Vent-a-Hood 300 CFM B100, 900 CFM B200, 900 CFM B100, 600 CFM B200 Dual, B200 Dual Installation Instructions Manual

Read and Save These Instructions

All Hoods Must Be Installed By A Qualified Installer

INSTALLATION INSTRUCTIONS

WALL MOUNT RANGE HOOD

Read All Instructions Thoroughly Before Beginning Installation

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring must be done by qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction. Switch power off at service panel

and lock the service disconnecting means to prevent power from

being switched on accidentally during installation.

B. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

C. Ducted fans must always be vented to the outdoors.

D. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to

prevent back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA), and

the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and local code authorities.

WARNING - TO REDUCE THE RISK OF FIRE, USE ONLY METAL

DUCTWORK

Page 1

L110

(Rev. 02/08)

U

CUS

R

L

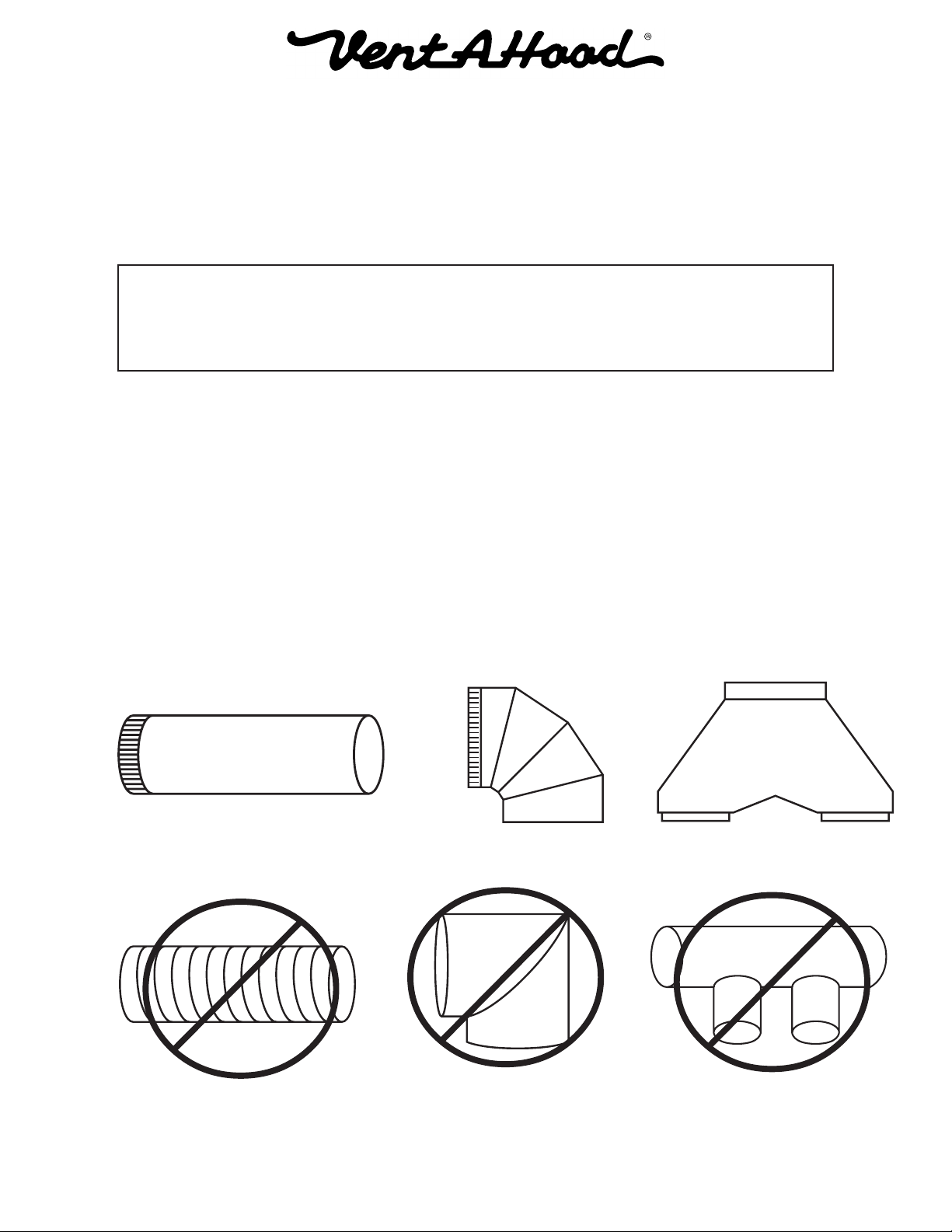

Ducting Do’s and Don’ts

NEVER restrict the duct size. The single blower unit (B100) requires 6” round duct or equivalent

