OPERATOR’S MANUAL

VENTRAC 4500K

ENTRAC 4500P

V

ENTRAC 4500Y

V

ENTRAC 4500Z

V

Revised 02/18/13

09.10081

500 Venture Drive

C

Vanguard

C

Kubota - front or side

of valve cover

C

Kawasaki - front of

engine block

PO Box 148

Orrville Oh 44667

www.ventrac.com

To the Owner

Contact Information and Product Identifi cation

If you need to contact an authorized Ventrac dealer for information on servicing your product,

always provide the product model and serial numbers.

Please fi ll in the following information for future reference. See the picture(s) below to fi nd the

location of the identifi cation numbers. Record them in the spaces provided.

Date of Purchase: __________________________________________________________________

Dealer: ___________________________________________________________________________

Dealer Address: ____________________________________________________________________

____________________________________________________________________

Dealer Phone Number: ______________________________________________________________

Dealer Fax Number: ________________________________________________________________

Model # (A): ___________________________

Serial # (B): ____________________________

Affi x Part/Serial Number label here.

Engine Serial # (C) _________________________

A

Vanguard

B

Kubota - front or side

of valve cover

C

Kawasaki - front of

engine block

C

C

Venture Products Inc. reserves the right to make changes

in design or specifi cations without obligation to make like

changes on previously manufactured products.

2

TABLE OF CONTENTS

INTRODUCTION PAGE 7

Product Description ................................................................................................................................ 8

Why Do I Need an Operator’s Manual? .................................................................................................8

Using Your Manual .................................................................................................................................9

Manual Glossary ....................................................................................................................................9

Safety Decals .......................................................................................................................................10

SAFETY PAGE 13

General Safety Procedures .................................................................................................................. 14

Training Required .................................................................................................................................14

Personal Protective Equipment Requirements ....................................................................................14

Operation Safety ..................................................................................................................................14

Preventing Accidents ............................................................................................................................ 15

Keep Riders Off ....................................................................................................................................15

Operating On Slopes ............................................................................................................................16

Roadway Safety ...................................................................................................................................16

Truck Or Trailer Transport ....................................................................................................................16

Maintenance .........................................................................................................................................17

Fuel Safety ...........................................................................................................................................17

Hydraulic Safety ...................................................................................................................................18

Roll Over Protective Structure (ROPS) ................................................................................................19

Operator Access System ......................................................................................................................19

Propane Safety (if applicable) ..............................................................................................................20

Operator Safety Interlock System ........................................................................................................21

OPERATIONAL CONTROLS PAGE 22

Standard Operational Control Locations ..............................................................................................22

Optional Operational Control Locations ...............................................................................................23

Information Cluster Gauge (A) .............................................................................................................24

Warning Cluster Gauge (B) .................................................................................................................. 24

Warning Alarm (C) ................................................................................................................................24

Ignition Switch (D) ................................................................................................................................24

Throttle Lever (E) .................................................................................................................................25

Headlight Switch (F) ............................................................................................................................. 25

Power Take Off (PTO) Switch (G) ........................................................................................................25

Choke Handle (H) ................................................................................................................................ 25

Parking Brake (I) ..................................................................................................................................25

Neutral Assist Lever (J) ........................................................................................................................ 25

Front Hitch Lever Lock (K) ...................................................................................................................25

Front Hitch Latch Lever (L) .................................................................................................................. 25

Auxiliary Hydraulic Quick Couplers (M) ................................................................................................25

PTO Belt Tensioner Rod (N) ................................................................................................................26

High/Low Shift Lever (O) ...................................................................................................................... 26

Weight Transfer Traction Control Select Lever (P) ...............................................................................26

SDLA Control Lever (Q & R) ................................................................................................................26

Steering Wheel (S) ............................................................................................................................... 27

3

TABLE OF CONTENTS

Hydraulic Cooler Fan Switch (T) ..........................................................................................................27

Seat Slide Lever (U) ............................................................................................................................. 27

Fuel Shut-off Valve (V) .........................................................................................................................27

Circuit Breaker & Battery Disconnect (W) ............................................................................................27

Seat Prop Plate (X) ..............................................................................................................................27

Seat Latch Strap (Y) .............................................................................................................................27

Work Light Switch (AA) ........................................................................................................................27

Strobe Light Switch (BB) ......................................................................................................................27

Slope Indicator Gauge (CC) ................................................................................................................. 27

Slope Warning Light (DD) ....................................................................................................................27

Directional Signal Switch (EE) ............................................................................................................. 28

Hazard Flasher Switch (FF) .................................................................................................................28

Gas/Propane Selector Switch (GG) .....................................................................................................28

Horn Switch (HH) .................................................................................................................................28

Front Hitch Valve (II) ............................................................................................................................28

Foot Pedal (JJ) ..................................................................................................................................... 28

3 Point Hitch & Rear Auxiliary Control Handles (KK, LL, & MM) ..........................................................29

Rear Auxiliary Quick Couplers (NN) .....................................................................................................29

12 Volt Rear Switches & 4-Pin Socket (OO, PP, & QQ) .......................................................................29

12 Volt Front Switches & 4-Pin Socket (RR, SS, & TT) .......................................................................29

Electric PTO Remote Socket (UU) ....................................................................................................... 29

Back Up Alarm (VV) .............................................................................................................................29

GENERAL OPERATION PAGE 30

Daily Inspection .................................................................................................................................... 30

Starting The Engine .............................................................................................................................30

Forward And Reverse .......................................................................................................................... 32

Stopping The Power Unit .....................................................................................................................32

Shutting Off The Engine ....................................................................................................................... 32

Attaching ..............................................................................................................................................32

Detaching .............................................................................................................................................33

Operating Attachments ......................................................................................................................... 33

Front Hitch ............................................................................................................................................33

PTO Drive Belt & Pulley .......................................................................................................................33

Front Auxiliary Couplers ....................................................................................................................... 33

Weight Transfer ....................................................................................................................................33

High/Low Range ...................................................................................................................................34

Turning Radius ..................................................................................................................................... 34

Roll-Over Protection System ................................................................................................................ 34

3 Point Hitch (Optional Accessory) .......................................................................................................35

12 Volt 4-Pin Auxiliary Outlets (Optional Accessory) ............................................................................35

Directional/Hazard Flasher Operation (Optional Accessory) ................................................................35

Suspension Seat Weight Adjustment (Optional Accessory) ................................................................. 35

Operating On Slopes ............................................................................................................................36

Towing Or Pushing The Power Unit .....................................................................................................36

4

TABLE OF CONTENTS

SERVICE PAGE 37

Service And General Maintenance .......................................................................................................37

Cleaning And Appearance Care .................................................................................................. .........37

Service Access Points ......................................................................................................... .................37

Lubrication Locations ...........................................................................................................................38

Checking Hydraulic Oil Level ...............................................................................................................39

Checking Rear Transaxle Oil ...............................................................................................................39

Changing Hydraulic Oil And Filters ......................................................................................................39

Servicing Closed Loop Hydrostatic Drive Circuit ..................................................................................39

Servicing Hydraulic Oil Cooler .............................................................................................................39

Checking Engine RPM .........................................................................................................................39

Checking Engine Oil Level ...................................................................................................................40

Changing Engine Oil And Filter ............................................................................................................41

Changing Air Filter Elements ................................................................................................................42

Filling The Fuel Tank ............................................................................................................................42

Changing The Propane Cylinder(s) ......................................................................................................43

Checking The LPG System For Leaks .................................................................................................43

Changing The In-line Fuel Filter ...........................................................................................................44

Priming The Fuel System .....................................................................................................................44

Fuel Care for 4500Z with Propane Option ...........................................................................................44

Checking The Fan (Alternator) Belt (Kubota Engines) .........................................................................44

Adjusting Fan (Alternator) Belt Tension (Kubota Engines) ...................................................................44

Cleaning Engine Compartment & Engine ............................................................................................45

Servicing The Cooling System .............................................................................................................45

Checking The Cooling System .............................................................................................................46

Cleaning The Radiator And Screen ......................................................................................................46

Draining The Cooling System ..............................................................................................................46

Flushing The Cooling System ..............................................................................................................47

Servicing The Battery ...........................................................................................................................47

Removing The Battery .........................................................................................................................48

Installing The Battery ...........................................................................................................................48

Cleaning The Battery And Terminals ....................................................................................................48

Charging The Battery ...........................................................................................................................48

Jump Starting Procedure .....................................................................................................................49

TCM (Tractor Control Module) Explanation .........................................................................................49

Replacing Fuses (Power Relay Module) ..............................................................................................49

Replacing Fuses (Front Fuse Panel) ...................................................................................................50

Replacing Fuses (Rear Fuse Panel) ....................................................................................................50

Replacing Fuses (Engine) ....................................................................................................................51

Replacing Light Bulbs (Headlights & Work Lights) ...............................................................................51

Replacing The Taillights ...................................................................................................... .................52

Replacing The Turn Signal Lights .............................................................................................. ..........52

Replacing The Strobe Light Bulb .........................................................................................................52

PTO Belt Inspection .............................................................................................................................52

PTO Belt Tension Adjustment ..............................................................................................................53

PTO Belt Replacement ........................................................................................................................53

5

TABLE OF CONTENTS

Wheel Removal & Installation ..............................................................................................................53

Outer Dual Wheel Removal & Installation ............................................................................................54

Tire Pressure ........................................................................................................................................54

ROPS And Seat Belt Inspection ...........................................................................................................55

Parking Brake Inspection & Adjustment ...............................................................................................55

Neutral Adjustment ...............................................................................................................................56

Neutral Switch Adjustment ...................................................................................................................57

Storage .................................................................................................................................................58

4500K Maintenance Schedule .............................................................................................................60

4500K Maintenance Checklist ..............................................................................................................61

4500P Maintenance Schedule .............................................................................................................62

4500P Maintenance Checklist ..............................................................................................................63

4500Z & 4500Y Maintenance Schedule ...............................................................................................64

4500Z & 4500Y Maintenance Checklist ...............................................................................................65

TROUBLESHOOTING PAGE 66

Electrical Troubleshooting Using The Tractor Control Module (TCM) ..................................................66

Electrical Troubleshooting Guide .............................................................................................. ...........68

Engine ..................................................................................................................................................69

Electrical ...............................................................................................................................................70

Hydraulic ..............................................................................................................................................71

Power Unit ............................................................................................................................................72

SPECIFICATIONS PAGE 73

Engine ..................................................................................................................................................73

Electrical ...............................................................................................................................................73

Power Train ..........................................................................................................................................73

Controls & instrument Panel ................................................................................................................73

Other features ......................................................................................................................................73

Dimensions ..........................................................................................................................................74

Fluid Capacities ....................................................................................................................................74

Belt Chart .............................................................................................................................................75

WARRANTY PAGE 76

6

INTRODUCTION

enture Products Inc. is pleased to provide you with your new

Ventrac power unit! We hope that Ventrac equipment will

V

provide you with a ONE Tractor Solution.

Listed below are just some of the items that can provide you

versatility as you use your 4500. Please visit our web site, or

contact your authorized Ventrac dealer for a complete list of

items available for your new power unit.

