Ventcroft Ltd.

Goddard Road,

Astmoor, Runcorn,

Cheshire WA7 1NQ,

Great Britain.

Phone: 01928 581098

Fax: 01928 581099

E-Mail: info@ventcroft.co.uk

http://www.ventcroft.co.uk

Manufacturing Global Security in Great Britain.....with PrideManufacturing Global Security in Great Britain.....with Pride

VI40.1 Created 05/11/2001 Issue 1.3

SPEClFlCATlONS

If you experience any difficulties with this product,

please call our Technical Help-Line

01928 581098

FIRE DETECTION PANEL

Mains Supply Voltage

Transformer Primary Thermal Fuse

Quiescent Current standby

Maximum Overall Current Supply

Maximum Sounder Supply Current

Maximum Zone Output Current

Current Draw - Fault Buzzer On

Current Draw - Fault Buzzer Off

Current Draw - Fire Alarm

Power Supply

Battery Standby

220V dc 50 Hz

o

1A 102 C (Non Replaceable)

48 mA (Buzzer Muted)

1A dc (MAX)

750 mA (0.75A)

50 mA (0.050A)

61 mA (0.61A)

53 mA (0.53A)

95 mA (0.95)

Number of Zones

Detector Voltage Supply

Maximum Current Supply

Monitoring

Maximum Detectors per Zone

Maximum Call Points per Zone

Zone Circuit

FT1BS: 1 Zone

FT2BS: 2 Zones

21 V dc +/- 10%

50 mA dc

Healthy 2mA <> 7.5mA (Nom.)

Fire 17mA <> 41mA (Nom.)

Short Circuit >43mA (Nom.)

Open Circuit <2mA (Nom.)

20 (Low Current Types 30uA)

Unlimited

Switch Voltage Output

Max Current

Outputs

Monitoring

Sounders Outputs

27.2 V dc +/- 10%

750 mA DC (MAX)

2 Independently fused

Open Circuit

Short Circuit

Reversed

Battery Charging Voltage

Monitoring

Battery Input

27.2 V dc (adjustable)

Open Circuit

Short Circuit

Less than 22 V dc

Reversed

F1 - Bell 1

F2 - Bell 2

F3 - Battery

F4- Mains Supply

Mains Thermal Safety Fuse

Fuses

1A Anti Surge 20 mm Glass

1A Anti Surge 20 mm Glass

1A Anti Surge 20 mm Glass

1A Fast Blow Mains 20 mm Ceramic

o

102 C (non replaceable)

Contacts

Maximum Current

Maximum Voltage

Auxiliary Relay

NO, C, NC (Voltage Free)

1A dc/ac

30 V dc

Front Cover

Back Box

Polycarbonate - Fire Retardant

Polycarbonate - Fire Retardant

Housing

Europan

British

Ingression Protection Rating

CE

To conform to BS5839:Part 4 1988

IP20

CE

Compliance

1 Zone

2 Zone

FT1BS

FT2BS

Re-Ordering

Warranty

2 Years from Date of Manufacture

(Date of manufacture can be found marked on the PCB)

