Velp Scientifica UDK 139 Operating Manual

1

UDK 139

188

Semi-automatic Distillation Unit

Operating manual

Velp Scientifica thanks you for choosing the UDK 139 Semi-automatic Distillation Unit. The

UDK 139 is designed to perform nitrogen and protein content determination according to the

Kjeldahl Method (TKN) in the Food & Feed industry and has several other applications in

environmental control (nitrogen in water, soil and lubricants) and in the chemical and

pharmaceutical industry according to official AOAC, EPA, DIN e ISO procedures.

Safety warnings:

Do not dispose of this equipment as urban waste

This unit must be used for laboratory applications only.

The manufacturer declines all responsibility for any use of the unit that does not comply with

the instructions.

SAFETY PRECAUTIONS

In order to prevent the risk of electric shock, fire and personal injury when the unit is in use,

basic safety measures must always be taken including:

Ensure that liquids do not come into contact with the electric power cable or with the

Check that the power supply corresponds to the rating plate on the rear of the unit.

When replacing the power cable, make sure that the new cable has the same

Do not use the unit if it is not working correctly. In case of malfunctioning, contact your

The personal protective equipment must be compatible with the possible risks posed by

The test tube reaches a temperature of 100°C during distillation and also during the

The vessels and the products used during the work-cycle must be compatible with the

For further information on the handling of the reagents see Chapter 2 “Chemicals”.

Leave the transparent guard in place when the unit is running.

Follow the cleaning instructions described in this manual

The safety of the instrument is no longer guaranteed in the case of improper use or if the

instructions in this manual are not followed.

Before using the unit, please read the operating manual supplied with the apparatus

carefully.

Warning! Hot surface!

electrical parts of the instrument.

characteristics as the original and that it is earthed.

nearest service centre.

the material being processed and the glass of the containers.

cooling phase. Use the pincer supplied to remove the test-tube at the end of distilling.

temperatures reached by the unit (approx. 100°C).

10004762/B5

Velp Scientifica – UDK139 Operating Manual

2

189

RÈGLES DE SÉCURITÉ

Pour éviter tout risque de choc électrique, incendie ou blessure corporelle pendant l'utilisation

de l'appareil, toujours appliquer les mesures de sécurité de base, y compris les

recommandations suivantes :

S'assurer que les liquides n'entrent pas en contact avec le cordon d'alimentation ou avec

toute autre pièce électrique à l'intérieur de l'appareil.

Vérifier que le cordon d'alimentation est inséré dans une prise électrique (dans une

position facilement accessible) correspondant aux valeurs décrites sur la plaque de

l'appareil.

Utiliser uniquement des cordons d'alimentation à trois bornes, c'est-à-dire avec cordon de

mise à la terre.

Ne pas utiliser l'appareil en cas de dysfonctionnement. Si cela se produit, contacter le

Service Après-Vente le plus proche.

Les équipements de protection individuelle doivent être compatibles avec les risques

encourus pour les matériaux à traiter et le verre des récipients.

Le tube à essai atteint une température de 100°C pendant la phase de distillation, mais

également pendant la phase de refroidissement. Utiliser les pinces fournies pour retirer le

tube à la fin de la distillation.

Les récipients et les produits utilisés pendant les analyses doivent être compatibles avec la

température réglée sur l'appareil (environ 100°C).

Pour toute autre information sur l'utilisation des réactifs utilisés, voir Chapitre 2 “Produits

chimiques”.

S'assurer que la protection transparente est en place lorsque l'appareil fonctionne.

Respecter les instructions d'entretien de l'appareil décrites dans ce manuel.

Le fabricant décline toute responsabilité pour toute utilisation de l'appareil non conforme à ces

instructions.

This unit has been designed and produced in compliance with the following standards:

Safety requirements for electrical apparatus for

measurement and control and for laboratory use IEC/EN 61010-1

IEC/EN 61010-2-010

IEC/EN 61010-2-081

UL Std. 61010-1 2

CAN/CSA 61010-1-04 2

nd

Ed.

nd

Ed.

CAN/CSA 61010-2-010-04

CAN/CSA 61010-2-081

Electrical equipment for measurement, control

and laboratory use - EMC requirements IEC/EN 61326-1 (2006)

FCC CFR 47 Part 15 Sub part B

Restrictions of the use of certain hazardous substances

in electrical and electronic equipment 2011/65/EU (RoHS)

On waste electrical and electronic equipment (WEEE) 2002/96/EC (WEEE)

The manufacturer is committed to constantly improving the quality of the products and reserves

the right to modify the characteristics without prior notice.