Item Description

Three Point Hitch 70.4100 Weight Transfer Kit (4500K only) 70.4115

Dual Wheels (All Terrain Tires) 70.4067 4500K Accessory Option Kit (Factory Install only) 70.4116-99

Dual Wheels (Turf Tires) 70.4068 Raised Foot Platform Kit 70.4108

Dual Wheels (Bar Tires) 70.4069 Electric PTO Remote Kit 70.4106

Wheel Extensions 70.4098 12 Volt Front Kit 70.4104

Weather Cab 70.2009 12 Volt Rear Kit 70.4105

Propane Kit (4500Z Kubota Gas Engine only) 70.4110 Horn Kit 70.4120

Foot Control Kit 70.4107 ES220 Spreader 39.55500

Suspension Seat 70.4111 SS575 Salt Spreader 70.2010

Backup Alarm Kit 70.4101 Rear Counter Weight Bar 39.56116

Front Hitch Valve Kit 70.4121 Two -N-One Front Hitch 70.2001

Accessories

Work Light Kit 70.4113

Strobe Light Kit 70.4114

Directional / Hazard Signal Kit 70.4119

Slope Indicator Kit 70.4112

Item Description

Aerator with Open Spoon Tine 39.55490 Stump Grinder 39.55300

Aerator with Slitter/Slicer Tine 39.55492 Terra Rake - 52” 39.55431

Aerator with Coring Tine 39.55494 Tiller 39.55220

AeraVator (seeder kit available) 39.55460 Tough Cut Mower - 68” 39.55104

Blade - 48” 39.55251 Trencher 39.55455

Blade - 60” 39.55252 Turbine Blower 39.55340

Blade - 72” 39.55253 V-Blade 39.55271

Blower 39.55440 Versa-Loader 39.55600

Broom 39.55400 Reel Mower - 74” 39.55130

Edger 39.55330 Rear Discharge Mower - 60” 39.55120

Excavator - 30” 39.55236 Contour Mower - 84” 39.55160

Excavator - 48” 39.55230

Finish Mower - 60” 39.55105

Attachments

Finish Mower - 72” 39.55106

Finish Mower - 72” (6-1/2” offset) 39.55107

Generator - 15,000 Watt 39.55315

Power Rake 39.55435

Slip Scoop - 30” 39.55216

Slip Scoop - 48” 39.55210

Snow Blower 39.55427

Sod Cutter 39.55520

Part Num

Part Number

ber

Item Description Part Number

Accessories

Item Description Part Number

Attachments

Introduction - 7

INTRODUCTION

Product Description

The Ventrac 4500 tractor combines All Wheel Drive and an articulating chassis with a low center of gravity

to provide superior traction, braking, stability, and security on tough terrain and slopes without disturbing

turf when turning. The attachment is placed out front in natural view, offering greater precision, as well as

maximum protection for the operator.

Ventrac’s patented SDLA control, located next to the operator, allows for easy control of Speed, Direction,

Lift, and Auxiliary functions with one hand.

Standard features include:

• a fold down roll bar.

• a computer controlled onboard diagnostic system for the electrical circuits.

• a wiring harness that is pre-wired for optional accessories.

• an electronic instrument panel that includes a tachometer, speedometer, fuel gauge, hour meter, and

temperature gauge.

• a six function warning gauge and alarm that includes engine coolant temp, hydraulic oil temp, engine oil

temp, low voltage, low engine oil pressure, and parking brake indicator.

• a complete electrical system circuit breaker and battery disconnect.

• an automotive pull style park brake.

• a hydraulic oil cooler with a thermostatically controlled, reversible fan.

Why Do I Need an Operator’s Manual?

This manual has been created to help you gain the important knowledge of what is needed to safely

operate, maintain, and service your machine. It is divided into sections for convenient reference of the

appropriate section.

You must read and understand the operator’s manual for each piece of Ventrac equipment you own. Reading the operator’s manual will help you become familiar with each specifi c piece of equipment. Under-

standing the operator’s manual will help you, as well as others, avoid personal injury and/or damage to the

equipment. Keep this manual with the machine at all times. The manual should remain with the machine

even if it is sold. If this manual becomes damaged or unreadable, it should be replaced immediately. Contact your local Ventrac dealer for a replacement.

When using a Ventrac attachment, be sure to read and follow the safety and operating instructions of both

the power unit and the attachment being used to ensure the safest operation possible.

The information in this manual provides the operator with the safest procedures to operate the machine

while getting the maximum use out of the unit. Failure to follow the safety precautions listed in this manual

may result in personal injury and/or damage to the equipment.

Introduction - 8

INTRODUCTION

Using Your Manual

Throughout this manual, you will encounter special messages and symbols that identify potential safety

concerns to help you as well as others avoid personal injury or damage to the equipment.

SYMBOL DEFINITIONS

ATTENTION

This symbol identifi es potential health and

safety hazards. It marks safety precautions.

Your safety and the safety of others is involved.

There are three signal words that describe the level of safety concern: Danger, Warning, and Caution.

Safety should always be the #1 priority when working on or operating equipment. Accidents are more likely

to occur when proper operating procedures are not followed or inexperienced operators are involved.

Note: Right-Hand and Left-Hand orientations may be referred to at different places throughout this manual.

Right-Hand and Left-Hand is determined as if sitting on the power unit seat facing forward.

SIGNAL WORD DEFINITIONS

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme cases.

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury and/or property damage. It may

also be used to alert against unsafe practices.

Manual Glossary

Power Unit A Ventrac tractor or other Ventrac engine powered device that may be operated by itself or

with an attachment or accessory.

Attachment A piece of Ventrac equipment that requires a Power Unit for operation.

Accessory A device that attaches to a Power Unit or Attachment to extend its capabilities.

Machine Describes any “Attachment” or “Accessory” that is used in conjunction with a power unit.

