Termoregolatori

Digitali

FHT ...

Manuale d’uso

User Manual Digital Heat Regulators

Table of contents

■ Safety instructions Page 30

■ Technical specifi cations Page 30

■ Device description Page 32

■ Wiring Page 33

■ Glossary Page 33

■ Operation Page 38

■ Setting regulation parameters Page 38

■ Parameter menu Page 40

■ Error messages Page 50

■ Serial communication Page 50

■ Reference standards Page 51

■ Dimensions and wiring diagrams 33x75 mm Page 52-53

■ Dimensions and wiring diagrams 4-DIN Page 54-55

English

- 29 -

User Manual – Thermoregulator FHT

SAFETY INSTRUCTIONS

■ During the installation and operation of the device observe the following

instructions:

1) Device must be installed by a qualifi ed person

2) To install device, carefully respect wiring diagrams

3) Do not power or connect the device if any part of it is damaged

4) Before making contact with terminals, ensure that conductors to be

connected to the device are not live

5) Connection wires must be able to resist maximum operating temperature

(Tmax), calculated by adding maximum ambient temperature (Ta) estimated

+ 20° C (Tmax = Ta +20°C)

English

6) The device guarantees an isolation factor between low-voltage sections

(250 V) and very low-voltage sections

7) If any external switches are connected to the device, minimum isolation

of 250 V AC at operating temperature must be guaranteed or they must be

protected with isolation of equal value

8) Contacts: all type 1C (EN 60730-1 and variations)

9) The device does not require maintenance

TECHNICAL SPECIFICATIONS

■ This series of digital temperature thermoregulators satisfi es the basic requirements

of thermoregulation.

They may be used as heating or cooling controllers or as maximum/minimum alarms.

■ Two models designed for probe input:

- PTC temperature probes

- TC Thermocouples – J, K, L, R, S, T, E, N FHT

- Linear probes FHT

- NTC temperature probes (Negative Temperature Coeffi cent) FHT NTC

• For each individual model, probe input can be confi gured by keyboard

• Models FHT NTC have two probe inputs so that the measuring of two temperatures

can be displayed alternately by opening and closing an outside source connected to

the device

• Available in versions with 1 or 2 changeover contact relays

• Thermoregulators with 3 seven-segment digits plus decimal point led display

• Relay-on signalling LED

• T2-reading warning LED (only models FHT NTC-2DA)

• Display Range: -99 ÷ +999 °C

(Positive Temperature Coeffi cent)-Ni100, Pt100

FHT

- 30 -

User Manual – Thermoregulator FHT

• Display resolution: 0,1 °C (-9,9 ÷ +99,9 °

C) and 1 °C (< -9,9 °C and > +99,9 °C)

• Accuracy: ± 0,5 % of scale limit value ±1 digit

(at ambient temperature 23 °C)

• Sampling time: 0,5 s

• Digital confi guration of parameters:

- Set-point

- Differential

- Dead band

- Timing of output activation

- Digital-input operation and delay

- Alarm/Buzzer start delay

- Probe calibration OFFSET

- Reading Resolution

- Temperature measurement unit

- Measurement display fi lter (update speed)

- Type of probe input

- Password

- Operation mode (regulation):

— ON/OFF Direct and/or Reverse action with or without Dead Band

— PWM, Direct, Reverse and Dead Band action

— ALARM

— Cooling Mode

— Special Mode

• 2 independent set-points

• Outputs: 1 or 2 changeover contact relays 8A/250 V AC1

• Analog output (excluding model FHT NTC): 0 ÷ 10 V

(applicable for power supply >/=15 V AC/DC), 4 ÷ 20 mA

• Optoisolated serial communication output RS 485 (MODBUS communication protocol)

• Digital input: 1 with confi gurable-function external consent external alarm, ON/OFF

regulation, selection of probe to be displayed, set-point switching, Direct/Reverse

switching,...)

• Acoustic and visual alarm system for: external alarm (from digital input), probe alarm

(malfuction), minimum or maximum alarm

• Infrared receiver with RC-5 protocol (excluding model FHT NTC-2DA) for remotecontrol (accessory available separately for remote programming)

• Available for models with: backboard mounting 33x75mm and 4 DIN modular

mounting

• Power supply: See table on next page

• Nominal power: 3VA for 33x75 backboard-mounting models 4,5 VA for 4 DIN

modular-mounting models

• Max. power input: 100 mA at 12 V; 50 mA at 24 V (1 channel)

• Operating Temperature: 0 ÷ +50 °C

• Operating humidity: <80%

• Storage Temperature: -10 ÷ +70 °C (<80% RH)

• Protection degree: front IP54 (IP40 for 4 DIN model)

terminals IP20

- 31 -

User Manual – Thermoregulator FHT

English

Backpanel 33x75 mm

Code Model Power (*) Relay n° Analog Digital Infrared

output input receiver

VM666500 FHT 1P3D 12÷24V AC/DC 1 YES YES YES

VM667300 FHT 2P3D 12÷24V AC/DC 2 YES YES YES

VM668100 FHT NTC-2P3D 12÷24V AC/DC 2 NO YES YES

4-DIN version

Code Model Power (*) Relay n° Analog Digital Infrared

output input receiver

VM669900 FHT 1DA 24/230V AC 1 YES YES YES

VM670700 FHT 2DA 24/230V AC 2 YES YES YES

VM671500 FHT NTC-2DA 24/230V AC 2 NO YES NO

English

(*) AC powered; frequency 50/60 Hz, power tolerance AC/DC + 10%

DEVICE DESCRIPTION

Display

• 3-digit with decimal point LED display.

Reading range for all models is:

- minimum reading: -99 °C or -9,9 °C

- maximum reading: 999 °C or 99,9 °C

Note: reading resolution is:

0,1°C in -9,9 ÷ 99,9°C range and 1°C in -99 ÷ -10°C and 10 ÷ 99°C

Relay-on signalling LED

• Out 1:

LED remains off if relay one is OFF and on if relay one is ON, fl ashing if relay one in

OFF position is about to turn ON because of set timing.

