Verasys LC-VAC300 0 Series Installation Instructions Manual

*2410143015

24-10143-01515, Rev —

Verasys® 32 Point 24 VAC Application Controller

Installation Instructions

LC-VAC300x-0

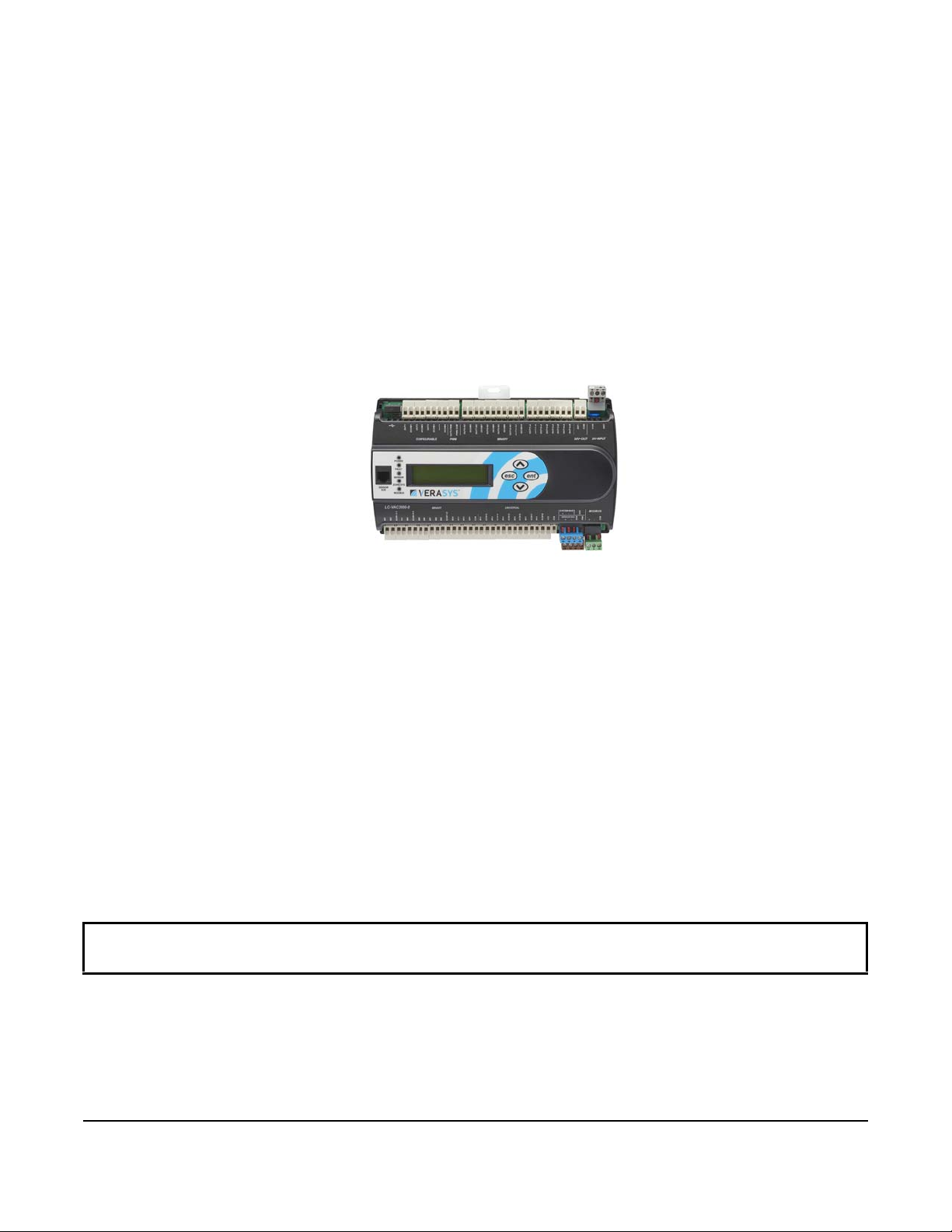

Application

The Verasys® Application Controller is part of the SMART Equipment Controller family. The Verasys Application

Controllers run pre-engineered applications and provide the inputs and outputs required to monitor and control a

wide variety of HVAC equipment.

