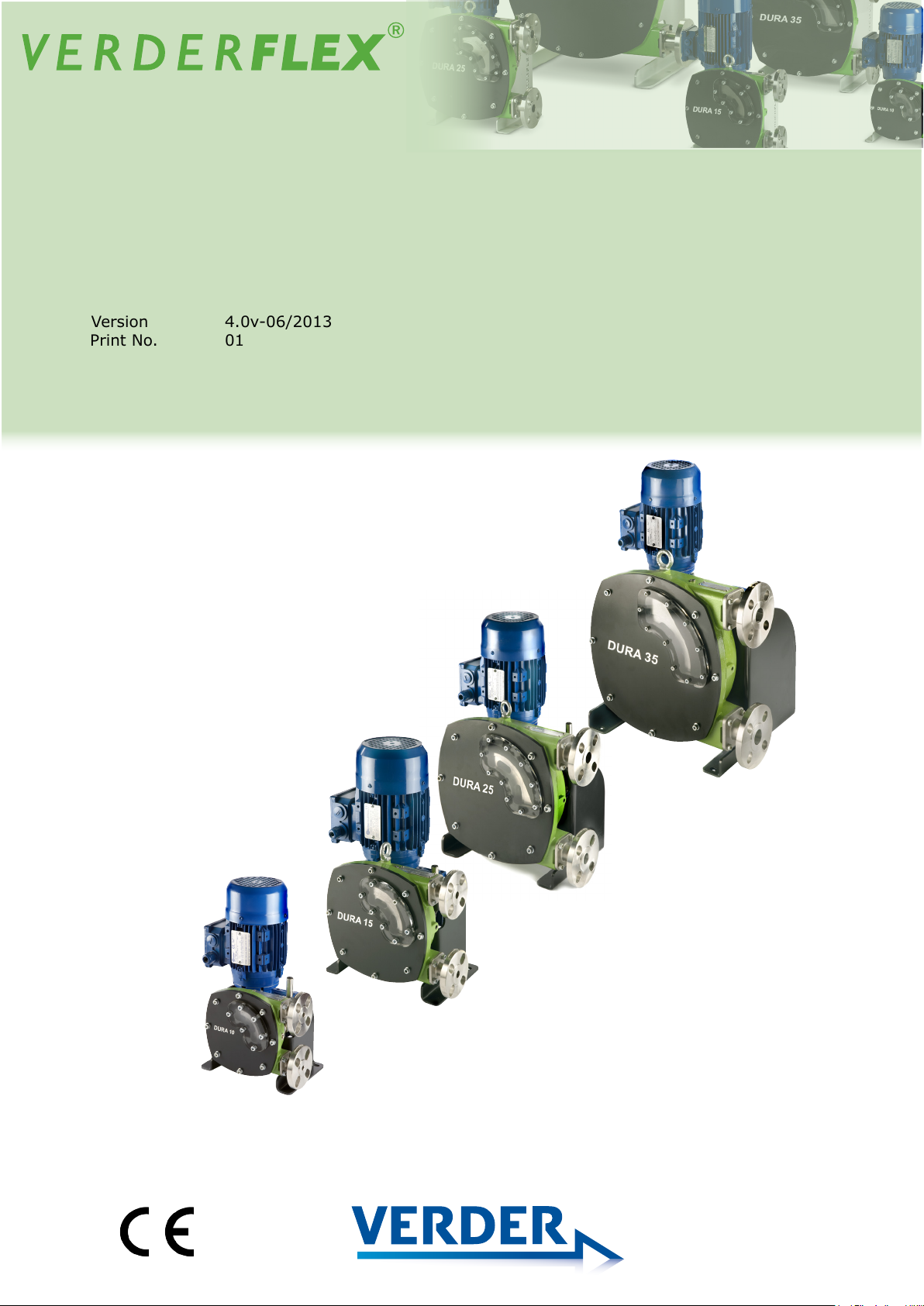

Verderflex Dura 7, Dura 5, Dura 10, Dura 25, Dura 35 Operating Manual

...