• Out 2:

LED remains off if relay two is OFF and on if relay two is ON, fl ashing if relay two in

OFF position is about to turn ON because of set timing.

Keys

• Parameters are confi gured using three keys:

To confi rm parameters set/viewed.

OK

To increase parameter or move on to next parameter.

To decrease parameter or exit menu.

- 32 -

User Manual – Thermoregulator FHT

WIRING

• Carefully follow all the information in the Safety instructions and Wiring diagrams

sections.

GLOSSARY

Set-point

• The set-point is the reference value where the device cuts in to keep the parameter

controlled at the desired value.

Differential (or hystheresis)

• The differential is the maximum allowable parameter deviation from the set-point

before the device cuts in.

It is usually set in a way as to avoid rapid changes around the set-point which could

cause the device, or the equipment it is connected to, to turn on and off frequently.

Direct action

• When a regulator restricts parameter

increase, it operates in a direct way.

As in a refrigerating system for example:

as temperature increases, the heat

extraction rate produced also increases

in order to lower the temperature

“Reverse” action

• When a regulator tends to restrict

parameter decrease, it operates in

reverse.

For example a decrease in temperature

in a heating system corresponds to an

increase of heat production.

Neutral zone or Dead band

• Indicates an interval of values spanning

above and below the set-point, in which

the parameter regulated can change

without having to activate any output.

It is usually used in devices which, due to substantial system inertia, the set-

point can be exceeded even after the equipment is switched off, or to avoid the

overlapping of heating and cooling actions.

OFF

OFF

Direct Mode

ON

D

Set

Set + Diff

Temperature

Reverse Mode

ON

R

Set - Diff

Set

Temperature

English

- 33 -

User Manual – Thermoregulator FHT

No output is activated within

the dead band; outside

the dead band the device

operates by direct action

if the parameter controlled

increases and by reverse

action if it decreases.

ON

OFF

Set - Diff (R) - ZN

PWM operating mode

(time-controlled proportionate)

• Dead-band operation

featuring relays activated

periodically by impulse

(settable timing, see Output

English

menu).

The PWM mode modulates

the power based on the

position of the parameter

within the differential (power

increases as deviation from

set-point increases).

Warning: Not recommended for use with compressors, as this would cause

short start/stop periods.

Direct operating mode [PRO=0]

• When in this mode, all outputs

operate in direct.

Set-point 1 [ST1] and

differential 1 [DF1] must be

assigned values.

Hysteresis is to the right of

the set-point.

If both outputs are used, the

hysteresis of each output is

equal to half of the differential.

In this case output 1 will turn on when the parameter measured reaches value

[ST1]+[DF1]/2; output 2 will turn off on reaching this value.

ON

OFF

Set - Diff (R) - ZN

OUT 1

ON

D

OFF

Diff. 1

Set 1

1 output 2 outputs

Reverse

operating mode [PRO=1]

• When in this mode, all outputs

operate in reverse.

Set-point 1 [ST1] and

differential 1 [DF1] must be

assigned values.

Hysteresis is to the left of the

set-point.

User Manual – Thermoregulator FHT

OUT 1

ON

R

OFF

Diff. 1

1 output 2 outputs

- 34 -

Set 1

R

R

Mode PRO=0

Mode PRO=1

Dead band Mode

ZN

ZN

Set

Temperature

PWM Mode

ZN

ZN

Set

Temperature

OUT 1

ON

D

OFF

Set 1

OUT 2

ON

R

OFF

D

Set + Diff (D) + ZN

D

Set + Diff (D) + ZN

OUT 2

Diff. 1

OUT 1

Diff. 1

D

R

Set 1

If both outputs are used, the hysteresis of each output is equal to half of the

differential. In this case output 1 will turn on when the parameter measured reaches

the value [ST1]-[DF1]/2; output 2 will turn off on reaching this value.

Dead-band operation mode [PRO=2]

• When in this mode output 1 operates in reverse and output 2 in direct.

It is necessary to confi gure parameters set-point 1 [ST1], differential 1 [DF1] and

dead band [DBN], which typify both outputs.

The regulator will tend to keep the parameter within the dead band. Outside the dead

band output 2 will turn on if the parameter tends to increase; conversely output 1

will turn on if the parameter tends to decrease. If only one output is present, it will

operate in reverse, with the hysteresis to the left of the value [DBN].

Mode PRO=2

OUT 1

ON

R

OFF

PWM operating mode [PRO=5]

• The regulation logic of this operating mode is the same as that of the dead band

operating mode.

It is therefore necessary to confi gure parameters set-point 1 [ST1], differential 1

[DF1] and dead band [DBN], which typify both outputs. When in this operating mode,

relays are activated by impulses with the timing given by value [TCL] (see output

menu).

During that period the relay remains on for a variable length of time that is

proportionate to parameter deviation from the set-point (considering the dead band

when present). Beyond the differential value, the relay remains active 100% of the

time.

ON

OFF

ZN

Diff. 1

Set 1

1 output 2 outputs

Mode PRO=5

OUT 1

ZN

R

Diff. 1

Set 1

1 output 2 outputs

User Manual – Thermoregulator FHT

OFF

OFF

OUT 1

ON

R

Diff. 1

OUT 1

ON

R

Diff. 1

- 35 -

OUT 2

D

ZN

ZN

Diff. 1

Set 1

OUT 2

ZN

ZN

D

Diff. 1

Set 1

English

Operating mode with Direct/Reverse change-over

from digital input [PRO=6]

• When in this mode both outputs operate in direct (with set-point 1 and differential

1) or both in reverse (with set-point 2 and differential 2) depending on digital input

status.. More precisely, in direct if the digital output is open and in reverse if it is

closed. Operating functions are the same as in modes 0 and 1. Therefore both setpoints [ST1] and [ST2] and both differentials [DF1] and [DF2] must be confi gured.