Introduction - 9

SAFETY

E

G

H

J

K

A

B

C

D

E

F

M

M

Directional/Hazard Light Kit

L

Vanguard Air Cooled Engine only

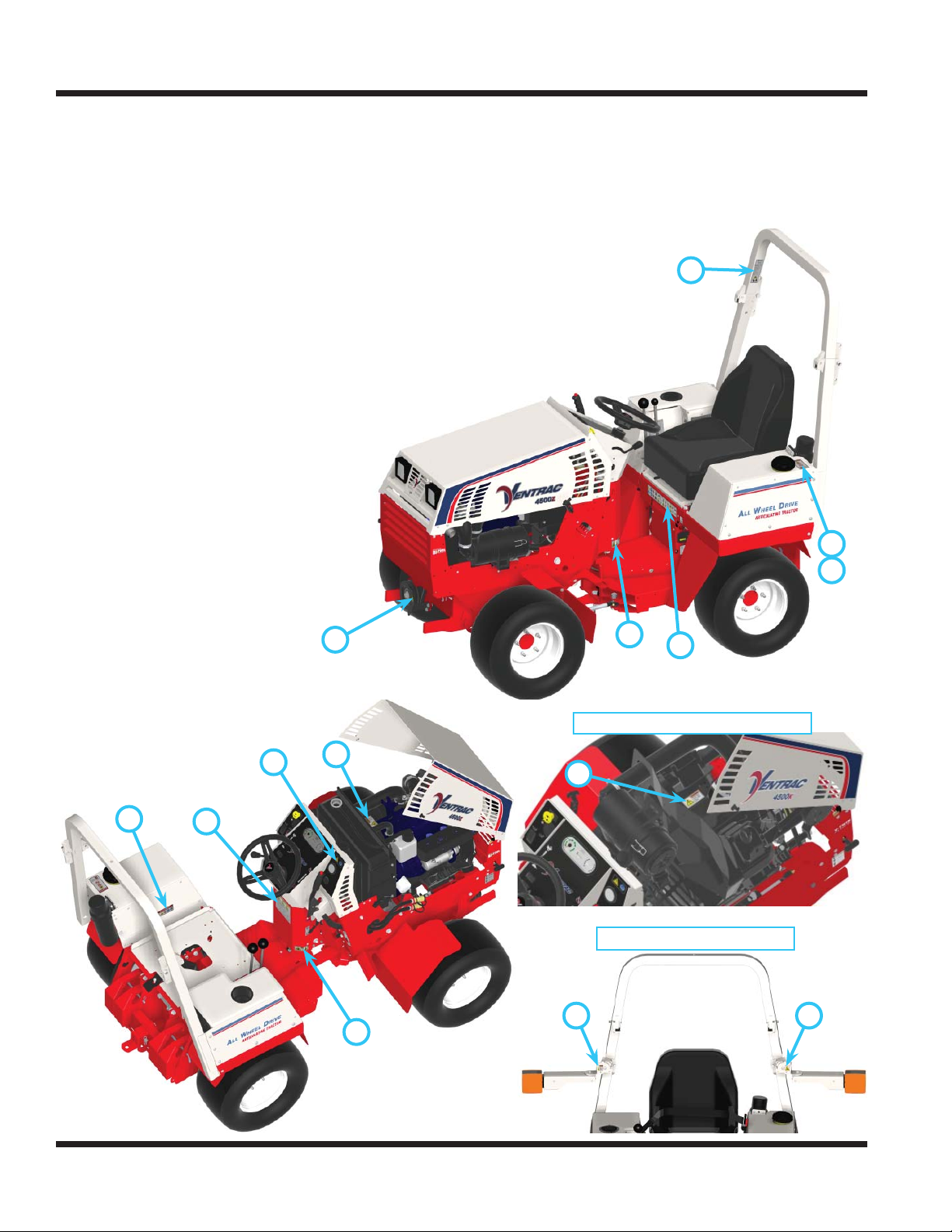

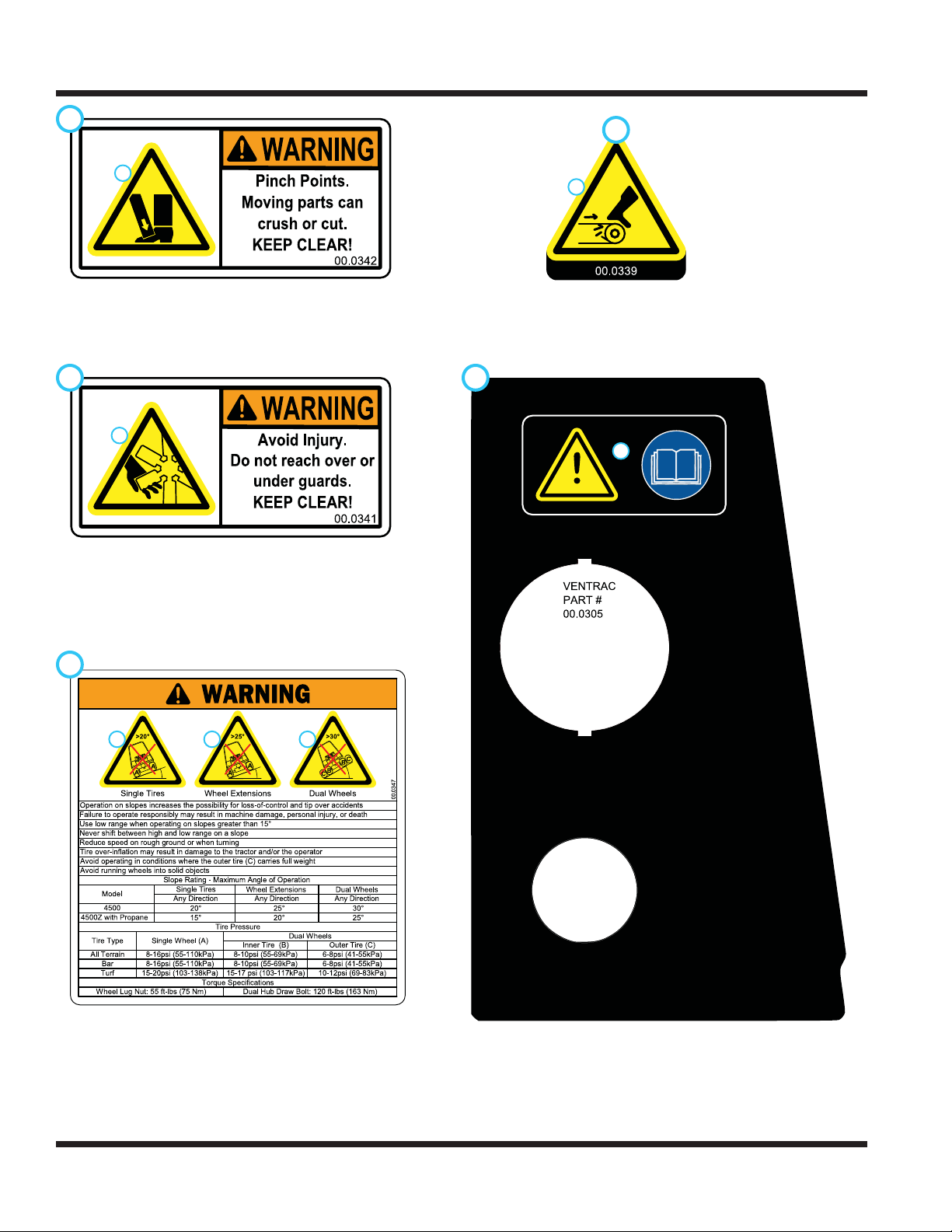

Safety Decals

The following safety decals must be maintained on your Ventrac 4500 power unit.

Keep all safety decals legible. Remove all grease, dirt, and debris from safety decals and instructional

labels. If any decals are faded, illegible, or missing, contact your dealer promptly for replacements.

When new components are installed, be sure that current safety decals are affi xed to the replacement

components.

A

B

C

E

F

G

H

K

J

L

Vanguard Air Cooled Engine only

Directional/Hazard Light Kit

D

M

E

Safety - 10

M

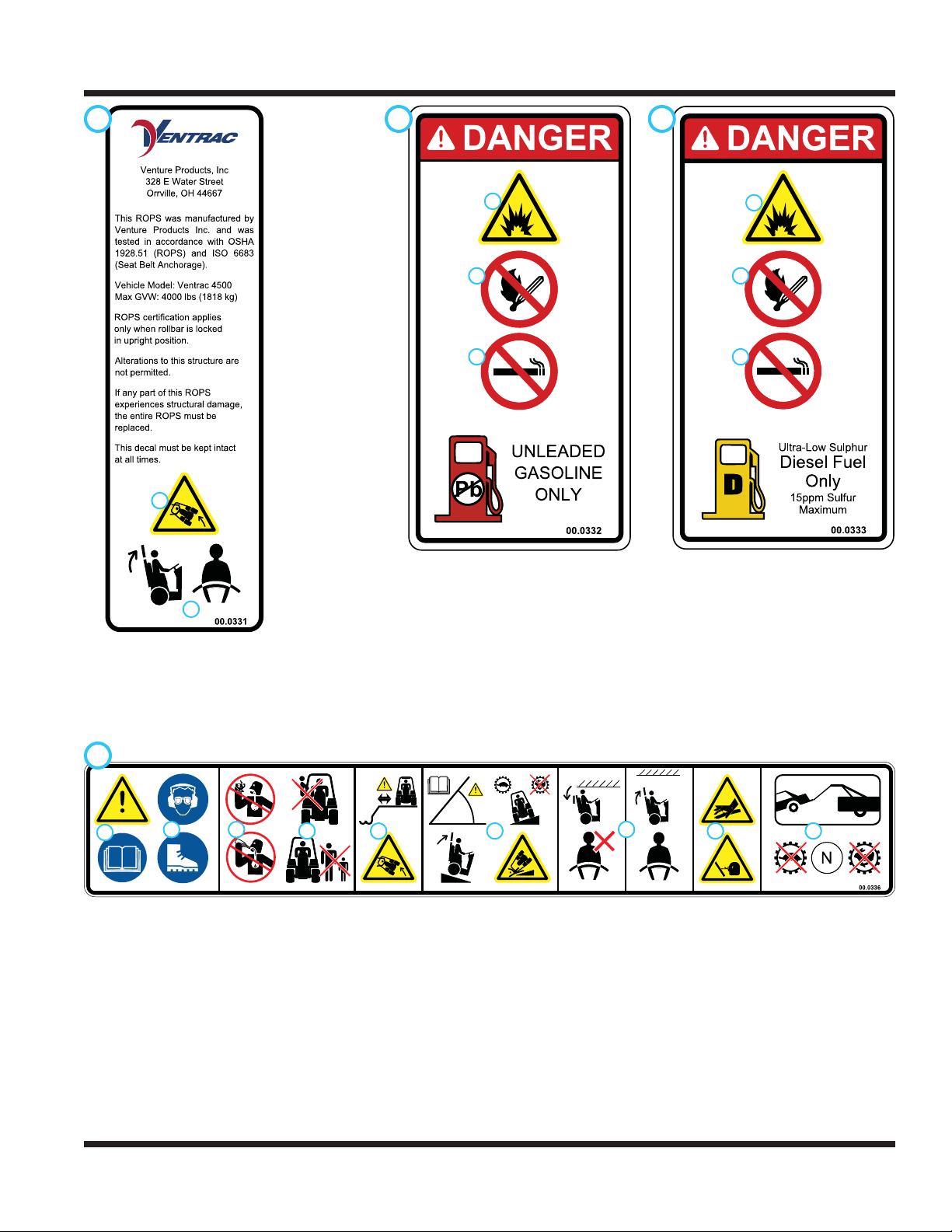

SAFETY

A

1

2

B

1

2

3

C

1

2

3

D

1

2

3

4

5

9

8

7

6

SAFETY

B

A

1

2

1

2

3

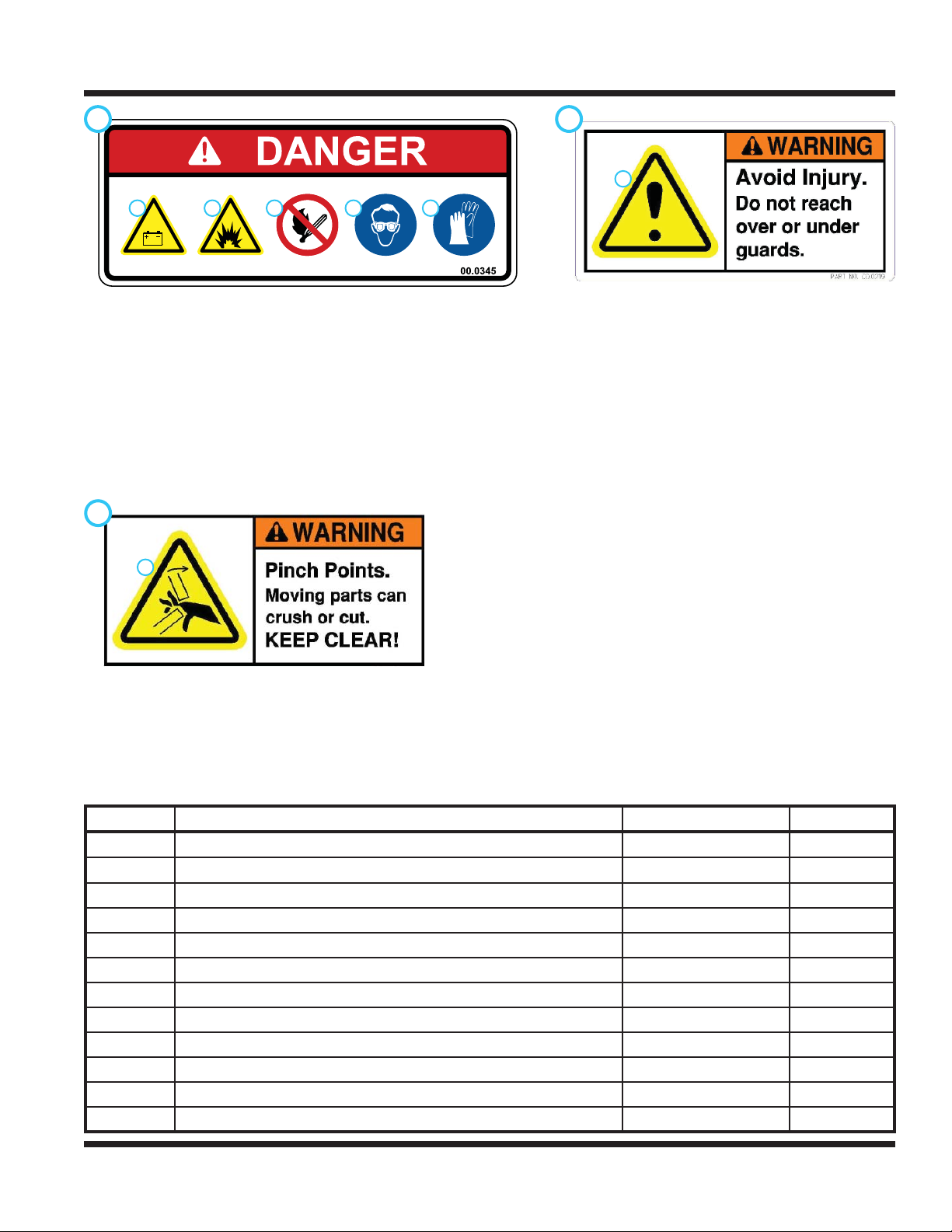

1. DANGER: Explosion/Fire Hazard

2. Keep away from fi re, sparks, and pilot lights when refueling or storing

machine and fuel.

3. Smoking is prohibited.

C

1

2

3

1. WARNING: Rollover!

2. Keep the roll bar in the raised and locked position

and the seat belt securely fastened during operation.

D

2

1

1. WARNING: Read operator’s manual

2. Wear personal protective gear, such as safety glasses, closed toe

shoes or boots, and ear protection.

3. Do not operate while under the infl uence of drugs or alcohol.

4. Do not carry passengers. Stop the machine if someone enters the area.

5. WARNING: Keep a safe distance from the edge of drop-offs, ditches,

and embankments. The machine could roll over if a wheel drops over

the edge or if the edge caves in.

6. WARNING: Read slope operation instructions. Use low range when

operating on slopes. Keep the roll bar in the raised and locked position

and the seat belt securely fastened.

3

4

5

7

6

7. Only lower the roll bar if there is low overhead clearance. DO NOT

wear a seat belt when operating with the roll bar in the lowered position. As soon as there is clearance, raise the roll bar to the upright

position and lock it in place. ALWAYS wear a seat belt when operating

with the roll bar in the raised position.

8. WARNING: Hydraulic fl uid is under high pressure and can penetrate

skin, causing injury. Keep hands, face, and body away from pinholes

or nozzles that eject hydraulic fl uid under high pressure.

