OWNER/OPERATOR’S

MANUAL

VENTRAC

3000

Venture Products Inc. Orrville, OH

REVISED 09-30-05

09.10038

Orrville, OH

www.ventrac.com

TO THE OWNER

Congratulations on the purchase of a new VENTRAC 3000! The purpose of this

manual is to assist you in its safe and effective operation and maintenance.

With proper usage and care, the machine will provide many years of service. Please

read and understand this manual entirely before using the machine. Keep this

manual on file for future reference.

Please fill in the following information for future reference:

Date of Purchase: Month _________________ Day __________ Year ____________

Serial Number: ________________________________________________________

Dealer: _______________________________________________________________

Dealer Address: ________________________________________________________

_________________________________________________________

Dealer Phone Number: ___________________________________________________

Dealer FAX Number: ____________________________________________________

Venture Products Inc. reserves the right to make changes in design or

specifications without incurring obligation to make like changes on

previously manufactured products.

ii VENTRAC 3000 VPI

TABLE OF CONTENTS

INTRODUCTION Section A

Description .....................................................................................................................A-1

Specifications .................................................................................................................A-2

SAFETY Section B

Before Operating ............................................................................................................B-1

On Slopes ........................................................................................................................B-2

Operator Personal Safety, General Safety.......................................................................B-3

Seat Belt & Roll Cage ....................................................................................................B-4

OPERATION Section C

Profile, Control Selector..................................................................................................C-1

Front Controls..................................................................................................................C-2

Side Controls ...................................................................................................................C-3

Fenders, Battery...............................................................................................................C-4

Seat, Owner’s Manual .....................................................................................................C-5

Front Hitch & PTO Drive ...............................................................................................C-6

PTO Driven Attachments ...............................................................................................C-6

Attaching Attachments ...................................................................................................C-7

Mower Attachments .......................................................................................................C-7

Detachment .....................................................................................................................C-8

PTO Engagement ............................................................................................................C-8

Lights ..............................................................................................................................C-9

Starting Procedure ..........................................................................................................C-9

Operating on Slopes .....................................................................................................C-10

MAINTENANCE & SERVICE Section D

Engine ............................................................................................................................ D-1

General Instructions ....................................................................................................... D-1

Fuel In-line Filter ...........................................................................................................D-2

Transaxles, Hydraulic Oil .............................................................................................. D-2

Hydraulic Oil, Battery..................................................................................................... D-3

Brake Adjustment .......................................................................................................... D-4

Neutral Adjustment ........................................................................................................ D-4

Towing, Free-wheeling................................................................................................... D-5

VPI VENTRAC 3000 iii

TABLE OF CONTENTS (CONT.)

MAINTENANCE & SERVICE (cont.)

Drive Belts.......................................................................................................................D-6

Belt Replacement ...........................................................................................................D-7

PTO Drive Belt ...............................................................................................................D-8

PTO Belt Replacement ...................................................................................................D-9

SERVICE SCHEDULE Section E

Service Schedule .............................................................................................................E-1

Daily ............................................................................................................................... E-1

Visual .............................................................................................................................. E-1

Oil & Filter Change ........................................................................................................E-1

Transaxle Oil & Filters ...................................................................................................E-1

Storage ............................................................................................................................E-1

ELECTRICAL DIAGRAM Section F

WARRANTY

iv VENTRAC 3000 VPI

SECTION A

INTRODUCTION

Description

* The Ventrac Series 3000 is a unique all-wheel-drive vehicle that distributes its power to four equal-sized

flotation tires for excellent control, traction, stability, maneuvering and braking.

* An innovative, tandem drive train on the new VENTRAC 3000 creates a quiet, efficient and powerful allwheel-drive performance. Hillsides, ditches, slopes and wet or snowy surfaces become fair game for this

machine that makes all 4 tires push, steer and pull! Tandem hydrostatic pumps blend their power into a unified

speed, direction, brake and stop action.

* A tight, 45 degree articulated chassis plus 12 degrees of oscillation makes the VENTRAC 3000 easy-on-turf,

sharp-on-corners and a gripper-on-tough terrain. Its centered articulation, four wide flotation turf tires and

vehicle balance guarantees a gentle, near effortless movement on the most sensitive turf and in the sharpest

turn.

* The VENTRAC 3000s power steering tightens its turning radius to 28 inches to maneuver in and around

tight places and then “unwinds” for the straight-away with optimum speed and ease. A small pull on the

hydraulic lever will bring the front mounted attachment off the ground for repositioning or for transport. An

auxiliary option offers a second lever for hydraulic control on an attachment such as tilting or angling.

* A rugged uni-body frame system, a fast-hitch design and a high torque weight transfer mechanism create a

variety of attachment possibilities for the VENTRAC 3000. The PTO drive train operates effectively through

the entire hitch stroke of 30 degrees. A rear tow hitch is also a standard feature.

* Up-front visibility for the mid-mounted operator gives the best attachment view and the best operator ride.

Power steering, power lift and a powerful rear mounted engine create operational ease, exceptional

maneuverability and engine weight, heat, exhaust and noise ideally located behind the operator.

* The hydrostatic directional control lever is conveniently located on the right side of the operator. Forward

and reverse travel is easily accomplished by moving this lever in the desired direction of travel. The farther the

lever is moved, the greater the speed. An optional foot control adds versatility for operator preference. The

hydraulic hitch lift control is located just next to the directional control.

* The open left fender area enhances getting on and off the VENTRAC 3000. Extend the right foot into place

like getting into a car or truck, then simply sit on the seat and lift the left foot to the platform. To dismount,

reverse the process.

* Numerous attachments can be used on the VENTRAC 3000. Those needing only hitch and hydraulic

connections can be shared from its larger counter part, the VENTRAC 4000.

VPI VENTRAC 3000 A-1

SECTION A

INTRODUCTION

Engine: Kawasaki, Gasoline, Model FH641V, 21 hp, 2 cylinder, vertical shaft, air-cooled

Displacement: 675 cc

Drive:

Tires:

Electrical:

2 HTC Hydrostatic transaxles

Multi trac C/S 18 x 10.50-10 NHS

Battery – 450 Cold Cranking Amps 12 volt

Alternator – 13 amps

Instrument

Panel:

Dimension:

Ground Speed:

Weight:

Tachometer/Hour Meter, Lights & PTO Switch (with indicator

light), Ignition Switch, Manual Choke, Throttle

Wheelbase:

Width:

Width with optional tires:

Overall height (seat):

Length:

At 3250 engine rpms

With optional multi trac tires

36 inches

38 inches

40 inches

49 inches

73 inches

5 mph*

5.7 mph

710 pounds

OPTIONS:

Control:

Hydraulic:

Tires:

Roll cage with

Left Foot pedal kit

Auxiliary control package

Turf Trac RIS 18 x 9.50 x 8 NHS

39.36106

seat belt:

* Speeds vary according to tire size, type and inflation

Revised 10-29-02

A-2 VENTRAC 3000 VPI

SECTION B

SAFETY

This symbol identifies potential

health and safety hazards.

It marks safety precautions!!

Before Operating:

Read and understand this manual before operating the Ventrac 3000 machine. Study the

operating section and take time to get familiar with all controls and their functions.

Always use proper safety precautions. Observe all safety decals.

Only experienced and mature personnel should operate equipment. No minors!

Inexperienced operators should be trained by experienced or qualified instructors.

Check engine fluid levels before starting.

Check brake/park function before operating and adjust or service as needed.

Inspect machine before operating. Be sure shields and guards are in good condition and

securely in place. Be sure hardware is tight. Repair or replace parts that are missing,

badly worn or damaged. Check that wheel nuts are tight several times during the first

100 hours of operation and after any wheel change.

Never Allow Riders:

Allow only the operator on the machine. Riders have no designated or secure place to sit.

Riders also obstruct the operator’s view.

Use Caution Around Children:

Never assume that children will remain where you saw them last...they are attracted to

motion and noise; stay alert to their presence and movement.

Before you reverse the machine, look behind you. Always look in the direction of travel.

When approached by others, stop the PTO and engage the park brake.

Safe Transport:

When driving on public roads, use a Slow Moving Vehicle sign. Flashing lights may be

advisable or required. Check and abide by local traffic laws.