Mode PRO=6

OUT 1

ON

Digital

input

English

Direct operating mode with set-point and differential change-over

from digital input [PRO=7]

• When in this mode both outputs operate in direct, with set-point 1 /differential 1

or set-point 2/differential 2) depending on digital input status. More precisely, with

set-point 1/differential 1 if the digital input is open and set-point 2/differential 2 if it

is closed. Operating functions are the same as in mode 0. Both set-points [ST1] and

[ST2] and both differentials [DF1] and [DF2] must be confi gured.

open

Digital

input

closed

Digital

input

open

Digital

input

closed

D

OFF

Diff. 1

Set 1

OUT 1

ON

R

OFF

Diff. 2

Set 2

1 output 2 outputs

OUT 1

ON

Mode PRO=7

D

OFF

Diff. 1

Set 1

OUT 1

ON

D

OFF

Diff. 2

Set 2

1 output 2 outputs

- 36 -

User Manual – Thermoregulator FHT

OFF

OFF

OFF

OFF

OUT 1

D

OUT 2

R

OUT 1

D

OUT 1

D

Diff. 1

Diff. 2

Diff. 1

Diff. 2

OUT 2

D

OUT 1

R

Set 2

OUT 2

D

OUT 2

D

ON

Set 1

ON

ON

Set 1

ON

Set 2

Reverse operating mode with set-point and differential change-over

from digital input [PRO=8]

• When in this mode both outputs operate in reverse, with set-point 1 /differential 1 or

set-point 2/differential 2, depending on the status of the digital input. More precisely,

with set-point 1/differential 1 if the digital input is open and set-point 2/differential 2

if it is closed.

Operating functions are the same as in mode 1. Therefore both set-points [ST1] and

[ST2] and both differentials [DF1] and [DF2] must be confi gured.

Digital

input

open

Digital

input

closed

Mode PRO=8

OUT 1

ON

ON

R

OFF

Diff. 1

Set 1

OUT 1

ON

OFF

ON

R

OFF

Diff. 2

Set 2

1 output 2 outputs

OFF

OUT 2

R

OUT 2

R

Diff. 1

Diff. 2

OUT 1

R

Set 1

OUT 1

R

Set 2

Operating mode with outputs 1 and 2 respectively in reverse with

set-point 1 and diff.1 and direct with set-point 2 and diff. 2 [PRO=9]

• When in this mode output 1 operates in reverse and output 2 in direct.

It is necessary to confi gure set-points 1 [ST1] and differential 1 [DF1] for output 1,

and set-point 2 [ST2] and differential 2 [DF2] for output 2.

Operating functions are the same as in modes 0 and 1.

If only one output is present it will operate in reverse.

English

Mode PRO=9

OUT 1

ON

R

OFF

Diff. 1

Set 1

1 output 2 outputs

Alarm operating mode [PRO=10]

• When in this mode output 1 operates in reverse (with dead band) whilst output 2 is

reserved for the alarm.. It is necessary to confi gure set-point 1 [ST1], differential 1

User Manual – Thermoregulator FHT

OFF

OUT 1

ON

R

Diff. 1

Set 1

- 37 -

Set 2

OUT 2

D

Diff. 2

ON

OFF

[DF1] and dead band [DB1] for output

1, and all parameters on the alarm menu

for output 2. The maximum alarm trips

when the value [ST1]+[HIA] is reached

and is disengaged on reaching value

[ST1]+[HIA]-[DFA]. The minimum alarm

trips when the value [ST1]-[LOA] is

reached and is disengaged on reaching

value [ST1]-[LOA]+[DFA].

When only one output is provided, it will be reserved for the alarm with the same

functions.

Alarm ON

Alarm OFF

DFA

LOA

Mode PRO=10

Set 1

Alarm output

DFA

HIA

English

Normal operation

Operation when parameters are not being programmed/confi gured.

When in this status, the device effects regulation based on the temperature

measured and the parameters set. The information displayed is:

• Temperature measured by the sensor

• Status of output OUT1 and, in devices with two outputs, OUT 2

OPERATION

SETTING REGULATION PARAMETERS

There are two types of programming for regulation parameters:

- Simple programming

- Advanced programming

Note: to restore default factory-set values, turn on the device while

pressing the “OK” key.

Simple programming

To change parameters in the Regulation menu [REG] only. This programming is

accessed by pressing the“OK” key.

Depending on the selected operating mode, the following parameters can be

confi gured (see System menu [SYS]):

– set, differential, regulation ON/OFF, minimum sensor reading, maximum sensor

reading

Parameter labels can be scanned in a circular motion by using the “up” (▲) key. To

exit the menu and return to normal operation, press the “down” (▼) key at any time

- 38 -

User Manual – Thermoregulator FHT

(which occurs automatically if no key is pressed for at least 40 s). To switch from

parameter label reading to the reading of the relevant numeric value, press the “OK”

key.

To change a parameter:

- from label or value reading, hold the “OK” key pressed for at least three seconds.

- the display will begin to fl ash the parameter value.

- use the “up” (▲) and “down” (▼) keys respectively to increase or decrease said

value.

- press the “OK” key to confi rm the change and exit (the display will stop

fl ashing).

Note: if no key is pressed within 40 seconds, the device will quit parameter

confi guration and no changes will be stored.

During the display and change of parameters the device will continue

operating with the previous settings.

If “password 1” is enabled (access password for the protection of settings - see

system menu), the display will read “- - - ” when the “OK” key is pressed from

normal status.

To proceed with parameter confi guration, enter the previously set password (a

numeric value from 0 to 255) using the “up” (▲) and “down” (▼) keys and then

press “OK” to confi rm.

If the password entered is correct the regulation menu will appear; otherwise normal

status will return.

Advanced programming

To enter advanced programming from normal status, press the “up” (▲) and

“down” (▼) keys simultaneously for at least 3 seconds.

