Verderflex Dura 45 Operating Manual

Peristaltic Hose Pump

Operating Manual Dura 45

Version 3.1v-07/2016

Print-No. 01

Dura 45 3.1v-07/2016

Version 3.1v-07/2016

Print-No. 01

2 | Page

Dura 45

The information in this document is essential for the safe operation and servicing of Verderex®

pumps. This document must be read and understood thoroughly prior to installation of unit,

electrical connection and commissioning.

Dura 45 3.1v-07/2016

1. About this document

1.1 Target groups

1.2 Warnings and symbols

2. Safety

2.1 Intended use

2.2 General safety instructions

2.2.1 Product safety

2.2.2 Obligation of the operating company

2.2.3 Obligation of personnel

2.3 Specic hazards

2.3.1 Hazardous pumped liquids

2.3.2 Lubricants

2.3.3 Sharp edges

3. Layout and function

3.1 Design details

3.2 Labelling

3.2.1 Name Plate

3.3 Layout

3.4 Bearings and Lubrication

4. Transport, storage and disposal

4.1 Transport

4.1.1 Unpacking and inspection on delivery

4.1.2 Lifting

4.2 Treatment for storage

4.3 Interim storage before installation

4.4 Disposal

5. Installation and connection

5.1 Preparing for installation

5.1.1 Checking the ambient conditions

5.1.2 Preparing the installation site

5.1.3 Preparing the foundation and surface

5.2 Installation at site

5.3 Planning the pipes

5.3.1 Specifying supports and ange connections

5.3.2 Specifying nominal diameters

5.3.3 Specifying pipe lengths

5.3.4 Optimizing cross-section of pipe work

5.3.5 Providing safety and control devices

(recommended)

5.4 Shimming

5.5 Electrical connection

5.5.1 Installing motor and gearbox (where not supplied)

5.5.2 Installing motor gearbox on bare-shaft pump

5.5.3 Connecting to power supply

5.6 Installing the hose

5.6.1 Inserting the hose

5.6.2 Fitting the port ange

5.6.3 Filling the pump with lubricant

5.6.4 Fitting the inspection window

5.7 Connecting the pipes

5.7.1 Installing the piping

6. Operation

6.1 Pre-commissioning the pump

6.1.1 Checking the direction of rotation

with dry pump

6.1.2 Starting the pump

6.1.3 Switching off

6.2 Operation

6.2.1 Switching on

6.2.2 Switching off (Refer to -> 6.1.3)

6.3 Shutting down the pump

6.4 Start-up following a shutdown period

6.5 Operating the stand-by pump

7. Maintenance

7.1 Inspections

7.2 Maintenance

7.2.1 Cleaning the pump

7.2.2 Maintenance schedule

7.3 Repairs

7.3.1 Preparations for dismounting

7.3.2 Returning the pump to the manufacturer

7.3.3 Rebuild / Repair

7.3.4 Re-alignment of Rotor after a stall

7.4 Hose change

7.4.1 Dismounting the hose

7.4.2 Re-installing the hose, port anges, lubricant

rell and tting the inspection window

7.5 Ordering spare parts

8. Storing pumps and hoses

8.1.1 Pre-Storage Actions

8.1.2 Cleaning Protocol for hoses

8.1.3 Storage Conditions

9. Troubleshooting

9.1 Pump malfunctions

10. Appendix

10.1 Technical Specications

10.1.1 Pump Specications

10.1.2 Ambient conditions

10.1.3 Tightening torques

10.1.4 Preservatives

10.1.5 Cleaning agents (After hose is removed)

10.1.6 Lubricants

10.1.7 Shimming

10.1.8 Rotor setting distance

11. List of Figures and Tables

11.1 List of gures

11.2 List of tables

12. Declaration of conformity according

to EC Machine Directive

Table of contents

3 | Page

Dura 45 3.1v-07/2016

4 | Page

Verderex Peristaltic pump, Dura 45, has been developed according to the latest technology and

subject to continuous quality control. These operating instructions are intended to facilitate familiarization with

the pump and its designated use. The relevant information will act as a guideline for you in operating the pump;

alternative courses of action are also described should you be unable, for any reason, to follow those

procedures initially given. You are advised to follow these guidelines to achieve maximum efciency.