Version 4.0v-06/2013

Print No. 01

Peristaltic Industrial Hose Pump

Operating Manual Dura 5, 7, 10, 15, 25, 35

Version 4.0v-06/2013

Dura 5, 7, 10 , 15, 25, 35

pumps. This document must be read and understood thoroughly prior to installation of unit,

Print-No. 01

The information in this document is essential for the safe operation and servicing of Verderflex®

Dura

electrical connection and commissioning.

Dura 5 - 35 4.0v-06.2013 2 | Page

Table of contents

Table of contents

1. About this document

1.1 Target groups

1.2 Warnings and symbols

2. Safety

2.1 Intended use

2.2 General safety instructions

2.2.1 Product safety

2.2.2 Obligation of the operating company

2.2.3 Obligation of personnel

2.3 Specific hazards

2.3.1 Hazardous pumped liquids

2.3.2 Lubricants

2.3.3 Sharp edges

3. Layout and function

3.1 Design details

3.2 Labelling

3.2.1 Name Plate

3.3 Layout

3.4 Bearings and Lubrication

4. Transport, stor age and disposal

4.1 Transport

4.1.1 Unpacking and inspection on delivery

4.1.2 Lifting

4.2 Treatment for storage

4.3 Interim storage before installation

4.4 Disposal

5. Installation and connection

5.1 Preparing for installation

5.1.1 Checking the ambient conditions

5.1.2 Preparing the installation site

5.1.3 Preparing the foundation and surface

5.2 Installation at site

5.3 Planning the pipes

5.3.1 Specifying supports and flange connections

5.3.2 Specifying nominal diameters

5.3.3 Specifying pipe lengths

5.3.4 Optimizing cross-section of pipe work

5.3.5 Providing safety and control devices

(recommended)

5.4 Assembling the pump

5.4.1 Assembling pump case

5.4.2 Installing the drive shaft

5.4.3 Installing the rotor

5.4.4 Assembling the front cover

5.4.5 Assembling Gear motor unit

5.5 Electrical connection

5.5.1 Connecting to power supply

5.6 Installing the Hose

5.6.1 Inserting the hose

5.6.2 Fitting the port flange (Standard assembly)

5.6.3 Fitting the port flange (Split flange assembly)

5.6.4 Filling the pump with lubricant

5.7 Connecting the pipes

5.7.1 Installing the piping

Operation

6.