9. When towing or pushing the power unit, the transaxles must be disengaged by moving the high/low range shift handle to the neutral position.

8

9

Safety - 11

SAFETY

G

1

F

1

1

E

H

1

2

3

J

1

E

1

F

1

1. Cutting/crushing hazard - Stay away from moving parts.

G

1

1. Cutting/dismemberment/entanglement hazard - Stay

away from moving parts.

J

1

2

3

1. Cutting/entanglement hazard Stay away from moving parts.

H

1

1. WARNING: 20° maximum rating when equipped with

single wheels.

2. WARNING: 25° maximum slope rating when equipped

with 3” wheel extensions.

3. WARNING: 30° maximum slope rating when equipped

with dual wheels.

1. WARNING: Read operator’s manual

Safety - 12

SAFETY

K

1

2

5

4

3

L

1

M

1

SAFETY

K

1

1. Danger: Battery acid is caustic and can cause chemical burns. Keep

bystanders a safe distance from the battery.

2. Explosion hazard - batteries produce fl ammable and explosive gases.

3. Do not expose batteries to arcs, sparks, or open fl ames. Do not use

smoking materials near batteries.

4. Wear eye protection, such as goggles or a face shield, when checking or

servicing batteries.

5. Wear appropriate protective gear, such as rubber gloves and an apron,

when checking or servicing batteries.

M

1

2

3

4

5

L

1

1. Warning: Do not reach over, under, or around guards,

covers, or shields. Stay away from moving parts.

1. Cutting/crushing hazard - Stay away from moving parts.

Decal Description Part Number Quantity

A ROPS Certifi cation 00.0331 1

B Danger, Gasoline Only 00.0332 1

C Danger, Diesel Only 00.0333 1

D 4500 Safety 00.0336 1

E Warning, Pinch Point 00.0342 2

F Moving Parts 00.0339 1

G Warning, Fan (liquid cooled engines) 00.0341 1

H Right Dash 00.0305 1

J Warning, 4500 Slope 00.0347 1

K Danger, Battery 00.0345 1

L Warning, Do Not Reach (Vanguard Air Cooled only) 00.0219 1

M Warning, Pinch Point (directional/hazard light kit) 00.0218 2

Safety - 13

SAFETY

General Safety Procedures

for Ventrac Power Units, Attachments, & Accessories

Training Required

• The owner of this machine is solely responsible for properly training the operators.

• The owner/operator is solely responsible for the operation of this

machine and prevention of accidents or injuries occurring to him/herself, other people, or property.

• Do not allow operation or service by children or untrained personnel.

Local regulations may restrict the age of the operator.

• Before operating this machine, read the operator’s manual and understand its contents.

• If the operator of the machine cannot understand this manual, then it

is the responsibility of this machine’s owner to fully explain the material

within this manual to the operator.

• Learn and understand the use of all controls.

• Know how to stop the power unit and all attachments quickly in the event of an emergency.

Personal Protective Equipment Requirements

It is the responsibility of the owner to be sure that the operators use the proper personal protective equipment while operating the machine. Required personal protective equipment includes, but is not limited to,

the following list.

• Wear a certifi ed ear protection device to prevent loss of hearing.

• Prevent eye injury by wearing safety glasses while operating the machine.

• Closed toe shoes must be worn at all times.

• Long pants must be worn at all times.

• When operating in dusty conditions, it is recommended that a dust mask be worn.

Operation Safety

• Inspect machine before operation. Repair or replace any damaged, worn, or missing parts. Be sure

guards and shields are in proper working condition and are secured in place. Make all necessary

adjustments before operating machine.

• Some pictures in this manual may show shields or covers opened or removed in order to clearly illustrate

any instructions. Under no circumstance should the machine be operated without these devices in place.

• Alterations or modifi cations to this machine can reduce safety and could cause damage to the machine.

Do not alter safety devices or operate with shields or covers removed.

• Before each use, verify that all controls function properly and inspect all safety devices. Do not operate

if controls or safety devices are not in proper working condition.

• Check parking brake function before operating. Repair or adjust parking brake if necessary.

• Observe and follow all safety decals.

• All controls are to be operated from the operator’s seat only.

• Always wear a seat belt if the machine has a roll cage/bar installed and in the upright position.

• Ensure the attachment or accessory is locked or fastened securely to the power unit before operating.

• Ensure that all bystanders are clear of the power unit and attachment before operating. Stop machine if

someone enters your work area.

• Always be alert to what is happening around you, but do not lose focus on the task you are performing.

Always look in the direction the machine is moving.

• Look behind and down before backing up to be sure of a clear path.

• If you hit an object, stop and inspect the machine. Make all necessary repairs before operating machine again.

• Stop operation immediately at any sign of equipment failure. An unusual noise can be a warning of equipment

failure or a sign that maintenance is required. Make all necessary repairs before operating machine again.

Safety - 14

SAFETY

General Safety Procedures

for Ventrac Power Units, Attachments, & Accessories

Operation Safety (continued)

• If equipped with a high/low range feature, never shift between high and low range while on a slope.

Always move the machine to level ground and engage the parking brake before shifting range.

• Do not leave machine unattended while it is running.

• Always park the machine on level ground.

• Always shut off engine when connecting attachment drive belt to the power unit.

• Never leave the operator’s seat without lowering the attachment to the ground, setting the parking

brake, shutting off the engine, and removing the ignition key. Make sure all moving parts have come to

a complete stop before dismounting.

• Never leave equipment unattended without lowering the attachment to the ground, setting the parking

brake, shutting off the engine, and removing the ignition key.

• Only operate in well-lit conditions.

• Never direct the discharge of any attachment in the direction of people, buildings, animals, vehicles, or

other objects of value.

• Never discharge material against a wall or obstruction. Material may ricochet back towards the operator.

• Use extra caution when approaching blind corners, shrubs, trees, or other objects that may obscure vision.

• Do not run the engine in a building without adequate ventilation.

• Do not touch the engine or the muffl er while the engine is running or immediately after stopping the engine.

These areas may be hot enough to cause a burn.

• Do not change the engine governor settings or over-speed the engine. Operating engine at excessive speed

may increase the hazard of personal injury.

• To reduce the hazard of fi re, keep the battery compartment, engine, and muffl er areas free of grass, leaves,

and excessive grease.

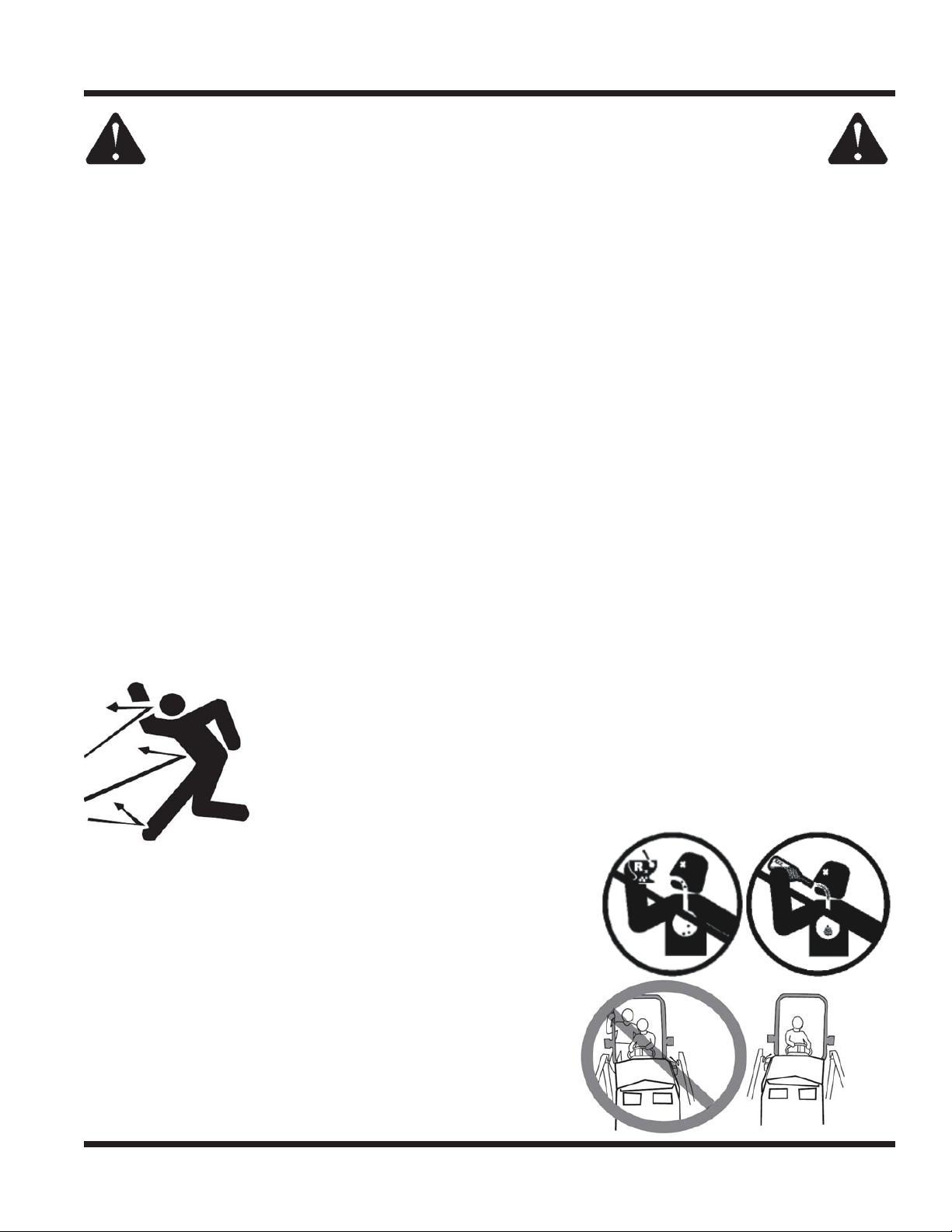

Preventing Accidents

• Clear working area of objects that might be hit or thrown from machine.

• Keep people and pets out of mowing area.

• Know the work area well before operation. Do not operate where traction or

stability is questionable.

• Reduce speed when you are operating over rough ground.

• Equipment can cause serious injury and/or death when improperly used.

Before operating, know and understand the operation and safety of the power

unit and the attachment being used.

• Do not operate machine if you are not in good physical and

mental health, if you will be distracted by personal devices, or

are under the infl uence of any substance which might impair

decision, dexterity, or judgment.

• Children are attracted to machine activity. Be aware of children

and do not allow them in the working area. Turn off the machine

if a child enters the work area.

Keep Riders Off

• Only allow the operator on the power unit. Keep riders off.

• Never allow riders on any attachment or accessory.