Verasys Application Controllers operate on an RS-485 BACnet® (MS/TP) Bus as BACnet Advanced Application

Controllers (B-AACs) and integrate into Johnson Controls® and third-party BACnet systems.

Verasys Application Controllers have an integral real-time clock. The clock functionality monitors and controls

schedules, calendars, trends, and operate for

the system network.

IMPORTANT: Use this Verasys Application Controller only as an operating control. Where failure or

malfunction of the Verasys Application Controller could lead to personal injury or property damage to the

controlled equipment or other property, additional precautions must be designed into the control system.

Incorporate and maintain other devices, such as supervisory or alarm systems or safety or limit controls,

intended to warn of or protect against failure or malfunction of the Verasys Application Controller.

extended periods of time as stand-alone controllers when o ffline from

Part No. 24-10143-01515, Rev A

Issued May 2018

IMPORTANT: Utiliser ce Verasys Application Controller uniquement en tant que dispositif de contrôle de

fonctionnement. Lorsqu'une défaillance ou un dysfonctionnement du controller risque de provoquer des

blessures ou d'endommager l'équipement contrôlé ou un autre équipement, la conception du système de

contrôle doit intégrer des dispositifs de protection supplémentaires. Veiller dans ce cas à intégrer de façon

permanente d'autres dispositifs, tels que des systèmes de supervision ou d'alarme, ou des dispositifs de

sécurité ou de limitation, ayant une fonction d'avertissement ou de protection en cas de défaillance ou de

dysfonctionnement du Verasys Application Controller.

V e rasys 32 Point 24VAC Application Controller Features

The Verasys Application Controllers are used in a Verasys system. The Verasys 32 Point 24 VAC Application

Controller comes without an application, but you can load custom built applications into this controller. Depending

on your market, you can access an application library in certain markets. Contact your local Verasys

representative. The Verasys 32 Point 240VAC Application Controller has the following features:

• Input/Output (I/O) quantities and characteristics of the Verasys Application Controller

• Real-time clock with local display

• Built-in BACnet schedule objects and calen da r s

• Mobile Access Portal (MAP) Gateway compatibility for configuration through smart mobile devices

connectivit

• Verasys Smart Building Hub ( S BH) compatible through the BACnet MSTP system bus connection

• Dedicated Sensor bus for Johnson Controls smart end-devices

• Dedicated Modbus port for third-party end-device integ ration with Modb

y

us

and remote

•

Multi-protocol support for BMS integration BACnet MSTP, N2 and Modbus RTU, through on-board display

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

1

North American Emissions Compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when this equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with th e instruction manua l,

may cause harmful interference to radio com munica tions. Op er ation o f this eq uip ment in a re sid ential a rea may

cause harmful interference, in which case users will be required to correct the interference at their own expense.

Canada

This Class (A) digital apparatus meets all the requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la Classe (A) respecte toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

Installation

Follow th ese guidelines when you install a Verasys Application Controller:

• To help

• V e r ify that all parts ship with the controlle r.

• Do not drop the controller or subject it to physical shock.

minimize vibration and shock damage, transport the controller in the original container.

Parts Included

• One Verasys 32 point 24V Application Controller

• One installation instruction sheet

Materials and Special To ols Needed

• Three fasteners appropriate for the mounting surface, such as M4 screws or #8 screws

• One 20 cm (8 in.) or longer piece of 35 mm DIN rail and appropriate hardware for DIN rail moun t only

• Small straight-blade screwdriver for securing wires in the terminal blocks

Mounting

IMPORTANT: Only qualified personnel should install or service Verasys products. These instructions are a

guide for such personnel. Mount the Verasys controllers on a wall or DIN rail inside an enclosure (rated at least

IP20). Carefully follow all instructions in this document and all instructions for the controller.

Follow these guidelines when you mount a field controller:

• Ensure the mounting surface can support the controll er , DIN rail, and any user-supplied enclosure.

• Mount the controller horizontally on 35 mm DIN rail whenever possible.

