USER’S MANUAL

CBF 110/130

CBF 110/130 T/TH/TP

CBF 110/130 LIGHT

CBF 110/130 LIGHT T/TH/TP

Centrifugal ceiling fan

CBF

CONTENTS

Safety requirements .....................................................................................................................................................................2

Purpose ................................................................................................................................................................................................ 4

Delivery Set ....................................................................................................................................................................................... 5

Designation key ............................................................................................................................................................................ 5

Technical data .................................................................................................................................................................................. 6

Design and operating principle ........................................................................................................................................... 7

Mounting and set-up ................................................................................................................................................................ 9

Connection to power mains ................................................................................................................................................. 12

Maintenance .................................................................................................................................................................................... 14

Storage and transportation regulations ........................................................................................................................ 16

Manufacturer’s Warranty ........................................................................................................................................................... 17

Acceptance certificate .............................................................................................................................................................. 17

Seller information ......................................................................................................................................................................... 18

Installation certificate .................................................................................................................................................................. 18

Warranty card ...................................................................................................................................................................................18

This user’s manual is the primary operating document intended for technical, maintenance and operations staff.

The user’s manual contains information regarding the field of application, delivery package, operating principle, and design of the centrifugal

fan CBF fan and all its modifications.

Technical and maintenance staff must have proper theoretical knowledge and practical training specific to ventilation systems as well as the

necessary skills to carry out the work in accordance with labour safety and construction regulations and standards applicable in the respective

territory.

The information provided in the present document is true as at the document preparation.

Due to the continuous product development the company reserves the right to update the technical specifications, design or delivery

package of its products.

No part of the present publication may be reproduced, uploaded or saved in reference-providing information systems or translated into other

languages in any form whatsoever without the company’s prior written consent.

READ AND SAVE THESE INSTRUCTIONS

SAFETY REQUIREMENTS

• Please read the user’s manual carefully prior to installing and operating the unit.

• All user’s manual requirements as well as the provisions of all the applicable local and national construction, electrical, and technical

norms and standards must be observed when installing and operating the unit.

• The warnings contained in the user’s manual must be considered most seriously since they contain vital personal safety information.

• Failure to follow the rules and safety precautions noted in this user’s manual may result in an injury or unit damage.

• After a careful reading of the manual, keep it for the entire service life of the unit.

• While transferring the unit control, the user’s manual must be turned over to the receiving operator.

UNIT INSTALLATION AND OPERATION SAFETY PRECAUTIONS

• Disconnect the unit from power mains prior

to any installation operations.

• The unit must be grounded!

• Unpack the unit with care.

• While installing the unit, follow the safety

regulations specific to the use of electric

tools.

2

vents-us.com

• Do not change the power cable length

at your own discretion. Do not bend the

power cable. Avoid damaging the power

cable. Do not put any foreign objects on the

power cable.

• Do not use damaged equipment or cables

when connecting the unit to power mains.

• Do not lay the power cable of the unit in

close proximity to heating equipment.

• Do not operate the unit outside the

temperature range stated in the user’s

manual. Do not operate the unit in

aggressive or explosive environments.

• Do not touch the unit controls with wet

hands. Do not carry out the installation and

maintenance operations with wet hands.

• Do not allow children to operate the unit.

• Do not store any explosive or highly

flammable substances in close proximity to

the unit.

• Do not open the unit during operation.

• Do not block the air duct when the unit is

switched on.

• Do not wash the unit with water. Protect

the electric parts of the unit against ingress

of water.

• Disconnect the unit from power mains prior

to any technical maintenance.

• When the unit generates unusual sounds,

odour, or emits smoke, disconnect it from

power supply and contact the Seller.

• Do not direct the air flow produced by the

unit towards open flame or ignition sources.

• In case of continuous operation of the unit,

periodically check the security of mounting.

• Do not sit on the unit and avoid placing

foreign objects on it.

THE PRODUCT MUST BE DISPOSED SEPARATELY AT THE END OF ITS SERVICE LIFE.

DO NOT DISPOSE THE UNIT AS UNSORTED MUNICIPAL WASTE.

vents-us.com

• Use the unit only for its intended purpose.

3

PURPOSE

The centrifugal ceiling extract fan CBF is designed for extract ventilation of small to medium-sized premises.

