Venture Cycle LandRider Assembly Instructions Manual

ASSEMBL Y INSTRUCTIONS

Version 4

ASSEMBLY TIPS

If you carefully follow each step in order, assembly should take approximately 30 minutes.

We recommend that you have a friend help you assemble the LandRider .

Relax and be patient. Your safety is important.

CUSTOMER SERVICE

If you have any questions please call LandRider at: 1-800-945-5335 or email us at

service@landrider .com

WARNING: These Assembly Instructions are a supplement to your Owner’s Manual.

This information is limited to the assembly instructions for the LandRider and does

not include general safety and product information on the LandRider or bicycling.

For a complete understanding of the LandRider and all warnings and cautions, you

must thoroughly read and completely understand your LandRider Owner’ s Manual.

Copyright: Venture Cycle, LLC. 2001

1

STEP 1: ASSEMBLY PREPARATION

A) Using a pair of scissors, carefully cut all the ties holding the bike parts together .

DO NOT USE A BLADE, AS THIS IS DANGEROUS AND COULD PUNCTURE THE TIRE.

B) Carefully free Front Wheel which is supported by Crank Arm and Handlebar Stem.

DO NOT REMOVE THE PROTECTIVE WHITE CARDBOARD SLEEVES WRAPPED AROUND

THE FRAME UNTIL THE BIKE IS COMPLETEL Y ASSEMBLED.

C) Remove the protective caps from the Wheel Hubs on the Front and Rear Wheels.

STEP 2: PRE-ASSEMBLY CHECK

Lay out all the components and tools for a pre-assembly check list. If any parts are missing, call

LandRider at: 1-800-945-5335.

