Page 1

The UBA (Ultimate Battery Analyzer) is a battery analyzer, charger, discharger and reconditioner. It’s also a data

logger, thermometer and electronic load . Wow! That’s a lot of stuff in such a small box. How do we do it? Easy. We

get the PC to do most of the work.

The first three chapters in this guide show you how to setup the UBA then takes you step by step through a complete

battery analysis. Once you’ve done your first battery analysis, you can use the online help that comes with the UBA

Software to learn more. We recommend that you read these first three chapters before you run your first battery

analysis (it won’t take that long).

Notes:

●

The latest version of software and online help is available at the private area of our web site. To get there, run

UBA Console and click on Get latest news on Vencon Website (Help menu), or go to:

http://www.vencon.com/UBA4News/B-0.96.html, or use the shortc ut on the installation CD.

●

If you need help using the software or testing batteries, don’t hesitate to call or email us. You can also email

us your battery analysis results for assistance in interpreting them.

Printed September 2007 for UBA Console version 1.0.

The UBA Let's Get Started Guide Page i

Page 2

Batteries are electro-chemical devices that have the potential to burn, explode, or emit harmful chemicals.

Please read these safety warning s:

Safety Warnings:

●

Observe battery temperature. Allow cold batteries to warm up and hot batteries to cool

before charging. Stop the battery test if the battery becomes very hot.

●

Do not attempt to charge non-rechargeable batteries such as alkaline, carbon-zinc,

or non-rechargeable lithium batteries. Attempting to charge them may result in explosion.

●

Do not short the positive and negative battery terminals together.

●

Do not exceed the battery manufacturer’s recommended charge current and voltage limits.

Doing so may damage the battery and result in venting or explosion.

●

Charge and discharge lithium batteries in a fire proof container.

●

Double check the settings before starting a battery analysis.

Page ii The UBA Let's Get Started Guide

Page 3

Table of Contents

1.Setting Up The UBA.........................................................................................................................................................1

1.1.Connecting the UBA to a Power Supply..................................................................................................................1

1.2.Connecting the UBA to a Computer........................................................................................................................2

1.3.Connecting More than One UBA to a Computer.....................................................................................................2

1.4.Extending the Serial Cable......................................................................................................................................2

1.5.Ventilation................................................................................................................................................................3

1.6.Battery Cables..........................................................................................................................................................3

2.UBA Console Installat ion instr uctions..............................................................................................................................4

2.1.Installing UBA Console............................................................................................................................................4

2.2.Starting UBA Console..............................................................................................................................................5

2.3.Initializing the UBAs.................................................................................................................................................5

2.4.Locating and Installing the UBA Calibration File(s).................................................................................................6

3.Is My Battery any Good? The Battery Analysis...............................................................................................................6

3.1.The Multitester.........................................................................................................................................................6

3.2.Setting Up the Bat tery Anal ysis...............................................................................................................................7

3.3.Starting the Battery Analysis..................................................................................................................................10

3.4.Monitoring the Battery Analysis.............................................................................................................................11

3.5.Interpreting the Results – Is My Battery Any Good?.............................................................................................11

4.Creating a Battery Analysis Routine.......................................................................................... ....................................13

4.1.“Advanced” BAR Concepts....................................................................................................................................17

4.2.BAR Actions...........................................................................................................................................................19

4.3.BARs Included with UBA Console.........................................................................................................................19

5.Advanced Topics............................................................................................................................................................20

5.1.Choosing and Setting Up a Power Supply.............................................................................................................20

5.2.Importing Results into a Spreadsheet...................................................................................................................22

5.3.Warnings................................................................................................................................................................22

5.4.Current and Power Limitations..............................................................................................................................23

Appendix A – Troubleshooting..........................................................................................................................................24

Appendix B – FAQs...........................................................................................................................................................25

Appendix C – Included Battery Analysis Routines............................................................................................................27

UBA Accessories – Optional Temperature Probes...........................................................................................................29

UBA Accessories - Channel Combiner.............................................................................................................................33

UBA5 Specifications..........................................................................................................................................................35

Two Year Limited Warranty...............................................................................................................................................35

The UBA4 Let's Get Started Guide Page iii

Page 4

Regulatory Compliance

FCC Class B Information

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential or

commercial installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one

or more of the following measures:

●

Reorient or relocate the receiving antenna.

●

Increase the separation between the equipment and receiver.

●

Connect the equipment into an outlet on a circuit different from that to which the receiver in connected.

●

Consult the dealer or an experienced radio/TV technician for help.

CE Compliance for Europe

This equipment has been verified to comply with

CISPR22/EN55022 - Class B - Limits and methods of measurements of radio disturbance characteristics of

Information Technology Equipment and

EN50082-1 - Generic Immunity Standards, Residential, Commercial and Light Industry.

The UBA Let's Get Started Guide Page v

Page 5

1. Setting Up The UBA

●

Unpack the UBA shipping box and check that you’ve received the following:

●

The UBA battery analyzer, charger, and conditioner.

●

Vencon UBA Console CD, which contains the software for the UBA.

●

A 2 metre 9 pin male to female shielded serial cable.

●

Two sets of test leads with alligator clips.

●

A printed copy of this guide.

●

A power supply (if you purchased a UBA Combo).

What you need to get started (in addition to the above):

●

A power supply (included with the UBA Combo).

●

A PC with a free serial port or a USB port and a USB to serial converter.

1.1. Connecting the UBA to a Power Supply

The UBA requires a power supply with a DC voltage from 15 to 24V (see section 5.1 “Choosing and Setting Up a

Power Supply” for more information). Connect the power supply output cable to the back of the UBA and plug the

power supply’s AC cable into a wall outlet. The battery red LEDs will flash once, the fan will spin a couple of times and

the power LED will turn on. If this doesn’t happen then check the voltage on the power cable: it should be at least 15V

with the centre pin positive.

If you use your own power supply ensure that it has a 2.1mm DC barrel plug that mates with the power input on the

back of the UBA. The UBA is reverse voltage protected, if you reverse wire the DC supply cable no damage will result,

but the UBA won't turn on. Also ensure that the power supply voltage is no more than 25V no-load, otherwise you risk

damaging the UBA.

The UBA Let's Get Started Guide Page 1

Page 6

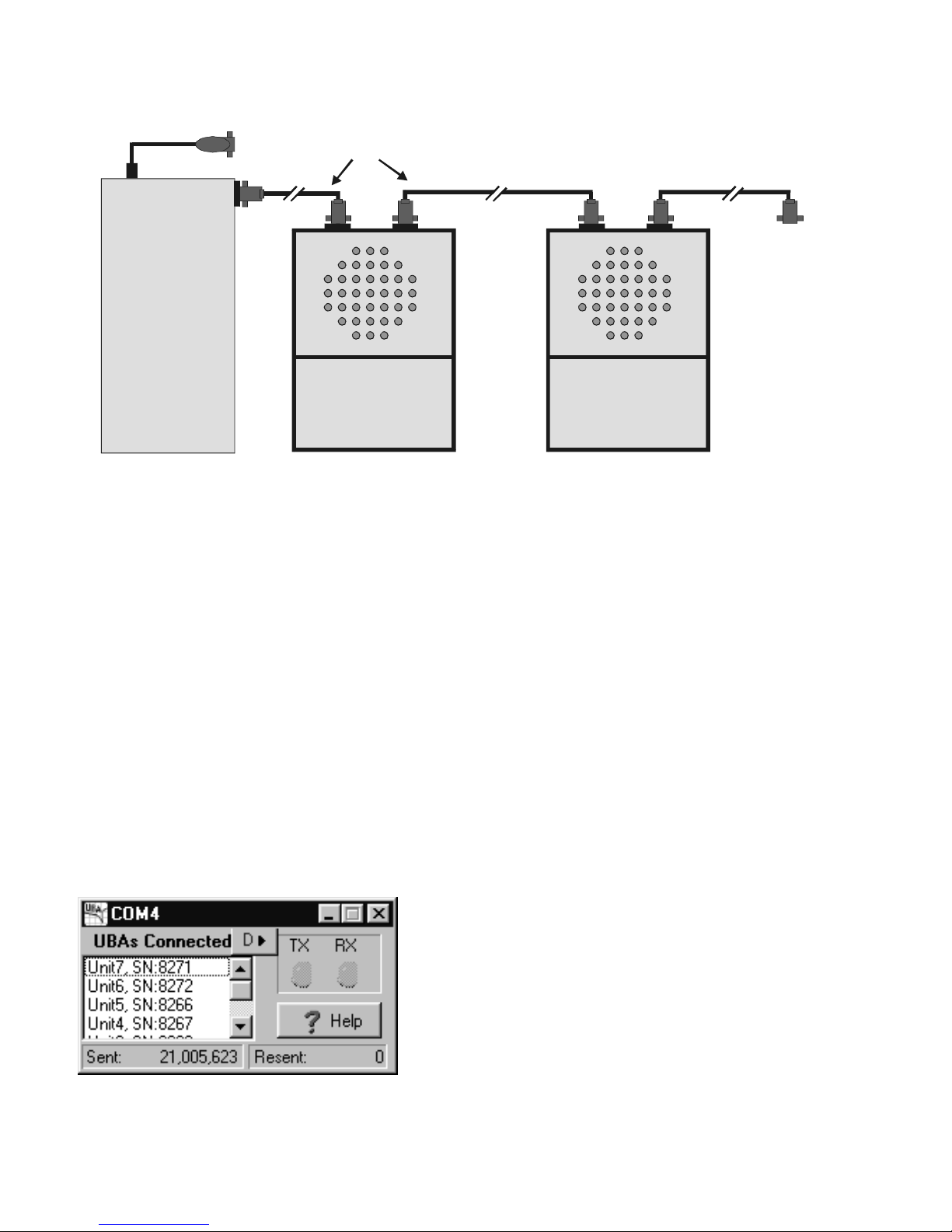

1.2. Connecting the UBA to a Computer

UBA

Vencon

To Additional

USB Converter

Serial cable

(1 per UBA)

USB

Port

Serial

Port

UBAs

PC

Vencon

UBA

First UBA

Figure 1: UBA serial port connections for one or more UBAs.

The UBA connects to any unused serial port the PC. You can use a USB port with a USB to serial port converter contact us for purchase information. Connect one end of the supplied serial cable to the UBA (the connector marked

“RS232 from Computer or other UBA”) and the other end to the PC serial port or USB converter.

Second UBA

1.3. Connecting More than One UBA to a Computer

If you are using more than one UBA, then connect the first one to the PC as described above and the second UBA to

the first UBA. No adapters or gender changers are required. Repeat this for any additional UBAs (the maximum is

253 UBAs per serial port, but performance and memory limits are reached before that). Each UBA requires its own

power supply or they can share a single power supply with enough current to power them all. You can connect the

UBAs while they are on, but you will have to re-initialize the UBA network for any new UBAs to be recognized.

