

Verify that the jumper settings below are correctly set for Commander.

– JP9—CL current selector: 20mA, 30mA, or 45mA (default)

– JP10—Select Communication mode: 1-2=Current Loop (CL),

2-3=RS232(default)

– JP11—A test point ground that should remain empty

(no jumper)

– JP13—Select Master/Client board: 1-2=Master, 2-3=Client

Installing the RS485 Boards

The RS485 Board 8-Channel Interface Kit (Kit # 29376-01) supports RS485

communications and must be used for Dresser Wayne CAT/Ovation, Tokheim

DPT, Bennett Secure Payment Module (SPM), and Verifone Secure PumpPAY

installations.

To install the RS485 boards:

1. Locate the RS485 board (P/N 18806-01-R) provided with the RS485 kit.

August 11, 2016

Page 26

18 Forecourt Controller Interface Installation Guide

Mounting Post Locations

1

2

3

4

2. Locate the mounting posts on the FCI box.

August 11, 2016

Page 27

Forecourt Controller Interface Installation Guide 19

Screw Locations (4)

COM Ports

3. Locate the four screws (P/N SCR-0001) provided with the RS485 Board

kit.

4. Position the RS485 board over the mounting posts in location 1 above.

Secure the board to the posts using the four screws.

August 11, 2016

5. Repeat these steps to install additional boards, installing the boards in

locations 2, 3, and 4 as shown in the picture in step 2 above.

Jumper Settings for RS485 Boards

– JP3—Connects signal ground (GND) to chassis ground (default is

connected)

Note: The jumper settings should not be changed.