THE UNIT SHOULD NOT BE OPERATED BY CHILDREN OR PERSONS WITH REDUCED

PHYSICAL, MENTAL, OR SENSORY CAPACITIES, OR THOSE WITHOUT THE APPROPRIATE

TRAINING. THE UNIT MUST BE INSTALLED AND CONNECTED ONLY BY PROPERLY

QUALIFIED PERSONNEL AFTER THE APPROPRIATE BRIEFING.

THE CHOICE OF UNIT INSTALLATION LOCATION MUST PREVENT UNAUTHORIZED

ACCESS BY UNATTENDED CHILDREN.

WARNING: NOT SUITABLE FOR USE WITH SOLIDSTATE SPEEDCONTROLS

AVERTISSEMENT : NE CONVIENT PAS A DES REGULATEURS DE VITESSE A SEMI

CONDUCTEURS.

THE UNIT MUST NOT BE OPERATED IN KITCHEN PREMISES.

CBF

CAUTION! FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO EXHAUST

HAZARDOUS OR EXPLOSIVE MATERIALS AND VAPORS

The unit is rated for continuous operation.

Transported air must not contain any flammable or explosive mixtures, evaporation of chemicals, sticky substances, fibrous materials, coarse

dust, soot and oil particles or environments favourable for the formation of hazardous substances (toxic substances, dust, pathogenic germs).

4

vents-us.com

DELIVERY SET

NAME QUANTITY

Fan 1 pc.

LED lamp (for fans with the Light option) 2 pcs.

Cable gland 1 pc.

Mounting bracket 4 pcs.

Fastening kit 1 pc.

User’s manual 1 pc.

Packing box 1 pc.

