Verderflex Dura 15, Dura 25, Dura 10, Dura 35 Operation And Maintenance Manual

CHAPTER 1

PURPOSE A ND PLANNING INFOR MATION

CONTENTS

Para Page

1 Disclaimer of Warranty and Limitations of Liability ................................................................................... 1.0

7 Introduction ................................................................................................................................................ 1.1

Safety Issues ............................................................................................................................................. 1.1

11 Warnings................................................................................................................................................ 1.1

12 Safety First............................................................................................................................................. 1.2

18 Pump Safety Features .......................................................................................................................... 1.2

20 Warranty Registration ........................................................................................................................... 1.3

24 Complaints procedure ........................................................................................................................... 1.3

26 Product shelf life .................................................................................................................................... 1.4

27 Verder Group Literature ........................................................................................................................ 1.4

Table

1 Product shelf life ........................................................................................................................................ 1.4

DISCLAIMER OF WARRANTY AND LIMITATIONS OF LIABILITY

1 Verderflex® Dura pumps are warranted against defects in workmanship and material under normal use (rental use

excluded) f or two years f rom date of purc hase. This is to th e extent that Verder wi ll at its option replace, repair or

refund, in full, the purchase price of the instrument of any part thereof manufactured b y Verder, which in our op inio n is

defective. Also provided the instrument has been operated in stric t accordance with this document, and has not been

subjected to tampering, abuse or exposed to highly corrosive and/or unspecified explosive conditions.

2 This warranty does not cover the conditions arising as follows:

2.1 Failure of Verder manufactured parts or components including hose, due to normal wear or any damage or

failure; that in Verder’s judgment ari ses fro m misuse.

2.2 Failure to implement the necessary safety procedures for use in the European Community (EC) of a pum p

within an explosive atmosphere as laid down in latest EC ATEX directive from 1st July 2003. The Dura is not currently

ATEX accredited.

2.3 Failure to disclose the use of a pump (intended or unauthorized) within a known explosive atmosphere.

Verder MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY

WARRANTIES OF FITNESS OR MERCHANTABILITY, EXCEPT AS EXPRESSLY SET FORTH ABOVE. Verder

SHALL NOT BE LIABL E FOR ANY INJUR IES, L OSSE S OR D AM AGES INC LUDI NG, BUT NOT LIM ITED T O ANY

PERSON AL INJURIE S, ANTICIPATED OR LOST PROFITS, INCIDENTAL DAMAGES, CONSEQUENTIAL DAMAGES,

COSTS, TIME CHARGES, OR OTHER DAMAGES OR LOSSES, IN CONNECTION WITH THE INSTRUMENT, IT S USE

OR ANY REPLACEMENT PA RTS THEREFORE :

3 Full completion of the warranty card is essential in order to be covered by Verder Ltd’s outstanding warranty schemes.

Please be aware of the declaration that you undertake to use only Verder spare parts - this is an essential part of the warranty

scheme and is legally binding. The card will also act as a record of y our dealings with Verder Ltd and it distributors.

4 This warranty is voided if the customer fails to follow any and all instructions, warnings or cautions in this document.

Verder has made every effort to illustrate and describe the p roduct(s) in thi s document. Such illustrations and descriptions are,

however, for the sole purpose of identification and do not express or imply a warranty that the produ cts are merchantable or fit

for a particular purpose, or that the products will necessarily conform to the illustration or descriptions.

Issue 3:0 Chap 1

Feb 12 Page 1.0

5 If a manufacturing defect is found, Verder will replace or repair the instrument or replace any defective par t thereof

without charge. However, Verder's obligation hereunder does not include the cost of transportation of the instrument to

Verder or its return to the customer; these costs must be borne by the customer. Verder assumes no responsibility for

damage in transit; any claims for such damage should be presented to the carrier by the purchaser.

6 In addition, instead of replacing or repairing the instrument as aforesaid, Verder may, at its sole option, take back the

defective instrument and reimburse the customer for the purchase price in full settlement of any and all potential claims related

to the purchase or use of the Verderflex® hose pump.

INTRODUCTION

7 The Verder Group of companies have offices located in Austria, Belgium, China, Czech Republic, France, Germany,

Hungary, Japan, Netherlands, Norway, Poland, Romania, Slovakia, South Africa, Switzerland, United States and the UK. A

network of worldwide distributors support our products in other countries of which a full list can be seen at

www.verderflex.com. Group headquarters are in the Netherlands.

8 Verder’s in-house designers and application engineers have developed a new generation of products, the range of

Peristaltic hose pumps, which are designed by Verder’s own production team. Full product training and documentation is

available, and Verder takes no responsibility for malfunction of the pump caused by failure to follow these operating

procedures; if operators do not read and understand this document, they are not considered by Ver der to be qualified to

assemble, install, operate or maintain this equipment. As any pump is no more or no less than one component part of an

overall process, it is essential for the successful completion of the total process for the pump to be working to its fullest

potential, and for the operator to be fully conversant with the operating principles of our hose pump.

9 Verder strives to maintain quality standards based upon ISO 9000 standards. It is Verder policy to supply its

documentation in a number of languages and software options, and your Verder distributor will be able to assist you with the

options available.

10 Verder recognizes its responsibilities to its customers around the world, and will always seek to meet or exceed their

expectations. Customer comments and feedback are always warmly welcomed and input to the development of procedures

and products, is common. Should you have any issues on which you wish to comment, please return your comments to your

local Verder distributor who will then forward them for action by Verder.

