VEM KPE Series, G10 Series, K10 Series, K20 Series, K21 Series Operating And Maintenance Instruction Manual

...

V

Operating and

Maintenance Instruction

Three Phase

Asynchronous motors

with squirrel cage

version II2G EEx d(e) IIC T 3-6

EM motors GmbH

Ausgabe 07.2005

I

Dezember 1996

0

y

.

R

5

Werknorm EW-N 120

EC-Certificate of Conformit

Blatt 1 Seite 2

VEM motors GmbH ab:1. 12. 1996

Carl-Friedrich-Gauß-Str. 1 verbindlich:

D-38855 Wernigerode bis:

The electrical apparatus

three-phase asynchronous motors with squirrel cage rotor

three-phase asynchronous motors with slip-ring rotor

of series

KP./KPE./K10./K11./K20./K21. G10./G11./G20./G21./GS10./GS11.

BP./BPE./B10./B11./B20./B21. CP./CPE./C10./C11.

AR. YP./YPE./Y10./Y11./Y20./Y21.

A10./A11../A20./A21

SP./SPE./S10./S11. S81.

WE1./W20./W21. M21. 132 up to 180 (MMGE..., EDU...)

R10./R11./R20./R21.

K22.. 355 / B22. 35

are in conformity with the instructions of

73/23/EWG

Low Voltage Directive

amended by RL 93/68 /EWG

K81R/K82R/B82

89/336/EWG

Directive about Electromagnetic Compatibility

amended by RL 91/263/EWG, 92/31/EWG and 93/68/EWG

The conformity with the instructions of these Directives is proved by the observation

of following standards:

European Standard German Standard / VDE-Classification

EN 50082-1:1997 DIN EN 50082-1/11.97 - VDE 0839-82-1/11.97

EN 61000-6-4:2001 DIN EN 50081-2/03.94 - VDE 0839-81-2/03.94

EN 55014-1:2001 DIN EN 55014-1/11.01 - VDE 0875-14-1/11.01

EN 55014-2:1997 DIN EN 55014-2/10.97 - VDE 0875-14-2/10.97

EN 61000-3-2:2000 DIN EN 61000-3-2/12.01 – VDE 0838-2/12.01

EN 61000-3-3:2001 DIN EN 61000-3-3/11.98 – VDE 0838-3/11.98

EN 60034-5:2001 DIN EN 60034-5/12.01 – VDE 0530-5/12.01

EN 60034-6:1993 DIN EN 60034-6/08.96 - VDE 0530-6/08.96

EN 60034-9:1997 DIN EN 60034-9/06.98 - VDE 0530 Teil 9/06.98

EN 60034-1:200 DIN EN 60034-1/09.00 - VDE 0530-1/09.00

EN 60034-2:1996 DIN EN 60034-2/09.98 - VDE 0530-2/09.98

DIN IEC 60038/05.87

Wernigerode, the..................

Sander Beutner

Manager Factory Manager

This certificate attests the conformity with the named Directives, however, it is not a promise

of properties in the meaning of product liability.

In case of electronical communication, the signature does not appear.

Erarb. Gepr. Genehm. Änderungszustand

Warning!

Hazardous electrical current!

Ensure protection against explosions!

Before installing

Make sure that device cannot be switched on again by accident.

Switch off the power to the device.

Make sure that the device is de-energized.

Connect to earth and short out.

Cover or close off any neighboring live parts with a barrier.

Follow carefully the assembly instructions provided for the device.

Only qualified personnel as per EN 50110-1/-2 (VDE 0105, part 100) can perform any work on this de-

vice/system.

The electrical connections are to be made as per the relevant specifications (e.g. cross-section of the supply

line, fuses, protective connection).

Opening the motor - save for the terminal box - during the warranty period without the manufacturer's permission

shall lead to the termination of the warranty.

Original spare parts are to be used for the approved repairs or repairs not falling under the warranty.

Live and rotating parts of electrical motors can cause major or deadly injuries.

Any shipping, installation, start-up and maintenance works are to be carried out only by qualified personnel (fol-

low carefully any regulations on explosion protection such as EN 60079-14 and EN 50821-1-2 as well as any

other national accident prevention regulations).