These operating instructions Do not take into account local regulations; the operator must ensure that such

regulations are strictly observed by all, including the personnel called in for installation.

1. About this document

1.1 Target groups

Operating company

Qualied personnel, tter

Table 1 Target groups and their duties

Read, observe and follow this manual and the other applicable

documents, especially all safety instructions and warnings.

Symbol

Table 3 Symbols and their meaning

Meaning

Safety warning sign in accordance with DIN 4844 - W9

Take note of all information highlighted by the safety warning sign

and follow the instructions to avoid injury or death.

Instruction

Multiple-step instructions

1., 2.,

Precondition

Cross-reference

g

Information, recommendation

1.2 Warnings and symbols

Warning

Immediate acute risk

Potential acute risk

Potential hazardous situation

Potential hazardous situation

Death, serious bodily harm

Death, serious bodily harm

Minor bodily harm

Material damage

Table 2 Warnings and consequences of disregarding them

Risk Level Consequences of disregard

DANGER

WARNING

CAUTION

NOTE

Keep this manual available at the operation site of the equipment,

also available for later reference.

Ensure that personnel read and follow the instructions in this

manual and the other applicable documents, especially all safety

instructions and warnings.

Observe any additional rules and regulations referring to the system.

Target groups Duty

Dura 45 3.1v-07/2016

5 | Page

2. Safety

The manufacturer does not accept any liability

for damage resulting from disregard of this

documentation.

2.1 Intended use

Only use the pump to handle compatible uids as

recommended by the manufacturer

(g 10.1 Technical specications).

Adhere to the operating limits.

Consult the manufacturer regarding any other use

of the pump.

Pumps delivered without a motor must be tted

with a motor in accordance with the provisions of

EC Machine Directive 2006/42/EC.

Prevention of obvious misuse (examples)

Note the operating limits of the pump with regard to

temperature, pressure, ow rate and motor speed

(g 10.1 Technical specications).

Do not operate the pump while the inlet/outlet valve

is closed.

Only install the pump as recommended in this manual.

For example, the following are not allowed:

– Installing the pump without proper support.

– Installation in the immediate vicinity of extreme hot

or cold sources.

2.2 General safety instructions

Observe the following regulations before carrying

out any work.

2.2.1 Product safety

These operating instructions contain fundamental

information which must be complied with during

installation, operation and maintenance. Therefore

this operating manual must be read and

understood both by the installing personnel and

the responsible trained personnel / operators prior

to installation and commissioning, and it must

always be kept easily accessible within the

operating premises of the machine.

Not only must the general safety instructions laid

down in this chapter on “Safety” be complied with,

but also the safety instructions outlined under

specic headings.

Operate the pump only if the pumping unit and all

associated systems are in good functional

condition.

Only use the pumping system as intended, fully

aware of safety and risk factors involved,

and in adherence to the instructions in this manual.

Keep this manual and all other applicable documents

complete, legible and accessible to personnel at all

times.

Refrain from any procedure or action that would pose

a risk to personnel or third parties.

In the event of any safety-relevant faults, shut down the

pump immediately and have the malfunction

corrected by qualied personnel.

The installation of the pump, associated pipe work and

electrical ttings must comply with the requirements

of installation given in this manual and any local

national or regional health and safety regulations.

2.2.2 Obligation of the operating company

Safety-conscious operation

Ensure that the following safety aspects are observed

and monitored:

– Adherence to intended use

– Statutory or other safety and accident-prevention

regulations

– Safety regulations governing the handling of

hazardous substances if applicable

– Applicable standards and guidelines in the country

where the pump is operated

Make personal protective equipment available

pertinent to operation of the pump; as required.

Qualied personnel

Ensure that all personnel tasked with work on the pump

have read and understood this manual and all other

applicable documents, including the safety,

maintenance and repair information, prior to use or

installation of the pump.

Organize responsibilties, areas of competence and

the supervision of personnel.

Have all work carried out by specialist technicians

only.