SAFETY ISSUES

Warnings

11 Warnings are used throughout this document. Each warning contains important safety information. Warnings are

generally used for potential hazards (indicated by a black on yellow triangle) and definite hazards (white on red triangle).

Below are some examples of warnings that can be found in this publication.

PERSONNEL HAZARD. Ensure that all local standing operating proceedures and all current

health & safety regulations are complied with, when carrying out any of the proceedures

documented within this publication.

HEAVY WEIGHT. Due consideration must be given to the regulations governing the lifting of

heavy weights when moving this equipment.

SAFETY HAZARD. Do not walk or work under a suspended pump cover.

Chap 1 Issue 3.0

Page 1.1 Feb 12

LETHAL VOLTAGES. Dangerous voltages exist in this equipment. When carrying out work on

any electrical equipment during failure diagnostics, refer to chap 4.

EQUIPMENT DAMAGE. Before test running the pump; check that all tools are removed,

particularly from pump casing.

Safety First

12 The information in this document is essential for the safe operation and servicing of Verderflex® pumps. This document

must be read and understood; in particular Chap 2 before operating or servicing such pumps.

13 The employer shall instruct each employee in the recognition and avoidance of unsafe conditions and the regulations

applicable to his work environment to control or eliminate any hazards or other exposure likely to cause injury.

14 It is understood that safety rules within individual companies vary. If a c onflict exists between the material contained in

this document and the rules of a using company, the more stringent rules should take precedence.

15 This document should be kept available to operating and maintenance personnel. Additional copies of this document

may be acquired free of charge from Verder via your distributor.

16 Safety suggestions from users will be given the most serious consideration. This is especially true of advice for

minimizing problems associated with safety misuse, which cannot be identified in advance during the production of the pump

unit. Comments and recommendations should be submitted to Verder via your distributor.

17 Throughout this document these safety warning and cautions are repeated. The relevant information will act as a

guideline for you in operating the pump; alternative courses of action are also described should you be unable for any reason

to follow those procedures initially given for any procedure. You are advised to follow these guidelines to achieve maximum

efficiency.

Pump Safety Fea tures

18 The Verderflex® Dura has a number of in-built features, which have been designed specifically to ensure your safety

during operation and maintenance of the unit:

18.1 Disaster proof design – the casing will contain most spillages preventing leaks and contamination of product.

18.2 Use of specially formulated Verderflex® lubricants, which prolong the working life of the pump.

18.3 One-piece tapered hose connection giving quicker and simpler hose change.

18.4 Pressure relief plugs in housing to allow safe relief of any built up pressure inside the pump housing.

18.5 Designed for safe and easy assembly and maintenance.

18.6 Fast and simple Geared Motor Unit (GMU) change reducing downtime.

19 Safety instructions and guidance are divided into operational safety , maintenance safety and safety advice for assembly,

installation and commissioning, with each category having its own rules and philosophy. This section covers operational

functions that are reasonably foreseeable. Many warnings and admonitions are included in this document; unfortunately

there are too many to incorporate into “on unit” labels. For this reason it is essential that the document be treated as part of

the product and made mandatory reading for personnel associated with the product and system.

Issue 3:0 Chap 1

Feb 12 Page 1.2

Warranty Regis tration

20 Your Verder distributor will have completed a warranty card on your behalf, which is returned to Verder for registration on

Verder’s warranty scheme. Please ensure that the distributor has the following details from your initial and any subsequent

orders for pump(s)/spare(s):

20.1 Pump / spares make and type

20.2 Serial number

20.3 Application

20.4 Media to be pumped

20.5 Pressure

20.6 Temperature

20.7 Capacity

20.8 Suction

20.9 Motor size

20.10 Date of order and delivery

20.11 Verder reference

21 Full completion of this card is essential for you to be covered by Verder’s outstanding warranty schemes. Please be

aware of the declaration that you undertake to use only Verder spare parts - this is an essential part of the warranty scheme

and is legally binding. The card will also act as a record of your dealings with Verder.

22 This information will similarly be required if and when you should need to order spare parts from your local Verder

distributor.

23 Should you have cause to return the pump for any reason, please ensure that you inform the local distributor as fully as

possible of the details of the problem; the distributor has the necessary documentation for completion of the warranty

application to Verder and is aware that this has to be completed in full before Verder can examine the application

Complaints Pro cedure

24 Verder takes its responsibilities to its customers extremely seriously and prides itself on its comprehensive complaint

procedures. Should you be dissatisfied with your Verder pump(s) or with any aspect of the service you have received, then

please contact your local Verder distributor in the first instance to discuss the matter fully .

25 The distributor will then take the matter up with Verder, acknowledging his actions to the customer and indicating a time

scale by which he will reply. You will receive a response from the distributor w ith Verder’s initial co mments and propose d plan

of any further action. If you feel that your complaint has still not been resolved satisfactorily, you should contact Verder Ltd

directly.