10004762/B5

3

190

CONTENTS

1.1. Parts included .......................................................................................................... 6

1.2. Instrument description ................................................................ ............................. 7

2. Chemicals ................................................................ .............................................. 10

2.1. Products used ....................................................................................................... 10

2.2. Substances generated by digestion and distillation ................................................ 11

3. Assembly and installation ....................................................................................... 12

3.1. Hydraulic connections ........................................................................................... 13

3.2. Connection to the electric power supply ................................................................. 14

3.3. Connection to external devices .............................................................................. 15

3.4. Printer 15

3.4.1. Mouse .......................................................................................................... 16

3.5. Preliminary operations ........................................................................................... 16

4. Using the menus ................................................................ .................................... 17

4.1. Quick Guide .......................................................................................................... 17

4.2. Main menu ............................................................................................................ 19

4.3. Analysis 21

4.3.1. Wash-down .................................................................................................. 21

4.3.2. Distillation .................................................................................................... 23

4.4. Methods 26

4.5. Set-up 28

4.6. System 31

4.6.1. Check-up ..................................................................................................... 31

4.6.2. Calibration .................................................................................................... 38

4.6.3. Maintenance ................................................................................................ 39

4.6.4. Service ......................................................................................................... 40

5. Operating Controls ................................................................................................. 42

5.1. Safety devices, signals and warnings .................................................................... 42

5.1.1. Safety devices .............................................................................................. 42

5.1.2. Reserves and overfilling ............................................................................... 43

5.1.3. Warning signals and messages .................................................................... 44

5.1.4. Black-out ...................................................................................................... 45

5.2. Graph of steam production .................................................................................... 45

5.3. Graph of tap water consumption related to the water flow rate and temperature .... 46

6. Work cycle ................................................................................................ ............. 47

6.1. Analysis 47

6.2. Devarda’s analysis ................................................................................................ 47

7. End-of-work operations .......................................................................................... 48

8. Maintenance .......................................................................................................... 49

8.1. Routine maintenance ............................................................................................. 49

8.2. Extraordinary maintenance .................................................................................... 50

8.2.1. Periodic maintenance ................................................................................... 50

8.2.2. Operations to be performed only when necessary ........................................ 52

8.3. Expedients for transport......................................................................................... 53

9. Disposing of the unit ............................................................................................... 54

10. Accessories ........................................................................................................... 54

11. Spare parts ............................................................................................................ 55

12. Technical features .................................................................................................. 56

13. Wiring diagram ....................................................................................................... 58

14. Hydraulic scheme .................................................................................................. 60

15. Warranty 62

16. Suggestions ........................................................................................................... 62

17. General description of Kjeldahl's method for the measurement of organic Nitrogen 63

18. AOAC, method 960.52, Microchemical determination of nitrogen- Micro-Kjeldahl

method .............................................................................................................. 68

19. Analytical procedure Typical analytical scheme for organic Nitrogen ...................... 70

10004762/B5

Velp Scientifica – UDK139 Operating Manual

4

191

20. Analytical Methods ................................................................................................. 71

1 - Kjeldahl method to determine the protein content on milk and derived products ...... 71

2 - Kjeldahl method to determine the protein content on almonds, nuts, hazelnuts ....... 72

3 - Kjeldahl method to determine the protein content on coconuts ................................ 73

4 - Kjeldahl method to determine the protein content on peanuts and Brazil nuts ......... 74

5 - Kjeldahl method to determine the protein content on beer ....................................... 75

6 – Kjeldahl method to determine the protein content on barley malt ............................ 76

7 - Kjeldahl method to determine the protein content on cereals and feed .................... 77

8 - Kjeldahl method to determine the protein content on wheat .................................... 78

9 - Kjeldahl method to determine the protein content on oats, barley, corn, rice, rye .... 79

10 - Kjeldahl method to determine the protein content on soya beans and lupins ......... 80

11 - Kjeldahl method to determine the protein content on canned cat/dog food ............ 81

12 - Kjeldahl method to determine the protein content on forage and straw .................. 82

13 - Kjeldahl method to determine the protein content on bacon, ham, hot dog, salami,

sausage ............................................................................................................... 83

14 - Kjeldahl method to determine the protein content on meat and derived products .. 84

15 - Kjeldahl method to determine the protein content on bread and baked products ... 85

16 - Kjeldahl method to determine the protein content on compressed and granular

yeast ............................................................................................................... 86

17 - Kjeldahl method to determine the protein content on liver patè ............................. 87

18 - Kjeldahl method to determine the protein content on sugar, syrup, molasses ........ 88

19 - Kjeldahl method to determine the protein content on wheat spaghetti and macaroni,

egg pasta ............................................................................................................... 89

20 - Kjeldahl method to determine the protein content on grain spaghetti, macaroni .... 90

21 - Kjeldahl method to determine the protein content on plants (vegetable) ................ 91

22 - Kjeldahl method to determine the protein content on mushrooms ......................... 92

23 - Kjeldahl method to determine total nitrogen on crude oil and fuels (ISO n. 333) .... 93

24 - Kjeldahl method to determine total nitrogen on ABS, SAN, rubber ........................ 94

25 - Kjeldahl method to determine total nitrogen in urea ............................................... 95

26 - Kjeldahl method to determine total nitrogen on water ............................................ 96

27 - Kjeldahl method to determine total nitrogen on soil ............................................... 97

28 - Kjeldahl method to determine gelatin on paper ..................................................... 98