• Mount the controller in the proper mounting position, see Figure 1.

• Use shi ms or was hers to mount the cont rolle r secur ely and evenly on the mounting surface.

• Mount the controller in an area free of cor rosive va pors a nd fo llow the am bien t conditio n re quireme nts l isted in

Table 11.

• Ensure suffic ien t space around the con troller for

ventilation through the controller. Provide a minimum of 50 mm (2 in.) on the top, bottom, and front of the

controller.

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

cable and wire connections for easy cover removal, and good

2

• Do not mount the controller on surfaces prone to vibration, such as duct work.

Horizontal Mount Position

Required for DIN Rail Mounting

• Do not mount the controller in areas where electromagnetic emissions from other devices or wiring can

interfere with controller communication.

Follow these additional guidelines when you mount a field controller in a panel or enclosure:

• Mount the controller so that the enclosure walls do not prevent cover remova l and obstruct ventilation throug h

the controller.

• Mount the controller so that the power tran sfo rmer and other devices do not radiate excessive heat to

controller.

• Do not install the controller in an airtight enclosure.

• Use a zip-tie to secure the controller when you ship it.

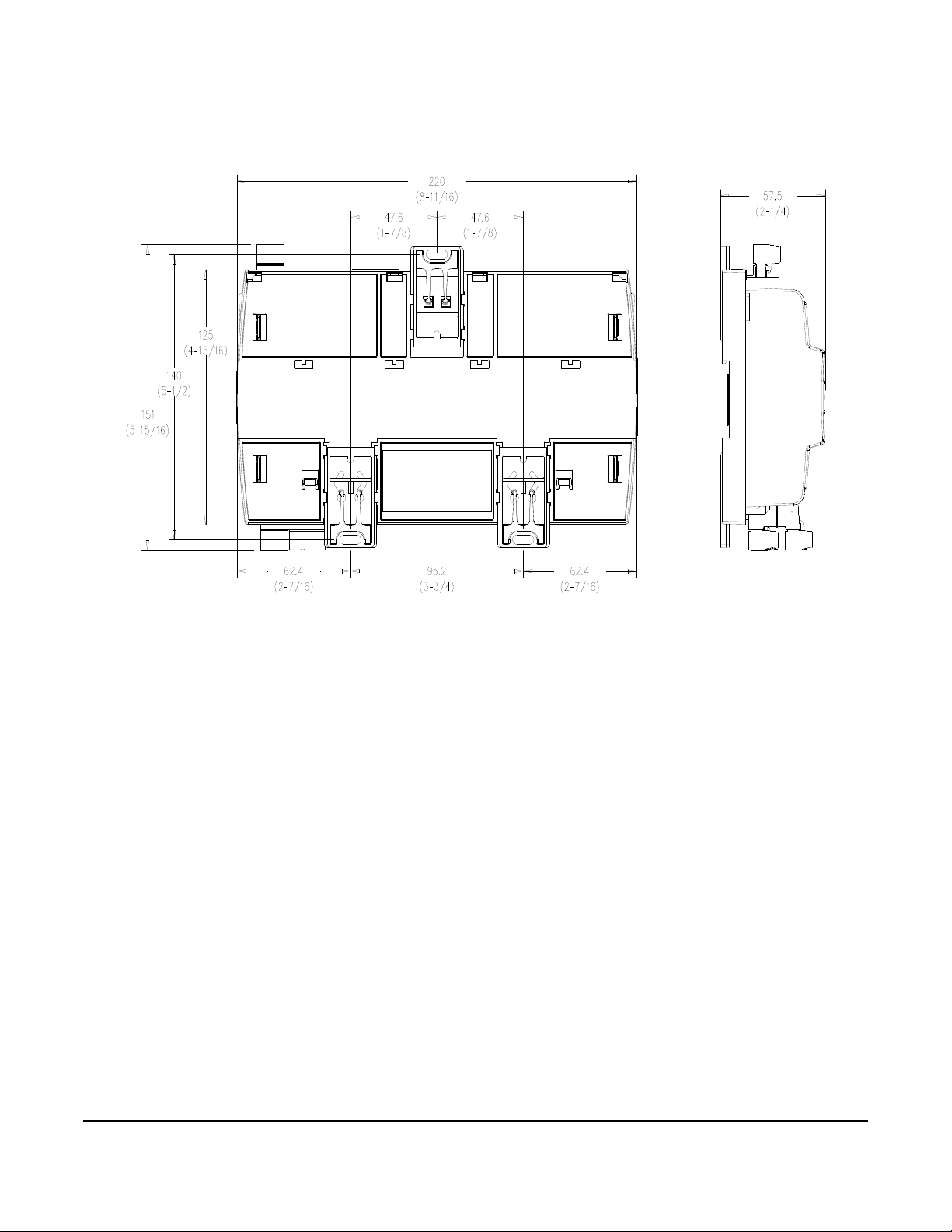

Figure 1: Verasys Application Controller mounting position

DIN Rail Mount Applications

Mounting the field controller horizontally on 35 mm DIN ra il is the preferred mounting method.

To mount a field controller on 35 mm DIN rail, complete the following steps:

the

1. Securely mount a 20 cm (8 in.) or longer section of

space so that the controller mounts as in in Figure 1.

2. Pull the two lower mounting clips outward from the controller to the extended position.

3. Hang the controller on the DIN rail by the hooks at

and position the controller snuggly against the DIN rail.

4. Zip tie the controller to the DIN rail when you ship.

5. Push the bottom mounting clips inward (up) to secure the controller on the DIN rail.

To remove the controller from the DIN rail, pull the bottom mounting clips out to the extended position and

carefully lift the controller off the DIN rail.

IMPORTANT: Do not overtighten the mounting screws. Overtightening the screws may damage the mounting

clips.

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

a