Pre-Assembly Check List

Main Box

1. Frame Assembly (including Handlebars)

2. Seat Assembly (including Seat Post)

3. Front Wheel Assembly

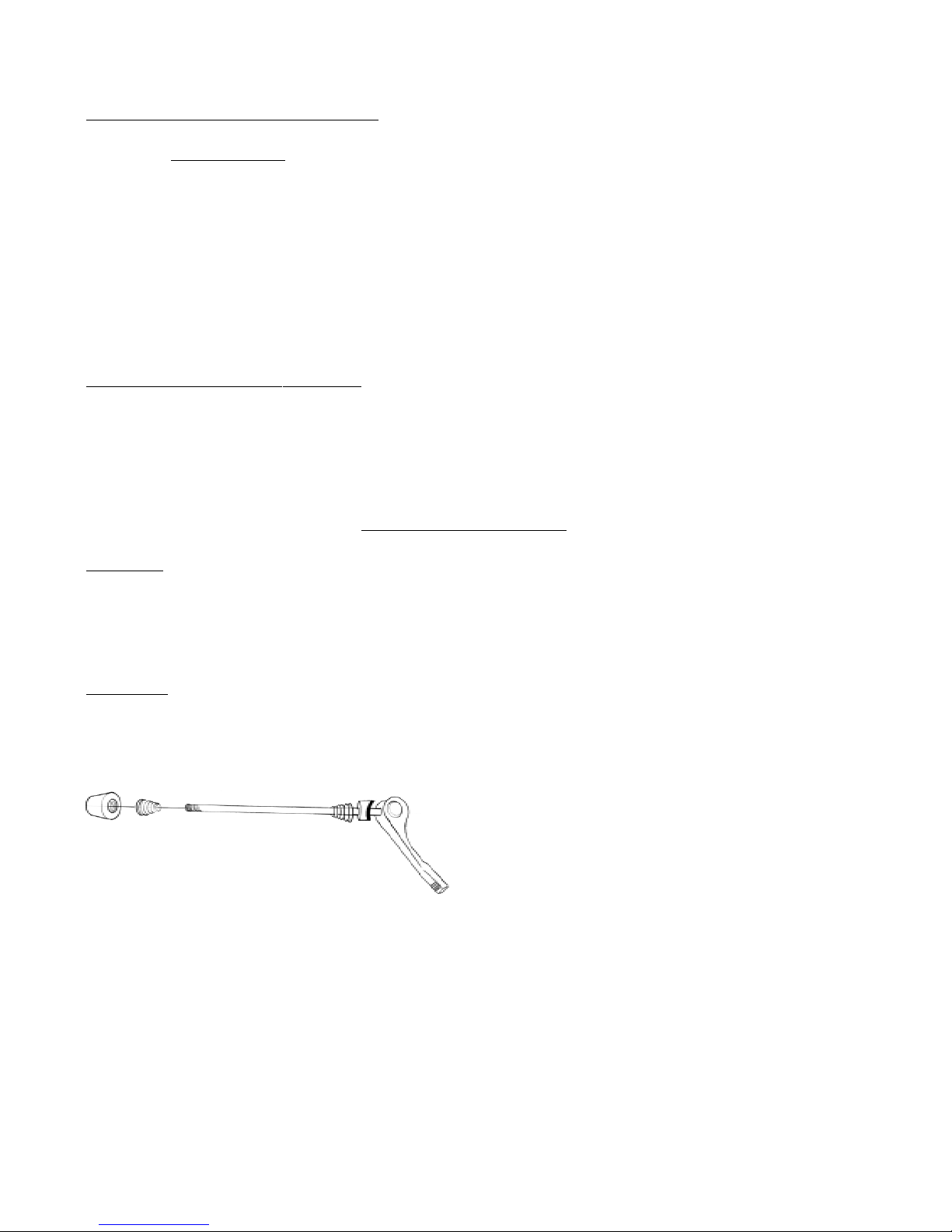

Small Box

4. Pedal (right)

5. Pedal (left)

6. Front Wheel Quick Release for Front Wheel Assembly

7. Wrench (14/15 mm)

8. Multi Tool Set (includes 2,2.5,3,4,5 & 6 mm Allen Keys, Philips head and regular screw driver)

2

STEP 3: MANUAL

Open the Owner’ s Manual to page 3 which shows a photo of the LandRider identifying all the

components. This will help you while assembling the LandRider.