1.4. Extending the Serial Cable

You can extend the UBA's serial cable with a shielded extension cable. We have successfully run the UBA with a 30m

(100ft) cable. Check for resent commands in the communication port display (accessible from the UBA Network

window by right clicking on the comm port). You really shouldn't have any, but if you do, don't worry as the UBA uses

advanced error correction so that any corrupted transmissions are resent.

Figure 2: Communication port display showing UBAs connected and the number of commands sent and resent

(commands are resent if there is a communication error). Here 21 million commands were sent without error.

This is an actual image from our burn-in station where UBAs are run for at least 12 hours.

Page 2 The UBA Let's Get Started Guide

Page 7

1.5. Ventilation

Battery

The UBA can generate up to 90 Watts of heat during a battery discharge or charge. Do not obstruct the air holes on

the top or bottom. Be careful when touching the UBA during a high current discharge or charge, as it can get quite hot

(the fan automatically turns on when the UBA gets too warm). Avoid running a high power discharge or charge when

the UBA is in a hot environment (greater than 30 degrees Celsius).

It is normal for the UBA to get get warm (some might call it hot) before the fan turns on. You can check that the fan is

functioning by watching if it turns on when power is applied to the UBA or during network initialization or you can turn it

on from the Multitester instrument (described later). If you would prefer that the fan turn on earlier, there is an option

for this in the Options... menu (under File, click on Options... and select the General tab).

1.6. Battery Cables

-

+

Vencon

UBA

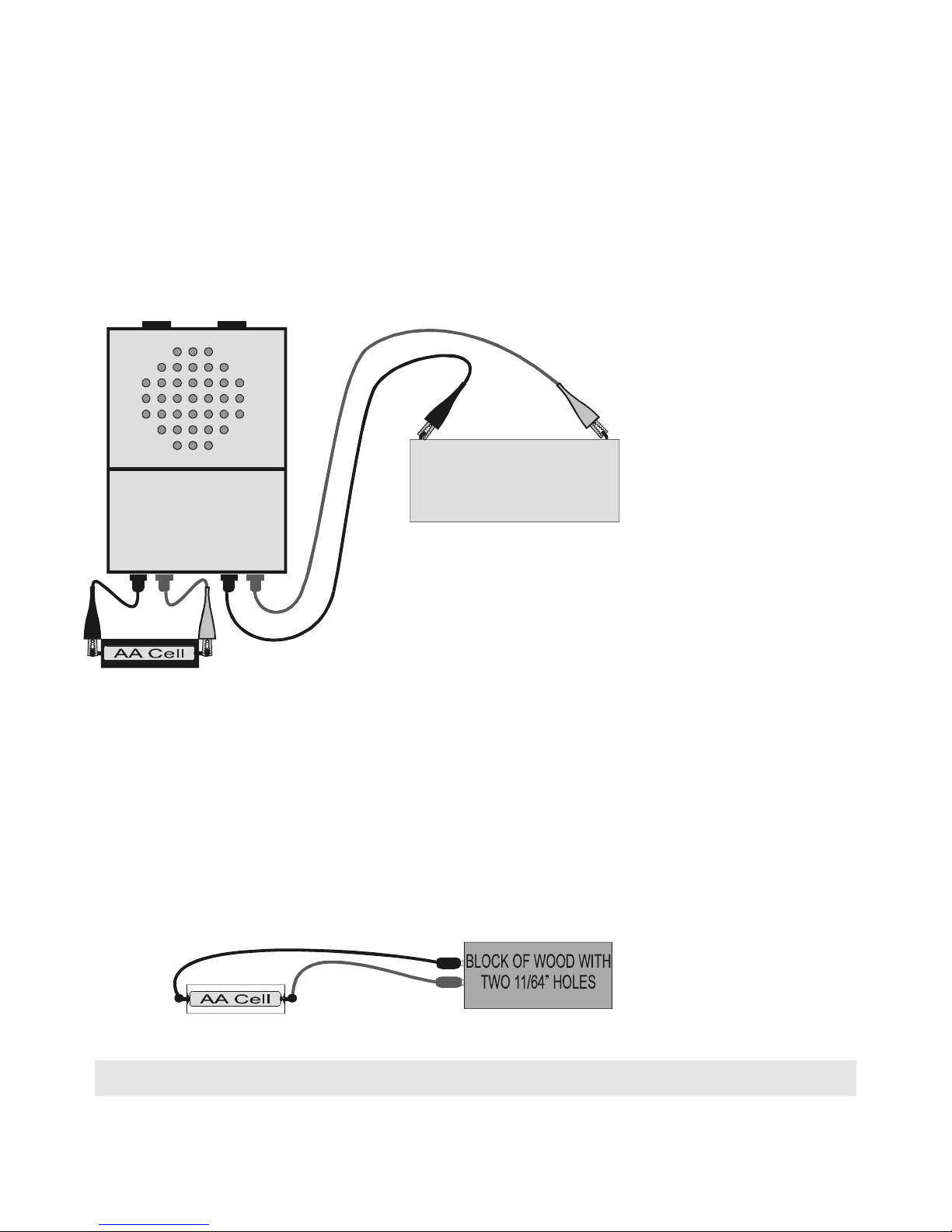

Figure 3: Connecting a battery to the UBA.

banana jacks for its battery connections and comes with two sets of battery cables with alligator clips. Additional plugs

or cables are available from us. Plug the cables into the front of the UBA and connect the red clip to the positive

terminal of the battery being tested and the black clip to the negative terminal of the battery.

NOTE: The UBA inputs are polarity protected, thus connecting the battery backwards will not damage your battery,

nor the UBA.

CAUTION: When the battery cables are connected to a battery but not plugged into the UBA, the banana plugs can

touch each other resulting in very high currents potentially causing burns or the battery might gas or explode. For this

reason, we recommend that the banana plugs be plugged into the UBA before connecting them to your battery. In our

lab banana plugs connected to a battery, when not connected to a UBA, are inserted into a piece of wood with 11/64”

(4.5mm) holes that keep the plugs safely apart.

The UBA uses standard

Figure 4: Using a block of wood to keep battery banana plugs from shorting.

Hint: If you expect to be testing cylindrical cells (like AA, AAA, C, ...) then consider using battery connectors

with magnets. Contact us for ordering information.

The UBA Let's Get Started Guide Page 3

Page 8

2. UBA Console Installation instructions

The software that runs on the PC and controls the UBA is called UBA Console. Install it on a PC running Microsoft

Windows (Win95 or later) or Linux (we have an application note on our website explaining how to do run UBA Console

under Wine).

Windows 95 and NT users: If you will be installing UBA Console on a PC with a fresh install of Windows 95

or NT then you might have to install the HTML help application and some other upgrades to your operating

system. See the troubleshooting section at the back of this guide.

2.1. Installing UBA Console

Insert the UBA CD into the PC’s CD drive. Installation should start automatically. If it doesn’t, run SETUP.EXE on the

CD. If you’re installing from a file that you downloaded from our website, then run that file.

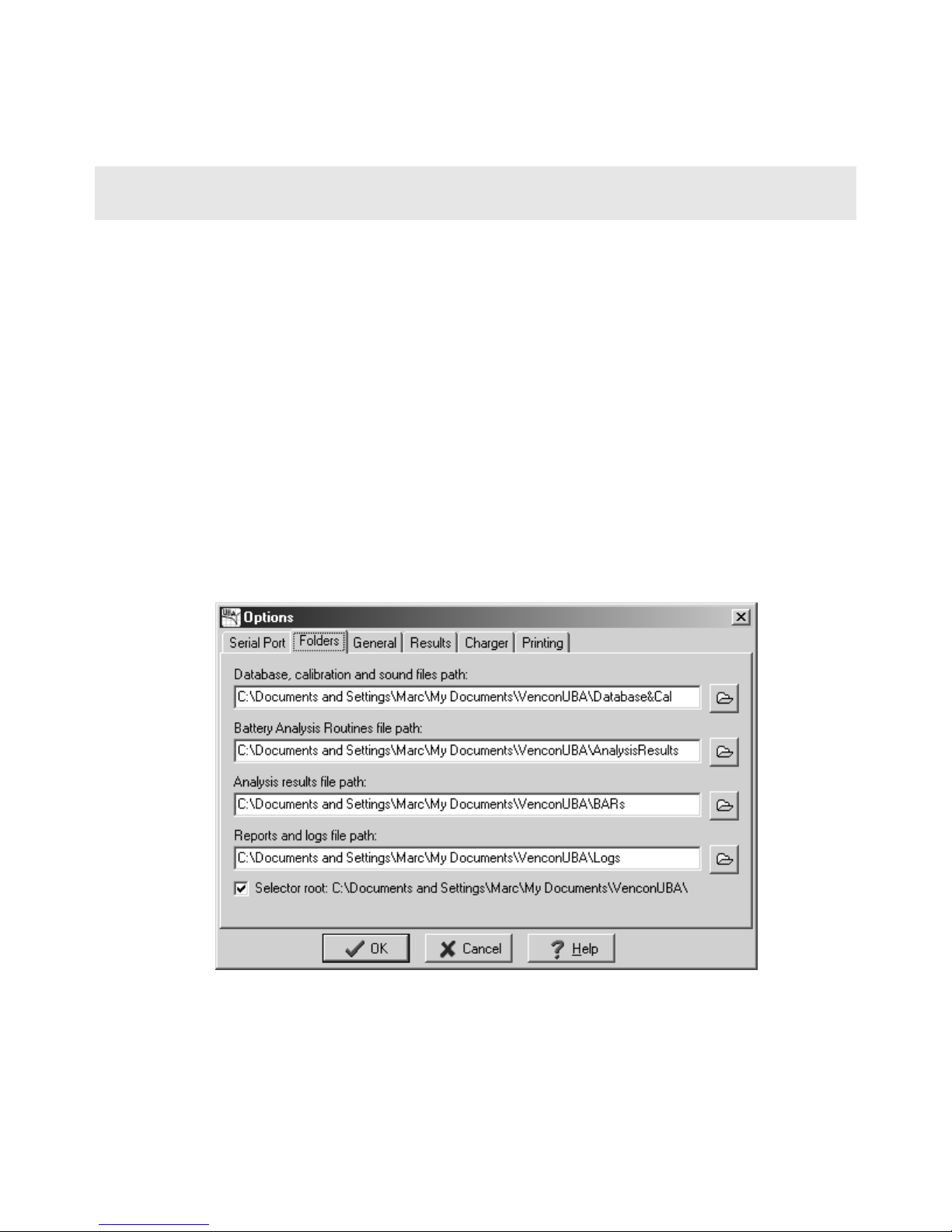

Important -- Data Location:

During the installation you will be asked where to locate the “application's database”. This folder, called VenconUBA,

is where the files containing battery analysis routines are stored as well as where the analysis results are stored. By

default it's put in the same folder as UBA Console, i.e.:

C:\Program Files\Vencon\Ve nco nUB A <- default (not recommended)

We recommend you choose a different location which is regularly backed up. For example on our PCs we put it in My

Documents:

C:\Documents and Settings\UserName\My Documents\VenconUBA <- recommended

You can change the folder location after UBA Console has been installed by moving (or dragging) the VenconUBA

folder to the new location then specifying it on the Folder tab in the Options dialog box (File menu).