FIRETRAXFIRETRAX

TM

Designed to Comply with BS5839 part 4 1988

FT1BS

FT2BS

Page 12

1.0 - Introduction

1.1 - Description Page 3

1.2 - Features Page 3

1.3 - Box Contents Page 3

2.0 - Connections

2.1 - Terminal Diagrams Page 4

2.2 - Field Connections Page 4

2.3 - Key Switch Page 4

2.4 - A/C Input Page 4

2.5 - Internal Buzzer Page 4

3.0 - Operating Controls / Indicators

3.1 - Keys Switch Page 5

3.2 - Control Buttons Page 5

3.3 - Internal Buzzer Page 5

3.4 - Front Panel Indicators Page 6

3.5 - Internal PCB Mounted LED Indicators Page 6

4.0 - Guide to Planning a fire alarm system

4.1 - Introduction Page 6

4.2 - Install Planning Page 7

4.3 - System Types - Levels of Protection Page 7

4.4 - General Information Page 7

4.5 - Detection Devices Page 7

4.6 - Automatic Point Detectors Page 8

4.7 - Manual Call Points Page 8

4.8 - Remote Indicator Modules Page 8

4.9 - Auxiliary Relay Page 8

4.10 - Sounders Page 8

4.11 - Remote Ring Page 9

5.0 - Installation and Wiring Guide

5.1 - Mounting the Control Indicator Equipment (CIE) Page 9

5.2 - Pre-Installation Testing Page 9

5.3 - Mains Connection Page 9

5.4 - Installing The Battery Page 10

5.5 - Adjusting the Battery Charge Voltage Page 10

5.6 - Automatic Detection Devices and Manual Call Points Page 10

5.7 - End of Line Resistance Monitoring Page 10

5.8 - Page 10

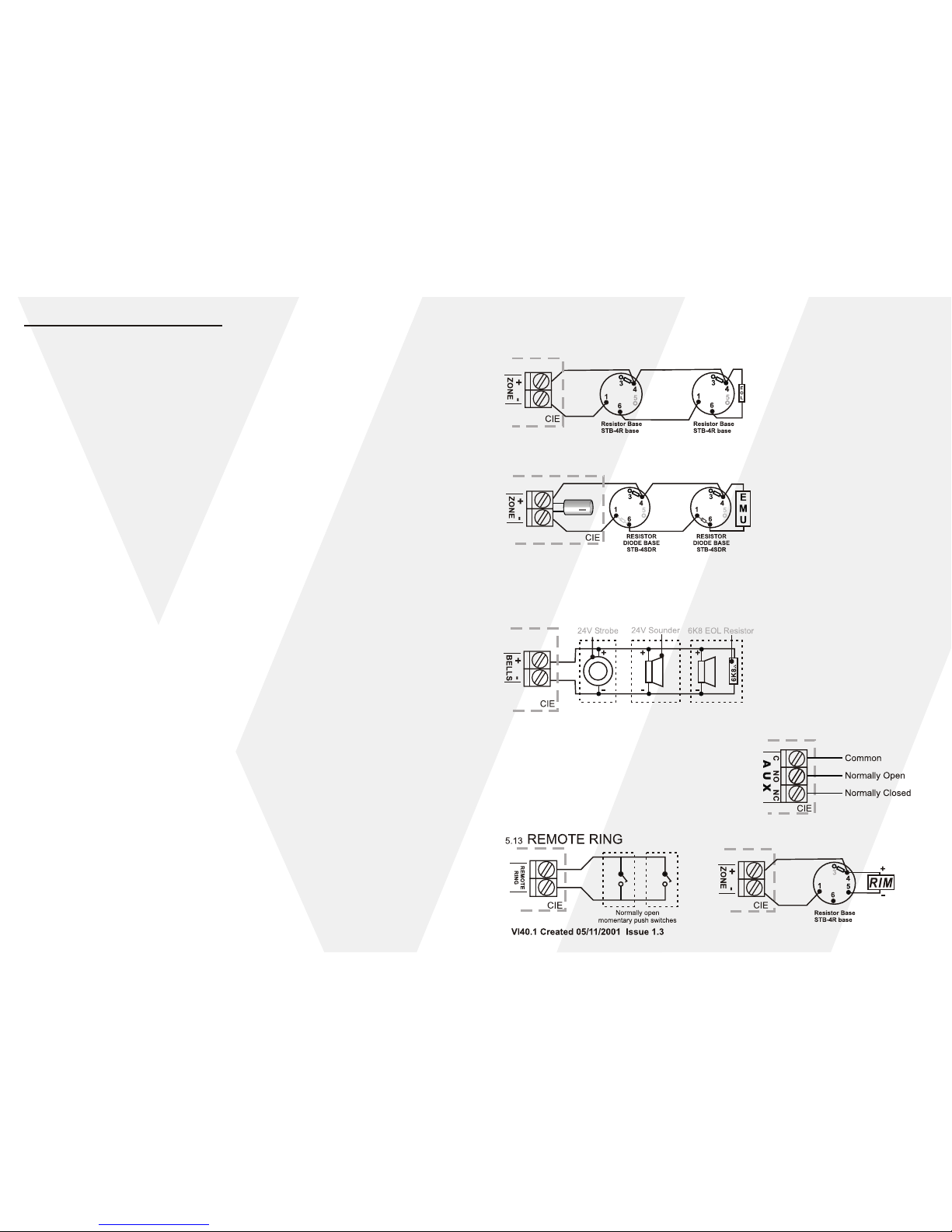

5.9 - Practical Wiring of Resistor Bases Page 11

5.10 - Practical Wiring of Diode Resistor Bases Page 11

5.11 - Sounders Page 11

5.12 - Auxiliary Relay Wiring Page 11

5.13 - Remote Ring Page 11

5.14 - Remote Indicator Module Page 11

6.0 - Specifications Page 12

7.0 - Commissioning Certificate / User Systems Details

7.1 - Certificate of Installation / Commissioning Page B1

7.2 - Commissioning and Maintenance Record Page B2

7.3 - Event Log Page B3

7.4 - User Operating Instructions Page B4

End of Line Electronic Monitoring Unit

Table of Contents

Page 2 Page 11

5.11 SOUNDERS

2

All sounder wiring should be in fire retardant type cables. 1mm or greater copper cables should

be used to avoid minimum volt drop. Its may be necessary on long cable runs to use greater cable

sizes, there should be no spurring or "T offs" from the main run.

5.9 PRACTICAL WIRING OF RESISTOR BASES

FOR RESISTOR END OF LINE MONITORING

Diode bases should never be used when using EOL resistor monitoring

5.10 PRACTICAL WIRING OF DIODE RESISTOR

