VEM KPE Series, G10 Series, K10 Series, K20 Series, K21 Series Operating And Maintenance Instruction Manual

...

V

Operating and

Maintenance Instruction

Three Phase

Asynchronous motors

with squirrel cage

version II2G EEx d(e) IIC T 3-6

EM motors GmbH

Ausgabe 07.2005

I

Dezember 1996

0

y

.

R

5

Werknorm EW-N 120

EC-Certificate of Conformit

Blatt 1 Seite 2

VEM motors GmbH ab:1. 12. 1996

Carl-Friedrich-Gauß-Str. 1 verbindlich:

D-38855 Wernigerode bis:

The electrical apparatus

three-phase asynchronous motors with squirrel cage rotor

three-phase asynchronous motors with slip-ring rotor

of series

KP./KPE./K10./K11./K20./K21. G10./G11./G20./G21./GS10./GS11.

BP./BPE./B10./B11./B20./B21. CP./CPE./C10./C11.

AR. YP./YPE./Y10./Y11./Y20./Y21.

A10./A11../A20./A21

SP./SPE./S10./S11. S81.

WE1./W20./W21. M21. 132 up to 180 (MMGE..., EDU...)

R10./R11./R20./R21.

K22.. 355 / B22. 35

are in conformity with the instructions of

73/23/EWG

Low Voltage Directive

amended by RL 93/68 /EWG

K81R/K82R/B82

89/336/EWG

Directive about Electromagnetic Compatibility

amended by RL 91/263/EWG, 92/31/EWG and 93/68/EWG

The conformity with the instructions of these Directives is proved by the observation

of following standards:

European Standard German Standard / VDE-Classification

EN 50082-1:1997 DIN EN 50082-1/11.97 - VDE 0839-82-1/11.97

EN 61000-6-4:2001 DIN EN 50081-2/03.94 - VDE 0839-81-2/03.94

EN 55014-1:2001 DIN EN 55014-1/11.01 - VDE 0875-14-1/11.01

EN 55014-2:1997 DIN EN 55014-2/10.97 - VDE 0875-14-2/10.97

EN 61000-3-2:2000 DIN EN 61000-3-2/12.01 – VDE 0838-2/12.01

EN 61000-3-3:2001 DIN EN 61000-3-3/11.98 – VDE 0838-3/11.98

EN 60034-5:2001 DIN EN 60034-5/12.01 – VDE 0530-5/12.01

EN 60034-6:1993 DIN EN 60034-6/08.96 - VDE 0530-6/08.96

EN 60034-9:1997 DIN EN 60034-9/06.98 - VDE 0530 Teil 9/06.98

EN 60034-1:200 DIN EN 60034-1/09.00 - VDE 0530-1/09.00

EN 60034-2:1996 DIN EN 60034-2/09.98 - VDE 0530-2/09.98

DIN IEC 60038/05.87

Wernigerode, the..................

Sander Beutner

Manager Factory Manager

This certificate attests the conformity with the named Directives, however, it is not a promise

of properties in the meaning of product liability.

In case of electronical communication, the signature does not appear.

Erarb. Gepr. Genehm. Änderungszustand

Warning!

Hazardous electrical current!

Ensure protection against explosions!

Before installing

Make sure that device cannot be switched on again by accident.

Switch off the power to the device.

Make sure that the device is de-energized.

Connect to earth and short out.

Cover or close off any neighboring live parts with a barrier.

Follow carefully the assembly instructions provided for the device.

Only qualified personnel as per EN 50110-1/-2 (VDE 0105, part 100) can perform any work on this de-

vice/system.

The electrical connections are to be made as per the relevant specifications (e.g. cross-section of the supply

line, fuses, protective connection).

Opening the motor - save for the terminal box - during the warranty period without the manufacturer's permission

shall lead to the termination of the warranty.

Original spare parts are to be used for the approved repairs or repairs not falling under the warranty.

Live and rotating parts of electrical motors can cause major or deadly injuries.

Any shipping, installation, start-up and maintenance works are to be carried out only by qualified personnel (fol-

low carefully any regulations on explosion protection such as EN 60079-14 and EN 50821-1-2 as well as any

other national accident prevention regulations).

As regards any equipment subject to these guidelines, it is important to adopt the necessary safety precautions

to protect the personnel against possible injuries.

The personnel must be duly instructed to proceed with caution and according to regulations during shipping,

hoisting, and positioning and while repairing the motor.

Do not lift the motor together with the drive equipment by the motor lifting eyebolts.

Do not use the supplied lifting eye bolts at ambient temperatures below –20°C, in accordance with DIN 580.

Lower temperatures could lead to the ring screws breaking and consequent breaking and consequent injury to

personnel and/ or damage to the installation.

Do not load the eyebolts as per DIN 580 no more than 45° compared to the screwing direction. The use of

crossbeams is recommended. See the operating instructions for the layout dimensions of the lifting eyebolts and

the minimum dimensions of the loading crossbeams and chain lengths.

In the case of motors with built-in brake appropriate safety measures are to be adopted against the possible

failure of the brake especially in applications involving the pulling of loads.

Operating the motor with the supplied shaft protection cover alone is forbidden.

Contact with the capacitor for the start-up and running of single-phase motors is to be avoided until the unload-

ing procedure is carried out securely.

If a high-voltage test is necessary, the procedures and precautionary measures set forth in accident prevention

regulations are to be followed.

I

Physikalisch-technische Bundesanstalt PTB

Braunschweig und Berlin

(1) EC-TYPE-EXAMINATION CERTIFICATE (Translation)

(2) Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres –

Directive 94/9/EC.

(3) EC-type-examination Certificate Number:

PTB 99 ATEX 1098

(4) Equipment: Three-phase motor of the type series K8. 56..., K8.. 63..., K8.. 71...,

K8.. 80..., K8.. 90..., K8.. 100..., K8.. 112..., K8.. 132...,

K8.. 160..., K8.. 180..., K8.. 200..., K8.. 225..., K8.. 250...,

K8.. 280..., K8.. 315..., K8.. 355...

(5) Manufacturer: VEM motors GmbH

(6) Address: Veckenstedter Weg 23, D-38855 Wernigerode

(7) This equipment and any acceptable variation thereto are specified in the schedule to this

certificate and the documents therein referred to.