As regards any equipment subject to these guidelines, it is important to adopt the necessary safety precautions

to protect the personnel against possible injuries.

The personnel must be duly instructed to proceed with caution and according to regulations during shipping,

hoisting, and positioning and while repairing the motor.

Do not lift the motor together with the drive equipment by the motor lifting eyebolts.

Do not use the supplied lifting eye bolts at ambient temperatures below –20°C, in accordance with DIN 580.

Lower temperatures could lead to the ring screws breaking and consequent breaking and consequent injury to

personnel and/ or damage to the installation.

Do not load the eyebolts as per DIN 580 no more than 45° compared to the screwing direction. The use of

crossbeams is recommended. See the operating instructions for the layout dimensions of the lifting eyebolts and

the minimum dimensions of the loading crossbeams and chain lengths.

In the case of motors with built-in brake appropriate safety measures are to be adopted against the possible

failure of the brake especially in applications involving the pulling of loads.

Operating the motor with the supplied shaft protection cover alone is forbidden.

Contact with the capacitor for the start-up and running of single-phase motors is to be avoided until the unload-

ing procedure is carried out securely.

If a high-voltage test is necessary, the procedures and precautionary measures set forth in accident prevention

regulations are to be followed.

I

Physikalisch-technische Bundesanstalt PTB

Braunschweig und Berlin

(1) EC-TYPE-EXAMINATION CERTIFICATE (Translation)

(2) Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres –

Directive 94/9/EC.

(3) EC-type-examination Certificate Number:

PTB 99 ATEX 1098

(4) Equipment: Three-phase motor of the type series K8. 56..., K8.. 63..., K8.. 71...,

K8.. 80..., K8.. 90..., K8.. 100..., K8.. 112..., K8.. 132...,

K8.. 160..., K8.. 180..., K8.. 200..., K8.. 225..., K8.. 250...,

K8.. 280..., K8.. 315..., K8.. 355...

(5) Manufacturer: VEM motors GmbH

(6) Address: Veckenstedter Weg 23, D-38855 Wernigerode

(7) This equipment and any acceptable variation thereto are specified in the schedule to this

certificate and the documents therein referred to.

(8) The Physikalisch-Technische Bundesanstalt, notified body No.0102 in accordance with

Article 9 of the Council Directive 94/9/EC of 23 March 1994, certifies that this equipment

has been found to comply with the Essential Health and Safet y Requirements relating to the

design and construction of equipment and protective systems intended for use in potentially

explosive atmospheres, given in Annex II to the Directive.

The examination and test results are recorded in the confidential report PTB Ex 99-19163

(9) Compliance with the Essential Health and Safety Requirements has been assured by

compliance with

EN 50014:1997 EN 50018:1994 EN 50019:1994.

(10) If the sign „X” is placed after the Certificate number, it indicates that the equipment is

subject to special conditions for safe use specified in the scheduleto this certificate.

(11) This EC-type-examination Certificate relates only the design and construction of the

specified equipment in accordance with Directive 94/9/EG. Further requirements of this

Directive apply to the manufacture and supply of this equipment.

(12) The marking of the equipment shall include the following:

II 2 G EEx d IIC T3 – T6 or EEx de IIC T3 – T6

Zertifizierungsstelle Explosionschutz Braunschweig, 4 August 1999.

By order

(signature)

Dr.-Ing. U.Klausmeyer

__________________________________________________________________________________________________________________

EC-type-examination Certificates without signatu re and official stamp shall not be valid. The certificates may be circulated only without altera tion.

Extracts or alteriations are subject to approval by the Physikalisch -Technische Bundesansta lt. In case of dispute, the German text shall prevail.

Pysikalisch-Technische Bundesanstalt . Bundesallee 100 . D-38116 Braunschweig

Physikalisch-technische Bundesanstalt PTB

Braunschweig und Berlin

(13) Schedule

(14) EC-TYPE-EXAMINATION CERTIFICATE PTB 99 ATEX 1098

(15) Description of equipment

Three-phase motors of the type of protection flameproof safety „d” with terminasl

compartment or direct cable entries. The terminal compartment is carried out in the type of

protection flameproof enclosure „d” or increased safety „e”.