BASES FOR EMU END OF LINE MONITORING

5.14 REMOTE INDICATOR MODULE

5.12 AUXILIARY RELAY WIRING

The Auxiliary relay should be considered as a low

current switch, and should not be connected

directly to magnetic door holders and should only

be used to switch a larger switching relay.

Page 10

Page 3

1.1 DESCRIPTION

The Ventcroft FIRETRAX (FT2BS & FT1BS) are both fire control panels designed to comply with

BS5839:Part 4 1988 used in systems in the detection of fire, described in this manual as

CIE(Control Indicator Equipment). The CIE has 1 or 2 fire detection circuits(model dependent) for

the connection of fire detection and call point devices. The CIE is powered from the mains supply

and utilizes a backup circuit to allow the connection of stand-by batteries allowing the CIE to

function with a mains failure.

In the event of fire detection two sounder outputs are provided to drive 24V sounder or strobe units

to communicate evacuation, the sounder output can also be remotely triggered via the remote ring

input. A relay provides a switchable voltage free output which changes state during a fire activation

and can be utilized, for example to switch devices such as digital phone communicators or to

indirectly release power to fire door holding devices.

1.0 INTRODUCTION

1.2 FEATURES

! MAINS POWER LED

! ZONE FIRE ALARM LED'S

! FACE MOUNTED CONTROL BUTTONS

! ZONE FAULT LED'S

! GENERAL FAULT LED'S

! TWO FUSED SOUNDER OUTPUTS

! FUSED BATTERY INPUT

! KEY SWITCH ENABLE

! MICROPROCESSOR CONTROLLED

! INTERNAL SYSTEM FAULT LED'S

! POLYCARBONATE HOUSING

! ACTIVE END OF LINE OPTION

! END OF LINE RESISTOR MONITORING

! CLASS CHANGE FACILITY

! DOUBLE POLE AUXILIARY RELAY

! 1 AMP TOTAL POWER SUPPLY

! INTERNAL SPACE FOR UP TO 2 x 2.1 Ah 12 V BATTERIES

! COMPLIES WITH B.S. 5839 PART 4 1988

! UP TO 20 AUTOMATIC DETECTION DEVICES PER ZONE

! UNLIMITED NUMBER OF CALL POINTS PER ZONE

! CE

5.6 INSTALLING MANUAL CALL POINTS AND

AUTOMATIC DETECTION DEVICES

Manual Call Points must be installed before automated detection devices as

shown below in (fig. 5.7), when using End of Line resistor monitoring. In the very last device a 6K8

ohm resistor must be placed across the device to provide end of line monitoring. In all detection

devices automatic or manual a 470 ohm resistor should be connected in series with its terminals

which are presented to the CIE.

