Vemm Tec PTZ-BOX 3.0 User Manual

GAS-VOLUME CONVERSION DEVICE

PTZ-BOX 3.0

Manual

Specifications

Technical Description

Mounting instructions

Configuration

Single-channel gas conversion device

Approved for installation in potentially explosive atmospheres.

IOM_Manual_EN_PTZ-BOX 3-0_097-102-003_2017 02.docx

February 2017

Safety Measures

This measurement device can be operated only by an operator trained in

compliance with the technical terms, safety regulations, and standards. It is

necessary to consider any other legal and safety regulations stipulated for special

applications. Similar measures also apply for special applications. Similar measures

also apply for using the accessories. The operator training must be in compliance

with Decree no. 50.1978 Coll.

The information in this manual does not have the power of a legal obligation from the

manufacturer’s side. The manufacturer reserves the right to implement changes. Any

changes in the manual or in the product itself can be performed at any time without any

previous alert, with the goal of improving the device or fixing any typographical or technical

mistakes.

IOM_Manual_EN_PTZ-BOX 3-0_097-102-003_2017 02.docx

TABLE OF CONTENTS

1 Introduction ............................................................................................. 3

1.1 Basic device description ....................................................................................... 3

1.2 Function principle ................................................................................................ 4

1.3 Device dimensions ............................................................................................... 8

2 Device technical description ..................................................................... 8

2.1 Device architecture .............................................................................................. 8

2.2 Power supply ....................................................................................................... 9

2.3 Security seals ......................................................................................................12

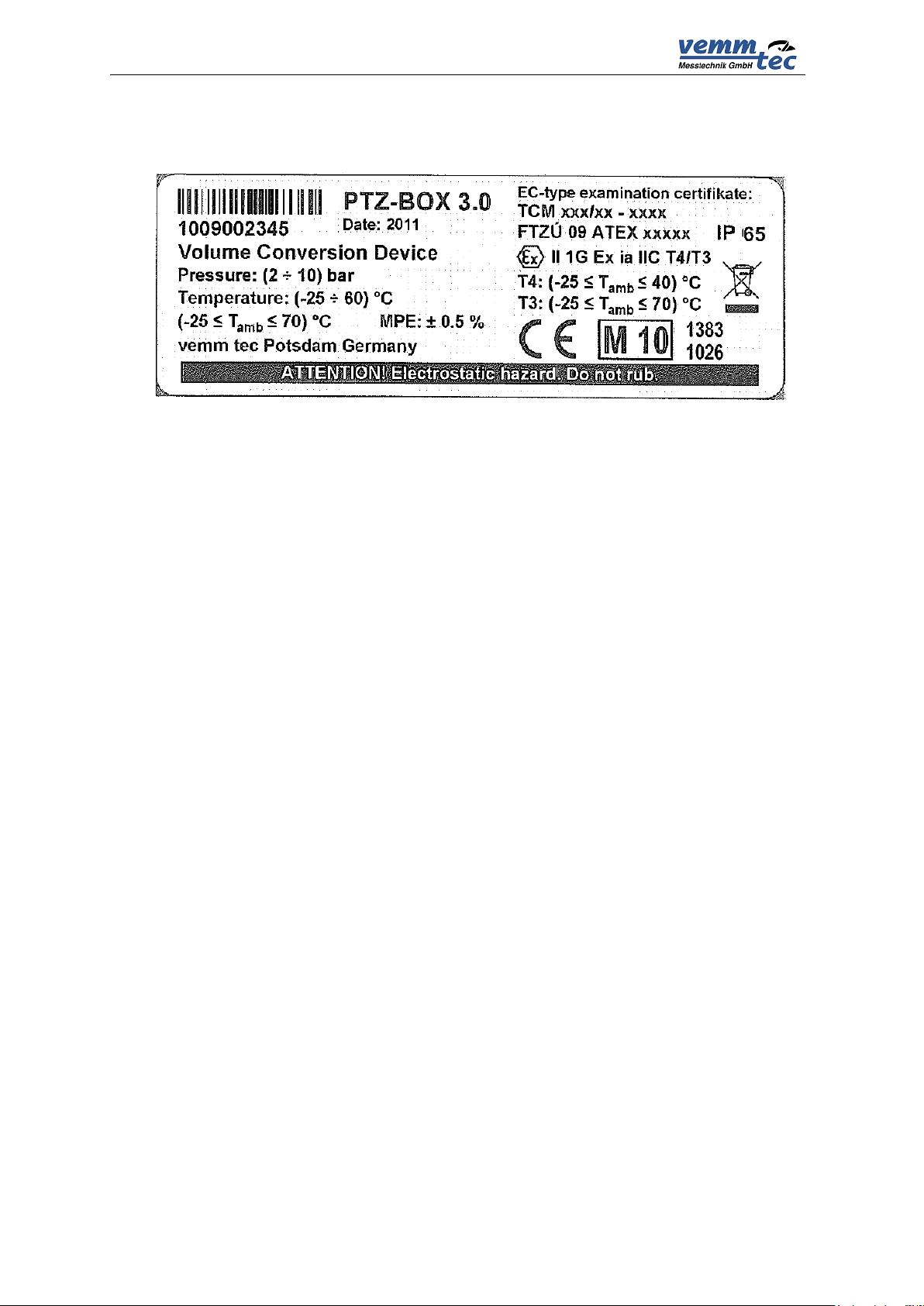

2.4 Product label ......................................................................................................13

3 Safety instructions ................................................................................... 14

3.1 General ..............................................................................................................14

3.2 Use in potentially explosive atmosphere .............................................................14

3.3 Risks of use .........................................................................................................14

3.4 Special conditions of use .....................................................................................15

3.5 Using different groups of gas ..............................................................................15

4 Metrological characteristics .................................................................... 16

4.1 Temperature measurement ................................................................................16

4.2 Pressure measurement .......................................................................................16

4.3 Compressibility calculation .................................................................................17

4.4 Volume measurement and calculation ................................................................18

5 Inputs and outputs .................................................................................. 20

5.1 Inputs .................................................................................................................20

5.2 Outputs ..............................................................................................................22

6 Communication with the PTZ-BOX 3.0 ..................................................... 24

6.1 RS-232 and RS-485 interfaces ..............................................................................24

6.2 Optical interface IEC-1107 ...................................................................................26

7 Functions ................................................................................................. 27

7.1 Parameter indication ..........................................................................................27

7.2 Actual values ......................................................................................................27

7.3 Archives .............................................................................................................28

7.4 Device configuration ...........................................................................................31

7.5 Other device functions ........................................................................................31

7.6 Securing the device against a change of metrological values ...............................32

IOM_Manual_EN_PTZ-BOX 3-0_097-102-003_2017 02.docx

7.7 Access passwords ...............................................................................................33

8 Starting the device .................................................................................. 37

9 Operation ................................................................................................ 38

9.1 Keypad ...............................................................................................................38

9.2 Menu system ......................................................................................................39

9.3 Initial display ......................................................................................................39

9.4 Menu structure ..................................................................................................40

9.5 Quick Access Buttons ..........................................................................................49

9.6 Change settings via the keypad ...........................................................................49

10 Mounting instructions ............................................................................. 51

10.1 Mechanical mounting of the device ....................................................................51

10.2 Cable connection, grounding...............................................................................54

11 Accessories (options) ............................................................................... 56

11.1 Assembly accessories ..........................................................................................56

11.2 Intrinsically safe power supply ............................................................................56

11.3 Barrier and communication modules ..................................................................56

11.4 GPRS communicators ..........................................................................................56

11.5 Other accessories ...............................................................................................56

12 Specifications .......................................................................................... 57

13 Intrinsically safe parameters ................................................................... 62

14 Configuration .......................................................................................... 64

14.1 Checking after installation ..................................................................................64

14.2 Connecting the PTZ-BOX 3.0 with a PC ................................................................64

14.3 Configuration with the GASCcomm software ......................................................65

14.4 Password in the device .......................................................................................76

15 Configuration examples ........................................................................... 78

15.1 Parameters display modes ..................................................................................78

15.2 Setting the gas meter impulse factor ...................................................................78

15.3 Pulse outputs setting ..........................................................................................81

15.4 Analogue output setting .....................................................................................86

15.5 Limits of measured values ..................................................................................89

15.6 Monitoring the external power supply ................................................................91

15.7 Setting of communication with MODBUS protocol ..............................................93

15.8 Configuration of Quick Access buttons ................................................................96

IOM_Manual_EN_PTZ-BOX 3-0_097-102-003_2017 02.docx

16 Exchange of pressure and temperature sensors .................................... 100

16.1 Pressure and temperature sensor replacement procedure in the PTZ-BOX 3.0 ... 100

16.2 Software settings for a new temperature sensor ............................................... 101

16.3 Software settings for a new pressure sensor ..................................................... 103

17 Additional external digital temperature or pressure sensor................... 104

17.1 Fitting an additional digital pressure or temperature sensor ............................. 104

17.2 Configuring the digital sensor in the parameter file ........................................... 106

17.3 Final verification after replacement of a sensor or adding a digital sensor ......... 107

18 What if something does not work ......................................................... 109

19 Literature .............................................................................................. 111

20 Documentation ..................................................................................... 111

21 Software................................................................................................ 112

22 Used trade marks .................................................................................. 112

23 List of figures ......................................................................................... 113

24 List of Tables ......................................................................................... 114

IOM_Manual_EN_PTZ-BOX 3-0_097-102-003_2017 02.docx

PTZ-BOX 3.0

Symbol

Description

Unit

AGA8-G1

Compressibility calculation method

AGA8-G2

Compressibility calculation method

AGA8-92DC

Compressibility calculation method

AGA NX-19 mod

Compressibility calculation method

ASC

Accredited Service Centre

BTS

Base Transceiver Station

CL-1 Module

Analogue output module (4-20mA)

CRC

Checksum – used for data protection

CTR

Communication protocol

Kx MODULE

Some of the products of series Kx module (K1

MODULE, K2 MODULE, K3 MODULE, K3/A MODULE,

K4 MODULE, K4/A MODULE)

DLMS

Communication protocol

DC

Direct Current voltage

dE

Increment of energy

MJ

dV

Increment of primary volume Vm or Vc

m3

dVb

Increment of base volume

m3

dVc

Increment of corrected primary volume

m3

dVm

Increment of primary volume

m3

E

Energy

MJ

Es

Estimated value of energy

MJ

PA1.1

Digital pressure sensor PA1.1 (RS485/Modbus

connection)

TA1.1

Digital temperature sensor TA1.1 (RS485/Modbus

connection)

EMC

Electromagnetic compatibility and resistance

EMI

Electromagnetic radiation

firmware, FW

Software equipment loaded in the device

GOST NX-19

Compressibility calculation method ( related with

AGA NX-19 mod) according to VNIMS directive (valid at

temperature range -23°C to +60°C)

Hs

Combustion heat (Superior heating value)

MJ/m3

IS

intrinsic safety, intrinsically safe

JBZ-0x

Some of the JBZ-01, JBZ-02, JBZ-02/A products

Modbus

Communication protocol designed by Modicon [15]

M900

Specific communication protocol

SGERG-88

Calculation method of gas compressibility factor, more

details in [17]

SNAM

Communication protocol

SW

Software for PC

C

Conversion factor

-

K

Ratio of compressibility factors (Z/Zb)

