MA-SE-RIO0-01-03 Manuale Rio eng rev3 Rev.3 Page 1 of 6

INSTALLATION MANUAL

SOUNDER MODELS

RIO L – RIO LS

MA-SE-RIO0-01-03 Manuale Rio eng rev3 Rev.3 Page 2 of 6

GENERAL DESCRIPTION

Sounder mod. RIO L self-powered 12 Vdc sounder with high-brightness low-consumption LED flashing unit – anti-opening and antiremoval tamper – programmable sounds and timings – alarm counting – microprocessor self-check of: recharge, battery and

speaker with corresponding negative output for anomalies – possibility to choose the sounder trigger type – input for speaker

block – permanent or momentary optical indication of alarm system ON/FF (arming/disarming) – electronic circuit protected against

polarity inversion and tropicalized by resin immersion.

External cover and sounder base are in ABS while the internal cover is made of zinc-plated steel.

The tamper devices detecting removal, sounder opening, foam and shock are to be connected in series. In case of tamper attempt, they

open the contact between the two TAMPER terminals thus triggering off the alarm.

Sounder mod. RIO LS: technical features as RIO L with double micro switch anti-foam circuit provided of anti-shock technology against hard

hits.

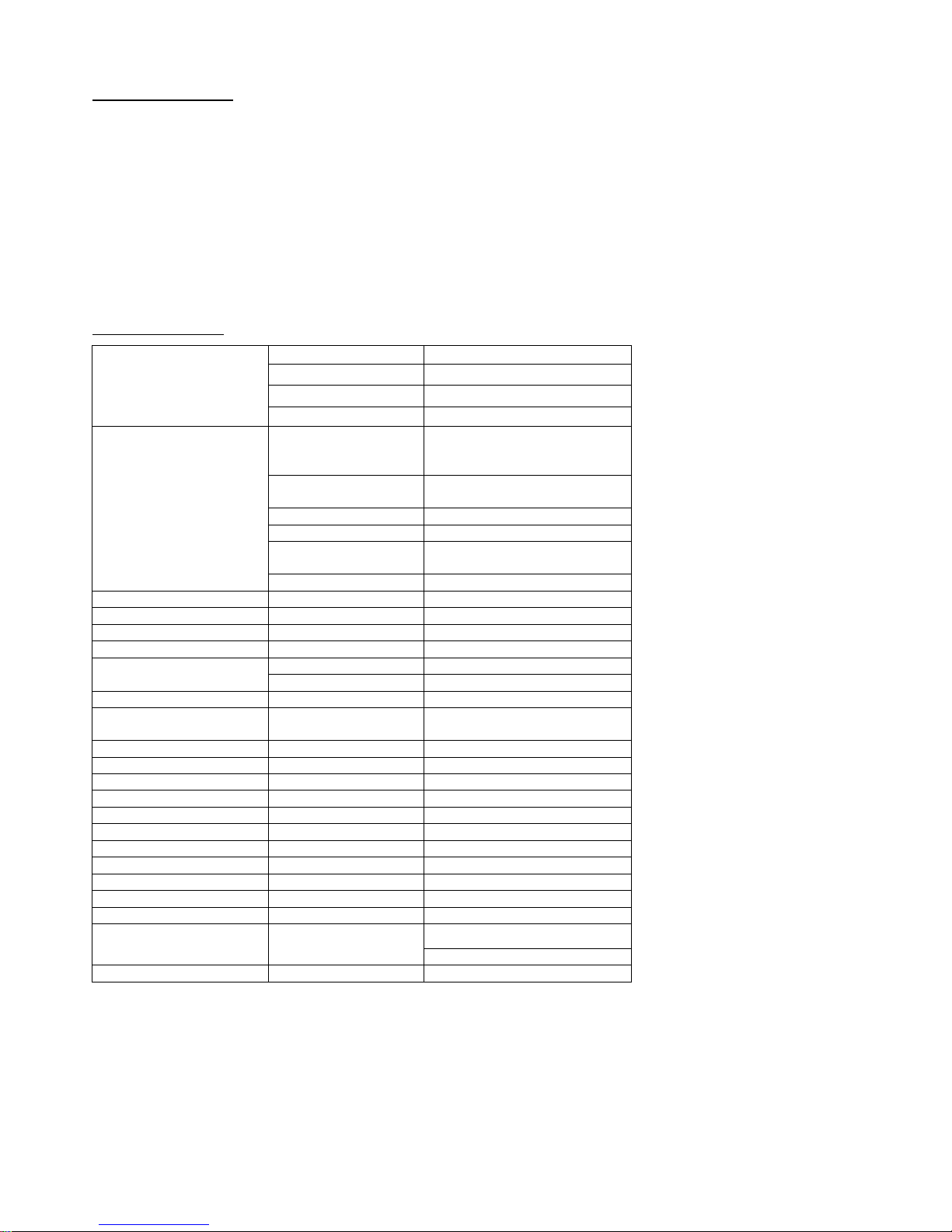

TECHNICAL FEATURES

Voltage

Nominal battery recharge

13.0 13.8 Vdc

Minimum command

4.1 Vdc

Minimum supplying

10 Vdc

Max supplying

15 Vdc

Current

Max consumption from

control panel (for battery

recharge and sound)

500mA 100 mA

Battery consumption in

alarm

1.3 A +100/-300 mA

Flashing unit consumption

90mA 10 mA

Consumption in stand-by

15mA

Consumption from control

inputs

+0.5 mA @Vc=12V; -0.3 mA @Vc=0V

Open collector

-10mA Max

Fundamental frequency

See CHART 6

Sound pressure

See DIAGRAM 1

Life of LED flashing light

1,000,000 flashes

Timings

3 minutes, settable at 8 min

Battery

Housing capacity

12V 1.2Ah or 12V 2.2 Ah max

Duration in stand-by

120 hours using 12V 2.2 Ah model

Control panel command

2 or 3 wires

Tamper switch

N.C. 0.2 A max; cover opening and

sounder removal from wall

Mechanic

Cover

Painted ABS

Base ABS

Internal cover

Zinc-plated steel

Flash cover