(16) Report PTB Ex 99-19163

(17) Special conditions for safe use

note

(18) Essential health and safety requirements

met by compliance with standards

Zertifizierungsstelle Explosionschutz Braunschweig, 4 August 1999.

By order

(signature)

Dr.-Ing. U.Klausmeyer

__________________________________________________________________________________________________________________

EC-type-examination Certificates without signatu re and official stamp shall not be valid. The certificates may be circulated only without altera tion.

Extracts or alteriations are subject to approval by the Physikalisch -Technische Bundesansta lt. In case of dispute, the German text shall prevail.

Pysikalisch-Technische Bundesanstalt . Bundesallee 100 . D-38116 Braunschweig

About this Manual

These operating instructions apply to AC motors of the following series:

K8.R and B8.R.

Besides the general assembly instructions, these guidelines are to be followed for the installation, start-up and maintenance of explosion-protected AC motors with a degree of protection of "pressure-resistant encapsulation" marked:

(II..), EEx de II. T or EEx d II. T.

Any independent manufacturing equipment mounted on or built into the motors like brakes, rotary encoders or frequency converters, etc. have their own operating instructions which are to be duly followed.

Target readership

This manual is addressed to the specialists in charge of installing, operating and servicing the motors. Besides conventional technical training they must possess knowledge in the field of explosion protection.

Abbreviations and symbols

This manual uses abbreviations and symbols having the following meanings:

indicates handling instructions

>

draws your attention to interesting tips and additional information

Please note!

warns against minor damages to property.

Caution!

warns against major damages to property and minor injuries.

Warning!

warns against major damages to property and major injuries or death.

1 Explosion-protected Motors

Intended use

The motors are to be operated only according to the data specified on the rating plate. According to the relevant

marking on the rating plate, the motors are fit for use in areas subject to explosion hazards.

The motors are fit to be built into another machine. Start-up is forbidden until the conformity of the final product with

Directive 89/392/EEC as amended by 98/37/EC is determined.

Liability and Warranty Guarantee

We cannot be held liable for any damage or malfunctions resulting from assembly errors, the failure to follow these

operating instructions or improper repairs.Original spare parts are manufactured and tested specifically for these

motors.

We recommend that you obtain any spare parts and accessories only from the manufacturer.

We hereby specify that any spare parts and accessories not supplied by the manufacturer require our approval.

Under any circumstances the mounting and use of third-party products can negatively affect the motor's original

structural properties and impair the safety for persons, the motor or other real values (explosion protection).

The manufacturer shall not be liable for any damages resulting from the use of spare parts or accessories not authorized by the manufacturer.Any unauthorized conversions and alterations to the motor shall not be approved for

safety reasons and the manufacturer cannot be held liable for any resulting damages.

Servicing

VEM customer service is available for all technical information concerning VEM motors.

Should a problem occur,contact us or one of our local branch offices.

When ordering spare parts, in addition to the listed designation of the part required, please indicate the motor type

and serial no.

Delivery, Storage, Transport

Delivery

>

Check the motor for damages during transportation.

In case of damage during transportation an investigation of fault is to be performed by the forwarding agent.

>

Report any covert damages to the forwarding agent or manufacturer no later than seven days from the transfer

of the motor.

The entire packaging material can be recycled by means of the Dual System.

Storage

Storage up to a maximum of 36 months is possible in the following conditions:

• In order to prevent a drop in the insulation resistance, the surrounding environment must be dry and dust-free.

• The room temperatures should not drop below +5 °C or exceed +30 °C with an air humidity of < 70 % and register

changes in temperature greater than 10 °C/day.

• In order to prevent damage during storage any occurring oscillations must amount to V

• For motors with regreasing systems repress an amount of grease double that specified on the motor at standstill

before storage.

Please note!

In case of storage conditions deviating from those specified above the measures set forth

in the separate storage instructions must be adopted.

Transport

Do not lift the motor together with mounted driven machines such as, for instance, pumps, gearing, etc. by the motor

lifting eyebolts.

Do not use eyebolts as per DIN 580 at ambient temperatures lower than –20 °C.

