Vent 125 Derapage 2019, 125 Baja RR 2019, 125 Baja 2019, 125 Derapage RR 2019 Use And Maintenance Manual

USE AND MAINTENANCE

MANUAL

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

This manual is an integral part of the vehicle and must always be so, even when the

vehicle is sold.

VENT is entitled to modify its own models,

except for the essential characteristics described and illustrated herein.

All rights of electronic memory, reproduction and total or partial adaptation, whatever the means, are reserved in all countries.

Mentions of products or services provided

by third parties are for information purposes

only and do not represent any commitment

whatsoever.

VENT cannot be held liable for the services

or the use of these products.

Edition: 03/2019.

Produced by:

DUESSE SERVICE srl

Samarate (VA)

www.duesse.it

On behalf of:

VENT srl

I - 23815 Introbio (Lecco) Via V. Veneto, 9

Phone: +39 (0341) 901-533 (R.A.)

Fax: +39 (0341) 901-457

E-mail: info@ventmoto.it

2 use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

MAIN INDEX

SAFETY MESSAGES ....................................... 4

WARNINGS - CAUTION -

GENERAL WARNINGS ................................ 4

CatalytiC exhaust system .................... 4

SAFETY RULES ............................................... 4

Permitted use ........................................... 5

Clothing .................................................... 5

aCCessories ............................................. 5

luggage ..................................................... 5

Fuel ............................................................. 5

engine oil................................................... 6

Brake Fluid ................................................ 6

Cooling Fluid ........................................... 7

exhaust Fumes ......................................... 7

Battery ....................................................... 7

saFe driVing .............................................. 7

Parking ....................................................... 8

VehiCle identiFiCation............................. 9

engine identiFiCation .............................. 9

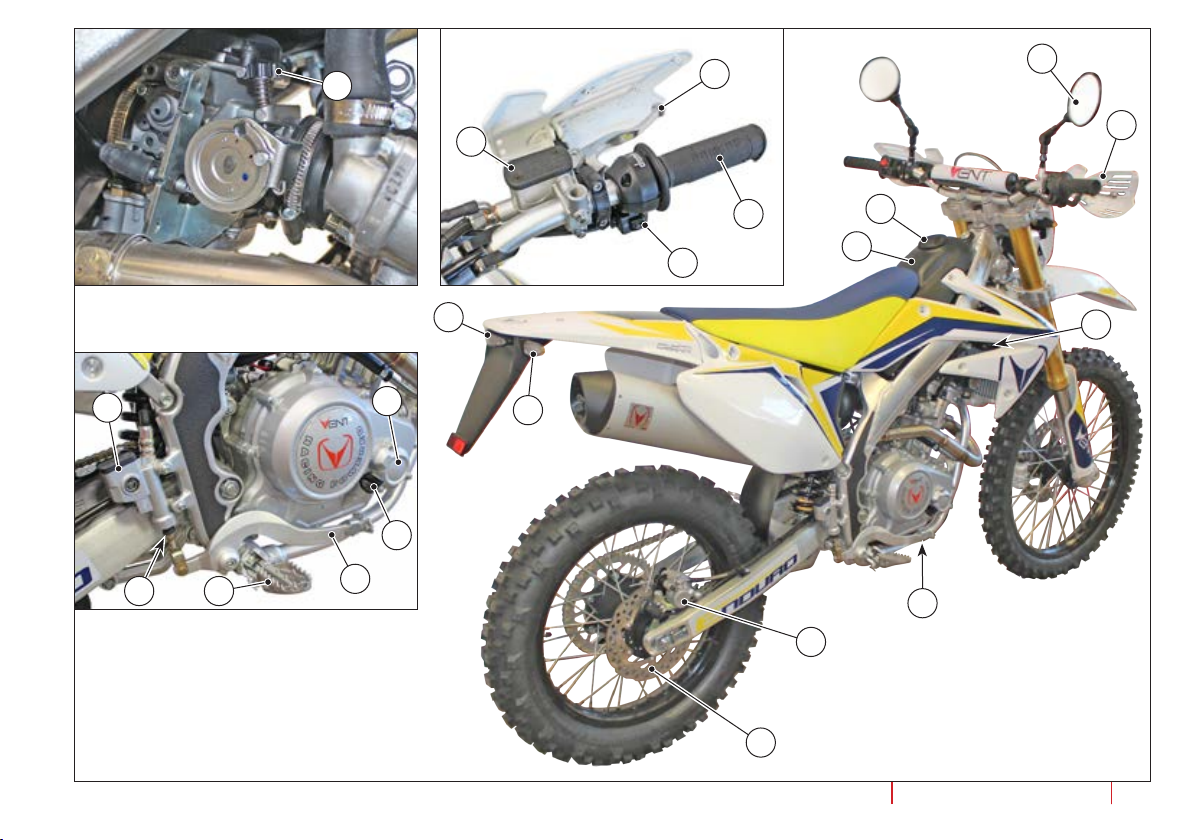

MAIN ELEMENTS.......................................... 10

main elements on the leFt side ........ 10

main elements on the right side ...... 10

COMMANDS ................................................. 14

start switCh ........................................... 14

start Button .......................................... 14

leFt switCh ............................................. 15

ClutCh Command .................................. 16

aCCelerator Command ....................... 16

Front Brake Command ........................ 16

ComBined Braking Command ............. 16

ClutCh Command leVer ....................... 17

steering loCk ........................................ 17

Fuel taP .................................................... 17

INSTRUCTIONS TO USE THE VEHICLE ..... 20

general CheCks Prior to use ........... 20

ClimBing on and oFF the VehiCle ...... 20

Break-in.................................................... 21

adjusting rear-View mirrors ................ 21

PlaCing the VehiCle on

the side kiCkstand ................................ 22

Fuelling ................................................... 22

STARTING THE ENGINE ............................... 23

on your way ........................................... 24

stoPPing the VehiCle ........................... 25

stoPPing the engine ............................. 25

Preliminary oPerations ...................... 25

SCHEDULED MAINTENANCE SHEETS ...... 27

Parts remoVal ....................................... 29

remoVing the seat ................................ 29

remoVing the leFt Front

ConVeyor ................................................ 29

remoVing the wheels .......................... 30

disassemBling the Front

light BraCket ............................................32

COMMANDS ................................................. 33

engine oil leVel CheCk ........................ 33

Brake Fluid leVel CheCk ..................... 34

Brake lining CheCk ............................... 35

Cooling Fluid leVel CheCk ................. 35

CheCking the tyres .............................. 36

insPeCtions and regulations ............ 37

side kiCkstand ........................................ 37

handleBar ............................................... 37

swingarm................................................. 38

Fuel tank CaP ......................................... 38

air Filter .................................................. 39

transmission Chain .............................. 40

Front susPension ................................. 42

rear susPension ................................... 42

sPark Plug .............................................. 43

Front Brake Command leVer ............ 44

ComBined Braking Command leVer .. 44

ClutCh Command leVer ....................... 45

aCCelerator Command regulation ...... 46

idling sPeed regulation ...................... 46

Battery ..................................................... 47

tyPe oF reCharge ................................. 48

FUSES ............................................................ 48

light Beam ............................................... 49

Front headlight BulBs ....................... 50

rear headlight BulB ............................ 51

Front and rear Blinkers .................... 51

TRANSPORTATION ....................................... 51

CLEANING ..................................................... 52

washing ................................................... 52

storage ................................................... 53

TECHNICAL INFORMATION ........................ 54

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

3use and maintenance manual

SAFETY MESSAGES

This symbol indicates a safety message.

When this symbol appears in the

manual, pay particular attention to the

potential risk of harm. Failing to heed the

warnings that contain this symbol may

compromise your own safety as well as

that of other people and of the vehicle!

The following words are used throughout

the manual to indicate:

DANGER

Potential risk of serious injury or death

for the operator or other people.

WARNING

Potential risk of light injuries for the operator or other people, or damage to the

vehicle.

NOTE: The term “NOTE” precedes important information or instructions.

WARNINGS - PRECAUTIONS GENERAL WARNINGS

Before using or operating the vehicle, read

this manual very carefully, paying particular

attention to the chapter “SAFETY RULES”.

Your safety and that of others depend on:

- Being familiar with the vehicle in your

possession;

- Theefciencyandmaintenancestatusof

your vehicle;

- Being familiar with and respecting the

Highway Code;

- Your familiarity with movements on the

vehicle.

To familiarise yourself with the vehicle,

choose an area awayfromtrafcanddevoid of dangers to practice.

VENT thanks you for choosing one of

our products and wishes you a pleasant

drive.

Catalytic discharge system

The catalytic discharge system must be

able to work at high temperatures, which remain for a certain period of time even after

the engine has been turned off.

DANGER

Do not touch or move objects, especial-

ly ammable ones, near the catalytic

discharge system until it is completely

cold.

Park the vehicle away from dry brush or

places accessible to children.

WARNING

To avoid damage to the catalytic discharge system, use only lead-free gasoline.

SAFETY RULES

- To drive this vehicle it is necessary to

possessallrequisitesdenedbythelaw

in force in the country where it is used.

- Taking certain medications, alcohol or

other drugs increases the risk of accidents. Make sure you are psychologically and physically able to drive, focusing particularly on physical fatigue and

drowsiness.

- Anothersignicantcauseofaccidentsis

driver’s inexperience. DO NOT entrust

the vehicle to beginners, and make sure

the driver possesses the necessary requisites to drive.

- Always respect road signs and highway

laws, nationally and locally.

- Avoid sudden manoeuvres, which are

dangerous for yourself and for others (for

4 use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

example, wheeling, failing to respect the

speed limit etc).

Assess driving conditions:

- Visibility;

- Road conditions;

- Trafc;

- Presence or possible presence of pedestrians.

Rule out and avoid obstacles that may

cause damage to the vehicle or lead to

loss of control of the vehicle.

- Respect and maintain all safety distances.

- Always drive holding the steering wheel

with both hands, with your feet resting on

the driver’s footrests, i.e. In the proper

driving position.

- Pay maximum attention to the act of driv-

ingandtothetrafcontheroad.

- If the vehicle has been in an accident or

has been in a crash or fall, make sure the

command levers, the tubes, the cables,

the braking system, the wheels, the tyres

and all other parts are intact.

If the damage is persistent or if you are

uncertain of its conditions, take the car to

a VENT dealer, where the vehicle will be

tested and inspected.

Always report any case of malfunctioning

to make it easier for the technicians and/

or mechanics to solve the problem.

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

Do not drive or allow anyone to drive the

vehicle if the damage it has suffered is

compromising its safety.

- Itis forbiddento carryout anymodica NOTE: Making modications to the vehi-

- It is advisable to follow all national and

- It is forbidden to use the vehicle to race,

Permitted use

Baja models are intended for use on the

road and off-road.

Derapage models are intended exclusively

for use on the road.

Clothing

- Always wear and properly snap shut the

- It is advisable to wear protective gar-

Do not wear exceedingly loose or abun-

DANGER

tion to the vehicle.

cle will result in warranty annulment.

local laws and regulations regarding vehicle equipment.

except for competitions in tracks set

apart for this purpose.

helmet, which must be approved according to the laws in force in the country

where it is being used.

ments in the event of falls, such as jacket, trousers, gloves, boots etc, suitable

for motorcycle use.

dant garments or accessories, as they

may impair driving manoeuvres.

- Do not keep in your pockets any sharp

objects that could potentially cause harm

in a fall, such as:

- Keys;

- Pens;

- Glass containers etc.

This also applies to the passenger.

Accessories:

It is advisable to purchase and install original accessories from a VENT dealer.