6.1 Pre-commissioning the pump

6.1.1 Checking the direction of rotation with dry

pump

6.1.2 Starting the pump

6.1.3 Switching off

6.2 Operation

6.2.1 Switching on

6.2.2 Switching off (Refer to → 6.1.3)

6.3 Shutting down the pump

6.4 Start-up following a shutdown

period

6.5 Operating the stand-by pump

7. Maintenance

7.1 Inspections

7.2 Maintenance

7.2.1 Cleaning the pump

7.2.2 Maintenance schedule

7.3 Repairs

7.3.1 Preparations for dismounting

7.3.2 Returning the pump to the manufacturer

7.3.3 Rebuild / Repair

7.4 Hose change

7.4.1 Dismounting the hose

7.4.2 Re-installing the hose, port flanges, lubricant

refill and fitting the inspection window

7.5 Ordering spare parts

8. Storing pumps and hoses

8.1.1 Pre-Storage Actions

8.1.2 Cleaning Protocol for hoses

8.1.3 Storage Conditions

9. Troubleshooting

9.1 Pump malfunctions

10. Appendix

10.1 Technical Specifications

10.1.1 Pump Specifications

10.1.2 Ambient conditions

10.1.3 Tightening torques

10.1.4 Preservatives

10.1.5 Cleaning agents (After hose is removed)

10.1.6 Lubricants

10.1.7 Rotor options

10.2 List of Figures and Ta ble s

10.2.1 List of figures

10.2.2 List of tables

10.3 Declaration of conformity according to EC

Machine Directive

Dura 5 - 35 4.0v-06.2013 3 | Page

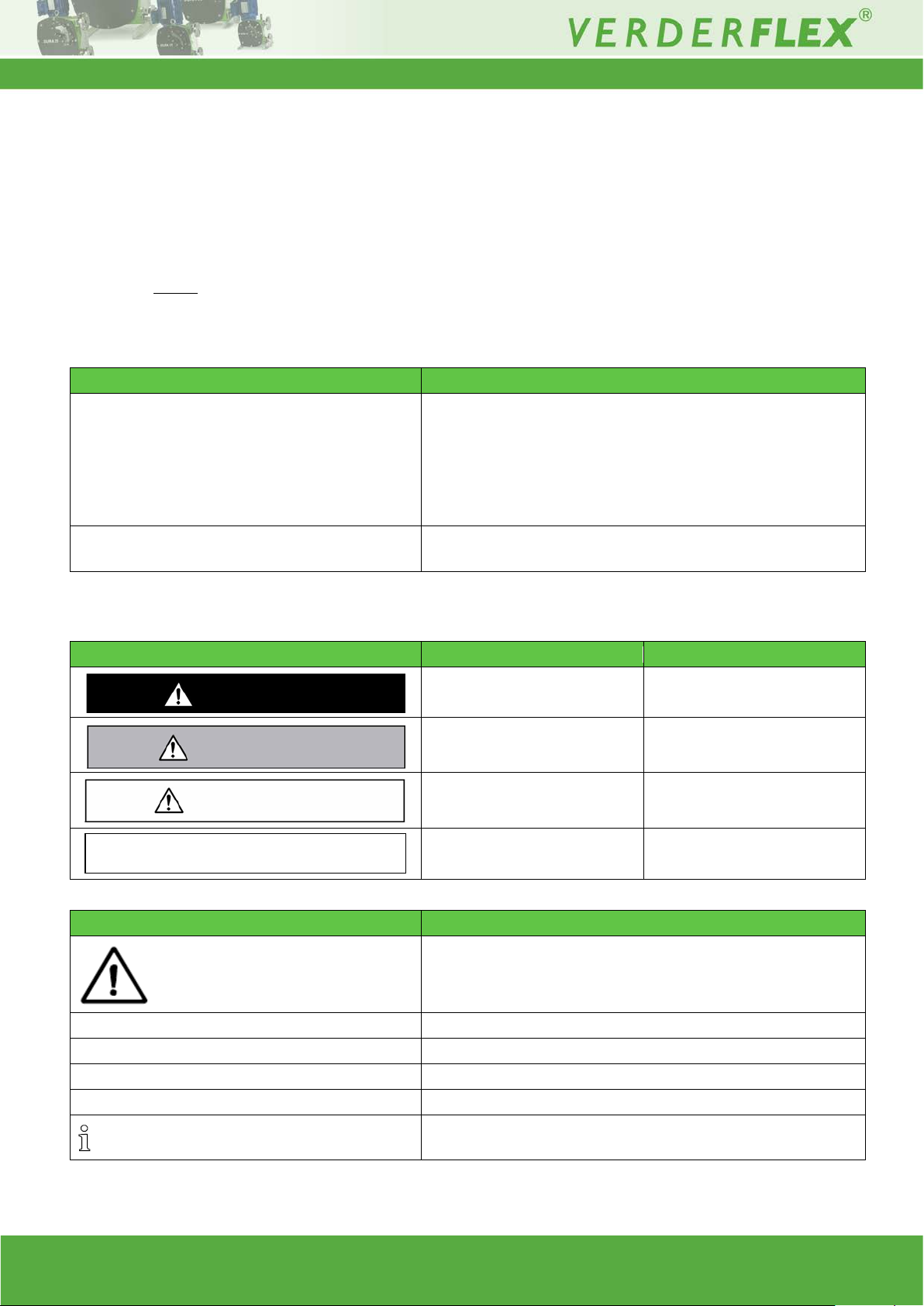

About this document

Target group

Duty

Operating company

Keep this manual available at the operation site of the equipment,

Ensure that personnel read and follow the instructions in this

manual and the other applicable documents, especially all safety

itional rules and regulations referring to the

Qualified personnel, fitter

Read, observe and follow this manual and the other applicable

Warning

Risk level

Consequences of disregard

Immediate acute risk

Death, serious bodily harm

Potential acute risk

Death, serious bodily harm

Potential hazardous situation

Minor bodily harm

Potential hazardous situation

Material damage

Symbol

Meaning

Safety warning sign in accordance with DIN 4844 - W9

safety warning sign

Instruction

1. , 2. , ...