-

kp

Gas meter constant (number of impulses per 1 m3)

imp/m3

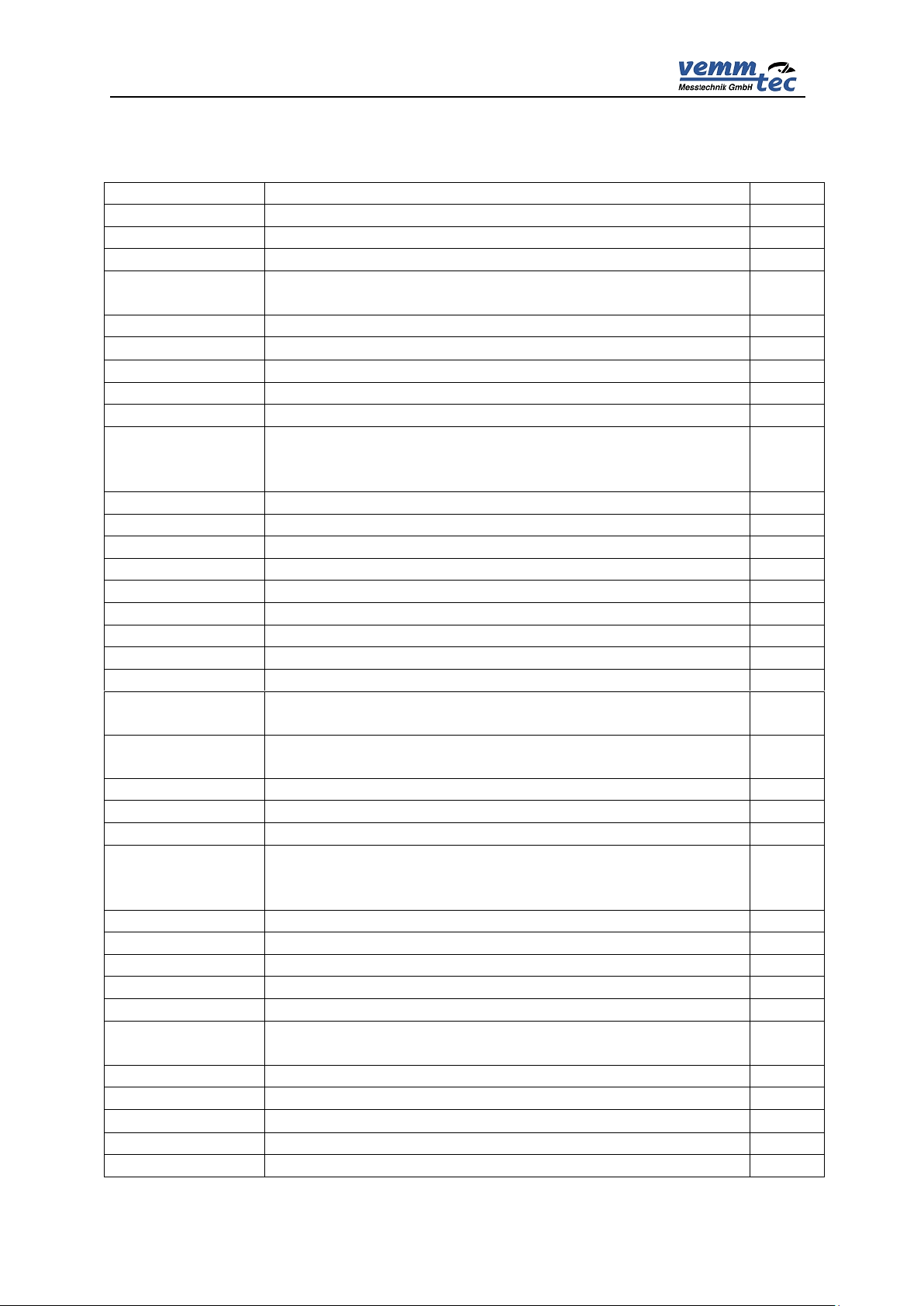

Used symbols and definitions

1

PTZ-BOX 3.0

Symbol

Description

Unit

N

Number of input impulses from gas meter

imp

p

Absolute pressure at measurement conditions

kPa

pb

Absolute pressure at base conditions

kPa

Qm

Flowrate at measurement conditions (further primary

flowrate)

m3/h

Qb

Flowrate at base conditions

m3/h

T

Absolute temperature at measurement conditions (T = t +

273.15)

K

t

Gas temperature

°C

Tb

Absolute temperature at base conditions

K

V

Volume Vm or Vc

Vm

Volume at measurement conditions (further primary

volume)

m

3

Vc

Corrected volume at measurement conditions (volume

corrected based on correction curve of gas meter)

m3

Vb

Volume at base conditions (hereinafter also the

standardized volume)

m3

Vbs

Error volume at base conditions (hereinafter also the

error standardized volume)

m3

Vs

Error volume at measurement conditions (hereinafter

also the error operational volume)

m3

Vd

Difference of primary volume

m3

Vbd

Difference of base volume

m3

Vf

Tariff counter of primary volume

Vbf

Tariff counter of base volume

Z

Compressibility factor at measurement conditions

Zb

Compressibility factor at base conditions

2

PTZ-BOX 3.0

1 Introduction

1.1 Basic device description

The Electronic gas volume converter PTZ-BOX 3.0 (hereinafter called: “the

device”) is a measuring instrument designed for the conversion of the gas volume

measure at measurement conditions to volume at base conditions.

The information on the gas volume passing through is measured using the

impulse outputs of the gas meter. The gas temperature and pressure are measured

by integrated converters. The device calculates the ratio of compressibility factors of

gas using standard methods or a constant value is used.

The device has been constructed and approved according to the EN 12405-1

standard as a conversion device type 1 (compact system) and can be supplied as a

T, PT, or PTZ conversion device.

From safety point of view the device is constructed according to EN 60079-11

as intrinsic safe.

It is manufactured and supplied in compliance with the following European

Parliament directives:

2014/34/EU Equipment and protective systems for use in potentially explosive

atmospheres

2014/30/EU Electromagnetic compatibility

2014/32/EU Directive on measuring instruments

Device is put on the market and into usage according to above mentioned

standards and is marked with CE mark.

The device is built in a casing with sturdy plastic with IP65 protection. It is

equipped with a graphic display and a 10-button keypad. Furthermore, it has impulse

inputs for the connection of a gas meter with LF or HF impulse output and binary

inputs. The device is also suitable for connection to encoder outputs of a gas meter.

The binary inputs can work as check inputs to check the connection with a gas meter

or can have a different function, e.g. monitoring the conditions of safety snap locks,

doors, etc. The device has 4 available outputs. These can be configured as impulse

or binary outputs, or as data outputs for the CL-1 module. When using this module,

an analogue current output can be realized.

The device is powered by a lithium battery. The life cycle of the battery is 6

years in the standard work mode. An external power supply source can be used in

applications with higher demands.

The device has a data archive of the measured values with an adjustable

structure and storing period. The binary archive stores changes on the binary inputs

and the occurrence of the monitored events (limits, etc.) Error conditions are stored

in a status archive. It is possible to program the storing of important parameters and

calculations and storage of some statistical values in the daily and monthly archive.

The archive has settings for service and metrology; in case of changing the settings,

these settings, as well as the counter values, date and time are recorded. Other

available logs are mentioned in 7.3.

3

PTZ-BOX 3.0

V =

N

kp

K =

Z

Zb

C =

p * Tb

*

1

pb

(t + 273.15)

K

For communication with a superior system, the device has a serial interface

(RS-232 and RS-485). Various communication protocols installed in the device allow

easier connection to SCADA systems. The device cooperates with common phone,

radio, GSM, and GPRS modems, and in case of an alarm condition, it can initiate the

connection.

The device can be extended by one non-metrology sensor for measuring

pressure or temperature. This extension can be performed without breaking the

official mark on an already installed device.

Basic configuration of the PTZ-BOX 3.0 offers:

- analogue input (pressure P - metrological channel)

- analogue input (temperature T - metrological channel)

- 4x digital input DI1 to DI4 (binary, pulse); input DI1 can be used for connecting a

NAMUR encoder

- 4x digital output DO1 to DO4 (binary, pulse, analogue)

- communication channel RS485/RS232 for communication with superior system

- input of external power supply

- option: connection of one digital pressure sensor PA1.1 or one digital

temperature sensor TA1.1 (non-metrological) to the internal bus via the EDT

expansion board. This extension can be accomplished by the end user on an

already installed device without breaching metrological seals.

The device can be configured using the supplied SW [22] for PCs. This SW also

allows the readout, display and archive of both the immediate measured values as

well as the contents of the internal device archives.

1.2 Function principle

1.2.1 Conversion using the equations of state

The device obtains data on the gas volume via impulses (N) from an LF or HF

sensor located in the gas meter. The volume at the measuring conditions (V) is

calculated from the number of impulses (N) and gas meter constant (kp).

The device obtains other data on the gas from the temperature and pressure

sensors. This data is used to calculate the conversion factor (C) which is influenced

also by: Absolute temperature at base conditions (Tb), absolute pressure at base

conditions (pb) and compressible factor of the gas at base conditions (Zb).

Volume at measuring conditions (operational volume):

Ratio of compressibility factor:

Conversion factor:

4

PTZ-BOX 3.0

Volume at base conditions (standardized volume):

Vb = V * C

The gas compressibility factor expresses the deviation of properties of natural

gas from the properties of an ideal gas. By setting the parameters, it is possible to

choose a specific method for calculation of the compressibility factor according to the

standard (AGA NX-19 mod, AGA8-G1, AGA8-G2, SGERG-88 or AGA8-92DC). A

constant compressibility value can be used for other gases besides natural gas. If the

pressure or temperature value gets out of the limits of the validity of the chosen

standard, the device calculates using a default compressibility value.

The device calculates the gas flow from the impulse frequency on the input in

real time using mathematical filtration from the input signal.

Operational flow:

Q = ∆V / ∆t [m3/h]

Where: ∆V ............................ increment of operational volume

∆t ............................. time between the impulses with an accuracy

of one hundredth of a second

The value of the flow displayed on the converter display is updated every 10

seconds.

Standardized flow:

Qb = C * ∆V / ∆t [m3/h]

1.2.2 Error values of volumes at measuring conditions and volumes

at base conditions

For calculation during error conditions (i.e. in case of a sensor error, deviation of

the parameter value from the working range, or device error), the device has

counters of the error volume at measuring conditions (Vs) and error volume at base

conditions (Vbs). These counters are interconnected with the pertinent counters of

volume at normal conditions.

A detailed description of device behaviour during normal and error conditions is

in paragraph 4.4.

1.2.3 Volume correction at measurement conditions

Device enables to compensate gas meter error according to predefined

correction curve from gas meter test certificate. This function and parameters Vc can

be activated only by the manufacturer or by an accredited service center to ensure

that the used gas meter correction curve as a function of the flowrate Qm is valid

within the working conditions.

The error of measurement is corrected by using the function f(Qm). The

corrected volume is:

Vc = Vm x f(Qm)

5

PTZ-BOX 3.0

Vc

Corrected volume at measurement conditions

Vm

Primary volume

Qm

Primary flowrate

where

Linear interpolation method is used for getting values between calibration

points. The file with correction values is to be inserted into the device by using the

service software [21]. Information about the insertion of a correction curve into the

device is logged in the setup archive.