In some installations it may not be convenient for all call points to be installed before the

automated detection devices , in these cases an EMU (Electronic Monitoring Module) provides

active end of line monitoring and allows the different types of detection devices to be mixed in any

order. The EMU device must be placed in the furthest most detector. When using an EMU a

capacitor must be placed across the zone terminals in the CIE. Shown in fig 5.8

2

Devices should be wired in 1mm or greater copper cable, should be no spurring or "T offs"

from the main run.

there

1.3 Box Contents

1x FIRETRAX FT1BS OR FT2BS - Fire CIE Panel

1x Instructions VI40.1

1x User Insert VI41.1 for Instructions VI40.1

1x Accessory Bag Including

2x 816 Keys

2x Self Tapping Screws - For Fixing Front Cover to the Base

1x Purple Fast-on to Fast-on Lead

1x Black Fast-on to Tinned End Lead

1x Red Fast-on to Tinned End Lead

2x Spare 1A 20mm Glass Fuses

2x 6K8 Resistors

5.7 USING EOL (End of Line) RESISTOR MONITORING

Resistor basses must be used, diode resistor bases must never be used as fault will not be reported.

5.8 USING EOL ELECTRONIC MONITORING UNIT

When using electronic monitoring devices it may be necessary to fit a capacitor in the CIE, correct polarity

must be observed when connecting the capacitor. Diode resistor basses must be used, shown below

VI40.1 Created 05/11/2001 Issue 1.3

5.5 ADJUSTING THE BATTERY CHARGING VOLTAGE

On completion of the installation and during regular maintenance the battery

charging voltage should be 27.2 V dc, measured at the battery input terminals on

TB3 14 & 15 while not connected to the battery. The battery charging voltage may

be set by adjusting potentiometer VR1 whilst measuring across the battery

terminals 14 & 15 on TB3. Access to VR1 is gained from the rear of the PCB.

5.4 INSTALLING THE BA TTERY

Install the 24 V battery normally made of 2x12 V SLA

batteries connected in series. Correct polarity connection

must be observed. The pre installed 6K8 resistor must be

removed before connecting the batteries.

Page 4

5.0 INSTALLATION AND WIRING GUIDE

5.1 MOUNTING THE CIE EQUIPMENT

Identify a suitable location for mounting the CIE (Control Indicator Equipment) taking into

consideration the routing of cables and access to the CIE for both installation and user. Remove

the PCB and keep safe, mark the location of the holes to be drilled by offering the CIE rear

enclosure to the wall. Drill holes for suitable rawl plugs to provide a strong and secure installation.

2.0 CONNECTIONS

2.1 Terminal Diagrams

2.2 FIELD CONNECTIONS - TB3

These terminals provide the outputs to drive the internal and external sounders and strobes.

There are two separately fused outputs, both circuits are monitored for open and short

circuits conditions with EOL monitoring resistors (6K8). Sounders must be polarised, fully

suppressed and designed for 24VDC operation. The total load for both circuits must not

exceed 750mA. If the sounders or strobes are not polarized a fault will be indicated. The

same wiring rules apply as for the detector circuits.

+

BELL 1

-

+

BELL 2

-

REMOTE

RING

The REMOTE RING terminals can be used to force trigger the bell relay without a fire

condition occurring or operating the auxiliary relay. This gives the ability to wire remote

evacuation switches. This is NOT a latching trigger and will return to a normal state when the

connection is broken. Often used as a class change.

C

NO

NC

AUX

The CIE is fitted with a double pole auxiliary 1 Amp relay which operates only when a fire

condition is recognised. The relay does not operate if the manual SOUND ALARM is pressed.

+

BATT

-

These terminals provide connection for a 24V backup battery. 12V batteries are connected in

series. The 6K8 Ohm resistor must be removed before fitting any battery to this terminal.