Multiple-step instructions

Precondition

→

Cross-reference

Information, recommendation

NOTE

CAUTION

WARNING

DANGER

1. About this document

Verderflex range of P eristaltic pumps, Dura 5 - 35, has be en developed according to the latest technology a nd

subject to continuo us qualit y control. These op erating i nstructions are int ended to facilitat e fam iliarization with the

pump and its designated use. The relevant information will act as a guideline for you in operating the pump;

alternative courses of actio n are also describ ed shoul d you be unable, f or any r eason, t o follow t hose proce dures

initially given. You are advised to follow these guidelines to achieve maximum efficiency. These operating

instructions do not

observed by all, including the personnel called in for installation.

1.1 Target groups

tak e into accoun t local regulatio ns; the operator m ust ensure that s uch regulations ar e strictly

also available for later reference.

instructions and warnings.

Observe any add

system.

Tab. 1 Target groups and their duties

1.2 Warnings and symbols

Tab. 2 Warnings and consequences of disregarding them

Take note of all information highlighted by the

documents, especially all safet y instructi ons and war ni ngs.

and follow the instructions to avoid injury or death.

Tab. 3 Symbols and their meaning

Dura 5 - 35 4.0v-06.2013 4 | Page

2. Safety

The manufacturer does not accept any liability for

damage resulting from disregard of this

documentation.

Observe the following regulations before carrying out

any work.

2.1 Intended use

Only use the pump to handle compatible fluids as

recommended by the manufacturer (→ 10.1 Technical

specifications).

Adhere to the operating limits.

Safety

Keep this manual and all other applicable documents

complete, legible and accessible to personnel at all times.

Refrain from any pro ced ure or action that would pose a risk

to personnel or third parties.

In the event of any safety-relevant faults, shut down the

pump immediately and have the malfunction corrected by

qualified personnel.

The installation of the pump, associated pipe work and

electrical fittings must comply with the requirements of

installation given in this manual and any local national or

regional health and safety regulations

Consult the manufacturer regarding any other use of the

pump.

Pumps delivered without a mo tor must be f itted with a motor

in accordance with the provisions of EC Machine Directive

2006/42/EC or local regulations when outside EC.

Prevention of obvious misuse (examples)

Note the operating limits of the pump with regard to

temperature, pressure, flow rate and motor speed (→ 10.1

Technical specif ic atio ns).

Do not operate the pump while the inlet/outlet valve is

closed.

Only install the pump as recommended in this manual. For

example, the following are not allowed:

–

Installing the pump without proper support.

–

Installation in the immediate vicinity of extreme hot or

cold sources.

2.2 General safety instructions

2.2.1 Product safety

These operating instructions contain fundamental

information which must be complied with during

installation, operation and maintenance. Therefore this

operating manual mu st be r ead and understood both by

the installing personnel and the responsible trained

personnel / operators prior to installation and

commissioning, and it must always be kept easily

accessible within the operating premises of the

machine.

Not only must the general safety instructions laid down

in this chapter on “Safety ” be complied w ith, but also th e

safety instructions outlined under specific headings.

2.2.2 Obligation of the operating company

Safety-conscious operation

Ensure that the following safety aspects are observed and

monitored:

–

Adherence to intended use

–

Statutory or other safety and accident-prevention

regulations

–

Safety regulations governing t he ha ndl ing of

hazardous substances if appl icable

–

Applicable standards and guidelines in the country

where the pump is operated

Make personal protective equipment available pertinent to

operation of the pump; as required.

Qualified personnel

Ensure that all personnel tasked with work on the pump

have read and understood this manual and all other

applicable documents, including the safety, maintenance

and repair information, prior to use or installation of the

pump.