Users are personally responsible for choosing and installing accessories.

Luggage

- Be prudent when loading luggage. Do

not overload.

- Maintain the luggage as close as possible to the barycentre of the vehicle.

- Distribute the load uniformly on both

sides to reduce imbalances.

- Theloadmustbermlyanchoredtothe

vehicle.

- Never rest any loads on the handlebars,

swingarm or front mudguard.

- Exceedingly voluminous loads, or anything that protrudes too much from the

limits of the vehicle, may cause crashes and therefore injury and damage to

animals or things and compromise the

stability of the vehicle, with dangerous

5use and maintenance manual

consequences.

-

It is forbidden to transport any load that

protrudes exceedingly or that covers

the acoustic and visual signalling devices.

-

Overloading the vehicle compromises

its stability and manoeuvrability.

Fuel

DANGER

Fuel is highly ammable, harmful for the

health and dangerous for the environment.

DANGER

Do never use your mouth to pump fuel

from the tank using tubes or any other

means.

- Whenllingup thetank,never usefree

ames,do notsmoke,andkeeptheen-

gine off.

Avoid inhaling fuel fumes and keep the

fuel from coming into contact with eyes

or skin.

If any fuel comes into contact with your

clothes, change them immediately.

WARNING

If you feel ill due to inhaling fuel fumes,

stay outdoors and seek medical help. If

fuel comes into contact with your eyes,

rinse abundantly with water. If it comes

6 use and maintenance manual

into contact with your skin, wash abundantly with water and soap.

In the event of fuel ingestion, seek

medical help immediately.

DANGER

Be careful not to pour fuel over the en-

gine or the exhaust pipe; re hazard. If

this happens, wash and rinse the area

involved.

DANGER

KEEP AWAY FROM THE REACH OF

CHILDREN.

DO NOT DISPOSE OF ENGINE OIL IN

THE ENVIRONMENT.

- Neverllupthetanktothetop;stopat

the maximum level permitted, indicated in the relative paragraph “Refuel-

ling”.

Engine oil

DANGER

Engine oil is highly ammable, harmful

for the health and dangerous for the environment.

- During maintenance operations, always

wear latex gloves to protect your hands.

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

WARNING

If the oil comes into contact with your

eyes, rinse abundantly with water. If it

comes into contact with your skin, wash

abundantly with water and soap.

In the event of engine oil ingestion, seek

medical help immediately.

DANGER

KEEP AWAY FROM THE REACH OF

CHILDREN.

DO NOT DISPOSE OF ENGINE OIL IN

THE ENVIRONMENT.

-

Used oil must be collected in a suitable

container and taken to a recycling centre.

Brake uid

DANGER

Brake uid is highly ammable, harmful

for the health and dangerous for the environment.

-

During maintenance operations, always wear latex gloves to protect your

hands.

WARNING

If brake uid comes into contact with

your eyes, rinse abundantly with water.

If it comes into contact with your skin,

wash abundantly with water and soap.

In the event of brake uid ingestion,

seek medical help immediately.

Cooling uid

DANGER

Cooling uid is highly ammable, harmful for the health and dangerous for the

environment.

- When lling up or replacing cooling u-

id,neverusefreeames,donotsmoke,

and keep the engine off.

Avoidinhalingcoolinguidandkeepthe

fuel from coming into contact with eyes

or skin.

If any cooling uid comes into contact

with your clothes, change them immediately.

WARNING

If brake uid comes into contact with

your eyes, rinse abundantly with water.

If it comes into contact with your skin,

wash abundantly with water and soap.

In the event of brake uid ingestion,

seek medical help immediately.

DANGER

Be careful not to pour cooling uid over

the engine or the exhaust pipe; risk of

re with invisible ames. If this happens, wash and rinse the area involved.

DANGER

KEEP AWAY FROM THE REACH OF

CHILDREN.

DO NOT DISPOSE OF ENGINE OIL IN

THE ENVIRONMENT.

- Neverll uptheradiatortothetop;stop

at the maximum level permitted, indicated in the relative paragraph “Cooling

uid level check”.

Exhaust fumes

DANGER

Exhaust fumes consist of carbon monoxide, an extremely harmful substance

if inhaled.

Avoid starting the engine in closed spaces or anywhere with poor ventilation.

Failure to follow this recommendation

may result in loss of senses and even

death by asphyxia.

Battery

DANGER

The battery releases explosive gases;

keep away from sparks and free ames.

Do not smoke. When recharging the battery, make sure there is sufcient air circulation in the area.

SAFE DRIVING

This paragraph offers some suggestions for

driving/riding safely.

ACCELERATION. Accelerating and decelerating repeatedly without true need may

cause loss of vehicle control and result in

fall, with serious consequences for yourself,

for others, and for the vehicle.

BRAKING. To reduce speed in a uniform,

optimal manner:

- Decelerate and always use both brakes,

suitably dosing the amount of force applied on the brake levers;

- Avoid close braking whenever possible.

Using only one of the brakes:

- Reduces braking force;

- Risks locking the braking wheel;

- Contributes to loss of adherence and to

the possibility of falling, with serious consequences for themselves and for others, as well as for the vehicle.

BRAKING IN ASCENT. Decelerate completely and use both brakes to keep the vehicle in place.

Using motion force (using the accelerator)

to keep the vehicle in place causes anomalous overheating of the engine and of the

clutch.

Keeping the vehicle in place using only

physical strength may cause loss of balance and fall, with serious consequences

for yourself, for others and for the vehicle.

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

7use and maintenance manual

FACING AND RIDING A

CURVE. Do not ride into a curve at high

speed.

Donotunderestimatethedifcultyinvolved

in negotiating a curve; slow down before

facing it.

When you see a curve up ahead, reduce

your speed by decelerating and then braking. Negotiate the curve at constant speed

or at moderate acceleration, being careful

not to lose adherence with the terrain or

control of the vehicle. If it is necessary to

use the brakes, do it with moderation and

attention.

NEGOTIATING DESCENTS: Never ride

the vehicle with the engine off in descents.

Using only the brakes when riding down a

slope causes overheat in the friction material (brake linings or shoes) and consequently reduces brake effectiveness.

Combine the use of brakes and the compression of engine power (scaling the shifts

correctly).

DRIVING WHEN VISIBILITY IS POOR. It is

obviously not advisable to drive/ride when

visibility is poor (due to rain, fog, mist etc);

if possible, it is always better to stop and

wait until visibility conditions improve before

resuming your trip.

DRIVING/RIDING WHEN ROAD ADHERENCE IS POOR.

Whenever possible, avoid driving/riding

in such conditions (snow, ice, mud etc). If

necessary, proceed at moderate speed and

avoid sudden manoeuvres; always brake

with caution so as to avoid losing control of

the vehicle.

OBSTACLES AND TRAPS ON THE

ROAD.

Disconnected roads, manholes, sudden

depressions, bumps, rail tracks, road signs

painted over, metal slabs belonging to building sites along the road, may all be slippery

or otherwise jeopardise, even if only temporarily, vehicle stability, causing falls with serious consequences for yourself, for others

and for the vehicle.

CHANGING LANES OR DIRECTION. Always activate the blinkers when changing

lanes or direction, and carry out the manoeuvres with regularity.

Turn off the blinkers after use.

OVERT AKE CAREFULLY Whenever overtaking another vehicle or when you are

being overtaken yourself, be particularly

attentive. Water splashes when the road

is wet and the slipstream caused by the

motion of large vehicles can cause loss of

control of the vehicle and the possibility of

falling, with serious consequences for yourself, for others and for the vehicle.

WARNING

Always follow the recommended indications when driving/riding.

PARKING

DANGER

Accidentally falling from the vehicle can

cause:

- Fuel leaking from the tank, resulting

in re hazard;

- Cooling uid leaks;

- Engine oil leaks;

- Damages to people, things and the vehicle itself.

To avoid accidental falls with the vehicle,

choose asolid,atterrain and an area of

suitable size for the vehicle and for parking

manoeuvres.

DANGER

Make sure the terrain is not exceedingly

inclined.

Always check the motorbike for stability

after lowering it on its kickstand.

If you must park on inclined terrain, park

your motorbike facing uphill, so that its

weight will keep the kickstand in place and

prevent it from caving in.

- Do not leave the vehicle sideways on the

ground or leaning on walls, fences, handrails etc.

- The vehicle must always be parked on its

kickstand.

8 use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

DANGER

The parked vehicle, and in particular its

overheated parts, must not be a hazard

for children, people or animals. NEVER

leave the vehicle parked with the engine

running.

NOTE: The kickstand is designed to sustain

the combined weight of vehicle and luggage.

- Always use the steering lock.

WARNING

Avoid parking or lounging beneath

plants or trees.

During some seasons, certain plants and

trees drop or release residues, resin, fruits

or leaves containing substances that can

damage the vehicle (especially its body).

IDENTIFICATION

Every request made to the dealer must be

accompanied by the V.I.N. of the vehicle in

question, so that the dealer can recognise

the vehicle and meet your demands.

B

A

Engine identication

The engine number (C) is printed on the

base of the engine casing, on the left lower

side.

Vehicle identication

Each VENT vehicle comes with a vehicle

identicationnumber(V.I.N.)

This vehicle displays its V.I.N.:

- On the chassis, on the steering head on

the right side (A);

- On the SUMMARY PLATE (B), located

on the right side of the chassis, near the

steering head.

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

C

use and maintenance manual

9

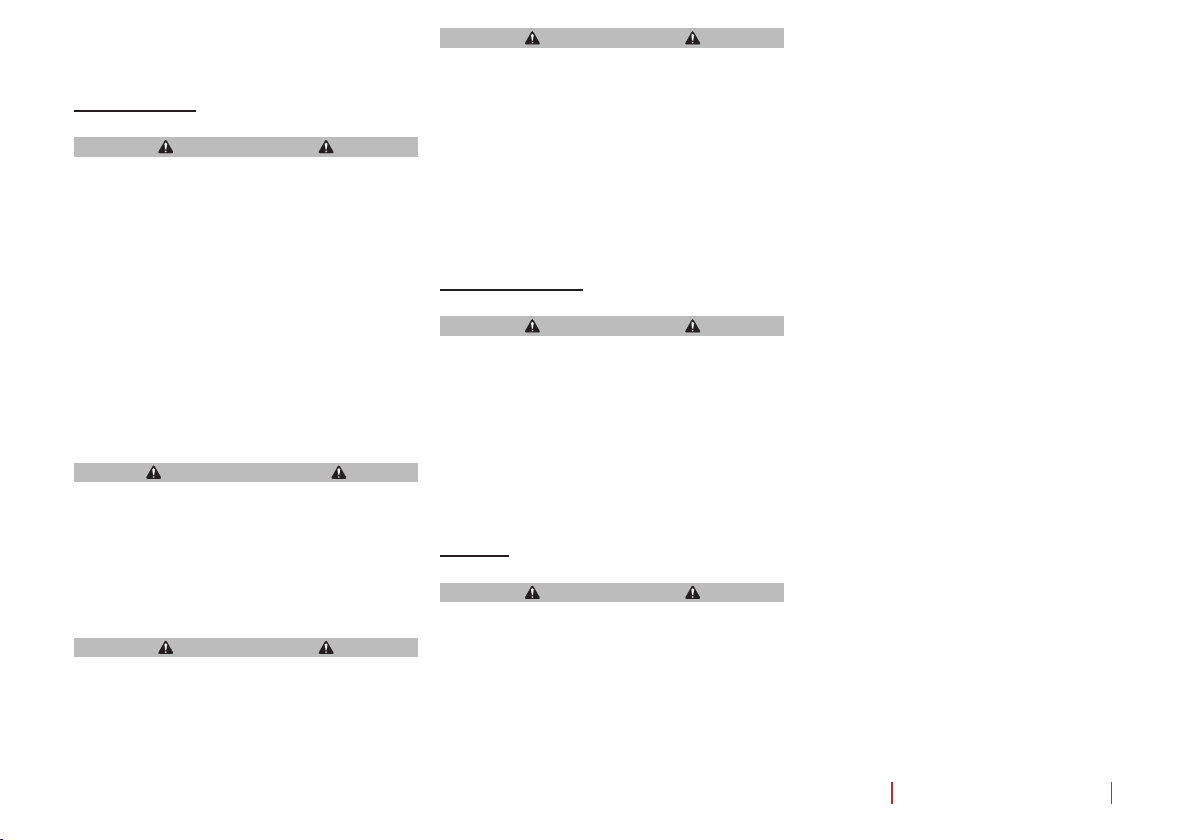

MAIN ELEMENTS

Main elements on the left side

1. Left rear view mirror.

2. Buzzer button “

3. Light switch “

4. Blinker switch “

5. Buzzer

6. Airlter

7. Cold-start device.

8. Fuse holder (main and secondary).

9. Clutch lever.

10. Fuel tap (FUEL).

11. Clutch command lever.

12. Pilot’s left foothold (with spring, always

open).