(8) The Physikalisch-Technische Bundesanstalt, notified body No.0102 in accordance with

Article 9 of the Council Directive 94/9/EC of 23 March 1994, certifies that this equipment

has been found to comply with the Essential Health and Safet y Requirements relating to the

design and construction of equipment and protective systems intended for use in potentially

explosive atmospheres, given in Annex II to the Directive.

The examination and test results are recorded in the confidential report PTB Ex 99-19163

(9) Compliance with the Essential Health and Safety Requirements has been assured by

compliance with

EN 50014:1997 EN 50018:1994 EN 50019:1994.

(10) If the sign „X” is placed after the Certificate number, it indicates that the equipment is

subject to special conditions for safe use specified in the scheduleto this certificate.

(11) This EC-type-examination Certificate relates only the design and construction of the

specified equipment in accordance with Directive 94/9/EG. Further requirements of this

Directive apply to the manufacture and supply of this equipment.

(12) The marking of the equipment shall include the following:

II 2 G EEx d IIC T3 – T6 or EEx de IIC T3 – T6

Zertifizierungsstelle Explosionschutz Braunschweig, 4 August 1999.

By order

(signature)

Dr.-Ing. U.Klausmeyer

__________________________________________________________________________________________________________________

EC-type-examination Certificates without signatu re and official stamp shall not be valid. The certificates may be circulated only without altera tion.

Extracts or alteriations are subject to approval by the Physikalisch -Technische Bundesansta lt. In case of dispute, the German text shall prevail.

Pysikalisch-Technische Bundesanstalt . Bundesallee 100 . D-38116 Braunschweig

Physikalisch-technische Bundesanstalt PTB

Braunschweig und Berlin

(13) Schedule

(14) EC-TYPE-EXAMINATION CERTIFICATE PTB 99 ATEX 1098

(15) Description of equipment

Three-phase motors of the type of protection flameproof safety „d” with terminasl

compartment or direct cable entries. The terminal compartment is carried out in the type of

protection flameproof enclosure „d” or increased safety „e”.

(16) Report PTB Ex 99-19163

(17) Special conditions for safe use

note

(18) Essential health and safety requirements

met by compliance with standards

Zertifizierungsstelle Explosionschutz Braunschweig, 4 August 1999.

By order

(signature)

Dr.-Ing. U.Klausmeyer

__________________________________________________________________________________________________________________

EC-type-examination Certificates without signatu re and official stamp shall not be valid. The certificates may be circulated only without altera tion.

Extracts or alteriations are subject to approval by the Physikalisch -Technische Bundesansta lt. In case of dispute, the German text shall prevail.

Pysikalisch-Technische Bundesanstalt . Bundesallee 100 . D-38116 Braunschweig

About this Manual

These operating instructions apply to AC motors of the following series:

K8.R and B8.R.

Besides the general assembly instructions, these guidelines are to be followed for the installation, start-up and maintenance of explosion-protected AC motors with a degree of protection of "pressure-resistant encapsulation" marked:

(II..), EEx de II. T or EEx d II. T.

Any independent manufacturing equipment mounted on or built into the motors like brakes, rotary encoders or frequency converters, etc. have their own operating instructions which are to be duly followed.

Target readership

This manual is addressed to the specialists in charge of installing, operating and servicing the motors. Besides conventional technical training they must possess knowledge in the field of explosion protection.

Abbreviations and symbols

This manual uses abbreviations and symbols having the following meanings:

indicates handling instructions

>

draws your attention to interesting tips and additional information

Please note!

warns against minor damages to property.

Caution!

warns against major damages to property and minor injuries.

Warning!

warns against major damages to property and major injuries or death.

1 Explosion-protected Motors

Intended use

The motors are to be operated only according to the data specified on the rating plate. According to the relevant

marking on the rating plate, the motors are fit for use in areas subject to explosion hazards.

The motors are fit to be built into another machine. Start-up is forbidden until the conformity of the final product with

Directive 89/392/EEC as amended by 98/37/EC is determined.

Liability and Warranty Guarantee

We cannot be held liable for any damage or malfunctions resulting from assembly errors, the failure to follow these

operating instructions or improper repairs.Original spare parts are manufactured and tested specifically for these

motors.

We recommend that you obtain any spare parts and accessories only from the manufacturer.

We hereby specify that any spare parts and accessories not supplied by the manufacturer require our approval.

Under any circumstances the mounting and use of third-party products can negatively affect the motor's original

structural properties and impair the safety for persons, the motor or other real values (explosion protection).

The manufacturer shall not be liable for any damages resulting from the use of spare parts or accessories not authorized by the manufacturer.Any unauthorized conversions and alterations to the motor shall not be approved for

safety reasons and the manufacturer cannot be held liable for any resulting damages.

Servicing

VEM customer service is available for all technical information concerning VEM motors.

Should a problem occur,contact us or one of our local branch offices.

When ordering spare parts, in addition to the listed designation of the part required, please indicate the motor type

and serial no.

Delivery, Storage, Transport

Delivery

>

Check the motor for damages during transportation.

In case of damage during transportation an investigation of fault is to be performed by the forwarding agent.

>

Report any covert damages to the forwarding agent or manufacturer no later than seven days from the transfer

of the motor.

The entire packaging material can be recycled by means of the Dual System.

Storage

Storage up to a maximum of 36 months is possible in the following conditions:

• In order to prevent a drop in the insulation resistance, the surrounding environment must be dry and dust-free.

• The room temperatures should not drop below +5 °C or exceed +30 °C with an air humidity of < 70 % and register

changes in temperature greater than 10 °C/day.

• In order to prevent damage during storage any occurring oscillations must amount to V

• For motors with regreasing systems repress an amount of grease double that specified on the motor at standstill

before storage.

Please note!

In case of storage conditions deviating from those specified above the measures set forth

in the separate storage instructions must be adopted.

Transport

Do not lift the motor together with mounted driven machines such as, for instance, pumps, gearing, etc. by the motor

lifting eyebolts.

Do not use eyebolts as per DIN 580 at ambient temperatures lower than –20 °C.