Figure 5: Example folder paths.

The following four folders are created in the VenconUBA folder:

AnalysisResults – Analysis results are stored here.

BARs – Battery Analysis Routines are stored here.

Page 4 The UBA Let's Get Started Guide

Page 9

Database&Cal – Database, calibration, and sound files are stored here.

Logs – Log files are stored here.

2.2. Starting UBA Console

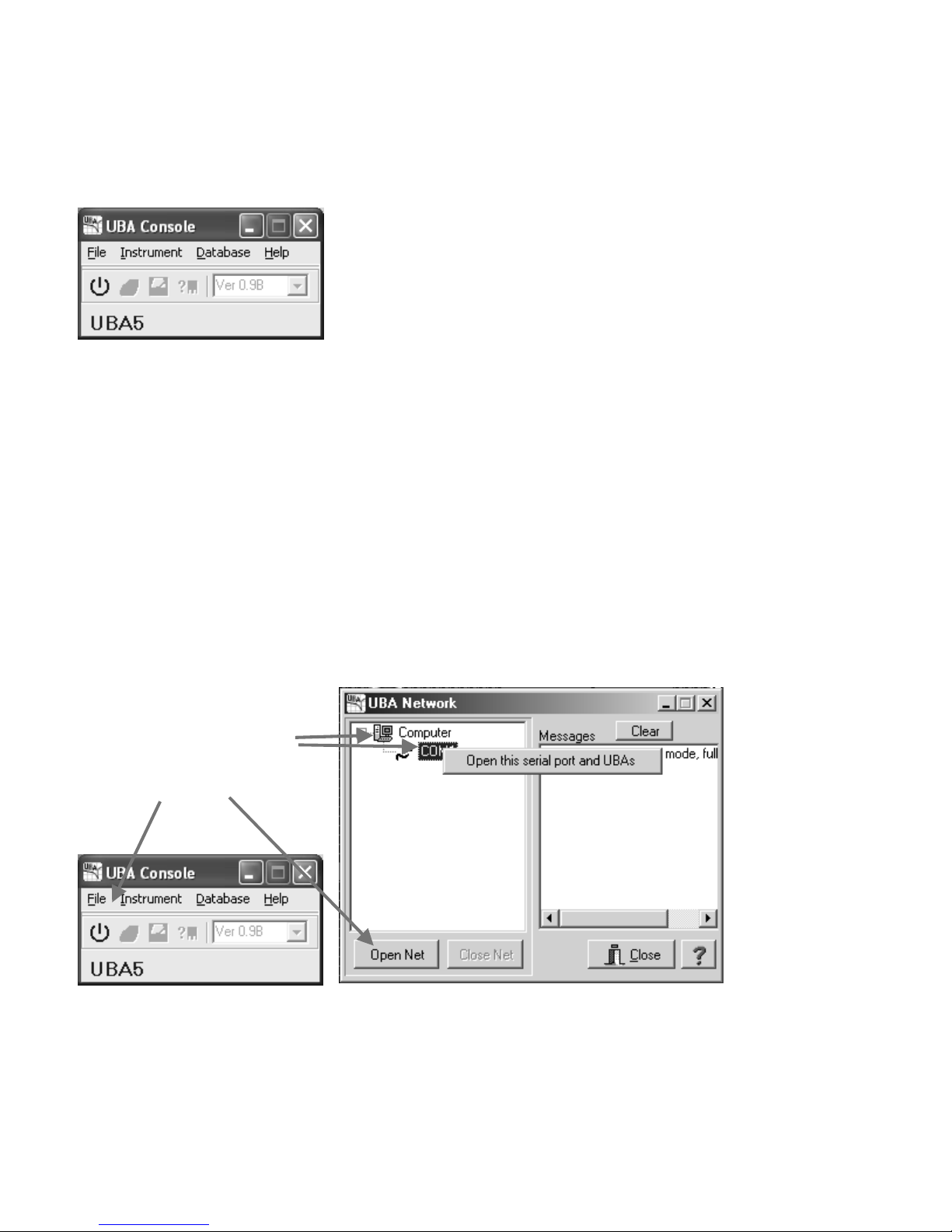

Start UBA Console (accessible from the Windows Start menu).

Figure 6: UBA Console - UBA Network not yet initialized.

If you don’t get this, see Appendix A - Troubleshooting.

Don’t be surprised if your version of UBA Console appears slightly different then this as we’re always improving the

software.

2.3. Initializing the UBAs

UBA Console is now running, but its not yet communicating with the UBA. For that to happen, you have to initialize the

UBA Network. Tell the software which comm port(s) to use on the Serial Port tab in the Options dialog box (File

menu). Only free comm ports are displayed. You can choose more then one comm port, UBA Console will check

them all for a UBA each time you initialize the UBA network.

You can initialize the UBA Network by clicking on the first icon on the main menu (the “on/off” switch) or by the other

ways shown below.

Four ways to initialize the UBA

network:

Right click here or here.

or click here or here

Figure 7: Multiple ways to initialize the UBA Network.

Either way UBA Console will try to connect to the UBA using the serial ports that you have selected. You can close the

UBA Network window by clicking on the Close button or the X (this does not close the UBA network).

The UBA Let's Get Started Guide Page 5

Page 10

2.4. Locating and Installing the UBA Calibration File(s)

Every time UBA Console initializes a UBA Network, it reads the calibration file for each UBA that it detects. If it can’t

locate the calibration file in the VenconUBA\Database&Cal folder, it will put up a Calibration file not found dialog box.

Every UBA comes with a calibration file that can be found on the installation CD or it was emailed to you. Once

located, UBA Console copies it into the VenconUBA\Database&Cal folder so that it can find it next time.

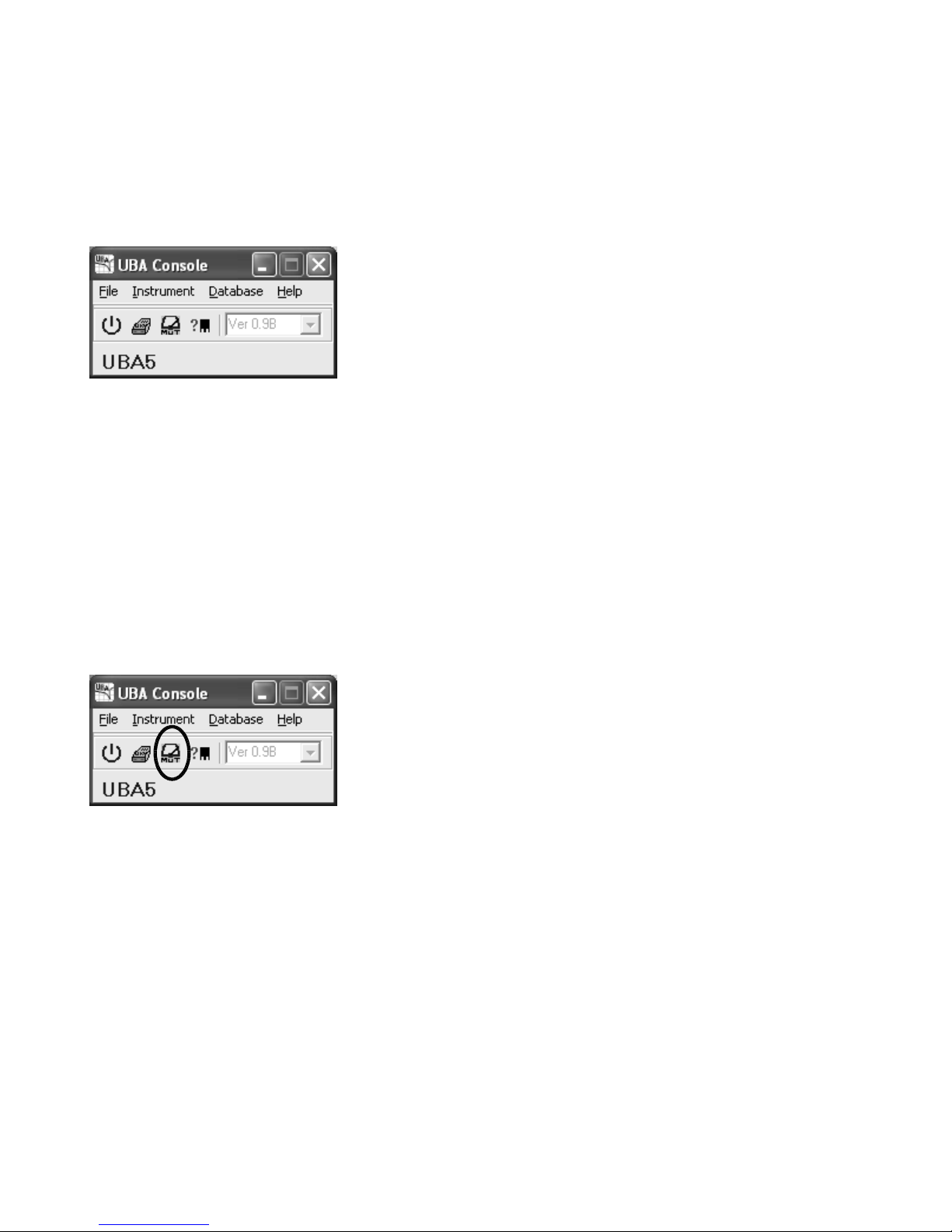

Don’t lose the UBA’s calibration file, but if you do, don’t panic. We keep a copy. If you’ve made it so far you should

see this:

Figure 8: UBA Console with the UBA network initialized (icons are enabled).

UBA Console has now established communications with the UBA(s) and you can start any instrument.

3. Is My Battery any Good? The Battery Analysis

In this chapter, we're going for a quick tour of the UBA and to run a battery analysis. Start up UBA Console and

initialize the UBA Network.