(28 square inches), and the dual blower unit (B200) requires 8” round duct or equivalent (50

square inches). When combining ducts together, the square inch area must reflect the total

square inch area of the ducts being combined. Using Vent-A-Hood transitions (back page) will

ensure proper efficiency.

Blower Duct Size Sq. Inch Area Vent-A-Hood Transition

Single (B100) 6” round or equivalent 28” N/A

Dual (B200) 8” round or equivalent 50” N/A

Single and Dual (B100 & B200) 10” round or equivalent 79” VP562 (Optional)

Two Dual (Two B200s) 12” round or equivalent 113” VP563 (Optional)

Do not use flexible or corrugated duct. This type of duct will restrict airflow and reduce

performance. Only use smooth, galvanized, metal duct. Observe local codes regarding special

duct requirements and placement of duct against combustibles. Make the duct run as short and

as straight as possible with as few turns as possible. Avoid sharp-angled turns. Instead, use

smooth, gradual turns such as adjustable elbows or 45 degree angled turns. For duct runs over

20 feet, increase the duct diameter by one inch for every ten feet of duct. A 90 degree elbow is

equal to 5 feet of duct. Using Vent-A-Hood roof jacks or wall louvers (back page) will ensure

proper efficiency. Airflow must not be restricted at the end of the duct run. Do not use screen

wire or spring-loaded doors on wall louvers or roof jacks. Do not terminate venting into an attic

or chimney. Where possible, seal joints with duct tape. The hood must be ducted to the outdoors

without restrictions.

L110

YES

NO

Smooth Duct

Flexible Duct

Smooth Gradual Turn

Sharp Angled Turns

Page 2

(Rev. 02/08)