Note: to restore factory-set default values, turn on the device while

pressing the “OK” key.

These parameters are classifi ed by type into nine menus:

1) Regulation (indicated by label [REG]): set-point, differential, dead band

2) Output (indicated by label [OUT]): timing of output activation, timing of

PWM cycle

3) Digital input (indicated by the label [ING]): function, delay time

4) Alarm (indicated by label [ALR]): probe alarm output status, minimum/maximum

shift, differential, delay time, buzzer on/off

5) Display (indicated by label [DSP]): set-point limits, probe offset, resolution,

measurement unit, reading fi lter

6) Sensor (indicated by label [SNS]): sensor type, sensor parameters

7) System (indicated by label [SYS]): password, change enabling, operating mode

English

- 39 -

User Manual – Thermoregulator FHT

8) Analog output (indicated by label [ANG]): type of analog output

9) Advanced (indicated by label [ADD]): dependency, type, insertion,

differential/logic

All the parameters within the nine menus and their corresponding values, are listed

in the following section.

- To scan the nine menus in sequence use the “up” (▲) key

- To enter the selected menu press the “OK” key

- Confi gurable parameter labels can be scanned within each menu by pressing

the “up” (▲) key; to view a parameter value press “OK” (to view parameter label

again press the “OK” key one more time).

- To change the parameter value, hold the “OK” key pressed for at least three

seconds.

- The parameter value will begin fl ashing: increase/decrease using the “up” (▲) and

English

“down” (▼) keys respectively.

- To confi rm the change press “OK”.

The parameter will stop fl ashing and the new value will be displayed

- It is possible to return to normal operation at any time by pressing the “down” (▼)

key (or not pressing any key for at least 40 seconds)

Note: if when confi guring parameters no key is pressed within 40 seconds

, the parameter label will be displayed again and none of the changes

entered will be saved.

Note: During the display and change of parameters the device will continue

operating with the previous settings.

If “password 2” has been enabled (access password for the protection of

settings - see system menu), the display will read “- - - ” when the “up”

(▲) and “down” (▼) keys are simultaneously pressed for three seconds from

normal status.To proceed with parameter confi guration, enter the password

previously set (a numeric value from 0 to 255) using the “up” (▲) and “down”

(▼) keys and press “OK” to confi rm.

If the password is correct the fi rst menu label will appear, otherwise normal status

will return.

PARAMETER MENU

To simplify device programming, parameters have been classifi ed into the following

various menus:

— [REG] regulatation menu

— [OUT] output menu

- 40 -

User Manual – Thermoregulator FHT

— [ING] external input menu

— [ALR] alarm menu

— [DSP] view menu

— [SNS] sensor menu

— [SYS] system menu

— [ANG] analog output menu

— [ADD] special parameter setting me

Parameter description

The tables show parameter labels in the same order in which they appear in the

various menus of the device.

[REG] regulation menu

Confi gurable Parameter

parameter Description unit value default notes

labels min max

ST1 set-point 1 degrees LO1 HI1 20.0 (1)

DF1 set-point 1 differential degrees 0.1 100 2.0

ST2 set-point 2 degrees LO2 HI2 30.0 (2)

DF2 set-point 2 differential degrees 0.1 100 2.0 (2)

DBN neutral zone (dead band) degrees 0 100 2.0 (2)

I-O regulation on/off - on (3)

HIO maximum value measured

by sensor 0 degrees --- (4)

LOO minimum value measured

by sensor 0 degrees --- (4)

HI1 maximum value measured

by sensor 1 degrees --- (4)

LO1 minimum value measured

by sensor 1 degrees --- (4)

Note:

(1) for values LO1/2 and HI1/2 see display menu [DSP]

(2) parameter is active only if it applies to the operating mode

(3) turns regulation on/off from keypad if ON there is normal operationif OFF:

- display reads “OFF”

- relays 1 and 2 take on status as established by parameter [SUI], menu [ING],

respecting the timing of menu [OUT]

(4) Maximum/minimum value read by sensors 0 and 1 is stored in these parameters.

The value can be reset by pressing the OK key for about 3 seconds (which starts a

new parameter updating control)

English

- 41 -

User Manual – Thermoregulator FHT

[OUT] output menu

Confi gurable Parameter

parameter Description unit value default notes

labels min max

ETR relay time control activation - 0 0 3 (5)

DON minimum time between

2 starts of same relay min 0 200 0 (6)

TOF minimum ON time

of relay min 0 200 0 (7)

TON minimum OFF time

of relay min 0 200 0 (8)

INI initial delay

English

from device start min 0 200 0 (9)

TCL PWM cycle time sec 1 200 200 (10)

Note:

(5) this parameter enables the control of times set in DON, TOF, and TON for each

output as follows:

0 timing disabled for both relay outputs

1 timing enabled only for relay 1 output

2 timing enabled only for relay 2 output

3 timing enabled for both relay 1 and 2 outputs

(6) this parameter restricts the number of starts per hour for the equipment connected

to the device (parameter frequently used e.g. for compressors)

(7) minimum time in which output must remain ON

(8) minimum time in which output must remain OFF

(9) output activation delay time from reset of the device

(10) the period that can be set for PWM regulation. This reading is displayed only if the

operating mode selected is PRO=5 (see system menu).

[ING] outside input menu

Confi gurable Parameter

parameter Description unit value default notes

labels min max

TID digital input function - 0 4 0 (11)

DID digital input delay min 0 200 0 (12)

SUI output status with

dig. input enabled (open) - 0 3 0 (13)

Note:

(11) Confi gurable values are: 0 disabled

User Manual – Thermoregulator FHT

- 42 -

1 external alarm (with open contact) with “DID” delay time and automatic reset

after alarm goes off.Output status then turns to “SUI”

2 manual-reset external alarm (with open contact).