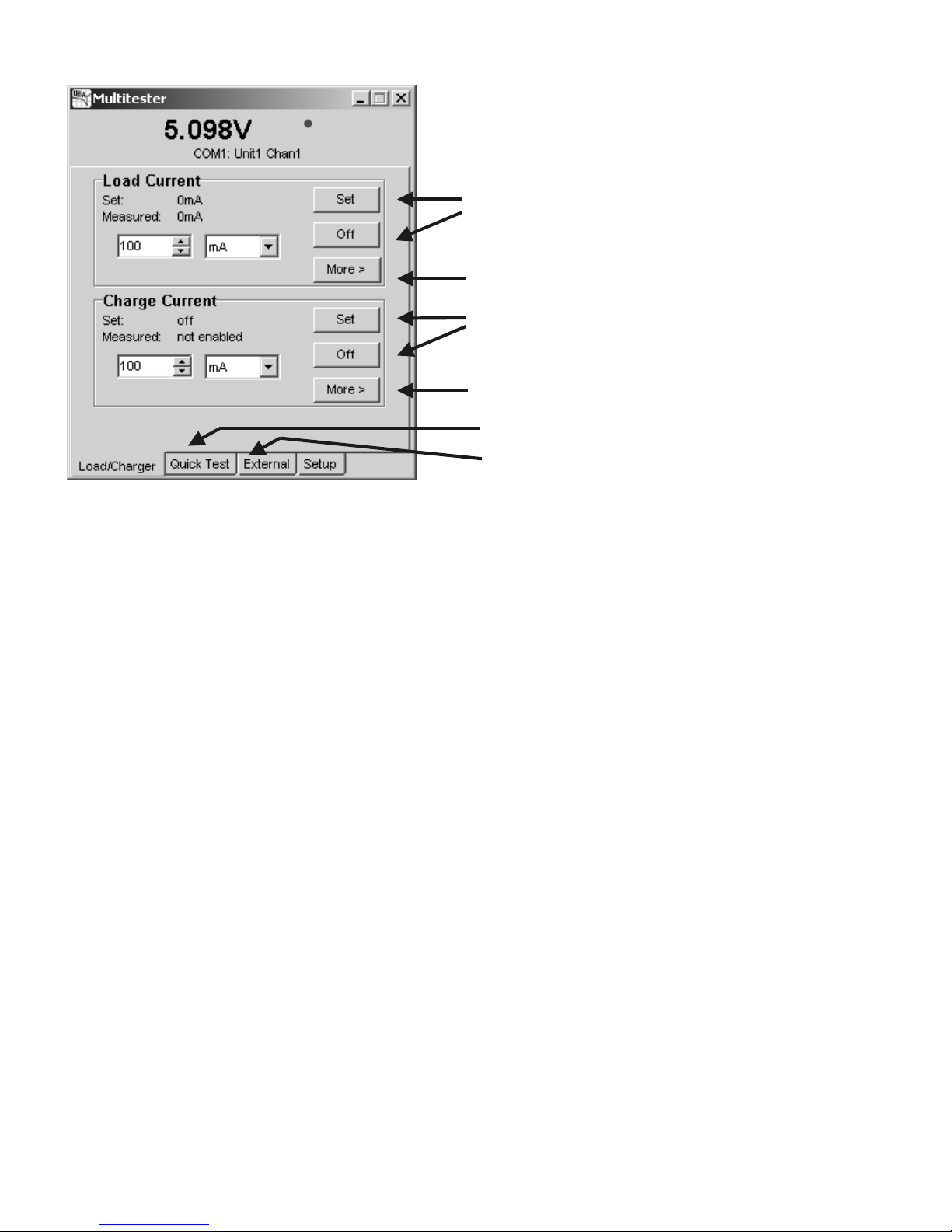

3.1. The Multitester

Before starting a battery analysis, let’s do some exploring. Click on the third icon, which starts the Multitester. The

Multitester is a great place to start, as you can check the battery’s voltage and the operation of the UBA.

Figure 9:

UBA Console ready to start an instrument. Click on the circled icon to start a Multitester.

Page 6 The UBA Let's Get Started Guide

Page 11

This is what the Multitester looks like:

Sets the load to the requested

current, or turns it off.

More options include:

constant resistance and power.

Sets the charger to the requested

current, or turns it off.

More options include:

Constant voltage and PWM

Quick Test page.

External load control.

Figure 10: Multitester Instrument. Use it to monitor the battery voltage while applying a

load or charge current, plus other functions.

With a battery connected, if the Multitester says 0V (zero volts) then check the connection to your battery – it should be

connected to channel one with the correct polarity.

For this test don’t use a battery pack that has any protection circuitry inside that might interfere with the testing. You

can test those batteries once you are comfortable using the UBA.

For this example, I am using a four cell 600mAh NiCd battery.

Enter a small test current (100mA for example) into the load or charge current edit boxes and click the corresponding

Set button. The battery voltage should rise a bit if you set a charge current or drop a bit if you set a load current. This

verifies that the UBA charger and load are functioning and that you have a good connection to the battery. Note, you

can’t run the load and the charger at the same time.

Besides applying a load or charge current, the Multitester can also do a constant voltage charge, a quick test

(measures battery internal resistance), or read the UBA temperature probes (if connected). Press F1 for more

information from the online help. Experiment with some of the options.

Warning: The Multitester does not check the suitability of the charge or load current that you are using. Unless you

know your battery’s condition, you should limit the charge and load current to just a few seconds so you don’t damage

it.

Close the Multitester window so that you can start a battery analyzer on that channel: it is not possible to run two

instruments on the same channel at the same time.

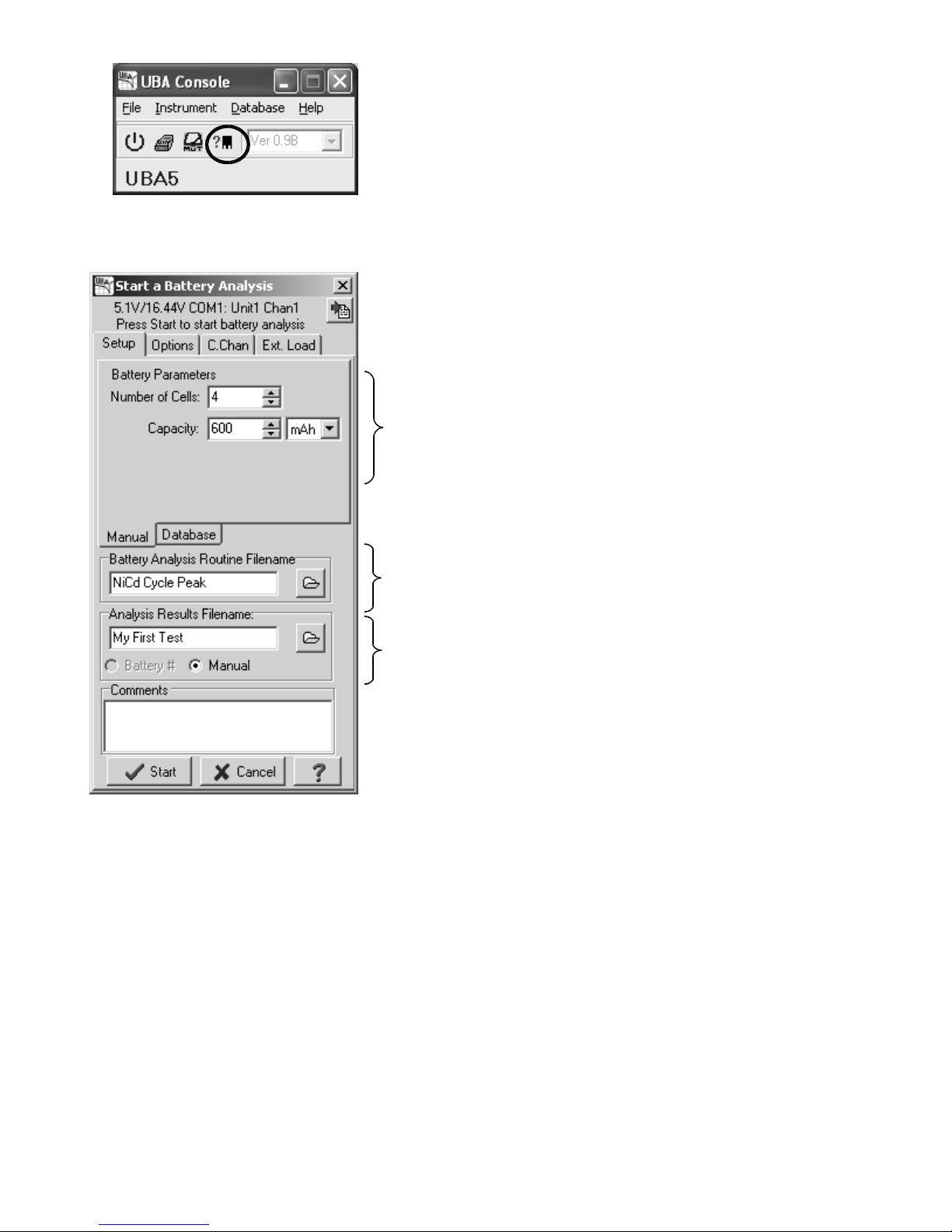

3.2. Setting Up the Battery Analysis

Open a battery analyzer by clicking on the battery analyzer icon on the tool bar.

The UBA Let's Get Started Guide Page 7

Page 12

Start a battery analysis.

Figure 11: UBAConsole: Starting a battery analysis. Click on the circled icon.

This opens up the Start a Battery Analysis dialog box:

Battery Parameters

Choose a BAR

Choose filename to store results.

Figure 12: Start a Battery Analysis dialog box: Entering analysis parameters.

There are three sections that need to be filled in before you can start the analysis.

Battery Parameters: Number of Cells and Capacity

Enter the number of cells (in series) and rated capacity of the battery. For battery packs the rated capacity and

nominal voltage should be printed on the pack. Calculate the number of cells by dividing the nominal pack voltage by

the nominal cell voltage.

Page 8 The UBA Let's Get Started Guide

Page 13

Battery Chemistry Nominal Cell Voltage (Volts per cell)

1Ah

1Ah

1Ah

NiCd or NiMH 1.2 V

SLA, lead acid or gel cells 2 V

Lithium ion or lithium polymer 3.6 V

Same battery examples:

12V Lead Acid 6 cells

4.8V NiCd or NiMH 4 cells

7.2V NiCd or NiMH 6 cells

9.6V NiCd or NiMH 8 cells

12V NiCd or NiMH 10 cells

3.7V Li-ion or Li-polymer 1 cell

7.4V Li-ion or Li-polymer 2 cells

Sometimes the battery pack manufacturer prints a nominal voltage that’s a bit higher then the standard values, in this

case round down the number of cells to a whole number.