Chap 1 Issue 3:0

Page 1.3 Feb 12

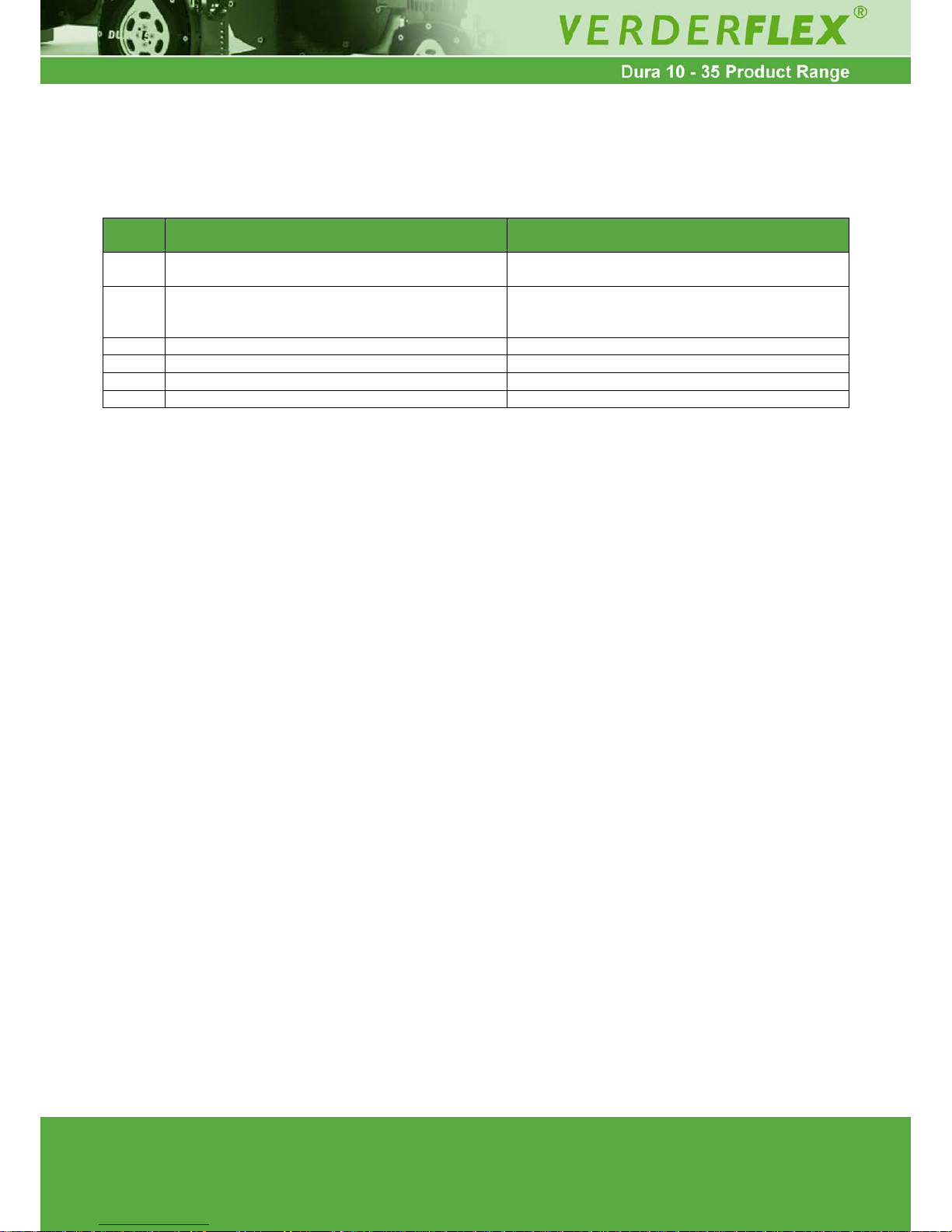

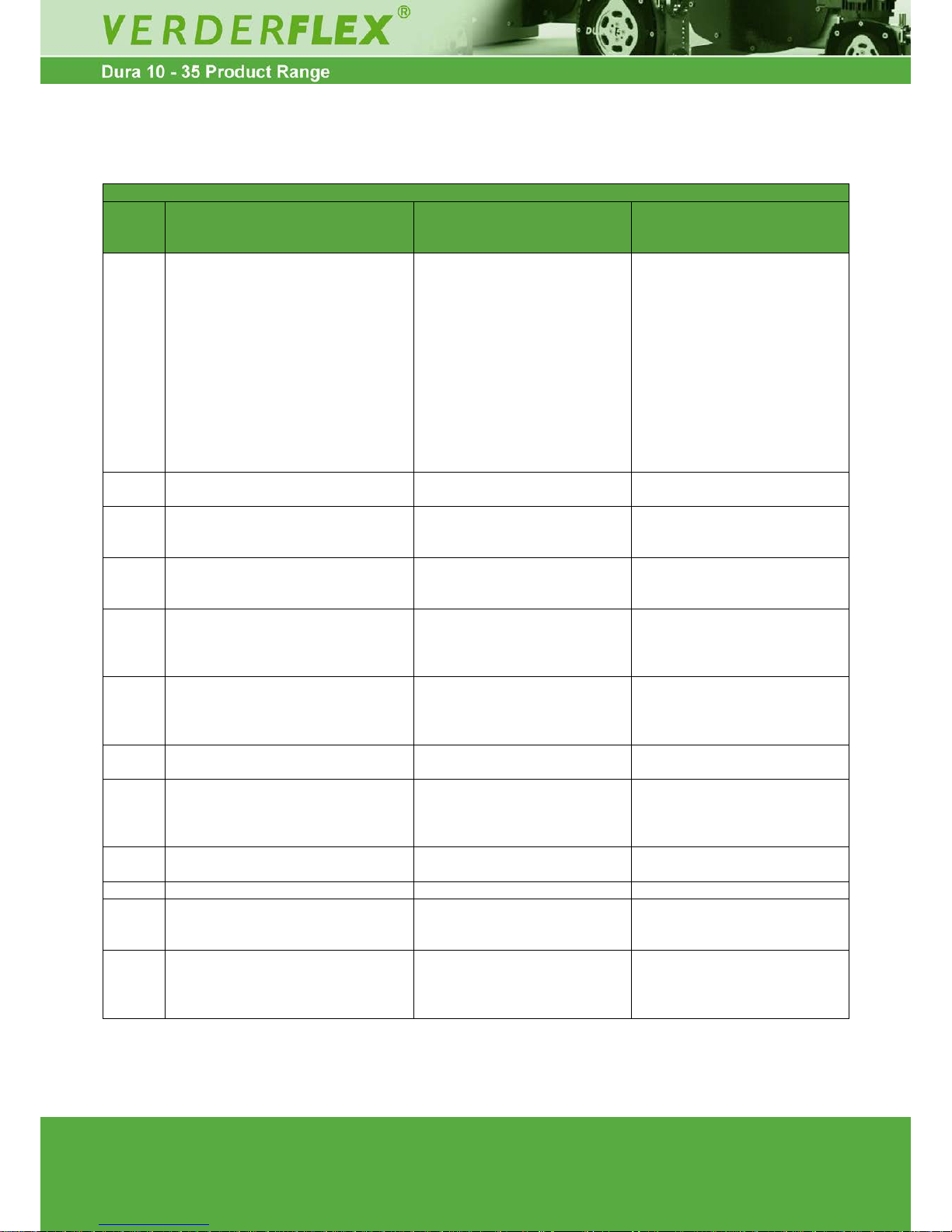

Product shelf l ife

26 Table 1 lists the expected product shelf life of Verder products; for further information, please contact your local

Verderflex® di stributor or contact the Verderflex® team at info@verderflex.com.

TABLE 1 PRODUCT SHELF LIFE

Ser

(1)

Product

(2)

Shelf life

(3)

1 Pump assembly

No shelf life; providing pu mp stored in a dry

atmosphere

2

Natural Rubber (NR), Nitrile Buna Rubber (NBR),

Nitrile Buna Rubber Foo d Grade (NBRF), Hypalon®

(CSM) hoses

2 years from date of supply*

3

EPDM hoses

3 years from date of supply*

4

Verderlube® lubricant

1 year from date of supply*

5

Verdersil® lubricant

3 years from date of supply*

6

Gearbox and motor

In accordance with manufacturer’s recommendations

* Shelf life is based on th e produc t being kep t out of direc t sunlig ht and not in tempe ratures above a mbien t.

Verder Group Literature

27 Verder supplies its range of Group literature and product documentation in a number of languages and variety of

software packages - please advise your Verder distributor if you are interested in receiving other information on Verder,

indicating languages and formats.

28 Verder and its distr ibutors undertak e to conduct al l its dealings with you as comprehe nsively, courteous ly and

promptly as possible. Customer care is one of Verder’s top priorities.

Issue 3:0 Chap 1

Feb 12 Page 1.4

INTENTIONALLY LEFT BLANK

Chap 1 Issue 3:0

Page 1.5 Feb 12

CHAPTER 2

OPERATING INFORMATION/COMMISSIONING

CONTENTS

Para Page

1 General – tools and facilities ..................................................................................................................... 2.0

Operational Safety (WARNINGS) ............................................................................................................. 2.1

Assembly and Preparation ........................................................................................................................ 2.1

3 Assembly ............................................................................................................................................... 2.1

4 Preparation ............................................................................................................................................ 2.1

9 Commissioning .......................................................................................................................................... 2.2