13. Side kickstand.

14. Transmission chain.

15. Battery.

16. Contactor

17. Contactor fuse

18. Left handguard

19. Front brake pincers

20. Front brake disk

21. Front headlight

22. Front blinkers

”.

”.

”

16

17

10

15

6

8

11

12

10

use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

1

9

7

18

2

4

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

3

21

20

19

22

13

5

14

use and maintenance manual

11

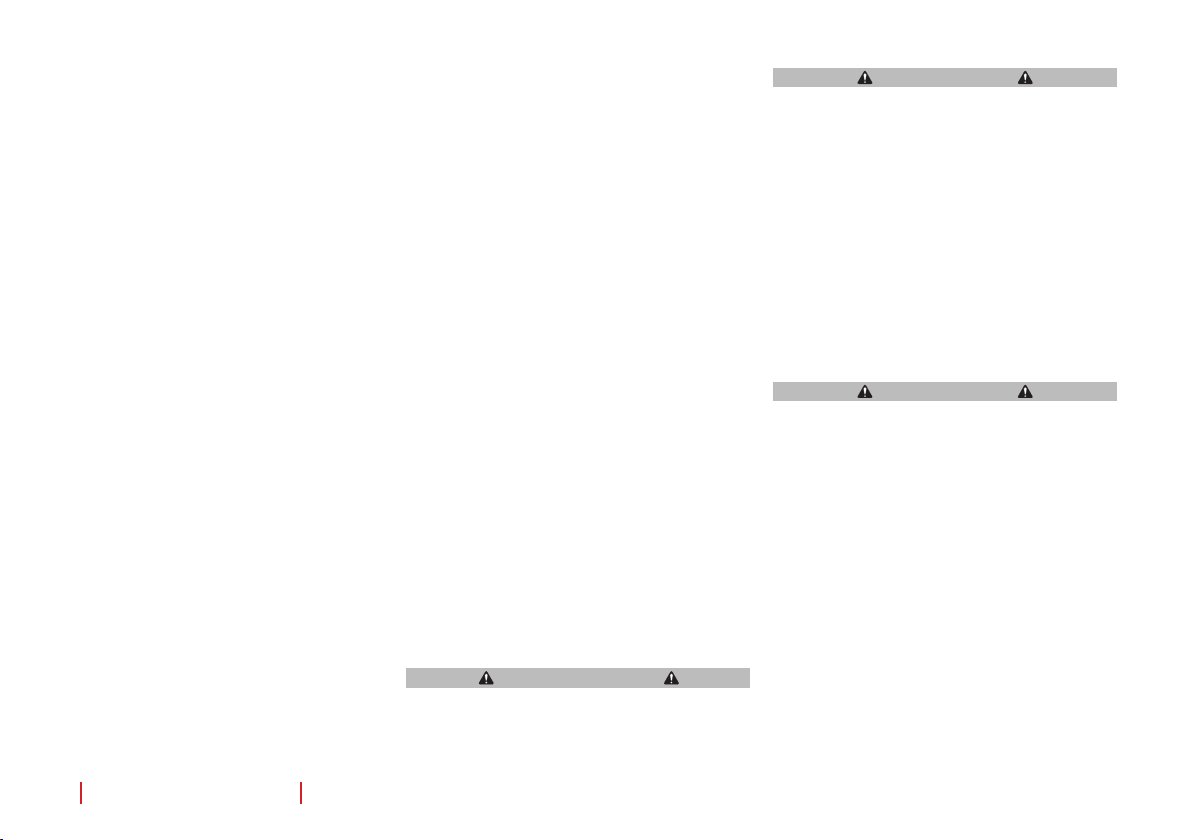

Main elements on the right side

1. Start and stop switch.

2. Right rear view mirror.

3. Fuel tank cap.

4. Fuel tank.

5. Coolinguidradiatorcap.

6. Coolinguidradiator.

7. Engine oil level rod-cap.

8. Engine oil drain plug.

9. Rear brake command lever.

10. Pilot’s right foothold (with spring,

always open).

11. Frontbrakeuidreservoir.

12. Front brake command lever.

13. Accelerator.

14. Dashboard.

15. Steering lock.

16. Spark plug.

17. Start button.

18. Rearbrakeuidreservoir.

19. Engineoilltercap.

20. Rear brake lever knob.

21. Engine idling speed knob.

22. Cooling fan.

23. Right handguard.

24. Rear brake pincers.

25. Rear brake disk.

26. Rear light/plate light.

27. Rear blinkers

14

15

5

1

6

16

12

use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

21

12

2

18

11

23

13

3

4

17

19

26

27

22

7

1020

9

8

24

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

25

use and maintenance manual

13

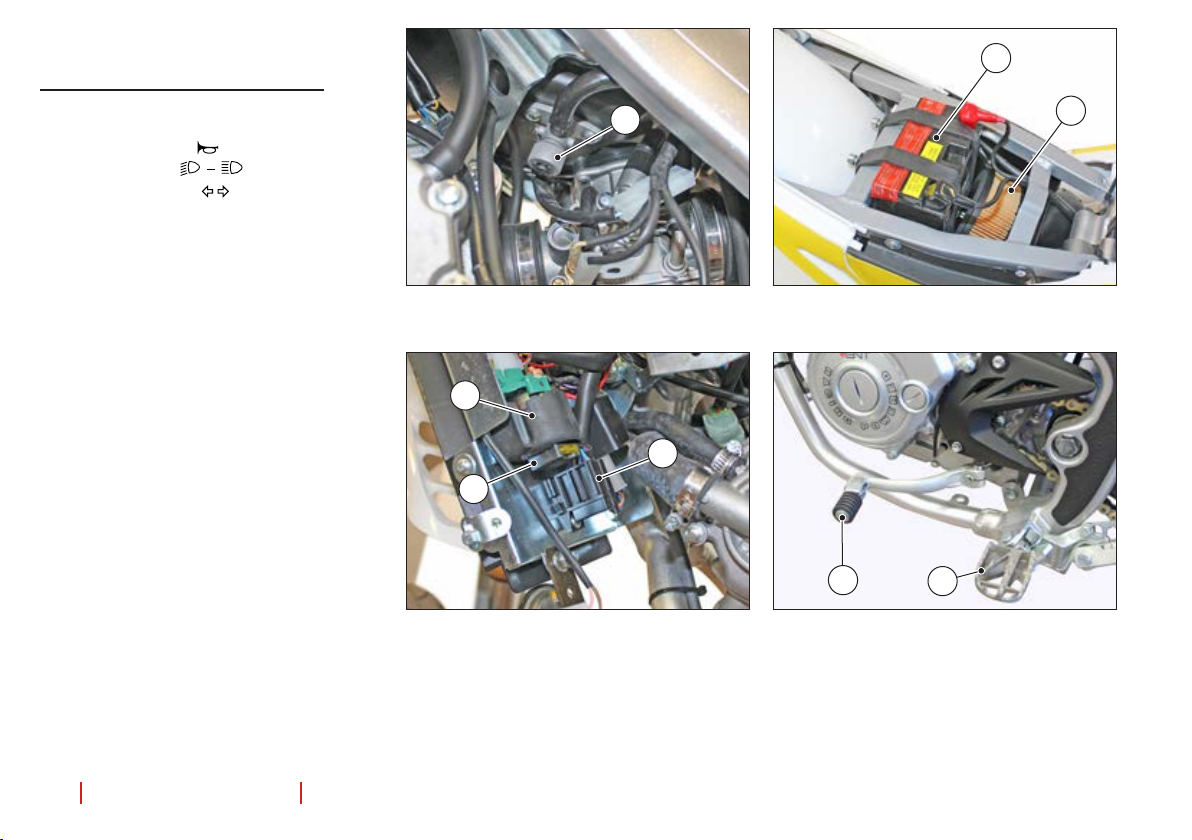

COMMANDS

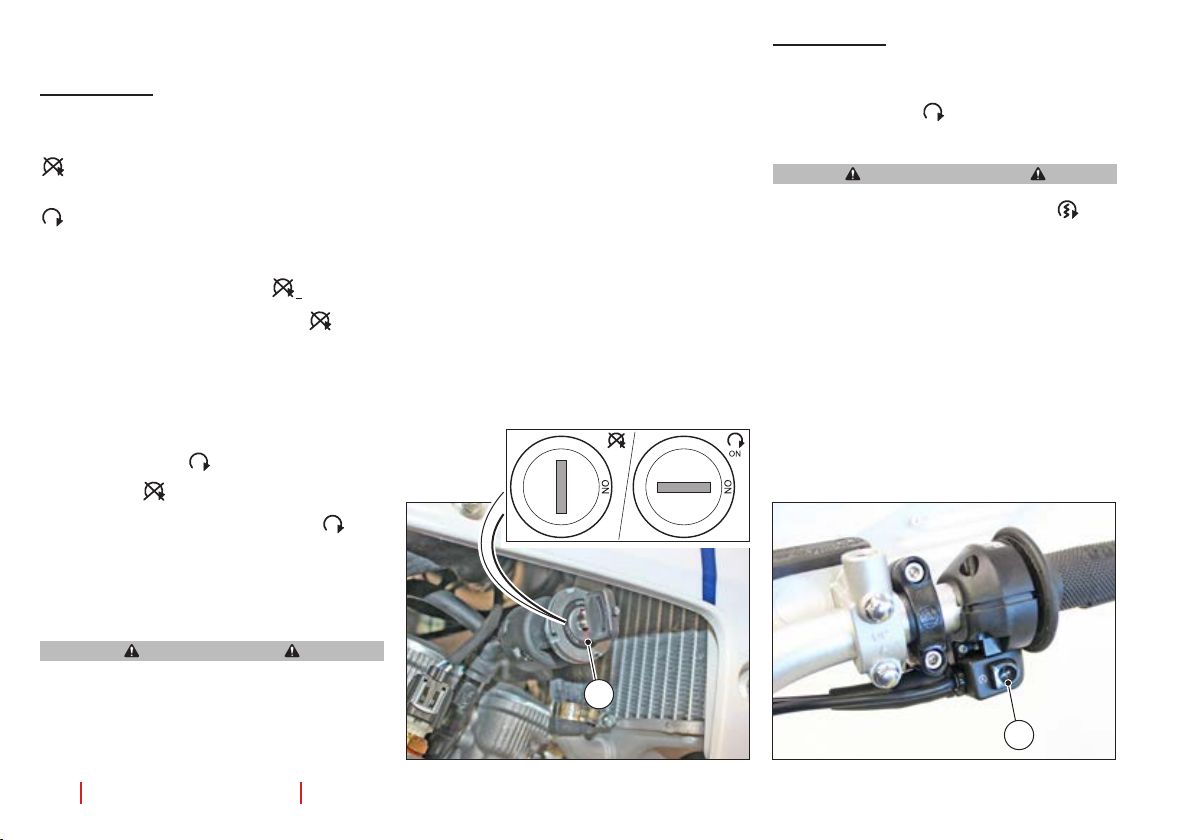

Start switch

The start switch has two positions:

“OFF” position, key removal;

“ON” position, motorbike start (key

cannot be removed);

might damage the engine and especially

cause loss of vehicle control, with possible serious consequences for people,

things and the vehicle itself.