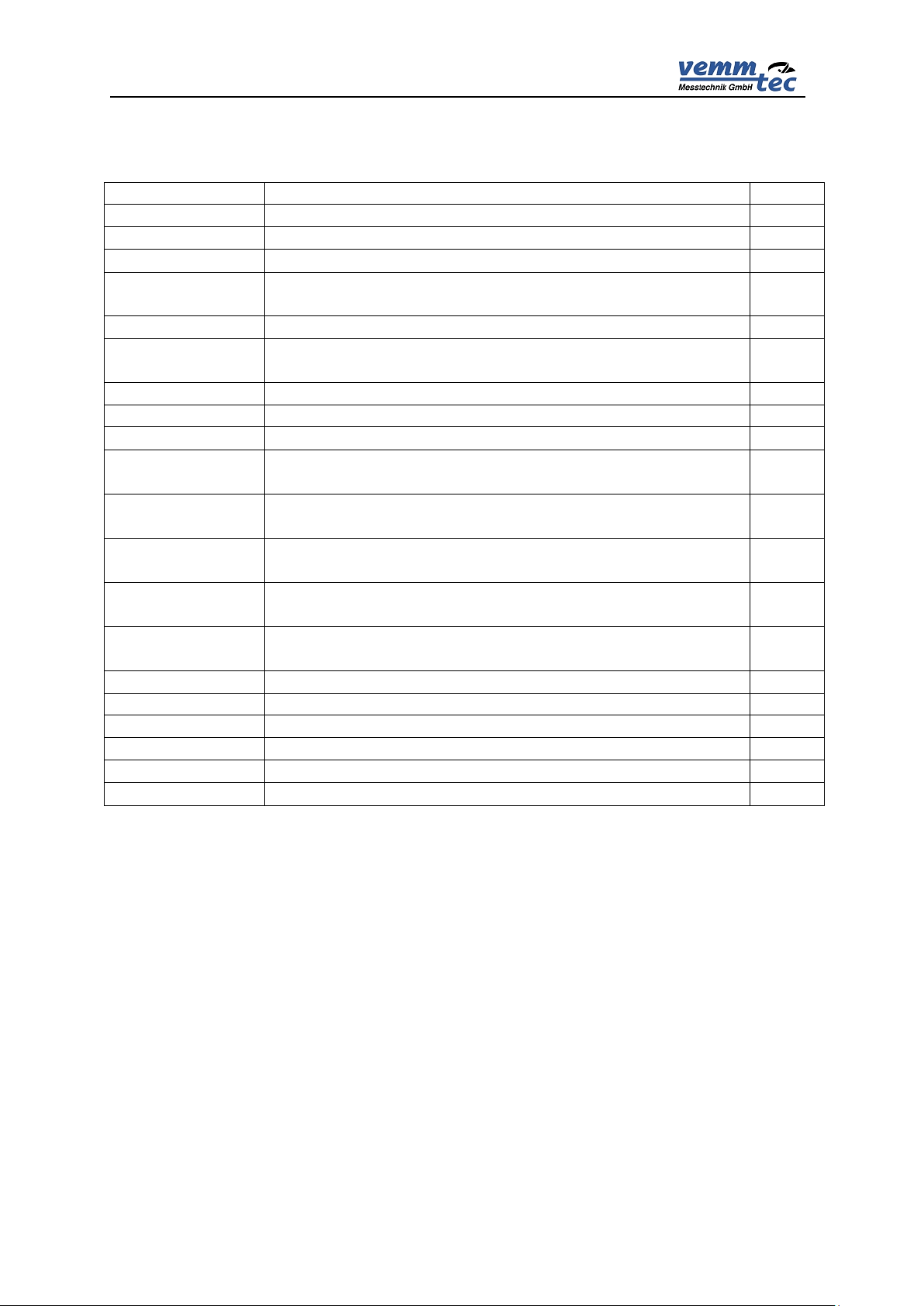

The principle of the volume calculation is explained in Fig. 1

Condition for use of volume correction.

1. Correction is possible only in the case that the gas meter transmits at least

10 pulses per second which means the use of HF sensors is required.

2. Under Q

correction coefficient given for Q

the correction is not applied and over Q

min

will be used.

max

the value of the

max

1.2.4 Conversion of volume to energy

The device can calculate the energy content from the consumed quantity of

gas. This conversion uses the value of the combustion heat Hs. The calculation is

made with the differences dVb (and dVbs) multiplied by the actual value of the

combustion heat Hs.

dE=Hs x dVb, dEs=Hs x dV

Two counters (energy counter E and error energy counter Es) are dedicated for

measurement in units that can be selected to present the value in MJ, kWh or Btu.

No conversion of the absolute counter value (E or Es) is performed after the change

of measurement units. Following increases are added in the new units.

Principle diagram of energy calculation is drawn at Fig. 1

Combustion heat Hs

To get a correct conversion it is necessary to enter the right value of the

combustion heat and the related conditions. Then the device will make a new

conversion of the relative temperature for the defined relative conditions and the final

value will be used for the energy calculation. In case of the AGA8-92DC method the

combustion heat is not entered as a fixed value but calculated from the gas

composition according to EN ISO 6976. For the other methods the value of Hs

(MJ/m3) must be entered manually and always under the conditions:

combustion temperature/ temperature of gas = 25°C / 0 °C

bs

6

PTZ-BOX 3.0

Fig. 1 Volume and energy calculations - Scheme

7

PTZ-BOX 3.0

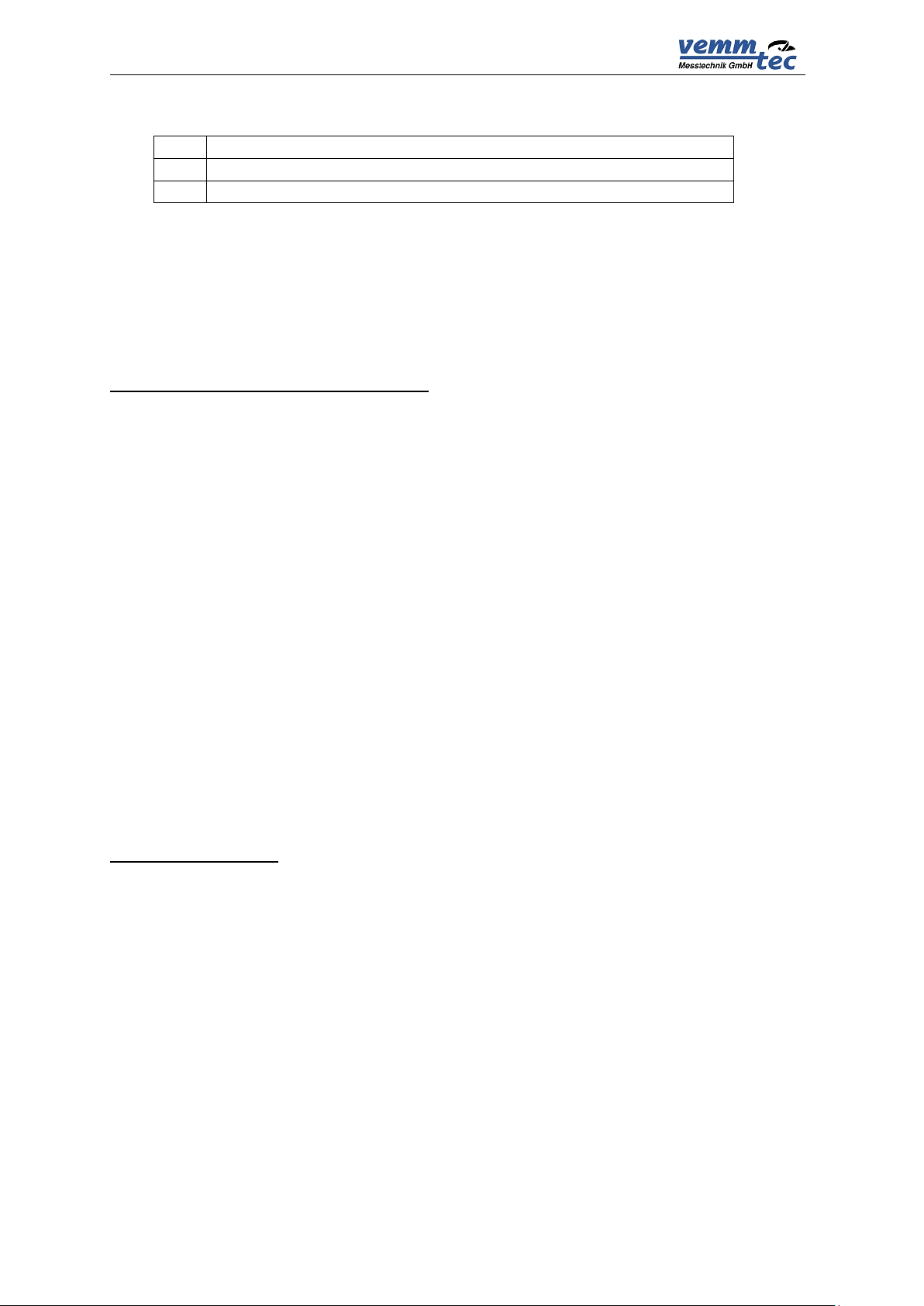

1.3 Device dimensions

Fig. 2 Device dimensions

2 Device technical description

2.1 Device architecture

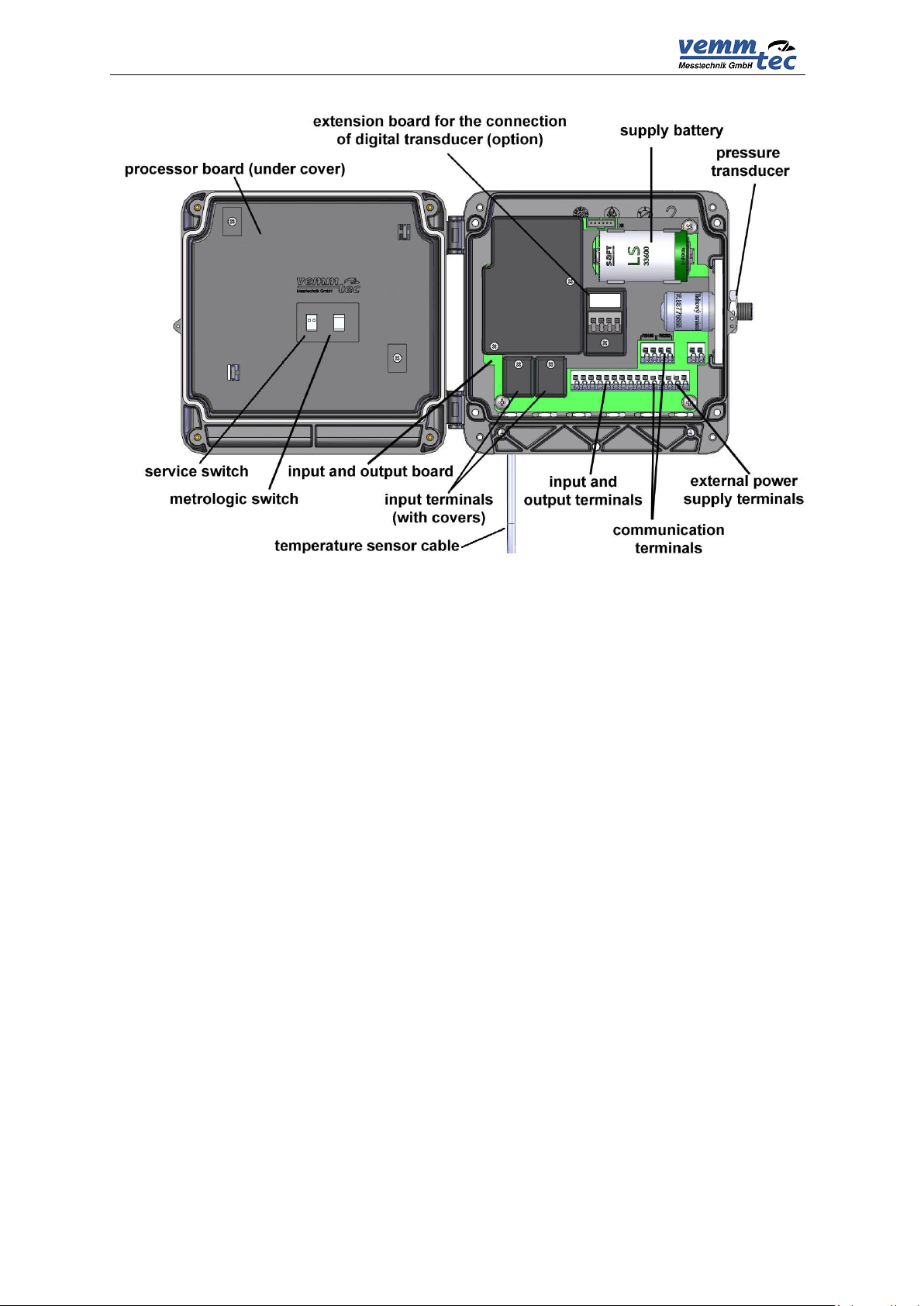

The device’s electronics are laid out on three basic boards.

The bottom part of the casing contains the input/output board with the battery

and back-up battery and terminals for connecting the pressure and temperature

sensors and device inputs and outputs. The connections related to the metrological

function of the converter are protected by covers which are secured with official

seals.

Optionally, the input board can have an extension board (EDT port) for

connecting an additional digital pressure sensor (PA1.1) or digital temperature

sensor (TA1.1). This additional digital sensor communicates with the converter using

the Modbus RTU protocol (via RS-485). More information can be found in chapter 17.

The lid of the housing contains a processor board that is protected by a cover

and secured by an official seal. The board cover has an opening for access to the

service switch. The service switch can be used to enable/disable the setting of the

device parameters using a service SW.

8

PTZ-BOX 3.0

Fig. 3 Main parts of the device

2.2 Power supply

2.2.1 Main supply battery

The device is powered by a built-in (lithium) battery with a voltage of 3.6 V. The

life cycle of the battery depends especially on the configuration of the device, the

frequency of communication, and the time the display is on. The consumed capacity

is calculated during the device’s activity and the capacity decrement is recorded in its

memory. The device will issue an alert to replace the battery 90 days before the

expected discharge (error message E9 – see paragraph 9.4.8.

Standard mode for a life cycle of the main supply battery of more than 5 years:

Archiving period of the data archive 1x per hour

Communication with device 2 min/day

Activating the display 2 min/day

Frequency of input impulses ≤10 Hz

Measuring period 15 s

Ambient temperature 25 °C

If the device is operated with higher consumption than in the defined mode, it

is necessary to count on a more frequent replacement of the battery or use a network

power source.

9

PTZ-BOX 3.0

Replacement of main supply battery is allowed in the hazardous area but

only with recommended type of battery.

To correct the calculation of the remaining battery capacity after

replacement it is necessary to reset the battery calculation with service SW

[22]. In the parameter file, select the hardware module and press the button

„Change battery“.

2.2.2 Replacement of main supply battery

It is advised to disconnect a discharged battery as soon as possible. While the

battery is being replaced, the device does not measure pressure or temperature, but

counts the incoming LF impulses (but does not convert the number of pulses, this will

be performed when the supply battery is connected again) and insures that the real

time clock is running. The data stored in the device archives and parameter settings

will remain.

Discharged batteries are in the hazardous waste category. According to

European directives and other internal directives batteries must not be disposed

together with household waste.

2.2.3 Back-up battery

The battery ensures the back-up of important functions in case of the discharge

or replacement of the supply battery. The back-up battery can be replaced in an

accredited service center after the official and security seal is broken (replacement

cannot be performed in a potentially explosive atmosphere). It is necessary to use

the same type of battery: Only recommended battery type may be used.

Standard mode for a life cycle of the back-up battery of 10 years

Storage temperature 25 °C

Backed-up inputs (DI1 – DI4) not connected or connected contacts

disconnected

Does not depend on the presence of the supply battery

Standard mode for a life cycle of the back-up battery of 4 years

Backed-up inputs (DI1 – DI4) short-circuited

Without powering battery

10

PTZ-BOX 3.0

12 VDC

EEx

P0

DI 1

DO 4

K3 MODULE

DO 1

DO 2

DO 3

P2

6V OUT

DI 3

DI 2

DI 4

POWER

DI1

DI2

DI3

DI4

INPUTS

DO1

DO2

DO3

DO4

OUTPUTS

PTZ-BOX 3.0

RS232

INPUT T

RS485

INPUT P

INT. BUS (optional)

Ex i

POWER

DI1

DI2

DI3

DI4

INPUTS

DO1

DO2

DO3

DO4

OUTPUTS

PTZ-BOX 3.0

RS232

INPUT T

RS485

INPUT P

INT. BUS (optional)

Ex i

=12V

=8V

JBZ-02

EEx

12 Vdc

12 Vdc

Hazardous area Safe area

Safe area

Hazardous area

Self-discharging of batteries

The back-up and supply batteries are lithium type. Their capacity drops due to

self-discharging. The recommended time frame for their replacement is 10 years,

even if the battery was never connected.

2.2.4 External power supply

Use of an external power supply is required in case of:

- NAMUR HF pulse input

- Binary output

- NAMUR encoder.

External power supply is recommended in case of increased current consumption

like:

- frequent communication (more than once a day),

- frequent LCD displaying

An approved intrinsically-safe power source must be used for the external

power supply. The internal power sources of the communication modules Kx

Modules can be used if no NAMUR sensors are connected.

If a NAMUR sensor is connected: always use an external power source JBZ-02

or JBZ-01.