Organize responsibilities, areas of competence and the

supervision of personnel.

Have all work carried out by specialist technicians only.

Ensure that trainee personnel are under the supervision of

specialist technicians, at all times, when working on the

pumping system.

Safety equipment

Provide the following safety equipment and verify its

functionality:

–

For hot, cold and moving part s: safety guar ding should

be provided by the operating company.

–

For potential build up of electrostatic char ge: ens ure

appropriate grounding if and when required.

Operate the pump only if the pumping unit and all

associated systems are in good functional condition.

Only use the pumping system as intended, fully aware of

safety and risk factors involved, and in adherence to the

instructions in this manual.

Dura 5 - 35 4.0v-06.2013 5 | Page

Layout and function

The warranty is voided if the customer fails to follow

any and all instructions, warnings and cautions in this

document. Verder has made every effort to illustrate

and describe the product(s) in this document. Such

illustrations and descr iptions are, how ever , for t he sole

purpose of identificat ion and

express or imply a

warranty that the product s are merchantabl e or fit for a

particular purpose, or that the products will

necessarily conform to the illustration or descriptions.

Obtain the manufacturer's approval prior to carrying

out any modifications, rep airs or alterations during the

warranty period. Only use genuine parts or parts that

have been approved by the manufacturer.

For further details regarding warranty, please refer

terms and conditions.

It is imperative that the instructions contained in

this manual are complied with by the operating

personnel at all times.

Peristaltic hose pump, Verderflex Dura, is simple by

design in its construction and operation. The medium

to be pumped does not come into contact with any

moving parts and is totally contained within a robust,

heavy

consists of an inner

layer, two – six reinforcement layers and an outer

layer. A rotor passes along the length of the hose,

compressing it. This motion forces the contents of the

hose directly in front o f the roto r to move forw ard along

the length of the hose in a ‘positive displacement’,

peristaltic movement. In the wake of the rotor’s

compressing action, the natural elasticity of the

polymer reinforced rubber forces the ho se to open an d

regain its round profile, creating suction pressure,

which recharges the pump.

Verderflex Dura is a twin lobe, single rotor, peristaltic

pump with quick-fit tapered port flange design which

clamps and seals in one easy movement to speed

hose replacement.

Warranty

do not

2.2.3 Obligation of personnel

Pump and associated components:

–

Do not lean or step on them or use as climbing aid

–

Do not use them to support boards, ramps or beams

–

Do not use them as a fixing point for winches or

supports

–

Do not de-ice using gas burners or similar tools

–

Do not remove the safety guarding for hot, cold or

moving parts during operation.

Reinstall the safety equipment on the pump as required by

regulations after any repair / maintenance work on the

pump.

3. Layout and function

-duty hose, which usually

3.1 Design details

3.2 Labelling

3.2.1 Name Plate

2.3 Specific hazards

2.3.1 Hazardous pumped liquids

Follow the statutory safety regulations when handling

hazardous pumped liquids (e.g. hot, flammable, poisonous

or potentially harmful). Use appropriate personal protective

equipment when carrying out any work on the pump.

2.3.2 Lubricants

Ensure that the lubricant and p umpe d liq uid ar e co mpat ibl e

with each other. This is a precautionary measure in case of

accidental hose burst whereby the pumped liquid comes in

contact with the lubricant (Refer datasheet for lubricant to

ensure compatibility)

2.3.3 Sharp edges

Pump parts, such as the shims, can be sharp

–

Use protective gloves when carrying out any work on

the pump

Dura 5 - 35 4.0v-06.2013 6 | Page

Figure 1 Name plate

1 Pump type

2 Serial number

3 Year of manufacture

Note: When requesting spares, the model and serial

number should always be quoted.