Proper Combining

of Two Ducts

Improper Combining

of Two Ducts

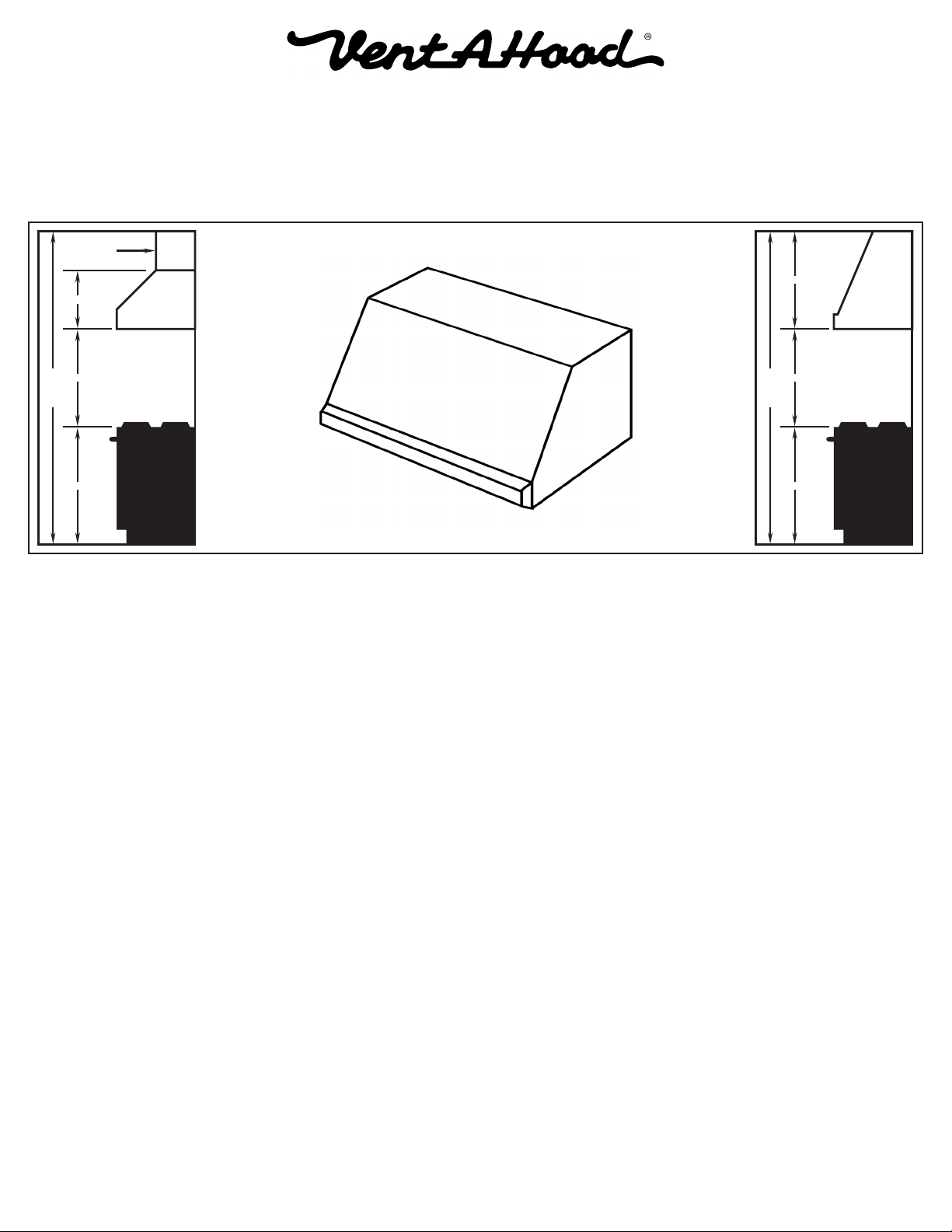

Installation Details

1) Read all instructions thoroughly before beginning installation. Note: These instructions apply to standard hoods only.

Custom hoods may require additional specification consideration.

2) When installing a wall mount range hood, it is recommended that the bottom edge of the hood be located no more than

30" above the cooking surface. Exceeding recommended mounting height may compromise performance.

Optional

Duct Cover

30”

18”

30”

8’ Ceiling

36”

30”

8’ Ceiling

36”

3) Select the appropriate installation method.

Method 1 is suitable for applications where the top of the hood (blower outlet(s) location) is accessible after the hood

is mounted on the wall.

Method 2 is suitable for applications where the top of the hood (blower outlet(s) location) is not accessible after the

hood is mounted on the wall.

4) IF THE HOOD IS TO BE “BACK VENTED”, PROCEED DIRECTLY TO STEP 5.

Consult the connection diagrams (on next page) for further details on exhaust outlet placement.

Method 1: Install the duct(s) from the outside of the home down to the location of the exhaust outlet(s) on the top of

the hood allowing room for the transition (if applicable). If a transition is used, install duct down to the

location of the transition outlet plus 1". This will allow the transition to engage 1" inside of duct.

Method 2: Install the duct(s) from the outside of the home to the ceiling over the exhaust outlet(s) on the hood. The

end of the duct(s) should extend 1" below the ceiling.

Use duct tape to seal all joints. A complete listing of available Vent-A-Hood ducting materials is provided on the back

page of this instruction sheet.

Transition heights are as follows:

Single Blower (B100): 6" round duct will connect directly to the top of the hood.

Dual Blower (B200): 8" round duct will connect directly to the top of the hood.

Single and Dual Blower (B100 & B200): 6" round duct will connect directly to the top of the hood; 8” round will

connect directly to the top of the hood. Optional 10" round combination

transition (VP562, sold separately) is 17 1/2" tall.

Two Dual Blowers (Two B200s): Two 8” round ducts connect directly to the top of the hood. Optional 12”

round combination transition (VP563, sold separately) is 16 1/2” tall.

Page 3

L110

(Rev. 02/08)

Loading...

Loading...