2.5A Electronic

Single phase speed controller

Installation and Wiring Instructions

PLEASE READ INSTRUCTIONS IN CONJUNCTION WITH ILLUSTRATIONS.

PLEASE SAVE THESE INSTRUCTIONS.

Stock Ref. N°

W103 03 102M

Fitting & Wiring Instructions 2.5A Single Phase speed Controller

IMPORTANT

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE COMMENCING INSTALLATION

1. It is recommended that this controller is installed by a qualified electrician.

2. The installation and wiring must comply with current IEE Regulations, BS7671, or the

appropriate standards in your country.

3. This controller is not suitable for use in rooms containing a fixed bath or shower.

4. This equipment MUST be earthed

On receipt of your controller, check that:

a). It is the correct rating for the size of

motor

b). the voltage and frequency are correct.

Location

The controller may be sited in any

convenient position that is unaffected by

direct heat sources such as radiators,

boilers, etc. Do not site the controller

where it may be subject to water spray,

condensation, damp or wet conditions.

Ensure the controller is installed in a

ventilated area. Ensure that the

enclosure is securely mounted using

appropriate fixing screws or bolts.

Fitting

Unscrew the two screws and remove the

lid/switch from the mounting box. The

mounting box may be fixed to most

single or double gang recessed metal

outlet boxes or alternatively fixed direct

to the wall for surface cable entry. When

using surface wiring that is not being

contained in conduit, the supply and

output cables must be securely clipped to

the mounting surface, close to the

controller.