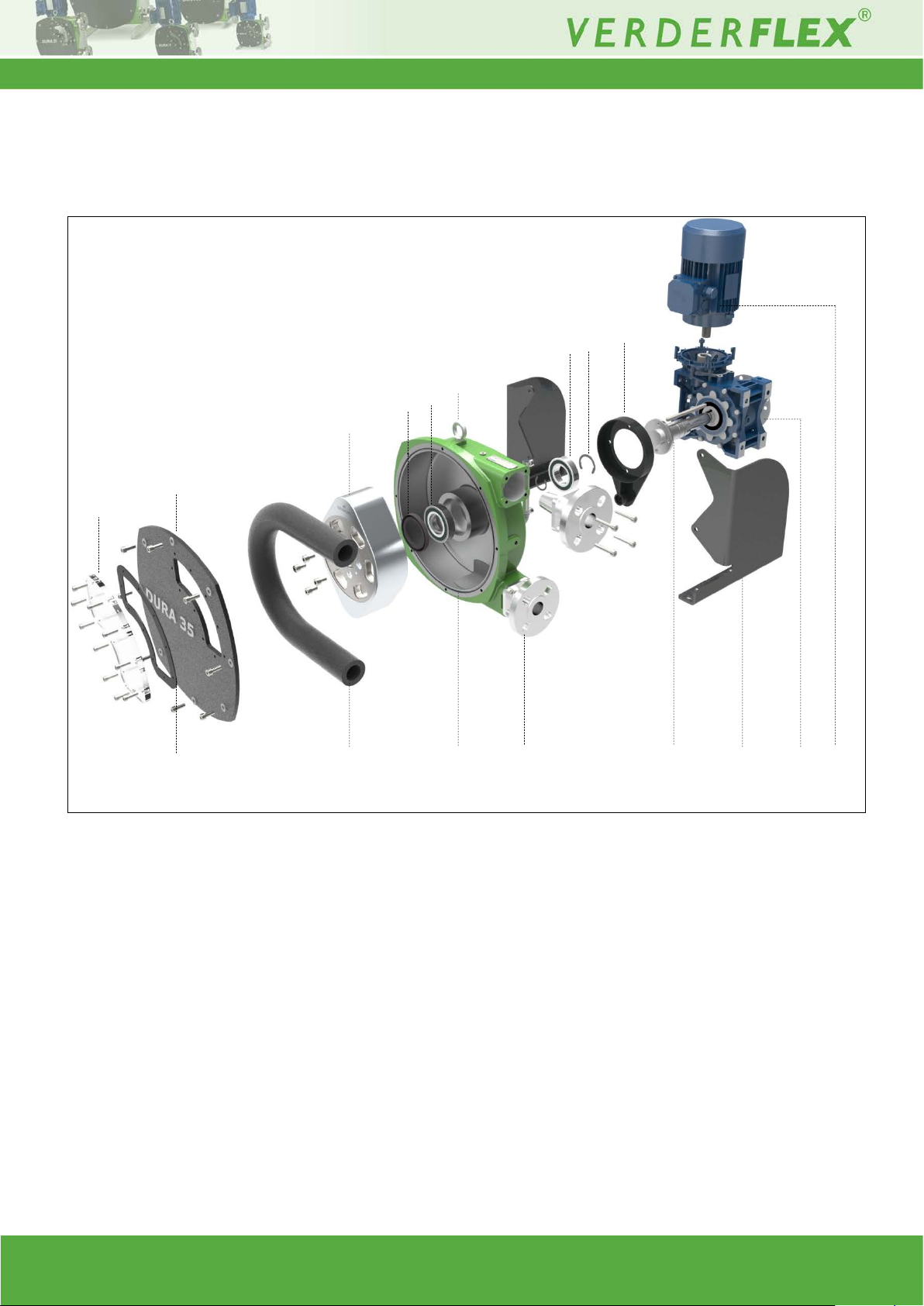

3.3 Layout

1 Inspection window

7 Front Bearing

13 Torque arm

2 Inspection window gasket

8 Pump casing

14 Drive shaft

3 Front cover

9 Lifting eye

15 Frames

4 Hose

10 Port flange

16 Gearbox

5 Rotor

6 Lip seal

11 Bearings

12 Crescent clip

17 Motor

1 2 4

10 9 11

14

16 3 5

17

13 8 15 6 7

12

Layout and function

Figure 2 Layout (generic view)

3.4 Bearing s an d Lubrication

Pump: To be filled at installation with appropriate

lubricant if not supplied pre filled. (→10.1.6

Lubricants)

Bearings are sealed units and need no additional

lubricant

Dura 5 - 35 4.0v-06.2013 7 | Page

Always transport the unit in an upright position and

ensure that the unit is securely attached to the pallet.