29 - Kjeldahl method to determine casein on paper ...................................................... 99

30 - Kjeldahl method to determine total nitrogen on sludges from wastewater treatment

plants ............................................................................................................. 100

31 - Method to determine the alcohol strength on wines, musts and spirits by steam

distillation and volume ................................................................................................ 101

32 - Method to determine the residual urease activity in soya beans .......................... 103

33 - Method to determine urea nitrogen in feed and roughages.................................. 104

34 - Determination of the volatile acidity of tomato paste ............................................ 105

35 - Method to determine the volatile acidity of wines ................................................. 107

36 - Kjeldahl’s method to determine total nitrogen in crude oil, lubricants and fuel oils

(ASTM, D3228-96) ..................................................................................................... 110

37 - Method to determine nitric nitrogen on water after reduction to ammonia nitrogen

(Devarda’s alloy method) ........................................................................................... 112

38 - Method to separate ammonia in water from interfering substances ..................... 113

39 - Determination of phenols in drinking water and in industrial wastes .................... 114

40 - Separation of hydrocyanic acid from wastewaters ............................................... 116

41 - Method to control the efficiency of an anaerobic digester by determination of volatile

acids content in digesting sludge................................................................................ 118

42 - Determination of ammonia nitrogen in organic fertilizers according to the Kjeldahl

method ............................................................................................................. 120

43 - Determination of the total volatile basic nitrogen (TVBN) in fresh and frozen fish 121

21. Declaration of conformity ....................................................................... 122

10004762/B5

Velp Scientifica – UDK139 Operating Manual

5

3

4

192

Introduction

Steam distillation is applied in the laboratory for the fractionation of water insoluble

liquids or solids according to Dalton's law of partial pressures in a gas mixture.

It is also used for stripping chemicals from mixtures or solutions after displacement of

the ionic equilibrium by adding acids or bases, as in the well known Kjeldahl's

method for total Nitrogen determination.

The Kjeldahl method remains the most used method for determining Nitrogen and

protein contents in foods and feeds (official methods).

This is simply due to its precision and reproducibility.

Since its initial design, many improvements have been introduced aimed at reducing

energy consumption, space requirements and sample quantities.

The UDK 139 Semi-automatic Distillation Unit has a color touch-screen with

electronic control for simple and user-friendly programming of parameters such as

distillation time, the volume of reagents such as sodium hydroxide, water and the

regulation of steam production from 10 to 100% in order to carry out Semi-automatic

distillation.

By modifying the distillation time and steam output it is possible to carry out fast or

slow distillation according to the product being analyzed. For example, the distillation

time for the determination of the protein content according to the Kjeldahl method

can be reduced to three minutes. In other cases (e.g. volatile acids in food products),

the distillation time can be increased to 30 minutes or more.

Analysis times are reduced thanks to the optimization of the applications:

10 programs that can be customized directly by the user.

NOTE: the software can be browsed directly from the touch-screen. Select the option

by hand, using a stylus or a mouse.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

6

Description

Code

Q.ty

UDK 139 Semi-automatic

Distillation Unit 1

F30200130

1

Test tube Ø 42 x 300 mm 2

A00001080

1

Collecting flask 250 ml

(used only without titration)

10001106

1

Pincer for test tube

10000247

1

Touch pen

10004936

1

Inlet tube

10000280

1

Tubes with sensors:

Inlet tube for H2O

Inlet tube for NaOH

Outlet tube for distillation

residues

40000153

40001023

40000387

3

PVC tube Ø10x14

10000020

10001087

2

193

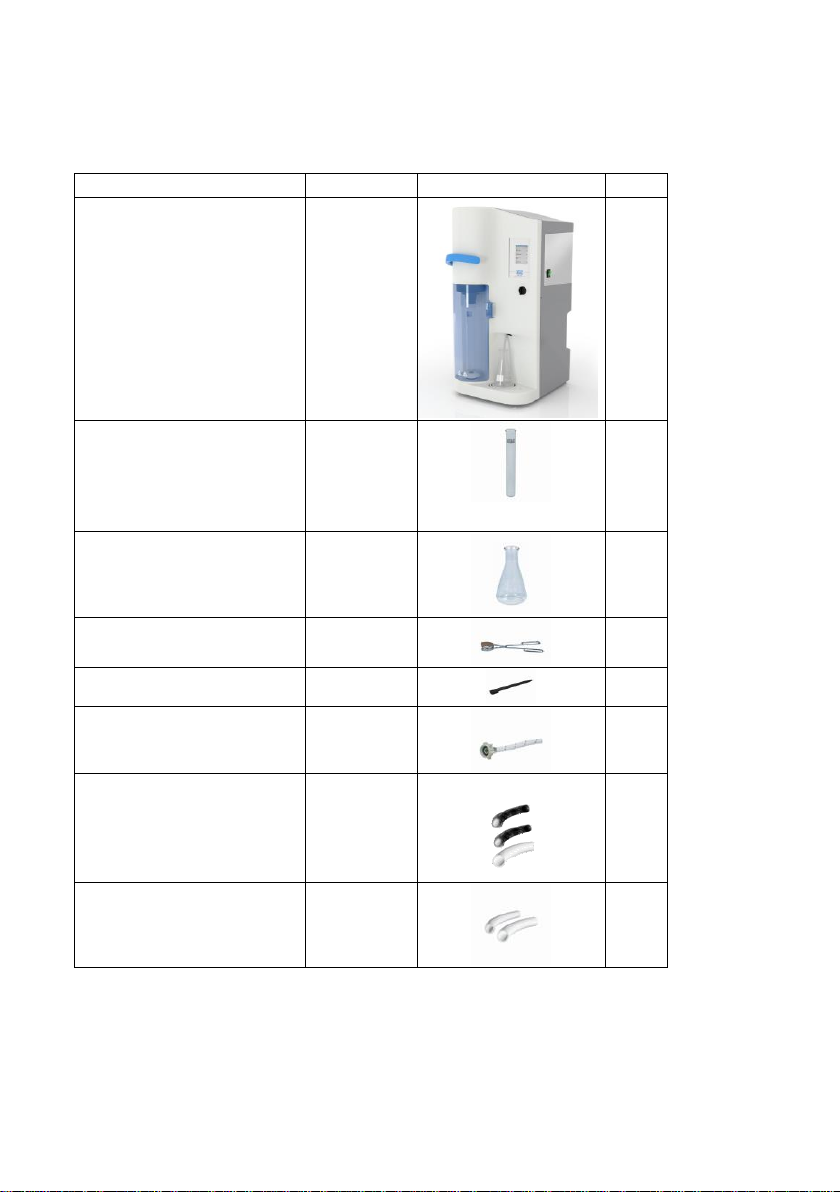

1.1. Parts included

Check that the unit is complete after unpacking.

The table below shows the parts included:

The operating manual is inside the distillation unit1 box .

The test tube2 is not sold separately (see chap. 10 Accessories).

The protective film for touch screen (code 40001798) is already placed on the

display.

NOTE: Keep the special shock-resistant packing material for future use.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