Use extra caution when crossing roadways or operating near traffic.

Operate only during daylight or with good artificial light.

VPI VENTRAC 3000 B-1

SECTION B

SAFETY

This symbol identifies potential

health and safety hazards.

It marks safety precautions!!

Use Extra Care:

Stay alert for holes, hidden objects, and uneven terrain or drop-offs.

Use extra care when you come to shrubs, trees, or other objects that may impair your

vision.

Clear objects from work area that might be thrown or interfere with safe operation of

machine and attachment.

Stop machine and inspect if you hit an object.

Avoid adverse conditions which limit performance and stability of equipment and could

result in injury or death.

Stay away from drop-offs.

DO NOT drive where machine could slide or upset.

Wet grass increases risk of sliding on banks and slopes.

DO NOT try to stabilize the tractor by putting your foot on the ground.

When pulling loads or using heavy equipment, use only the hitch points provided. Limit

loads to those you can safely control.

Slopes:

Roll cage with seat belt is recommended for driving on slopes.

Be careful when you change direction on a slope. Drive slowly.

Make allowances in speed selection for hills, slopes, and rough terrain. If the

operator is uncomfortable or there is uncertainty of the machine’s stability, the operator

should slow down or cease operation.

When parking, stop the machine on a level surface whenever possible; block tractor

tires if it must be parked in a location which is not level. ALWAYS use park brake.

Be sure to have plenty of fuel in tank to avoid unplanned stoppage.

NEVER TURN ENGINE OFF ON A HILL OR SLOPE WITHOUT FIRST

MAKING SURE THE PARKING BRAKE WILL HOLD THE TRACTOR IN

PLACE. Before leaving the seat, always set the control selector in “park brake”

position.

Always Use Common Sense!

B-2 VENTRAC 3000 VPI

SECTION B

SAFETY

This symbol identifies potential

health and safety hazards. It

marks safety precautions!!

Operator Personal Safety:

Be careful around moving parts. Wear close fitting clothes and use appropriate

safety equipment.

Wear earplugs or other protective device when needed. Do not use substances or

devices that must be hand held: e.g. cigarettes, cell phone, etc.

DO NOT operate machine if you are under the influence of alcohol or drugs or if you

are not feeling well.

Engine muffler may be hot; DO NOT touch!!

Operate all controls from operator’s seat.

Always use seat belt in conjunction with a roll cage or cab.

Use caution when handling the battery. Explosive battery gases and acid can cause

injury or blindness. Flush eyes immediately with water and seek medical attention.

Keep sparks, flames and cigarettes away from battery and fuel tank area.

Before leaving machine seat, stop PTO and set parking brake. Shut off engine if

machine is left unattended and remove ignition key.

Wait for engine and all moving parts to stop before leaving operator’s seat.

Before adjusting, cleaning, or lubricating this machine, set the parking brake, shut

down the engine and remove the ignition key. NEVER attempt to work on machine or

attachments with engine running.

General Safety:

A safety switch requires the 3-position control selector to be in the park position to

start the engine.

Always maintain adequate engine speed to prevent stalling during operation of the

machine.

Always LOOK before reversing direction.

Never leave seat without placing control lever in park position. If machine is to be left

unattended, shut off engine and remove key.

Shut off PTO when equipment is not in use.

Be alert for any sign or noise of equipment failure and take all precautions to

immediately control the situation; stop and park the machine and make appropriate

repairs before resuming operation.

DO NOT make sharp turns at high speeds! Turning reduces vehicle stability.

DO NOT tow!

Sudden starts or stops can up-end the tractor. Always use caution when starting and

stopping.

Always Use Common Sense!

VPI VENTRAC 3000 B-3

SECTION B

SAFETY

This symbol identifies potential

health and safety hazards.

It marks safety precautions!!

Seat Belt & Roll Cage:

Seat belt and roll cage are recommended for all situations where roll over is possible.

This includes but is not limited to: operation on slopes, climbing or descending banks,

operating without attachments for counter weight and stability.

NOTE: Machine stability is reduced in turning mode.

NOTE: Mounted attachments generally increase machine’s stability.

Seat belt must always be used if machine is equipped with a roll bar.

Machine towing:

Towing is not recommended but in some cases the machine may need to be pushed a

short distance. Park brake is functional in freewheeling mode. See page D-5 for

“freewheeling mode”.

B-4 VENTRAC 3000 VPI

The VENTRAC 3000 is a unique all-wheel drive,

machine that offers many advantages and some

variables over conventional tractors and vehicles.

The benefits and differences make it VERY

important for the operator to read and understand this

operator’s manual in order to facilitate safe,

enjoyable and effective operation of the VENTRAC

3000!

The first sight of the VENTRAC 3000 reveals its low

profile, four (4) identical drive tires and the

articulated frame. Less obvious is the easy-to-use

fast hitch and PTO drive that accommodates use of

other attachments.

SECTION C

OPERATION

The open left fender area enhances getting on and off

the VENTRAC 3000 (Figure 1). Extend the right

foot into place like getting into a car or pick-up, then

simply sit on the seat and lift the left foot into place.

To dismount, reverse the process.

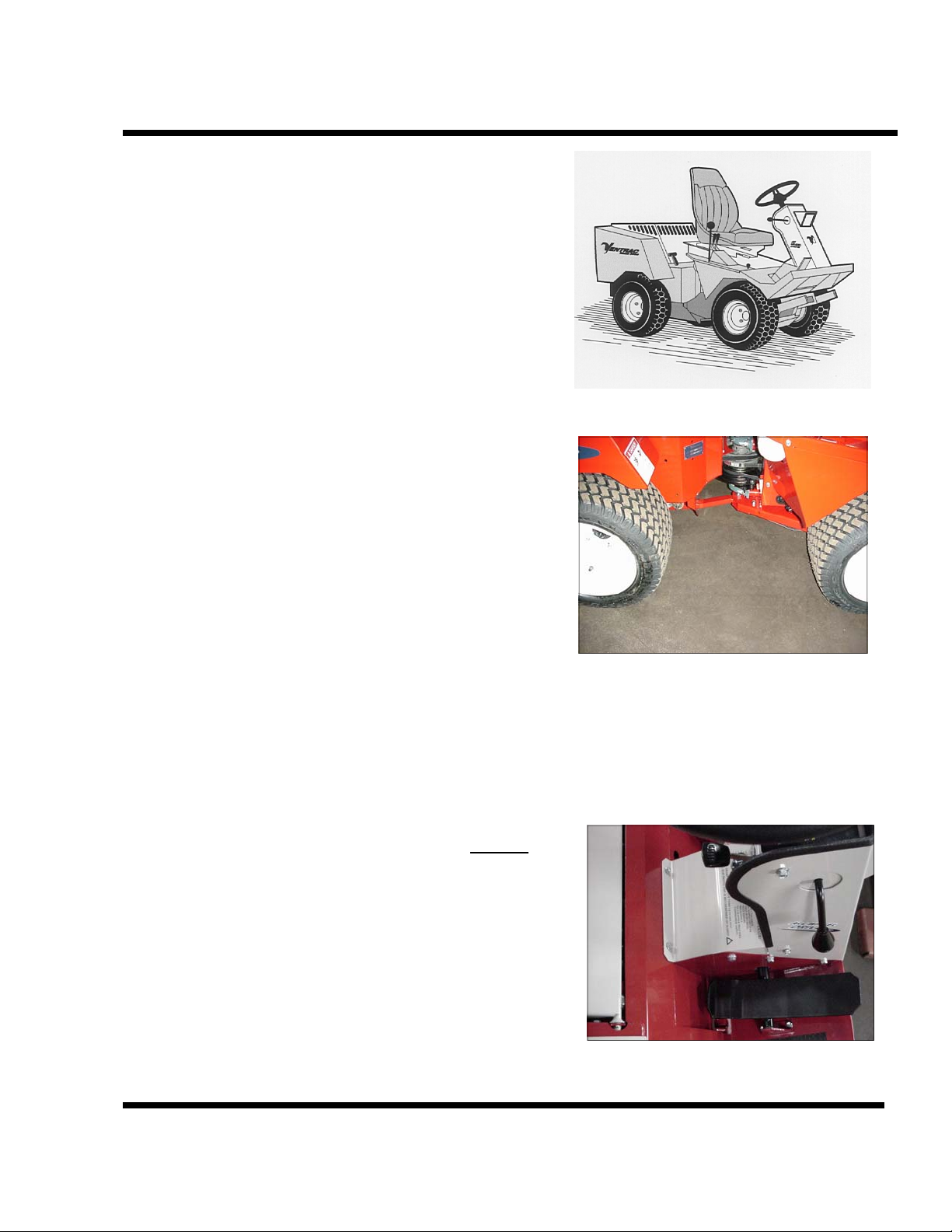

Always put the Control Selector (Figure 2) DOWN

in PARK BRAKE position before leaving the seat.