14 Operation ................................................................................................................................................... 2.2

16 Maintenance .............................................................................................................................................. 2.2

Verderlube® safety data sheet ................................................................................................................. 2.4

Verdersil® safety data sheet ..................................................................................................................... 2.9

Table

1 Normal operation pump speeds ................................................................................................................ 2.2

2 Normal Operation Risk & Preventative Measures .................................................................................... 2.3

3 Ecotoxicity classification criteria ................................................................................................................ 2.13

4 EPA SARA Title III Chemical Listings ....................................................................................................... 2.14

General – tools and facilities

1 Care should be taken at all times to ensure that any tools are used safely for the purpose for which they are designed

and in accordance with the manufacturer’s instructions. Ideally the pump should be installed using a drive, with facilities to

inch the pump along and which is able to operate in reverse. Any maintenance work will require a complete set of metric

spanners, a socket set and torque wrench; you should check your fastener kit to ensure you have all the correct sizes

available.

2 Lifting equipment will be required for several of the procedures. The lifting equipment to be used should be checked for

suitability for the task and capable of lifting the combined weight of the pump components. Always follow the manufacturer’s

instructions for safe operation of lifting equipment.

Issue 3:0 Chap 2

Feb 12 Page 2.0

Operational Sa fety

WARNINGS

LETHAL VOLTAGES. Dangerous voltages exist in this equipment. Always isolate the power

supply before working on the pump.

SAFE TY HAZ ARD. Never place hands or other parts of the body inside or near an y part of the

pump when it is in operation or when the power is not totall y isolated.