Safety - 15

SAFETY

General Safety Procedures

for Ventrac Power Units, Attachments, & Accessories

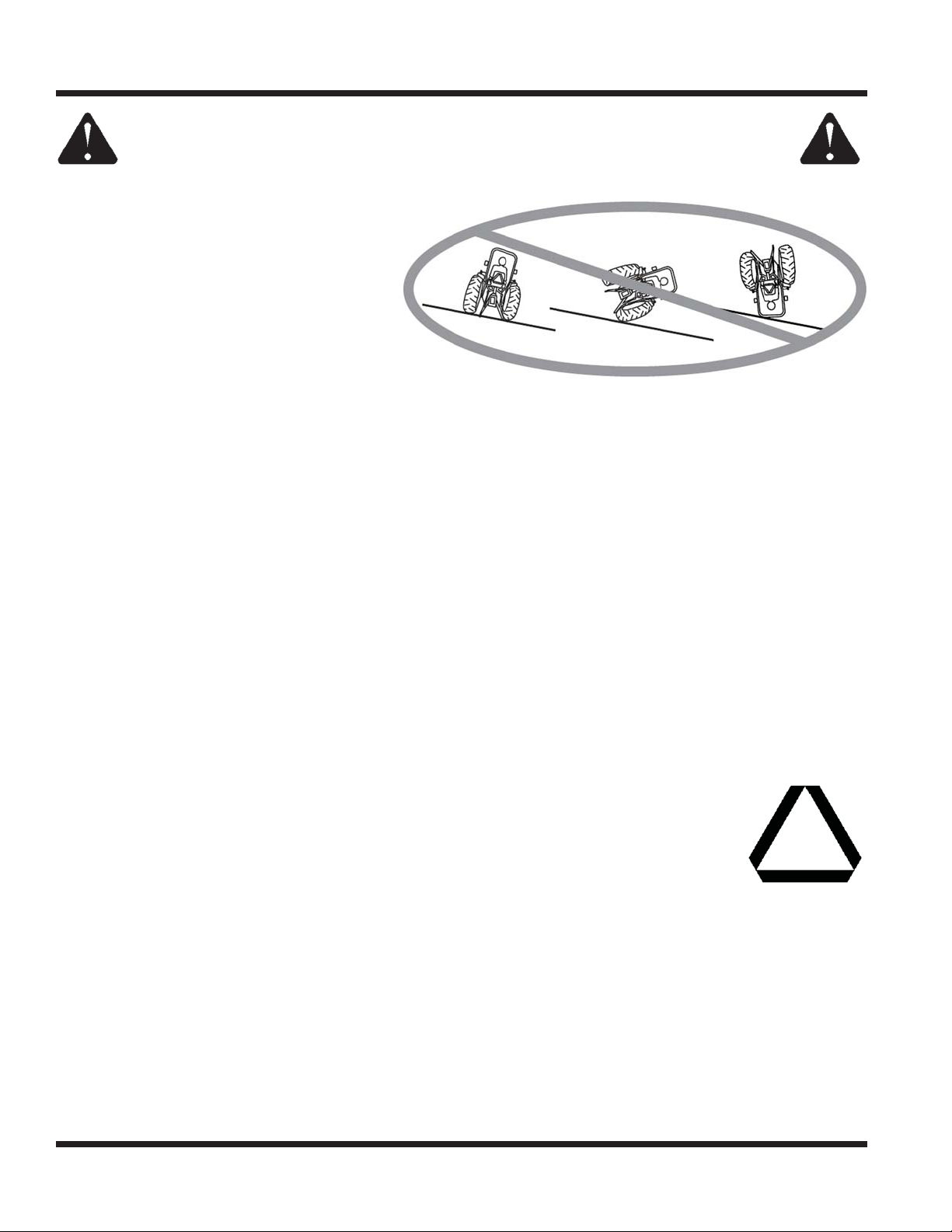

Operating On Slopes

• Slopes can cause loss-of-control and

tip-over accidents, which can result in

severe injury or death. Be familiar with the

emergency parking brake, along with the

power unit controls and their functions.

• If power unit is equipped with a fold down

roll bar, it must be locked in the upright

position when operating on any slope.

• Use low range when operating on slopes

greater than 15 degrees.

• Do not stop or start suddenly when operating on slopes.

• Never shift between high and low range while on a slope. Always move the power unit to level ground

and place the selector lever in park before shifting range.

• Variables such as wet surface and loose ground will reduce the degree of safety. Do not drive where

machine could lose traction or tip over.

• Keep alert for hidden hazards in the terrain.

• Stay away from drop-offs, ditches, and embankments.

• Sharp turns should be avoided when operating on slopes.

• Pulling loads on hills decreases safety. It is the responsibility of the owner/operator to determine loads

that can safely be controlled on slopes.

• Transport machine with attachment lowered or close to the ground to improve stability.

• While operating on slopes, drive in an up and down direction when possible. If turning is necessary

while driving across slopes, reduce speed and turn slowly in the downhill direction.

• Assure a suffi cient supply of fuel for continuous operation. A minimum of one-half tank of fuel is recommended.

Roadway Safety

• Operate with safety lights when operating on or near roadways.

• Obey all state and local laws concerning operation on roadways.

• Slow down and be careful of traffi c when operating near or crossing roadways. Stop before crossing

roads or sidewalks. Use care when approaching areas or objects that may obscure vision.

• If there is doubt of safety conditions, discontinue machine operation until a time when

operation can be performed safely.

• When operating near or on roadways, have a Slow Moving Vehicle Emblem clearly

displayed.

Truck Or Trailer Transport

• Use care when loading or unloading machine into a truck or trailer.

• The parking brake is not suffi cient to lock the machine during transport. Always secure the power unit

and/or attachment to the transporting vehicle.

• Shut off fuel supply to power unit during transport on truck or trailer.

• If equipped, turn the battery disconnect switch to the Off position to shut off electrical power.

Safety - 16

SAFETY

General Safety Procedures

for Ventrac Power Units, Attachments, & Accessories

Maintenance

• Keep all safety decals legible. Remove all grease dirt, and debris from safety decals and instructional labels.

• If any decals are faded, illegible, or missing, contact your dealer promptly for replacements.

• When new components are installed, be sure that current safety decals are affi xed to the replacement

components.

• If any component requires replacement, use only original Ventrac replacement parts.

• Always disconnect the negative battery cable from the battery when working with electrical components.

• Keep all bolts, nuts, screws, and other fasteners properly tightened.

• Always lower the attachment to the ground, engage parking brake, shut off engine, and remove the

ignition key. Make sure all moving parts have come to a complete stop before cleaning, inspection,

adjusting or repairing.

• If the power unit, attachment, or accessory requires repairs or adjustments not instructed in the opera-

tor’s manual, the power unit, attachment, or accessory must be taken to an authorized Ventrac dealer

for service.

• Never perform maintenance on the power unit and/or attachment if someone is sitting in the operator’s seat.

• Always use protective glasses when handling the battery.

• Check all fuel lines for tightness and wear on a regular basis. Tighten or repair them as needed.

• To reduce the hazard of fi re, keep the battery compartment, engine, and muffl er areas free of grass,

leaves, and excessive grease.

• Do not touch the engine, the muffl er, or other exhaust components while the engine is running or imme-

diately after stopping the engine. These areas may be hot enough to cause a burn.

• Do not change the engine governor settings or over-speed the engine. Operating engine at excessive

speed may increase the hazard of personal injury.

• Springs may contain stored energy. Use caution when disengaging or removing springs and/or spring

loaded components.

• An obstruction or blockage in a drive system or moving/rotating parts may cause a buildup of stored

energy. When the obstruction or blockage is removed, the drive system or moving/rotating parts may

move suddenly. Do not attempt to remove an obstruction or blockage with your hands. Keep hands,

feet, and clothing away from all power-driven parts.

• Dispose of all fl uids in accordance with local laws.

Fuel Safety

• Do not refuel machine while smoking or at a location near fl ames or sparks.

• Always refuel the machine outdoors.

• Do not store machine or fuel container indoors where fumes or fuel can reach an open

fl ame, spark, or pilot light.

• Only store fuel in an approved container. Keep out of reach of children.

• Never remove fuel cap or add fuel with the engine running. Allow engine to cool before refueling.

• Replace all fuel tank and container caps securely.

• Do not overfi ll fuel tank.

• If fuel is spilled, do not attempt to start the engine. Move the power unit away from the fuel spill and

avoid creating any source of ignition until fuel vapors have dissipated.

• If the fuel tank must be drained, it should be drained outdoors into an approved container.

• Dispose of all fl uids in accordance with local laws.

• Check all fuel lines for tightness and wear on a regular basis. Tighten or repair them as needed.

• The fuel system is equipped with a shut-off valve. Shut off the fuel when transporting the machine to

and from the job, when parking the machine indoors, or when servicing the fuel system.

Safety - 17

SAFETY

General Safety Procedures

for Ventrac Power Units, Attachments, & Accessories

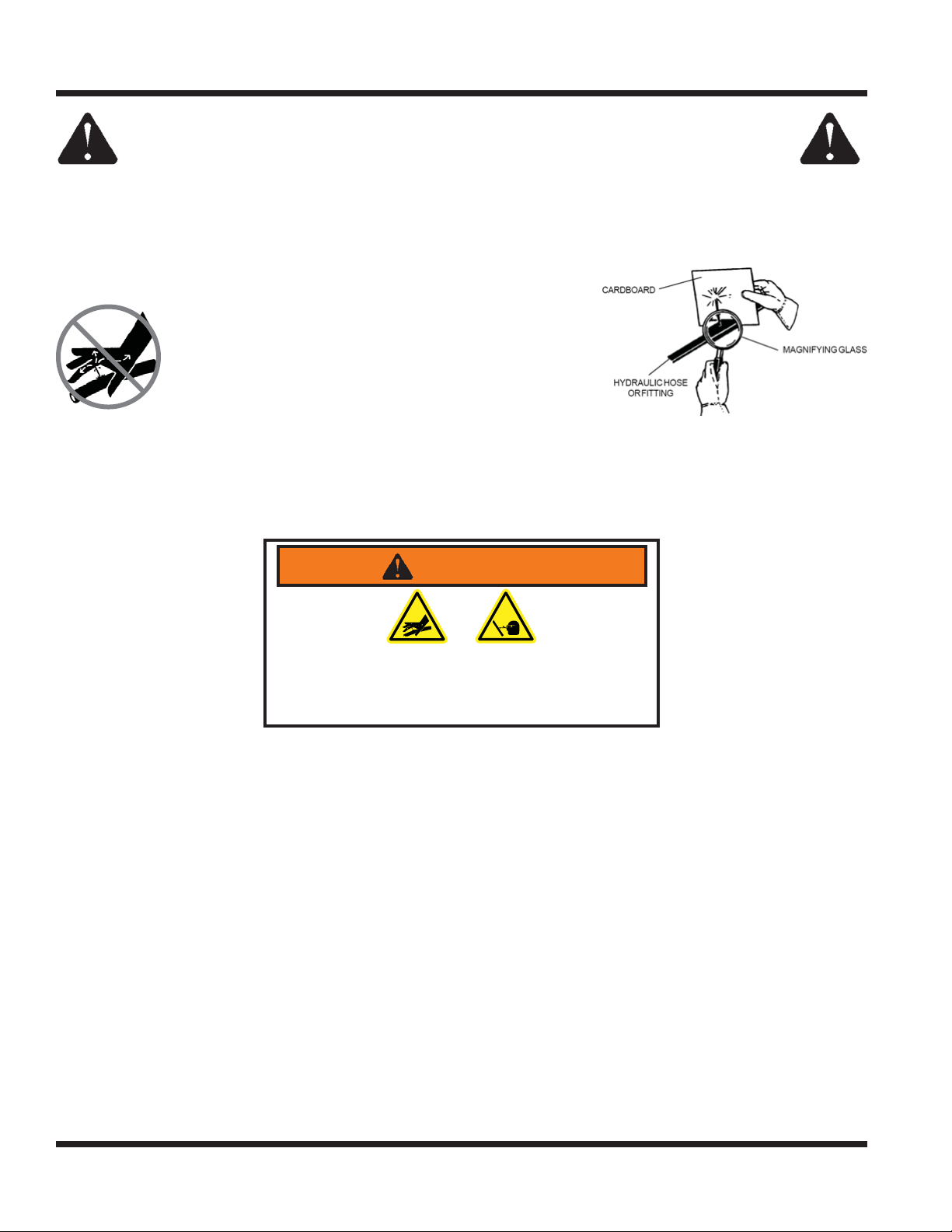

Hydraulic Safety

• Make sure all hydraulic connections are tight and all hydraulic hoses and tubes are in good condition.