Page 28

20 Forecourt Controller Interface Installation Guide

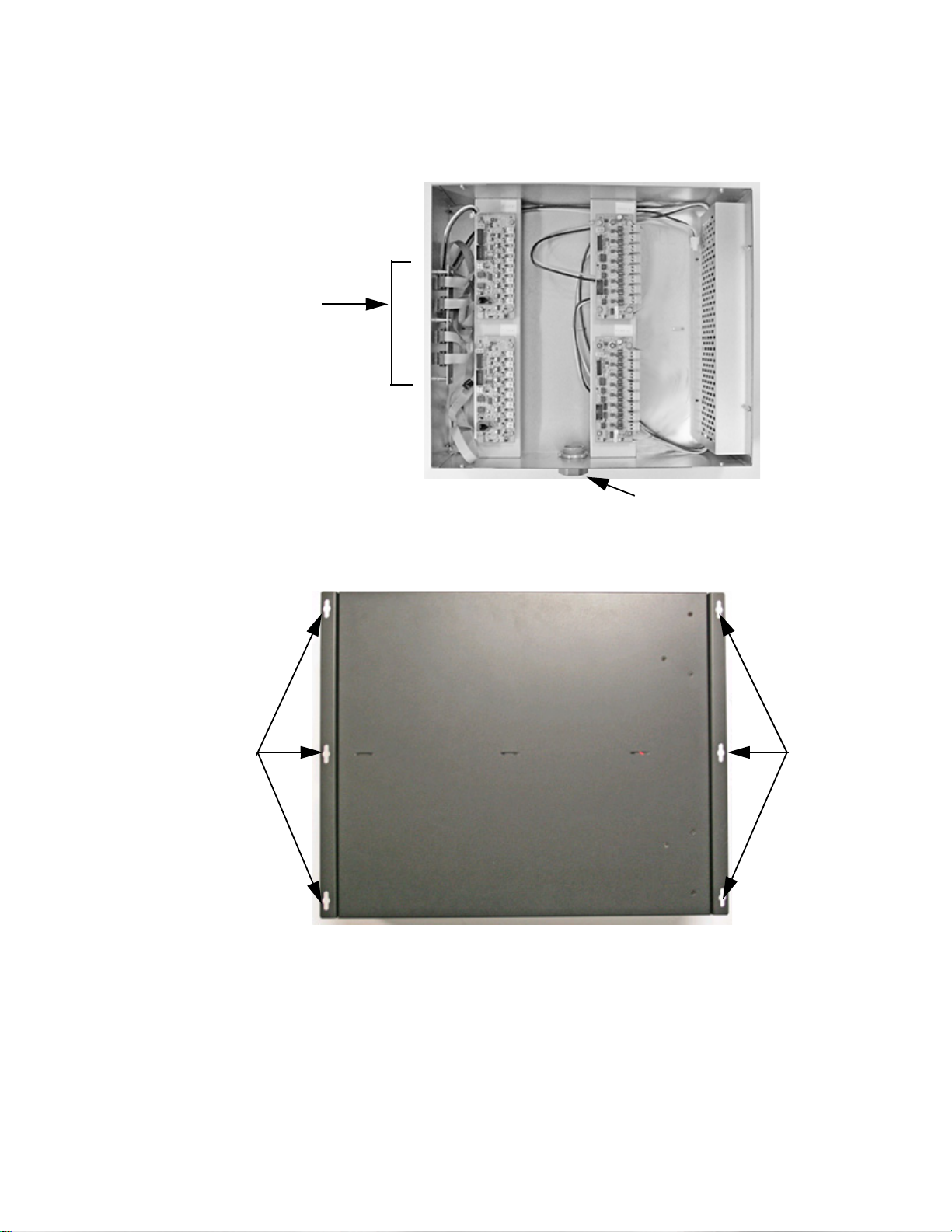

Knockout Locations

Mounting the Unit

Before you mount the unit, remove one or more of the 1-inch knockouts into

which to install 1-inch conduit fittings for routing the dispenser control wires.

The number of knockouts to be removed will depend on how many dispenser

control wires there are. It will be easier to do this now than after the units are

mounted.

Install 1-inch metallic conduit fittings into the knockout holes where the

dispenser control wires will enter the enclosure. More than one fitting may be

needed, depending on the number of dispenser control wires.

Mount the FCI unit in the orientation shown in to the following illustration. This

provides convenient access to the dispenser control cables, which, at most

sites, come up through a conduit in the floor.

August 11, 2016

Page 29

Forecourt Controller Interface Installation Guide 21

COM

Ports

Forecourt Controller Interface Box

Conduit Fitting

Screw

Holes

Screw

Holes

Rear View

Mount the FCI box securely to the wall with toggle bolts through the pre-drilled

tabs.

August 11, 2016

To mount the FCI Box:

1. Using the box as a template, mark the hole placement for the four toggle

bolts on the desired wall location where the distribution boards can be

easily connected to the existing dispenser control cables.

Page 30

22 Forecourt Controller Interface Installation Guide

Dispenser Control

Cable

2. For mounting into drywall, use four 1/8-inch toggle bolts, 3 inches long.

To install the toggle bolts:

a. Open a hole of the recommended size (usually 3/8 or 1/2 inch) at the

center of the holes marked in step 2.

b. Mount the toggle bolts to the pre-drilled tabs on the unit.

c. Push the toggle bolts through the wall hole and tighten securely.

Connecting the Dispenser Control Cables

Note: Before connecting the dispenser control cables to the FCI box, the

Megger Test must be used. The Megger Test checks the quality of the

cable insulation. The dispenser control cables routed from the dispenser

to the FCI box must not be less than six inches to the proximity of power

or other data cables.

Dispensers are connected to the FCI using the existing dispenser control cables

previously connected to the distribution box.

1. Locate the dispenser control cables previously removed from the

distribution box.

2. Do one of the following:

– For Gilbarco dispensers, remove the wire nuts that connect the

dispenser control wires to the existing distribution box connectors.

Set aside the wire nuts for reuse.

– For Wayne dispensers, strip 1/2-inch of insulation from each wire on

the dispenser control cable twisted pair, if not already stripped.

August 11, 2016

Page 31

Forecourt Controller Interface Installation Guide 23

Conduit

Fitting

Dispenser Control

Wires

Positive (+) Wire

Protective

Tips

3. Route the dispenser control wires through the conduit fittings installed

earlier.

Connecting to Current Loop Boards

1. Locate the loop cables provided with the Current Loop Board kit. Eight

loop cables can be connected to each distribution board. Connecting all

cables will result in connections for 8 dispensers. These cables will be

spliced to the dispenser control cables.