Ensure that trainee personnel are under the

supervision of specialist technicians, at all times, when

working on the pumping system.

Safety equipment

Provide the following safety equipment and verify its

functionality:

– For hot, cold and moving parts: safety guarding

should be provided by the operating company.

– For potential build up of electrostatic charge:

ensure appropriate grounding if and when

required.

Dura 45 3.1v-07/2016

6 | Page

2.3.3 Sharp edges

Pump parts, such as the shims, can be sharp

– Use protective gloves when carrying out any

work on the pump

3. Layout and function

Peristaltic hose pump, Verderex Dura, is simple by

design in its construction and operation. The medium

to be pumped does not come into contact with any

moving parts and is totally contained within a robust,

heavy-duty hose, which consists of an inner layer, two

– six reinforcement layers and an outer layer. A rotor

passes along the length of the hose, compressing it.

This motion forces the contents of the hose directly in

front of the rotor to move forward along the length of

the hose in a ‘positive displacement’, peristaltic

movement. In the wake of the rotor’s compressing

action, the natural elasticity of the polymer reinforced

rubber forces the hose to open and regain its round

prole, creating suction pressure, which recharges the

pump.

3.1 Design details

Verderex Dura is a twin lobe, single rotor,

peristaltic pump with quick-t tapered port ange

design which clamps and seals in one easy movement

to speed hose replacement.