At these temperatures the eyebolts may break and hence injure the personnel and/or damage the machinery. Do not

load the eyebolts as per DIN 580 no more than 45° compared to the screwing direction. The use of crossbeams is

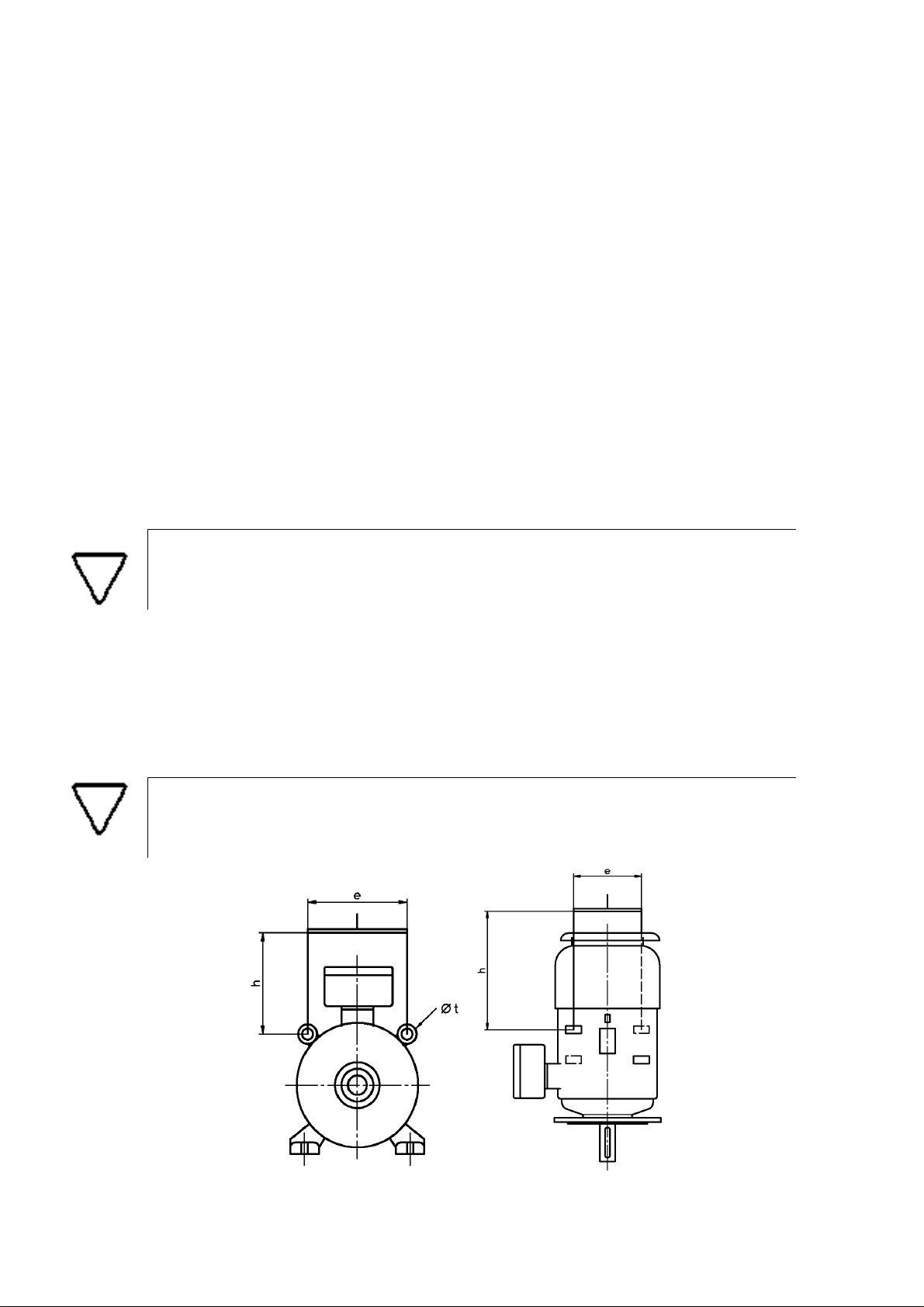

recommended. Layout dimensions of the lifting eyebolts and the minimum dimensions of the loading crossbeams

and chain lengths.

Please note!

When mounting vertical motors from the horizontal position, the shaft must not touch the

floor to avoid damaging the bearings.

< 0.2 mm/s.

eff

Figure 1: Eyebolt dimensions

Table 1:Minimum dimensions for lifting eyebolts and crossbeams

Frame size

Ø

t

horizontal

e

h

vertical

e

h

90 20 167 100 220 187

100 20 185 112 242 201

112 20 202 103 262 236

132 25 243 170 307 247

160 30 262 206 314 293

180 30 294 223 402 372

200 35 390 219 451 399

225 40 366 230 510 490

250 40 435 282 546 548

280 40 498 301 600 574

315 50 640 337 700 595

355 60 629 397 816 893

400 60 790 312 890 771

450 60 833 317 980 660

2 Installation

Mechanical checks

After removing the shipping braces and shaft blocks (see also the marking on the motor), the motor shaft must be

rotated by hand. In the case of brakemotors the brake must be vented at standstill (maximum of 10 min). This must

be performed after applying voltage as per the circuit diagram at page 15.

Please note!

Save the shipping braces and shaft blocks for subsequent transportation, as the bearings

risk being damaged during transportation.

Site

The completely closed motors are intended for operating sites in which they are exposed to soiling, humidity and

other open air conditions as per the relevant degree of protection.

The motors must be installed in a place with ambient temperatures of –20 °C to a maximum of +40 °C and a max. of

1000m above sea level. Any permissible ambient temperatures (T

above must be specified on the rating plate. Lower temperatures and values not found on the rating plate require the

use of space heaters

Table 2: Minimum distance (LE) of an obstacle from the air opening, see Fig. 2.

) and heights (MSL) other than those indicated

a

Please note!

The ventilator hood air inlet and outlet must not be obstructed, as there is the risk of heating beyond the permissible temperature class and of reducing the life of the winding insulation.

This applies in particular to the use of soundproof covers. The air ducts must checked

and cleaned regularly in factories with heavy soiling.