2. Remove the black protective tips and strip I/2-inch from each wire and

twist the ends. Leave the protective tips on wires that will not be spliced

to dispenser control cables.

August 11, 2016

Page 32

24 Forecourt Controller Interface Installation Guide

Twisted

Loop

Cables

Pair

Loop Cables

Connected to

Board

3. Using wire nuts, connect one dispenser control wire to each FCI current

loop wire. Connect positive (

distribution board. Note that it might be necessary to reverse some of

the connections after you check the communications from the FCI to the

dispensers.

Note: At sites that have both Gilbarco and Wayne dispensers, both can

be connected to the same FCI unit but the dispenser control

wires must be connected to different distribution boards.

4. Connect all loop cables to the loop cable distribution board.

+) to positive. Repeat for each current loop

August 11, 2016

Page 33

Forecourt Controller Interface Installation Guide 25

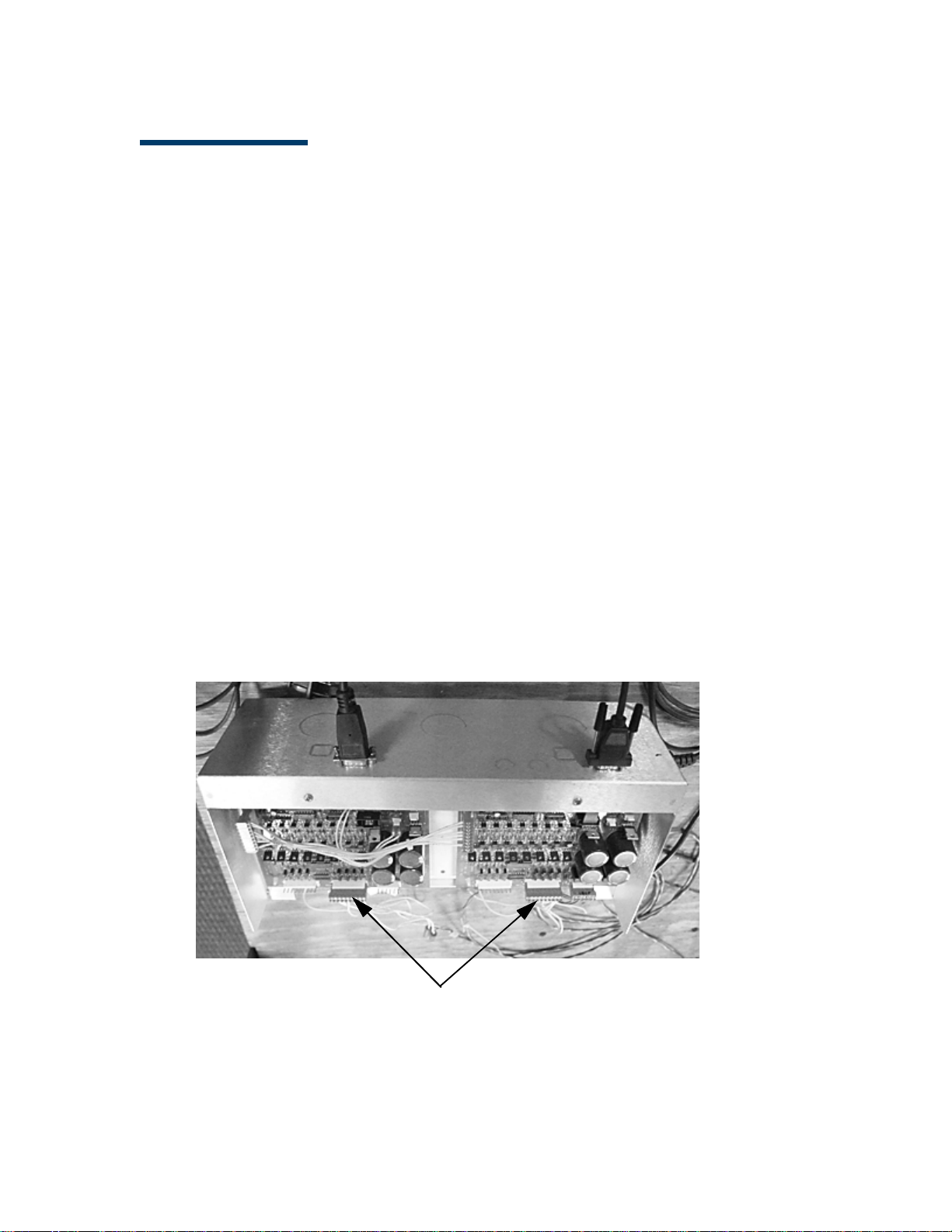

Board 1 Board 2 Board 3 Board 4

Power

Cable

Ribbon

Cable

5. Connect the power cable and one of the communications ribbon cables

to the current loop board. Connect the ribbon cables in the order shown.

6. Repeat steps 1 - 5 to connect additional current loop boards.

August 11, 2016

Page 34

26 Forecourt Controller Interface Installation Guide

Single Wire

Chassis Ground

Drain/Ground Wires

Connector Blocks (8)

Connecting to RS485 Boards

Note: At sites with Tokheim and Bennett, all of the drain or ground wires are

tied together to a single wire connected to chassis ground using a wire

nut as shown below.

The RS485 board has eight connector blocks, which can support up to 16 fueling

points with two DCR wires connected to each block, or up to 32 fueling points

with four wires connected to each block.

1. Unplug the required number of connector blocks for the number of

dispenser points.

August 11, 2016

Page 35

Forecourt Controller Interface Installation Guide 27

Connector Block with 2 Wires

Screws

—

+

Connector Block with 4 Wires

Screws

—

+

2. Strip 1/4-inch of insulation from each DCR wire and twist the ends.

Connect the wires to the connector blocks and secure by tightening the

screws on the connector block.

3. Insert the connector blocks back into the RS485 board.

August 11, 2016

Page 36

28 Forecourt Controller Interface Installation Guide

Board 1 Board 2 Board 3 Board 4

Power

Cable

Ribbon

Cable

4. Connect the power cable and one of the ribbon cables to the current