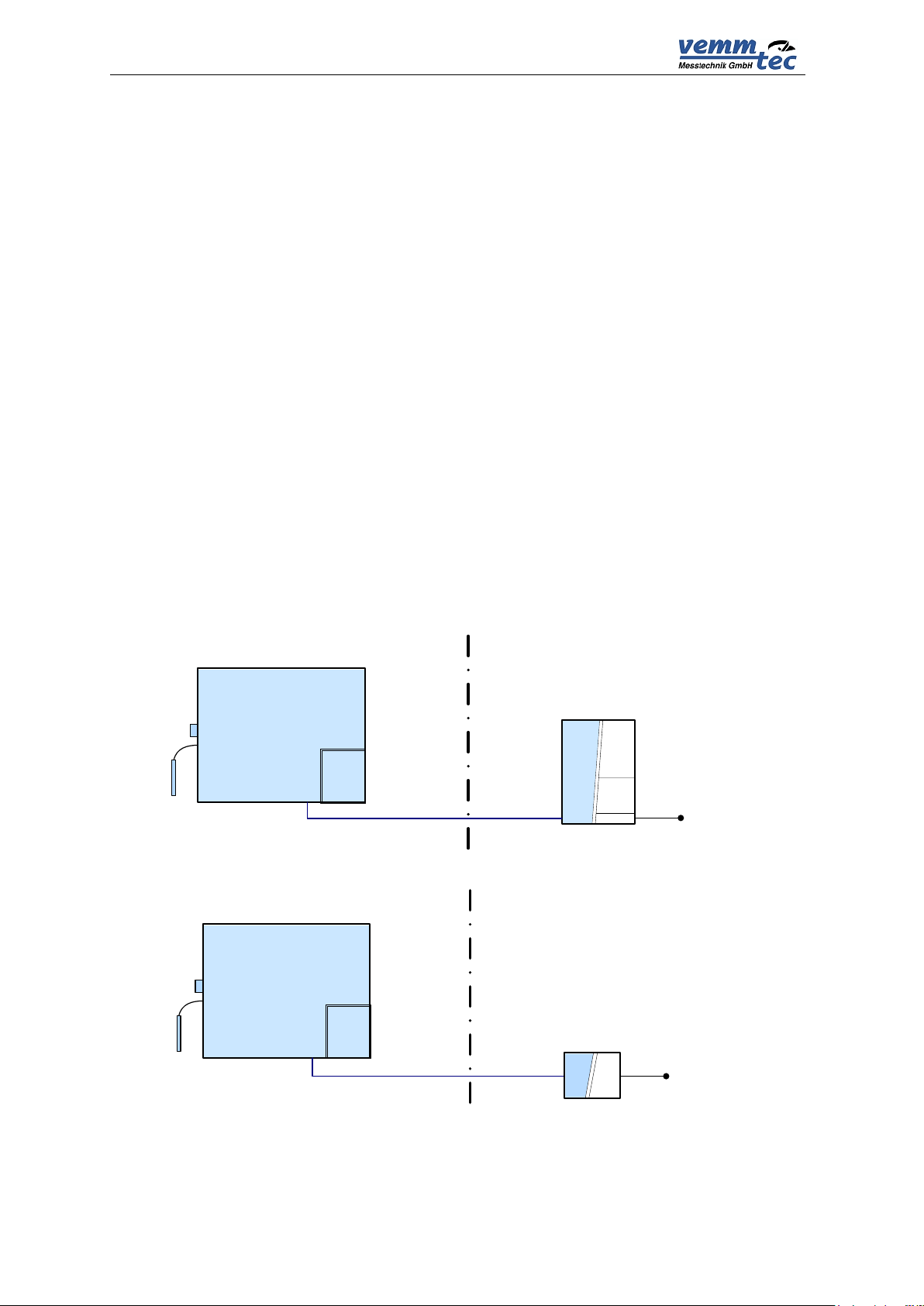

Fig. 4 Examples of external power supply

11

PTZ-BOX 3.0

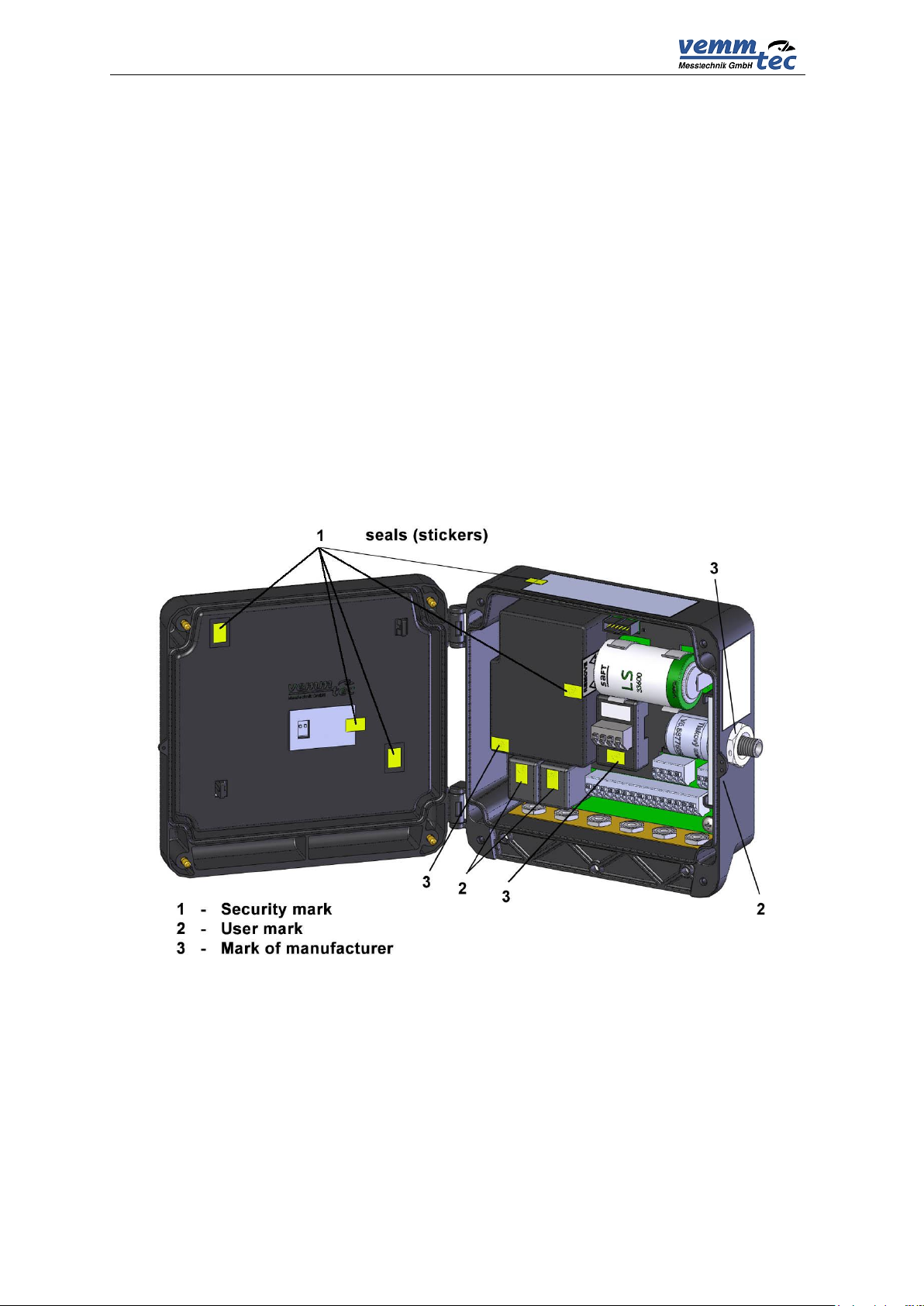

2.3 Security seals

Security seals located on the device indicate the technical condition of the

device regarding unauthorized handling.

Security seal of the manufacturer (metrological seal)

- its design is stipulated by the Approval certificate on the quality management

system for production, output control, and testing pursuant to Enclosure no. 2,

procedure D, ND no. 464/2005 Coll., issued by the Notified Body no. 1383. Such

security mark has the same importance for the user as the so called official seal

according to the Act on Metrology.

In case such a seal is broken, the manufacturer does not guarantee that the

properties of the device are in compliance with the EC Certificate on type verification.

User seal

- control seal of the user (seals) as needed

Seal of the manufacturer

- control seal of manufacturer as needed

Fig. 5 Security marks

12

PTZ-BOX 3.0

2.4 Product label

13

PTZ-BOX 3.0

II 1G Ex ia IIC T4/T3

PTZ-BOX 3.0

Zone 0

The device has been constructed and approved as intrinsically safe. That

means that only approved devices (intrinsically safe devices, consecutive

devices) or so called simple devices complying with the EN 60079-11 standard

and complying with the intrinsically safe parameters listed in the

EC Certificate on type verification [16] can be connected to the device

connectors.

The applicable safety standards must be met when connecting.

3 Safety instructions

3.1 General

The device has been approved according to the guideline 94/9/CE

(2014/34/EU) and an EC certificate on type approval (ATEX) has been issued for its

use in potentially explosive atmospheres. Respecting this guideline is mentioned in

the CE compliance notation.

3.2 Use in potentially explosive atmosphere

Device is fully in compliance with EN 60079-26 ed.2 (see [4]).

Based on the EC certificate in the verification 11 ATEX 0015X, the device can

be operated in potentially explosive atmospheres with a classification of ZONE0.

Indication of the device regarding safety against explosion:

Environment temperature for temperature class T4: -25 °C to +40 °C

Environment temperature for temperature class T3: -25 °C to +70 °C

When connecting a device, it is necessary to consider the electrical

characteristics of the connecting cables and respect the requirements of the

applicable safety standards. Furthermore, it is necessary respect the Special

conditions of use provided these certificates contain them. The parameters of nonexplosiveness of the device are listed in chapter 13.

3.3 Risks of use

Device cabinet is made of polycarbonate. A keypad foil of polystyrene is placed

on the top cover. In some extreme cases electrostatic charge accumulated on

surface of cabinet could cause explosion. To avoid explosion it is strictly

recommended to keep the following rules:

At hazardous the zones device must not be installed at places where

ambient conditions could create an electrostatic charge.

Device may only be cleaned by humid wiper.

14

PTZ-BOX 3.0

Group of gas

Device variant

IIC

IIB

IIA

PTZ-BOX 3.0

yes

yes

yes

1. The device must not be installed or located in an environment with a

potential danger of electrostatic charge of the device casing (e.g. by

flowing air, etc.) Only a damp cloth must be used if the device is being

cleaned, to prevent the creation of electrostatic charge.

2. Only the following types of batteries are allowed to be used in the device:

Main supply battery: Saft LS33600, Backup battery: Saft LS14250.

3.4 Special conditions of use

3.5 Using different groups of gas

Individual variants of device can be used only with certain groups of gas

according to this table.

15

PTZ-BOX 3.0

4 Metrological characteristics

4.1 Temperature measurement

This device uses the PT1000 temperature sensor to measure temperature. The

temperature sensor’s connection is two-wired. The influence of the length and the

characteristics of the cable used are considered during calibration and therefore do

not influence the accuracy of the temperature measuring.

The temperature measuring range is -25 °C to +60 °C. The measuring period is

equal for both the temperature and pressure sensor and it can be custom set at a

range from 1 s to 30 s. The temperature measurement units can be adjusted.

Replacement of the temperature sensor is protected by the security seal of the

manufacturer (metrological seal) and can be performed solely at an Accredited

Service center (ASC).

During device configuration, the user must enter the Default temperature

value. This value will be used for the calculation of compressibility instead of the

measured temperature value in the following cases:

- The value of the measured temperature are out of the measuring range

- An error occurred when measuring the temperature

4.2 Pressure measurement

Pressure measurement is performed by an analogue converter. The converter

contains a piezoresistive silicon sensor with a resistant stainless steel membrane.

The device electronics ensures the correction of non-linearity and the temperature

dependency of the pressure sensor based on the calibration data saved in the device

memory. The measuring range of the pressure converter must be requested by the

customer when ordering the device. The available pressure ranges are listed in

chapter 12.

The measuring period is equal for both the measuring of temperature and

pressure, and can be custom set at a range from 1 to 30 s. The pressure measuring

units can be set.

Replacement of the pressure converter is protected by a security seal of the

manufacturer (metrology mark) and can be performed solely at an Accredited Service

center (ASC).

During device configuration, the user must enter the constant parameter

Default pressure value. This value will be used for the calculation of compressibility

instead of the measured pressure value in the following cases:

- The value of the measured pressure are out of the measuring range

- The device is manufactured without the pressure converter (so called TZ

or T corrector)

- An error occurred when measuring the pressure

16

PTZ-BOX 3.0

Pressure

measuring range

Method

AGA NX-19

mod

SGERG-88

AGA8-G1

AGA8-G2

AGA8-92DC

80 ÷ 520 kPa

-25 ÷ +60 °C

-25 ÷ +60 °C

-25 ÷ +60 °C

-25 ÷ +60 °C

200 ÷ 1000 kPa

N/A

-25 ÷ +60 °C

-25 ÷ +60 °C

-25 ÷ +60 °C

400 ÷ 2000 kPa

N/A

-25 ÷ +60 °C

-25 ÷ +60 °C

-25 ÷ +60 °C

700 ÷ 3500 kPa

N/A

-10 ÷ +60 °C

-10 ÷ +60 °C

-25 ÷ +60 °C

1400 ÷ 7000 kPa

N/A

-10 ÷ +60 °C

-10 ÷ +60 °C

-25 ÷ +60 °C

80 ÷ 1000 kPa

N/A

-25 ÷ +60 °C

-25 ÷ +60 °C

-25 ÷ +60 °C

400 ÷ 7000 kPa

N/A

-10 ÷ +60 °C

-10 ÷ +60 °C

-25 ÷ +60 °C

4.3 Compressibility calculation

4.3.1 PTZ, TZ conversion

The compressibility factor is calculated from the composition of the gas, using

one of the following methods implemented in the device: AGA NX-19-mod, SGERG88, AGA8-G1, AGA8-G2 or AGA8-92DC.

Calculation of the compressible factor is performed in each measuring period. In

the SGERG-88 and AGA8-G1 methods the value of the heating value is entered for

the combustion temperature 25°C / gas temperature 0°C. The service SW contains a

built-in calculator for the conversion of the heat of combustion at different

temperatures.