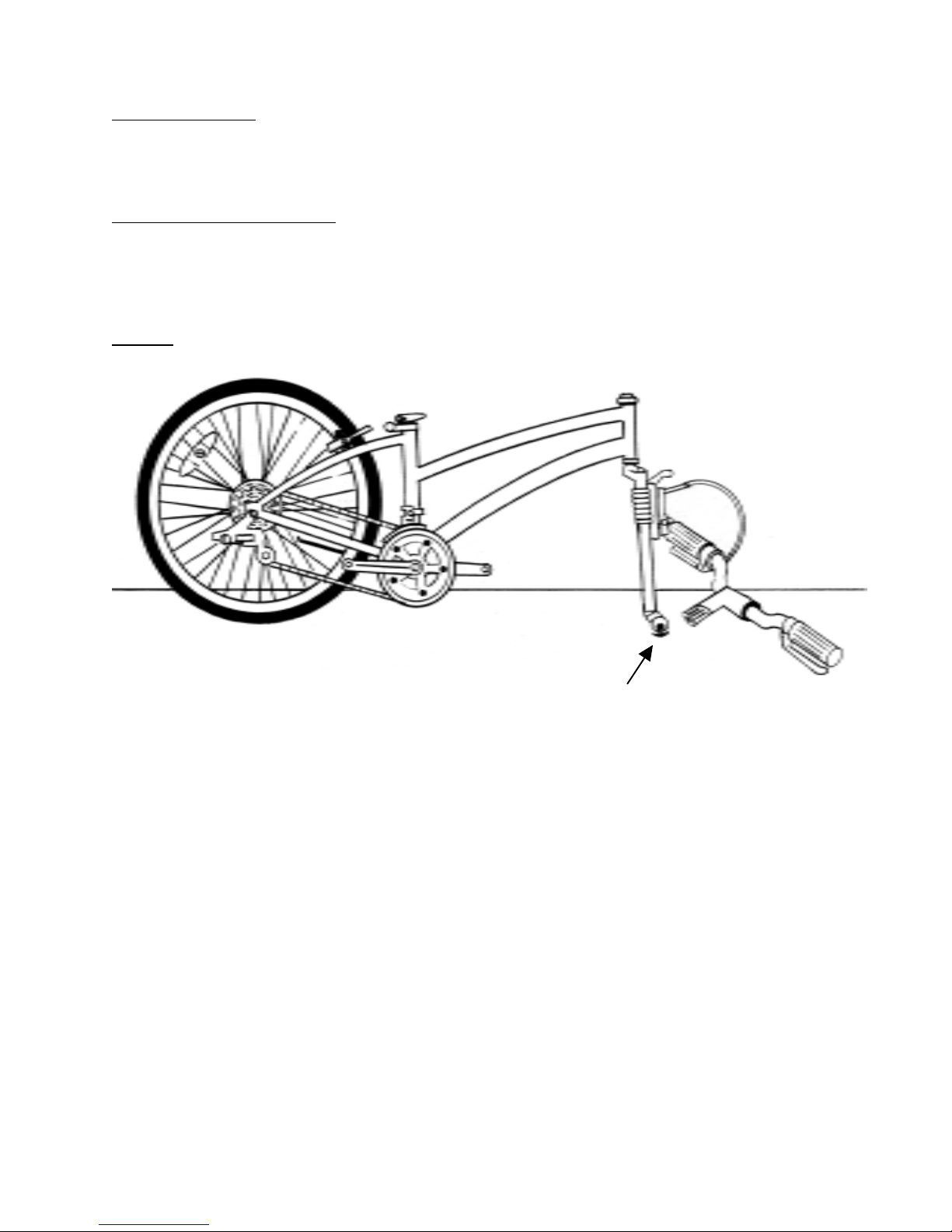

STEP 4: STAND FRAME UP

Carefully stand the bike up using the Fork ends as a stand. Make sure the Fork is facing forward

as per the drawing below.

FIG. 1

Fork Protective Spacer

( for shipping only )

3

STEP 5: CONNECTING HANDLEBAR

A) Remove the protective cardboard and rubber cap from the bottom of the Handlebar Stem Cone. (See FIG. 2).

B) Remove plastic plug on top of Stem Bolt. Before inserting the Stem into the Head Tube you may need to

loosen the Stem Bolt slightly 1-3 turns counter clockwise so the Stem Cone will fit into theHead Tube (See FIG. 2).

C) Now insert the Handlebar Stem into the Head Tube of the bicycle Frame so there is approximately

2 inches from the top of the Head Tube to the Handlebar T ilt Arm. (See FIG. 2 & 3). Do not raise the Stem

above Minimum Insertion Line. The approximate maximum Stem height is 3.75”. Firmly tighten clockwise the

Handlebar Stem Bolt with the large 6mm Allen Key . (See FIG. 2). Y ou will adjust the Handlebar later .

FIG. 2 FIG. 3

Stem Bolt Plug

2.0”

Handlebar Stem

Bolt (6mm)

3.75”

Minimum

Insertion Line

Stem Cone

Head Tube

See pages 14-16 for a more complete understanding of the Handlebar if necessary.

D) Before going any further, make sure the Brake and AutoMax cables are not tangled and Cables are

correctly engaged into Brake Handles. (See FIG. 4 & 5). Y ou will adjust the Handlebar later .

Remove

Cap

FIG. 4 FIG. 5

YES NO!

4

STEP 6: CONNECTING SEAT POST

The action of the Quick Release Cam squeezes the Seat Collar around the Seat Post to hold the Seat Post

securely in place. The amount of clamping force is controlled by the T ension Adjusting Nut. T urning the

T ension Adjusting Nut clockwise while keeping the Quick Release Lever from rotating increases clamping

force; turning it counterclockwise while keeping the Lever from rotating decreases clamping force.

A) Release the Seat Post Quick Release on the Seat Tube by opening the Quick Release Lever . (See FIG. 8).

B) Insert the Seat Post into the Seat Tube and lower the Seat Post all the way (See FIG. 7). Y ou will adjust

seat height later. Do not raise the Seat Post above Minimum Insertion Line.

C) Keeping the Seat parallel with the Frame turn the T ension Adjusting Nut clockwise with one hand while

holding the Quick Release Lever with the other hand. Turn the T ension Adjusting Nut until it is as tight as you

can get it by hand. (See FIG. 8).

D) Now close the Quick Release Lever so that the Seat Post is secured in the Seat Tube. The full force of the

Quick Release Cam is required. Quick Release Lever should be turned towards Front Wheel. Check Rear

Reflector is straight and tight.

FIG. 6 FIG. 7

Rear

Reflector

Minimum

Insertion Line

FIG.

Tension Adjusting Nut

LOOSEN

TIGHTEN

Quick Release Lever

IMPORT ANT: If you can fully close the Quick Release and the Lever does not leave a clear imprint in the palm

of your hand, the tension is insufficient. Open the Lever; turn the T ension Adjusting Nut clockwise a quarter turn;

then try again. If the Lever cannot be pushed all the way to a closed position, return the Lever to the OPEN

position. Then turn the T ension Adjusting Nut counterclockwise one-quarter turn and try tightening the Lever

again.

8

CLOSED

OPEN

5

Loading...

Loading...