Failure to remove the resistor will not enable the panel to test the batteries health.

2.3 KEY SWITCH - TB2

KEYSW

These terminals provide the connection for the on board key switch which enables and

disables the control buttons. When the switch is closed the control buttons are enabled. No

other connection should be made to these terminals.

2.4 A/C SUPPLY INPUT - TB1

A/C

These terminals provide the connection from the on board transformer, which provides

approximately 32 V ac. No other connection should be made to these terminals

2.5 INTERNAL BUZZER - TB4

BUZZER

These terminals provide the connections to supply a wired internal buzzer. These terminals

are only fitted when the on board buzzer SND1 is not fitted. No other connection should be

made to these terminals.

+

ZONE 2

-

+

ZONE 1

-

These terminals provide the inputs allowing the connection of smoke heads and alarms

points to the CIE. All devices must be connected in parallel to the CIE. 22V DC is supplied to

the zone terminals suppling a maximum current of 50 mA per zone, a 6K8 Ohm end of line

resistor must be fitted in the further most detection device from the CIE. To produce a fire

state the detector should draw sufficient current to trigger a fire alarm and have a 470 Ohm

resistor in series. Not only do the terminals detect a fire state but they offer detection of open

and short circuit of the cables.

FIRETRAX CIE PANEL

4.11 REMOTE RING

The connection of a normally open switch to the remote ring terminals, will allow the external sounders to be

used for ancillary functions for example 'Class Change.' Multiple switches can be used by connecting the

switches in parallel.

This work must be carried out by a suitably qualified engineer and installed to the latest mandatory

Fire Alarm Installation Regulations which are applicable at the time of installation. The correct

polarity must be observed and a good earth must be used.

The Fire Alarm system must not share its mains supply with any other electrical circuit and should

be connected via an isolating protective device and labelled 'FIRE ALARM DO NOT SWITCH

OFF.'

Wire To Mains

Power Supply

5.3 MAINS CONNECTION

T erminate the mains connection using suitable earthed mains cable to a fused supply, ensuring all

power is isolated before attempting to terminate and wires. This supply should not be shared with

any other appliances.

5.2 PRE-INSTALLATION TESTING

It is STRONGLY recommended that the panel is powered up and tested prior to the external

system circuits being connected.

• Make sure the external system wiring has been tested and the results recorded.

• Connect the batteries together (see FIG 5.4, page 10) and connect the + & - 'spade terminals'

to the PCB terminal block. Ignore the fault indication at this stage.

• Connect the mains supply (see FIG 5.3, page 9). The fault indication will be removed

• In turn, temporally disconnect each of the monitoring resistors from the terminals, check for

a fault indication, and reconnect for the fault to reset.

• In turn, use a 470 ohm resistor to temporally connect across the detector circuit terminals

to create a FIRE condition. Reset as per the Operating Instructions.

Once the panel has been tested and the operating procedure is understood, the external

connections can be made, ONE CIRCUIT AT A TIME.

Page 9

VI40.1 Created 05/11/2001 Issue 1.3

Page 5

Page 8

3.1 KEYSWITCH

The Keyswitch is used to enable or disable the three control buttons. SOUND ALARM,

MUTE and RESET . The key can only be removed in the control disabled position, with

the key inserted and turned clockwise the controls are enabled.

3.0 OPERATING CONTROLS

The key switch and three buttons on the front of the CIE allows the user and engineer to

access the CIE different operation functions.

The sounder mute push button is used to silence the system sounders and

the internal buzzer during a fault condition. When the mute button is pressed

during a fire activation the system sounders will be silenced but the internal

buzzer will sound continuously until the reset button is pressed. The mute

button is also used to silence the system sounders when the SOUND

ALARM button has been pressed. If the mute button is pressed during fault

condition the internal buzzer will cease to sound continuously and will only

bleep once every 5 seconds. Labelled on the PCB as S2 Mute.