In general, NiCd, NiMH, lead acid and gel cell battery packs have all the cells in series. Therefore, the number of cells

that you enter is the number of cells in the battery pack and the capacity is the capacity of each cell, not the sum of the

capacity of all the cells (i.e. the cell capacity is the same as the pack’s capacity). For example, the following pack,

which consists of three 1Ah cells, has a rated capacity of 1Ah and a cell count of three.

1Ah 1Ah

Figure 13: Example battery pack. Pack capacity: 1Ah, cell count: 3.

Lithium-io n packs can have cells in parallel and series. The number of cells that you enter is the number of cells in

series and the capacity is the rated capacity of the pack (sum of the capacity of parallel cells). For example, the

following pack, which consists of six 1Ah cells, has a capacity of 2Ah and a cell count of three.

1Ah 1Ah

Figure 14: Example battery pack. Pack capacity: 2Ah, cell count 3.

The UBA Let's Get Started Guide Page 9

1Ah 1Ah

Page 14

Note, you have to enter a battery capacity, even if it's not required for the BAR that you'll be using. For example, if you

are using the Datalog BAR you can enter any value for the capacity – 1mAh works fine.

Battery Analysis Routine Filename

The battery analysis routine (BAR) contains a sequence of actions that describe the battery analysis that is to be

performed. UBA Console includes BARs that you can use right away. Click on the folder icon beside the BAR

filename to display them. Select the BAR you want to use and click Open.

Select NiCd Test with Peak Charge, NiMH Test with Peak Charge, or SLA Test depending on the chemistry of the

battery that you'll be testing. Note, lithium batteries have a nasty habit of exploding or catching fire if over charged,

they should be tested in a fireproof container.

In Chapter 4 Creating a Battery Analysis Routine I’ll show you how to create your own BARs.

Hint: Double clicking on the BAR filename will open that BAR in the BAR designer.

Analysis Results Filename

In the Analysis Results Filename edit field, enter a filename to store the analysis results. I suggest that you use a

filename that contains information describing the battery you’re testing. For example, use the job number, warranty

return number or battery serial number.

Comments (optional)

Enter any comments that you would like stored in the battery analysis results file; for example, “This battery was

returned by a customer who says that it doesn't work.”. You can edit the comment text in the results file after the

analysis ends using a text editor.

3.3. Starting the Battery Analysis

Once you’ve entered in all the parameters, start the battery analysis by clicking on the Start button. If the Start button

is grayed out then some information is missing or the channel is being calibrated. The battery analysis window should

look like this:

Figure 15: A running Battery Analysis.

The battery analysis is now running. The buttons on the tool bar offer the following options in order:

• Restart the battery analysis (grayed out while battery analysis is running, click on stop first).

• Stop the battery analysis.

• Skip to the next step in the battery analysis.

Page 10 The UBA Let's Get Started Guide

Page 15

• Show the results graph.

• Hide this window (use Active Instruments on the Instruments menu to redisplay).

• Show the starting parameters.

Right click on this battery analyzer window and select Grow (or Show More Information) for more information.

Tool bar

Battery voltage. Move the mouse cursor

over the voltage to get the per cell value.

Summary of events and test results.

Current action and the elapsed time.

Additional information available on these tabs:

Measured: various measured values.

Programmed: the “set to” values.

Finished: conditions for the current action to finish.

Figure 16: Battery Analysis window (after right clicking on it and selecting Grow).

Hint: hold your mouse cursor over the Discharged value for percentage discharged, double click on it to

change the displayed value to percentage. Double click again to switch back.

3.4. Monitoring the Battery Analysis

Note that in this example the battery analysis starts in discharge. This is the default behavior of most of the BARs that

come with UBA Console. When the battery voltage reaches the cut-off value (the voltage where the battery is

considered fully discharged) the load is shut off and the charging starts (sometimes after an optional rest).

Click the View Results icon on the tool bar to get a graphical view and summary of the progress so far.

The battery analysis is finished when either the word “Finished” appears or the battery is in trickle charge (assuming

that trickle charge is the last action in the BAR).

3.5. Interpreting the Results – Is My Battery Any Good?

When the analysis is over, press the View Results icon on the tool bar to get a graph of the battery voltage and the

test results. If you've closed the battery analysis window, you can view the results from Battery Analysis Results File

Viewer from the File menu.

The UBA Let's Get Started Guide Page 11

Page 16

The analysis that I received is shown on the next page. During the discharge portion the battery voltage follows the

classic NiCd/NiMH form: an initial fast drop in voltage, a gradual decrease as the battery loses its charge, and a fast

drop at the end when the battery is fully discharged. After discharge, the charger is turned on and the battery voltage

rises quickly as it recovers, then rises gradually as the battery accepts the charge, and then peaks when it’s fully

charged. The voltage drops after the peak as the charge current is reduced from the 600mA peak charge current to

the 60mA equalization charge current.

“Battery discharged” is the tested

capacity of the battery.

Figure 17: Sample battery analysis result of a discharge followed by a charge cycle.

Now look at the text below the graph. In the One Hour Discharge: section you can see that the battery with a rated

capacity of 600mAh, was discharged 580mAh. This battery tested at 97% of rated capacity (580mAh / 600mAh x

100%). A battery with a capacity of over 90% of its rated value is considered in good condition. One with between

80% and 90% of its rated capacity is acceptable, however one below 70% to 80% should be replaced (these figures

depend on the battery and it's intended application). For the discharge capacity to be used as an acceptance criteria,

the battery must be fully charged before the test. The NiCd and NiMH BARs that come with UBA Console run for two

cycles, the first cycle leaves the battery fully charged so that the next cycle can give an accurate result. For SLA and

lithium batteries either start the test with a fully charged battery, edit the BAR so that the discharge follows a charge or

run the BAR twice.

Page 12 The UBA Let's Get Started Guide

Page 17

In the Peak Charge section notice that the battery was quick charged for 738mAh. This is greater than the measured

capacity of the battery, which is to be expected since charging is always less than 100% efficient. This also means

that the battery received the full peak charge and didn’t false peak. A false peak is a voltage peak that can occur

during the beginning of the charge cycle. It normally occurs on a new battery or a battery that hasn't been cycled in

over a couple of months. Also a poor electrical connection to the battery can cause a premature peak. Had the

charged capacity been less than the discharged capacity then, most likely, something interrupted the charging, and the

battery wasn’t fully charged. The 3h Equalization Charge is programmed for 3 hours at 60mA which equalizes the

cells and ensures that each one is 100% charged.

Note: for this example we used a simplified version of the “NiCd Test with Peak Charge.bar” BAR with just one

discharge and one charge cycle.

Conclusion:

This battery is in good condition. Cycle it regularly to keep it effective and replace it when its capacity drops to below

70 or 80%.

Hints:

• To zoom, use your mouse to select an area (top left to bottom right).

• To pan, press the right mouse button and drag.

• To change the title, click on Title (Edit menu).

Congratulations! You've completed a battery analysis. You now know how to setup and initialize the UBA, start a

battery analysis and interpret the results. The next stage is to create your own BARs so that you can get the UBA to

do exactly the analysis that you want.

4. Creating a Battery Analysis Routine

I consider the battery analysis routines the most exciting part of UBA Console. We designed the battery

analysis routine from the ground up to be so powerful and expandable that you'll be able to analyze your

batteries using methods that you never thought possible -- this has certainly been our experience. Once

you've used our battery analysis routine designer you'll never want to go back to the old "fill in the blank" type

of battery analysis.

Marc A. Venis P.Eng., M.A.Sc

President Vencon Technologies Inc.

The Battery Analysis Routine (BAR) Designer allows you to create a battery analysis using graphical techniques.

Once you learn the basics of how to design a simple BAR, you'll be able to design your own advanced BARs that can

form, recondition, and life test batteries, create and erase memory in NiCd/NiMH cells, and many other advanced

functions.

Let's create a simple BAR: a NiCd battery test based on IEC (International Electrotechnical Commission)

specific ations. From the UBA Console main window select Battery Analysis Routine Designer (File menu). You

should get an empty routine like this:

The UBA Let's Get Started Guide Page 13

Page 18

Figure 18: An empty BAR (Battery Analysis Routine).

We want our BAR to first charge the battery, so we'll add a quick charge cycle or action. Actions are the building

blocks of the BAR. There's no limit (except for screen size) to the number of actions that a BAR can contain.

Right click on the gray background and choose: NiCd/NiMH | Add Cycle | Quick Charge Cycle.

Figure 19: Adding a new action (Quick Charge Cycle) to the BAR.

Now add a standard charge cycle by right clicking and choosing NiCd/NiMH | Add Cycle | Standard Charge Cycle.

Finally add a cycle that will discharge the battery and measure its capacity. Right click again and choose

NiCd/NiMH | Add Cycle | Discharge Cycle.

Now would be a good time to save what you’ve done. Choose Save As... (File menu) and save the file as NiCd IEC

Test. You should get this:

Figure 20: The BAR with actions (action parameters not yet specified).

The BAR starts at the "Begin" circle and proceeds from left to right to the "End" circle. Each action is executed in this

left to right sequence. Click Animate (Window menu) to see this.

Page 14 The UBA Let's Get Started Guide

Page 19

Now to get this BAR to actually analyze a battery you need to set the charge and discharge values. Click on the NiCd

Quick Charge action and enter the parameters as shown below.

Enter “1” for the Charge Current

which gives a current of 1C.

This will charge the battery in

approximately one hour.

Enter “10” for the Sample Time.

The battery voltage and charge

current will be saved every 10

seconds to the results file.

Figure 21: Charge Action: Entering the charge current parameters.

Now click the Finished tab to enter the parameters that determine when the quick charge cycle ends.

Figure 22: Charge Action: Entering the finished parameters.

Enter “1.3” for the Maximum

Charge Capacity. Thus quick

charging will end when the battery

has been charged 1.3 times its

rated capacity. This is a fail safe

feature to limit over charging.

Click on the Peak Charge

checkbox. This adds a Peak

Charge page.

The UBA Let's Get Started Guide Page 15

Page 20

Enter “10” (mV/cell) for the

Peak Charge finish criteria. Thus

when the cell voltage drops 10mV

below its peak value, charging

stops.

Enter “0.05” for the

Minimum Charge so that during

the first 5% of the charging any

voltage peaks are ignored. This

skips false peaks that can occur

at the beginning.

Figure 23: Charge Action: Entering the peak charge parameters.

Click OK to save the changes.