35 mm DIN rail horizontally and centered in the appropriate

the top of the DIN rail channel on the back of the contr oller

3

Figure 2: Back of Controller Showing Extended Mounting Clips, DIN Rail Channel, and Mounting

Dimensions, mm (in.)

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

4

Wiring

Risk of Electric Shock.

Disconnect power from the controller before making any adjustments. Do not touch any part of the printed circuit

board while power is applied. Failure to follow these precautions can result in personal injury or death.

Risque de décharge électrique.

Déconnecter l'alimentation du controller avant toute opération de réglage. Veiller à ne toucher aucune partie du

circuit imprimé lorsque celui-ci est sous tension. Le non-respect de ces précautions peut p rovoquer des blessur es

graves, voire mortelles.

Risk of Electric Shock.

Disconnect or isolate all power supplies before making electrical connections. More than one disconnection or

isolation may be required to completely de-energize equipment. Contact with components carrying hazardous

voltage can cause electric shock and may result in severe personal injury or death.

Risque de décharge électrique.

Débrancher ou isoler toute alimentation avant de réaliser un branchement électrique. Plusieurs isolations et

débranchements sont peut-être nécessaires pou r -couper entière ment l'alimentation de l'équipement. Tout contact

avec des composants conducteurs de tensions dangereuses risque d'entraîner une décharge électrique et de

provoquer des blessures graves, voire mortelles.

IMPORTANT: Do not exceed the controller electrical ratings. Exceeding controller electrical ratings can result

in permanent damage to the controller and void any warranty.

IMPORTANT: Use copper conductors with a rating of at least 75°C (167°F). Make all wiring in accordan ce with

local, national, and regional regulations.

IMPORTANT: Electrostatic discharge can damage controller components. Use proper electrostatic discharge

precautions during installation, setup, and servicing to avoid damaging the controller.

For detailed information on configuring and wiring an MS/TP Bus, System Bus, and Sensor Bus, refer to the

Verasys® BACnet® MS/TP

Communications Bus T echnical Bulletin (LIT-12012362).

Verasys Appl ication Controller Terminal Blocks and Bus Ports

See Figure 11 for terminal block, spade location, and bus port locations on the LC-VAC300x-0 controller. Use the

following guidelines when wiring a controller.