Due to the required accuracy of the device, the use of the individual methods of

calculation of compressibility is limited by the pressure and temperature ranges

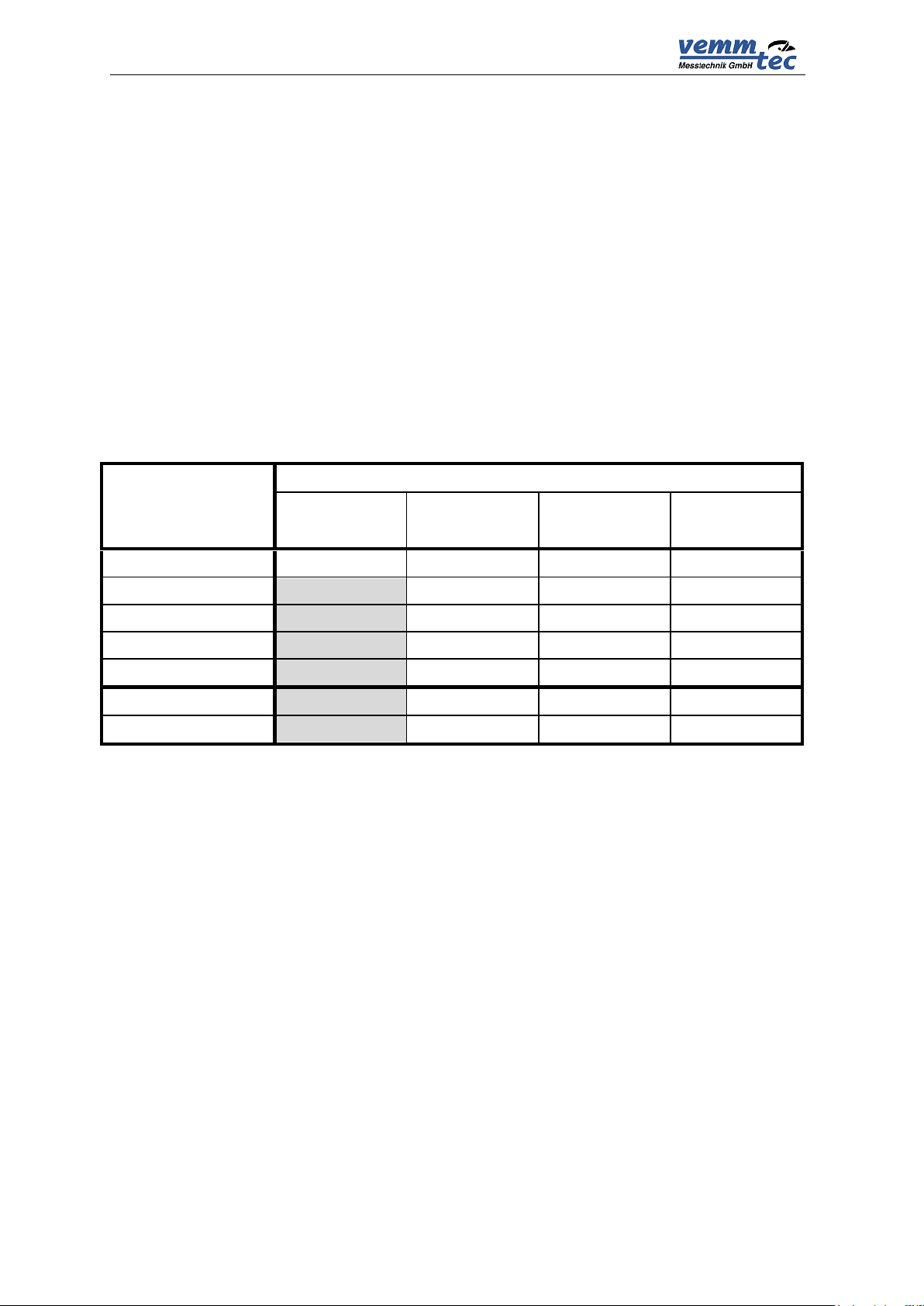

according to the following table:

Table 1 Limitation of standard validity range of compressibility calculation

Note:

Additionally the GOST NX-19 method is applied which is not approved in the

MID certificate. The use of the GOST NX-19 method is limited to a temperature

range from -23°C to +60°C.

Default compressibility

For the set method during each calculation, it is checked whether the measured

pressure and temperature value are in the valid range of the selected method. If

values are outside the valid range, the so called default compressibility is used for

the conversion. The value of the default compressibility must be entered by the user

during device configuration.

4.3.2 PT, T conversion

The device also allows the setting of the ratio of compressibility factors (K) as a

fixed constant. The range of the entered constant is not limited.

17

PTZ-BOX 3.0

Vm

Primary volume counter (Actual volume)

Vc

Corrected volume counter (volume corrected based on gas meter

correction curve)

V

Volume Vm or Vc

Vs

Counter of the actual volume under error conditions (error actual

volume)

Vb

Counter of volume at base conditions (standardized volume)

Vbs

Counter of standardized volume under error conditions

4.4 Volume measurement and calculation

For measurement and volume calculation the following counters are used for

each channel.

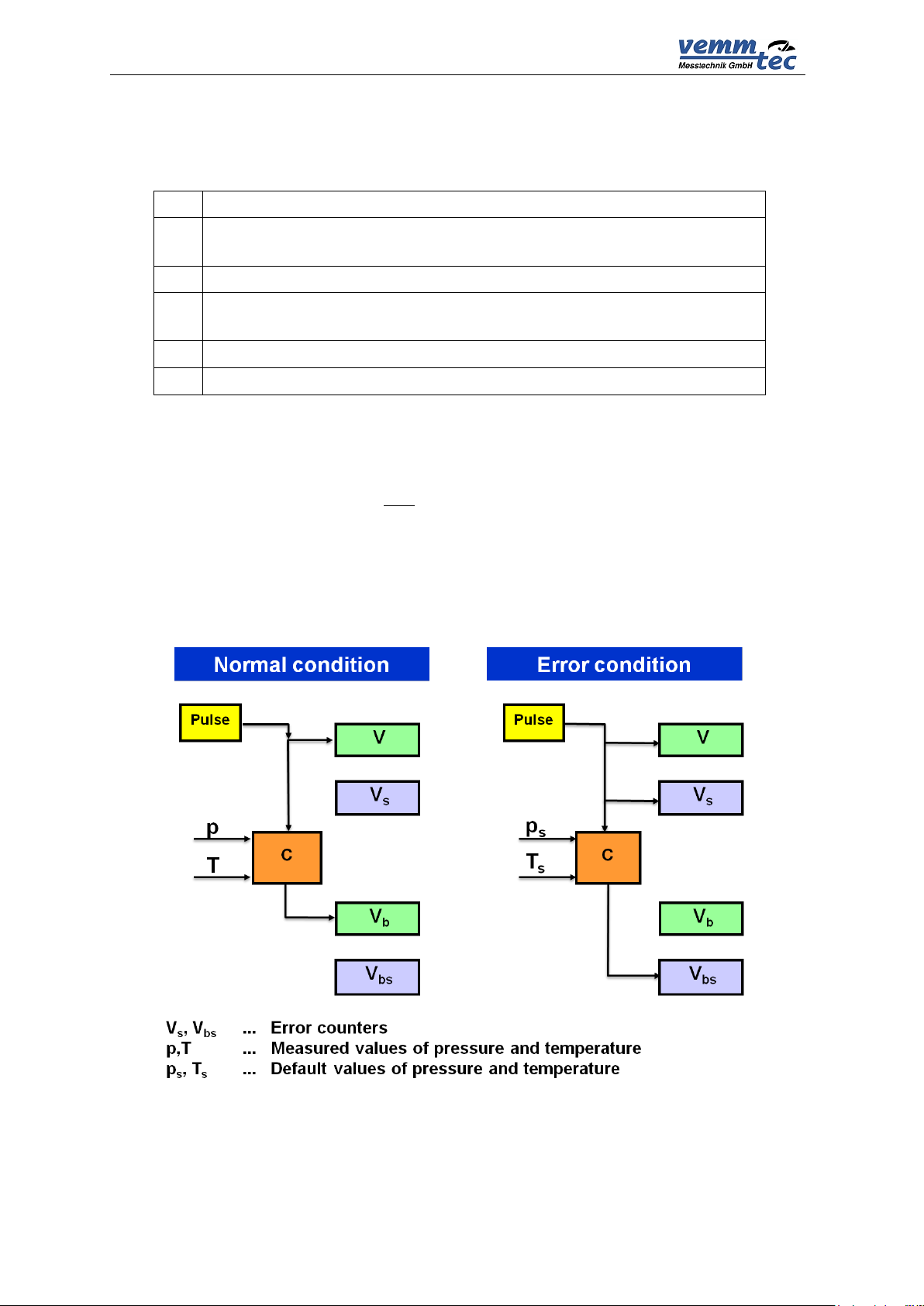

4.4.1 Operation at error conditions

In case of error conditions, the device will count the actual value as well in the

counter of the actual volume (V) and in the counter of the error volume at measuring

conditions (Vs). The values of the volumes at base condition (Vb) will stop being

counted in the counter of the volume at base conditions (Vb), and will calculate from

the default values of pressure or temperature and will be stored in the counter of the

error volume at base conditions (Vbs). During this condition, the values are not stored

in the counter of volume at base conditions (Vb).

Fig. 6 Storing impulses in counters

18

PTZ-BOX 3.0

If a default compressibility is used during the calculation (when temperature or

pressure are out of the valid range of the compressibility calculation formula) (see

article 4.3.1), whereas pressure or temperature are not outside the measuring range;

the converted volume is stored in the error counter.

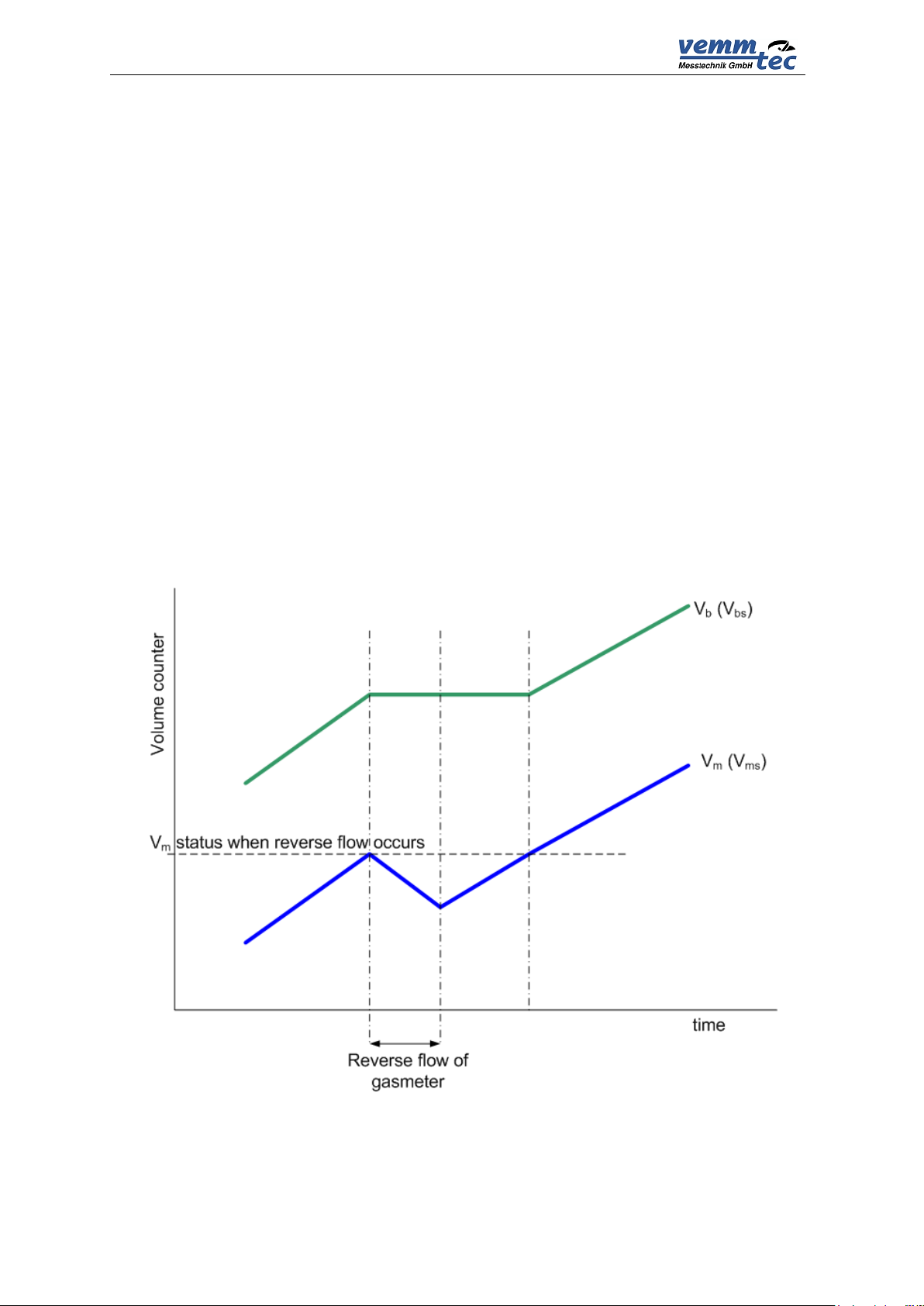

4.4.2 Recognition of a changing gas flow direction

Flow direction detection is enabled for gas meters equipped with two phases

shifted LF sensors or encoders. Corrector evaluates gas flowrate respecting direction

changes (Pic. 7) under following terms:

- If primary volume additions are positive: volume processing is made by

standard procedure (for example increasing of Vm and Vb, or Vms and Vbs).