Repeat for the NiCd Standard Charge action but use these parameters:

• Charge Current: 0.1 C (this is a slow C/10 charge that equalizes the cells without overcharging).

• Write to results every: 30 seconds (saving the results more often than this gives no additional useful

information).

• Capacity (fraction): 0.3 (at the C/10 charge rate this gives about 3 hours of charge).

Click OK to save these changes.

Now click on the NiCd Discharge action and fill in the fields as show below:

Load:

Select Relative.

Enter “0.2” for the Discharge Current.

This is the IEC standard and wil l

discharge the battery in approximately

five hours.

Enter “30” for the sample time. Since it

will take five hours to discharge the

battery it's not necessary to save the

voltage and current more often then this.

Figure 24: Discharge Action: Entering the discharge current parameters.

Click the Finished tab:

Page 16 The UBA Let's Get Started Guide

Page 21

Enter “1.0” for the Cut Off Voltage. This is

the value specified in the IEC standard.

Figure 25: Discharge Action: Entering the finished parameters.

Click OK to save these parameters and then Save (File menu) to save the BAR file.

That’s it. You’ve created a new BAR that you can use whenever you want.

4.1. “Advanced” BAR Concepts

Renaming and Deleting Actions

Right click on an action to rename or delete it.

Rearranging Actions

If you would prefer to have the order of actions changed, drag any action to a new location. Don’t forget to save

afterwards.

Figure 26:

The "One Hour Discharge" action is dragged to be after the "Equalization Charge."

Using BAR Routines

In order to keep the BAR layout uncluttered and easy to maintain, you can use subroutines, called routines, to group

actions. For example, to add a battery analysis routine (a discharge cycle followed by a charge cycle) right click on the

background and choose: "NiCd/NiMH | Add Routine | Battery Analysis Routine. Now if you click on the newly

created button you'll get the BAR subroutine. Click on Animate (Window menu) to see the action flow.

The UBA Let's Get Started Guide Page 17

Page 22

Figure 27: Action flow in a subroutine.

Relative Currents and Time

You might have noticed the use of relative currents (based on the battery's C current) and time based on capacity.

This is different from other battery analysis systems. The use of relative currents allow you to design BARs that work

independently of battery capacity. If you prefer, you can still specify absolute values.

Figure 28: Here we have a relative load current of 1C. If you ran this BAR on a 600mAh

battery you'd get a 600mA load, on a 2Ah battery you'd get a 2A load.

Page 18 The UBA Let's Get Started Guide

Page 23

4.2. BAR Actions

There are five actions that you can use to build a BAR:

Figure 29: All available actions .

NiCd/NiMH Quick Charge Cycle, Standard Charge Cycle and Trickle Charge Cycle:

These are actually all the same – just a blank constant current action than can be terminated by a number of methods.

You would normally use this for charging NiCd and NiMH cells. But you can use it for other functions. We use it to

prequalify a lithium ion battery.

NiCd Discharge and Li-ion/SLA Discharge:

These are the same discharge action. You can choose the load (constant current, power, or resistance) and the

termination method. You would specify about 1 V per cell for the cut off for NiCd or NiMH, about 2.75 V for lithium,

and about 1.75 V for SLA.

Li-ion/SLA Standard Charge

This is the constant voltage charging action designed for lithium ion, lithium polymer and SLA/gel cells/lead acid

batteries.

Routine (from NiCd/NiMH->Add Routine->Empty Routine)

This is an empty routine. Click on it to open the subroutine. There a couple of routines already populated with some

actions. They are accessible from: NiCd/NiMH->Add Routine->.

Goto

This branches either forward or backwards. You can specify the number of times to branch (i.e. run a

charge/discharge cycle 10 times) and allow a discharge action to break out of the loop before the repeat count is

reached.

4.3. BARs Included with UBA Console

Although making your own BARs isn’t very difficult (we just did one last section, remember?), there’s no glory in

reinventing the wheel; therefore we’ve included a few BARs with UBA Console that have been written by our resident

battery expert, me! I suggest that you use them, at least until you have gained enough confidence to write your own.

And remember, when using a new BAR for the first time, watch the battery analysis while it's running the first time to

ensure sure that it does what you intended it to do.

Actually the easiest way to create BARs is to modify existing ones. Modify ours, we don’t mind. There are many

parameters in a BAR and it’s easy to over look something. By modifying a working one you increase the chance of

getting it working the first time.

The UBA Let's Get Started Guide Page 19

Page 24

Hint: the BARs that came with your software are designed to minimize the chance of your overwriting them

(specifically, the Owner field is filled in), but if you do, you can get a new copy from your install CD in the

Image/BARs folder.

See Appendix C for a list of the BARs included with UBA Console.

5. Advanced Topics

5.1. Choosing and Setting Up a Power Supply

The UBA requires a 15 to 24V DC voltage at sufficient current to power both its internal chargers. The voltage needs

to be at least 3V greater than the maximum battery pack voltage during charge (for NiCds and NiMH this would be

about 1.6V per cell, for sealed lead acid: 2.5V per cell and for Li-ion: 4.2V per cell). An unregulated power supply can

be used, but the charge current measurements will be less accurate.

If you are using a power supply that can’t provide the full 2A per channel charge current with an additional 250mA for

the UBA itself then you can set the UBA to limit the current that it draws. This is done in the calibration file or entered

manually each time UBA Console is run, as explained below.

Power Supply Description Lines in Calibration File

Each UBA has its own calibration file (xxxx.uba, where xxxx is the serial number of the UBA). In t he calibration file

there’s three lines that describe the power supply that’s powering the UBA.

For example, the 19V 4.5A power supply that comes with the UBA5GP combo is described as follows:

PowerSupplyV: 19

PowerSupplyI: 4.5

PowerSupplyR: 0

If you purchased a UBA combo from us then we’ve already entered the power supply parameters into the calibration

file. If the UBA is used with a different power supply or if it wasn't purchased as a combo then you can edit the

calibration file to prevent overloading of the power supply. An overloaded power supply will either shut down, drop the

output voltage or burn out.

You can edit these lines with a text editor (notepad works fine). UBA Console only uses the maximum current value

(PowerSupplyI), the voltage and resistance lines are ignored, but the voltage value should be filled in for future

compatibility. Note, a value of 0 for the power supply current means that no current limiting is necessary (i.e. your

power supply has a current output of at least 4.25A).

Temporarily Changing the Power Supply Current Limit

You can view the current limit by clicking on the "General" tab in the UBA Window:

Page 20 The UBA Let's Get Started Guide

Page 25

Figure 30: UBA Display window (click on the UBA icon in the UBA Network window to

get this display, then click on the General button). In this example, the UBA Console S/W

will limit its power supply current draw to no more than 1.0A.

You can change this value by entering in a new one, but note that this number is not saved into the calibration file.

Remember that a value of 0 (zero) means that the UBA will not limit its power supply current draw (but will never

exceed 4.25 A).

Sharing Power Supply Current Between Both Channels

You can specify that both channels equally share the power supply current by checking the Evenly divide between

channels radio button on the Charger tab in the Options dialog box (File menu). This evenly divides the power

supply current among both channels so that each channel can have up to half the maximum current.

Figure 31: Option dialog box showing the Charger current settings.

Examples:

1. You have a power supply with a 4.25A or greater output current rating. Since the power supply can supply

both channels with their maximum current rating (2A) with at least 250mA left over for the UBA's electronics,

then no output current limiting is necessary. Either a setting of 4.25 or greater or 0 in the power supply rating

box is acceptable. The Power Supply Current radio button selection has no effect.

The UBA Let's Get Started Guide Page 21

Page 26

2. You have a 1.0A power supply which doesn't supply enough current to power both channels at their maximum

charge current. You should enter 1.0 as the power supply current in the UBA's calibration file. The setting of

the Pow er Supply Current radio selection box is important. If Evenly divide between channels is selected

then each channel will get up to almost 500mA charge current. If Share as required between channels is

selected then one channel can use almost the full 1A charge current and the other channel gets nothing.

Notes:

• If you enter in power supply rating higher then what your power supply can provide then you risk damaging

your power supply.

• If your power supply can't provide the maximum current to each channel and you have checked the Share as

required between channels radio button then you should only run one battery analysis at a time. Otherwise

one channel can have little or no current available for charging. The software isn't able to delay starting a

charging cycle on a channel until the required current is available.

• If you are running the UBA off of two power supplies, one for the UBA's electronics and one for charging (i.e.

the UBA5-30V) then enter a negative number, i.e. -3.0 if you have a 3A power supply. The negative sign

means that the power supply is not powering the UBA's electronics and no margin need be made for that.

• The UBA uses the peak current from each channel for sharing the power supply current. So if one channel is

on PWM charge (i.e. the charge current is pulsing) the peak current is used. This is very conservative and will

be looked into in the future.

• If you are using the UBA exclusively for testing primary batteries then set the maximum power supply current

to 0.001 (1mA), not 0. The UBA will then never turn on the charger

5.2. Importing Results into a Spreadsheet

You can import the results file (.uba file) into a spread sheet for further analysis or graphing.

Microsoft Excel

In Microsoft Excel, select Open... (File menu). For Files of type: choose Text Files (*.prn *.txt, *.csv), type “*.uba”

into the File name: box and press Enter or click Open. Choose a results file and cl ick Open. In the Text Import

Wizard dialog box choose Delimited, click Next and then select Comma as the delimiter. Click Finished.

A faster method is to add a “.csv” file extension after the “.uba” on the results file (i.e. My Test.uba.csv). Double click

on the file and Excel will start up and import the results file.

In the private section on our web site you’ll find a macro for Excel that imports and graphs results files automatically.

OpenOffice.org Calc

In OpenOffice.org Calc, select Open... (File menu). For Files of type choose Text CSV (*.csv, *.txt), type “*.uba into

the File name box and click Open. Now locate the file you want to import. The Text Import window will pop open.

Choose Comma for the Separator options and click OK. The UBA results file will be imported into Calc ready for

graphing.

5.3. Warnings

The negative battery inputs on both channels are connected to the ground on the PC and to the ground/earth on the

UBA power supply. Only test batteries that are floating (i.e. not connected to anything). We sell a self powered RS232

opto-isolator designed specifically for the UBA that will isolate the UBA from the PC’s ground for testing batteries that

aren’t floating (contact us for assistance).

Page 22 The UBA Let's Get Started Guide

Page 27

5.4. Current and Power Limitations

Load Limit: 3A and 45W

The UBA can discharge at up to 3A per channel, with a maximum dissipation of 45W. During discharge, the UBA

converts the battery current into heat which it dissipates with its chassis. The power is limited to 45W per channel to

prevent over heating the chassis and load transistors. The UBA's internal fan turns on at a power dissipation of 10W

on either channel.