3.2 Labelling

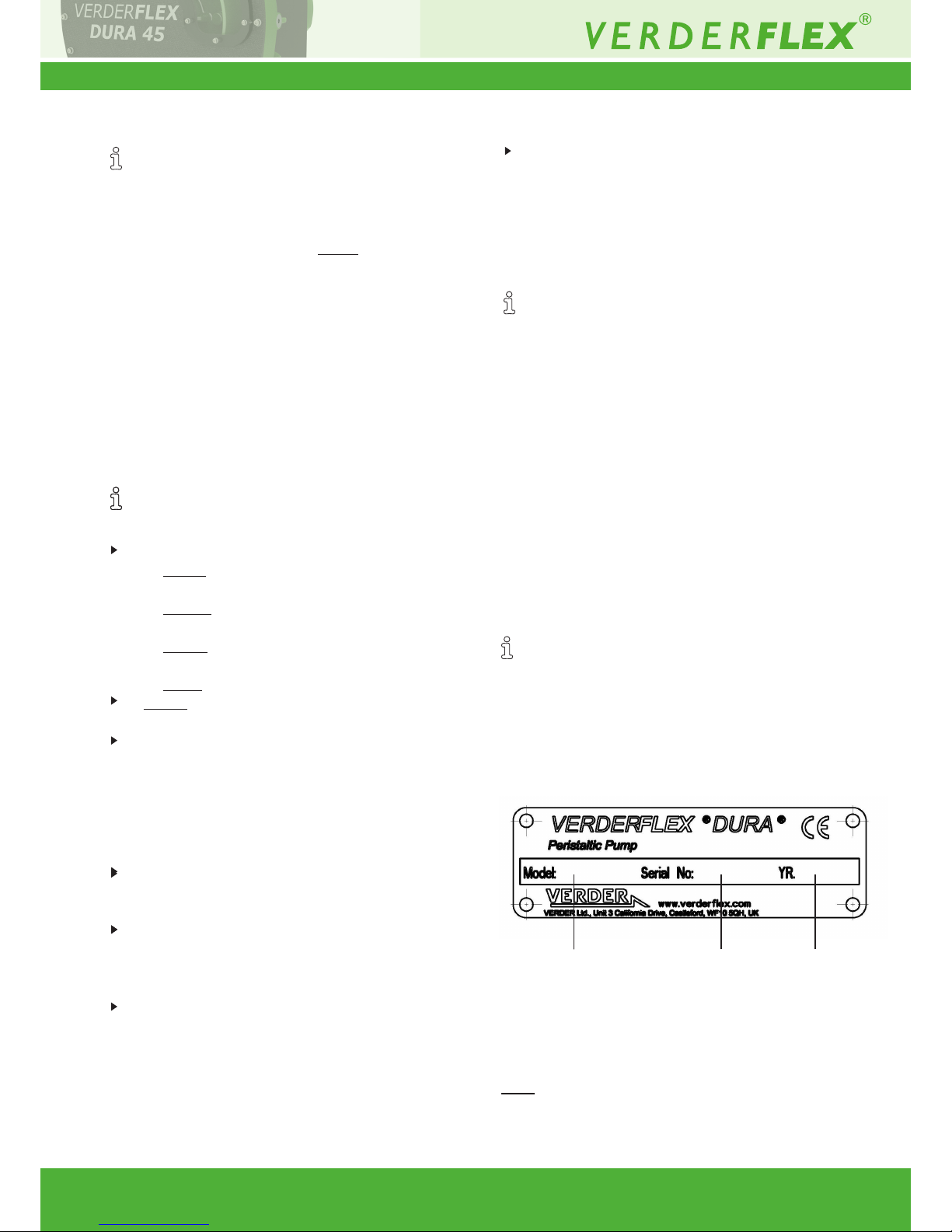

3.2.1 Name Plate

1. 2. 3.

Figure 1: Name plate

1. Pump type

2. Serial number

3. Year of manufacture

Note: When requesting spares, the model and serial

number should always be quoted.

Warranty

The warranty is voided if the customer fails to follow

any and all instructions, warnings and cautions in this

document. Verder has made every effort to illustrate

and describe the product(s) in this document. Such

illustrations and descriptions are, however, for the sole

purpose of identication and Do not express or imply a

warranty that the products are merchantable or t for a

particular purpose, or that the products will necessarily

conform to the illustration or descriptions.

Obtain the manufacturer’s approval prior to carrying

out any modications, repairs or alterations during the

warranty period. Only use genuine parts or parts that

have been approved by the manufacturer.

For further details regarding warranty, please refer

terms and conditions.

2.2.3 Obligation of personnel

It is imperative that the instructions contained in this

manual are complied with by the operating personnel

at all times.

Pump and associated components:

– Do not lean or step on them or use as climbing

aid

– Do not use them to support boards, ramps

or beams

– Do not use them as a xing point for winches

or supports

– Do not de-ice using gas burners or similar tools

Do not remove the safety guarding for hot, cold or

moving parts during operation.

Reinstall the safety equipment on the pump as

required by regulations after any repair / maintenance

work on the pump.

2.3 Specic hazards

2.3.1 Hazardous pumped liquids

Follow the statutory safety regulations when handling

hazardous pumped liquids (e.g. hot, ammable,

poisonous or potentially harmful).

Use appropriate personal protective equipment when

carrying out any work on the pump.

2.3.2 Lubricants

Ensure that the lubricant and pumped liquid are

compatible with each other. This is a precautionary

measure in case of accidental hose burst whereby

the pumped liquid comes in contact with the

lubricant.

(Refer datasheet for lubricant to ensure

compatibility)

Dura 45 3.1v-07/2016

7 | Page

3.4 Bearings and Lubrication

Pump: To be lled at installation with appropriate

lubricant if not supplied pre lled. (g10.1.6

Lubricants)

Bearings are sealed units and need no additional

lubricant.