Repair any leaks and replace any damaged or deteriorated hoses or tubes before starting the machine.

• Hydraulic leaks can occur under high pressure. Hydraulic leaks require special care and attention.

• Use a piece of cardboard and a magnifying glass to locate suspected hydraulic leaks.

• Keep body and hands away from pinhole leaks

or nozzles that eject high pressure hydraulic fl uid.

Hydraulic fl uid escaping under high pressure can

penetrate the skin causing serious injury. If hydraulic fl uid is injected into skin, seek immediate medi-

cal attention.

• Hydraulic system may contain stored energy. Before performing

maintenance or repairs on the hydraulic system, remove attachments, engage parking brake, disengage

weight transfer system (if equipped), shut off engine, and remove ignition key. To relieve pressure on the

auxiliary hydraulic system, shut off the power unit engine and move the secondary S.D.L.A. lever left and

right before disconnecting the auxiliary hydraulic quick couplers.

• Dispose of all fl uids in accordance with local laws.

WARNING

Hydraulic fl uid is under high pressure and can

penetrate skin, causing injury. Keep hands, face,

and body away from pinholes or nozzles that eject

hydraulic fl uid under high pressure.

Safety - 18

SAFETY

KN4500 Safety Procedures

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after handling!

Battery Warning

CALIFORNIA PROPOSITION 65

Diesel Exhaust Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects, or other reproductive harm.

• Power unit hydraulic system may contain stored energy. Before performing maintenance or repairs on

the auxiliary hydraulic circuit, remove attachments, engage the park brake, disengage weight transfer

system (if equipped), shut off engine, and remove the ignition key.

• Weight transfer spring may contain stored energy. Always disengage the weight transfer system (if

equipped) before performing maintenance or repairs on the weight transfer system, the front hitch, or

the lift hydraulics.

Roll Over Protective Structure (ROPS)

CALIFORNIA PROPOSITION 65

WARNING

Keep the ROPS locked in the upright position and

the seat belt securely fastened during operation.

Failure to do so could result in serious injury or

loss of life.

Alterations or modifi cations to this machine and/or

the ROPS structure can reduce safety and could

cause damage to the machine. Do not alter the

ROPS. Do not alter any other safety devices.

WARNING

Your power unit is equipped with a Roll-Over Protective Structure (ROPS). This ROPS was tested in accordance with OSHA 1928.51 (ROPS) and ISO 6683 (Seat Belt Anchorage). This ROPS is certifi ed for use on

a Ventrac 4500 with a maximum GVW of 4,000 pounds (1818 Kg).

• ROPS certifi cation applies only when the roll bar is locked in the upright position.

• Alterations to the ROPS structure are not permitted.

• Lower the roll bar only when absolutely necessary and raise the roll bar to the upright position as soon

as clearance allows.

• Always wear the seat belt when the roll bar is locked in the upright position.

• Do not wear a seat belt when the roll bar has been lowered to the down position.

• If any part of this ROPS experiences structural damage, the entire ROPS must be replaced.

• Inspect the seat belt for wear or damage before use. Failure to inspect or maintain the seat belt can

cause injury or loss of life.

Operator Access System

• The operator access system is on the left side of the power unit. Mount and dismount the 4500 only on

the left side of the power unit.

Safety - 19

Propane Safety (if applicable)

SAFETY

KN4500 Safety Procedures

DANGER

Propane is fl ammable and explosive.

Contact with escaping vapors or liquid may cause

freezing of tissue or frostbite.

Notice

Use of propane must be in compliance with any applicable governmental regulations, including National

Fire Protection Association (NFPA) Code # 58.

•

Check all fi ttings before use to ensure tight, leak free connections.

• Propane cylinders contain pressurized, fl ammable liquid and gas. Make sure that anyone who changes

or uses the propane cylinders is aware of its dangerous potential.

• Propane cylinders must be used only in compliance with all applicable governmental regulations.

• All persons who operate this machine or services the propane cylinders must be trained in proper procedures and regulations.

• Secure propane cylinders when transporting.

• Always refi ll propane cylinders outdoors.

• Use commercial propane only.

• Fill propane cylinders at a reputable dealer.

• Do not overfi ll. Follow approved procedures for fi lling propane cylinders.

• Do not store either empty or fi lled propane cylinders in a building or enclosed trailer.

• Turn off the liquid withdrawal valve on the propane cylinder when storing or transporting the power unit.

• Do not expose propane cylinders to fi re or heat above 120° F (49° C).

• Do not attempt repairs on a propane cylinder or its components. Contact an authorized LPG dealer or

service center.

• If cylinders are dented, gouged, bulging, or corroded, they must be removed from service and replaced.

• When removing a propane cylinder from service, contact an authorized LPG dealer or service center for

assistance in proper disposal.

• Propane cylinders must be tested at specifi c intervals. Contact an authorized LPG dealer or service

center for regulations regarding propane cylinder testing.

Use only commercial liquid propane or HD-5

propane.

Use only liquid withdrawal 33 lb. capacity

aluminum propane tanks. Do not use steel or

fi berglass tanks.

WARNING

Safety - 20

SAFETY

KN4500 Safety Procedures

Operator Safety Interlock System

The 4500 power unit is equipped with a safety interlock system. This system:

• Prevents the engine from starting unless the parking brake is engaged and SDLA control is in neutral.

• Prevents the PTO from starting if the operator is not in the seat.

• Prevents the power unit from driving if the parking brake is engaged.*

• Shuts off the PTO if the operator leaves the seat^.

• Shuts off the engine (and fuel pump) if the operator leaves the seat without engaging the parking brake.

• Shuts off the engine if the forward / reverse controls (SDLA lever or foot pedal) are moved from neutral

while the parking brake is engaged.

*The parking brake must be completely disengaged before moving the SDLA lever forward or backward or the power unit engine will shut off.

^If power unit is equipped with PTO remote kit # 70.4106 and is using an attachment with a remote PTO shut-off switch, the safety interlock system performs additional functions.

Testing the Safety Interlock System

WARNING

Never operate the power unit if the safety interlock

system is malfunctioning. Do not disengage or bypass

any switch. Failure to heed warning could result in

injury to yourself and others, or damage to property.

The daily inspection should be performed only

when the engine is shut off and all fl uids are cold.

Lower attachments to the ground, engage the

parking brake, and shut off the engine.

CAUTION

Perform the following safety interlock tests daily. Before testing, park the power unit on a level surface,

place wheel chocks in front and back of wheels, and place the high/low range shift lever in the neutral

position. After testing is complete, place the high/low shift lever in either high or low range, set the parking

brake, and remove the wheel chocks.

Turn the ignition key to the run position. Tests 1 - 4 test the engine start function, tests 5 - 9 test the engine

run function, and tests 10 - 13 test the PTO function.

Engine

Start

Engine

Run

PTO

Test

Number

1 No Yes Yes No

2 Yes No Yes No

3 Yes Yes No Yes

4 Yes Yes Yes Yes

Test

Number

5 Yes Yes Yes Yes

6 Yes Yes No Yes

7 Yes No No No

8 Yes No Yes No

9 No Yes No No

Test

Number

10 Off Yes Off

11 Pull to ‘On’ Position No No

12 Pull to ‘On’ Position Yes Yes

13 On

Parking Brake

Engaged

Parking Brake

Engaged

Forward/Reverse Control

(SDLA) in Neutral

Forward/Reverse Control

(SDLA) in Neutral

PTO Switch Operator Present in Seat PTO Clutch

Operator Present in Seat Engine Starts

Operator Present in Seat Engine Runs

Raise Operator Body Weight

from Seat

PTO Disengages

(1/2 second delay)

If the power unit fails any one of the safety interlock tests, refer to the troubleshooting section for using the

TCM (tractor control module) to diagnose electrical problems.

Safety - 21

OPERATIONAL CONTROLSOPERATIONAL CONTROLS

A

B

C

D

E

F

G

H

I

L

N

J

K

M

O

P

U

V

W

X

Y

Q

R

T

S

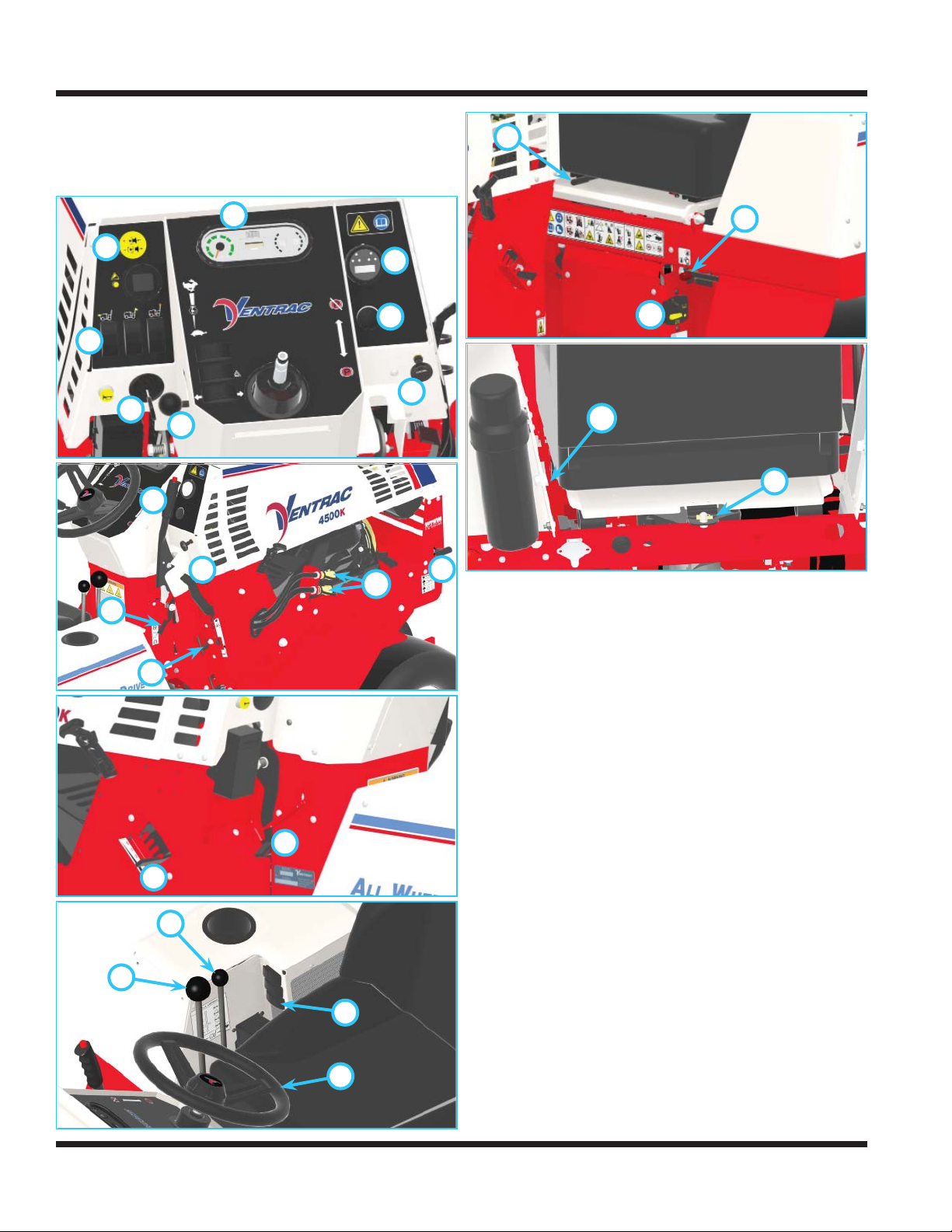

Standard Operational Control Locations

Use the following images to help identify the locations

of operational controls. The letter next to each control

can be referenced to the list that follows these images.