- If gas flow direction is changed device will fix the value of primary volume

counter at the moment of turn. When gas flows back only primary

volume Vm (or Vms) is updated. The other counters are frozen.

- After returning back to the correct direction counting will get blocked out

into appropriate counters (Vb, Vbs) only after reaching level of primary

volume where reversed flow was started up. Primary volume counter is

equivalent to gas meter counter all the time.

Fig. 7 Processing of volumes during reversed flow

19

PTZ-BOX 3.0

Input

Binary

contact

Binary

NAMUR

LF

impulse

HF

impulse

NAMUR

encoder

DI1 √ √

√ √ √

DI2 √ √

√ √ -

DI3 √ - √ - - DI4 √ - √ -

-

5 Inputs and outputs

5.1 Inputs

A total of 4 digital inputs marked as DI1 to DI4 can be connected to the device.

The inputs are provided at the terminal board inside the device. The digital inputs can

be adjusted as a binary or as a LF impulse by using the service SW. The DI1 and DI2

can also be set as HF NAMUR impulse or as a binary NAMUR type. In devices with

FW ver. 4.xx input DI1 may be setup also for connection with NAMUR encoder.

Table 2 Digital inputs setting options

5.1.1 LF impulse inputs

Serves to read impulses from a gas meter. The flow measuring function can be

chosen for these inputs. The back-up battery ensures preservation of counters’

conditions and reading the impulses of the LF inputs also in case of the discharge or

replacement of the supply battery. After connection of the supply battery, the

impulses read during missing voltage of the supply battery are added to the error

counters. The LF impulse input is, on the DI1 and DI2 inputs, connected between the

terminals LF+ and LF- (see Fig. 8).

Changing measuring units, setting the gas meter constant

The measuring units of the impulse inputs can be changed using the service

SW [22]. The conversion constants of the gas meter and S/N of gas meter can be set

using the service SW as well, as also directly from the device keyboard. When

setting the value of the gas meter constant, only decimal folds or fractions in range

from 0.01 to 100 are expected.

Number of places of counters of LF impulse inputs

In the case of LF impulse inputs, the counter works with 9 valid digits, the gas

meter constant influences the size of the maximum number from 9 999 999.99 (for

constant = 0.01) to 99 999 999 900 (for constant = 100).

5.1.2 HF impulse inputs (NAMUR)

The inputs DI1 and DI2 can be configured for processing HF NAMUR impulses.

Due to the fact that these sensors require a supply voltage higher than the voltage of

the supply battery of the device, the converter must have an external supply voltage

higher than 7 Vdc (e.g. from JBZ-02) for the registration and processing of HF

impulses.

The flow measuring function can be chosen for these inputs. The back-up

battery ensures the preservation of counters’ conditions in case of a failing external

power supply even in the case of discharge or replacement of the supply battery, but

20

PTZ-BOX 3.0

it does in this case not count the impulses. The terminals for the HF NAMUR inputs

are marked HF+ and HF- (see Fig. 8).

Changing measuring units, setting the gas meter constant

The impulse inputs measuring units and the gas meter constant can be

adjusted using the service SW. The gas meter constant and S/N of gas meter can

be also set from the device keyboard.

Number of places of counters of the HF impulse inputs

In the case of HF impulse inputs, the counter works with 9 digit places.

5.1.3 Connection with gas meter via encoder

Gasmeter can be connected with corrector via an NAMUR encoder. In this case

the digital value of the gas meter counter is transferred into EVC. The use of an

encoder is approved for metrological use by the EC- MID type approval.

NAMUR Encoder

No special HW is required for the use of a NAMUR encoder. The only condition

for NAMUR encoder data processing is the use of an IS external power supply

(JBZ-02 or JBZ-01).

NAMUR Encoder input

Connection between EVC and encoder is made with a shielded two wire cable.

The NAMUR encoder can only be connected via the digital input DI1. Terminals for

the encoder are the same as for HF pulse inputs marked HF+ and HF- (correct signal

polarity is important.). NAMUR encoder connection must be setup in the EVC

parameters with service SW [22].

5.1.3.1 Device specification with encoder

Data from an encoder are transferred into EVC via shielded two wires cable.

Together with the absolute value of gas meter counter there are transferred other

additional data like S/N, gas meter constant, nine positions for counter overturning).

These additional data are read out with service SW [22] usable at device

configuration.

In case of an error in the communication between EVC and encoder then an

asterisk symbol “ * “ after the actual primary volume. Manual setup of primary volume

counter Vm is not allowed at encoder input.

Installation and replacement of gas meter

When the actual counter value of the gas meter is transferred into the EVC after

connection of the encoder and the EVC a big difference might occur at the primary

volume Vm. To prevent against affection of base volume Vb (Vbs) it is necessary to

keep following instruction:

1. In service SW [22]: display device parameters; select subject „Hardware“

and the push button „Change gas meter“. During encoder exchange the

processing of the primary volume from the gas meter will be stopped.

(Follow further follow instructions on the PC display).

2. Physically connect the encoder to the EVC.

21

PTZ-BOX 3.0

3. After connection of the encoder finish installation/exchange with OK button.

During installation/exchange (point 1) no differences are added to the applicable

counters which are marked on display with exclamation mark. If point 3 is not finished

by one hour exchange procedure will be closed automatically at service SW.

5.1.4 Binary inputs

These inputs monitor the input signals with the option of an evaluation of the

condition “connected” (i.e. log. 0) or “disconnected” (log. 1). The device allows

evaluation of binary inputs from no-potential outputs (reed contact or open collector –

these signals are on DI1 and DI2 inputs connected to terminals LF+, LF-) or from

NAMUR sensors (DI1 and DI2 inputs, terminals HF+, HF-). NAMUR sensors require

an external power supply of the converter higher than 7 V (JBZ-01 or JBZ-02).

By setting the parameter, the user can choose the display of the actual values

on the display, storing the changes of these inputs in the archive; display the

headline for condition log. 0 and log. 1, and active signal level.

Fig. 8 Inputs and outputs terminals

5.2 Outputs

The device has 4 digital outputs DO1 to DO4 which can be configured as

binary, impulse, or data. A data output serves the CL1 analogue output module (4-20

mA) which should be connected to this output.

The outputs can be controlled by the device using calculation equations

entered by the user in the device parameters (for example, it is possible to generate

outputs according to the gas flow, indication of alarm condition, exceeding the set

limits of pressure or temperature, etc.).

22

PTZ-BOX 3.0

INPUTS

POWER

GND

+

HF+

LFHF-

LF+

HF+

-+-

+

PTZ-BOX 3.0

GND1

CTS

RxD

TxD

RS232

Ex i

OUTPUTS

DO1

DO2

DO3

DO4

GND

LF+

LFHF-

DI1

DI2

DI3 DI4

1. channel (analog)

Pt1000

Pt1000

GND

Vce

UT

UP-

UP+

1W

GND1

U1+

D1 -

D1+

RS485

INT. BUS RS485

(optional)

U+

D-

D+

GND

K3 MODULE

P2-RS232

1

9

5

6

Um = 250 V

DIGITAL OUTPUTS

DO3

D -

DO2

DO1

GND

DIGITAL INPUTS

GNDU+DI1

DI2

DI3

DI4

P0 – RS485

GNDU+D-D+GND

U+

D-

D+

6V OUT

GND

U+

DO4

D +

+

GND

12V

P2-RS485

DIN 12V

4-20mA

-

+

CL-1

GNDDIGND

+

+

-

~

~

12VDC

230VAC

U2 U4

230 V/50Hz

Hazardous area

Safe area

relay

pulse | binary

output (DO1)

current output

4-20mA

(DO2)

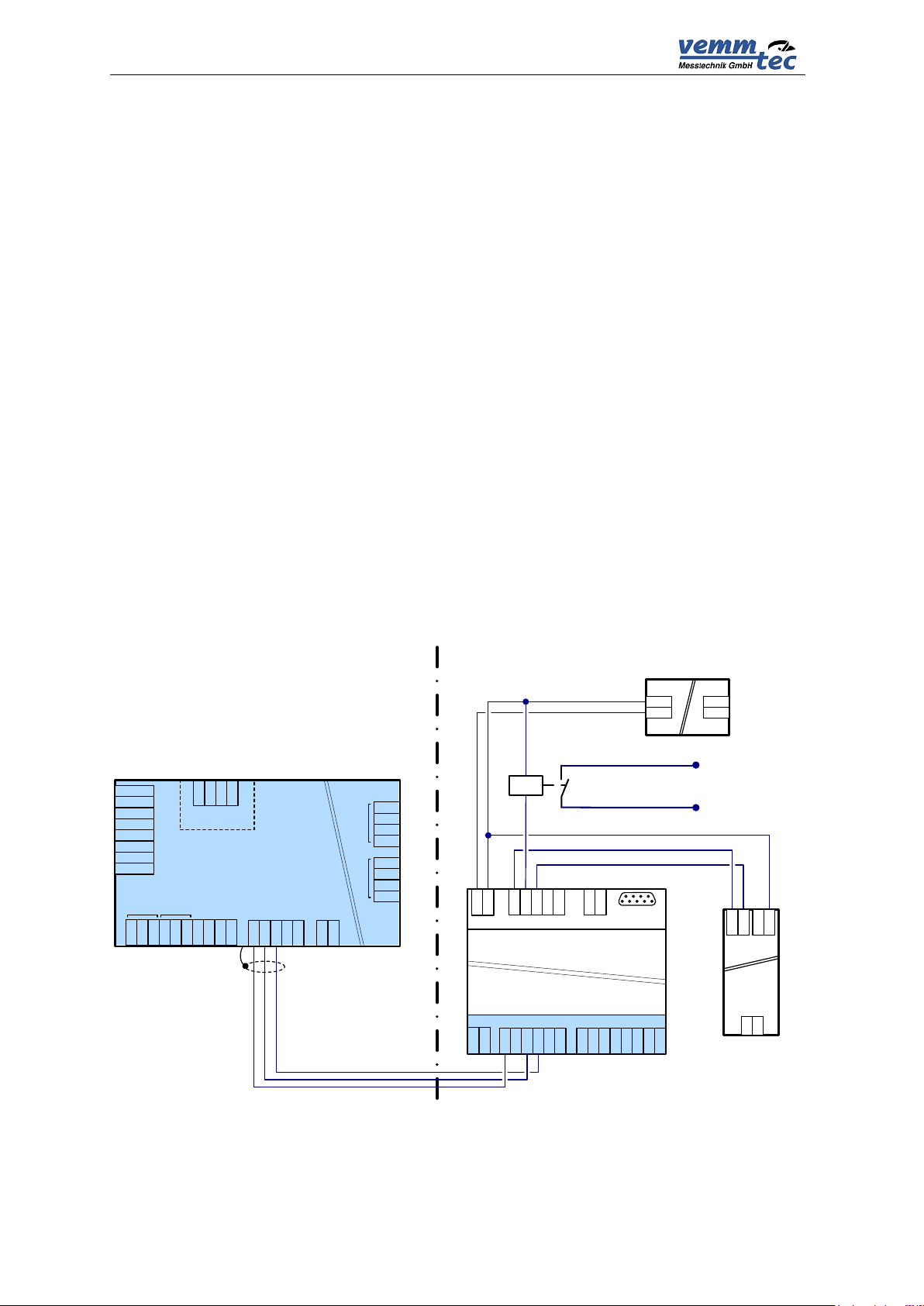

The device structure allows the generation of outputs even when the device is

powered solely by the battery with no effect on the battery life cycle. The outputs are

“open collector” type and are not galvanic separated. All four outputs have a joint

GND conductor.