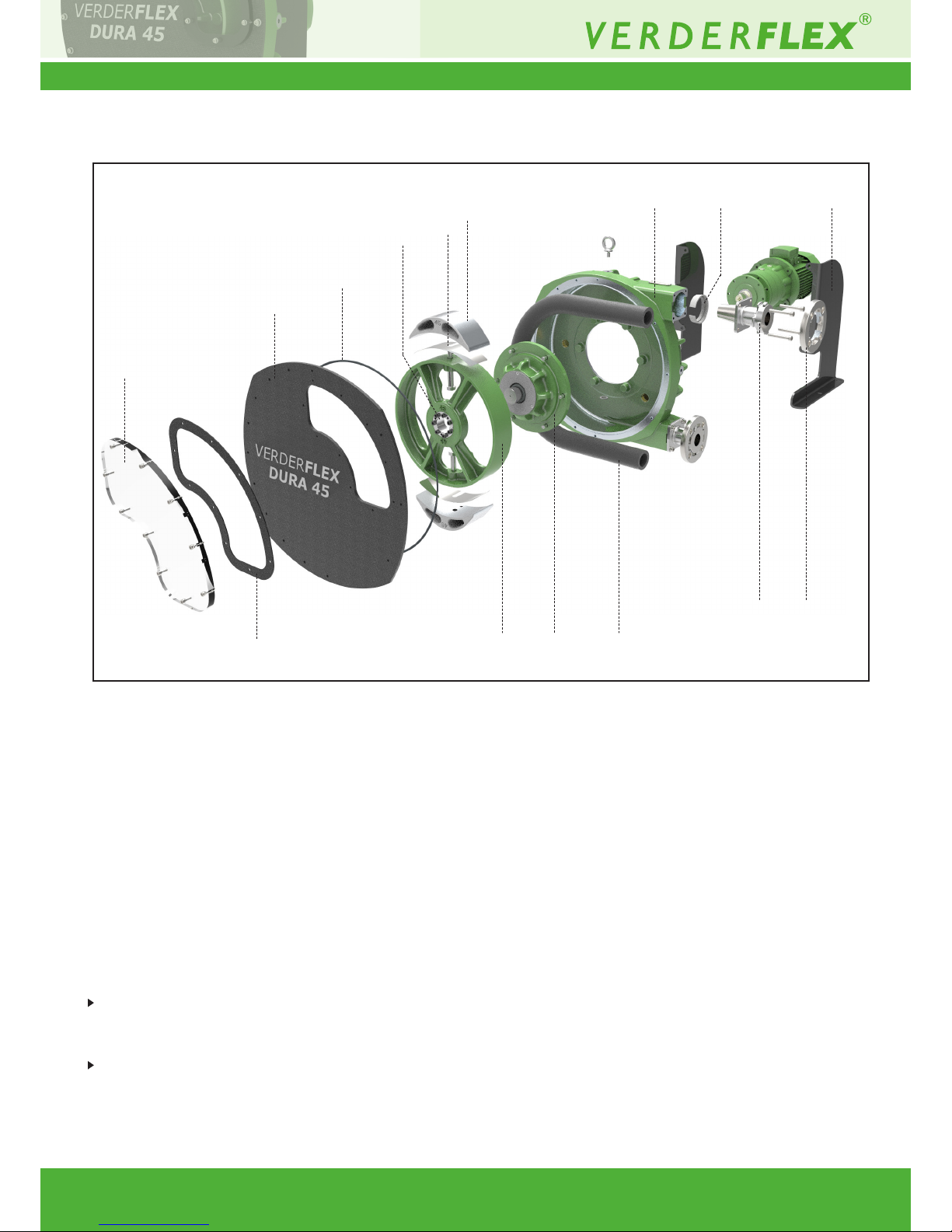

Figure 2 Layout

1 Inspection window 6 Shims 11 Pump casing

2 Inspection window gasket 7 Rotor shoe 12 Clamp ring

3 Front cover 8 Rotor 13 Port ange

4 Front cover o-ring 9 Hose 14 ¼ turn ange

5 Slip bush 10 Bearing housing 15 Mounting frame

3.3 Layout

1

2

3

4

5

6

7

11

8

9

13 14

15

12

10

Dura 45 3.1v-07/2016

8 | Page

4. Transport, storage and

disposal

4.1 Transport

Always transport the unit in an upright position and

ensure that the unit is securely attached to the

pallet.

4.1.1 Unpacking and inspection on delivery

1. Unpack the pump/pump unit upon delivery and

inspect it for transport damage.

2. Report any transport damage to the manufacturer/

distributor immediately.

3. Retain the pallet if any further transport is required.

4. Dispose all packaging material according to local

regulations.

4.1.2 Lifting

Death or crushing of limbs can be caused by falling

loads!

1. Use lifting gear appropriate for the total weight to be

transported.

2. Fasten the lifting gear to the lifting eye as shown in the

following illustration.

3. Do not stand under suspended loads.

DANGER

Figure 3 Fastening lifting gear to pump unit

Loading...

Loading...