SAFETY HAZARD. When the pump is running, you should not touch the pump and should

maintain an adequate safe distance around it.

SAFETY HAZARD. Do not climb onto the pump or connecting pipe work.

SAFETY HAZARD. Maintain a clean environment around the pump. The Verder pump is

manufactured from c ast iron, and therefore the flanges and casings etc may have sharp edges slipping or falling against the pump may cause serious injury.

Wear appropriate Personel Protection Equipment (PPE) when operating on or work ing

near the pump.

Assembly and Preparation

Assembly

3 The Verderflex® Dura can be supplied built or as a bareshaft pump.

Preparation

4 Prepare the workspace in which the pump is to be worked on, ensuring there is a clean and level work surface with

sufficient room for not only the pump, but also to allow you sufficient access to the pump and fit pipe work, etc.

5 Carefully open the packaging and check for completeness by ensuring all the parts listed are present; remove all the

loose components and set them out on a workbench. It is recommended that the fastener kit is sorted into piles of like items

and kept in a safe place to avoid losing parts or using an incorrect part.

Chap 2 Issue 3:0

Page 2.1 Feb 12

6 If the pump casing or any parts are found to be damaged, the wrong type, specification or are missing; then you should

record the appropriate serial number from the casing identification plate and/or the quality check seal on the packaging, and

inform Verder Ltd.

7 The power supply and control panel should be pre-installed. If the pump is to be operated remotely, a separate control

panel with STOP and START functions should be installed near the pump (but at least 3 metres/9 feet distance from the

pump).

8 Pipe work should:

8.1 Be as short and direct as possible.

8.2 Be oversized relative to the hose bore of the pump (min. 150%)

8.3 Be aligned correctly, free from stress and securely anchored.

8.4 Include a short, removable section adjacent to the port flanges to allow easy access when changing hoses,

ideally this should be a flexible hose able to withstand the system pressure.

8.5 Include suction and discharge valves (if a discharge valve is fitted, a high pressure safety device will be required

to prevent excess pressure build up when the pump is running with the discharge valve is closed).

8.6 Include drainage taps to allow safe removal of product, and a minimum number of long radius elbows where a

change of direction is necessary.

Commissioning

9 Check all fasteners are tightened to the required settings (refer to chap 4). Before connecting any pipe work to the pump

carryout the following:

9.1 Run the pump dry for 10-20 re volutions in both directions to ensure that the hose is properl y secured.

10 Connect the pipe work and torque-tighten all fasteners to the required settings.

11 Close all drainage taps and open all valv es.

12 Run the pump for 10-20 revolutions; check for any leaks.

13 Test the pump for leaks at operating pressure and correct fl ow rate. Carry out re-adjustments as necessary.

Operation

14 The pump should only be used for the purpose it was sold. For normal continuous operation of each Dura pump;

speeds should NOT exceed t he speeds stated in Table 1 unless expressively advised by your Verder distributor.

TABLE 1 NORMAL CONTINUOUS OPERATION PUMP SPEEDS

Dura 10 Dura 15 Dura 25 Dura 35

SP

HP

SP

HP

SP

HP

SP

HP

76 40 76 40 76 35 80 n/a

15 Operating pressure should not be altered to operate outside the toleran ces recommended by your Verder distributor.

Maintenance

16 It is good practice to wash down the external surfaces of the pump prior to carrying out any maintenance operations.

This will prevent the interior of the pump being contaminated with dirt or debris.

Issue 3:0 Chap 2

Aug11 Page 2.2

TABLE 2 NORMAL OPERATION & RISK PREVENTATIVE MEASURES

17 Table 2 lists possible malfunctions of the pump and its components du ring normal operation; and preventative measures

in place to avoid any malfunctions.

NORMAL OPERATION ASSESMENT

Ser

(1)

Normal Operation

(2)

Malfunction

(3)

Preventative Measures

(4)

1

Pressure too high in casing

Blocked Pump

Pressure in tube during replacement

Tube rupture causing hazardous

medium to spray out

Do not exceed the maximum

working pressure of 12 bar (174

PSI). Install a suitable safety

valve in the discharge line in

order to prevent overpressurization. This must be

in turn checked on a regular

basis. Do not work on a

running pump near to filler

tube/inspection window. When

dismantling the pump isolate

the power supply and relieve

any pressure build up

2

Incorrect a ssemb ly

Observe correct build procedure

(refer to chap 4)

3

Exceeds recommended temperatures

Tube rupture causing hazardous

medium to spray out

Ensure lubricant level is correct.

Rotor is shimmed correctly.

Fitting of a temperature monitor

4

Polypropylene flange use

Distortion at high operating

temperatures >35°C (95°F)

Check operational specification

and use alternative stainless

steel/ P VDF flange.