This assures the neutral locking of the directional

control and the park brake engagement.

Figure 1

Figure 2

VPI VENTRAC 3000 C-1

SECTION C

OPERATION

FRONT CONTROLS

Many of the controls are located directly in front of

the operator on the dash and steering column.

(Figures 3, 4 & 5). Decals reveal their position,

function and motion.

Figure 4

Figure 3

The right side of the dash has IMPORTANT

operational and safety instructions for the three-(3)

position Control Selector (Figure6).

1. DOWN – activates the park and

emergency brake. ALWAYS return lever to this

position when the tractor is not in use. The lever

must be in this position to START the engine.

2. LEVEL – causes the directional control

lever beside the operator to have a spring-assist-to-

neutral action. This position makes neutral easy to

find and maintain. If the tractor creeps when in

neutral, see “Neutral Adjustment” section.

3. UP – puts the directional control lever

beside the operator into an “Easy Shift” mode. This

position is recommended only for open area

operation where travel speed and direction is

relatively constant and control is very easy to

maintain. “Easy Shift” reduces operator arm fatigue

when machine is operated for an extended length of

time.

Figure 5

Figure 6

C-2 VENTRAC 3000 VPI

SIDE CONTROLS

Right side directional and front hitch lift control

(Figure 7) is standard on all VENTRAC 3000s. The

primary lever with the large round knob is the

directional control (sometimes called the Forward/

Reverse lever, or F/R).

I.) Once in the seat and the park brake released, the

lever can be moved. Forward movement from the

neutral position will cause the tractor to move

forward. The farther the lever is moved, the faster the

machine will travel. Returning toward the neutral

position will slow the machine and in neutral it will

stop. Note that the directional lever operates the

same for reverse and works equally well for starting

and STOPPING! This shift-on-the-go feature with

engine power and brake power to all four tires makes

the VENTRAC 3000 an amazing performer. Yet

extreme caution is critical to avoid unexpected and

difficult situations that could cause serious injury or

damage to operator or equipment. (See safety

section)

SECTION C

OPERATION

Figure 7

II.) Next to the directional control is the hydraulic

control lever for the front hitch (Figure 8). Pulling

the lever back raises the hitch. Moving it forward

lowers the hitch. Continuing forward puts the front

hitch in the FLOAT

position. Always use the float

position for mowing and other tasks where

flotation of the attachments is desired or

necessary.

Figure 8

Next to the hitch control lever is an optional lever

(Figure 8) that controls the auxiliary hydraulic

circuit. This lever activates attachments with

functions that have hydraulic hoses to the front quick

couplers.

VPI VENTRAC 3000 C-3

SECTION C

OPERATION

FENDERS

The right front fender has a small covered toolbox. It

also houses the optional auxiliary quick couplers

(Figure 9).

The left rear fender houses the 4 gallon fuel tank.

Always note the type of fuel: Unleaded gasoline or

Diesel. If decal is missing or unreadable, contact

your dealer or the factory for a replacement decal.

Determine fuel type before filling. Never over fill!

Stop before fuel spills over the fill tube.

A long slot in the left fender visible from the

operator’s seat serves as a fuel gauge (Figure 10).

Always keep sufficient fuel in the tank to prevent an

unexpected engine shut-off. When operating on

slopes, fuel level should be kept above the 1/4 mark.

Figure 9

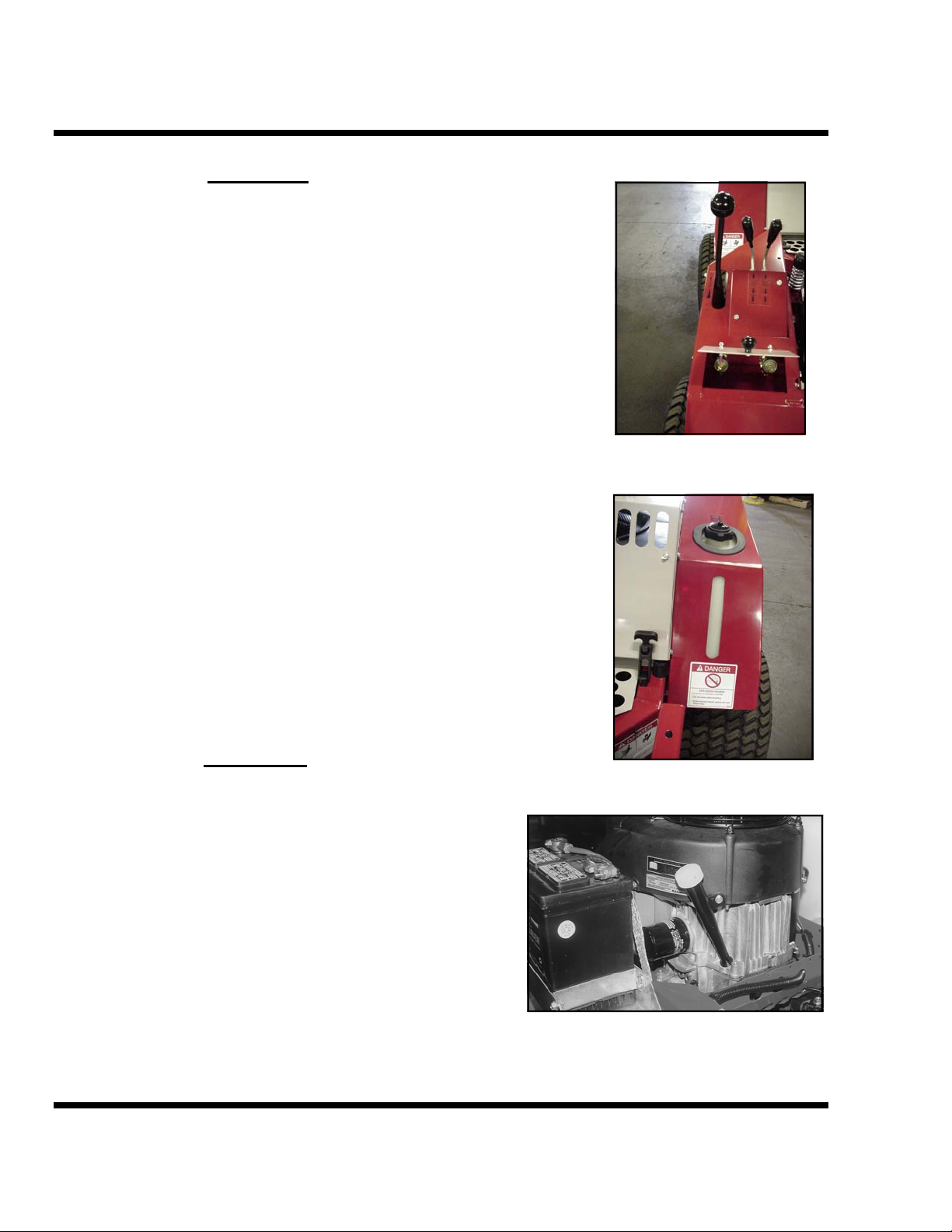

BATTERY

Figure 10

The battery is located under the right rear fender

(Figure 11). Tilting the engine cover gives full

access to the battery. Before using jumper cables

or connecting a battery charger, always check

polarity. The RED cover means POSITIVE. The

BLACK cover means NEGATIVE. The negative

wire should always be connected to the frame!

Figure 11

C-4 VENTRAC 3000 VPI

SEAT

Each VENTRAC 3000 has an adjustable seat — fore

and aft. Each operator should adjust the seat for the

greatest control and comfort. (Figure 12). Note: Seat

plate mounting hole options are available for

additional variables in seat positioning. The seat can

be tilted forward during nonuse for inspection and

servicing access. To tilt the seat forward, press down

on the back of the seat with one hand and push down

the front of the seat locking bracket with the other.