Polycarbonate

Temperature conditions

from –25° to +55° C

Environmental class

Class IV

IP protection

IP 44

Relative humidity condition

from 20% to 100% of RH

Size 330x220x110 (H x W x D)

Weight

1.850 gr

Standards compliance

T031:2014

EN50131-4:2010

Security

Grade 3

MA-SE-RIO0-01-03 Manuale Rio eng rev3 Rev.3 Page 3 of 6

MOUNTING:

1. Screw the sounder on the wall and check if the tamper works properly;

2. Insert the connection cables through the holes located on the lower part of the sounder base;

3. If necessary, modify the default settings by acting on the dipswitches as shown in the charts below;

4. Connect battery and power supplying to the alarm control panel;

5. Close both internal and external covers using the screws provided.

6. Battery must have UL94-HB flammability rate;

7. Power supply must be of SELV type

Attention: not to have condensation in the sounder, it is important to avoid any air flow inside the duct. To such purpose, once the

sounder is connected, seal the hole using some silicon or any other plaster. This operation prevents condensation from forming inside

the sounder; condensation mostly appears in winter and it is usually caused by warm and humid air coming out of the wall where the

sounder is installed and passing through the holes located on the sounder base.

CONNECTION SCHEMES

1. FOUR-WIRE CONNECTION

Connect 13.8 Volt supplying coming from control panel to the dedicated terminals:

-RIC negative; +RIC positive; +C positive-missing trigger; RES negative trigger for flash reset.

Note: by default, DIPSWITCH N°2 is set in OFF position, POSITIVE-MISSING TRIGGER

LEFT FLASH

RIGHT FLASH

ANTI

-

DRILLING

DIP

SWITCH

6

5

4

3

2

LED 1

TAMPER TERMINALS

LOUDSPEAKER

AND BATTERY

CONNECTOR

JUMPER 5

Negative Recharge

Positive Recharge

Positive missing trigger

Main tamper line

Micro-switch wires

MAIN

Flash reset trigger

MA-SE-RIO0-01-03 Manuale Rio eng rev3 Rev.3 Page 4 of 6

2. THREE-WIRE CONNECTION

Connect 13.8 Volt supplying coming from control panel to the dedicated terminals:

-RIC negative; +RIC positive. (+C trigger must be jumped to +RIC ); RES negative trigger for flash reset.