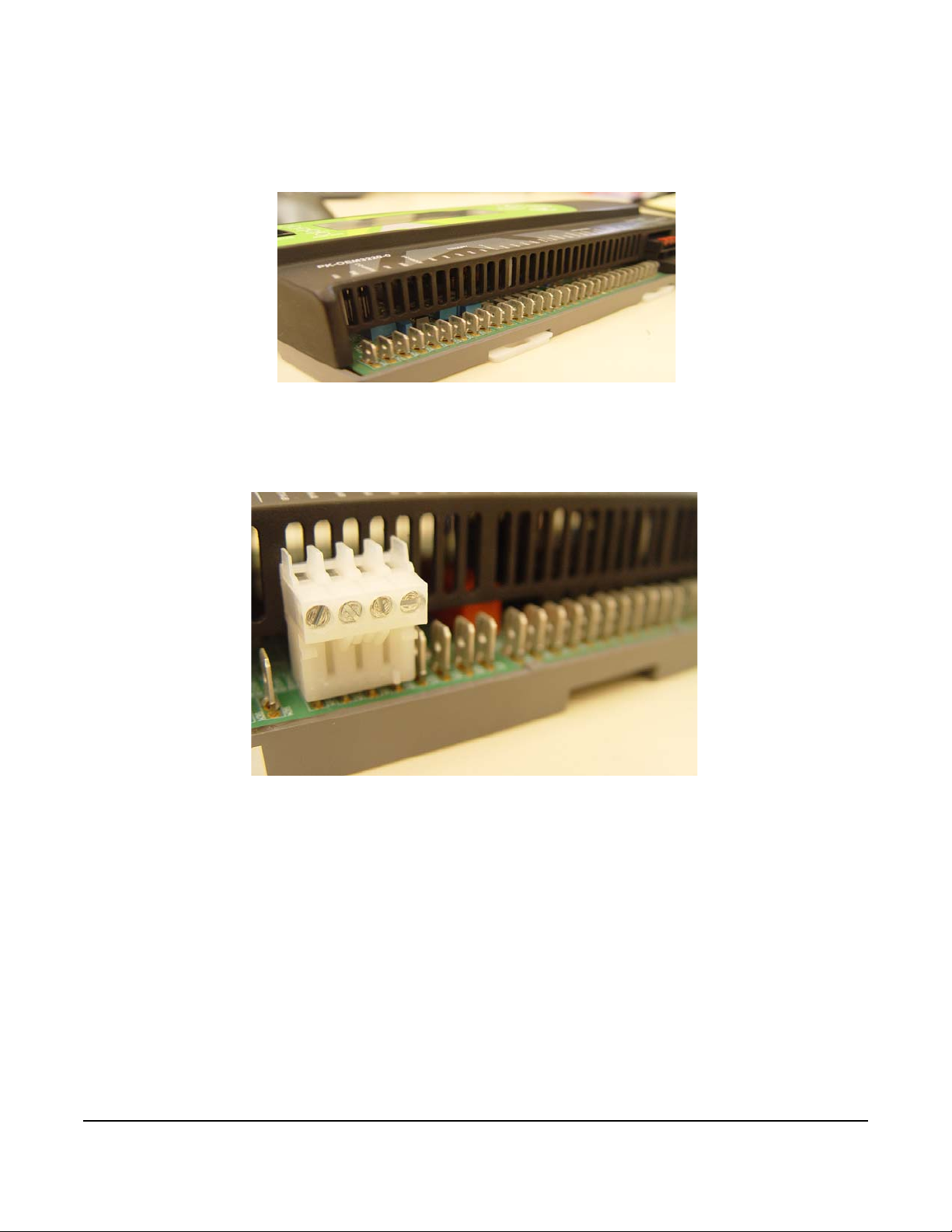

Input and Output T e rm in al Blocks

On most field controller models, all of the input terminal blocks or spade terminals are mounted on the bottom of the

controller and the output terminal blocks and s p a d e t e r m i n a l s a re mounted on the top of the cont ro l le r. See Table 5

for more information about I/O

terminal functions, requirements, and ratings.