A prop bracket is attached to the seat plate to prop

the seat in the tilted position. The seat and seat plate

can be removed by disconnecting the two seat switch

wires, removing the cotter pin on the right, tilting the

seat to the steering wheel, and moving it slightly to

the left. (Figure 13)

SECTION C

OPERATION

Figure 12

Figure 13

OWNER’S MANUAL

Owner’s manual is located in tube under the right

rear fender directly behind the battery. Release hood

latches, tilt hood and remove top tube cover to access

manual (Figure 14).

Figure 14

VPI VENTRAC 3000 C-5

SECTION C

OPERATION

FRONT HITCH & PTO DRIVE

The two rail, EASY-TACH, front hitch (Figure 15)

creates a stable and secure mounting of attachments

to the VENTRAC 3000! Just align the two rails to

the two corresponding receiver arms on the

attachment. Lower the tractor hitch for the initial

contact with the attachment arm tabs. Lift the

machine hitch to an in-line relationship and complete

the engagement. The EASY-TACH spring loaded

LOCKS secure the attachments. Always confirm that

the lock action has been completed.

Note: Engagement of attachment can be assisted by

opening the spring loaded “locks” by moving the

EASY-TACH lever (Figure 16) to the left side of the

hitch. Moving the lever to the right can assist the

closing action of the locks when necessary.

PTO DRIVEN ATTACHMENTS

After the EASY-TACH lever has been “locked,”

with engine stopped, put the PTO belt on the lower

groove of the PTO idler pulley (Figure 16) and

engage the tension lever on the attachment (Figure

17).

Figure 15

Figure 16

Figure 17

C-6 VENTRAC 3000 VPI

A TT ACHING A TT ACHMENTS

Most front mounted attachments can be positioned so

that it is convenient to drive into the hitch harness

with nearly correct alignment (Figure 19). Some

adjustment is usually required to complete the hitch

engagement.

When completely engaged, move the “Easy Tach”

lever to “lock” position (Figure 20). If lever will not

move into “lock” position, check the attachment for

complete engagement.

MOWER A TT ACHMENTS

Mower attachments have a floating hitch. If mower

cutting height is set near the highest position, the

machine can be driven to the hitch arm. Then raise

the hitch until the mating arms are parallel.

1. Shut off the engine and engage the park brake.

2. Walk to the front of the mower and push it into the

machine as far as the hitch will allow. Make sure

both sides are completely engaged and locked.

(Figure 21).

3. Install the mower PTO belt on the drive pulley

between the hitch arms (Figure 20).

Note:

1. Attachment change is made easier and safer by

always using level clean surfaces.

2. Heavy duty, close tolerance latch hooks (Figure

21) make complete engagement of attachment hitch

necessary on both sides before “Easy Tach” lock can

close.

SECTION C

OPERATION

Figure 19

Lock

Figure 20

Figure 21

VPI VENTRAC 3000 C-7

SECTION C

OPERATION

DETACHMENT

Attachments are detached by reverse sequence of

the attaching steps.

Note: EASY-TACH lever between the hitch arms

must be moved to the left side of the machine to

release the attachment. (Figure 23)

Note for mower hook up— If mower arms are too

low for the initial engagement, lift the mower

cutting height to a high position. This will position

the hitch arms high enough for drive-in contact.

PTO ENGAGEMENT

Move

Figure 23

When engaging power to front attachments, it is

necessary for the operator to be seated in the seat.

Increase the engine speed to at least 2500 RPM’s.

(See RPM indicator on the dash). Check that all is

clear before engaging the PTO switch (Figure 24).

When the PTO switch is engaged, an operation light

will come on. When the engine is cold, stalling is

possible at the moment of engagement. Increase the

engine RPM’s and/or increase the warm-up time and

try again. The VENTRAC 3000 is equipped with a

heavy-duty electric clutch causing potential engine

stalls by the abrupt and forceful transfer of power.

An integral brake system stops the PTO within 7

seconds when the switch is moved to OFF or the seat

switch is deactivated.

Figure 24

C-8 VENTRAC 3000 VPI

LIGHTS

(Figures 25 & 26)

Head and taillights improve safety and operational

visibility. Their use is highly recommended

especially at dawn or dusk and at night. The

headlight can be adjusted to the operator’s preference

by loosening, the mounting bolt directly under the

light fixture. The fixture can be moved so that the

light beam moves up or down, right or left. Once in

the desired position, retighten the mounting bolt.

STARTING PROCEDURE

1. Check engine oil, water, and fuel levels.

2. Read and understand operational and safety

instructions.

3. Make sure the right side, three (3) position control

selector is in start position (DOWN).

4. Move throttle forward about 1/4 stroke. (Engines

vary)

5. For gasoline models, pull the choke out. For diesel

models, turn the key counter-clockwise and hold

until the glow light goes off.

6. Turn the key clockwise until the engine starts. If

the engine fails to start in 15 seconds, stop. Check if

there is fuel in the tank. Make several more attempts

to start. If the engine does not start, contact a

mechanic or the dealer.

7. Once the engine is started, let it warm up. Always

check to see if the steering system is responsive

before attempting to drive. In cold weather

conditions, extend the warm-up period.

8. For the PTO to operate, the operator has to be

sitting on the seat.

SECTION C

OPERATION

Figures 25 & 26

VPI VENTRAC 3000 C-9

SECTION C

OPERATION

OPERATING ON SLOPES

Operation on slopes decreases machine stability and

increases the possibility for unexpected difficulties.

Only experienced VENTRAC 3000 operators should

operate the machine on slopes and extra caution

should be applied that include: (See drawings at

right.)

1.— avoiding uneven, loose or wet terrain.

2.— staying clear of drop-offs, holes, ditches,

rocks, or objects that could cause a sudden and/or

unexpected force on the machine.

3.—using sufficient engine rpms to prevent

engine stall.

4.—using sufficient fuel in tank to assure

continuous operation.

5.—making slow and cautious starts, stops,

and turns.

6.—limiting maximum operation to 20/25

degrees respectively.

7.—ceasing operation if machine instability

is suspected or evident, or if the operator is

uncomfortable or unsure of continuing safely.

8.—using an attachment as much as possible.

Mounted attachments increase the overall length and

can add stability to the machine.

9.—reducing the degrees of turns and/or

turning down hill as much as possible.

10.—using roll cage and seat belt

11.—Do not operate carelessly!

.

x

a

m

s

e

e

r

g

e

d

0

2

.

x

a

m

s

e

e

r

g

e

d

5

2

Turning reduces vehicle stability!

Keep engine oil level near full mark

when operating on slopes.

The ultimate responsibility for safe

operation on slopes is the

responsibility of the operator!

IF IN DOUBT...DON’T!!

C-10 VENTRAC 3000 VPI

SECTION D

SERVICE & MAINTENANCE

SERVICE & MAINTENANCE

ENGINE

See engine manufacturer’s OWNERS MANUAL in

your VENTRAC 3000 manual pocket for details on

engine care.

GENERAL INSTRUCTIONS

Daily:

Check oil level daily

Check/clean air intake screen

8 Hours:

initial oil change

25 Hours:

Clean air intake foam element

100 Hours:

Change oil and oil filter

Clean air cleaner paper element

300 Hours:

Replace air cleaner paper element

Service intervals indicated are to be used as a guide.

Service should be performed more frequently in

severe operating conditions.

For engine problems, see “Trouble Shooting” guide

in engine manual.