3 input acts as switch: device is on when contact is closed and off when contact is

open

4 input acts as display change-over between probes S0 and S1 (open contact - S0

probe, closed contact - S1 probe)

Digital input function is excluded when one of the following operating

modes is selected in the system menu [SYS]: mode=6, mode=7 and

mode=8

(12) the delay after which the device responds to a signal received from the digital input

(13) when the digital input is active and “DID” time has elapsed, the output may take on

the following status:

0 both relays OFF

1 relay 1 ON and relay 2 OFF

2 relay 1 OFF and relay 2 ON

3 both relays ON

[ALR] alarm menu

Confi gurable Parameter

parameter Description unit value default notes

labels min max

SUA output status

in probe alarm condition - 0 3 0 (14)

LOA minimum alarm shift degrees 0.1 100 50 (15)

HIA maximum alarm shift degrees 0.1 100 50 (15)

DFA alarm differential degrees 0.1 100 2

TRA alarm activation delay time min 0 200 0

SUO buzzer activation - no yes no (16)

EAC timed alarm message

activation - no yes no (17)

RAR automatic relay reset and min/max

alarm message reset on alarm end - no yes yes (18)

RAA automatic min/max alarm

message reset on alarm end - no yes yes (19)

TRP min/max alarm generation delay

from power-on hours 0 15 0 (20)

English

Note:

(14) output status when in probe alarm condition (see note n°13)

(15) value to be added or subtracted to the established set-point, respectively for

maximum or minimum alarm

- 43 -

User Manual – Thermoregulator FHT

(16) if “yes” both key beep and alarm-condition buzzer are enabled. If “no” both are

disabled

(17) If “yes” the type of alarm is displayed even during timing of the same, if “no” the

type of alarm is displayed only after the timing

(18) if “yes”, at the end of a min/max alarm it will be necessary to dismiss alarm type

reading and reset the relay manually

(19) if “yes”, at the end of a min/max alarm it will be necessary to dismiss alarm type

reading manually (the relay will automatically reset instead)

(20) blocks the generation of max/min alarms for a period

[DSP] view menu

Confi gurable Parameter

parameter Description unit value default notes

English

labels min max

LO1 lower limit of set-point 1 degrees -99 HI1 -99

HI1 upper limit of set-point 1 degrees LO1 999 999

LO2 lower limit of set-point 2 degrees -99 HI2 -99 (21)

HI2 upper limit of set-point 2 degrees LO2 999 999 (21)

SOF probe 1 calibration offset degrees -50 +50 0.0 (22)

SIF probe 2 calibration offset degrees -50 +50 0.0 (22)

RIS reading resolution - HI LO HI (23)

UNI temperature measurement unit - C F C (24)

FIL measurement fi lter - no yes yes (25)

Note:

(21) parameter is active only if it applies to the operating mode

(22) value added to the measure to compensate for an inaccuracy of the same

(23) reading resolution:

0.1 if “HI” or 1.0 if “LO”

(24) Attention: when unit of measurement is changed, parameter settings are not

converted automatically and must be recalibrated.

(25) if the parameter is set to “yes” a moving average of 8 measurement values (i.e. of

about 4 seconds) is calculated, if “no” the average is not calculated

- 44 -

User Manual – Thermoregulator FHT

[SNS] sensor menu

Confi gurable Parameter

parameter Description unit value default notes

labels min max

TYO sensor type 0 - 0 16 (26)

TY1 sensor type 1 - 12 16 (27)

S01 display of sensor 1 or 2 - S0 S1 S0 (27)

Note:

(26) default parameter and sensor values depend on device model. All sensors available

are listed as follows:

Temperature probes NiPt

sensor type display reading

Pt100 (*) PtE (*)

Ni100 nI

* Device default setting

Thermocouples JK

sensor type display reading

J J

K C

L L

T t

E E

N n

R r

S s

Linear probes

sensor type display reading

0-20mA 020

4-20mA 420

0-1V 0-1

User Manual – Thermoregulator FHT

English

- 45 -

Temperature probes NTC

sensor type display reading

(**) nt0

(**) nt1

type 4 nt2 (*)

(**) CSt

* Device default setting, which corresponds to the use of temperature probe NTC

code VN870200 (see “Red line” in catalogue under the section Thermoregulation

- temperature probes)

** When using sensors other than “type 4” as noted above (see note *), it is possible

to select one of the three items “nt0, nt1, Cst” corresponding to probes with

different temperature/resistance ratios. In these cases, in order to identify the

type of sensor to be selected, we recommend contacting the Technical Assistance

English

Service Department directly.

(27) parameter displayed only on models NTC

[SYS] system menu

Confi gurable Parameter

parameter Description unit value default notes

labels min max

PS1 password 1 - 0 255 0 (28)

PS2 password 2 - 0 255 0 (28)

NEN enables parameter changing - yes no no (29)

PRO operating mode - 0 12 0 (30)

ADR serial address - 1 247 1

COM serial communication

parameters - 0 11 0 (31)

Note:

(28) password is enabled if setting is other than 000

(29) if setting is “yes” all other parameters can be viewed but not changed

(30) the following operating modes are possible:

0 relay output 1 and 2 in direct with set-point 1 and differential

1 (hysteresis to the right of the set-point)

1 relay output 1 and 2 in reverse with set-point 1 and differential

1 (hysteresis to the left of the set-point)