Shaft height

up to 160 35

180 to 225 85

over 250 125

LE [mm]

Figure 2: Minimum distance of obstacles from the air opening

The motors are intended for use in areas subject to explosion hazards. The following data on the rating plate distinguish the motor as explosion-protected equipment:

• Degree of protection

• Explosion group

• Temperature class

Depending on the appliance category the motor is assigned to the relevant zone of the operating site.

Mounting

The motors are mounted either on the motor feet or on the flange at the installation site. All motors with shaft heights

of up to 355 mm can be mounted either horizontally or vertically thanks to their bearing layout. This applies also for

motors to be mounted with the feet on roofs and side walls. Motors with reinforced bearings are to be operated at a

minimum load to ensure the smooth operating of the anti-friction bearings.

The bearings may be damaged if the minimum load is exceeded. Trial runs with no-load should last only a few minutes.

You can find the max. permissible loads in our catalogue or contact the manufacturer.

Align the motors according to the requirements of the coupling or pulley manufacturer. The feet are to be positioned

evenly and, if necessary, lined.

Table 3: Minimum load on the shaft collar for motors with reinforced bearing

Shaft

height

Minimum

load

Shaft

height

Minimum

load

Shaft

height

Minimum

load

112 1100N 200 3400N 315 8000N

132 1600N 225 3800N 355 2000N

160 1900N 250 4900N 400 2000N

180 2700N 280 5500N 450 2300N

Please note!

Make sure that the fastening screws are duly dimensioned.

Data on the foundation loading generated by the motor can be requested from the manufacturer by specifying the

motor number. The fastening screws must be duly tightened according to their layout and secured to prevent loosening during operation and hence the damaging of the drive.

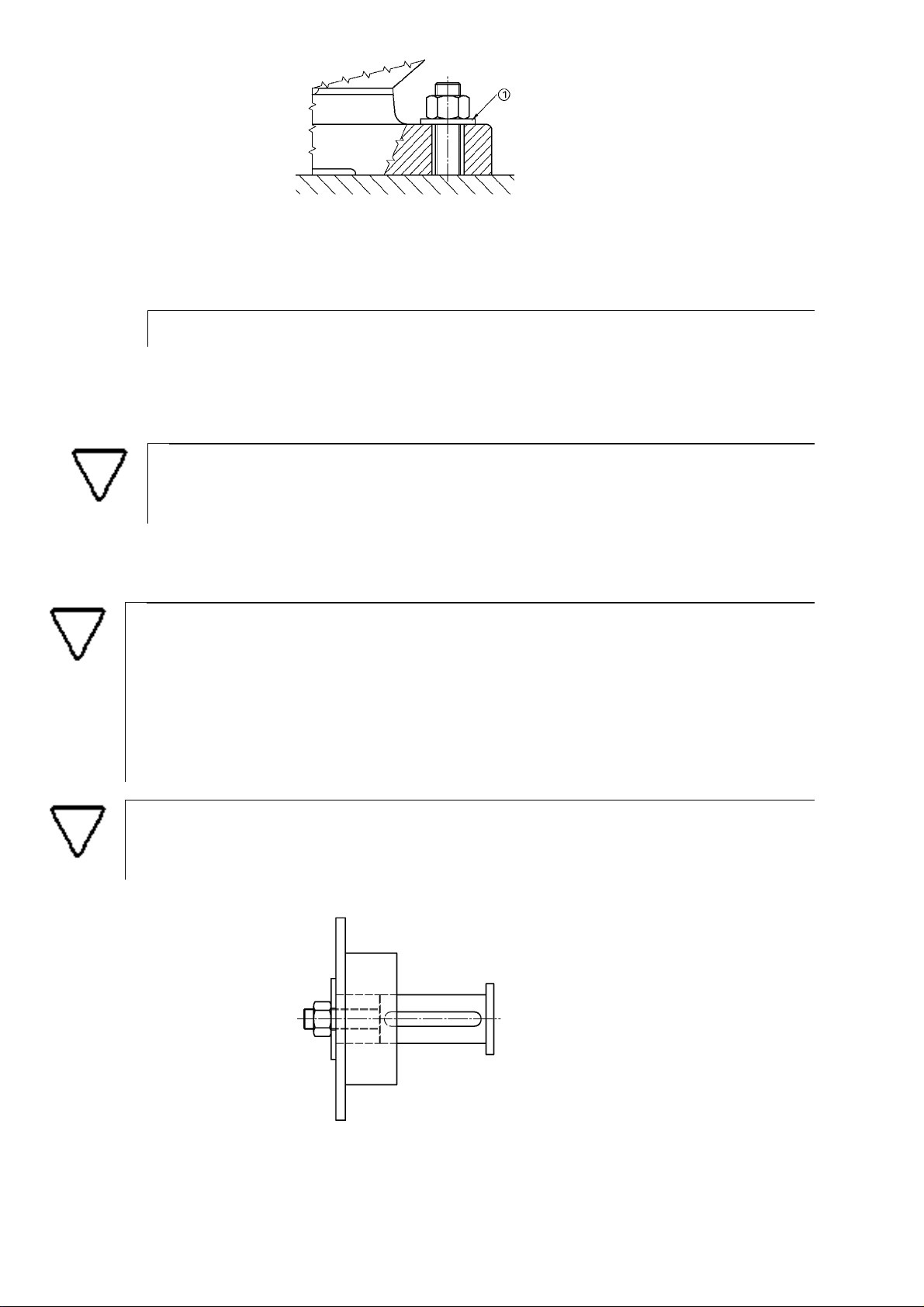

Figure 3: Motor Fastening

Large-surface Washer

In order to achieve an adequately large contact surface, apply a large-surface washer under each nut or screw head

.

>

Alternatively use flange nuts or bolts.

If the motors' shaft end points up or down (vertical mounting arrangement), it is necessary to fit an appropriate cover

to prevent any foreign bodies from dropping in the driven machine through the air inlet and outlet openings in the

ventilator hood.

Please note!

The flow of cooling air through the motor must not be limited by said cover.

The balance of the motors is specified on the shaft end plate and/or on the rating plate (H = half key, F = full key, N

= no key).

The design of the coupling or pulley must match the motor's balance.

Please note!

If balancing with half key (H), work on the vertical (visible) key components on the shaft diameter

or cover these with washers with keyway along the relevant length.