7

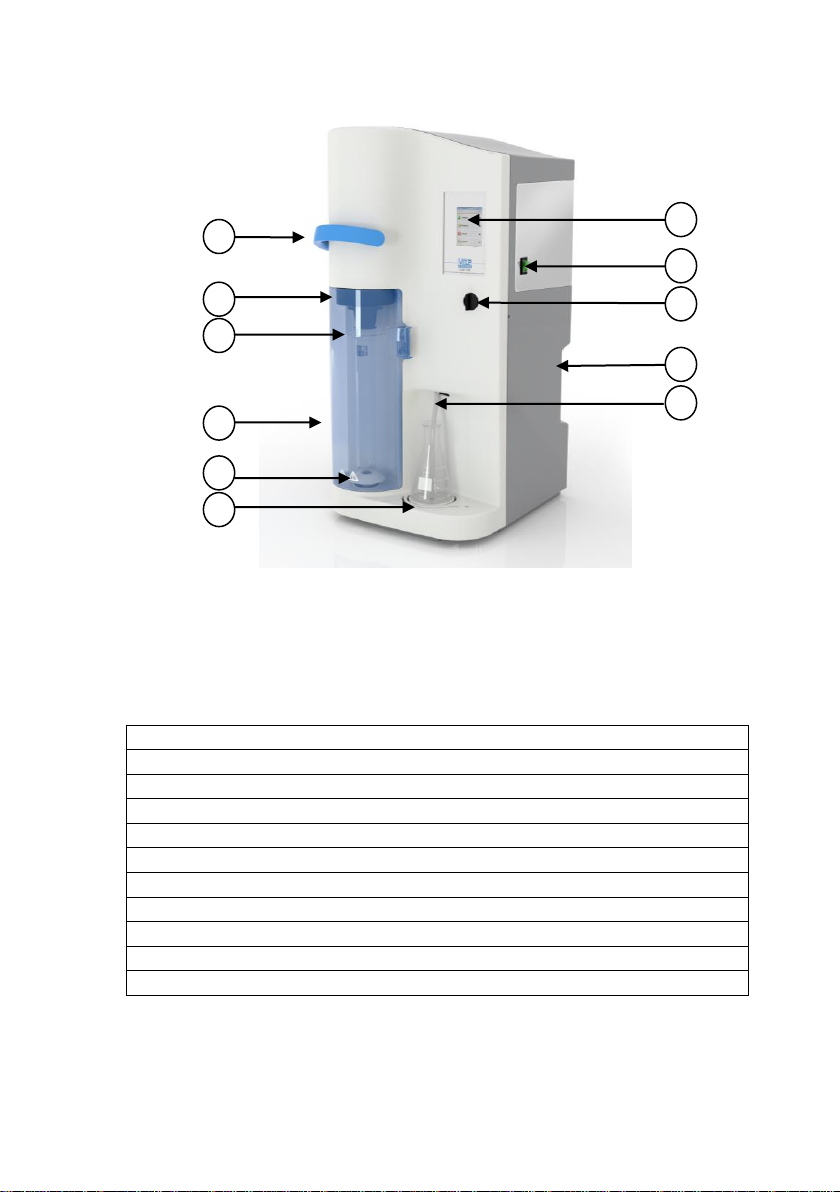

1 Color Touch Screen with protective film

2 On/Off switch

3 Service door catch

4 Flask stand

5 Safety guard

6 Lever for insertion of test tube

7 Test tube press

8 Test tube connection

9 Plastic guard for test tube connection

10 Socket panel

11 Distillate outlet tube

2 5 6 3 1

7 8 4

9

11

10

194

1.2. Instrument description

The UDK 139 Semi-automatic Distillation Unit uses innovative technology and

advanced electronics for the automation of the various stages and the highest

standards of reliability and safety.

The UDK 139 carries out all the stages of the distillation process such as the addition

of single reagents and the removal of distillation residues automatically.

Main components of the distillation unit:

The Semi-automatic distillation unit UDK139 is fitted with innovative devices and is

manufactured using innovative materials and advanced technology:

The instrument has a polymer structure that ensures greater resistance

against chemical reagents used during analysis and a high durability.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

8

195

The patented Velp Scientifica steam generator uses deionised or distilled water

and produces a constant and stable quantity of steam ensuring the

reproducibility of the analysis without requiring any routine maintenance. The

steam flow is controlled by a software which enables the user to choose

between rapid or slow distillations according to the product to be analyzed.

The innovative titanium condenser achieves outstanding heat exchange,

reduces water consumption, offers higher resistance than glass and is easily

and thoroughly cleaned. The display shows the water consumption during each

analysis.

The new technopolymer splash head assures optimal resistance to the high

temperatures and corrosive chemicals involved during the distillation process.

The graphic touch screen with its simple and user-friendly interface, enables

the user to program all the automatic distillation / titration parameters. The

protective film on the touch screen safeguards against wear and against the

majority of laboratory agents.

Choose from 6 different languages to communicate with the instrument.

The distillation unit can be connected to a printer via USB in order to print all the

information pertaining to the tests performed in accordance with GLP (Good

Laboratory Practice).

The UDK 139 ensures the highest safety standards: it signals the absence of

the test tube, test tube exchange at the end of analysis, safety guard open, the

absence of reagents and the absence of cooling water. The use of an innovative

system enables the operator to position the test tube in complete safety and

means that test tubes of various sizes can be used.

In a world where respect for the environment is increasingly important, the

distillation unit UDK 139 makes a significant contribution to this cause. The

cooling water supply shuts-off automatically during pauses considerably

reducing water consumption and the technopolymer housing is 100%

recyclable.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

9

196

The UDK series guarantees unmatched savings whist ensuring an extremely high

level of reliability.

The UDK139 is exceptional in providing savings, by using TEMSTM technology:

Time: Fast and frequent analyses; no heating delay between runs.

Energy: Cooling water consumption starting from only 0.5 l/min; excellent insulation

of internal parts.

Money: Cost reduction is substantial, in line with reduced power consumption.

Space: The extremely compact footprint saves useful laboratory bench space.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

10

197

2. Chemicals

2.1. Products used

The chemicals used for distillation and titration are potentially dangerous and must

be handled with care and with personal protective equipment: gloves, goggles and

pincer removal of the reaction hot test-tubes.

1) Boric acid (H3BO3): 4% solution. The low concentration is due to the fact that

boric acid crystallizes at low temperatures and this can cause problems in the

hydraulic circuits of the instrument. Ingestion or absorption may cause nausea,

vomiting and diarrhea. Diluted solutions are used as an antisceptic.

2) Sodium hydroxide (NaOH): Velp recommends a 30-35% w/v solution of sodium

hydroxide in order to avoid violent reactions in the test-tube. Corrosive to all body

tissues. Can cause severe burns. Protect the skin and the eyes. If the solution is

prepared using flakes or pellets, add these to water and not vice versa. Ingestion can

cause vomiting, prostration, collapse. Constrictive scarring can occur.

Caution: in case of ingestion DO NOT attempt to evacuate the stomach.

Chemicals used during the digestion phase:

3) Sulphuric Acid (H2SO4): concentrated (96-98%). Corrosive to all body tissues.

Skin contact can produce necrosis. Protect the skin and the eyes. When diluting, the

acid must be added to the diluent to prevent the generation of excessive heat and

the danger of splashes. Neutralize spills with dry sodium bicarbonate or calcium

carbonate powder.