A

G

F

D

E

I

B

C

H

U

V

W

X

Y

N

L

J

K

O

P

R

Q

M

T

S

A. Information Cluster Gauge

B. Warning Cluster Gauge

C. Warning Alarm (Continuous)

D. Ignition Switch

E. Throttle Lever

F. Headlight Switch

G. PTO Switch

H. Choke Handle (if equipped)

I. Parking Brake

J. Neutral Assist Lever

K. Front Hitch Lever Lock

L. Front Hitch Latch Lever

M. Auxiliary Hydraulic Quick Couplers

N. PTO Belt Tensioner Rod

O. High/Low Shift Lever

P. Weight Transfer Select Lever (if equipped)

Q. Primary SDLA Control Lever

R. Secondary SDLA Control Lever

S. Steering Wheel

T. Hydraulic Cooler Fan Switch

U. Seat Slide Lever

V. Fuel Shut-off Valve

W. Circuit Breaker & Battery Disconnect

X. Seat Prop Plate

Y. Seat Latch Strap

Operation - 22

OPERATIONAL CONTROLS

3 Point Hitch Arms

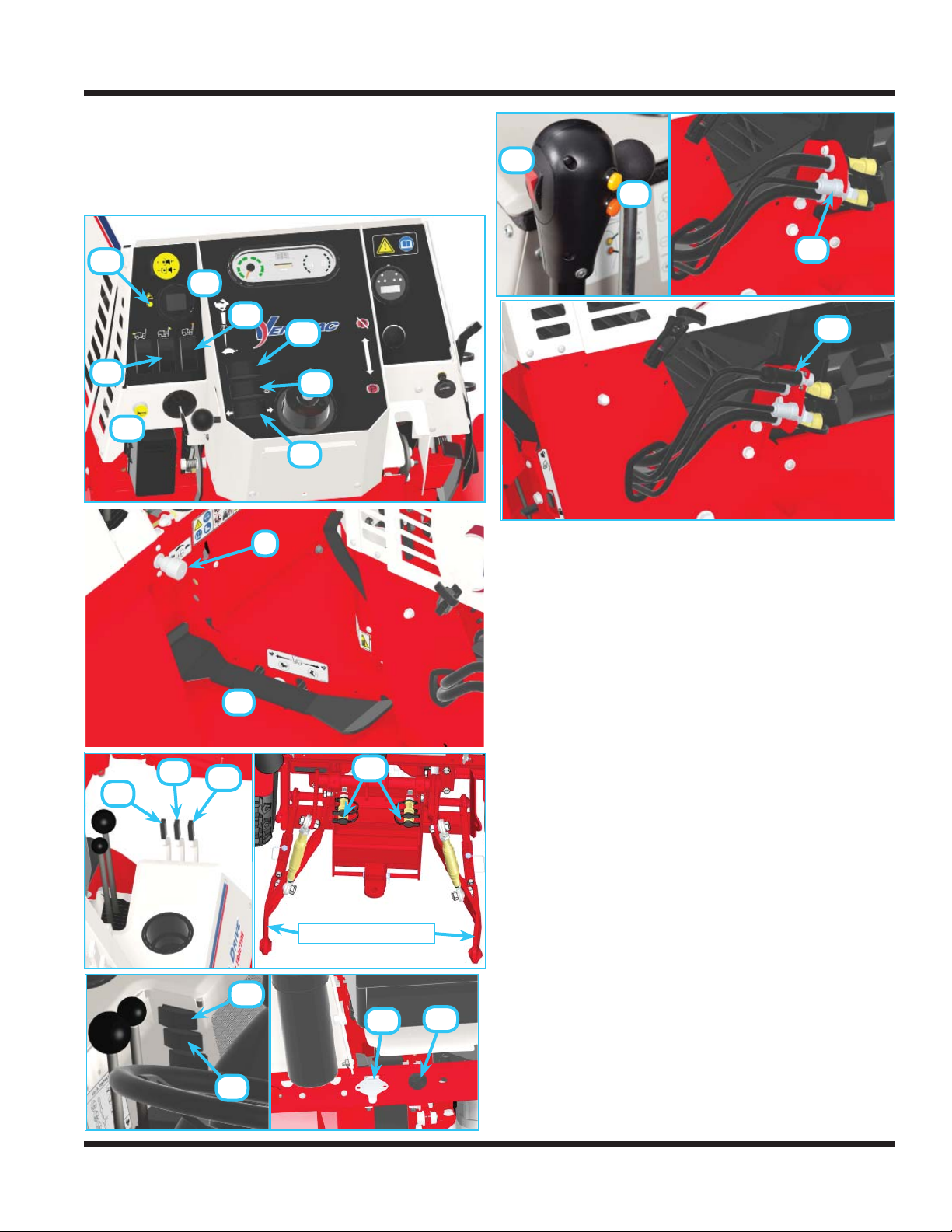

Optional Operational Control Locations

Use the following images to help identify the locations

of operational controls for optional kits. The letter next

to each control can be referenced to the list that follows these images.

RR

SS

DD

AA

HH

KK

LL

CC

MM

BB

JJ

OO

GG

FF

EE

II

3 Point Hitch Arms

NN

QQ

TT

UU

AA. Work Light Switch

BB. Strobe Light Switch

CC. Slope Indicator Gauge

DD. Slope Warning Light

EE. Directional Signal Switch

FF. Hazard Flasher Switch

GG. Gas/Propane Selector Switch (4500Z only)

HH. Horn Switch

II. Front Hitch Valve

JJ. Foot Pedal

KK. 3 Point Hitch Control Handle

LL. Left Rear Auxiliary Hydraulics Handle

MM. Right Rear Auxiliary Hydraulics Handle

NN. Rear Auxiliary Hydraulic Quick Couplers

OO. Rear 12V Switch (On/Off)

PP. Rear 12V Switch (Momentary On/Off/On)

QQ. Rear 12V 4-Pin Socket

RR. Front 12V Switch (On/Off)

SS. Front 12V Switch (Momentary On/Off/On)

TT. Front 12V 4-Pin Socket

UU. Electric PTO Remote Socket

VV. Back Up Alarm

VV

PP

Operation - 23

OPERATIONAL CONTROLS

1

2

6

5

4

3

1

2

6

5

4

3

1

3

2

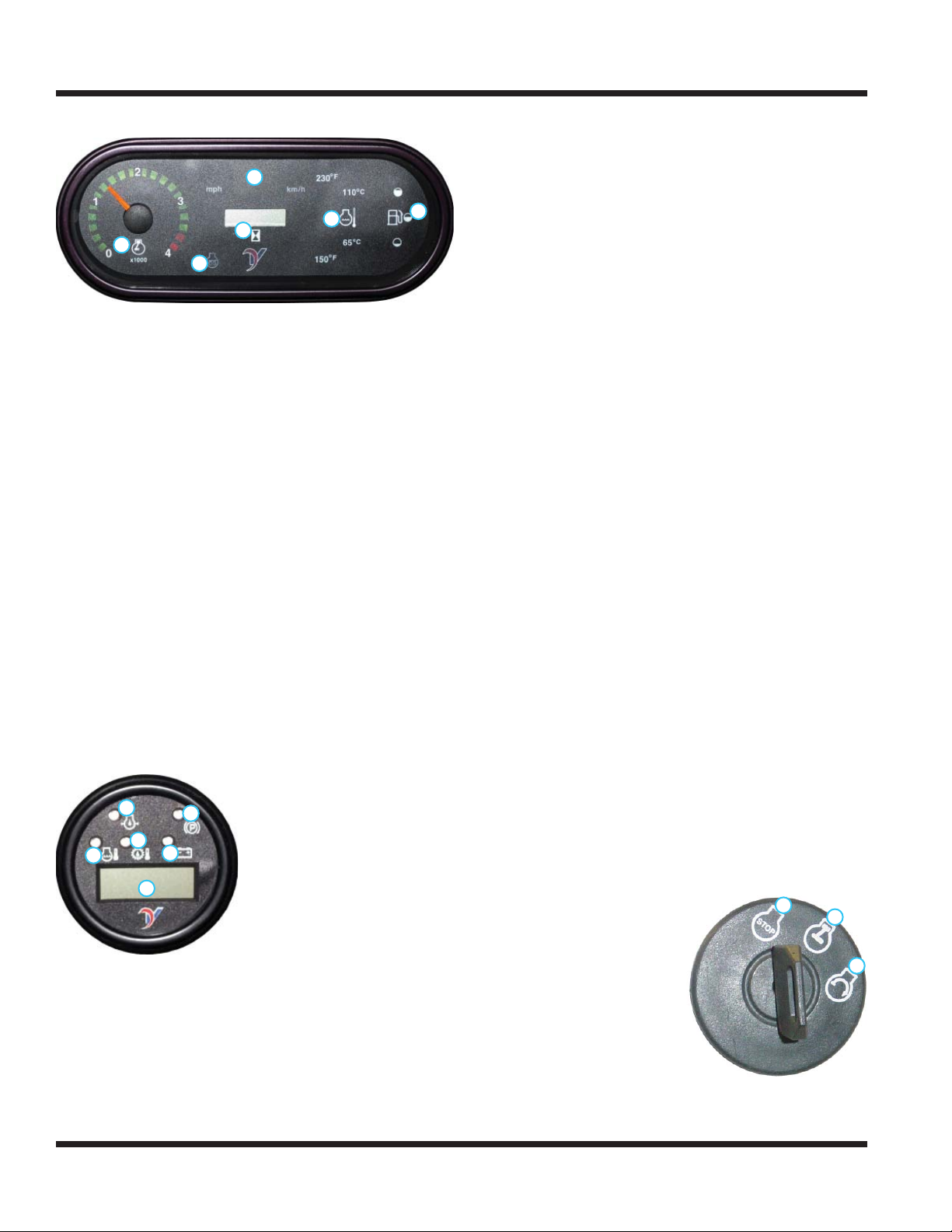

Information Cluster Gauge (A)

2

5

1

1. Tachometer

2. Speedometer

3. Hour Meter

4

3

6

4. Water Temperature Gauge

5. Fuel Gauge

6. Glow Plug Indicator Light

The information cluster gauge contains a tachometer, speedometer, hour meter, water temperature

gauge (liquid cooled engines only), fuel gauge, and

glow plug indicator light (diesel engine only).