Start button

Press the start button (1), with the start

switch at the ON “

will start.

Avoid pressing the start button “ ” (1)

when the engine is on: this might damage the starter.

” position, the engine

WARNING

- Key extraction position “

When the key is turned to the “

”

” position, the engine and the lights are turned

off and voltage is cut off from the circuits.

In this position, the key can be removed

from the switch.

- Start position “

From the “ ” OFF key removal position,

turn the key (1) clockwise to the “

”

” ON

position. The lights will light up and the

display will show that the circuits are live.

It is now possible to start the motorcycle.

DANGER

Do not tamper with the engine on/off

key (1) while the engine is running. This

would temporarily stop the engine and

then restart it when the key is used. This

14

use and maintenance manual

OFF OFF

OFF

1

For the engine start procedure, see the paragraph on “Starting the engine”.

1

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

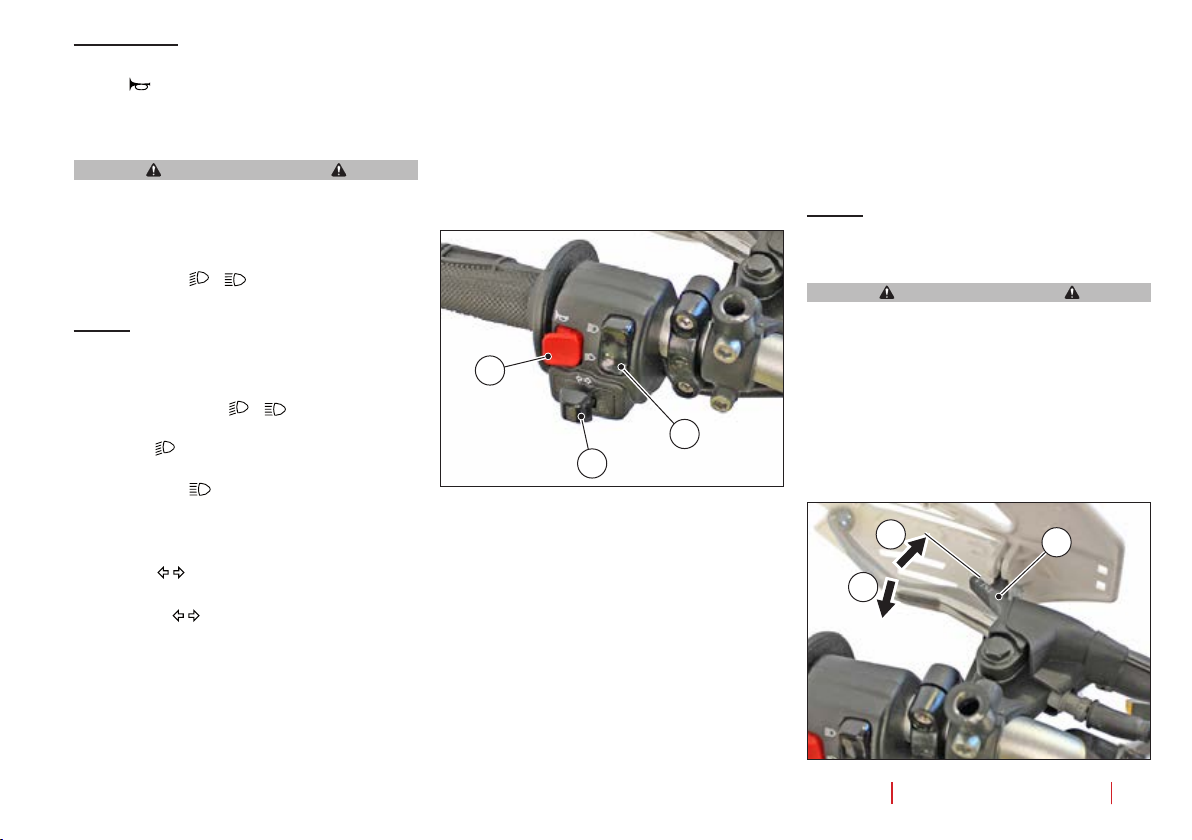

Left switch

Honk “ ”

Press the button (1) to honk.

WARNING

The use of the honk must be limited by

the laws of the road and to specic prohibitions.

Light switch “

NOTE: When the light switch is in “ON”

position, the passing and position lamp is

always switched on.

- The light switch “ - ” (2) has two positions.

In the “

are turned on.

In position “

lamp is switched on and the relative indicator lights up on the dashboard.

Blinkers “

The blinker “ ” (3) has three positions, re-

turning to the centre position.

- When moved to the right and released,

it turns on the right blinker. Its relative

warning light on the dashboard will turn

on;

- ”

”, position, the dipped beams

”, the driving and position

”

- When moved to the left and released,

it turns on the left blinker. Its relative

warning light on the dashboard will turn

on;

To turn off the blinker, press the lever (3)

once it is back in its central position.

1

2

3

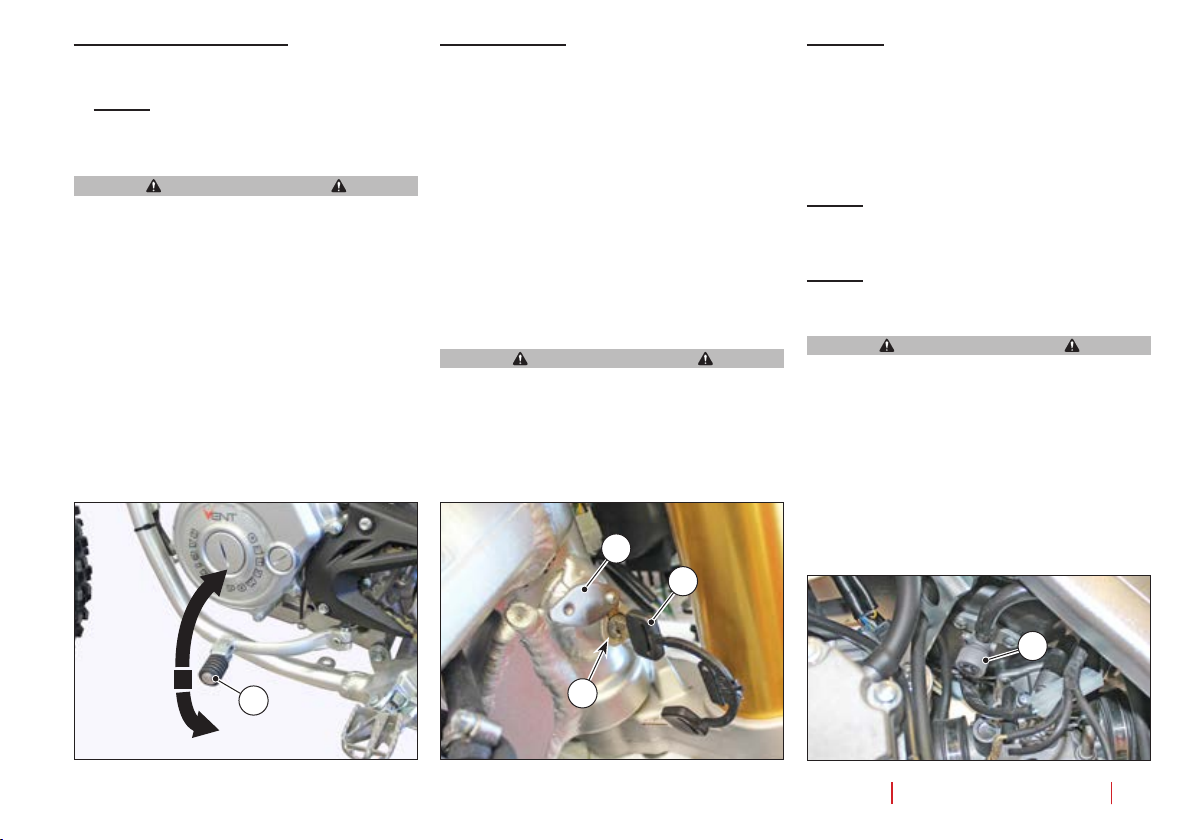

Cold-start device

This vehicle is equipped with a cold-start

device commanded by a lever (1).

- To activate the cold-start device, turn the

lever (1) counter-clockwise (B) and keep

it in position.

- After starting the vehicle, wait a few seconds until the engine’s regime of rotations per minute is settled (this depends

on the room temperature). Turn off the

cold-start device by releasing the lever

and making sure it returns to the “A” position.

NOTE: Prior to starting the engine, make

sure the lever (1) is completely rotated

clockwise (A).

WARNING

ONLY use the cold-start device when

the engine is off and cold. NEVER use

it while the engine is running. Use the

cold-start device only when necessary.

A

1

B

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

use and maintenance manual

15

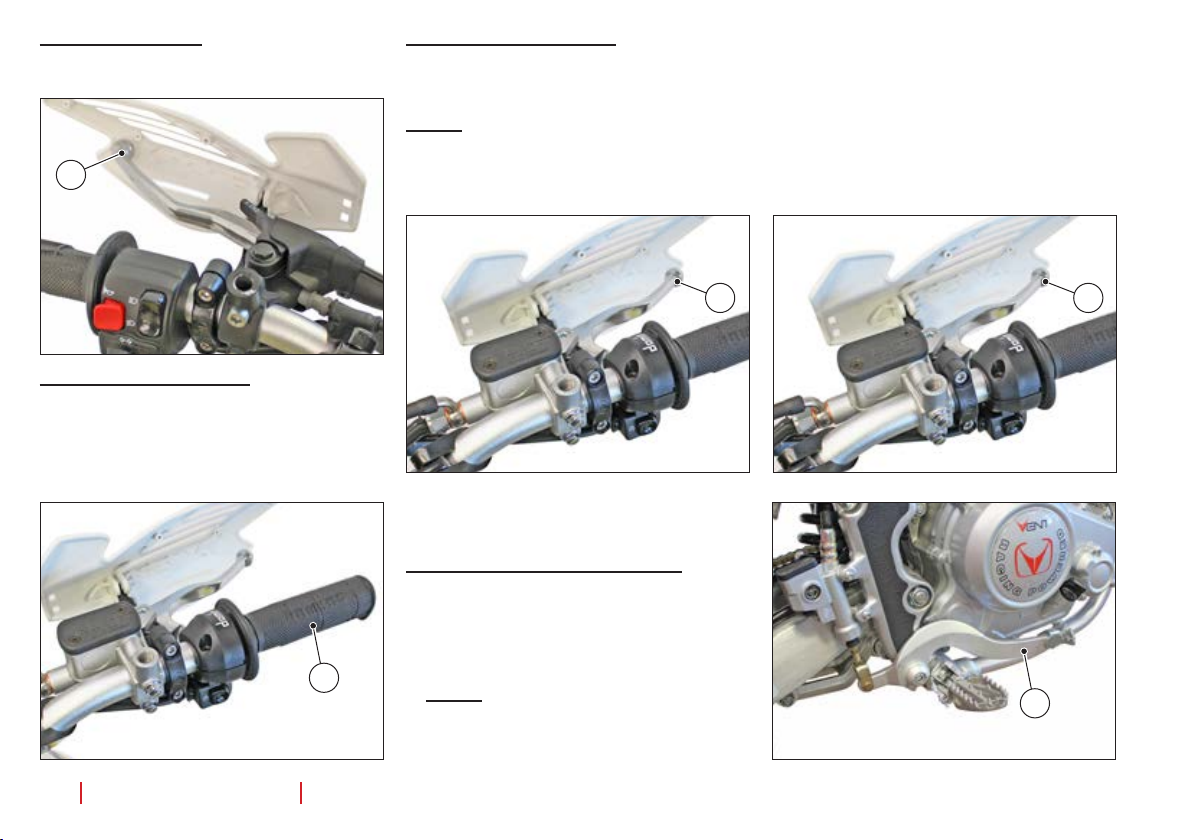

Clutch command

The command lever (1) for the clutch is located to the left of the steering wheel.