4) Hydrogen peroxide (H2O2): 30% w/w. Can cause severe burns. Wear goggles

and rubber gloves. Avoid contact with combustible materials: drying of concentrated

solutions on paper, clothing and so on, can cause combustion. Heavy metals and

their salts, dust, irregular surfaces, can cause rapid decomposition resulting in the

production of oxygen and increased pressure. Stored hydrogen peroxide solutions

decompose slowly but nevertheless bottles must be fitted with vent caps. Empty

bottles must be rinsed with clean water. In case of contact, rinse immediately with

plenty of water.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

11

198

2.2. Substances generated by digestion and

distillation

1) Sulphur dioxide and sulphur trioxide-containing fumes. During digestion with

sulphuric acid the development of fumes occurs which contain mostly sulphur dioxide

plus smaller amounts of sulphur trioxide. Both these gases are intensely irritating to

eyes and respiratory tract, causing coughing and discomfort. The fumes generated

must be removed using efficient devices (i.e. Recirculating Water Pump model JP

code F30620198) and preferably neutralized before being released into the

atmosphere (i.e. Scrubber model SMS code F307C0199).

2) Distillation residues containing toxic catalysts. The use of toxic metals such as

mercury, selenium or copper as catalysts for digestion means that these substances

are present in the distillation residues. These residues should be collected in a

suitable vessel and disposed of in an environmentally friendly way.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

12

199

3. Assembly and installation

After unpacking the instrument position it on a laboratory bench or on a nonflammable surface at a distance of at least 30 cm from the walls so as not obstruct

the air vents on the rear.

NOTE:

The instrument weighs 31kg. If you need to move the instrument suitable

lifting devices should be used.

Do not remove the protective film from the touch screen.

Position the instrument near the socket power supply because it is

The instrument must be placed near a water tap (necessary for cooling the distillate)

with a maximum pressure of 5 bar, and sink in order to discharge the waste water.

The instrument requires a tap water flow rate (depending on the temperature of the

tap water) of approximately:

- 0.5 l/minute at a temperature of 15°C

- 1 l/minute at a temperature of 30°C

Water is required during the distilling phase only and is interrupted automatically

during the other phases.

Position the tanks for NaOH and H2O solutions and for collecting distillation residues

below or behind the unit. The tanks are not supplied with the instrument because

their volume is chosen according to specific requirements. Usually polythene carboys

of 5, 10 or 20l are used.

considered a means of disconnecting the device

The hydraulic tubes are supplied with the

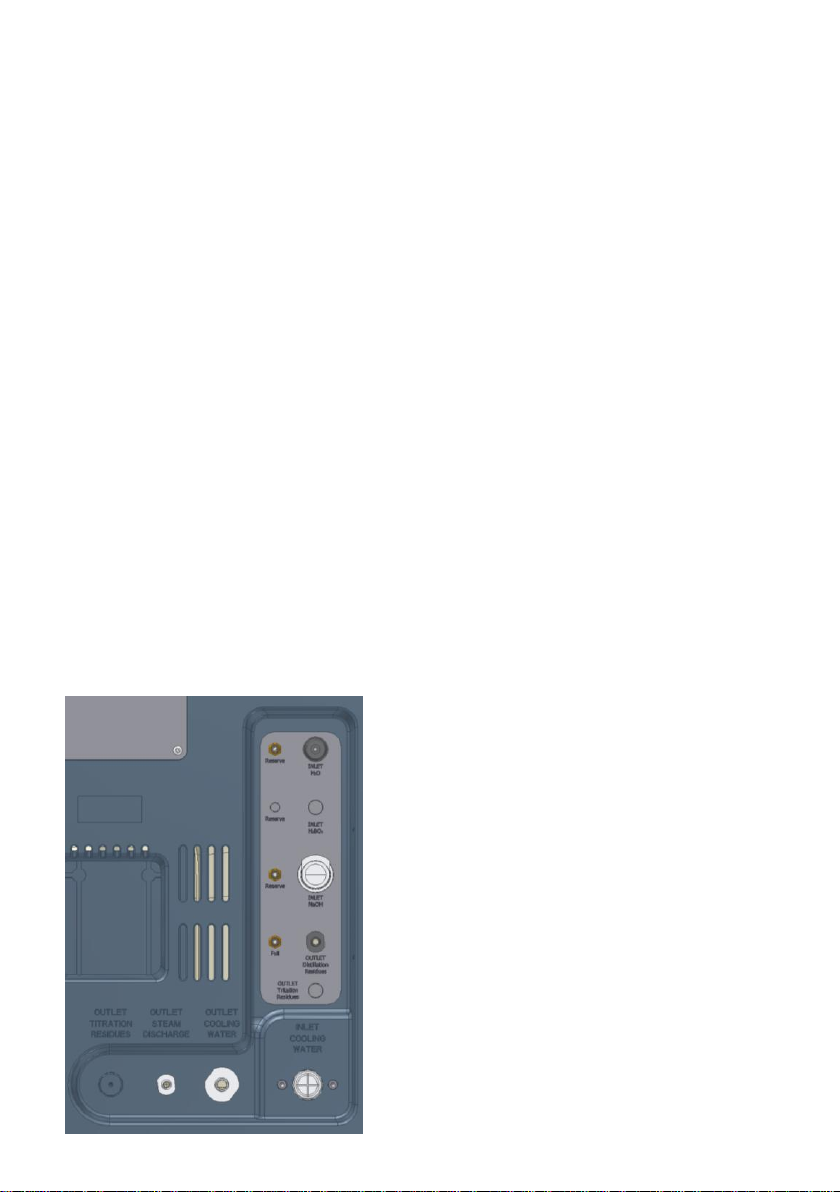

instrument and the hydraulic connections

are clearing identified on the rear of the

instrument.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

13

INLET

Cooling Water

Cooling water inlet (tap water).