5

Excessive no ise

Personal Injury

Observe safety regulations

governing operation in close

proximity. Wear appropriate

PPE

6

Product chemical reaction

Potentially explosive

Carry out product handling

measures during

installation/operation to ensure

operator safety

7

Drive spec to pump assembly

Ensure that an explosion proof

motor is fitted

8

Rotating coupling

Personal Injury

All flat packed long coupled

assemblies to carry guarding

advice or have guards installed

during the build

9

Hazardous medium in pump case

after tube burst

Personal Injury

Observe safety precautions. Use

of special tools to remove covers

10

Pump operational safety precautions

Personal Injury

Wear appropriate PPE

11

Construction materials not resistant to

pumped media

Adverse chemical reaction, heat

build up, personal injury

Ensure sub components other

than hose are compatible with

media being pumped

12

Verderlube® pu mp lubricant not

resistant to pumped media

Adverse chemical reaction to

glycerine based products with

strong acids and oxidising agents

with risk of explosion

Ensure Verderlube® l ubricant is

compatible with media being

pumped. Use of Verdersil may

be required

Chap 2 Issue 3:0

Page 2.3 Feb 12

VERDERLUBE® SAFETY DATA SHEET EDITION: FEB 2011

IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND OF THE COMPANY/UNDERTAKING

Identificati on of Substanc e or Preparation

Product Name Verderlube®

Chemical Identification Glycerine based blend

CAS number Preparation

Use Food grade – pu mp lubricant/coolant

Company Identi ficatio n

Producer/Supplier VERDER LIMITED

3 California Drive

Castleford

WF10 5QH

Great Britain

Tel number +44 (0) 1924 221 020

Fax number +44 (0) 113 246 5649

Emergency telephone number

For advice on this product call: +44 (0) 1924 221 020

COMPOSITION/INFORMATION ON INGREDIENTS

This product contains no substances classified as hazardous to health in concentrations that should be taken into account

according to EC directive 91/155/EC.

• Main constituent may cause irritation to eyes and skin.

• Irritating to respiratory system in the form of a mist.

HAZARDOUS IDENTIFICATION

This product is not classified as hazardous according to EC directive 91/155/EC.

• May cause irritation to eyes and skin.

• Irritating to respiratory system in the form of a mist.

• Contact with hot product may cause burns.

• Product is a lubricant and in the event of untreated spillage, can cause external surfaces to become slippery

when wet

FIRST AID MEASURES

Used lubricant may become contaminated with pumped product, also verify precautions and advice against relevant

product information.

Ingestion

Except as a deliberate act, the ingestion of large amounts of product is unlikely. If this should occur, do not induce vomiting,

obtain medical advice.

• If ingested give 500 ml of Water to drink.

Issue 3:0 Chap 2

Feb 12 Page 2.4

Inhalation

If inhalation of fumes from overheated material causes irritation to the nose or throat, or coughing, remove to fresh air. Obtain

medical advice if any symptoms persist.

Skin Contact

No first aid should be required but should any symptoms persist, seek medical advice. If contact with skin occurs:

• Wash thoroughly with mild soap and water as soon as reasonably practical.

• Remove heavily contaminated clothing and wash underlying skin.

Eye Contact

Direct contact may cause temporary redness and discomfort. Wash eye thoroughly with copious amounts of water, ensuring

eyelids are held open. Obtain medical advice if any pain or redness develops or persists.

FIRE FIGHTING MEASURES

Extinguishing Media

The best type of fire fighting media to use is:

• Alcohol resistant foam.

• Dry powder.

• Water fog.

Extinguishing Media to avoid

Do NOT use water jets.

Unusual Fire a nd Explo sion Hazards

Avoid spraying directly into storage containers due to a danger of boil over.

Special Protecti ve Equipme nt for Fire fig hters

Wear protective clothing and approved breathing apparatus when in close proximity of fire.

Poisonous Acrolein may be found during burning.

Accidental Release measures

Used lubricant may become contaminated with pumped product, also verify precautions and advice against relevant

appropriate product information

Personal Protecti on

Wear goggles and gloves. If spillage has occurred in a confined space, ensure sufficient ventilation and check that a safe,

breathable atmosphere is present before entry.

Environmental precautions

Protect drains from spills and preve nt entry of produc t. Treated ef fluent may be bio degradable. Recover cleaning

water for later treatment.

Chap 2 Issue 3:0

Page 2.5 Aug11

Methods for cleaning up

Contain and recover liquid, soak up with absorbent material (sand, peat, etc.) or contain and shovel into drums or containers.

Remove residue by spraying with water.

HANDLING AND STORAGE

Handling

Contact with hot product causes burns.

• Avoid contact with eyes. If splashing is likely to occur wear a full visor or chemical goggles to appropriate local

national standards.

• Avoid frequent or prolonged skin contact with fresh or used product.

• Wash hands thoroughly after use.

Storage

Store under cover; away from moisture and sources of ignition. Do not overheat in storage.

The lubricant/coolant is hygroscopic; keep the container tightly closed.

EXPOSURE CONTROLS/PERSONAL PROTECTION

Personal Protection

Hand Protection:

• PVC or Rubber Gloves

Eye Protection:

• Chemical goggles

Respiratory protection is unnecessary, providing concentration of vapour, mists or fumes is adequately controlled.

Occupational exposure limits

• Ensure good ventilation.

• Threshold limit Not tested

PHYSICAL AND CHEMICAL PROPERT IES

FORM Viscous liquid

COLOUR Blue. Col ourle ss may be supplie d to spe cial orde r

ODOUR Odourless

SOLIDIFICATION POINT -40°C/-40°F approx.

FLASH POINT 177°C/350°F approx. (COC: ISO 2592)

BOILING POINT 290°C/554°F

SOLUBILITY IN WATER Miscible (at 20°C)

VAPOUR PRESSURE (20°C/68°F) <0.01 mbar

(100°C/210°F) <1 mbar

VISCOCITY 700 mPaS approx. @ 20°C/68°F

pH 7 approx.