1

Accelerator command

The accelerator command (1) is located to

the right of the steering wheel.

According to how much it is turned, the

rotations per minute will increase or diminish.

1

Front brake command

The command lever (1) for the front brake

is located to the right of the steering wheel.

NOTE: The lever has a STOP switch: when

braking, it lights up the rear stop light.

1 2

Combined braking command

The motorcycle is equipped with combined

brakes.

- The command pedal (1) for the combined

braking is located on the right side of the

motorcycle.

NOTE: The pedal has a STOP switch:

when braking, it lights up the rear stop

light.

- Pull the lever (2) to brake with the front

brake;

- Press the pedal (1) for combined braking. The system will split the braking between the front and the rear brakes.

1

16

use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

Clutch command lever

This motorcycle is equipped with six gears.

- Use the lever (1) to change gears.

NOTE: After inserting a gear, release the

lever (1), which will return to its central

position.

WARNING

To change the gear, pull the gear lever

and lower the number of rpm using the

accelerator knob.

- From the N (neutral) position, press the

lever (1) downwards to insert the rst

gear.

- To change to the other gears, move the

lever (1) upwards.

- To reduce the gears, proceed in the opposite direction.

6

5

4

3

2

N

1

1

Steering lock

To lock the steering, do the following:

- Park the vehicle on its kickstand.

- Turn the handlebar completely to the left.

- Turn the protection cover (1).

- Insert the key (2) into the lock (3).

- Rotate the key (2) counter-clockwise.

- Press the key (2) inwards and turn it

clockwise.

- Remove the key.

To unlock the steering, follow the same instructions in the opposite order.

WARNING

Do not leave the key inserted after having unlocking the handlebar; when the

handlebar is turned, it may break the

key.

1

2

3

Fuel tap

This motorcycle is equipped with a screwing fuel tap (1).

- Completely closed (tightened), it closes

the feeding line of fuel to the carburettor;

- Completely open (unscrewed), it opens

the feeding line of fuel to the carburettor.

NOTE: Prior to starting the motorcycle,

make sure the tap (1) is completely open

(unscrewed).

NOTE: It is advisable to close (tighten) the

tap (1) when the motorcycle is not to be

used for a few days.

WARNING

This vehicle is NOT equipped with manual fuel reserve. The use of the fuel reserve is automatic, and is indicated by

its specic warning light on the dashboard. When the fuel reserve light on the

dashboard lights up, ll up the tank as

soon as possible.

1

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

use and maintenance manual

17

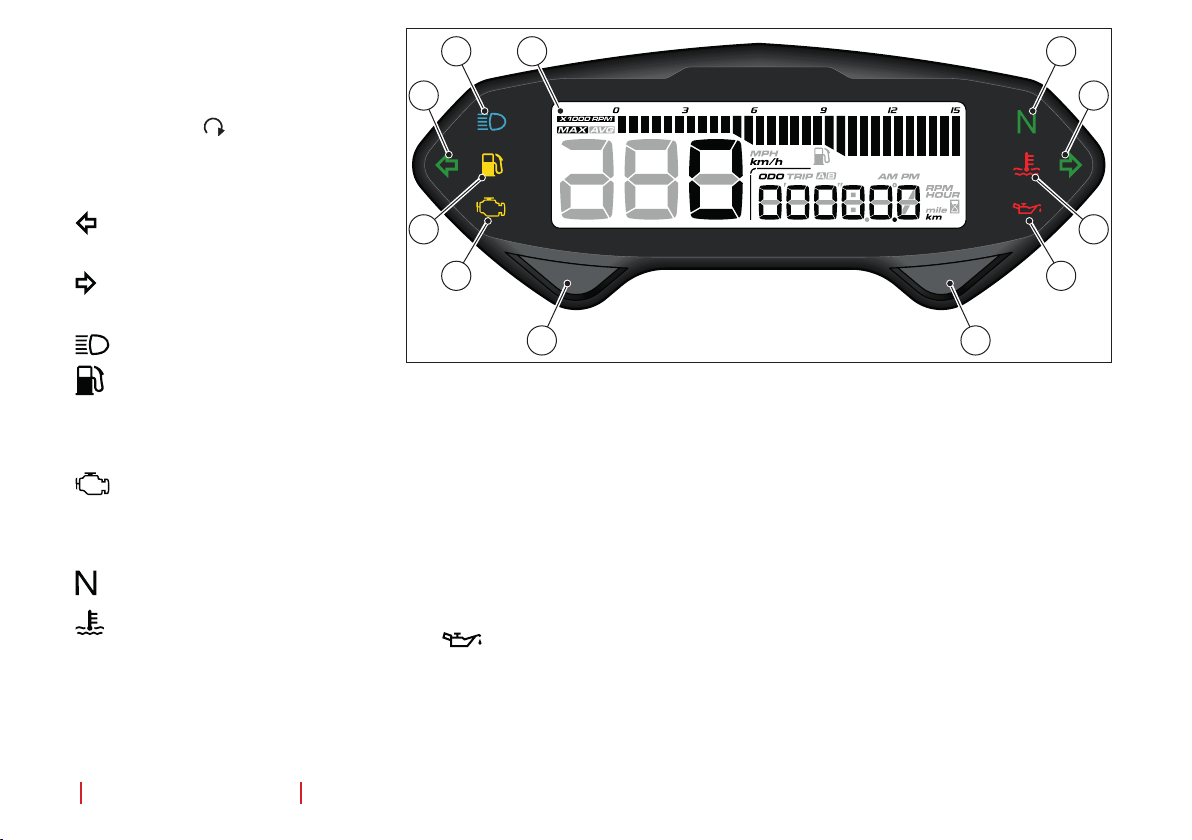

DASHBOARD

ODOMETER

The odometer is activated when the start key

is in the ON position.

Lights and buttons

1) Backlighted display

GREEN light, left blinker; it lights up

2)

when the left blinker is on.

3)

GREEN light, right blinker; it lights

up when the right blinker is on.

4)

BLUE light, high beams are on

4

1

2

5

6

10

11

7

3

8

9

5)

YELLOW light, fuel reserve.

This indicator lights up when the fuel

level is at its minimum. Drive to the

nearestfuelstationtollupthetank.

6)

YELLOW light; engine anomaly.

It lights up when an engine or exhaust

anomaly has happened. Go to the

nearest VENT Dealer.

7)

GREEN light, neutral gear.

8)

Cooling uid temperature alarm

light

18

use and maintenance manual

When the warning light is on, this

means the temperature of the cool-

ing

uid has reached its maximum

allowed temperature. Stop the vehicle, leave the engine at idle for a few

seconds, then turn it of

f. Wait until

the temperature of the cooling uid

drops then restart the engine. If the

light turns on again, do not use the

vehicle. Take it to the nearest VENT

Dealer.

9) Not used

10) Select button

Multi-function button. Pressing during

use will display, in sequence:

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

-

Start time (when the motorcycle is

turned off, the time will go back to zero)

- Battery voltage.

11)

Select button

Multi-function button. Pressing during

use will display, in sequence:

- Total km/miles

- Trip A

- Trip B

- Total hours running

- Trip A hours running

- Trip B hours running

- Maximum rotations per minute

achieved (optional)

- Maximum speed reached

- Average speed employed.

3

1

Display

1) Speedometer

Indicates the speed of the vehicle

2) Multidata display

This part of the display can show the

following information:

Odometer

- Total km/miles covered

- Maximum 99,999 km/miles; once this

maximum value has been reached,

the odometer resets itself and starts

counting from 0 again. Minimum: 1

km/mile

Partial “Trip A/B” km/mile counters

It is possible to set two partial counters,

Trip A and Trip B. Indicator of maximum

km/miles covered, maximum 9999.9

km/miles; once this maximum value has

been reached, the odometer resets itself

and starts counting from 0 again. Mini

mum: 0.1 km/mile

“Total” or partial running hours for

Trip A and Trip B

4

2

It is possible to set two partial counters,

Trip A and Trip B, and a Total hour counter.

Indicator of maximum hours covered,

maximum 9999.9 hours; once this maximum value has been reached, the odometer resets itself and starts counting from

0 again. Minimum: 0.1 hour

.

Indicator of total hours covered, maxi-

mum 99999.9 hours; once this maximum

value has been reached, the odometer

resets itself and starts counting from 0

again. Minimum: 0.1 hour

.

Maximum rpm achieved (optional,

with additional kit)

Maximum speed reached

Average speed employed

3) RPM indicator

(optional, with addition-

al kit)

4) Reserve fuel level indicator.

This indicator lights up when the fuel

level is at its minimum. Drive to the

nearestfuelstationtollupthetank.

1

Reset partial values

To reset the partial values Trip A, Trip B,

maximum rpm achieved, maximum speed

achieved, average speed covered, proceed

as follows:

- Press the “Set” (1) until the desired

screen is displayed, e.g. Trip A, then

press “Set” (1) again for 3 seconds to reset the value.

- Proceed in the same manner for all other

screens.

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

use and maintenance manual

19

INSTRUCTIONS TO USE THE

VEHICLE

General checks prior to use

Every time you are about to ride your motorcycle, go through this checklist:

- Rotate the start key to the ON position

and make sure the display lights up;

- Turn on the high beam and make sure its

warning light is on;

- Turn on the blinkers and make sure their

relative warning lights are on;

- Pull the front brake lever and press the

combined brake pedal; make sure the

rear stop light turns on;

- Check fuel and engine oil levels;

- Checkthebrakeuidlevelinitstank;

- Checkthecoolinguidlevel;

- Make sure the handlebar is working by

turning it all the way to the right and to

the left;

- Check pressure in the tyres;

- Make sure tension in the chain is adequate.

NOTE: For the inspection operations,

please consult their relative paragraphs.

Climbing on and off the vehicle

Pay attention to the instructions below.

They have the goal of keeping the pilot or

the passenger from falling from the vehicle

and/or the vehicle itself from toppling, which

would result in damages

to people, things and the vehicle itself.

- Only climb on and off the vehicle if you

have freedom of movement; your hands,

in particular, must not be holding objects,

such as helmet, gloves or glasses.

Climbing on the bike

- With the bike on the side kickstand, the

pilot must climb on the motorbike from

its left side, with both hands holding the

handlebar.