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

5

Factory Wiring

For all the I/O terminals listed in Table 5, use the correct gauge wiring. For each spade terminal in this application,

follow the guidelines in Table 5 and use a spade connector with screw terminals. Figure 3 shows

I/O spade terminals.

Figure 3: Verasys Application Controller Spade Terminals

Field Wiring

For all I/O terminals listed in Table 5, use the appropriate gauge wiring. For each spade ter minal in this appli cation,

follow the guidelines in Table 5 and use a spade connector with screw terminals.

Figure 4: Verasys Application Controller Spade Connector with Screw Terminals

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

6

Stacked System and Sensor Bus Terminal Block

Stranded 3-Wire Twisted Shielded Cable

Isolated Shield

Connection

Terminal

To N ex t

Device on

the System Bus

Segment

System Bus

Terminal

Block Plugs

Terminating Device

on System Bus Segment

To N ex t

Device on

the System Bus

Segment

Daisy Chained Device

on System Bus Segment

SHD

+

COM

SHD

+

COM

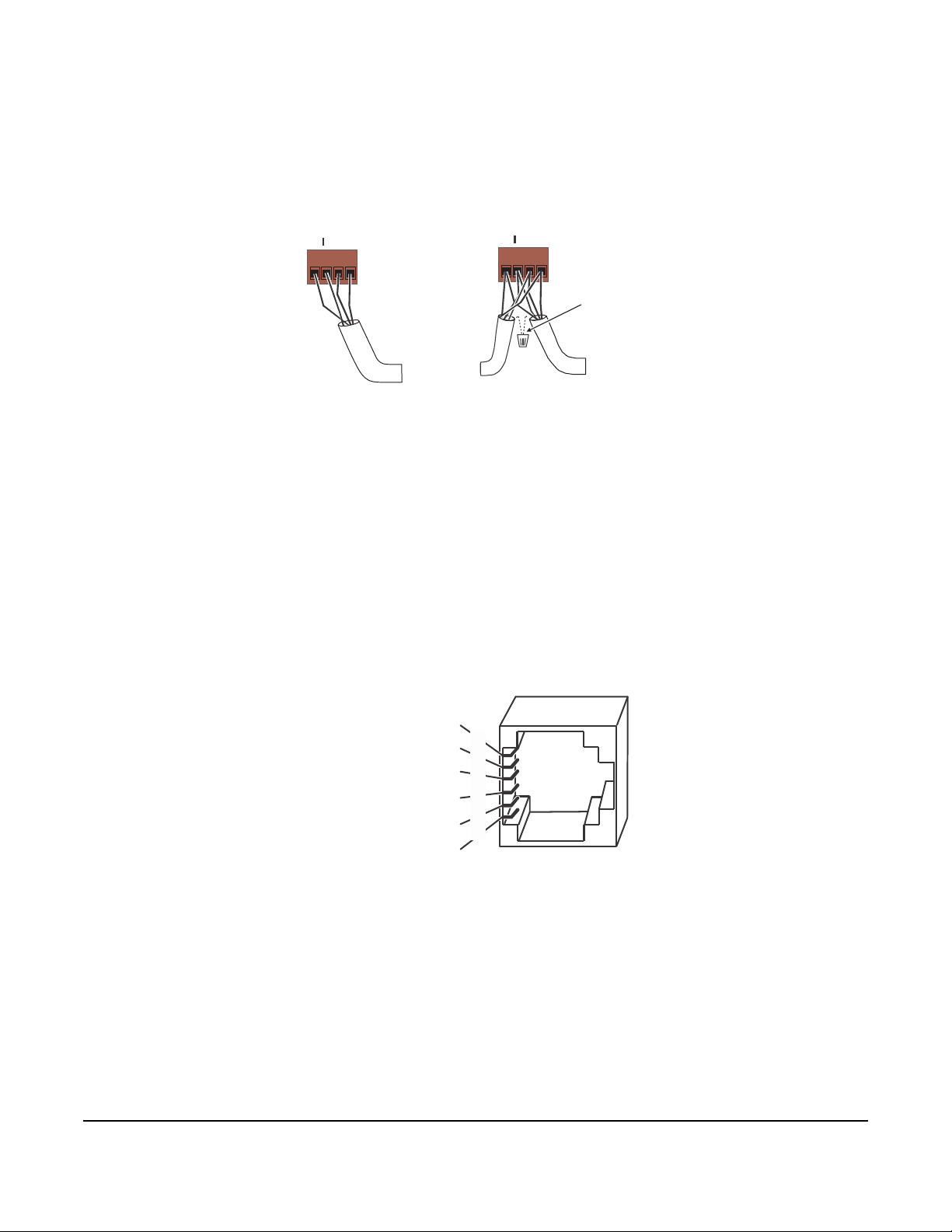

A dual-stacked connector serves as the system bus and sensor bus port on the V erasys Controllers. The upper row

on the connector is the system bus port. The lower connector row is the sensor bus port.

Figure 5: Stacked System and Sensor Bus Terminal Block

System Bus Te rminal Block

The System Bus terminal block is a blue, removable, 4-termin al pl ug that fits into a b oard -mounted jack. Wire the

removable system bus terminal block plugs on the controller on the top row of the stacked connector. Wire the other

field controllers in a daisy-chain configuration using 3-wire twisted, shielded cable, as shown in the following figure.

See Table 7 for more information on functions, ratings, requirements and cables.

Figure 6: System Bus Terminal Block Wiring