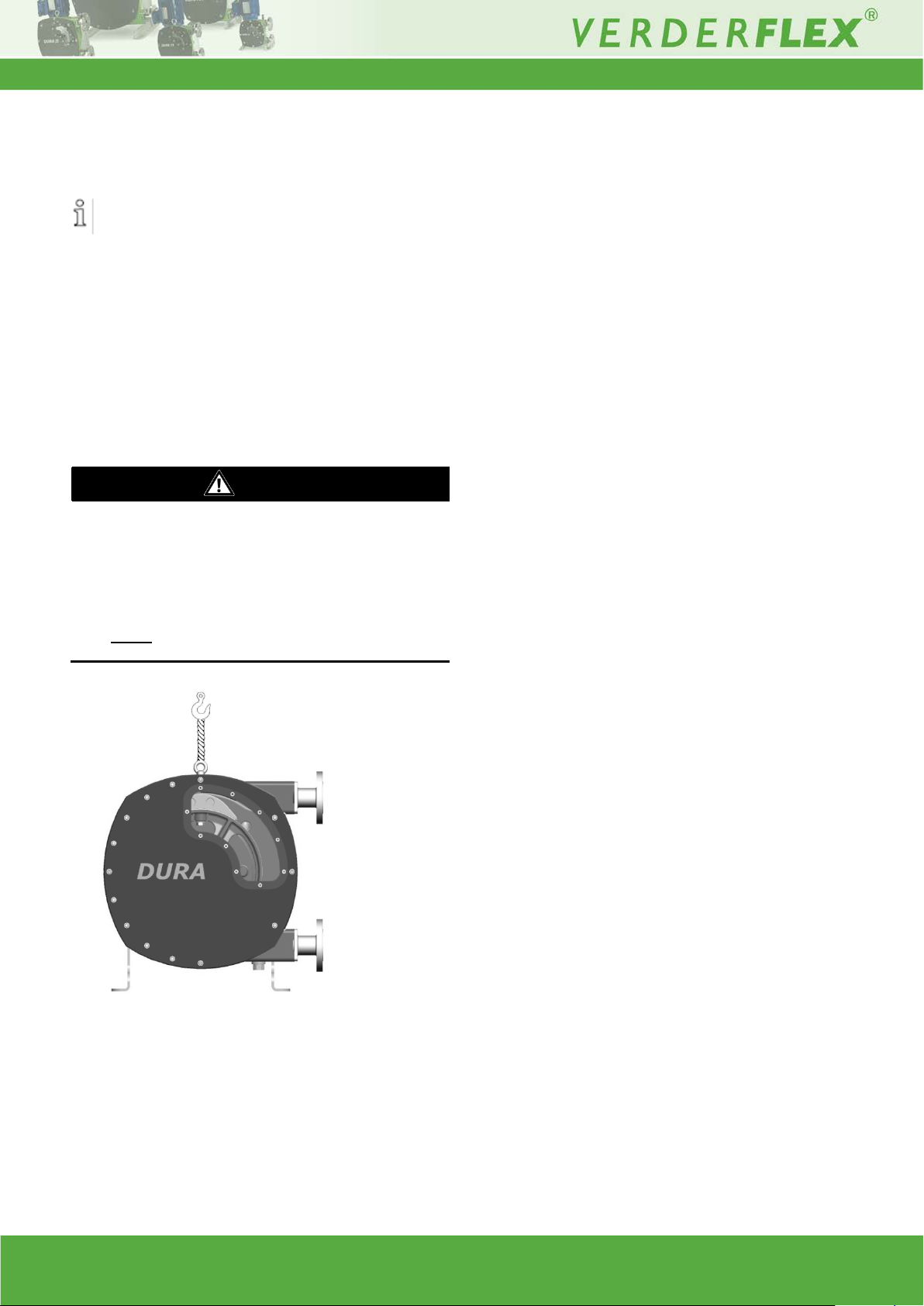

DANGER

can be caused by falling

Fasten the lifting ge ar t o the lift ing ey e as shown i n th e

4. Transport, storage and disposal

4.1 Transport

4.1.1 Unpacking and inspection on delivery

1. Unpack the pump/pump unit upon delivery and

inspect it for transport damage.