- Once the pilot is on the bike, lift the bike;

the side kickstand will automatically lift

as well.

DANGER

Make sure the side kickstand is fully lifted.

WARNING

Do not place the pilot’s or the passenger’s weight on the side kickstand.

NOTE: If you are unable to rest both your

feet on the ground on both sides of the bike,

rm your right foot on the ground and keep

the left one ready to offer support.

- The passenger must extract the rear

footrests and climb from the left side

of the bike, using the left footrest while

holding on to the pilot.

20 use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

Climbing off the bike

- First of all, the passenger must climb off the

left side of the bike, using the left footrest.

- Once on the ground, the passenger must

push the rear footrests back in.

- The pilotmustkeep his/herhands rmon

the handlebar and climb off the left side of

the motorcycle, resting his/her left foot on

the ground and lifting his/her right leg.

- Once on the ground, lower the kickstand

and make sure the motorcycle is resting

its weight on it (for kickstand operations,

please read the “Side kickstand” chapter).

Break-in

Breaking in is crucial for the proper working

and duration of the engine.

The break-in means the rst kilometres

covered.

During break-in, it is necessary to follow

certain rules to prepare the parts of the engine and of the vehicle itself for the maximum performance to be demanded later on

(after the break-in).

toexceed andnottostressinsufciently;in

both cases the engine and parts of the vehicle might suffer.

ITINERARIES Do not strain engine, brakes

and suspensions in mountain roads.

Give preference to roads with curves and

moderate hills, where the engine, the brakes

and the suspensions can alternate periods

under stress and periods with little or no

stress at all.

SPEED Always change the speed gradually, without sudden, complete accelerations.

Complete acceleration is allowed, but DO

NOT ride for long distances with the accelerator knob fully turned (full regime).

BRAKING New brake linings. In order to be

fully operative, the friction surface of brake

linings must be broken in, so it adheres

perfectly to the disk when braking. A good

break-in requires about 200 km (125 miles)

of urban distance. During this period, go for

longer braking distances and use the brake

lever with more intensity . Avoid sudden, long

brakes.

Adjusting rear-view mirrors

DANGER

Never ride the vehicle with the rear-view

mirrors rotated incorrectly.

Before you get going, always make sure

the mirrors are in their correct position

and adjusted accordingly.

- Climb on to the vehicle, to the pilot position.

- Use the joint (1) to regulate mirror height

(2) and the joint (3) to adjust inclination.

NOTE: Make sure you, as pilot, can properly see the rear part of the road from your

sitting position.

DANGER

Always adjust the mirrors with the motorcycle standing still.

Rules for a good break-in

These rules are only suggestions to help the

rider break in the motorcycle properly. Failing to follow them may not result in immedi-

NOTE: The rst 500 km (312 miles) are the

threshold of end of break-in, but only after

the rst 1,000 km (625 miles) do the vehicle’s best performances occur.

ate damage, but can have negative effects

on the performance of the engine and of the

different parts of the vehicle.

STRESS It is important to “stress” the engine and the other parts of the vehicle in an

The 500-km break-in threshold (312 miles)

requires carrying out the maintenance

operations dened for this distance.

appropriate manner. It is also important not

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

WARNING

1

1

2

2

3

3

use and maintenance manual

21

Placing the vehicle on the side

kickstand

This vehicle is only equipped with a side

kickstand.

- Hold the left handle and place your right

hand on the posterior part of the seat;

- Push the side kickstand (1) with your

right foot until it is fully extended;

- Keep the side kickstand in its extended

position, then incline the vehicle until the

kickstand is on the ground.

WARNING

Make sure the vehicle is stable.

- The rotation of the side kickstand (1)

must be free from obstacles.

DANGER

The side kickstand automatically goes

back to its place when the vehicle is

pulled up from its parking position to its

working position.

- Once you are sitting on the bike, use your

left foot to check the side kickstand and

make sure it is completely in its resting position again.

If it is not fully back in, go through the inspec-

tions indicated in the Maintenance chapter.

Fuelling

WARNING

For the type of fuel, tank capacity and

fuel reserve, please check the “Technical information” paragraph.

- Park the vehicle on its side kickstand;

- Unscrew and remove the cap (1) of the

fuel tank.

NOTE: If you are using a funnel or anything

of the kind, make sure it is perfectly clean

before use.

- Do not ll the tank to its maximum capacity; maximum fuel level must remain

beneath the lower edge (2) of the shaft.

- Afterllingup,closethefueltankcap(1)

again.

1

22

use and maintenance manual

1

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

MAX

2

Starting the engine

- Unlock the handlebar;

- Unlock or remove any additional anti-theft device installed;

- Climb on to the vehicle, to the pilot position.

NOTE: This vehicle is equipped with auto-

matic lights.

- Make sure the light switch (1) is in the

low beam position “ ”

- Make sure the fuel tap (2) is completely

open (unscrewed).

- Insert the key (3) and turn it to the ON

position “

- Pull the clutch lever (4).

-

Place the gear lever (5) in its neutral position; the display will show this symbol: .

- Lock at least one of the wheels using its

relative command.

”

NOTE: To start the engine, the gear lever

must be in its neutral position “ “ or in a

gear, with the clutch (4) lever pulled.

- Press the start button (6) without accelerating, then release it as soon as the

engine starts running.

WARNING

Avoid pressing the start button (6) when

the engine is running: this might damage the starter.

NOTE: To avoid excessive battery con-

sumption, do not keep the start button (6)

pressed for more than 5 seconds.

If the engine does not start within this pe-

riod, wait 10 seconds then press the start

button again.

Cold-start

When the surrounding temperature is too

low(aroundorbelow0°C),itcanbedifcult

tostarttheengineatrst.

- Prepare the motorcycle as indicated previously: before starting the engine, pull

the lever (7) of the cold-start device.

- Start the engine by pressing the start button (6).

- Release the lever (7) as soon as the engine starts running.

- If the idling speed is unstable, use the

accelerator knob (8) with small and frequent rotations, to warm up the engine

and obtain a constant idling speed.

4

1

2

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

3

7

N

5

use and maintenance manual

6

8

23

Starting the engine after a long time of

inactivity

If the vehicle has remained inactive for a

long period of time, starting the engine may

not be an easy task, as the fuel feeding circuit may be partially empty.

- It may be necessary to press the start

button(1)manytimesin orderto llthe

circuit again and allow the engine to start.

Starting the engine when it is ooded

After following the complete starting proce-

dureandobservingtheengineisooded:

- Press the start button (1) for a few seconds (so the engine runs empty) with the

accelerator knob (2) fully rotated.

- Completely release the accelerator knob

(2).

- Press the start button (1) without accelerating, then release it as soon as the

engine starts running.

2

1

On your way

DANGER

If you are travelling without a passenger,

make sure the passenger’s footrests are

closed. While riding, keep your hands

rmly on to the handlebar and your feet

on the footrests.

WARNING

Make sure the “ “ light goes off once

the engine is started. If this does not

happen, do not use the vehicle: take it to

the nearest dealer instead.

NOTE:

stop to ll up your tank as soon as possible.

- With the accelerator knob (2) released

- Inserttherstgearby pushingthegear

- Release the brakes activated during en-

If the display lights up this symbol “ ”,

and the engine at its idling speed, fully

activate the clutch lever (3).

lever (4) downward.

gine start.

3

DANGER

When leaving, releasing the clutch lever

too jerkily or quickly may cause the engine to stop and the vehicle to jib.

Do not accelerate jerkily or excessively while releasing the clutch lever; this

will keep the clutch from slitting and the

front wheel from coming off the ground.

- Slowly release the clutch lever (3), simultaneously accelerating by moderately rotating the accelerator knob (2).

The vehicle will begin to move forward.

- Increase speed by gradually rotating the

accelerator knob (2), without exceeding

the maximum speed limit and the suggested rpm.

- Change gears as indicated in the paragraph on “Gear lever”.

6

5

4

3

2

N

1

4

24

use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

OFF

WARNING

Change gears one at a time; stepping up

several gears at once may cause the engine to exceed its maximum power and

to overrev.

Before and during the “scaling up” from

one gear to another, always slow down,

releasing the accelerator to avoid overrevving.

Stopping the vehicle

- Release the accelerator knob (1), gradually activate the brakes and simultaneously “scale down” the gears to reduce

the speed.

- Pull the clutch lever (2) before fully stopping the vehicle, to keep the engine from

turning off.

- Place the gear lever (3) in its neutral position.

- Release the clutch lever (2).

- During a temporary stop, keep at least

one of the brakes activated.

1

Stopping the engine

- Stop the vehicle as indicated previously.

- Rotate the key (4) to the OFF position

“

” and remove it.

- Park the vehicle on its side kickstand as

described in its relative paragraph.

2

6

5

4

3

2

N

1

3

4

MAINTENANCE

DANGER

Danger of re or toxic fumes.

Never place ammable substances

(such as fuel, cooling uid, solvents etc)

near the electric parts.

Always wear suitable garments (working overalls) and working gloves, latex

gloves, protective goggles (or mask)

when doing the necessary maintenance

operations on the vehicle.

Preliminary operations

Before starting maintenance operations:

-

Turn off the engine;

- Wait until all overheated parts of the vehicle (engine, silencer etc) are down to

room temperature;

- Make sure the place has suitable ventilation and air circulation;

- Check the maintenance area (it must

not be dusty, dirty or occupied with other

components not involved in the operations or the vehicle);

- Make sure you have all the tools and

pieces of equipment you need for the

maintenance operations you must carry

out;

- Always wear suitable garments (working overalls) and working gloves, latex

gloves, protective goggles (or mask)

when doing the necessary maintenance

operations on the vehicle;

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

use and maintenance manual

25

- Make sure you have all spare parts and

uidsyou needforthemaintenanceoperations(e.g.brakelinings,oil,brakeu-

id,coolinguid).

DANGER

Always respect the torque for each

screw.

Before intervening on the vehicle:

- Check this manual for torque values and

ndatorquewrenchtoworkwith.

DANGER

If you cannot nd one, contact a VENT

Dealer.

DANGER

Never use your mouth to hold mechanical parts or to carry out interventions of

any kind.

The vehicle is made of inedible parts,

some of which are hazardous or toxic.

Things you should know

For maintenance interventions, assistance,

technical and non-technical consultancy,

contact a VENT Dealer. They will provide

you with accurate, friendly, up-to-date service in accordance with VENT’s specic

guidelines for your vehicle.

The FIRST SHEET refers to scheduled

maintenance, for users willing to do maintenance themselves. This sheet is called:

INTERVENTIONS TO BE MADE BY A

VENT DEALER (BUT CAN ALSO BE

CARRIED OUT BY THE USER).

DANGER

VENT refuses all liability, both civil and

criminal, for damage inected to people

and things deriving from maintenance

interventions carried out by the user.

The user must inform the VENT Dealer of

the maintenance operations carried out, so

as not to have them done twice.

Users unwilling or unable to carry out maintenance operations themselves should contact a VENT Dealer.

Even when the user has carried out all

maintenance operations, VENT advises a

road test at a VENT Dealer.

The SECOND SHEET for scheduled maintenance, for the exclusive use of VENT

Dealers, is called:

INTERVENTIONS TO BE CARRIED OUT

EXCLUSIVELY BY VENT Dealers.

The maintenance operations described in

this sheet require technical and updated

knowledge,andsometimesspecicequipment, only VENT Dealers possess.

DANGER

Do not attempt to carry out and do NOT

have third parties carry out the operations indicated in this sheet, as they may

result in damage to the vehicle.