Connect the unit to the tap water supply using the red and

white tube with ¾” GAS threaded connections.

Open the tap water in order to obtain a tap water flow rate

sufficient to cool the distillate (see chapter 5.3). Tap water is

used during the distilling phase only for a considerable

reduction in consumption.

INLET

H2O

Distilled water inlet (or deionized, ammonia free) for supplying

the steam generator and diluting the sample.

Connect the black tube and the relative reserve connector

using the rapid connection and push the other end of the tube

with level sensor right to the bottom of the carboy.

INLET

NaOH

Sodium hydroxide inlet (32-35%w/v for Kjeldahl analysis)

Connect the white tube and the relative reserve connector

using the rapid connection. The rapid connection is different

from the other two (H2O and H3BO3) in order to avoid errors

and possible damage to tubes and internal components.

Push the end of the tube with level sensor to the bottom of the

corresponding carboy.

OUTLET

Cooling Water

Cooling water outlet.

Push the PVC tube supplied (diameter 10x14 mm) onto the

corresponding tube holder by hand and place the other end of

the tube in a sink/drain

Check the flow rate of the cooling water discharged from the

condenser during the distillation/titration - the minimum flow

rate using tap water at a temperature of about 15°C should be

0.5 l/min. (see chapter 5.3).

OUTLET

Distillation

Residues

Distillation residues outlet

Distillation residues are discharged from the test tube at the

end of distillation (if selected in the work program).

Connect the black tube and the relative full connector. Place

the end of the tube with level sensor in the collecting carboy

and regulate the height of the sensor according to the type of

vessel used.

Caution: high temperature solution.

OUTLET

Steam

Discharge

Steam discharge outlet.

Discharge of hot water from the steam generator.

At the end of each distillation the steam generator discharges

the excess hot water to the distilled water tank for re-use.

Push the silicone tube supplied (diameter 6x9 mm) onto the

corresponding tube holder by hand and place the other end of

the tube in the distilled water tank.

200

3.1. Hydraulic connections

Connect the tubes supplied to the tube holders located on the rear panel following

the instructions below:

10004762/B5

Velp Scientifica – UDK139 Operating Manual

14

201

IMPORTANT

Place the carboys for the H2O and NaOH solutions on the floor and not at the

same level as the unit on the bench in order to avoid air locks in the suction

tubes.

The sodium hydroxide tubes must be kept full or, alternatively, the tubes can be

emptied and washed at the end of the work cycle. This precaution will avoid the

formation of crystals when the solution comes into contact with air which may

block the tube and prevent the instrument from working correctly.

If the level sensors and full sensors are not plugged-in the instrument will

operate normally but the reserve and full indicators will not be functional.

3.2. Connection to the electric power supply

Before connecting the instrument to the power supply, make sure that the mains

switch is turned off and that the values on the labels correspond to those of the

power supply. Make sure the electrical network is earthed. Connect the instrument to

the power supply using the cable and plug supplied.

The instrument requires a 220-240V power supply and a frequency of 50 or 60 Hz.

The instrument is delivered already programmed for 230V/50Hz. If the power supply

is 230V/60Hz, the correct values must be selected in the menu Set up/Frequency

menu (see chapter 4.5).

NOTE: the mains switch can be used to disconnect the instrument from the power

supply when not in use in order to reduce energy consumption.

NOTE: When the service door is opened the power supply cuts-off automatically.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

15

202

3.3. Connection to external devices

The UDK 139 Semi-automatic distillation unit can be

connected to various external devices useful for

optimizing operator productivity, using the sockets

on the rear:

Printer

Mouse

3.4. Printer

Connect the printer (item code A00001009) to one of the two USB ports in order to

obtain automatic print-outs at the end of analysis.

The serial port configuration of the printer should be:

Baud rate 4800

Data length 8

Parity None

Bit of Stop 1

Handshaking None Xon/ Xoff

For printer connection a USB/RS232 serial converter cable is required (item code

A00000195). Connect the RS232 converter plug to the printer and the USB plug to

the USB port on the instrument.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

16

203

3.4.1. Mouse

A mouse with USB plug can be connected to one of the two USB ports to navigate

the menus. Connect the mouse with the instrument turned on in order to activate the

pointer.

3.5. Preliminary operations

At the end of installation proceed as follows:

Open the safety guard;

Position the test tube;

NOTA: to position the test tube hold the blue handle down, slide the test tube into

place making sure that the Teflon tube remains inside the test tube and that the test

tube itself rests on the press test tube. Release the blue handle.

Close the safety guard;

Turn on the tap water;

Check that the distillate tube is in place in the flask.