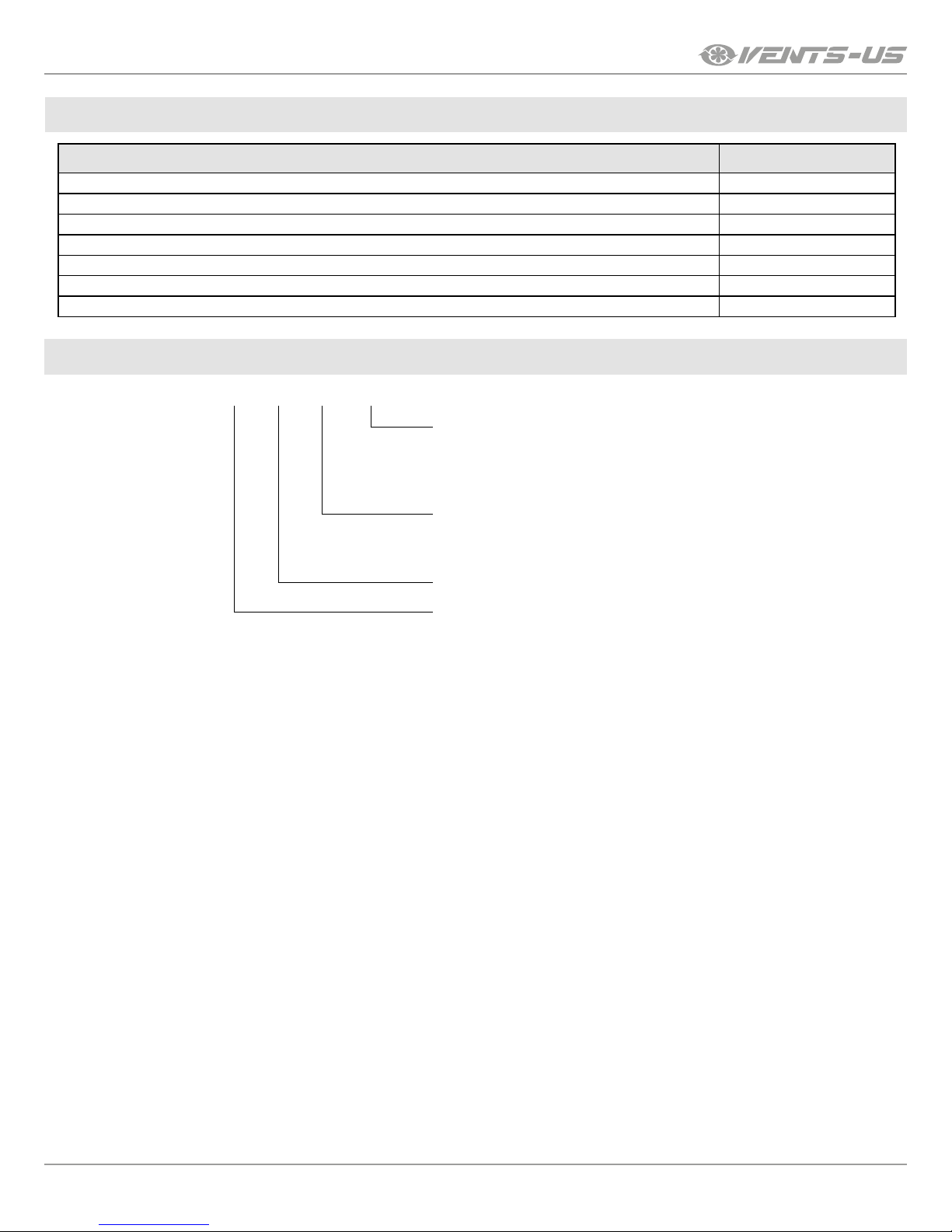

DESIGNATION KEY

Ceileo 130 Light TP

Additional options

T : timer

TH : humidity sensor and timer

TP : motion sensor and timer

Basic options

_ : no integrated light

Light : integrated LED light

Rated air capacity (CFM)