If the coupling is longer than the key, it is necessary to fill the keyway in the remaining part of the

coupling.

In case of failure to comply with the foregoing, out-of-balances liable of causing excessive vibrations may occur.

Please note!

Mount the pulleys or couplings only through the threaded bores in the shaft end to avoid damaging the anti-friction bearings.

Fig. 4: Fastening of the pulley or coupling

>

Screw the threaded bolts in the threaded bore.

>

Then mount the pulley or coupling on the shaft end: make sure to screw a nut with a washer having at least the

same diameter of the pulley hub or coupling on the threaded bolt.

Use the utmost care in mounting dynamically balanced pulleys or couplings on the shaft end. Machines to be connected to the motor by means of couplings are to be aligned according to the specifications of the coupling's manu

facturer.

Use only flexible couplings!

Mains and other electrical connections

The motors work as per VDE 0530 with mains voltage oscillations of up to ±10 % or frequency oscillations of up to –

5 % to +3 %. The mains ratings must match the voltage and frequency data specified on the ratings plate.

Connect the motors according to the connection diagrams attached to the terminal box. Use only the supplied original connection components.

Please note!

Carry out the motor, controller, overload protection and earthing connection operations in

compliance with local installation requirements.

Please note!

If the accidental starting of the system may expose the personnel to danger, do not use

any automatically restarting motor protective equipment.

Mains connection of explosion-protected motors

Besides any general installation regulations, follow carefully EN 60079-14 and EN 50281-1-2. Afterwards suitable

overload protection is to be provided either with a motor circuit breaker or similar protective devices. These may

include also PTC thermistors with tripping devices. These must be specified on the rating plate together with a tripping time t

.

A

In addition, any "Special Requirements" specified in the test certificate are to be complied with. These are marked

with an "X" after the test certificate number on the rating plate.

Motors with direct line lead-in

The free end of the cable inserted in the motor must be connected according to the regulations in force concerning

the connection area. If the line lead-in used on the motor is provided with pull relief, the cable can be laid freely; otherwise the cable must be secured with a pull relief device in the near vicinity.

The maximum operating temperature at the line lead-in must not

exceed 90° C.

Terminal box

Open the box by loosening the screws on the cover (Fig. 5) or, in the case of models with grub screw (Fig. 6), by

turning the grub screw counter-clockwise and then loosening the tapped cover.

Close the terminal box again after connecting the mains by following the same instructions in the opposite order.

In order to change the position of the cable and line lead-ins, you can turn the terminal box by 4

>

Loosen either

x

90°.

– the four fastening screws or

– the anti-rotation pins by means of the grub screw.

>

Turn the terminal box to the desired position.

-

Figure 5: Terminal box with fastening screw

Figure 6: Terminal box with grub screw

>

Then tighten the fastening components to the relevant torque, see the following table.

Table 4: Torque values for 8.8-type screws

Thread size

M5 6 Nm

M6 10 Nm

M8 25 Nm

M10 49 Nm

M12 85 Nm

M16 210 Nm

M20 425 Nm

Please note!

Terminal boxes fastened as per Fig. 6 are to be turned counter-clockwise by a maximum of

one turn away from the thread end stop. Screwed-on covers must be duly secured.

Anti-corrosion protection can be achieved with non-hardening sealing materials or sealing grease in particular on the

processed sealing surfaces of the covers of terminal boxes having the following degree of protection: "pressureresistant encapsulation, EEx d IIC(B) marking".

The approved sealing materials are:

• For threads and surfaces: Hylomar, by Marston-Domsel or

• for surfaces: Admosit and Fluid-D, by Teroson.

Please note!

In the case of "increased safety" terminal boxes the gaskets used are included in the

approval. Only original gaskets are to be used.

Please note!

"Pressure-resistant encapsulation“ terminal boxes must be sealed by means of approved cable or line lead-ins.

Torque

Cable and line lead-ins

Connect the motors with cable and line lead-ins or by means of a duct system as per EN 60079-14. These must

meet the following requirements:

• EN 50019 for wiring spaces with a degree of protection of "increased safety", (EEx e II marking on the component)

• EN 50018 for a degree of protection of "pressure-resistant encapsulation”, (component EEx d IIC(B) marking on

the component)

Specific test certificates must be provided for cable and line lead-ins.

Please note!

In case of motors complying with the new Directive 94/9/EC, (e.g. marking II 2G ...),

these must be mounted only with the supplied original lead-ins or lead-ins that meet

the requirements of the new directive.

Any openings that are not used must be closed with sealing plugs for which the relevant test certificates and/or the

aforementioned markings must be provided.

The supplied sealing plugs for the line lead-ins serve only as protection during transportation and are not an approved sealing means. This applies also for the storage of motors outdoors. In this case additional rain protection is

required.

The lead-ins supplied as a standard (version 1) are used for the insertion of firmly secured lines.

Version 3 available as a special accessory, with additional pull relief, is used for the insertion of lines in movable

motors.

Please note!

Cable lead-ins and sealing plugs that fail to meet these requirements are prohibited. The

cable and line diameters used must comply with the clamping range specified on the

lead-in.

Follow carefully the operating instructions of the cable and line lead-ins.

Motors with terminal boxes whose mains lead is located in the layer separating the upper and lower parts

Use only the supplied original gaskets to ensure compliance with the “Ex e II” degree of protection. Depending on

the type (see marking on the plug), the plugs are fit for the following diameters.

Follow carefully the operating instructions for the lead-in parts and sealing plugs.

Table 5: Cable diameter

>

After connecting the mains lead close the terminal box with the upper part.

>

Strip the skins of the plugs so that the following condition is fulfilled:

Type

RS-75 26 to 48 mm

RS-100 48 to 70 mm

Cable diameter

By stripping the skin, the plugs are adapted to the cable diameter so that a gap of less than 1 mm is obtained

between the cable and the plug applied on the cable.

Therefore, an extra layer of skin must be removed from one half of the module compared to other.

>

Lubricate the cutting edge and the sealing surfaces of the plug with the supplied grease.

>

Insert the plug halves over the cable and completely in the bushing opening.

>

Brace it with the screws until a perceivable resistance (maximum torque: 6 Nm) is achieved.