Thus for batteries 15V and lower you'll be able to use the full discharge current of 3A. For batteries higher then 15V the

UBA will reduced the current to keep within it's 45W maximum.

If you want a higher load current, then combine both channels (see the section UBA Accessories - Channel

Combiner) or use a series power resistor (contact us for more details). Don't worry about damaging the UBA from

over-current or over-power as UBA Console automatically limits the current to safe values.

Charger Limits: 2A (and 28W internal dissipation)

The UBA can charge at up to 2A per channel (power supply permitting). It uses a low noise linear constant current

charger that drops the voltage from the power supply to your battery. The difference between the power supply

voltage and the battery voltage is absorbed by the UBA's charger. The power is limited to 28W per channel to prevent

overheating the UBA.

Thus, when charging a single cell, the UBA might limit the charge current. For example if you have a UBA5GP with a

19V power supply and you want to charge a single 1.2V cell at 2A, the UBA would have to dissipate about 35W ((19 –

1.5V) x 2A). This is worst case, it's actually less than this as any wiring would drop the power supply voltage. So in

this case the UBA would reduce the charge current to about 1.7A. If you want to charge single cells or low voltage

battery packs at high currents then either combine two or more channels, use a lower voltage power supply (but not

less than 15V), charge the cell in series with other cells or add a resistor in series with the cell (contact us for more

details).

The UBA Let's Get Started Guide Page 23

Page 28

Appendix A – Troubleshooting

Win95 and NT: Software Installation Problems

UBA Console requires files that don’t come with a fresh install of Windows 95 or NT4. If you have a Microsoft Internet

Explorer or Microsoft Office installed, you shouldn’t have a problem. Otherwise you can get the missing files off of our

website (www.vencon.com/downloads/Win95-NT.html

website.

Icons on UBA Console Aren’t Displayed (for Win95/98 and NT only)

If the icons on the tool bar don't display correctly you need to upgrade your comctrl32.dll file (Microsoft Windows

Common Controls). The file 50comupd.exe installs the Internet Explorer version 5.0 version of this DLL. See above

for location of files.

A required .DLL file, HHCTRL.OCX, was not found (for Win95 and NT only)

If you get this error then you don’t have the Microsoft’s HTML Help software installed. Install it by running the

hhupd.exe file. See above for location of files.

The DLL with the name "SHLWAPI.DLL" is not found (for Win95 and NT only)

If you receive this error message, you will need to install shlwapi_Win95.exe or shlwapi_NT4.exe. See above for

location of files.

) , the UBA Console install CD (in the “Win95_NT”), or Microsoft’s

Self Test

The UBA does a self test every time it’s turned on. If the self test passes, it will flash the channel LEDs and the fan.

You can also test the serial communications by connecting the serial cable that came with the UBA between the two

serial connectors on the back of the UBA. Power on the UBA. If the UBA’s serial communication is functioning, the

UBA will continually do a self test and you’ll see the front channel LEDs flash.

Communication Monitor

Before the UBA is initialized, the channel one red LED will show very fast flashes when it detects any activity on the

serial port. So if you are having problems connecting to the UBA and the channel one LED isn't flashing during

initialization, then the UBA isn't receiving any commands.

Page 24 The UBA Let's Get Started Guide

Page 29

Appendix B – FAQs

Software

Can I run a life cycle test on my battery?

Yes. Change the repeat count in a BAR that cycles the battery to a large value (99,999 for example). Have the

charge or discharge actions only write to the results file every minute or so in order to reduce the size of the results file.

When the life time test is over (either by the number of cycles or the battery capacity), view the results file in the

Battery Analysis Results Viewer (File menu) and select Write Report (Results Viewer File menu). This will write a

comma separated table of capacity vs cycle number which can be loaded into your favorite spreadsheet. Note, a long

life test can take a few minutes to display. It’s best that you not view it while a battery test is running since you can

lose communications. Use a second computer, or start up a second instance of UBA Console for viewing the results

file.

How complicated can I make a Battery Analysis Routine (BAR)?

You can make a BAR as complicated as you want. We’ve even had customers make them with nested loops where

the inner loop simulated the load on their device (for example 5 seconds low load and 1 second high load for a twoway radio) and the main loop did a life cycle test. The only limit is screen size, and you can get around that by using

routines.

Battery Testing

How do I know how many cells are in my battery pack?

In order to get the number of cells in a battery pack, divide the battery pack’s nominal voltage (usually printed on the

pack) by 3.6V for li-ion cells, 1.2V for NiCd/NiMH cells or by 2V for SLA cells.

My battery pack has four 1000mAh cells in series. What’s the pack’s capacity?

In this case, the packs capacity is 1000mAh. It would be 4000mAh had the cells been in parallel.

What’s the quickest I can test a battery?

Well you can do a Quick Test in just a few seconds which measures your battery’s internal resistance. This tells you

how bad the battery is, but not how good it is. A high internal resistance means a battery is in poor shape, a low

internal resistance gives little indication about its capacity.

If you have the time, a full battery discharge is best. This can be done in as little as 1 hour (or 30 minutes if you don’t

mind stressing your battery a bit), provided the battery is initially fully charged and the load current is within the UBAs

capabilities. Unless the battery is designed for high rates of charge and discharge, discharging or charging it in less

than one hour is not advisable as it unnecessarily stresses the battery and gives low capacity results. A full chargedischarge cycle can take as little as three hours on a NiCd, NiMH, li-ion or li-polymer battery and as long as a day on a

SLA or gel cell battery. If you have a specific test requirement feel free to contact our technical support department for

assistance.

Can I test primary (non rechargeable) batteries with my UBA?

Sure. But you can only discharge them and the test is destructive (i.e. you can’t use the battery again, except, of

course, as a paperweight).

The UBA Let's Get Started Guide Page 25

Page 30

I have a lot of batteries (or cells) to test. Can I test them by putting them in series?

Yes and no. If the batteries are voltage charged, like lead acid or lithium ion, then the answer is no you can’t charge

them since any imbalance will result in some cells being overcharged and some undercharged. For NiCd or NiMH

batteries, you can charge them in series provided they are the same model and initial state of charge. For discharging

you’ll get the capacity of the weakest cell.

General

How to you pronounce UBA?

Spell it out, “U” “B” “A”. Do not call it an “Ooba”!

How many UBAs can be connected together?

Theoretically 253, although nobody has every tried that many (at least as far as we know). The record is 30 UBAs on

one serial port (that’s 60 channels). Don’t try this with Win95, Win98 or WinMe as they have limited graphical

resources.

How often does the UBA need to be calibrated?

We recommend a one year calibration interval. We have found that it’s rare for a UBA being recalibrated to require

any changes to the calibration file since there are no adjustable parts inside that can drift.

Can I use a UBA to turn on my charger? Can I use my charger to start a discharge cycle?

Yes and yes. The accessory port on the UBA, which is located inside, has two digital outputs and two analog inputs.

You can control the output lines with your BAR (use external battery load setting) and respond to the analog input

signals (simulate temperature). We sell a connector to bring the accessory port to the back of the UBA and also an

optical isolated output connector. More information can be found in our External Devices Manual located in the

Support : Reference Manuals section of our website.

My UBA gets hot during operation. Why isn’t the fan turning on?

The fan only turns on when the UBA gets very hot. You can have the fan turn on earlier by reducing the turn-on power

limit on the General tab in the Options dialog box (File menu). Enter a power less than 10 Watts (6 for example) and

the fan will turn on when that power (or more) is being dissipated.

My battery is very small and the minimum charge and load current are too high for it.

For small batteries, less than 100mAh, you might consider having the UBA customized by us for low currents. We

have expertise in customizing the UBA all the way down to 1uA full scale.

I have a question about the database.

Stay away from the database functions in UBA Console (unless you really need them). They are only partially

implemented and are not written very well. We will be rewriting them in the future and can’t guarantee backwards

compatibility.

So where is the power switch?

There is none. The UBA draws so little current when it’s not in use that there was no point in installing a power switch.

We’ve thought about having UBA Console turning off the green power LED when you close the UBA network, but that

would be confusing.

Page 26 The UBA Let's Get Started Guide

Page 31

Appendix C – Included Battery Analysis Routines

The following BARs are included with the UBA. You’re free to examine and modify them in the Battery Analysis

Routine Designer and save them under a different nam e.

Battery Analysis

Routine

NiCd Peak Charge NiCd

NiMH Peak Charge NiMH

NiCd Test with Peak

Charge

NiMH Test with Peak

Charge

NiCd Test with Timed

Charge

NiMH Test with Timed

Charge

NiCd Forming NiCd

NiMH Forming NiMH

NiCd Recondition NiCd

NiMH Recondition NiMH

Chemistry Used for:

NiCd

NiMH

NiCd

NiMH

Peak charging a NiCd or NiMH battery in any initial

charge state. If the battery hasn’t been cycled in a

while, the peak charge might end prematurely due to

false peaks. If this happens then you should use the

NiCd Test with Timed Charge or NiMH Test with

Timed Charge routine.

Cycling a battery to determine its capacity and

exercising it. Use this routine if the battery is regularly

cycled. If you’re getting premature false peaks while

charging then you should use the NiCd Test with

Timed Charge or NiMH Test with Timed Charge

routine.

Cycling a battery to determine its capacity and

exercising it. This routine takes longer then the NiCd

Cycle with Peak Charge / NiMH Cycle with Peak

Charge routine but it won’t false peak on a battery that

hasn’t been cycled in a while.

Forming new batteries or those that haven’t been

charged for a few months. It slow charges the battery

for 16 hours followed by a discharge and then peak

charge.

Reconditioning NiCd and NiMH batteries with low

capacity. It uses a two step discharge: the battery is

discharged then deep discharged followed by a peak

charge. This cycle is repeated twice. Restoration of

capacity works best on cells that don’t suffer from

physical deterioration (normally the separator).

The UBA Let's Get Started Guide Page 27

Page 32

Battery Analysis

Routine

Chemistry Used for:

Lithium-ion

Li-ion Charge

Lithium-polymer

Lithium-ion

Li-ion Test

Lithium-polymer

SLA Charge

SLA Test

SLA, gel cell or

lead acid

SLA, gel cell or

lead acid

Datalog N/A

Cyclone Test

Cyclone SealedLead cells

Charging a lithium ion or lithium polymer battery.

Before using this routine, check that the default charge

voltage (4.2V) is appropriate for the battery otherwise

the battery can be damaged or explode.

Cycling a lithium ion or lithium polymer battery to

determine its capacity. Before using this routine, check

that the default charge voltage (4.2V) is appropriate for

the battery otherwise the battery can be damaged or

explode.