Note: The System Bus Shield (SHD) terminal is isolated and you can use it to connect the shields, in a daisy-

chain configuration for system bus wiring.

Sensor Bus Termin al Block

The Sensor Bus terminal block is a brown, removable, 4-terminal plug tha t fits in to a boar d-m ounted jack.

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

7

Wire the removable Sensor Bus terminal block plugs on the lower port of the Dual Stacked Connector to the

Stranded, 4-Wire (2 Twisted Pair) Shielded Cable

(One twisted pair is the and leads.

+ -

The second pair is COM and PWR.)

Cable Shield

Connection

To N e x t

Device on

th e Sensor Bu s

Sensor Bus

Terminal

Block Plugs

Terminating Device

on S ensor Bus

Daisy Chained Device

on S ensor Bus

To N e x t

Device on

th e Sensor Bu s

PWR

+

COM

PWR

+

COM

Power

(15 VDC)

Sensor Bus +

Sensor Bus

-

Bus and Power Common

Power

(15 VDC)

Sensor Bus Po rt

(RJ-12 Modular Jack)

Bus and Power Common

2

3

4

5

6

1

controller, and other Sensor bus devices in a daisy-chain configuration using 4-wire twisted, shielded cable as

shown in Figure 7. See Table 7 for more information on functions, ratings, requirements and cables.

Figure 7: Sensor Bus T e r minal Block Wiring

Note: The Sensor BUS PWR terminal supplies 15 VDC. You can use the PWR terminal to connect, in a daisy-

chain configuration, the 15 VDC power leads on the Sensor bus.

Sensor Bus Port

The Sensor Bus port on the middle left side of the controller (Figure 11) is an RJ-12, 6-position modular jack that

provides a connection for the SBH, the VAV Balancing Too l, specified network sensors, or other Sensor Bus devices

with RJ-12 plugs.

The Sensor port connects internally to the Sensor bus terminal block. See Table 7 for more information . The sen sor

bus port pin assignment is shown in Fi gure 8.

Figure 8: Pin Number Assignments for Sensor Bus Ports on Verasys Application Controllers