(continued)

Issue 3:0 Chap 2

Feb 12 Page 2.6

PHYSICAL AND CHEMICAL PROPERTIES (Continued)

AUTO IGNI TI ON TE MPE RAT UR E 400°C / 750°F approx.

EXPLOSION LIMITS Not established

DENSITY (20°C/68°F) 1245 kg/m3 approx.

BEHAVIOUR WITH WATER AT 20°C Hygroscopic

STABILITY AND RE ACTIVITY

Conditions to avoid

Preparation is stable and unlikely to react in a hazardous manner under normal conditions of use.

No special precautions other than good housekeeping of chemicals.

Hazardous polymerization reactions are unlikely to occur.

This material is combustible.

Materials to avoid

Avoid contact with strong oxidizing agents, nitrogenous compounds and strong acids: risk of violent and or

explosive reactions with pure compounds.

Hazardous decomposition products

During burning, poisonous acrolein may be found – very toxic by inhalation.

Incomplete combustion / thermal decomposition will generate smoke, carbon dioxide and hazardous gases,

including carbon monoxide.

TOXICOLOGIC AL INFO RMATION

Toxicity Data

General purpose food grade lubricant/coolant.

LD

50

oral (rat) 12600 mg/kg (not harmf ul) *

Significant data with possible relevance to human health

Eyes Unlikely to cause more than transient stinging or redness (if accidental eye contact occurs).

Skin Unlikely to cause harm to the skin

Ingestion Unlikely to cause harm if ac cidentally swallowed in small doses, although larger quantities

should be avoided

Inhalation At ambient temperatures this product will be unlikely to present an inhalation hazard

ECOLOGICAL INFORMATION

Mobility

Spillage may penetrate the soil; unused preparation is food grade and is inherently harmless.

Chap 2 Issue 3:0

Page 2.7 Feb 12

Persistence and Degradability

This preparation is inherently biodegradable.

Bio Accumulative Potential

There is no evidence to suggest that bioaccumulation will occur.

Aquatic Toxicity

Verderlube® is miscible in water. It is not considered harmful in low concentrations.

Water pollution reactors gO

2

/g

BOD

5

: 0,87 (NEN 3235-5.4)

BOD

1

: 1.16 (NEN 3235-5.3)

Fish: goldfish LC50 (24h):>5000 mg/1 (modified ASTM D1345)

The aquatic toxicity (TLm

96

) is >1000mg/1, which is defined by NIOSH as an insignificant hazard

DISPOSAL CONSIDERATIONS

Waste Disposal Method(s)

• Where possible, arrange for unused product to be recycled.

• Disposal of preparation sh ould be via an author ized person/licens ed waste dispos al contractor in accor dance

with local regulations.

• Incineration may be carried out under controlled conditions provided that local regulations are met.

• Dispose of preparation an d container carefully and responsibly. Do not dispos e of preparation near ponds,

ditches, down drains onto soil.

TRANSPORT INFORM ATION

Not classified as dangerous for transport (RID/ADR-ADNE-IATA-IMDG-MARPOL-ICAO).

REGULATORY INFORM ATION

Classification not required.

Other Information

Employees of the Verder group have not experienced any harmful effect during normal handling and production.

Verderlube® and Verderflex® are registered trademarks.

*The information contained in this s heet is based on our knowledge of the preparation at its deliver y date and that the

informatio n cont ained h erei n is curr ent as of the da te of th is dat a shee t. Since the us e of this inf orm ation an d of thes e

opinions and the conditions of use of this preparation is not within the control of Verder Limited, it is the user’s

obligation to d et er mine the condit i o ns of saf e use of the prepar ation. The information contained in this sheet is based on

our knowledge of the product at its delivery date.

Issue 3:0 Chap 2

Feb 12 Page 2.8

VERDERSIL® SAFETY DATA SHEET EDITION: FEB 2011

IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND OF THE COMPANY/UNDERTAKING

Identificati on of Substanc e or Preparati on

Product Name Verdersil

Chemical Identification Silicone fluid (Polydimethyl siloxane 350 CPS)

CAS number Preparation

Use Pump lubricant/coolant

Company Identi ficatio n

Producer/Supplier VERDER LIMITED

Unit 3 California Drive

Castleford

WF10 5QH

Great Britain

Tel number +44 (0) 1924 221 020

Fax number +44 (0) 113 246 5649

Emergency telephone number

For advice on this product call: +44 (0) 1924 221 020

COMPOSITION/INFORMATION ON INGREDIENTS

This product contains no substances classified as hazardous to health in concentrations that should be taken into account

according to EC directive 91/155/EC.

• Main constituent may cause irritation to eyes and skin.

• Irritating to respiratory system in the form of a mist.

HAZARDOUS IDENTIFICATION

This product is not classified as hazardous according to EC directive 91/155/EC.

• May cause irritation to eyes and skin.

• Irritating to respiratory system in the form of a mist.

• Contact with hot product may cause burns.

• Product is a lubricant and in the event of untreated spillage, can cause external surfaces to become slippery

when wet

FIRST AID MEASURES

Used lubricant may become contaminated with pumped product, also verify precautions and advice against relevant

product information.

Ingestion

No first aid should be required but should any symptoms persist, seek medical advice.

Inhalation

No first aid should be required but should any symptoms persist, seek medical advice.