The tachometer displays the engine speed in RPM.

The speedometer displays the speed of the power

unit. The speedometer can be set to display either

miles per hour (mph) or kilometers per hour (kph).

The hour meter records the accumulated time the

ignition key has been switched to the on position.

The water temperature gauge displays the tem-

perature of the engine cooling system (liquid cooled

engines only).

The fuel gauge displays the level of fuel in the tank.

The glow plug indicator light indicates activation

of the glow plugs for preheating the engine (diesel

engine only). The glow plugs activate when the key

is turned to the on position. When the glow plug light

turns off, the engine is ready to start.

Warning Cluster Gauge (B)

3

5

4

2

6

1

The warning cluster gauge contains a volt meter, a

park brake indicator light, low engine oil pressure

warning light, high water temperature warning light,

high hydraulic fl uid temperature warning light, and

low voltage warning light.

The volt meter displays the voltage level of the

charging system.

The park brake indicator light activates when the

park brake is set.

1. Volt Meter

2. Park Brake Indicator Light

3. Low Engine Oil Pressure Warning Light

4. High Water Temperature Warning Light

5. High Hydraulic Fluid Temperature Warning Light

6. Low Voltage Warning Light

The low engine oil pressure warning light acti-

vates when the engine oil pressure is below safe

levels. The light comes on when the ignition key is

switched to the on position and stays illuminated until

the engine is started and safe oil pressure develops.

If this light comes on during operation, immediately

shut off the engine. Do not restart the engine until the

problem has been located and corrected.

The water high temperature warning light acti-

vates when the temperature of the engine cooling

systems reaches unsafe levels. If this light comes

on during operation, park the power unit, shut off

the engine, and allow the engine to cool. Check the

radiator screen and engine compartment and clean,

if necessary. If the engine continually overheats, refer

to the troubleshooting section for possible problems.

The hydraulic fl uid high temperature warning

light activates when the hydraulic fl uid reaches

unsafe levels. If this light comes on during operation, park the power unit and move the throttle lever

to the idle position. Check the hydraulic cooling fan

to ensure it is operating properly and refer to the

troubleshooting section for possible problems.

The low voltage warning light activates when the

voltage drops to unacceptable levels. If this light

comes on, shut off any unnecessary lights and

accessories to reduce current draw. If voltage continues to drop, park the power unit, shut off the engine,

and turn the ignition key to the off position. Refer to

the troubleshooting section for possible problems.

Warning Alarm (C)

The warning alarm works with the warning cluster

gauge to alert the operator to problems. The warning alarm sounds a continuous signal whenever a

warning is displayed on the warning cluster gauge.

If the warning alarm sounds, immediately check the

warning cluster gauge to determine the cause of the

warning and then take appropriate action.

Ignition Switch (D)

1. Off or Stop Position all 12 volt power going

through the key switch

is off.

2. On or Run Position engine run position, 12

volt power is sent to

accessories.

3. Start Position - when the

key is turned to the start

position, the starter will engage.

1

2

3

Operation - 24

OPERATIONAL CONTROLS

2

1

2

1

2

1

3

2

1

2

1

2

1

Throttle Lever (E)

Moving the throttle lever forward

1. Fast

2. Slow

1

toward the fast position increases the

engine Revolutions Per Minute (RPM). Moving the throttle lever backward toward the

slow position decreases the engine RPM.

Headlight Switch (F)

Depressing the top (1) of the head-

1. On

2. Off

light switch turns on the headlights

2

1

and taillights. Depressing the bottom (2) of the

switch turns the lights off.

2

Power Take Off (PTO) Switch (G)

Pulling up on the PTO switch engages the electric

clutch to provide power to the front

attachment.

Pushing down on the PTO switch

disengages the electric clutch and

1

applies the clutch brake to stop the

attachment. NOTE: the PTO will turn

off automatically if the operator leaves

the seat. The PTO can be restarted by

1. PTO Off

2. PTO On

turning the PTO switch off and then on again.

Choke Handle (H)

Pull the choke handle out to aid in starting a cold

engine. Push the choke handle in for operation.

NOTE: a choke control is not used on power units

with diesel or fuel injected engines.

Parking Brake (I)

When parking the power

unit, always engage the

parking brake to prevent

accidental movement of

the machine.

1

To engage the parking

brake, pull the brake

handle back toward the

operator.

To disengage the parking

brake, pull back slightly on

the brake handle to relieve

pressure, push down the

release button (3) on the

top of the handle, and

push the handle forward.

If the parking brake is

2

1. Parking Brake Disengaged

2. Parking Brake Engaged (Set)

3. Parking Brake Release Button

set, any attempt to move

the power unit will shut off the engine. If the operator

leaves the seat without fi rst setting the parking brake,

the engine will shut off.

3

Neutral Assist Lever (J)

1. Neutral Assist Off

2. Neutral Assist On

Placing the neutral assist lever in

the on position (2) engages the neutral assist

spring to help return the SDLA control levers

to the neutral position. This makes the neutral position easy to select and maintain. The

neutral assist on position is recommended

when learning the operation of the power unit,

loading or unloading, attaching and removing

attachments, and whenever the operator is unsure of

the power unit’s response to the task being performed.

Placing the neutral assist lever in the off position (1)

disengages the neutral assist spring. This position is

designed for experienced operators when using the

power unit in open areas where travel speed and

direction are relatively constant and control is easily

maintained. The neutral assist off position reduces

operator arm fatigue when using the power unit for

prolonged periods of time.

2

CAUTION

Stopping the power unit with the neutral assist

lever in the off position requires the operator to

manually return the SDLA control lever or foot

pedal to the neutral position.

Front Hitch Lever Lock (K)

The front hitch lever lock prevents the accidental release of the front hitch latch lever. To

release the front hitch latch lever, lift the tab

on the front hitch lever lock and then move the

front hitch latch lever to the unlock position.

Front Hitch Latch Lever (L)

The front hitch latch lever locks

or unlocks the hitch latch.

Raise the front hitch latch lever to unlock

the hitch latch when attaching or detaching

Ventrac attachments.

Lower the front hitch latch lever to lock the

hitch latch over the hitch arm pins on Ventrac

attachments. Ensure the lever is secured in

the frame notch and the front hitch lever lock

is in place.

Auxiliary Hydraulic Quick Couplers (M)

The two couplers are a part of the auxiliary hydraulic circuit and are used with an attachment which

requires hydraulics (e.g. to angle a dozer blade or

rotate the discharge on the snow blower).

1. Unlocked

2. Locked

1

2

1

2

Operation - 25

OPERATIONAL CONTROLS

2

1

9

8

7

6

5

4

3

10

2

1

2

3

1

PTO Belt Tensioner Rod (N)

The PTO belt tensioner rod

applies or releases belt tension

to the attachment drive belt.

After placing the attachment

drive belt onto the PTO drive

1

pulley, pushing the PTO belt

tensioner rod in (1) until it locks

2

applies tension to the attachment drive belt.

Pulling the the PTO belt ten-

1. Belt Tension Engaged

2. Belt Tension Released

sioner rod out (2) releases the

belt tension, allowing the operator to remove or install

the attachment drive belt.

High/Low Shift Lever (O)

1

CAUTION

Never shift while under load, while mov-

2

ing, or while on a slope. Always ensure

the shift lever is secured in the lock

position at the end of each shift stroke.

The high/low range shift lever shifts both the

3

front and rear transaxles simultaneously.

With the power unit parked on level

ground, push the shift lever forward to

select low range (1).

Move the shift lever to middle of the

shift stroke to place the transaxle gears

1. Low Range

2. Neutral

3. High Range

in neutral (2).

Pull the shift lever back toward the operator to

select high range (3).

Ensure the shift lever is secured in the lock position

at the end of each shift stroke.

Weight Transfer Traction Control Select Lever (P)

The weight transfer system transfers weight from

the attachment to the front wheels of the

power unit. Transferring weight from the

attachment to the power unit increases the

traction control, improves hillside maneuverability, aids in lifting the attachment,

reduces steering effort, and lessens the

attachment resistance when in contact with

the ground.

The operator can select different transfer

rates by selecting one of the fi ve positions

from no weight transfer (0) to maximum

weight transfer (4). Set the weight transfer

to 0 when attaching or detaching any attachment.

SDLA Control Lever (Q & R)

6

5

4

3

1

1. Forward Direction

2. Reverse Direction

3. Lift

4. Hold

5. Lower

The SDLA (Speed, Direction, Lift, and Auxiliary) is

the primary control for the power unit and consists

of two levers. The primary SDLA control lever (Q)

controls the speed, direction of travel, and lift of the

hitch arms. The secondary SDLA control lever (R)

controls the auxiliary hydraulic circuit.

S - Speed: the amount of forward or backward

movement of the primary SDLA lever controls

the ground speed of the power unit.

D - Direction: the forward or backward movement of

the primary SDLA lever controls the direction of

the power unit.

L - Lift: the lift function of the primary SDLA lever has

four positions: Up, Hold, Down, and Float Lock.

“Hold” is the default position; this holds the lift

arms from moving up or down. Pulling the lever

to the left raises the hitch arms. Pushing the lever

to the right lowers the hitch arms. Float position is

attained by pushing the lever to the right until the

fl oat detent locks the lever in place.

A - Auxiliary: the left or right movement of the

secondary SDLA lever controls the functions of

attachments that require the auxiliary hydraulic

circuit. An optional fl oat kit (part # 23.0111-7) is

available for the auxiliary circuit.

10

9

8

7

6. Float

7. Direction #1

8. Hold

9. Direction #2

10. Float (if equipped)

2

Operation - 26

OPERATIONAL CONTROLS

1

2

2

1

1

2

2

1

2

1

Steering Wheel (S)

Turn the steering wheel to the left (counterclockwise)

to turn the power unit to the left. Turn the wheel to the

right (clockwise) to turn the power unit to the right.

Hydraulic Cooler Fan Switch (T)

The hydraulic oil cooler fan

switch is normally set to the

automatic thermostatically

controlled position (1). This

allows the thermostat to turn

on the cooling fan when the

hydraulic fl uid reaches the set

temperature. The fan pulls air

through the right fender next

to the operator, through the oil

cooler, and discharges the air

out the back of the power unit.

2

1

The switch can be set to the

reverse position (2) to pull air

from the back of the power

unit, through the oil cooler,

1. Normal (auto) Operation

2. Reverse Operation

and discharge the warm air next to the operator.

This feature can be used to help provide warmth for

the operator during cold weather.

Seat Slide Lever (U)

Move the seat slide lever to the left to release the

seat lock. Move the seat forward or backward to the

desired position and release the seat slide lever to

lock the seat in place.

Fuel Shut-off Valve (V)

The fuel shut-off valve controls the

fl ow of fuel to the power unit engine.

1

Turning the valve to position 2 will

allow fuel to fl ow to the engine.

Turning the valve to position 1 shuts

off the fuel fl ow to prevent fuel leak-

age when changing fuel fi lters or

2

1. Fuel Off

2. Fuel On

servicing the fuel system. Turn off the fuel shut-off

valve when transporting the power unit on a truck or

trailer and when parking the power unit indoors.