Figure 7: Cable lead-in

Maximum two line lead-ins, Roxtec, Rox RS Type plugs

Mains and guard circuit connection

The mains can be connected either with or without cable lug both in models with terminal board and in those with

single-conductor bushings.

Connect the power line to the relevant terminals as per the supplied wiring diagram.

Figure 8: Line connection

Connection without cable lug

Clamp

Connection with cable lug

Single-wire conductor without cable lug

>

When connecting a single-wire conductor without cable lug to terminals with just one screw, bend the conductor end as illustrated

.

Figure 9: Conductor bushing

Connection without cable lug

Connection with two cable lugs

Connection with one cable lug

Take note of the maximum connectable conductor cross-section for the terminals. If no other data is available on the

terminals, refer to the following table.

Table 6: Rated cross-sections

Shaft height

Rated cross-section [mm

63 to 112 4

132 to 160 10 (r)

180 to 225 70

250 to 280 120

315 150/ 300 (depending on the model)

over 355 300

2

]

In the case of "increased safety" terminal boxes, make sure to comply with the clearances specified in EN 50019

between conductive parts having different potentials. Tighten the screws and nuts on the live parts to the specified

torque.

Table 7: Clearances

Rated voltage, U [V]

Minimum clearance [mm]

175 < U ≤ 275 5

275 < U ≤ 420 6

420 < U ≤ 550 8

550 < U ≤ 750 10

750 < U ≤ 1100 14

2200 < U ≤ 3300 36

5500 < U ≤ 6600 60

8300 < U ≤ 11000 100

Table 8: Torques and current intensities for live pins

Thread size Torque [Nm]

Permissible continuous current

[A]

Brass Copper

M4 1.2 16 -

M5 2 25 -

M6 3 63 -

M8 6 100 -

M10 10 160 200

M12 15.5 250 315

M16 30 315 400

M20 52 400 630

Depending on the model, additional terminals for instance for temperature monitoring or space heater are located

either in the main terminal box or in additional terminal boxes; see the supplied wiring diagram.

Please note!

Take note of the rating data imprinted on the terminals.

Please note!

Keep the wiring diagram supplied in the terminal box in the enclosure with the documents belonging to the drive.

Motors with unidirectional fan

Make sure that the fan's direction of rotation matches that of the motor.

Motors with separate cooling via separately powered external fans

Make sure by means of the electric control that the main motor can be operated with the motor switched-on for separate cooling.

Motors with temperature monitoring

The motors are equipped with PTC's as per DIN 44081. Take note of the temperature data and tripping time

t

on

A

the rating plate.

Connect the PTC to an approved tripping device with marking PTB 3.53-PTC/A or

Please note!

The tripping device is not explosion-protected. For this reason install them outside the areas subject

to explosion hazards.

II(2) G.

The marking confirms whether the electrical data on the interface between the temperature sensor circuit and the

tripping device have been fulfilled. The use of the tripping device with PTC temperature sensors as per DIN 44081 is

allowed for the thermal monitoring of explosion-protected electrical machinery.

Being the only overload protection as set forth in EN 60079-14, the temperature sensors herein described can be

used together with an approved tripping device only if the tripping time

t

is specified on the motor rating plate. (Re-

A

fer to Section 3, Operation & Repairs, page 17)

Motors with space heater

The rating data for the space heater are specified either on the rating plate or on a separate plate. Depending on the

model, there are two heating variants:

• by means of heater bands powered via terminals HE1-HE2

• by means of the stator winding by feeding AC voltage to terminals U1-V1.

Please note!

Make sure by means of the electric control that the motor

voltage and the heater voltage are not fed simultaneously.

Please note!

The heater is not explosion-protected. It must not be switched

on at motor temperatures below -20°C to heat the motor to at

least –20°C. On the contrary, its purpose is that of preventing

that the motor temperature falls below –20°C when idle.

Motors for operating on frequency converters

For operating on frequency converters, motors with temperature monitoring must be protected by PTC temperature

sensors rating data for this operating mode are specified either on the rating plate or on a separate plate. If the relevant plate is missing, see the data provided in the manufacturer catalogue "Explosion-protected high and low voltage

AC motors in II 2 G EEx d(e) IIC(B) T4...T6“.

Check the drive's "electromagnetic compatibility" as per EMC directive no. 89/336/EEC when operating on frequency

converters.

Make sure when operating motors on frequency converters with a DC intermediate circuit that the admissible voltage

peak value of 1160 V is not exceeded by the periodically occurring commutation voltage peaks (threshold value for

terminals, clearances and creep distances).

If pulse width-modulated voltage source converters (pulse converter) are used for feeding power to the motors,

make sure that no high-frequency transients with high voltage peak values are generated. These may be generated

by the sharp switching edges of the voltage pulse especially along longer supply lines between the converter and

motor and shorten the life of the winding insulation. The normal design of the terminals and bushings for 750 V is

suitable for peak voltages of 1200 V. Higher voltage peaks require the application of bushings and terminals for

1100 V. The approved value for the periodic peak voltage amounts to 1600 V. If the periodic voltage peaks exceed

1600 V, high-voltage insulation systems must be applied.

In the case of a converter output non-galvanically separated from the mains and with current limitation, follow the

requirements of DIN EN 50178 and VDE 0160 (equipment of high voltage installations with electronic devices) on

the overload protection of the protective earth conductor.

In rating the protective device in the outer conductors, bear in mind that the protective earth conductor current can

be greater than the outer conductor current in fault condition. The protective earth conductor is to be dimensioned

according to this fault current.

Take note of all of the data of the converter manufacturer for said fault condition.

Motors with brake

The mains line in the version with incorporated brake is connected in the motor terminal box and in the version with

the built-on brake in the separate brake terminal box. Observe the supplied connection diagram and the rated voltage visible on the rating plate. In the presence of an AC connection the brake coil is energized by means of a silicon

rectifier accommodated inside the explosion-proof encapsulation.

>

The temperature sensors applied both in the motor and brake are to be connected as envisaged in

Section "Motors with temperature monitoring", page 13.

Motors with brake or tachometer mounted under the ventilator hood

In order to connect brakes or tachometers mounted under the motor ventilator hood, the latter must be disassembled.