VPI VENTRAC 3000 D-1

SECTION D

SERVICE & MAINTENANCE

FUEL LINE FILTER

IN-LINE FILTER

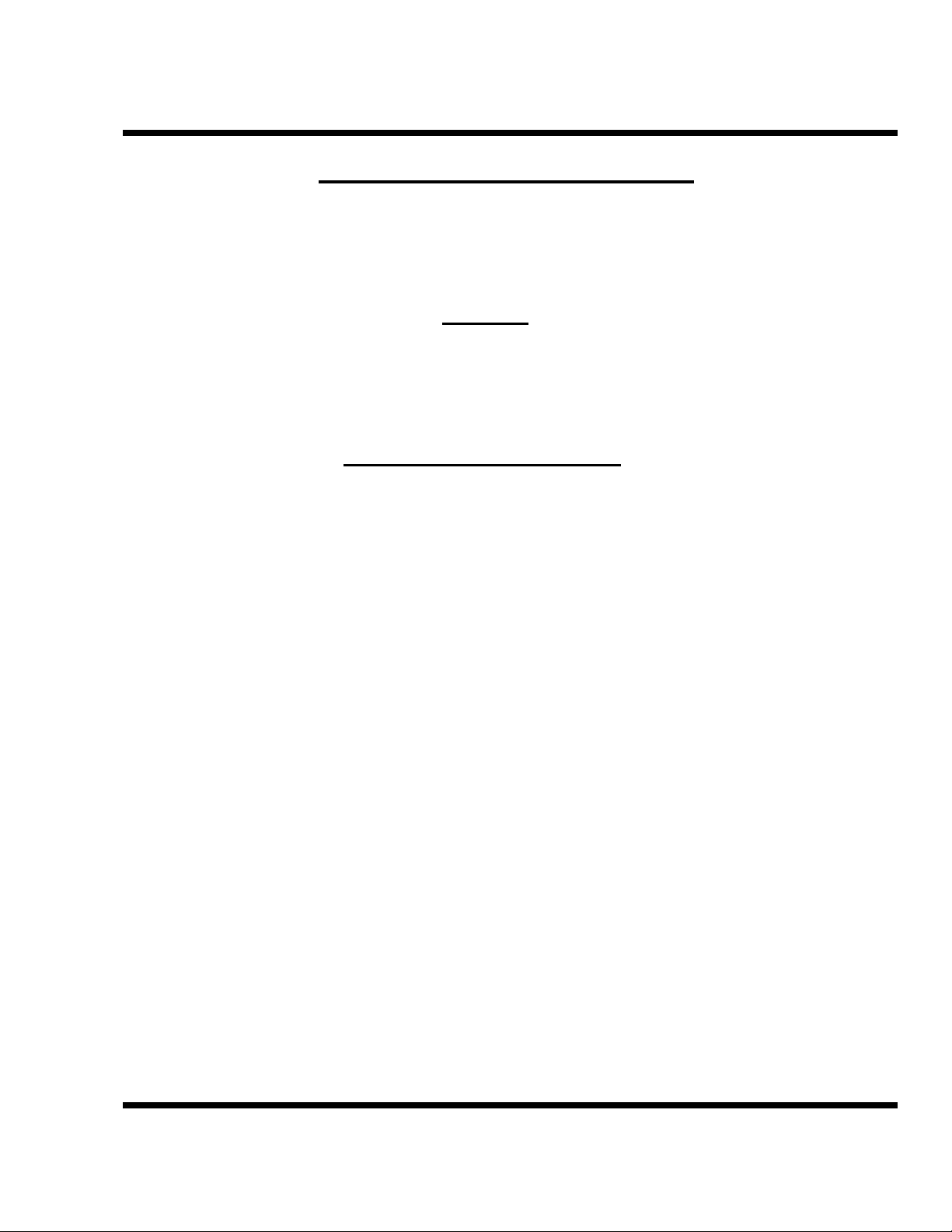

All VENTRAC 3000’s have an in-line fuel filter

(Figure 1) located next to the fuel tank.

Always use clean, fresh fuel. Keep the fill area clean

and the fuel cap in place except for filling. If or when

any of the above conditions are not met or the engine

lacks power, especially under load, the fuel filter

should be checked. If the in-line filter needs to be

replaced, be sure to install the new one with the flow

arrow pointing toward the engine.

TRANSAXLES

HYDRAULIC OIL

Rear transaxle is prefilled. Oil level should allow for

expansion from heat without over-flowing through

the vented cap on top of case. This oil level will

remain constant unless leakage occurs. Oil level

when cold to be 1-1/2” (4 cm) from top of the

transaxle housing. Note: side plug can be used to fill

and determine “full” on rear transaxle.

Front transaxle has an oil tank, vented cap, and

dipstick (Figure 2). Never fill oil above high level

on dipstick. Heat expansion could cause unwanted

over flow.

Additional oil may be required when new

attachments are connected to the auxiliary circuit

(optional). The attachment components are shipped

without oil. Additional oil is needed only after the

initial hook up.

HIGH

Figure 1

OPERATING

RANGE

LOW

Figure 2

REQUIRED OIL

SPECIFICATION

A M S O I L

Synthetic

Hydraulic Transmission Oil

TYPE ATH SAE 30

D-2 VENTRAC 3000 VPI

Hydrostatic Oil (Cont.)

Note: Activate attachment hydraulics full stroke in

both directions several times to purge the system of

air before replenishing oil in front transaxle

reservoir.

Hydraulic filter located behind the front right fender

(Figure 3) does not

need to be changed unless

serious or unusual contamination occurs to the

system. Contact dealer for further direction.

Note: Generally the hydrostatic oil level remains

constant except when:

1) New attachments are added that use the

auxiliary oil circuit. (front transaxle only)

2) There is an oil leak.

NOTE: Replacement of hydrostatic oil is

not recommended except in the

event of contamination.

SECTION D

SERVICE & MAINTENANCE

Figure 3

Transaxle capacity:

Approximately 1 gallon

BATTERY

Battery group—22 NF

When it is necessary to remove and/or replace the

battery, remove both cables. Then remove the front

or rear hold-down bracket (Figure 4). To install the

new battery, reverse the above instructions. Be sure

the new battery has the same dimensions, top

terminals, and is installed with the terminals on the

side toward the engine.

Figure 4

VPI VENTRAC 3000 D-3

SECTION D

SERVICE & MAINTENANCE

BRAKE ADJUSTMENT

A disk brake is activated when the control selector

on the right side of the steering column is moved

down into park position.

To adjust brake tension, use a 7/16 wrench on the

linkage at the brake on the left side of the front

transaxle (Figure 5). If the adjustment is too tight,

the control selector will be difficult to move to park

position. Brake adjustment should rarely be needed

because transaxles are automatically locked into

neutral when brake is engaged.

NEUTRAL ADJUSTMENT

Figure 5

The machine should always come to a complete stop

when the Control Selector is in the “park brake”

position (down) or in the “spring assist to neutral”

position (level) when the Directional Control lever is

released (Figure 6). If the machine consistently

wants to creep while in neutral, an adjustment must

be made.

Each transaxle has its own “neutral locator.” The

factory setting generally will not require adjustment.

The most likely adjustment needed is in the cable

connecting the two transaxle control mechanisms.

Simply lengthen or shorten one end of the cable

where it’s mounted to the frame

bracket (Figure 7 &

8). The connecting cable should allow each transaxle

mechanism to settle into its own neutral position.

Secure cable ends when that position is attained.

Note: Engine needs to be running to make the

neutral adjustment. Jacking one tire up on each

transaxle will prevent accidental movement and

possible injury. If uncertain or in doubt about this

procedure, contact your servicing dealer.

Figure 6

Figure 7-front

Figure 8-rear

D-4 VENTRAC 3000 VPI

TOWING/FREE-WHEELING

Each transaxle is equipped with leverage to release

hydrostatic pumps for slow, level, short distance

towing. Both are located in the center pivot area of

the tractor. See (Figure 9 and 10). Each handle

needs to be pulled out a short distance and must be

secured in notch. Always release BOTH handles

when towing is complete! Failure to release one or

both handles creates a potential free-wheeling

hazard. Park brake is still operative in free-wheeling

mode but must be released in order to tow.