The outputs are intrinsically safe, thus when connecting standard devices, the

devices must be connected via a safety barrier (e.g. K3 Module, see

Fig. 9).

Impulse outputs

The impulse outputs have adjustable width and impulse periods in folds of 0.1 s.

Collection of impulses for these outputs can reach max. 65535 pulses. An output

constant can also be configured in the setting equation of the output parameter.

Binary outputs

Output terminals are according to the setting and status in the connected or

disconnected state. In the resting state, the output terminals are disconnected

(condition log.1).

Data output

The digital output configured as a data output serves for communication with

the CL-1 module. An analogue output 4-20 mA can be realized using this module.

Using the calculation equations, the value of the output can be parameterized as

proportional to pressure, flow, daily consumption, etc. The CL-1 module must be

connected to the converter via a safety barrier (K3 module).

Fig. 9 Example of an impulse (binary) output and current output scheme

23

PTZ-BOX 3.0

6 Communication with the PTZ-BOX 3.0

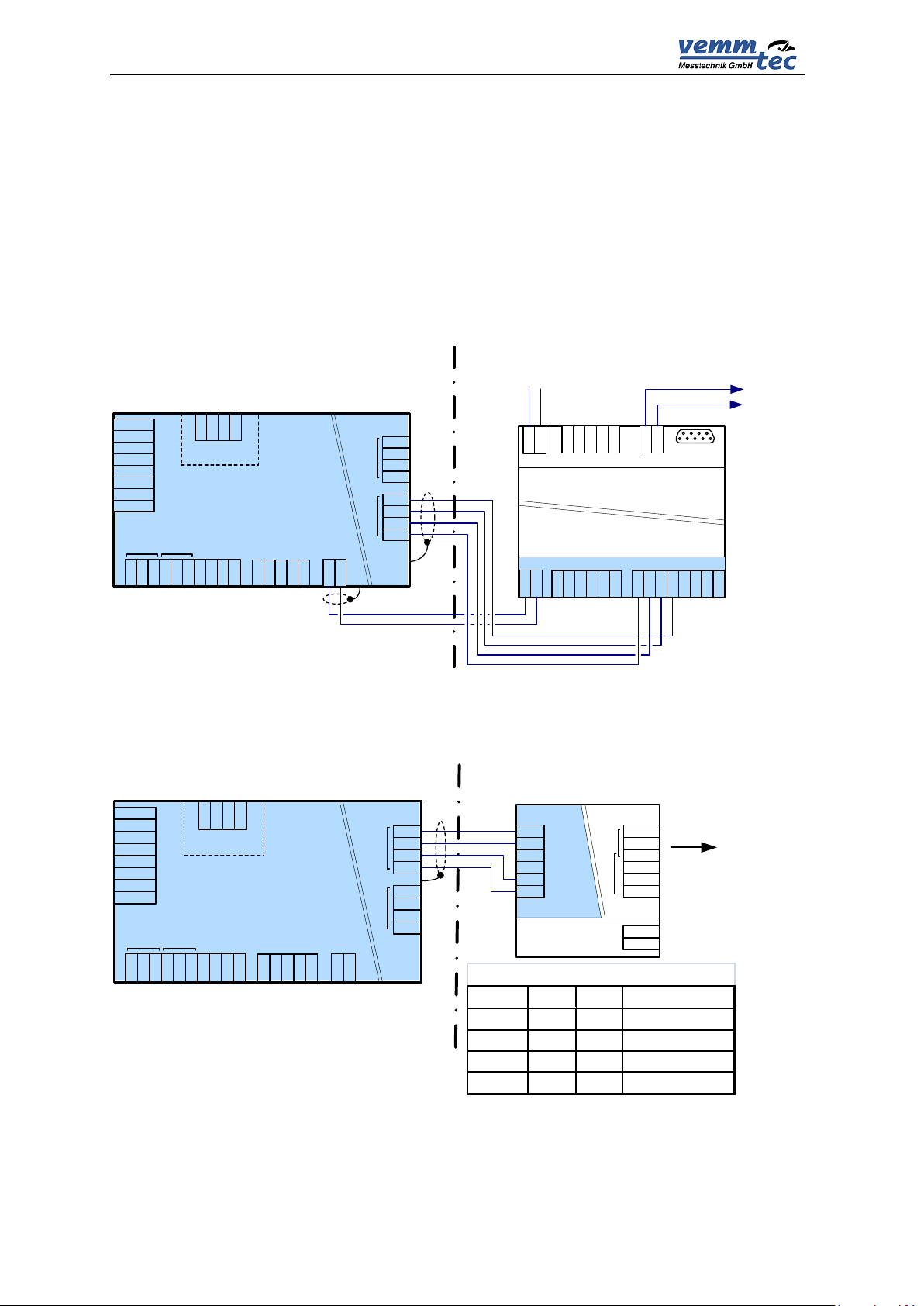

For communication with other devices, the PTZ-BOX 3.0 is equipped with one

communication channel with three possible communication interfaces. Either the

communication interface RS-232 or the RS-485 can be used for connection with a

superior system. The optical interface is designed as temporarily connection for

readout or device configuration.

In the current firmware version, the device is equipped with several

communication protocols. The device is prepared for extension by other protocols as

required by the customer. The standardly implemented protocols are VTC and

MODBUS RTU. Pre-set communication protocol is the same for all communication

interfaces. It is possible to change communication speed for fixed connections and

for optical interface independently.

The VTC protocol is the native protocol of the device. A complete set of

functions realized in the device is available. The service SW [22] solely uses this

protocol – in case it is necessary to switch to other link level, the VTC protocol is only

wrapped in one other link level (a so called “a tunnel”). The VTC protocol is used as

the only one for loading firmware (protected by the metrology seal).

The communication circuits are galvanic separated from other device circuits.

Because of the galvanic separation, the communication circuits must be powered

from outside, from a connected device (CTS signal in case of the RS-232 interface

and U1+ in case of the RS-485 interface).

6.1 RS-232 and RS-485 interfaces

Both interfaces are brought out to the internal terminal board and, although they

are simultaneously functioning, only one of these interfaces can be used (connected)

for communication at a time. Because both of the interfaces are intrinsically safe, it is

necessary during installation to separate the device in a potentially explosive

environment from the connected common device (computer, modem, etc.) by a

consecutive device (Sx Module, Kx Module, MTL 5051 etc.), or use a device with an

intrinsically safe design.

The communication speed of the interface (the speed is joint for both interfaces)

and the communication protocol can be set in the device parameters.

Communication via modem controlled by AT commands

Basic setting features of a modem for the correct cooperation with the device:

Sending answer (ATQ0)

Long format of the sent answers (ATV1)

Echo disabled (ATE0)

Automatic pickup (ATS0=1)

Set firmly serial port communication speed of the modem (e.g. for speed

38400 Bd is command AT+IPR=38400)

Ensure presence of power feeding on clamp DSR of the modem (by

command AT&S0). Clamp DSR is connected with CTS clamp of device.

More detailed information must be found in the manual of the used modem.

24

PTZ-BOX 3.0

INPUTS

POWER

GND

+

HF+

LFHF-

LF+

HF+

-+-

+

PTZ-BOX 3.0

GND1

CTS

RxD

TxD

RS232

Ex i

OUTPUTS

DO1

DO2

DO3

DO4

GND

LF+

LFHF-

DI1

DI2

DI3 DI4

1. channel (analog)

Pt1000

Pt1000

GND

Vce

UT

UP-

UP+

1W

GND1

U1+

D1 -

D1+

RS485

INT. BUS RS485

(optional)

U+

D-

D+

GND

K3 MODULE

P2-RS232

1

9

5

6

Um = 250 V

DIGITAL OUTPUTS

DO3

D -

DO2

DO1

GND

DIGITAL INPUTS

GNDU+DI1

DI2

DI3

DI4

P0 – RS485

GNDU+D-D+GND

U+

D-

D+

6V OUT

GND

U+

DO4

D +

+

GND

12V

P2-RS485

12 Vdc

RS485

Hazardous area

Safe area

INPUTS

POWER

GND

+

HF+

LFHF-

LF+

HF+

-+-

+

PTZ-BOX 3.0

GND1

CTS

RxD

TxD

RS232

Ex i

OUTPUTS

DO1

DO2

DO3

DO4

GND

LF+

LFHF-

DI1

DI2

DI3 DI4

1. channel (analog)

Pt1000

Pt1000

GND

Vce

UT

UP-

UP+

1W

GND1

U1+

D1 -

D1+

RS485

INT. BUS RS485

(optional)

U+

D-

D+

GND

Switches OFF ON meaning

SW1a X --- other modes

SW1b X --- 5V output

SW2a RS232 RS422 output interface

SW2b RS422 RS232 output interface

MTL 5051 setting

20÷30 Vdc

RS-232

3

4

6

5

2

1

RS-232

Rx 12

COM 11

Tx 10

Tx+ 9

Rx+ 8

Rx 7

RS-422

Vs+ 14

Vs- 13

MTL 5051

Ex i

Common

5V or 12V

Tx

Rx

HAZARDOUS AREA

SAFE AREA

Communication with GSM and GPRS modems

For the purpose of diagnostics during the modem installation, the device has

the option of displaying the information from the modem on the presence and

connection to a GSM network, and further information on the signal strength

measured by the modem. In the case of a GPRS connection, it is possible to display

the IP address.

Compatibility with the Siemens MC35, MC39 modem is necessary for correct

function in AT commands:

AT+CREG?, AT+CSQ?, AT+CGDCONT and AT^SGAUTH+CGDCONT.

Note: Communication output from K3 Module can be RS-485 or RS-232

Fig. 10 Safety separation of communication using module K3 Module for RS-485

Note: Communication output from MTL5051 can be RS-232 or RS-422

Fig. 11 Safety separation of RS-232 communication via separator MTL 5051

25

Loading...

Loading...