Unscrew any shock pulse sensors or regreasing devices. Loosen the fastening screws on the hood and remove the

hood from the motor.

Connect the brake of tachometer as per the attached circuit diagram and pass the cable along the shortest route

through the motor fins towards the main terminal box. It is recommended to insert a protective tube over the connection cable in the fin area to prevent wearing.

Fit the ventilator hood back on the motor and check the position of the boreholes for any shock pulse sensors and

regreasing devices. In the case of motors with an axial fan running into a nozzle, make sure that there is a uniform

air gap all around between the fan and nozzle. Secure the hood with the fastening hoods.

Check manually that the fan runs freely once the mounting is completely.

Motors with backstop

Motors with built-in backstop must be operated at a minimum rpm higher than the value specified on the rating plate

– e.g. FXM 850 min

–1

– to prevent excessively high temperatures.

Connection diagrams

The circuit diagram on the motor is to be followed.

Single-speed – one pole

∆

circuit

Y circuit

Pole changing

Low rpm High rpm

Dahlander connection

Low rpm High rpm

Dahlander connection

ow rpm High rpm L

1TP11TP2

Pre-alarm PTC U>2.5V not allowed Use tripping device with

PTB number or

marking II (2)G

2TP12TP2

1R1-R2 PT 100 resistance temperature sensor

Tripping PTC

HE1-

Space heater

HE2

Brakemotors with incorporated brake

Brake connection via motor winding

Y circuit

Terminals 1-2 can be connected directly to the

motor terminals to supply the brake. Compare

the motor/brake voltages to determine whether

the connection is to be made on U1-U2 or U1V1.

Terminals 3-4 must be bridged.

Y circuit

Brake

An external power supply can be applied on

terminals 1-2. Check the voltage data on the

rating plate. Terminals 3-4 must be bridged.

For a rapid engagement of the brake (DCvoltage side tripping) bridge 3-4 can be replaced by a contact. The contact must be

tripped simultaneously with the brake power

supply.

∆ circuit

BA1-BA4

1TP1-1TP2

2TP1-2TP2

HE1-HE2

TB1-TB2

In order to provide for the emergency venting

of the brake, e.g. to turn the motor manually,

you can apply a DC voltage source to terminal

1-4 (remove any other wiring before hand and

observe the polarity).

U voltage = = U~ x 0.45

U voltage~see brake voltage on the rating

plate.

Brake

Pre-alarm PTC

Tripping PTC

Space heater

Temperature monitoring: Microtherm T 10

U>2.5V not allowed Use tripping device

with PTB number or

marking II(2)G

y

Brake connection via external power supply

Y circuit ∆ circuit Brake connection

Pole changing

Low rpm High rpm

circuit Y circuit

Y

Pole changing Dahlander connection

Low rpm

∆ circuit

High rpm

circuit

Y Y

1-4 Brake

10-11 Tripping PTC Pre-alarm PTC Use tripping device with PTB number

12-13 Tripping PTC

70-71 Space heater

P1-P2 Temperature monitoring: Microtherm T 10

Brake power

supply via

terminals 1-2.

Observe the

voltage data

on the rating

plate. Terminal 3-4 must

For a rapid

engagement

of the brake

(DC-voltage

side tripping)

bridge 3-4

can be replaced by a

contact. The

contact must

be tripped

simultaneousl

with

3 Operation and Repairs

Duty types and thermal protection

• In S1 duty class motors a temperature sensor (TS) can be used in addition to the motor circuit breaker as required

by DIN EN 60079-14, VDE 0165.

• If in S1 duty cycle motors protection is to be provided against overheating only by means of the TS, a proven combination of TS and tripping device is to be used for said purpose.

• In the case of non-S1 duty cycle motors proven combinations of TS and tripping device must be used as protection

against overheating.

• The supplying of power to the motors via the frequency converter is permissible only if a proven combination of TS

on the windings and tripping device is used.

Special operating conditions

The operating of the motors at ambient temperatures outside the generally valid range of –20 to +40 °C is allowed also

without heater if an appropriate temperature range – e.g. –55 °C < T

Operation at less than –20°C is allowed also without any additional indication if the temperature of the entire motor is

maintained at least at -20 °C by means of a space heater.

At motor temperatures of less than -20°C the heater must not be started, as these are not explosion-protected.

Heat input through the driven machine

It must be ensured that no quantities of heat greater than the maximum heating values specified in table are conveyed

from a mounted machine to the interface with the motor (e.g. shaft and motor flange). This way it is guaranteed that no

point of the motor exceeds the temperature class.

Table 9: Permissible surface heating at an ambient temperature of 40°C:

< 60 °C – is specified on the rating plate.

amb

Item

T6 = 85°C T5 = 100°C T4 =135°C

1. Permissible heating on the shaft 30K 45K 65K

2. Permissible heating on the flange 30K 45K 65K

Temperature class

Start-up

Please note!

Before mounting or start-up the insulation resistance is to be measured by qualified technicians.

The resistance must be greater than 1 MΩ. A critical value is reached at 0.5 MΩ. If this value is not

reached, the motors must be dried.

The best way to do it is in an oven at temperatures up to 100 °C. To eliminate any humidity, open the motor. To be

entitled to any warranty claims, contact the manufacturer in advance.

These works must be carried out by qualified technicians; in the course of said works the manufacturer shall instruct

said technicians on how to ensure the explosion protection during reassembly. For the assembly and disassembly, see

the relevant repair instructions.

• Check the direction of rotation and operation during idle running. In case of unidirectional external fans (axial fans)

observe the sign for the direction of rotation on the motor. If the direction of rotation needs to be changed, invert the

two power lines and the fan.

• If the motor was stored and an additional quantity of grease was applied in the anti-friction bearings, the motor must

be run with no load for at least 0.5 h to ensure an adequate distribution of the grease and to avoid the overheating of

the anti-friction bearings.

• Make sure that the operating current matches the specified current values on the rating plate.

The protective equipment required as per EN 60079-14 is to be set according to the motor rating values specified on

the rating plate. The specified current value on the rating plate must not be exceeded in continuous duty conditions.

Please note!