Fan series

Ceileo : centrifugal ceiling fan

vents-us.com

5

TECHNICAL DATA

A

E

H

Ød

ØD

L2

L1

B

C

A

E

H

BL1

L2

Ød

ØD

h

C

b

a

h

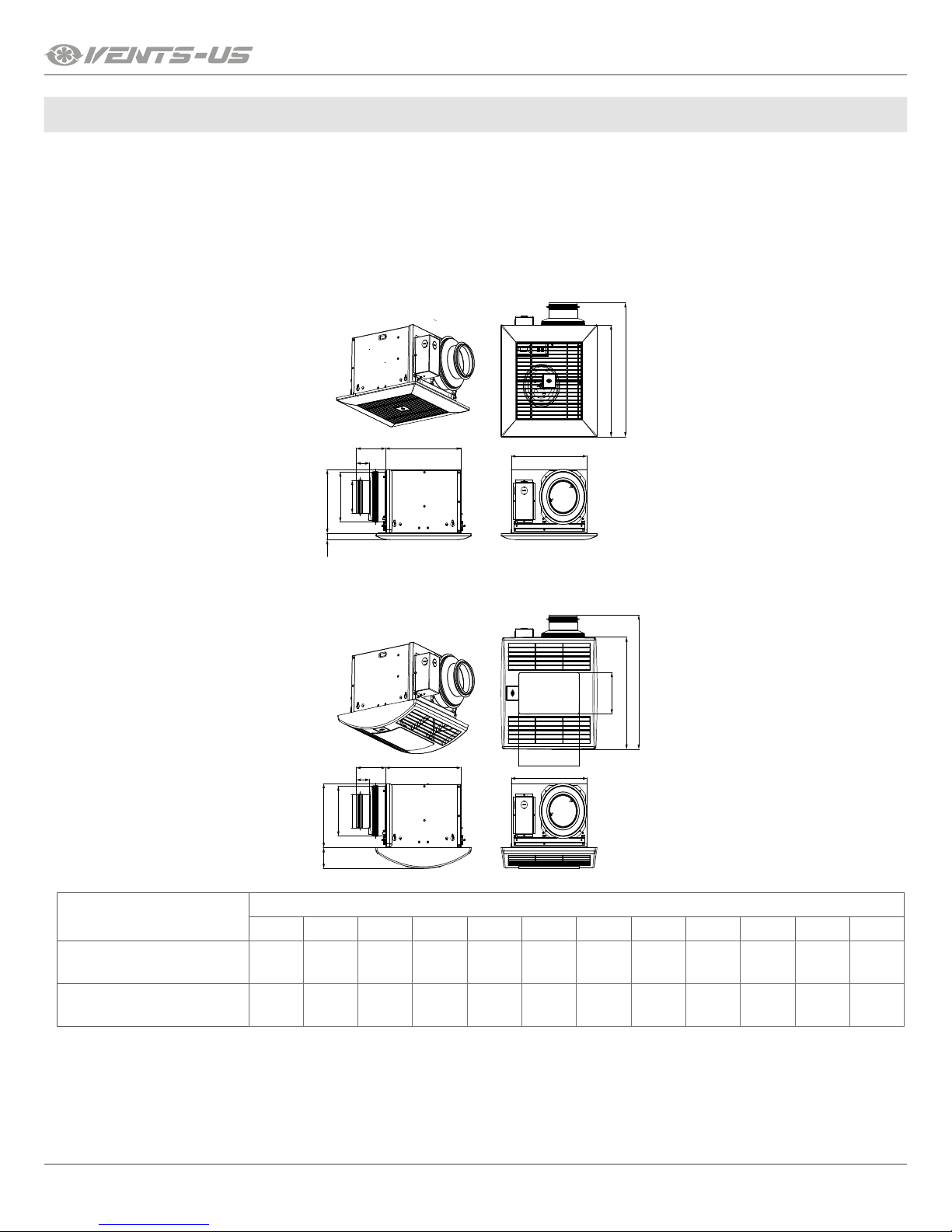

CBF 110/130 Light

CBF 110/130 Light T/TH/TP

CBF 110/130

CBF 110/130 T/TH/TP

The unit is designed for indoor application at ambient temperature from +34 °F up to +104 °F at max. RF 80 %.

Ingress protection rating against access to hazardous parts and water ingress is IPX4.

The unit design is constantly being improved, so some models may be slightly different from those ones described in this manual.

OVERALL AND CONNECTION DIMENSIONS OF THE FANS

CBF

Ceileo 110/130

Ceileo 110/130 T/TH/TP

Ceileo 110/130 Light

Ceileo 110/130 Light T/TH/TP

MODEL

DIMENSIONS, inch

D D L1 L2 A B C E H H A B

5 7/8” 3 7/8” 3 15/16” 1 3/4” 13” 10 3/16” 10 1/4” 15 9/16” 7 3/8”

11

/

16

- -

5 7/8” 3 7/8” 3 15/16” 1 3/4” 13” 10 3/16” 10 1/4” 15 9/16” 7 3/8” 2 7/6” 8 3/16” 4 13/16”

6

vents-us.com

TECHNICAL DATA

PARAMETER

CEILEO 110

CEILEO 110 T/TH/TP

CEILEO 110 LIGHT

CEILEO 110 LIGHT T/TH/TP

CEILEO 130

CEILEO 130 T/TH/TP

CEILEO 130 LIGHT

CEILEO 130 LIGHT T/TH/TP

Frequency [Hz] 60

Speed LS HS LS HS

Voltage [V] 1 ~ 120

Fan power [W] 16 27 23 35

Lamp power [W ]* 2 х 10

Max airflow, [CFM] 78 125 105 155

Max airflow, l/s 37 59 50 73

SFP, W/l/s 0,55 0,50 0,49 0,54

[kg] 5.3(6.4) 5.3(6.4)

Weight

[lbs] 11.7(14.1) 11.7(14.1)

IP X4

SEC class D C

* For fans with light only

DESIGN AND OPERATING PRINCIPLE

Exhaust spigot

Backdraft damper

Terminal box

Casing

Decorative grille

Protective cap / sensor panel

Control unit

Exhaust spigot

Backdraft damper

Terminal box

Casing

Decorative grille

Surface-mounted luminaire

Protective cap / sensor panel

CBF 110/130 DC T/TH/TP

CBF 110/130 DC LIGHT T/TH/TP

Socket for lamp connection

Control unit

Light sockets

vents-us.com

7

CBF

The fan casing is made of galvanized steel. The fan casing includes an exhaust spigot with a back draft damper to prevent back air flow.

The terminal box comprises the terminals for wiring of the fan and is attached to the fan casing. The decorative grille is fixed to the casing via

the springs inserted to the holders. The front panel is fixed via the grille slots. A single-phase electric motor with a centrifugal impeller with

forward curved blades is fastened inside of the casing. Depending on the fan model the fan may be equipped with a LED lamp, a timer, a

humidity or motion sensor.

Timer (t)

After an external switch, e.g. a light switch is turned off, the fan is turned on or goes to high speed after countdown of a set turn-on delay

time, adjustable from 0 to 3 minutes.

After the fan is turned off it keeps running for a set turn-off delay time, adjustable from 1 to 90 minutes and the reverts to the initial operation

status.

Motion sensor (tp)

In case of activation of the motion sensor the fan turns on or switches to the higher speed.

After no motion is detected more the fan keeps running for a set turn-off delay time, adjustable from 1 to 90 minutes, and the reverts to the

initial operation status.