Note: by default, DIPSWITCH N°2 is set in OFF position, POSITIVE-MISSING TRIGGER

3. OPTICAL INDICATION OF SYSTEM STATUS (MOMENTARY OR PERMANENT ON-OFF)

If a positive is given to terminal STI (System status) all LEDs of the flashing light make 3 flashes (ON);

If the positive is removed, all LEDs light on steady for 5 seconds (OFF) and the complete sounder test is launched (remote test).

By default, DIPSWITCH N°4 is set in OFF position (MOMENTARY ON-OFF)

DIPSWITCH N°4 in ON position (MOMENTARY ON-OFF) and 1 LED keeping on flashing as long as positive tension = 0V is given to terminal STI.

4. SOUNDER TIMING

By default, timing is 3 minutes (DIPSWITCH N°1 in OFF position) and it can be modified into 8 minutes.

5. TERMINAL 5 - NEGATIVE SOUND-BLOCK INPUT

It gives a 0V signal to terminal 5 thus activating the sound interruption trigger.

6. TERMINAL OUT ANM AND FAULTS LED

The microcontroller managing the sounder is able to check if recharge, battery, loudspeaker and drivers are working properly. In case of faults, the

open collector output OUT ANM opens while the LED located on the sounder board shows the type of fault by making a certain number of flashes

followed by a short pause (please see chart here below for FAULTS LED signalisation).

The microcontroller automatically performs every 4 hours the battery current test. Moreover, other tests are performed on regular basis. Usually, if

the sounder is properly supplied, the faults output (terminal 7) remains at 0V (max consumption 50mA). In case any of the tests performed fails,

the faults output disconnects from the ground and becomes free. Moreover, the microprocessor is always under self-test and in case of failure or

malfunctioning, it gives a free output with sound interruption.

To reset the fault appeared: eliminate the fault cause. Then:

- (see scheme below): wait 10 seconds, let terminal n°4 (STI) free, take it to 12V, wait 10 seconds and let terminal n°4 free again. This procedure

resets all faults;

- all faults are anyway reset after every alarm (+C), with the exception of those concerning the battery that are reset after 4 hours from battery

restore (replacement). The sounder performs all tests again and therefore updates battery faults too.

At the first sounder supplying (13.8V or battery), anomalies automatically reset once the cause disappears; this makes the installation easier. After

the first activation of the sounder, anomalies reset through a command to STI terminal or through +C.

To launch the remote test, see scheme here above. This action launches the test that lasts 60 seconds. During the test, the sounder verifies if it is

working properly and provides signalization of any faults through the faults output (OUT ANM) and the faults LED as shown in CHART 1: FAULTS

below.

In case a fault occurs, the LEDs of the flashing light flash faster.

FREE

ELIMINATE FAULT CAUSE – 10 SEC – FREE

12V

+12V

10 SEC

Negative Recharge

Positive Recharge

Positive recharge/command +13.8 Vdc

Main tamper line

Micro-switch wires

MAIN

Flash reset trigger

MA-SE-RIO0-01-03 Manuale Rio eng rev3 Rev.3 Page 5 of 6

CHART 1: FAULTS

FAULT TYPE

LED LD1

Output OUT ANM

Speaker interruption (test performed every 10s)

1 FLASH

OPEN

No recharge current (recharge V < 12V) (test performed every 10s)

2 FLASHES

OPEN

Battery not connected (test performed every 12 hours)

3 FLASHES

OPEN

Low battery (battery V < 10.5V) (test performed every 10s)

4 FLASHES

OPEN

Damaged battery – internal resistor over 3.5 Ohm (test performed every 12 hours)

5 FLASHES

OPEN

Speaker drivers failure

6 FLASHES

OPEN

No anomaly

OFF

0V

7. CONNECTION OF MICRO SWITCH ANTI-OPENING AND ANTI-REMOVAL TAMPER

Connect the tamper line coming from control panel in series to the two wires of micro switch located on the sounder using the dedicated terminals

TAMPER 8 and 9.