SECTION D

SERVICE & MAINTENANCE

Figure 9—Right side

Front frame

Figure 10—Left side

Rear frame

VPI VENTRAC 3000 D-5

SECTION D

SERVICE & MAINTENANCE

DRIVE BELTS

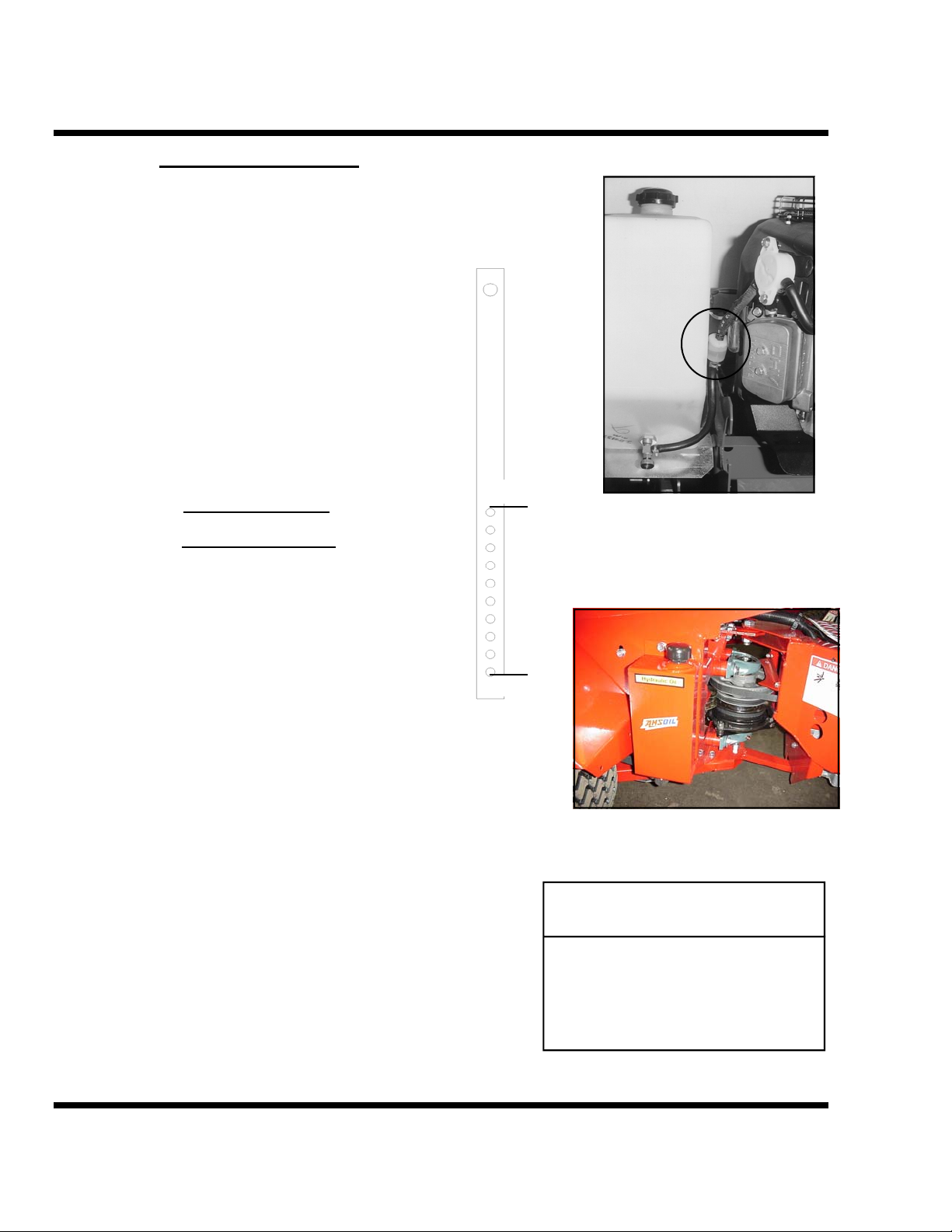

The VENTRAC 3000 has three drive belts: one

PRIMARY drive belt, one REAR transaxle belt and one

FRONT transaxle belt.

The PRIMARY DRIVE BELT (Figure LTB-A) connects

the engine pulley to the center drive shaft pulley in the

pivot area of the articulated frame. It is the top belt in the

drive system. It has two vee belt idlers. One fixed idler

just below the right front corner of the engine and other

spring-loaded idler on the opposite side.

The REAR TRANSAXLE BELT (Figure LTB-B) is the

lower belt. It connects the lower engine pulley to the rear

transaxle pulley with the plastic-cooling fan. It has one

vee belt idler located just below the primary drive belt

spring loaded idler.

The spring-loaded idlers have a unique torsion spring

tension system. The spring is mounted on the axis of the

leverage and has two extended prongs. The prongs can be

engaged individually making the tensioning process

manageable by hand. This leverage for the two rear drive

belts is located on the same axis (Figure 11).

The FRONT TRANSAXLE BELT (Figure LTB-C) is

located on the front chassis frame. It is on the same plain

as the rear transaxle belt. It goes from the center drive

shaft pulley to the front transaxle pulley with the plasticcooling fan. This belt has a fixed flat belt idler located

just below the crossover frame in the center pivot area of

the chassis. Figure 12).

All idlers should maintain proper alignment with the

belts. Mounting points should always position the idlers

in the same horizontal plain as the drive and driven

pulleys. Any angular positioning

will compromise the life of the

belt. Due to the vibration nature

of spring loaded idlers the bolts

securing them should be check

periodically to assure tightness.

Figure LTB-A

Figure LTB-B

Figure LTB-C

Figure 11

Figure 12

D-6 VENTRAC 3000 VPI

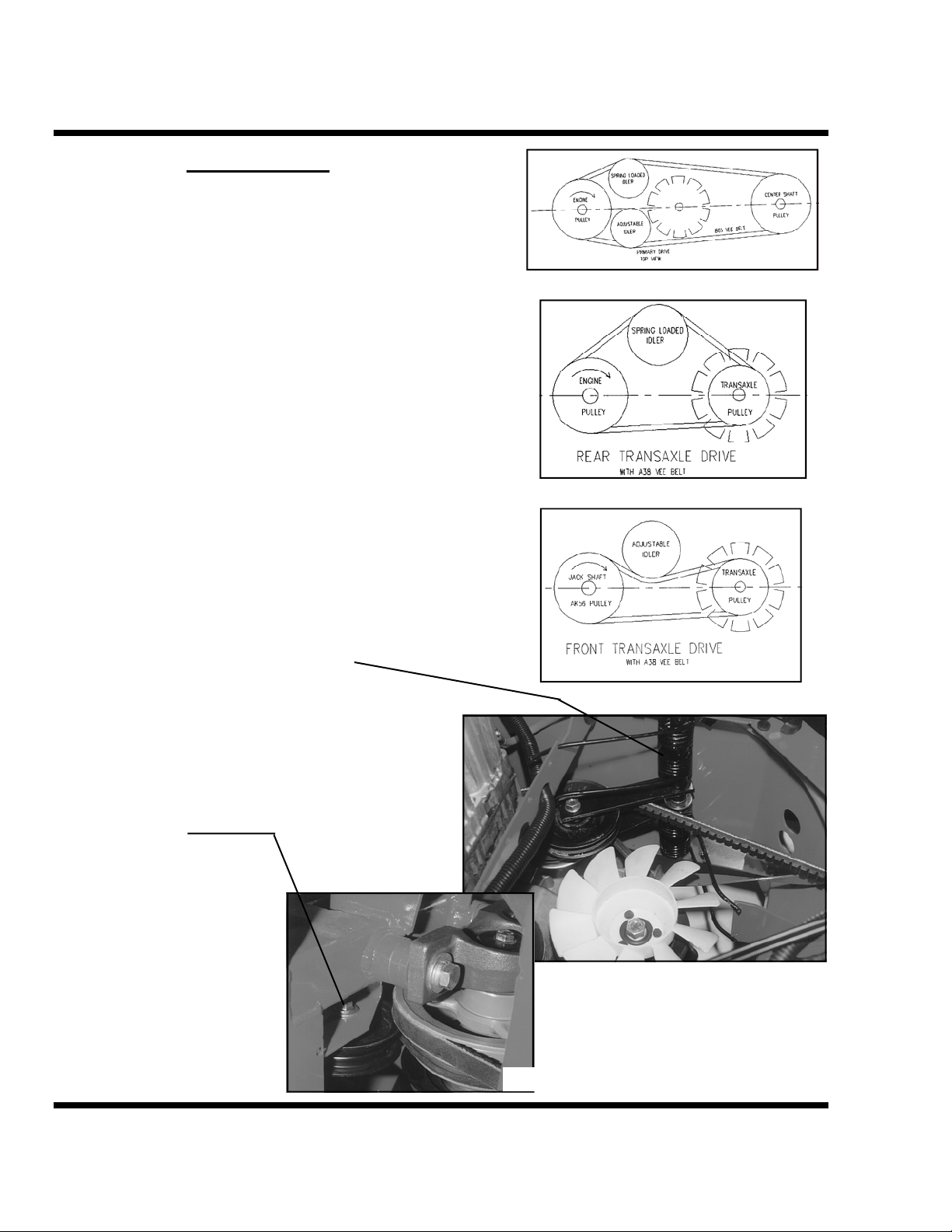

BELT REPLACEMENT

Remove cover plate over the rear chassis to access fan

and belt area (Figure 13) and center pulley cover on rear

frame. Release both spring prongs on each of the two- (2)

spring loaded idlers. The two springs are on the inside of

the rear frame on the left side. Remove belts from idler

engagement. Also disconnect shift cable from the

transaxle lever.