Run the motor with load for at least 1 hour and check that there is no unusual noise or heating exceeding the specified temperature class values.

Relubricate motors with regreasing equipment with the specified amount of grease during start-up.

Vibration severity values of V

< 3.5 mm/s (

eff

P

<15 kW) or 4.5 mm/s (

N

P

> 15 kW) in coupled operating mode are

N

not allowed. In case of deviations from normal operating conditions – e.g. higher temperatures or greater noise and

vibrations – find the cause and, if necessary,

contact Producent.

Please note!

The protective equipment must always be kept in service also during trial runs. In case of doubt

switch off the machine.

Maintenance

Inspection

• The motors are to be constantly monitored depending on the operating conditions.

• Keep the motors clean and the venting openings free

Any national regulations valid for the maintenance/repair of electrical equipment in areas subject to explosion hazards e.g. in Germany the Operational Safety Order, etc - are to be complied with.

During maintenance especially those parts on which the degree of protection depends must be checked; these include,

for instance, the integrity of the lead-in components and gaskets.

Lubrication

Please note!

In order to avoid damage the bearings and grease must be kept clean.

The deep groove ball bearings of motors up to frame size 280 are sealed on both sides and filled by the bearing manufacturer with a grease which is enough for normal operating conditions in 4 or multi-pole motors for 40000 operating

hours or in 2-pole motors for 20000 operating hours.

When changing the bearings, change also the shaft seals. To do so, dismount the motor so that the winding can be

cleaned at the same time. Disassembly and assembly as per the specific manufacturer repair instructions.

Motors starting from frame size 315 and motors with reinforced bearings are to be equipped with regreasing devices.

The bearings are to be regreased preferably with the motor running with a grease gun through the grease nipples located over the bearing plates or bearing caps.

The drip space in the bearing cap for outflowing old grease is large enough to collect the outflowing grease during the

nominal bearing service life with state-of-the art regreasing.

See the plate on the motor for the specified lubricating intervals and the type and quantity of grease to be used. The

manufacturer normally uses ESSO Unirex N3, a lithium complex soap/mineral oil grease.

Table 10: Standard regreasing intervals in hours

Ambient

temperature

Rpm up

to 1800 min

–1

Rpm up

to 3600 min

–1

40 °C 5000 h 2500 h

50 °C 2500 h 1000 h

Please note!

In motors with enhanced performance (motor type ...X), in heavy drive conditions like belt and gear

drive with additional bearing loads and in vertical designs the lubricating intervals are to be reduced

by 50%.

Observe the specified quantity of grease. Overgreasing can lead to a sharp increase in the bearing

temperature and hence to the failure of the bearing.

Caution!

If regreasing is carried out while the motor is running, provide for adequate protection against rotating parts!

Only resin-free and acid-free anti-friction bearing grease with a drop point of approx. 200°C is to be

used.

Explosion protection

The marking

(II2G), EEx de IIC T4, for instance, indicates where the motor is to be used and that it has been designed, built and approved according to the relevant European standards required for operation in areas subject to

explosion hazards.

Please note!

The motor must not be altered in any way whatsoever and the operating instructions set forth

herein are to be complied with always.

If the motor is altered or repairs need to be made, these are to be performed by the manufacturer or by repair workshops or factories that possess the necessary know-how. Before the starting the motors again, conformity with the

requirements of EC directives 76/ 117/EEC or 94/9/EC and 99/92/EC by said sites is to be ascertained and confirmed

by means of an appropriate marking on the motor or by issuing a test report.

If these requirements are not met, the motor is no longer classified as explosion-protected and the marking - see

above - is to be removed.

Instructions for ensuring explosion protection during operation

• All of the contact screws and nuts of the electrical connections are to be tightened securely to prevent excessively

high contact resistance values that may lead to an excessive degree of overheating of the contact point; torque

values.

• Use the utmost caution when connecting the mains cable. Observe the creep distances and clearances. Use duly

the sealing parts of the cable lead-ins and connections spaces as well as the lead-in parts envisaged for the pull

relief or as protection against torsion in order to maintain the degree of protection of the connection spaces.

• Eliminate any damages immediately and use only original spare parts. The proper performance of the works by the

aforementioned sites is to be examined as per the relevant EC directives, in Germany by a qualified expert as per

ElexV, abroad as per the relevant national regulations in force and to be confirmed by means of an appropriate

marking on the motor or by issuing a test report.

• The surfaces of ignition-protected gaps must not be reworked. Keep these surfaces metallically clean. Corrosion

protection can be achieved by means of non-hardening sealing materials or sealing grease. The approved sealing

materials include besides the corrosion protection greases available on the market: Hylomar, by Marston-Domsel

or Admosit and Fluid-D, by Teroson (follow the manufacturer's usage instructions). This must be observed in par-

ticular for the openings in the cover for connection spaces having a pressure-resistant encapsulation degree of

protection, marking EEx d IIC(B).

•

All the screws are to be tightened to the envisaged torque and just as many screws as necessary for the envisaged

fastening boreholes are provided. Any damaged screws are to be replaced only with screws of the same dimensions and quality.

Repairs

Repairs and changes to explosion-protected machines are to be carried out by one of the aforementioned sites as

per EC directives 94/9/EC and 99/92/EC, in Germany in compliance with the Operational Safety Order as well as

with the safety regulations and requirements of the repair instructions.

Any works relating to the explosion protection must be carried out by the manufacturer or by a specialized workshop

for electrical machinery. If said works are not performed by the manufacturer, these must be surveyed by an authorized qualified person.

In Germany a written certificate as per the Operational Safety Order is required for restarting. In foreign countries the

national regulations in force are to be complied with.

3 Additional dust protection requirements

(application in zones 21 and 22)

Intended use

A marking of at least IP 65 and

Installation and Operation

Cable and line lead-ins

Separately approved lead-ins belonging to category 2G with at least IP 65 or category are to be used. Any openings

that are not used are to be closed with duly approved plugs.

Operation and Repairs

The motors must not be operated with excessive dust deposits, as these may lead to the exceeding of the admissible surface temperature. Regular cleaning must be performed.

The radial shaft seal rings are included in the approval. Only original gaskets are to be used.

II 2D T …° C must be found on the motor's rating plate.

Loading...

Loading...