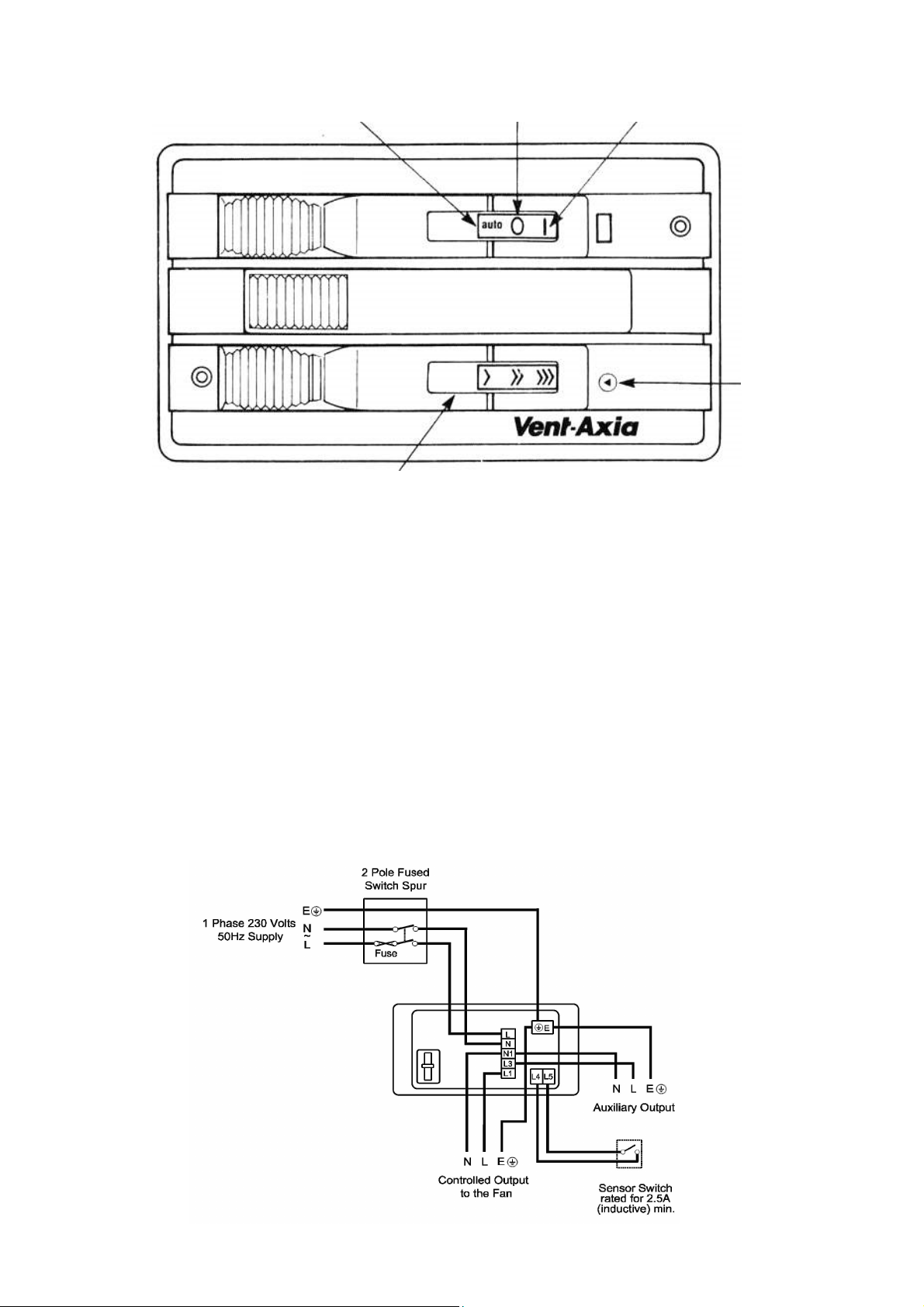

Wiring

WARNING: THIS APPLIANCE MUST

BE EARTHED

Ensure that mains supply is isolated

before proceeding with the wiring. The

installation must be provided with a

double-pole isolator switch, having a

contact separation of not less than 3mm,

and be protected with a 3 amp fuse

(U.K).

If using automatic control via electromechanical ON/OFF switched sensor e.g

electro-mechanical thermostat, timer,

relay etc. ensure sensor switch is

adequately rated for the switched load.

After making wiring connections, check

that they are all correct and secure,

replace lid.

NOTES ON RUNNING

Before switching on CHECK:

Control unit and motor/fan are secure

Earth connections have been made and

are secure

Switch on mains

Slide control to maximum and down to

minimum to ensure motor/fan operates

accordingly.

MINIMUM SPEED

The control unit has been factory set to

Vent-Axia’s recommended minimum

speed.

A minimum speed adjuster is located on

the front of the controller and is exposed

when the bottom slide bar is moved fully

to the left. This adjuster is used to vary

the lowest speed setting if the fan does

not revolve when the controller is set to

minimum speed.

Using a small screwdriver, turn the

adjuster clockwise to increase the

minimum speed setting.

After any adjustment, make sure the fan

will start from a stationary condition by

using the ON/OFF switch with the

variable speed slide knob set6 fully to the

left (minimum speed).

*Automatic

Fan

Fan

MIN. SPEED

ADJUSTMENT

VARIABLE FAN SPEED

*For AUTOMATIC REMOTE SWITCHING (If required)

See also relevant sensor wiring instructions.

Note:

Only mechanical or electro-mechanical switched sensors should be used, rated at 2.5A

inductive 220-240V AC.

Connect sensor switch leads to L4 and L5 in the terminal block.

When slide switch is in the position marked auto automatic switching from sensor/switch

(if fitted) will be obtained. Ensure sensor switch is adequately rated for the full switched

fan load.

For Shutter mechanism (if required) see also relevant shutter wiring instructions.

Note:- Connect the shutter cable to L3 when required. (Note: The load on L3 should be

kept to less than 0.25A (60W) we recommend the use of Vent-Axia 4 core cable when

shutter application is required.

Applicable only to products installed and used in the United Kingdom. For details of

guarantee outside the United Kingdom contact your local supplier.

Vent-Axia guarantees its products for two years from date of purchase against faulty material

or workmanship. In the event of any part being found to be defective, the product will be

repaired, or at the Company’s option replaced, without charge, provided that the product:-

Has been installed and used in accordance with the instructions given with each unit.

Has not been connected to an unsuitable electricity supply. (The correct electricity

supply voltage is shown on the product rating label attached to the unit).

Has not been subjected to misuse, neglect or damage.

Has not been modified or repaired by any person not authorised by the company.

Please return the complete product, carriage paid to your original supplier or nearest Vent-

Axia Centre, by post or personal visit. Please ensure that it is adequately packed and

accompanied by a letter clearly marked “Guarantee Claim” stating the nature of the fault and

The guarantee is offered to you as an extra benefit, and does not effect your legal rights

The Guarantee

IF CLAIMING UNDER TERMS OF GUARANTEE

providing evidence of date and source of purchase.

Head Office: Fleming Way, Crawley, West Sussex, RH10 9YX.

EU Authorised Representative:

Vent-Axia Bedrijvenweg 17 7442 CX Nijverdal Nederland authorisedrep@vent-axia.nl

UK NATIONAL CALL CENTRE, Newton Road, Crawley, West Sussex, RH10 9JA

SALES ENQUIRIES: Tel: 0344 8560590 Fax: 01293 565169

TECHNICAL SUPPORT: Tel: 0344 8560594 Fax: 01293 539209

Web:-www.vent-axia.com Email:- info@vent-axia.com

As part of the policy of continuous product improvement Vent-Axia reserves the right to alter specifications without notice.

462233 M 0921

Loading...

Loading...