1) Rear Transaxle Belt

To replace the rear transaxle belt, access it from the rear –

under the engine. Dislodge it from the engine pulley

(Figure 14). Push or pull it up between the transaxle and

the engine. Remove it from around the cooling fan pulley.

Replace the new belt by reversing these steps and tension

the idler.

2) Primary Drive Belt

To change the Primary Drive Belt access it from the rear under the engine. First remove the rear transaxle belt from

the engine pulley and let it lay down on the transaxle case

out of the way. Dislodge the primary belt from the engine

pulley and move it up between the engine and the

transaxle.

Second remove the two ½” bolts and the two spacers from

the top center shaft pillow block bearing (Figure 15).

This makes clearance for belts to be removed or installed

over the center shaft assembly. Do not

from shaft.

Third dislodge the front part of the belt from the center

shaft pulley and move it up through the pillow block

spacer clearance. Install the new belt with these same

steps in reverse order and tension the idler.

3) Front transaxle Belt

First remove the two ½” bolts and the two spacers from

the top center shaft pillow block bearing (Figure 15).

This makes clearance for belts to be removed or installed

over the center shaft assembly. Do not

from shaft.

Remove the adjustable flat belt idler on the front transaxle

belt located just below the crossover frame section

(Figure 16).

remove bearing

remove bearing

SECTION D

SERVICE & MAINTENANCE

Figure 13

Figure 14

Figure 15

Figure 16

VPI VENTRAC 3000 D-7

SECTION D

SERVICE & MAINTENANCE

Move the primary drive belt off the center shaft pulley

and let it lay in the open shaft area just above the pulley

(Figure 17).

Take the belt off of the transaxle pulley and cooling fan.

It may be necessary to rotate the fan to assist the belt removal. Fin can tolerate considerable deflection (Figure

18).

Pull the front transaxle belt into the center shaft area. Slip

it through the loop of the primary drive belt and out over

the top bearing assembly.

Reverse this procedure to install the new belt.

* * * * *

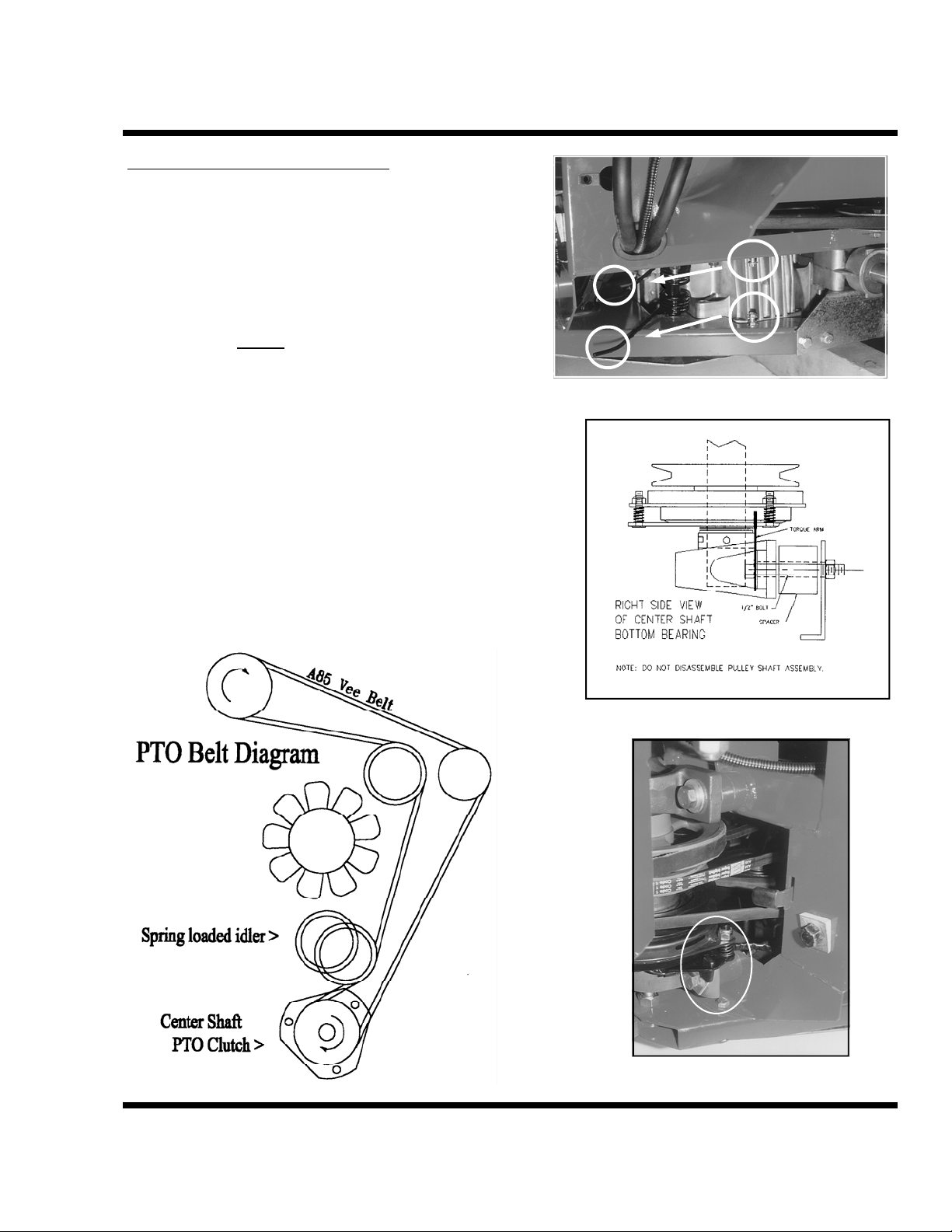

PTO DRIVE BELT

The PTO Drive Belt is the bottom belt on the center shaft

pulley assembly. It is directed around the front transaxle

to the double pulley located on the lift hitch (Figure 19).

A torsion, double prong spring activates the PTO idler. It

is accessed on the outside of the front frame down behind

the right front tire (Figure 20).

Figure 17

Figure 18

Figure 20

Figure 19

D-8 VENTRAC 3000 VPI

PTO BELT REPLACEMENT

Release the idler spring prongs on the lower, right side

(outside) of the front frame (Figure 21).

Remove the two ½” bolts from the bottom center-shaft

pillow-block bearing, the two spacers and the clutch

torque arm (Figure 22 & 23). This gives clearance to

remove or install belt over the lower end of the centershaft assembly. Do not

Dislodge belt from the front pulleys and lower it over the

clutch assembly and through the bearing mount spacer

area.

Reverse procedure to install the new belt. Be sure to

reinstall clutch torque arm (Figure 22 & 23).

Note: Remove seat assembly and any front mounted

attachment for greater access. See seat section (page C-5).

remove bearing from shaft.

SECTION D

SERVICE & MAINTENANCE

Figure 21

Figure 22

Figure 23

VPI VENTRAC 3000 D-9

SECTION E

SERVICE SCHEDULE

Service Schedule

The operator’s manual and decals should be read and understood before operating the machine or

attachments. This manual should be reviewed periodically or when in doubt about any function,

procedure, or safety factor on this equipment.