2 dead band with relay output 1 in reverse and relay output 2 in direct, set-point 1

and differential 1

3 same as in mode 0 but with differential centered on set-point

4 same as in mode 1 but with differential centered on set-point

- 46 -

User Manual – Thermoregulator FHT

0 960 9600 baud ODD parity 1 stop

1 480 4800 baud ODD parity 1 stop

2 240 2400 baud ODD parity 1 stop

3 120 1200 baud ODD parity 1 stop

4 96E 9600 baud EVEN parity 1 stop

5 48E 4800 baud EVEN parity 1 stop

6 24E 2400 baud EVEN parity 1 stop

7 12E 1200 baud EVEN parity 1 stop

8 96N 9600 baud EVEN parity 2 stop

9 48N 4800 baud EVEN parity 2 stop

10 24N 2400 baud EVEN parity 2 stop

11 12N 1200 baud EVEN parity 2 stop

5 PWM regulation with relay output 1 in reverse and relay output 2 in direct,

set-point 1 and differential 1 plus dead band if applicable

6 change-over between outputs in direct (with set-point 1 and differential 1) and

outputs in reverse (with set-point 2 and differential 2) from digital input

7 outputs in direct with change-over between set-point 1/differential 1 and set-

point 2/differential 2 from digital input

8 outputs in reverse with change-over between set-point 1/differential 1 and set-

point 2/differential 2 from digital input

9 relay output 1 in reverse with set-point 1 and differential 1 and output relay

2 in direct with set-point 2 and differential 2

10 if one relay output: alarm function if two output relays: relay output 1 in

reverse (with set-point 1, differential 1 and dead band) and relay output 2

in alarm

11 – (not available)

12 special mode

(31)

Parameter value serial parameter

In order to make internet connections easier, the following meaning applies to

status information found in the COM menu for OUT1 and OUT2 output:

- OUT1: if lit it indicates accurate reception of bus frame with the parameters set

- OUT2: if lit it indicates serial transmission is in process

English

- 47 -

User Manual – Thermoregulator FHT

[ANG] analog output menu

Confi gurable Parameter

parameter Description unit value default notes

labels min max

ANT type of analog output - 0 2 0 (32)

ALO value corresponding

to lower limit degrees -99 999 00.0 (33)

AHI value corresponding

to upper limit degrees -99 999 100 (33)

Note:

(32)

Analog output display reading

English

voltage 0-10 V 0-1

amperage 0-20 mA 020

amperage 4-20 mA 420

(33) it is possible to set an output range with AHI less than ALO to allow the output to

decrease with the increase of the measured parameter

[ADD] special parameters menu

Confi gurable Parameter

parameter Description unit value default notes

labels min max

DP0 output 1 dependency - 0 10 (34)

TI0 on/off type or PWM 1 - 0 1 (35)

DB0 dead band 1 - 0 1 (36)

IN0 cut-in 1 % -100 +100 (37)

DF0 logic 1 differential % -100 +100 (38)

DP1 output 2 dependency - 0 10 (34)

TI1 on/off type or PWM 2 - 0 1 (35)

DB1 dead band 2 - 0 1 (36)

IN1 cut-in 2 % -100 +100 (37)

DF1 logic 2 differential % -100 +100 (38)

Note:

(34) the parameter establishes in what way an output depends on a set-point or alarm

function. The values take on the following meanings:

0 output not active

1 output relative to set-point 1

2 output relative to set-point 2

3 change-over between output in direct (with set-point 1 and differential 1) and

output in reverse (with set-point 2 and differential 2) by means of digital input

(open - direct, closed - reverse).

- 48 -

User Manual – Thermoregulator FHT

onaila

tI

1 Channel

Operating mode

Parametro 012345 67 8910

IN0 100 -100 -100 50 -50 -100 * 100 -100 -100 0

DF0 -100 100 100 -100 100 100 * -100 100 100 100

IN1 100 -100 100 50 -50 100 * 100 -100 100 0

DF1 -50 50 -100 -50 50 -100 * -50 50 -100 100

2 Cannel

Operating mode

Parametro 012345 67 8910

IN0 50 -50 -100 0 0 -100 * 50 -50 -100 -100

DF0 -50 50 100 -50 50 100 * -50 50 100 100

IN1 100 -100 100 50 -50 100 * 100 -100 100 0

DF1 -50 50 -100 -50 50 -100 * -50 50 -100 100

4 change-over between set-point 1/differential 1 and set-point 2/differential 2 by

means of digital input (open – set 1, closed set 2)

5 output related to set-point 2 maximum alarm

6 output related to set-point 2 minimum alarm

7 output related to set-point 1 maximum alarm

8 output related to set-point 1 minimum alarm

9 output related to set-point 1 maximum/minimum alarm

10 output related to set-point 2 maximum/minimum alarm

(35) establishes whether the type of regulation is ON/OFF (value 0) or PWM (value 1)

(36) indicates if dead band is present (value 1) or not (value 0)

(37) indicates change-over point ON of relay compared to set-point set by

“dependency” parameter: the change-over point is calculated adding an “INO”

percentage of the differential (from -100% to +100%) to the set-point.

(38) indicates change-over point OFF of relay compared to the point where ON

change-over took place: the change-over point OFF is calculated adding a “DF0”

percentage of the differential (from -100% to +100%) to the ON-point.

Note: default values of these parameters depend on the operating mode and

number of channels, as indicated in the tables below:

English

* Default values for mode 6 are the same as in modes 0 and 1 based on direct or

reverse functionning of outputs.

- 49 -

User Manual – Thermoregulator FHT

ERROR MESSAGES

• In case of alarm or malfunction, measure reading and alarm type reading may be

displayed alternately.

Operating alarm/error messages are described in the following table.

Message Type of error Output status

ER0 Sensor 1 disconnected or short-circuted Same as in parameter (SUA)

ER1 Sensor 2 disconnected or short-circuted Same as in parameter (SUA)

ALL Minumim alarm Depending on operation mode

ALH Maximum alarm Depending on operation mode

ALE External input alarm Same as in parameter (SUA)

OFF Regulation blocked by external input Same as in parameter (SUA)

English

Note:

The “OFF” message does not switch to the measure reading, but remains fi xed on

the display

SERIAL COMMUNICATION

• The device is fi tted with an isolated serial output RS-485

• The data communication system is based on MODBUS protocol and can be

connected to a Master system (PC/PLC)...) on a multipoint line RS-485:

- up to 32 FHT’s (slaves) without signal amplifi ers, from a maximum distance

of 1000m

- up to 247 FHT’s (slaves) in groups of 32 separated by proper signal amplifi ers

• Communication occurs in half duplex and only the Master (PC/PLC...) can initiate

Query/Response type transaction with the Slaves (only one slave with address) or

directing the message to all the slaves (address 0) without receiving an answer

• The MODBUS protocol specifi cations are:

- Coding system: RTU (Remote Terminal Unit)

- Transmission speed (Baud Rate): 9600, 4800, 2400, 1200 bps (can be selected by

user)

- Byte format: 1 start bit, 8 data bits, 1 parity bit (can be selected):

none, odd or even, 1 stop bit

• Contact TAS (Technical Assistance Service dept.) to request documents regarding

MODBUS functions and use of registers.