Chap 2 Issue 3:0

Page 2.9 Feb 12

Skin contact

No first aid should be required but should any symptoms persist, seek medical advice. If contact w ith skin occurs:

• Wash thoroughly with mild soap and water as soon as reasonably practical.

• Remove heavily contaminated clothing and wash underlying skin.

Eye contact

Direct contact may cause temporary redness and discomfort. Wash eye thoroughly with copious amounts of water, ensuring

eyelids are held open. Obtain medical advice if any pain or redness develops or persists.

FIRE FIGHTING MEASURES

Extinguishing Media

The best type of fire fighting media to use is:

• Alcohol resistant foam.

• Dry powder.

• Water can be used to cool fire exposed containers.

Extinguishing Media to avoi d

None known.

Unusual Fire a nd Explo sion Hazards

None known.

Special Protecti ve Equipme nt for Fire fig hters

A self -contained respirator and protective clothing should be worn. Keep containers cool with water spray until well after the

fire is out. Determine the need to evacuate or isolate any area in accordance with local emergency plans.

Hazardous combustion products include Silica, Carbon Oxides and traces of incompletely burned carbon compounds may

form. Formaldehyde may also be found.

National Fire Protec tion A ssociation (N FPA) Profi le

Health: 0 Flammability: 1 Instability/reactivity: 0

ACC IDE NT AL R EL E ASE MEASURES

Personal Protection

Wear goggles and gloves. If spillage has occurred in a confined space, ensure sufficient ventilation and check that a safe,

breathable atmosphere is present before entry.

Environmental Precautions

Prevent from spreading or entering drains, ditches or rivers by using sand, earth or other appropriate barriers

Issue 3:0 Chap 2

Feb 12 Page 2.10

Methods for Cleaning Up

Determine the need to evacuate or isolate the area in accordance with local emergency plan. Very large spills should be

contained by bunding or similar methods. Contain and recover the liquid, soak up with absorbent material (sand, peat, etc.) or

contain and shovel into drums or containers.

Caution : Spilled product will produce an extremely slippery surface.

Handling and Storage

Handling

Contact with ho t produc t c aus es bur ns.

• Avoid contact with eyes. If splashing is likely to occur wear a full visor o r chemical goggles to appropriate local

national standard s.

• Avoid frequent or prolonged skin contact with fresh or used product.

• Wash hands thoroughly after use.

Storage

Store under cover away from moisture and sources of ignition. Do not overheat in storage.

EXPOSURE CONT ROLS / PER SONAL PROTECT ION

None of the components have assigned exposure limits.

Personal Protection

• Hand Protection PVC or Rubber Gloves

• Eye Protection Safety glasses should be worn

Respiratory Protection Respiratory protection is unnecessary, providing concentration of vapour, mists or

fumes is adequately controlled.

Occupational Exposure Limits

• Ensure good ventilation.

• No known assigned exposure limits .

Additional Information

These precautions are for room temperatu re handli ng

Use at elevated tempe ratures may requi re additi onal prec autions

PHYSICAL AND CHEMICAL PROPERT IES

FORM Viscous liquid

COLOUR Colourless

ODOUR Odourless

SOLIDIFICATION POINT -45°C/-60°F approx.

FLASH POINT 121°C/250°F approx. (Closed cup)

BOILING POINT >200°C/>390°F

Chap 2 Issue 3:0

Page 2.11 Feb 12

PHYSICAL AND CHEMICAL PROPERTIES (CONTINUED)

SOLUBILITY IN WATER 0 g/litre at 20 °C

VISCOCITY 350 mPaS approx. @ 20°C/68°F

pH 7 approx.

AUTO IGNI TI ON TE MPE RAT UR E >200°C / >390°F ap p rox .

EXPLOSION LIMITS Not expolosive

DENSITY (20°C/68°F) 970 kg/m3 approx.

STABILITY AND RE ACTIVITY

Conditions to avoid

Preparation is stable and unlikely to react in a hazardous manner under normal conditions of use.

No special precautions other than good housekeeping of chemicals.

Materials to avoid

Can react with strong oxidizing agents.

Hazardous Decomposition Products

Hazardous decomposition products including Formaldehyde and Silica can be formed, refer to Toxicology Information, section.

TOXICOLOGIC AL INFO RMATION

Toxicity Data

General non toxic lubricant/coolant.

Other than temporary discomfort on contac t with the e yes, no ad verse ef f ects are norm all y expected.

Significant data with possible relevance to human health

Eyes Unlikely to cause more than transient stinging or redness (if accidental eye contact occurs).

Skin Unlikely to cause harm to the skin

Ingestion Unlikely to cause harm if accidentally swallowed in small doses, although larger quantities

should be avoided

Inhalation At ambient temperatures this product will be unlikely to present an inhalation hazard

Product may emit Formaldehyde vapours at temperatures above 150°C/302°F in the presence of air.

Formaldehyde vapour is harmful by inhalation and irritating to the eyes and respiratory system at breathing

concentrations of less than 1 part per million (ppm).

ECOLOGICAL INFORMATION

Environmental Fate and Distribution

Air

This product is a high molecular weight liquid polymer, which has a very low vapour pressure (<1 mm Hg). As a result it is

unlikely to become an atmospheric contaminant unless generated as an aerosol.

Issue 3:0 Chap 2

Feb 12 Page 2.12

Loading...

Loading...