Daily

Check the oil and water levels (liquid cooled engines only) daily in the engine. Fuel level needs to be

checked every couple hours. When working on slopes, keep a minimum of 1/4 tank of fuel. Flywheel

or radiator screen and air intake filter should be checked frequently when working in a dirty

environment. Clean or change as needed. Keep equipment clean. Accumulated debris can restrict

performance, cause equipment failure and be a safety hazard.

Visual

Many equipment conditions are visible before operation. For example, an oil leak, low tire inflation,

obstructed flywheel screen, loose or missing hardware, shields or a broken belt. These should be

repaired or replaced before operation!

Some equipment conditions are not evident until operation. For example, a failing bearing, broken

electrical wire, faulty switch or loose part. These should be corrected as soon as evident. Operation

should cease immediately if an unsafe condition is observed!

Operators should always be alert for potential problems. Personal safety and the safety of others as

well as the performance of the equipment depend on the operator’s care and repair of the machine and

continuous caution and control of the same.

Engine Oil and Filter Change

Kawasaki — Initial change at 8 hours and every 100 hours thereafter.

Note: refer to engine manual for further details.

Transaxle Oil and Filters

Change oil and oil filter only if the system has been contaminated. Check oil levels every 100 hours.

If there is an oil leak or new attachments have been used that require “priming”, the front transaxle oil

level should be checked at that time.

Storage

Drain fuel tank, check for proper tire inflation and remove battery.

E-1 VENTRAC 3000 VPI

SECTION F

ELECTRICAL DIAGRAM

ELECTRICAL DIAGRAM

19 HP KAWASAKI ENGINE

HBA1346-HBA1425

21 HP KAWASAKI ENGINE

Beginning with Serial Number: JBA1426

Revised 10-29-02

VPI VENTRAC 3000 F-1

LIMITED WARRANTY – VENTRAC TURF EQUIPMENT

Venture Products, Inc. (shall be referred to as V.P.I.) warrants on the terms and conditions herein, that it

will repair, replace, or adjust any part manufactured by Venture Products Inc. and found by Venture

Products Inc to be defective in material and / or workmanship.

Effective September 1

generator) for Residential use only is limited to Three (3) years from original purchase date. Ventrac

Tractors & Attachments used Commercially or for any income producing purpose is limited to Two (2)

years from original purchase date. Ventrac ET200 turbine blower (turbine only) is limited to Two (2) years

from original purchase date. Ventrac HG100/HG150 generator is limited to One (1) year

purchase date. Ventrac Tractors & Attachments used for Rental

purchase date. (NOTE: All accessories such as: 3-point hitch, foot pedal, dual wheel kit, etc. will be

covered under the above warranty periods as they would apply provided they are installed by an Authorized

Ventrac Dealer.) This warranty may be transferred and will carry the remainder of the warranty starting

from the Original Purchase/Registration date with the dealership and/or V.P.I. In the event that product/s

originally registered as (3) year Residential use

would change to the remainder of (2) year Commercial use

Purchase/Registration date with the dealership and/or V.P.I.

If this warranty covers a consumer product as defined by the Magnusson-Moss warranty act, no warranties,

express or implied, (including, but not limited to, the warranty of merchantability or fitness for a particular

purpose) shall extend beyond the applicable time period stated in bold face type above.

If this warranty covers a product used commercially or for any income producing purpose, the foregoing

warranties are in lieu of all other warranties and no representations, guarantees or warranties, express or

implied, (including, but not limited to, a warranty of merchantability or fitness for a particular pu rpose), are

made by V.P.I. in connection with the manufacture or sale of its products.

The engine warranty is covered by its respective engine manufacturer. Please refer to the engine

manufacturer’s warranty statement that is included in the owner’s manual.

The Ventrac turf equipment, including any defective parts, must be returned to an Authorized Ventrac

Dealer within the warranty period. The warranty shall extend to the cost to repair or replace (as determined

by V.P.I.) the defective part. The expense of pickup and delivery of equipment, service call drive time

or any transportation expense incurred for warranty repair is the sole responsibility of the owner

and is not covered under warranty by Ventrac and/or V.P.I. V.P.I.’s responsibility in respect to claims

is limited to making the required repairs or replacements, and no claim of breach of warranty shall be cause

for cancellation or rescission of the contract of sale of any Ventrac equipment. Proof of purchase may be

required by the dealer to substantiate any warranty claim. Only warranty work performed and submitted by

an Authorized Ventrac Dealer may be eligible for warranty credit.

This warranty extends only to Ventrac turf equipment operated under normal conditions and properly

serviced and maintained. The warranty expressly does NOT cover: (a) any defects, damage or

deterioration due to normal use, wear and tear, or exposure; (b) normal maintenance services, such as

cleaning, lubrication, oil change; (c) replacement of service items, such as oil, lubricants, spark plugs, belts,

rubber hoses or other items subject to normal service replacement; (d) damage or defects arising out of, or

relating to abuse, misuse, neglect, alteration, negligence or accident; (e) repair or replacement arising from

st

2005, Ventrac warranty on Tractors & Attachments (excluding the HG100/HG150

from original

is limited to 180 days from original

are to be transferred to a commercial user the warranty

starting from the Original

9 - 2

LIMITED WARRANTY – VENTRAC TURF EQUIPMENT

operation of, or use of the turf equipment which is not in accordance with operating instructions

as specified in the operator’s manual or other operational instructions provided by V.P.I.; (f)

repair or

or modified so as to, in the determination of V.P.I., adversely affect the operation, performance or

durability of the equipment or that has altered, modified or affected the turf equipment so as to change the

intended use of the product; (g) repair or replacement necessitated by the use of parts, accessories or

supplies, including gasoline, oil or lubricants, incompatible with the turf equipment or other than as

recommended in the operator’s manual or other operational instructions provided by V.P.I.; (h) repairs or

replacements resulting from parts or accessories which have adversely affected the operation, performance

or durability of the turf equipment; or (i) damage or defects due to or arising ou t of repair of Ventrac turf

equipment by person or persons other than an authorized Ventrac service dealer or the installation of parts

other than genuine Ventrac parts or Ventrac recommended parts.

The sole liability of V.P.I. with respect to this warranty shall be repair and replacement as set forth herein.

V.P.I. shall have no liability for any other cost, loss, or damage. In particular V.P.I shall have no liability or

responsibility for: (i) expenses relating to gasoline, oil, lubricants; (ii) loss, cost or expense relating to

transportation or delivery of turf equipment from the location of owner or location where used by owner to

or from any Authorized Ventrac Dealer; (iii) travel time, overtime, after hours time or other extraordinary

repair charges or charge relating to repairs or replacements outside of normal business hours at the place of

business of an Authorized Ventrac Dealer; (iv) rental of like or similar replacement equipment during the

period of any warranty repair or replacement work; (v) any telephone or telegram charges; (vi) loss or

damage to person or property other than that covered by the terms of this warranty; (vii) any claims for lost

revenue, lost profit or additional cost or expense incurred as a result o f a claim of breach of warranty; or

(viii) attorney’s fees.

The remedies of buyer set forth herein are exclusive and are in lieu of all other remedies. The liability of

V.P.I., whether in contract, tort, under any warranty, or otherwise, shall not extend beyond its obligation as

set forth herein. V.P.I. shall not be liable for cost of removal or installation nor shall V.P.I. be responsible

for any direct, indirect, special or consequential damages of any nature. In no event shall V.P.I. be liable

for any sum in excess of the price received for the goods for which liability is claimed.

There are no representations or warranties which have been authorized to the buyer of the turf equipment

other than set forth in this warranty. Any and all statements or representations made by any seller of this

equipment, including those set forth in any sales literature or made orally by any sales representative, are

superceded by the terms of this warranty. Any affirmation of fact or promise made by V.P.I. or any of its

representatives to the buyer which relates to the goods that are the subject to this warranty shall no t be

regarded as part of the basis of the bargain and shall not be deemed to create any express warranty that such

goods shall conform to the affirmation or promise.

No employee, distributor, or representative is authorized to ch ange the foregoing warranties in any way or

grant any other warranty on behalf of V.P.I.

Some states do not allow limitations on how long an implied warranty lasts or allow the exclusion on

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to

you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

This warranty applies to all Ventrac turf equipment sold in the United States and Canada.

replacement arising as a result of any operation from Ventrac turf equipment that has been altered

9 - 3

Loading...

Loading...