MUTE

The reset button is used to reset and initialize the CIE after a fire activation or

from powering up. After a fire activation before the reset button can be

pressed the mute button must first be pressed, otherwise no reset will take

place. If reset button is pressed with or without a fault condition present the

CIE will re-initialize, illuminating all external LED's along with sounding the

internal buzzer for 3 seconds. The auxiliary supply to the zone terminals is

removed during the initialization period, resetting any smoke heads

connected to the zone inputs. Labelled on the PCB as S3 RESET .

RESET

The SOUND ALARM button is used to activate the sounder circuits, and can

be used to evacuate the building, resound or test the sounders. Labelled on

the PCB as S1 EVAC.

SOUND

ALARM

3.2 CONTROL BUTTONS

A constant tone from the buzzer will indicate either :

1. General Fault

2. Muted Fire Alarm

A rapid on / off tone indicates a fire activation

3.3 INTERNAL BUZZER

Constant

Fast Beep

4.7 MANUAL CALL POINTS

Call points should be sited with the following considerations, the rules below are mandatory.

1, On all escape routes.

2, On landings of stairways.

3, Near final exits to the open air.

4, Nobody has to travel 30 metres to reach a call point.

5, Call Points must be 1.4 metres above the floor and be free from obstruction.

4.10 SOUNDERS

Sufficient sounders should be installed so as to ensure alarm audibility in all areas of the building /

location ensuring a fast and full evacuation. Two sounder outputs are provided on the CIE (Control

Indicator Equipment) allowing the connection of two independent sounder circuits, see BS 5839

Part1:1988 section 9.4 for detailed information.

1. Sufficient sounders should be installed to ensure sufficient dB levels around the premises

to aid a complete evacuation, even in the event of a failure of one of the sounder circuits.

75dB should be provided at the bed head of a sleeping person (With al doors closed). 65 dB

should be provided in all other working areas or 5 dB above any noise the re-occur for more

that 30 seconds.

2. The minimum sound levels must be produced in all parts of the building / location. This

includes restricted area's that are infrequently visited, such as service ducts, store rooms,

toilets or lift shaft motor rooms etc.

3. All sounders in a building should be of similar type, do not mix electronic sounders with bells.

4.6 AUTOMATIC 'POINT' DETECTORS

There are four common types of automatic 'point' detectors installed to aid the detection of fires

within a residential / commercial building. Ionisation and Photoelectronic Devices detect the

products of combustion (smoke). Rate of Rise and fixed Temperature Devices detect changes

in temperature (heat). Optical smoke Devices are used for, slow burning smouldering fires, ie for

escape routes and corridors, wood or cardboard stores, do not use in steamy, dusty or smoky

areas such as kitchens and bathrooms etc. Ionisation Smoke Devices are used for fast burning,

high energy fires, ie for petrochemical or solvent stores, electrical switch rooms. Heat Devices

are used when the environment is subject to constant levels of smoke or dirt, ie loading bays,

boiler rooms, kitchens, laundries and plant rooms. Fixed Temperature Heat Devices are used

where high ambient temperatures exist, or in areas where sudden changes in temperature may

occur, ie near large windows or heat producing processes. Rate of Rise Devices have fixed

temperature operation, but also looks for sudden rises in temperature giving faster reaction than

standard fixed temperature detector. Sufficient detection devices should be installed to provide

adequate protection coverage.

4.8 REMOTE INDICAT OR MODULE

Remote Indicator Modules can be used to remotely indicate the state of an automatic detection

device. i.e. there may be 10 rooms on a single corridor, if a single detection device were to alarm

each room would haft to be inspected, which would take valuable time. A remote indicator module

can be placed outside each room to quickly guide a correct response.

4.9 AUXILIARY RELAY

The Auxiliary relay terminals can be used as a voltage free interface between the FIRETRAX

FT1BS / FT2BS CIE. T o such devices as magnetic fire door holding devices and communicating

devices to be connected to a phone line. The Auxiliary relay should be considered as a low

current switch, and should not be connected directly to magnetic door holders and should only be

used to switch a larger switching relay.

VI40.1 Created 05/11/2001 Issue 1.3

Loading...

Loading...