- 50 -

User Manual – Thermoregulator FHT

REFERENCE STANDARDS

■ For safety: EN 60730-2-9

■ For electromagnetic compatibility:

EN 55014-1

EN 55014-2

EN 61000-6-2

EN 61000-6-3

English

- 51 -

User Manual – Thermoregulator FHT

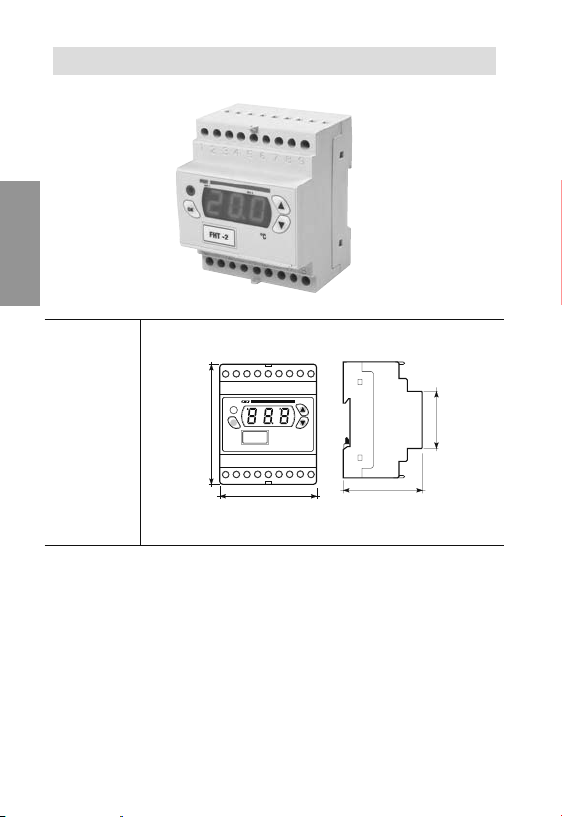

DIMENSIONS OF BACKBOARD MODEL 33x75 mm

o

nailatI

English

FHT-1P3D

FHT-2P3D

FHT NTC-2P3D

OK

75

- 52 -

User Manual – Thermoregulator FHT

33

81

70

33

82

D3P1-THFledoMD3P2-THFledoMTHFledo

M

CTN D

3

P2-

nailaI

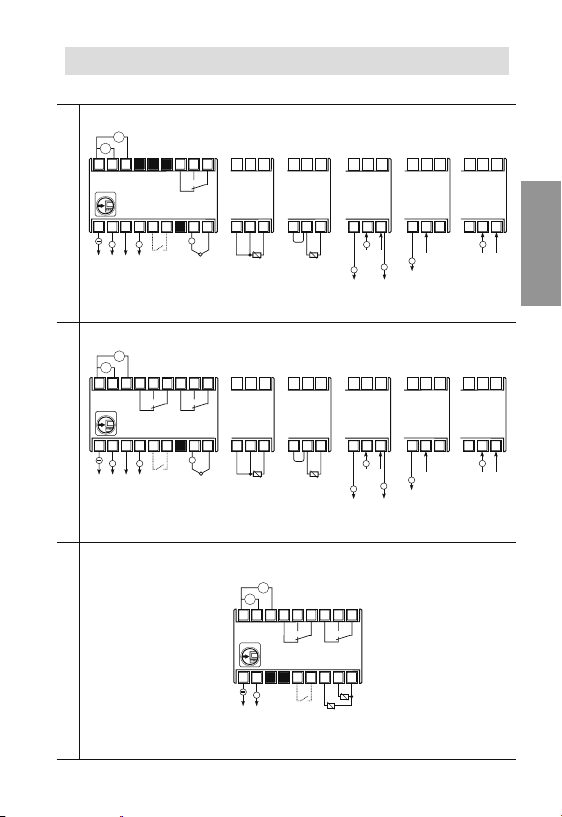

DIAGRAMS FOR 33x75mm BACKBOARD

Wiring diagram

Analog

output

0÷10V

RS-485

4÷20 mA

+

11

i

e

a

r

l

S

1

2346

Relay output

8(5)A/250 V~

RS-485

+

i

e

a

r

l

S

2

Relay output 1

8(5)A/250 V~

+

12 131510

14

16 17 18

5

7

89

7

7

8

8 9

6

+

~

A

e

l

i

n

m

o

i

e

z

n

a

t

External

External

Probe input

Probe

consent

consent

PTC 3 wires

input

input

TC

Analog

output

0÷10V

4÷20 mA

+

Output relay 2

8(5)A/250 V~

131510

141112

16 17 18

5

3 461

7

8 9

+

~

A

e

l

i

n

m

o

i

e

z

n

a

t

Probe

External

consent

input

TC

input

7

89

6

Probe input

External

consent

PTC 3 wires

input

input

RS-485

+

10

11

r

i

a

e

l

S

9

6

Jumper

Probe

External

consent

input

input

PTC

2 wires

7

89

6

Jumper

Probe

External

consent

input

input

PTC

2 wires

13

1412

15

7

89

6

6

+

Probe input

0÷1V

+

4÷20 mA

External

0÷20 mA

-

consent

+

input

Active

probe

supply output

9VDC max 30 mA

6

+

supply output

9VDC max 30 mA

9VDC max 30 mA

7

8 9

6

+

Probe input

0÷1V

+

4÷20 mA

External

0÷20 mA

-

consent

input

Active

probe

9VDC max 30 mA

Sensor - 3 wires to be powered Sensor - 2 wires to be powered

Sensor - 3 wires to be powered Sensor - 2 wires to be powered

Output relay 2

8(5)A/250 V~

16 17 18

89

External

consent

input

8

External

consent

input

7

9

8

6

+

Probe input

0÷1V

External

4÷20 mA

consent

0÷20 mA

input

89

English

External

consent

input

Self-powered sensor

7

9

6

+

Probe input

0÷1V

4÷20 mA

0÷20 mA

Self-powered sensor

7

Input

probe

4÷20 mA

0÷20 mA

Active

probe

supply output

7

Input

probe

4÷20 mA

0÷20 mA

Active

probe

supply output

A

l

i

m

- 53 -

5234

7

8 9

6

NTC1

NTC2

~

e

n

o

i

e

z

n

a

t

NTC probe

input