8. CONNECTION OF ANTI-FOAM (LS model)

Connect the two wires of the antifoam device in series to the micro switch and the tamper line coming from control panel.

Diagram 1

CONNECTION and SETTINGS

RIO LS DIP 3 in ON position

Angolo

dB (A) @1m

15°

102.3

45°

112.2

75°

113.2

105°

111.3

135°

108.7

165°

100.8

RIO L DIP 3 in ON position

Angolo

dB (A) @1m

15°

102.0

45°

110.6

75°

112.9

105°

111.8

135°

109.1

165°

100

Chart 3: wiring

Terminals

Connections

-RIC (1)

Negative supplying 0V GND

+RIC (2)

Positive supplying +13.8V

+C (3)

Sounder control chart 5

STI (4)

ON/OFF indication of alarm system status

5

Input for sound block

OUT ANM (6)

Fault output. Open collector, 0V = no anomaly

RES (7)

Flash reset

TAMPER (8)

Self-protection N.C.

TAMPER (9)

Self-protection N.C.

Chart 2: dipswitches and jumpers

DIP 1

Alarm timing

DIP 2

Polarity of alarm input +C

DIP 3

Tone selection

DIP 4

Alarm system STI (ON/OFF) notice setting

DIP 5

Flash reset mode

DIP 6

Alarm trigger mode +C

JUMPER

5

Max daily alarms

Chart 4: alarm timing

DIP

Alarm duration

OFF (default)

3 minutes

ON

8 minutes

Chart 5: polarity of alarm input +C

DIP 2

Terminal +C

OFF (default)

Positive-missing trigger (Alarm if not connected or 0V)

ON

Negative-missing trigger (Alarm if not connected or +12V)

112.9 dB (L)

113.2 dB (LS)

MA-SE-RIO0-01-03 Manuale Rio eng rev3 Rev.3 Page 6 of 6

INSTALLATION SUGGESTIONS

In case the sounder does not work properly, check if the on-board LED flashes. If it flashes, check FAULTS CHART here above.

WARRANTY

All Venitem products are granted against factory or material defects. In order to improve design and quality of the products, Venitem

reserves the right to modify the products without prior notice. All faulty or defective products must be returned to the supplier

Venitem srl

via del lavoro, 10 – 30030 Salzano (VE)

Tel.: +39 041 5740374

Fax: +39 041 5740388

Website: www.venitem.com

E-mail: info@venitem.com

Chart 6: tone selection

DIP 3

Tone

Frequency limits (Hz)

OFF (default)

Increasing-continuous-decreasing

1,200 ÷ 1,750

ON

Increasing-decreasing (NFC 48-265) – IMQ CERTIFIED

1,400 ÷ 1,600

Chart 7: Alarm system STI (ON/OFF) signalization setting

DIP 4

Terminal 4

Flash status (ON/OFF)

OFF (default)

+12V

All LEDs flash 3 times

Not connected or 0V

All LEDs remain steady on for 4 seconds then switch off

ON

+12V

All LEDs flash 3 times and 1 LED keeps on flashing

Not connected or 0V

All LEDs remain steady on for 4 seconds then switch off

Chart 8: flash reset mode

DIP 5

Flash behaviour – Terminals +C and RES

OFF (default)

Flash activates through +C trigger and deactivates through a negative signal to RES terminal (Flash reset)

ON

Flash activates through +C trigger and deactivates through +C trigger

Chart 9: Alarm trigger mode +C

DIP 6

Terminal +C

OFF (default)

Missing trigger

ON

Giving trigger

Chart 10: Max daily alarms

JUMPER 5

Number of alarms during 24 hrs after the first alarm

CONNECTED (default)

Infinite alarms

CUT

Restriction to 4 daily alarms (24 hours) of sound activation (STI resets the counter to zero)

Certified for Belgium

Compliant to T031

standards

Loading...

Loading...