NOTE: Carrying out schedule maintenance

operations does not mean you can forgo

the general check you should always per-

form before using the vehicle.

Maintenance has been purposefully di-

vided in two specic sheets

26 use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

Scheduled maintenance sheets

FIRST SCHEDULED MAINTENANCE

SHEET

INTERVENTIONS TO BE CARRIED OUT

BY THE VENT Dealer (BUT CAN ALSO BE

CARRIED OUT BY THE USER)

Key

➀ = check.

➁ = clean.

➂ = replace.

➃ = adjust.

➄ = lubricate.

NOTE: Carry out these procedures more

frequently if the vehicle is used in rainy or

dusty places, or in irregular roads.

(*) = Every 12 months:

(**) = Each tyre replacement

(***) = First replacement after 500 Km

then after each 2000 Km.

➂.

➃.

Components

Spark plug

Clutch command/ Clutch play

Airlter

Handlebar play

Swingarm fulcrum axis play/levers

Lights system

Coolinguid

Engine oil

Engineoillter

Engine idling speed

Wheel rims and spokes

Tyres

Tyre pressure

Transmission chain tension and lubrication

Swingarm protection skid and chain eye

Kickstand

Wearing of front and rear brake linings

(where present)

End of break-

in 500 km

(312 miles)

➀ ➁

Every 2,500 km

(1,560 miles) or

6 months

Every 1,000 km (625 miles): ➁ /

Every 2,500 km (1,560 miles): ➂

➀ ➃ ➀ ➃

➀ ➁ ➀ ➁ ➂

➀ ➃ ➀ ➃

➀ ➀

➀ ➀

➀ ➀

(***)

➂

➂

➂

---

➀ ➃ ➀ ➃

➀

(**)

➀

(**)

➀ ➀

➀ ➃ ➀ ➃

Every 500 km (312 mi):

➀ ➀ ➂ ➀ ➂

--- ---

---

➀ ➂

Every 5,000

km (3,120 mi)

or 12 months

---

---

---

---

---

---

➀ ➂

---

---

---

---

➀ ➂ ➃

➀

---

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

27use and maintenance manual

SECOND SCHEDULED MAINTENANCE

SHEET

INTERVENTIONS TO BE CARRIED OUT

EXCLUSIVELY BY THE VENT Dealer

Key

➀ = check.

➁ = clean.

➂ = replace.

➃ = adjust.

➄ = lubricate.

NOTE: Carry out these procedures more

frequently if the vehicle is used in rainy or

dusty places, or in irregular roads.

(*) = Every 12 months:

(**) = Each tyre replacement

➂.

➃.

Components

Rear damper

Transmission cables and commands

Wheel centring and spoke tension

Handlebar stem bearings and handlebar play

Wheel bearings

Brake disks

General functioning of the vehicle

Brakeuid

Coolinguid

Valve play

Bolt tightening

Final transmission (chain, crown, pinion)

Fuel tubes

Brake tubes

Clutch wear

End of break-

in 500 km

(312 miles)

---

Every 2,500 km

(1,560 miles) or

6 months

➀

➀ ➄ ➀ ➄

➃ ➃ ➃

➀ ➀

---

➀ ➀

➀ ➀ ➂

➀ ➀

➀

➀

--- ---

Every year:

Every 2 years:

➀ ➀

➀ ➁ ➃ ➄ ➀ ➁ ➃ ➄

---

---

---

➀

➀

➀

Every 5,000

km (3,120 mi)

or 12 months

---

---

---

---

---

➂

➂

➀ ➃

---

---

Every 4 years:

➂

Every 4 years:

➂

---

28 use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

PARTS REMOVAL

In order to carry out some of the maintenance operations/inspections, it is necessary to remove some parts of the vehicle.

Removing the seat

- Unscrew the screws (1) on the left and

right sides of the vehicle and recover the

spacers.

- Lift the seat (2) starting with its rear part

(A) and slide it towards the back of the

vehicle (B).

NOTE: When assembling the seat back,

the tabs (3) must be positioned internally to

the side panel in contact with the chassis.

- To reassemble the seat (2), place it on

the vehicle, press down on its central

part, then push it forward until it comes to

a complete stop.

NOTE: The seat must be hooked correctly

with the front (4) and central (5) hooks be-

neath the seat, with their relative seats (6)

and (7) on the vehicle.

- Screw back the screws (1) on both sides

of the vehicle.

Removing the left front conveyor

- Remove the seat as described in its relative paragraph.

- Unscrew the screws (1) and recover

1

2

A

B

3

5

4

the two spacers from the two (1a) lower

screws.

- Remove the conveyor (2).

1

2

1a

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

6

7

use and maintenance manual

29

Removing the wheels

WARNING

An inexperienced user may nd it dif-

cult and complex to disassemble and

reassemble the front wheel.

In case of need, contact a VENT Dealer.

If you do wish to do it yourself, follow

these instructions.

NOTE: When disassembling and reassembling the wheel, be careful not to damage

the brake tubes, disk and linings.

To disassemble and reassemble, wear

work gloves that ensure suitable protection

for ngers and hands.

Disassembling the front wheel

- Park the vehicle on the central support

kickstand, with the front wheel off the

ground.

- Have someone hold the vehicle by keeping the handlebar in its driving position.

-

A second operator can now loosen the

screw (1) that blocks the wheel pin and

unscrew the pin (2).

- Hold the front wheel and manually slide

out the wheel pin (2).

WARNING

Mark the spacers and keep them apart

so as not to invert their positions when

reassembling the wheel.

NOTE: Remove the wheel, carefully sliding

the disk from the brake fork.

Remove the wheel by sliding it forward.

WARNING

Do not activate the front brake after

removing the wheel, otherwise the

fork pistons can leave their seats and

cause braking uid to leak.

If this happens, contact a VENT Dealer.

Reassembling the front wheel

- Have someone hold the vehicle by

keeping the handlebar in its driving position.

- Moderately grease the outer seats of

the wheel hub.

- A second operator should position the

wheel beneath the parts of the fork, inserting the brake disk into the fork.

- Use grease on the wheel pin and slide

it completely with the spacer (3) into

the wheel hub (left side) and the spacer (4) (right side).

- Tighten the wheel pin (2).

Wheel pin torque: 80 Nm (8 kg/m).

- Remove the central kickstand.

- With the front brake lever activated,

press repeatedly on to the handlebar,

causing the swingarm to dip.

This will allow the swingarm parts to

settle appropriately.

- Park the vehicle on its kickstand.

- Tighten the screws (1) of the wheel pin

clamp (right side).

Wheel pin clamp screw torque: 10 Nm

(1.0 kgm).

DANGER

After reassembling, repeatedly activate the front brake lever and make

sure the braking system is functioning

properly.

1

2

4

3

30

use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

Disassembling the back wheel

- Park the vehicle on the central support

kickstand, with the back wheel off the

ground.

WARNING

Let the engine and the silencer to cool

down to room temperature before carrying out any of the next operations, to

avoid burns.

When disassembling and reassembling

the wheel, be careful not to damage the

speed sensor or the brake tubes, disk or

linings.

- Have someone support the vehicle.

- A second operator should unscrew the

screw nut (1), locking the wheel pin (1)

from the other side.

WARNING

Mark the spacers and keep them apart

so as not to invert their positions when

reassembling the wheel.

- Hold the rear wheel and manually slide

out the wheel pin (2).

- Remove the wheel towards the back,

carefully sliding the disk from the brake

fork.

WARNING

Do not activate the back brake after removing the wheel, otherwise the fork

pistons can leave their seats and cause

braking uid to leak.

If this happens, contact a VENT Dealer.

Reassembling the back wheel

- Moderately grease the outer seats of the

wheel hub.

- Make sure the hole (D) of the brake fork

support plate (3) is properly inserted in its

anti-rotation seat (E), on the inner part of

the right arm of the swingarm.

- Apply a small and uniform amount of

grease on the wheel pin (2).

- Insert the wheel, careful to centre the

disk on the brake fork and not to bump

into the speed sensor.

- Assemble the chain on the crown.

- Lift the wheel.

- Insert the wheel pin (2) into the bracket

(4) from the left side, assembling its relative spacer (6), and into the bracket (5)

from the left side, assembling its relative

spacers (7) and (8).

NOTE: Be careful and insert the brackets

(4) e (5) in their relative pins of the chain

adjustment screws.

Wheel pin torque: 90 Nm (9 kgm).

NOTE: Make sure tension in the chain is

adequate, if necessary.

7 8

5

1

6

2

4

D

- Lock the pin (2) and tighten the nut (1)

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

E 3

use and maintenance manual

31

Disassembling the front light holder

- Park the vehicle on its kickstand.

Removing the lamp bracket Model Baja

- Unscrew and remove the screw (1). Repeat

the operation on the other side of the vehicle.

- Remove the lamp bracket (2) “A” and lift it

“B” to unhook it from the seats (3) of the front

mudguard.

WARNING

The lamp bracket, complete with front

headlight, remains connected to the

electric cables.

DO NOT FORCE THE ELECTRIC CABLES.

- Disconnect the electric connector (4)

from the light cable.

NOTE: Place the lamp bracket on a clean,

soft cloth on a support surface, to avoid

damage to the bracket.

Removing the lamp bracket Model

Derapage

1

- Unscrew and remove the screws (1). Repeat

the operation on the other side of the vehicle.

-

Remove the lamp bracket (2) from the support.

WARNING

The lamp bracket, complete with front

headlight, remains connected to the

electric cables.

DO NOT FORCE THE ELECTRIC CABLES.

- Disconnect the electric connector from

the light cable.

B

NOTE: Place the lamp bracket on a clean,

soft cloth on a support surface, to avoid

A

damage to the bracket.

- Re-mount everything, proceeding in the

opposite order to disassembly.

2

- Re-mount everything, proceeding in the

opposite order to disassembly.

32

use and maintenance manual

1

4

2

3

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

MIN

CHECKS

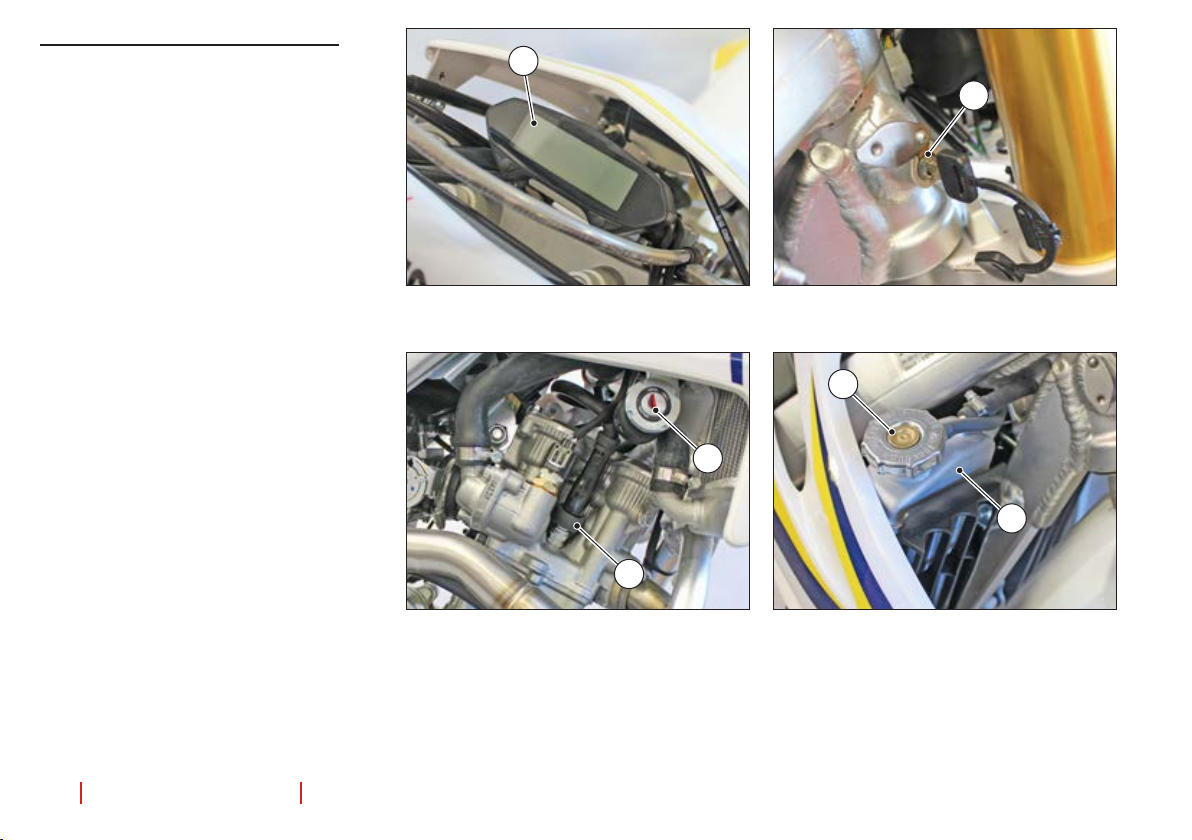

Engine oil level check

NOTE: The engine must be warmed up; the

check must be made after a trip or after 5

km (3 miles) in roads outside the city, suf-

cient to take oil temperature up.