Humidity sensor (th)

If the indoor humidity exceeds the set humidity point adjustable from 50 % up to 90 %, the fan either turns on or goes to the higher speed.

After indoor humidity drops down the fan keeps running for a set turn-off delay time, adjustable from 1 to 90 minutes and the reverts to the

initial operation status.

8

vents-us.com

MOUNTING AND SETUP

READ THE USER'S MANUAL BEFORE INSTALLING THE UNIT

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

• Use this unit only in the manner intended by the manufacturer. If you have questions, contact the

manufacturer.

• Before servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag,

to the service panel.

• Installation work and electrical wiring must be done by qualified person(s) in accordance with all

applicable codes and standards, including fire-rated construction.

• When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden

utilities.

• Ducted fans must always be vented to the outdoors. e) If this unit is to be installed over a tub or

shower, it must be marked as appropriate for the application and be connected to a GFCI (Ground

Fault Circuit Interrupter) – protected branch circuit”

• If this unit is to be installed over a tub or shower, it must be marked as appropriate for the

application and be connected to a GFCI (Ground Fault Circuit Interrupter) – protected branch

circuit

The fan is a component part and is not designed for stand-alone operation.

The fan is constructed for ceiling installation in the floor slab and fixation to the inter joist with the distance between the ceiling joists from

270 mm (10 5/8”) up to 680 mm (20 3/4”) using the removable fixing brackets or the fastening holes in the fan casing.

The installation place must be in compliance with local construction norms for units of this type.

Check the fan for mechanical damages prior to mounting .

Make sure that the casing comprises no foreign objects, such as paper or foil.

While mounting the fan sufficient service access for maintenance or repair operations must be provided.

The minimum gap between the fan and the ceiling is 5 mm (3/16”).

L = min 5 mm L = min 5 mm(3/16") (3/16")

vents-us.com

9

MOUNTING STEPS

1. Attach the fan to the interjoist using the screws. 2. Connect the air duct of a required diameter.

3. Connect the LED lamps (included in the delivery set) for the Light models.

Option: connect the humidity sensor or the motion sensor (specially ordered accessory).

For the Light models: connect the power socket of the LED lamp and the respective sockets in the terminal box.

For the TH models with a humidity sensor: remove the protective cap from the grille prior to its installation.

Route the contact socket of the sensor TH or TP via the opening in the grille and connect the sensor socket to the respective contact

socket on the control unit.

Fix the sensor in the grille opening and cover the opening with a protective cap.

CBF

Connection socket

of the humidity sensor

Connection socket

of the motion sensor

4. Install the decorative grille on the fan casing using the holders on the casing.

Connection socket

of the LED lamp

Connection socket

of the humidity sensor

Connection socket

of the motion sensor

10

vents-us.com

the ceiling joists using the mounting brackets

BASIC FAN INSTALLATION OPTIONS

Installation

between the ceiling joists

Side fixation

to one of the ceiling joists

Fixation between

Additional fastening holes in the fan casing may be used for mounting purposes

vents-us.com

11

CBF

CONNECTION TO POWER MAINS

DISCONNECT THE UNIT FROM POWER MAINS PRIOR TO ANY OPERATIONS.

THE UNIT MUST BE CONNECTED TO POWER MAINS BY A QUALIFIED ELECTRICIAN.

THE RATED ELECTRICAL PARAMETERS OF THE UNIT ARE SHOWN

ON THE RATING PLATE.

ANY TAMPERING WITH THE INTERNAL CONNECTIONS IS PROHIBITED

AND WILL VOID THE WARRANTY.

The fan is rated for connection to single-phase ac 120 V/ 60 Hz power supply.

The fan must be connected to power mains using durable, insulated and heat-resistant conductors (cables and wires) via the circuit breaker

QF integrated into the house cabling system.

The external circuit breaker installation place must ensure unhampered access for emergency shutdown of the unit.

WIRING DIAGRAMS

Х1QF

L

120 V

60 Hz

N

QF

L

120 V

60 Hz

N

L2

L1

N

L

LT

N

1234567

LIGHT

(contact socket is available only for

the models with LED light)

FAN

12

ACCESS TO THE TERMINAL BOX FOR WIRING THE FAN

Remove the decorative grille.

For accessing the connection terminals

loosen the screw on the terminal box

lid and take the lid off.