loop board. Connect the ribbon cables in the order shown.

5. Repeat steps 1 - 4 to connect additional RS485 boards.

August 11, 2016

Page 37

Forecourt Controller Interface Installation Guide 29

Connecting to a Tokheim TED

The TED will connect to a single channel of an RS485 board in the FCI. Tokheim

uses three wires for DPT connections (Positive, Negative and Ground). The single

ground wire coming into the FCI from the TED should be grounded to the lower

left mounting screw of the RS485 board.

August 11, 2016

Page 38

30 Forecourt Controller Interface Installation Guide

COM1 COM2 COM3 COM4

AC Power

Connector

Completing the Installation

This section provides instructions for closing up the box, connecting

communications cables between the Forecourt Controller Interface and the

Commander Site Controller, and connecting to the AC power supply.

1. Replace the cover on the enclosure and secure by tightening the two

thumbscrews.

2. Connect the serial cables with RJ45 connectors (provided with the

Commander Site Controller) to the RJ45 ports on the front of the FCI

box.

3. Route the serial cables to the Commander Site Controller and connect

according to the instructions in the Commander Site Controller

documentation.

Caution: When installing the cables, make sure they are protected from

damage or accidental disconnection. Route cables along a wall or

under a counter and secure with cable ties or clips. Do not route

cables near sources of possible interference, such as fluorescent

lights, microwaves, intercoms and so forth.

4. Locate the AC power cord provided with the unit.

5. Locate the AC power connector on the end of the FCI enclosure.

August 11, 2016

Page 39

Forecourt Controller Interface Installation Guide 31

6. Plug the female end of the power cord into the power connector on the

FCI box. Make sure the connector locks securely in place.

7. Plug the other end of the power cord into the dedicated AC outlet.

Caution: The circuit providing power to the FCI unit must not power other

devices. The AC outlet must be within six feet of the FCI unit. Do not

use extension cords.

The power supply cord must not be attached to the building surface

nor through walls, ceilings, floors, or similar openings in the

building structure.

Installation measures must be taken to prevent physical damage to

the power supply cord, including proper routing of the power supply

cord.

8. Restore power to the circuit.

August 11, 2016

Loading...

Loading...