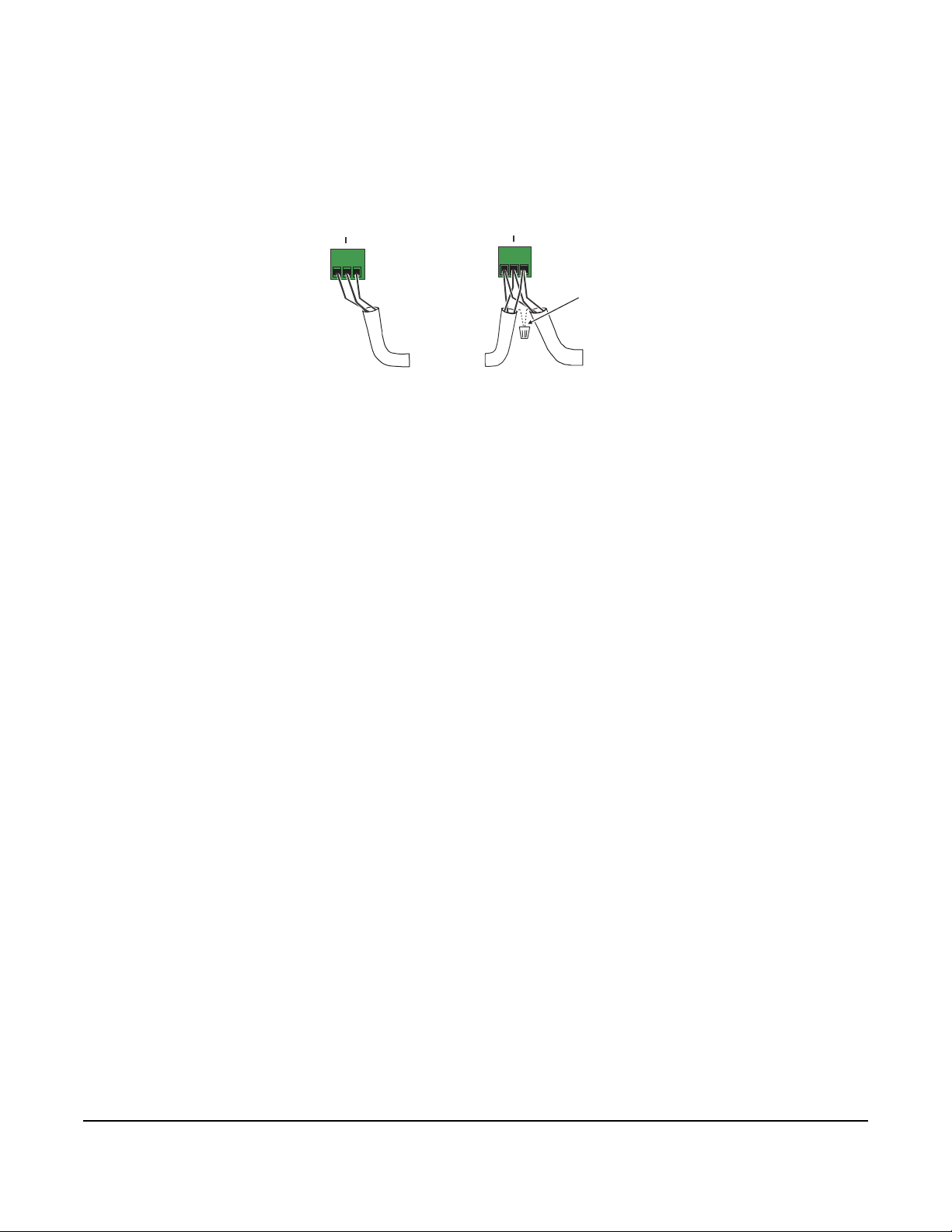

Modbus Terminal Block

The Modbus terminal block is a green, removable, 3-terminal plug that fits into a board-mounted jack.

Wire the removable Modbus terminal block plugs on the controller, and wire the other field controllers in a daisy-

chain configuration using 3-wire twisted, shielded cable as shown in Figure 9. See T able7 for more information on

functions, ratings, requirements and cables.

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

8

The Modbus port communicates as a Modbus device and connects to the Modbus network which can consist of

+

COM

Cable Shield

Connection

To N ex t

Device on

the Modbus

Segment

Modbus

Terminal

Block Plugs

Terminating Device

on Modbus

Daisy Chained Device

on Modbus

To N ex t

Device on

the Modbus

Segment

+

COM

one-to-many Modbus devices. Each Modbus device has a unique Modbus Re gister table and you must configur e it

within the application of the Verasys Controller.

Figure 9: Modbus Terminal Block

Verasys® 32 Point 24 VAC Application Controller Installation Instructions

9

Loading...

Loading...