Remove the protective cap and install the cable gland.

vents-us.com

CONTROL UNIT WITH A SPEED SWITCH

OFFHIGH LOW

Three-position switch

The fan with AC motor is controlled by a three-position switch. The switch has three positions:

OFF — the fan is turned off.

LOW — the fan operates at reduced performance (speed 1).

HIGH — the fan operates at maximum performance (speed 2).

When the power is turned on (~ 230 V), the fan will operate in one of the above modes.

MICROPROCESSOR CONTROL UNIT WITH INDICATION

The AC fan motor is operated by a microprocessor control unit. The front panel of the control unit comprises a light indicator, control buttons

and two connectors for connection of the humidity and motion sensors.

Indicator

Buttons

Connection

socket for humidity sensor

Connection

socket for motion sensor

After the fan is connected to power supply, the indicator displays for two seconds. After that the light indicator goes off and the fan

starts operating in set mode. Once the button is pressed the indicator displays the turn-off delay timer setting , the first Setup menu

entry. Use or buttons to navigate in the Setup menu. Press , to select a current entry in the Setup menu. After that the indicator

displays the selected parameter value (e.g., turn-off delay timer setting). Use or to change the value. Press to come back to the

Setup menu. If no button is pressed for 60 seconds, the indicator goes down.

Example

The indicator displays . Once the button is pressed, the Setup menu list goes one position down and the symbol is displayed

(refer to the Setup menu). Once the button is pressed, the indicator displays the turn-on delay timer setting, which can be edited with the

buttons and . Once the button is pressed again, the Setup menu is displayed again and the edited value is saved.

To reset the menu to the factory settings press and hold the buttons and synchronously. In 5 seconds the indicator displays , and

goes off. The fan keeps running in a normal mode with the factory settings.

INDICATOR SYMBOLS OF THE MICROPROCESSOR CONTROL UNIT

— turn-off delay timer adjustable from 1 to 90 minutes (default setting 15 minutes).

— turn-on delay timer adjustable from 0 to 180 seconds with the increment of 10 seconds (default setting 0).

— humidity set point adjustable from 50 % up to 90 % (default setting 75 %).

— access to submenu of the fan operation mode.

vents-us.com

13

Operation mode — the fan operates without any activation signal from the switch, humidity or motion sensor.

Operation mode

— back to the upper setup menu level.

— the fan operates with activation signal from the switch, humidity or motion sensor.

CBF

Once the switch is turned on or the humidity or motion sensor is activated, the fan switches from the mode to the mode .

is no more received from the sensor in case of the indoor humidity normalization, or no more motion is detected in case of the fan shutdown,

the fan keeps running for a set turn-off delay time and then switches from the mode

SETUP OF THE OPERATION MODES

The

Example 1

activated, the fan starts to run at reduced performance.

Example 2

is activated, the fan starts to run with the maximum capacity. This setting is factory set and is the default setting.

and modes can take the following values for the fan with an AC motor:

— the fan is turned off.

— the fan operates at reduced performance.

— the fan operates at maximum performance.

= , = — with these activated settings the fan is constantly turned off. Once the switch is turned on or a sensor is

= , = — with these activated settings the fan runs at reduced performance. Once the switch is turned on or a sensor

to the mode .

AND

After a signal

MAINTENANCE

DISCONNECT THE UNIT FROM POWER SUPPLY BEFORE

ANY MAINTENANCE OPERATIONS!

The fan maintenance includes regular cleaning of the surfaces of dust and dirt. Replace the filter as required, but at least every 6 months.

The impeller cleaning is shown below. Clean the impeller blades thoroughly every 6 months.

14

vents-us.com

LAMP REPLACEMENT

DISCONNECT THE UNIT FROM POWER SUPPLY BEFORE

ANY MAINTENANCE OPERATIONS!

1. Remove the decorative grille:

• Pull the grille to release the springs from the holders on the casing.

• Take out the lamp power socket from the respective socket on the casing.

• Take out the power socket of the sensors from the respective sockets on the control unit (applicable for TH and TP models).

2. Take off the surface-mounted luminaire.

• Press the holders on the reverse side of the grille frame and take off the surface-mounted luminaire.

3. Replace the lamps.

4. Reassemble the unit in the reverse order.

TROUBLE POSSIBLE REASONS TROUBLESHOOTING

No power supply.

The fan does not get started.

Motor jam.

Automatic circuit breaker tripping

during the unit turning on.