Charging a sealed lead acid (SLA) or wet lead acid

battery. It uses a two step charge algorithm consisting

of a current limited charge to 2.40V/cell followed by a

float charge at 2.3V/cell.

Cycling your battery to determine its capacity and

exercising it. It discharges the battery and then

charges it back up using a two step charge algorithm.

Logging the voltage on the battery or accessory input s

and logging temperature.

Cycling a Cyclone Sealed-Lead cell. This routine

discharges the cell and then charges it back up.

Page 28 The UBA Let's Get Started Guide

Page 33

UBA Accessories – Optional Temperature Probes

White Temperature Probe

If the UBA came with temperature probes then you'll be able to view and record the battery temperature during a

battery analysis. Afterwards you can load the results into a spreadsheet and plot the temperature curve along with

battery voltage and current.

That's not all. You can program the software to stop battery charging when the battery reaches a certain temperature

or rate of temperature rise (dT/dt).

Connecting The Temperature Probes to the UBA

The temperature probe set comes with two temperature probes, a blue and a white one, and a connector on the back

of the UBA. Except for the colour, they are identical. The two temperature probes plug into the back of the UBA, one

of them into the upper two pins, the other one into the lower two pins. The centre two pins are not used. In the

calibration file the probes are named “BlueTherm” and “WhiteTherm”. If you plug the blue probe into the upper part of

the connector and the white probe into the lower part of the connector then they will match the description in the

calibration file. If you wish, you can change the probe names in the calibration file.

Blue Temperature Probe

TEMPERATURE

PROBE

Temperat ure Probe Connector

(on back of UBA)

Figure 32: Temperature Probe connections on back of UBA chassis.

Checking the Operation of the Temperature Probes

Start UBA Console and initialize the UBA network. Start a Multitester and choose the Setup tab. Click on the Get

Battery temperature from: drop down list and choose a temperature probe (if a probe is in use, or an other accessory

is using the same accessory analog input, it won't appear as a selection). If there are no probes listed then your

calibration file isn't set up for temperature probes. Shortly after selecting a temperature probe, the probe's temperature

should appear.

Connecting the Temperature Probes to the Battery

We sell two types of temperature probes. The non-magnetic ones can be taped to the battery, ideally near the centre.

The magnetic ones will stick to the battery. If the battery is non-metallic then you can tape the magnetic probe on.

You want the probe to contact the warmest part of the pack.

The UBA Let's Get Started Guide Page 29

Page 34

Connecting to an existing Thermistor Inside the Battery

If the battery pack has a built in 10k thermistor with both leads floating or one connected to battery negative then you

can use it as the temperature sensor (you'll need a temperature probe connector on the back of the UBA for this).

Contact us for more information.

Running a Battery Analysis

When you are setting up a battery analysis, click on the Options tab and select a temperature probe. If you want the

charging to be controlled by temperature then you'll need to set this in the BAR. For NiCd/NiMH charging, open the

BAR in the BAR designer and click the charging action. Select the Finished tab and check Temperature Probe. On

the Temperature tab you can set the temperature rise rate and maximum temperature. When enabled, if either of

these conditions are met then the charging cycle ends.

Figure 33: Temperature conditions that terminate battery charging for NiCd/NiMH cells.

The BAR Designer has a option where if the temperature probe reaches a specified temperature, the battery analysis

is ended.

Figure 34: Maximum battery temperature in a BAR (mainly used for lithium cell charging).

Page 30 The UBA Let's Get Started Guide

Page 35

When Is a Battery Fully Charged?

The most important part in fast charging is when to stop. Overcharging a battery can damage it and is dangerous. In

the graph on the next page we deliberately overcharged a NiMH battery to show you what happens. Look at the

battery temperature line. It rises slowly at first then quickly rises when the battery is almost 100% charged. The fast

charging stops when the temperature reaches the maximum temperature of 45ºC as set in the BAR. If the fast

charging didn't stop then the temperature would continue to rise and the battery would eventually vent (release

electrolyte) causing permanent battery degradation. Overcharging a lithium-ion or lithium-polymer battery can result in

the battery bursting into flames.

Now look at the voltage graph. This is the most common method to terminate a NiCd/NiMH quick charge as it requires

no temperature sensing. The "X" axis is the fraction of charge being put into the battery. At "1.0", in theory, the battery

would be fully charged. In actuality the battery isn't fully charged until a bit past this value. The line at "A" is the point

where the battery voltage has dropped enough (about 2mV/cell) so that a peak charge would have stopped there.

Notice at "A" the battery receives about a 5% overcharge (based on a theoretical 100% efficiency charge) which is

acceptable.

Now look again at the temperature graph. We've drawn two temperature curves - one for the battery temperature and

the other for the rate of battery temperature change. The temperature peaks at line "B" which is when the charger was

turned off. A temperature cut-off works best as a backup method of ending the battery charge cycle. Temperature

rate of change (dT/dt) is a better method of determining when the battery is fully charged. In this example, if you would

have specified a maximum temperature rise of 1ºC/minute then the charging would have terminated exactly at the

100% efficiency fully charged mark. Since rate of temperature change is dependent on the battery pack construction

(the less cooling the faster the temperature will rise) it's difficult to come up an optimum value to use.

What's best? We recommend that you start with a maximum battery temperature of 35 to 40ºC and a maximum dT/dt

of 0.5ºC/minute to 1.0ºC/minute. If the charging is stopping too early then increase these values. You can tell what

caused the charging to stop from the text at the bottom of the results viewer.

You can use the UBA to create your own chart. Run a battery test with a temperature probe. Then import the results

file into a spreadsheet program and use a simple formula to get the dT/dt (in degrees Celsius per minute): ((Temp2Temp1)/(Time2-Time1) * 60). For this graph we matched up the end of fast charge and beginning of slow charge

which compensates for the voltage drop of the cable (during peak charge the battery voltage is sampled with the

charge current on, afterwards the battery voltage is sampled with the charge current off).

The UBA Let's Get Started Guide Page 31

Page 36

Over Charging a NiMH Battery Pack

A B

Voltage per Cell

1.60

1.55

1.50

1.45

1.40

1.35

1.30

1.25

50

40

Bat t ery Temp erature

30

20

Bat t ery V ol tage

10

dT/dt

0

-10

-20

0.00.51.01.5

dT/dt (ºC/Min) Temp (ºC)

Charging Capacity (1.0 = 100%)

Figure 35: Test results from deliberately over charging a battery pack.

Page 32 The UBA Let's Get Started Guide

Page 37

UBA Accessories - Channel Combiner

UBA

Channel Combiner

Single UBA

The channel combiner allows you to combine both channels of the UBA doubling the charge and discharge current

and power. To do this, connect the battery positive terminal to both positive battery inputs and the battery negative

terminal to the negative battery input (the negative battery inputs are already wired together).

The Channel Combiner makes this easy to do. Plug one end of the channel combiner into either positive input (red) on

the front of the UBA and the other end into the other positive input. The battery to be tested is then connected to one

of the negative (black) inputs (it does not matter which one) and to the banana input on the channel combiner. See

diagram below.

-

Battery

being

tested

Figure 36: Using the UBA Channel Combiner.

+

Two or More UBAs

Combine the channels of two or more UBAs the same as you combine the channels on one UBA, but in addition to

connecting the positive inputs in parallel you have to connect the negative inputs between the UBAs. If you don't do

this then battery current will flow through the serial cable and the power supply lines.

Software Instructions

Once you've physically connected the channels in parallel you have to set up a “virtual UBA” that controls these

combined channels. The virtual UBA acts as if it's a single channel, but with higher current and power limits plus some

additional features.

1. Start a virtual UBA by clicking on the Virtual UBA icon:

The UBA Let's Get Started Guide Page 33

Page 38

2. Add channels to it by clicking on the Channel menu:

3. Then start a battery test on the virtual UBA by clicking on the Instrument menu:

Figure 37: Software instructions for combining

channels and starting a battery analysis.

Page 34 The UBA Let's Get Started Guide

Page 39

UBA5 Specifications

Battery Types

Chemistry: NiCd, NiMH, lead acid, gel cell, Li-ion, Li-poly and all primary cells.

Two ranges: 0 to 6.5V & 0 to 24V, accuracy 0.2% rdg ±10mV.

Voltage &

Number of cells (in series):

Capacity: 20mAh to 120Ah (or more)

Internal Load (two per UBA)

Type: Programmable constant current.

Current: 12mA to 3000mA in 12mA increments with 45W limit.

Load cycle terminated by

any of the following conditions:

Accuracy: 0.5% reading ±2mA.

Resolution: 0.1mAh.

Internal Charger (two per UBA)

Type: Programmable constant current, voltage and duty cycle.

Current: 20mA to 2.0A in ~20mA increments with internal 28W limit.

Charge cycle terminated by any of the

following conditions:

o NiCd, NiMH: 1 to 16 cells.

o Lead acid, gel cell: 1 to 9 cells .

o Li-ion, Li-poly cells: 1 to 5 cells.

Cut off voltage.

Maximum time and/or capacity.

Temperature (with optional probes).

Peak (delta V).

Maximum time and/or charged capacity.

Temperature (limit or dT/dt - with optional probes).

Miscellaneous

Battery input: Banana connectors (two pairs of cables included).

Accessory ports: Two (extra analog and digital lines for accessories).

Power: DC: 15V to 26V, 4.5A max.

120/230VAC universal power supply comes with UBA “combos”.

Approvals: CE and FCC

Size, Weight: 130mm x 170mm x 75mm (WxLxH), 820g

Warranty: Two year parts and labour.

Software: UBA Console included (for Win9X/NT4/ 20 00/ XP/V is t a/ Linux-Wine)

Two Year Limited Warranty

Warrants that the UBA and accessories are free from defects in materials and workmanship for a period of two

years from the date of purchase. Within this period contact Vencon to obtain a RMA number then send any

malfunctioning units to an authorized repair centre prepaid. We will repair or replace it at our option without charge for

parts and labour and return it in a timely manner at our expense. Any product which has been subject to misuse or

accidental damage is excluded from this warranty.

The foregoing limited warranty is Vencon’s sole warranty and is applicable only to products sold as new. The

remedies provided herein are in lieu of a) any and all other remedies and warranties, whether expressed, implied or

statutory, including but not limited to, any implied warranty of merchantability or fitness for a particular purpose, and b)

any and all obligations and liabilities of Vencon for damages including, but not limited to accidental, consequential, or

special damages, or any financial loss, lost profits or expenses, or lost data arising out of or in connection with the

purchase, use or performance of the Product.

The UBA Let's Get Started Guide Page 35

Loading...

Loading...