At these temperatures the eyebolts may break and hence injure the personnel and/or damage the machinery. Do not

load the eyebolts as per DIN 580 no more than 45° compared to the screwing direction. The use of crossbeams is

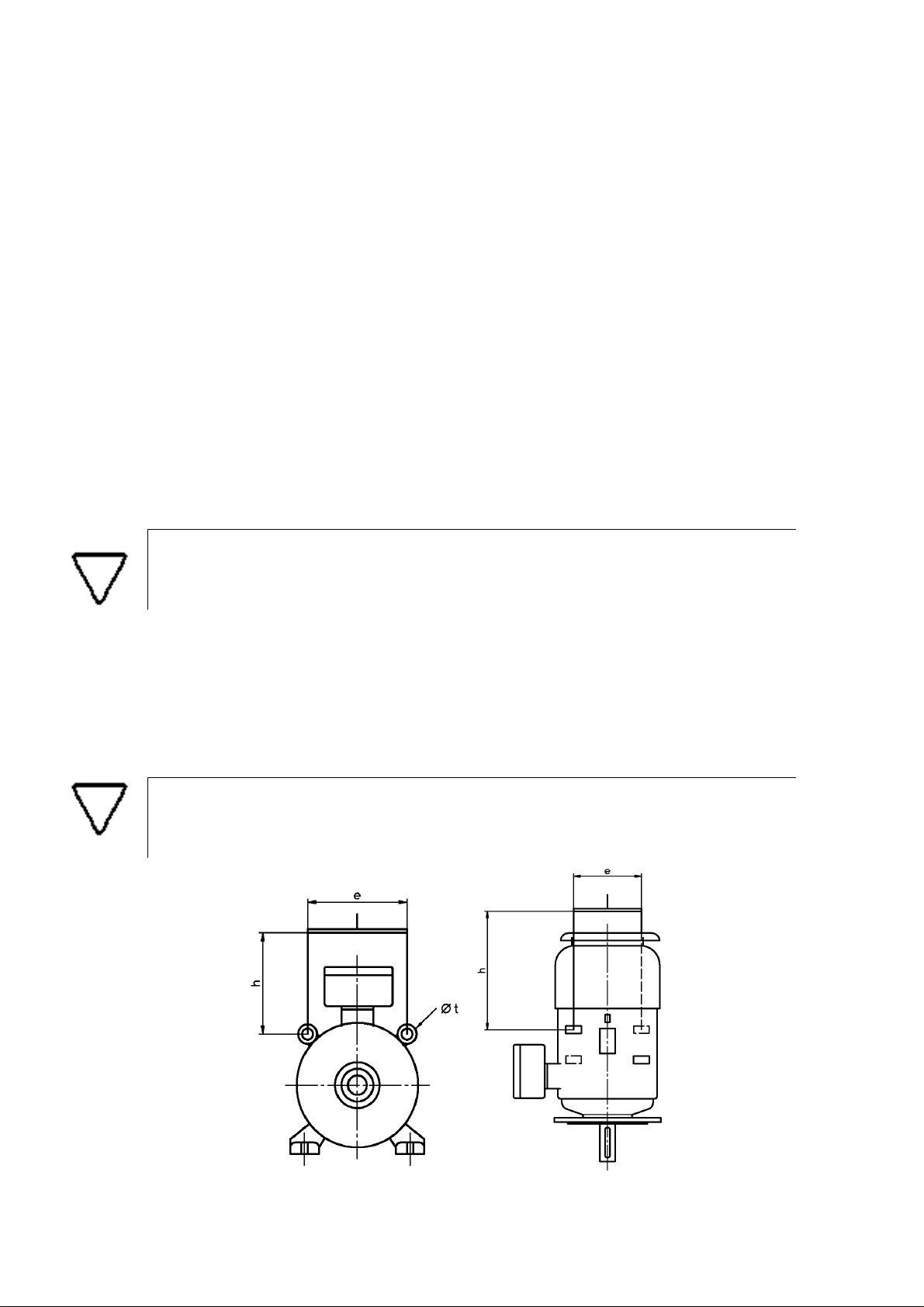

recommended. Layout dimensions of the lifting eyebolts and the minimum dimensions of the loading crossbeams

and chain lengths.

Please note!

When mounting vertical motors from the horizontal position, the shaft must not touch the

floor to avoid damaging the bearings.

< 0.2 mm/s.

eff

Figure 1: Eyebolt dimensions

Loading...

Loading...