External

consent

input

1

Output relay 1

8(5)A/250 V~

User Manual – Thermoregulator FHT

onailatI

English

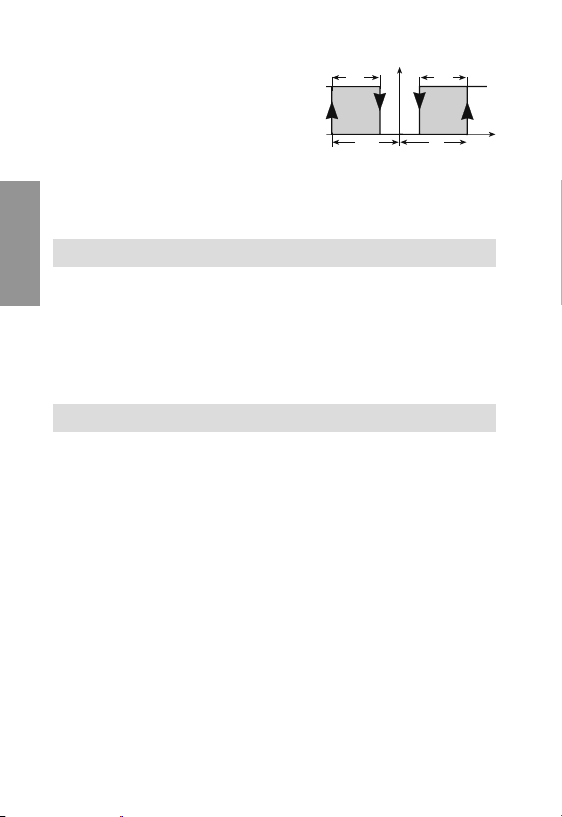

FHT-1DA

FHT-2DA

FHT NTC-2DA

DIMENSIONS OF 4 DIN MODULAR MODEL

8

7

6

345

2

1

OK

7

8

121314

11

10

9

17

16

15

18

70

65

54

- 54 -

User Manual – Thermoregulator FHT

onaila

tI

AD1-THFledoMAD2-THFledoMTH

FledoM

C

TN AD2-

DIAGRAMS FOR BACKBOARD 4 DIN MODEL

Wiring diagram

V

0

3

~

2

~

V

~

4

5

2

z

0

H

-

0

6

~

5

z

0

H

-

6

0

1

r

a

i

e

l

S

10

11

+

RS-485

V

0

3

2

~

V

~

4

5

2

0

-

6

0

~

5

z

0

H

-

6

0

1

2

r

a

i

e

l

S

10

11

+

RS-485

12 13

Analog

output

0÷10V

4÷20 mA

~

z

H

34

12 13

Analog

output

0÷10V

4÷20 mA

+

Relay output 2

8(5)A/250 V~

+

Relay output

8(5)A/250 V~

5234

9

7

8

6

14

16

17 18

15

+

External

consent

TC probe

input

input

Relay output 1

8(5)A/250 V~

5

89

7

6

14

16

17 18

15

+

External

consent

TC probe

input

input

16

16

Probe input

PTC 3 wires

16

Probe input

PTC 3 wires

5

1

10

RS-485

17 18

17 18

2

~

0

-

S

17 18

Jumper

Jumper

V

0

3

~

2

~

V

~

4

5

z

0

H

-

0

6

Relay output 2

8(5)A/250 V~

z

H

0

6

4

3

2

r

a

i

e

l

13

12

11

+

16

Probe input

PTC 2 wires

+

Sensor - 3 wire to be povered

16

17 18

16

Probe input

PTC 2 wires

+

Sensor - 3 wire to be povered

Relay output 1

8(5)A/250 V~

5

89

7

6

14

16

17 18

15

NTC1

NTC2

External

consent

NTC probe

input

input

17 18

+

Probe input

4÷20 mA

0÷20 mA

Active

probe

supply output

9VDC max 30 mA

17 18

+

Probe input

4÷20 mA

0÷20 mA

Active

probe

supply output

9VDC max 30 mA

16

181617 18

17

181617 18

17

+

Probe input

0÷1V

4÷20 mA

0÷20 mA

Self-powered sensor

+

Probe input

0÷1V

4÷20 mA

0÷20 mA

Self-powered sensor

English

Probe

0÷1V

input

+

4÷20 mA

-

0÷20 mA

Active

probe

supply output

9VDC max 30 mA

Sensor - 2 wire to be povered

16

Probe

0÷1V

input

+

4÷20 mA

-

0÷20 mA

Active

probe

supply output

9VDC max 30 mA

Sensor - 2 wire to be povered

- 55 -

User Manual – Thermoregulator FHT

Vemer S.p.A.

I - 32032 Feltre (BL)

Via Camp Lonc, 16

Tel +39 0439 80638

Fax +39 0439 80619

e-mail: info@vemer.it - web site: www.vemer.it

V3ISO0330-010-072007

Loading...

Loading...