Low air flow.

Over current as a result of short circuit

in the electric circuit leads to tripping of

the circuit breaker.

Air ducts or other components of the

ventilation system are clogged. The

impeller is clogged. The air ducts are

damaged. The air dampers are closed.

vents-us.com

TROUBLES AND TROUBLESHOOTING

Check the electric connections and the operation status of the

circuit breaker.

Turn the fan off. Troubleshoot clogging of the impeller. Restart

the fan.

Disconnect the fan from power supply and contact the product

Seller. Do not turn the fan on again!

Clean the air ducts, the impeller and other components of

the ventilation system. Make sure that the air ducts are not

damaged. Make sure that the air dampers and louvre shutters

are open.

15

STORAGE AND TRANSPORTATION REGULATIONS

• Store the unit in the manufacturer’s original packaging box in a dry closed ventilated premise with temperature range

from +5 ˚С (+41 ˚F) to +40 ˚С (+104 ˚F) and relative humidity up to 70 %.

• Storage environment must not contain aggressive vapours and chemical mixtures provoking corrosion, insulation, and sealing

deformation.

• Use suitable hoist machinery for handling and storage operations to prevent possible damage to the unit.

• Follow the handling requirements applicable for the particular type of cargo.

• The unit can be carried in the original packaging by any mode of transport provided proper protection against precipitation and

mechanical damage. The unit mustcan be transported only in the working position.

• Avoid sharp blows, scratches, or rough handling during loading and unloading.

• Prior to the initial power-up after transportation at low temperatures allow the unit to warm up at room temperature for at least 3-4

hours.

CBF

16

vents-us.com

MANUFACTURER’S WARRANTY

Production meets standard operating requirements in the USA and Canada.

VENTS US warrants to the original purchaser of the unit that it will be free from defects in materials or workmanship for a period of 24 months

from the date of original purchase. The VENTS US warrants to the original purchaser of the unit that the integrated control unit will be free

from defects in materials and workmanship for a period of 24 months from the date of original purchase.

THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During the stated warranty period, VENTS US will, at its option, repair or replace, without charge, any product or part which is found to be

defective under normal use and service. This warranty does not cover (a) normal maintenance and normal service or (b) any products or parts

which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by VENTS US), faulty installation or

negligence, accident, improper maintenance or repair (other than by VENTS US), faulty installation or installation contrary to recommended

installation instructions. Labor to remove and replace products is not covered. The duration of any implied warranty is limited to the time

period specified for the express warranty. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation

may not apply to you.

VENTS US OBLIGATION TO REPAIR OR REPLACE, AT VENTS US OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE

REMEDY UNDER THIS WARRANTY. VENTS US SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES

ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE.

Some states do not allow the exclusion or limitations of incidental or consequential damages, so the above limitation or exclusion may not

apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. This warranty

supersedes all prior warranties. If proof of sales date is absent, warranty period is calculated from the production date. The unit can be

exchanged at the following address:

Bodor Vents, LLC DBA: VENTS-US

11013 Kenwood Road Cincinnati, Ohio 45242

Phone: (513)348-3853

e-mail: sales@ventsus.com

Please follow guidelines in this manual for product problem-free operation.

ACCEPTANCE CERTIFICATE

Unit Type Centrifugal ceiling extract fan

Model CBF _______________________

Serial Number

Manufacture Date

Quality Inspector’s

Stamp

vents-us.com

17

SELLER INFORMATION

Seller

Address

Phone Number

E-mail

Purchase Date

This is to certify acceptance of the complete unit delivery with the user’s manual. The warranty terms are

acknowledged and accepted.

CBF

Customer’s Signature

INSTALLATION CERTIFICATE

The CBF _______________________ unit has been connected to power mains pursuant to the

requirements stated in the present user’s manual.

Seller

Address

Phone Number

Installation

Technician’s Full Name

Installation Date: Signature:

The unit has been installed in accordance with the provisions of all the applicable local and national construction,

electrical and technical codes and standards. The unit operates normally as intended by the manufacturer.

Signature:

WARRANTY CARD

Seller’s Stamp

Installation Company Stamp

Unit Type Centrifugal ceiling extract fan

Model CBF _______________________

Serial Number

Manufacture Date

Purchase Date

Warranty Period

Seller

18

Seller’s Stamp

vents-us.com

vents-us.com

19

VUSA166-1EN-01

Loading...

Loading...