2. Report any transport damage to the

manufacturer/distributor immediately.

3. Retain the pallet if any further transport is required.

4. Dispose all packaging material according to local

regulations.

4.1.2 Lifting

Death or crushing of limbs

loads!

1. Use lifting gear appropriate for the total weight to be

transported.

2.

following illustration.

3. Do not stand under suspended loads.

Figure 3 Fastening lifting gear to pump unit

Dura 5 - 35 4.0v-06.2013 8 | Page

4.2 Treatment for storage

Unpainted steel surfaces should be coated with rust

inhibitor and the unit should be stored in a dry, dust

free environment not exceeding 60°C

NOTE

–

Renew treatment if necessary.

NOTE

With prolonged use, pump parts can get contaminated

by poisonous or radioactive pu mped liquids to su ch an

extent that cleaning may be insufficient.

WARNING

Dispose of the pump unit and associated parts in

NOTE

NOTE

immediately before connecting the pipes to the pump

Material damage due to inappropriate treatment for

storage!

Treat all internal and external bare metal pump parts for

storage.

5. Installation and connection

Material damage due to unauthorized modification on

pump unit!

Do not make any structural modifications to the pump

unit or pump casing

Do not carry out any welding work on the pump unit or

pump casing

4.3 Interim storage before installation

Material damage due to inappropriate storage!

Treat the pump with preservatives compatible with

pumped media (precaution in case of spillage).

1. Close all opening s with blanks, plugs or plasti c covers.

2. Make sure the storage room meets the following

conditions:

–

Dry, humidity not to exceed 80%

–

Out of direct sunlight

–

Frost-free; temperature range 0 to 40°C

–

Vibration-free; minimize

–

Dust-free; minimize

*Storage information for pump s withdrawn from use is listed

in section 8, Storing pumps and hoses.

4.4 Disposal

Risk of poisoning and environmental damage by the

pumped liquid or oil!

Use suitable personal protective equipment when

carrying out any work on the pump.

Prior to disposal of the pump:

–

Drain and dispose the lubr ican t in accor dance w ith

local regulations .

–

Collect and dispose of any leaking pumped liquid

or oil in accordance with local regulations.

–

Neutralize residues of pumped liquid in the pump.

accordance with statutory reg u latio ns.

Material damage caused by ingress!

–

Do not remove any protective flange covers until

5.1 Preparing for installation

5.1.1 Checking the ambient conditions

1. Make sure that the operating conditions are complied

with (→ 10.1.1 Pump specifications)

2. Make sure the r equired ambient c onditions are fulfil led

(→ 10.1.2 Ambient conditions)

5.1.2 Preparing the installation site

Ensure the installation site meets the following

conditions:

–

Pump is freely accessible from all sides

–

Sufficient space is available for the

installation/removal of the pipes and for maintenance

and repair work, especially for the removal and

installation of the hose.

5.1.3 Preparing the foundation and surface

Make sure the foundation and surface meet the

following conditions:

–

Level

–

Clean (no oil, dust or other impurities)

–

Capable of bearing the w eight of the p ump unit and all

operating forces

–

Ensure the pump is stable and cannot tip over

–

Concrete foundation: Standard concrete strong

enough to support the pump unit under load.

5.2 Installation at site

1. Lift the pump unit (→ 4.1.2 Transport)

2. Put the pump unit down at the installation site.

3. Bolt the pump down; use all 4 holes.

Dura 5 - 35 4.0v-06.2013 9 | Page

Loading...

Loading...