- Park the vehicle on its kickstand.

- Stop the engine and let it cool down for at

least 10 minutes, to allow the oil to drain

into the housing and the oil itself to cool

down.

- Keep the vehicle in the upright position,

with both wheels touching the ground.

- Unscrew and remove the dipstick (1),

complete with its sealing ring (2).

WARNING

Check the sealing ring (2) for wear. Replace it if necessary.

- Use a clean cloth to clean the part that

comes into contact with the oil. Insert

the dipstick (1) completely in its seat (3),

without screwing it.

- Remove the dipstick (1) once again and

read the level visible on the stick:

MAX = maximum level

MIN = minimum level

- If the level visible on the stick is around

the MAX notch, it is correct.

WARNING

Do not ll over the MAX notch or below

the MIN notch, to avoid serious damage

to the engine.

- Ifnecessary,llup.

- Pour small amounts of oil into the oil

compartment (2) and wait about a minute before pouring some more. Do this

untiltheoilisowinguniformlywithinthe

housing.

- Checktheoillevelandcontinuellingup

if necessary.

- Screw and tighten the dipstick (1), complete with its sealing ring (2).

Dipstick (1) torque: 7 Nm (0.7 kg/m).

WARNING

Tighten the caps well and make sure no

oil is coming out.

Periodically check for oil leaks around

the housing lid seal.

NOTE: For instructions on changing the oil

and the lter, contact a VENT dealer.

1

2

3

MAX

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

use and maintenance manual

33

Brake uid level check

DANGER

Unexpected variations in the brake lever

play or elastic resistance on the brake

lever are caused by issues in the hydraulic system.

If normal inspections cannot be carried

out, of if you are in doubt regarding the

perfect functioning of the braking system, contact a VENT Dealer, which will

be ready to provide you with accurate,

friendly service.

DANGER

Be particularly sure that the brake disk

is not greasy or oily, especially after carrying out maintenance or inspections.

Make sure the brake tube is not twisted,

worn or cracked, cut or ssured in any

way.

NOTE: As the friction linings get worn, the

level of uid inside the reservoir diminishes,

to automatically compensate the wearing.

MIN = minimum level (Half of the inspec-

tion hatch)

- IftheuidisnotatorabovetheMINlevel

and the brake linings are not yet to be

replaced,llupthereservoir.

DANGER

For brake uid top-up, contact a VENT

dealer.

Rear brake uid level check

- Have someone hold the vehicle in its up-

rightposition, sothattheuidcontained

in the reservoir (1) is parallel with the

edge of the reservoir.

- Make sure the level contained in the reservoir is above the MIN notch.

MIN = minimum level (Half of the inspec-

tion hatch)

- IftheuidisnotatorabovetheMINlevel

and the brake linings are not yet to be

replaced,llupthereservoir.

DANGER

For brake uid top-up, contact a VENT

dealer.

1

Front brake uid level check

- Park the vehicle on its kickstand.

- Rotate the vehicle completely to the right,

sothattheuidcontainedinthereservoir

(1) is parallel with the edge of the reservoir.

- Make sure the level contained in the reservoir is above the MIN notch.

34

use and maintenance manual

1

MIN

MIN

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

ficacia frenante, la sicurezza e l’integrità

del disco sarebbero così compromesse.

Se lo spessore del materiale d’attrito (A)

[anche di una sola pastiglia anteri ore o po-

steriore] è ridotto sino al v alore di circa 1,5

mm (oppure se anche uno solo degli indi-

catori di usura non è più visibile):

Per la pinza freno anteriore. Fare sosti-

tuire entrambe le pastiglie della pinza

freno anteriore.

Per la pinza freno posteriore. Fare so-

stituire entrambe le pastiglie della pinza

Se utilizzato un imbuto o altro accesso-

rio, assicurarsi sia pulito.

Rabboccare con liquido refrigerante sino

a raggiungere il “livello di pieno”. (*1)

Se utilizzato un imbuto o altro accesso-

ficacia frenante, la sicurezza e l’integrità

del disco sarebbero così compromesse.

Se lo spessore del materiale d’attrito (A)

[anche di una sola pastiglia anteri ore o po-

steriore] è ridotto sino al v alore di circa 1,5

mm (oppure se anche uno solo degli indi-

catori di usura non è più visibile):

Per la pinza freno anteriore. Fare sosti-

tuire entrambe le pastiglie della pinza

freno anteriore.

Per la pinza freno posteriore. Fare so-

stituire entrambe le pastiglie della pinza

Brake lining check

- Park the vehicle on its kickstand.

NOTE: The brake fork comes with two

brake linings.

Visually inspect the area between brake

fork and linings, as follows:

- From above and from the front, for the

front brake fork (1);

- From above and from the back, for the

rear brake fork (2).

WARNING

If the friction material is worn beyond

acceptable limits, the metal support of

the lining might come into contact with

the disk, resulting in a metallic noise

and the formation of sparks against

the fork. The braking effectiveness, the

safety and the integrity of the disk would

therefore be compromised.

- If the thickness of the friction material (A)

(even if considering only one lining, either front or back) drops to about 1.5 mm

(or even if only one of the wearing indicators is no longer visible), it is necessary

to replace both linings.

DANGER

If this happens, contact a VENT Dealer.

Cooling uid level check

DANGER

While the engine is warm, the cooling

uid is under pressure and at a high

temperature.

Risk of burns on the skin and damage

to clothes.

Remove the cap (1) ONLY after the engine has cooled down to room temperature.

- Switch the engine off and wait until it

cools down.

- Keep the vehicle in the upright position,

with both wheels touching the ground.

- Turn the handlebar to the left.

- Unscrew (A) (counter-clockwise) the cap

(1) until it locks into place (one-fourth of

a turn).

Wait a few seconds to allow any remain-

ing pressure to be released.

- Press the cap (1) downwards (B), unscrew it completely (C) (counter-clockwise) and remove it (D).

- Make sure the cooling uid reaches its

maximum level (2). If the level is not

reached, top it up without exceeding the

maximum level (2).

- Replace and tighten the cap (1).

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

2

1

A

2

2

B

3

3

use and maintenance manual

C

1

1

D

35

Checking the tyres

Check the status of all tyres, which must not

presentssures,abrasionsetc.Inaddition,

check the tread for wear, using the indicators on the tyres themselves.

Minimum tread height:

Baja - Baja RR = 4 mm

Derapage - Derapage RR = 2 mm

- Check the pressure while the tyres are

at room temperature, and follow the indications on the “Technical information”

paragraph.

WARNING

The front and rear tyres must be of the

same make and model. Using different

types of tyres on the same car compromises vehicle stability and manoeuvrability.

NOTE: Tyres get old even if they do not

look worn. Side cracks or deformations on

the carcass are signs of ageing; have a tyre

repairer check your tyres before using the

vehicle.

WARNING

Riding the motorbike with tyres lled

with an incorrect pressure or with worn

or deteriorated tyres may cause serious

injuries and even death after losing control of the vehicle.

36 use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

INSPECTIONS AND REGULATIONS

Side kickstand.

- Make sure the springs (1) are not damaged, worn, rusted or weakened.

The kickstand must be free to rotate.

Grease its joint (2) if necessary.

- Check the two little rubbers (3) that work

as limit switches for wear, in the case

of motorbikes equipped with passenger

footrests.

3

2

Handlebar

Check the rotation

The handlebar has bearings that allow for

minimum play, which must be inspected periodically.

- Climb on to the vehicle, to the pilot position.

- Rotate the handlebar completely to both

directions.

NOTE: Make sure the handlebar can rotate

in a uid manner, without obstacles or noises.

The handlebar must be neither too hard nor

too loose.

DANGER

If you detect any functional anomaly or

if specialised intervention is required,

contact a VENT Dealer.

Checking the play

- Park the vehicle on the central support

kickstand, with the front wheel off the

ground.

- Have someone else keep the motorbike

still on the central kickstand, while the

other operator moderately shakes the

limber in the direction of the movement

(A).

DANGER

If the play detected is evident, contact a

VENT Dealer.

- Remove the central kickstand.

1

1

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

A

use and maintenance manual

37

Swingarm

Fuel tank cap

- Park the vehicle on the central support

kickstand, with the back wheel off the

ground.

- Have someone else keep the motorbike

still on the central kickstand, while the

other operator moderately shakes the

limber sideways (transversal do the direction of the movement) (B).

DANGER

If the play detected is evident, contact a

VENT Dealer.

- Remove the central kickstand.

B

Iftheoriceonthefueltankcapisobstructed, fuel aspiration may be compromised,

which would hamper the start and the performance of your vehicle.

Periodically check the status of the fuel tank

cap.

- Park the vehicle on its kickstand.

- Unscrew and remove the fuel tank cap

(1).

- Check the status of the seal (2) on the

fuel cap.

If the seal is worn, replace the fuel cap.

DANGER

DO NOT use your mouth to check air

passage through the orice on the fuel

tank cap.

- Checktheorices(3)onthefuelcap.

Iftheoricesareobstructed,cleanthem

with compressed air.

- If cleaning is not enough, replace the fuel

tank cap.

1

3

2

38

use and maintenance manual

VENT 125 Baja + Baja RR / VENT 125 Derapage + Derapage RR

Air lter

WARNING

Do not wash or damp the ltration

element. DO NOT use woollen cloths

or any other “furry” material, to avoid

leaving residues on the air lter.

Do not use screwdrivers or any other

tools on the lter.

- Remove the battery as described in its

relative paragraph.

- Use a cloth to clean the inside of the

ltercasingbeforeremovingtheltration element, to keep dust and foreign

bodies from entering the suction collector.

- Unscrew the screw (1) as much as

necessarytoremovetheairlter.

- Remove the entire ltration element

(2), complete with screws (1).

- Remove thescrews(1) fromthelter

and recover the washer (1a).

- Holdtheairlterrmlyandhititseveral times against a clean cloth.

- If necessary, clean the air lter with

compressed air (make the air blow