Turn the instrument on by pressing the mains switch POWER (led on) on the right of

the instrument. The instrument automatically carries out the following steps

simultaneously:

Preheating (this takes 3 minutes. A yellow strip at the top of the display

reading “preheating” indicates that preheating is in progress, the

countdown indicates the time left);

Tap water check to ensure the presence of cooling water;

NOTA: During pre-heating the instrument menus can be accessed with the exception

of work cycles requiring the production of steam.

An acoustic signal indicates that pre-heating is complete, the strip at the top of the

display is blue and reads “UDK139”.

IMPORTANT: before beginning analysis enter the CHECK-UP menu in order to

fill the tubes (see chapter 4.6.1).

10004762/B5

Velp Scientifica – UDK139 Operating Manual

17

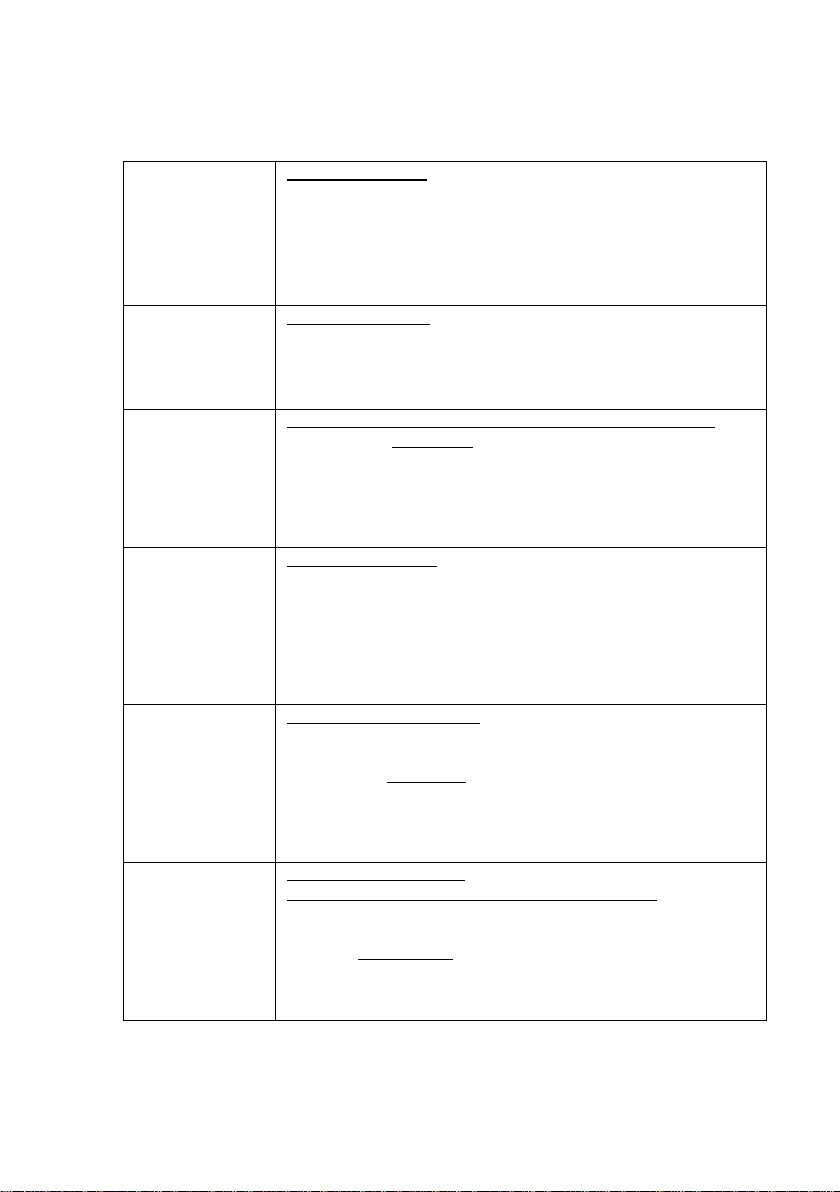

Analysis

● Wash-down

● Distillation

Methods

Set-up

● Date

● Time

● Language

● Frequency

● Keyboard

sounds

● Lab. name

● Print

● Type

● Automatic

System

● Check-up

● Manual

check-up

● Automatic

check-up

● Diagnosis

● Check safety

device

● Safety guard

● Safety test tube

● Safety lever

● Check inlet

tubes

● Inlet tube for H2O

● Inlet tube for NaOH

● Residues tube

● Cooling H2O

● Calibration

● Cal. H2O pump

204

4. Using the menus

4.1. Quick Guide

This page shows the instrument software. The purpose is to help the user identify the

different possibilities offered by the instrument and how to reach them easily.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

18

● Cal. NaOH pump

● Maintenance

● Clean NaOH circuit

● Clean filters

● Test tube connection

● N° analyses

● Service

● Upload software

● Advanced settings

205

10004762/B5

Velp Scientifica – UDK139 Operating Manual

19

206

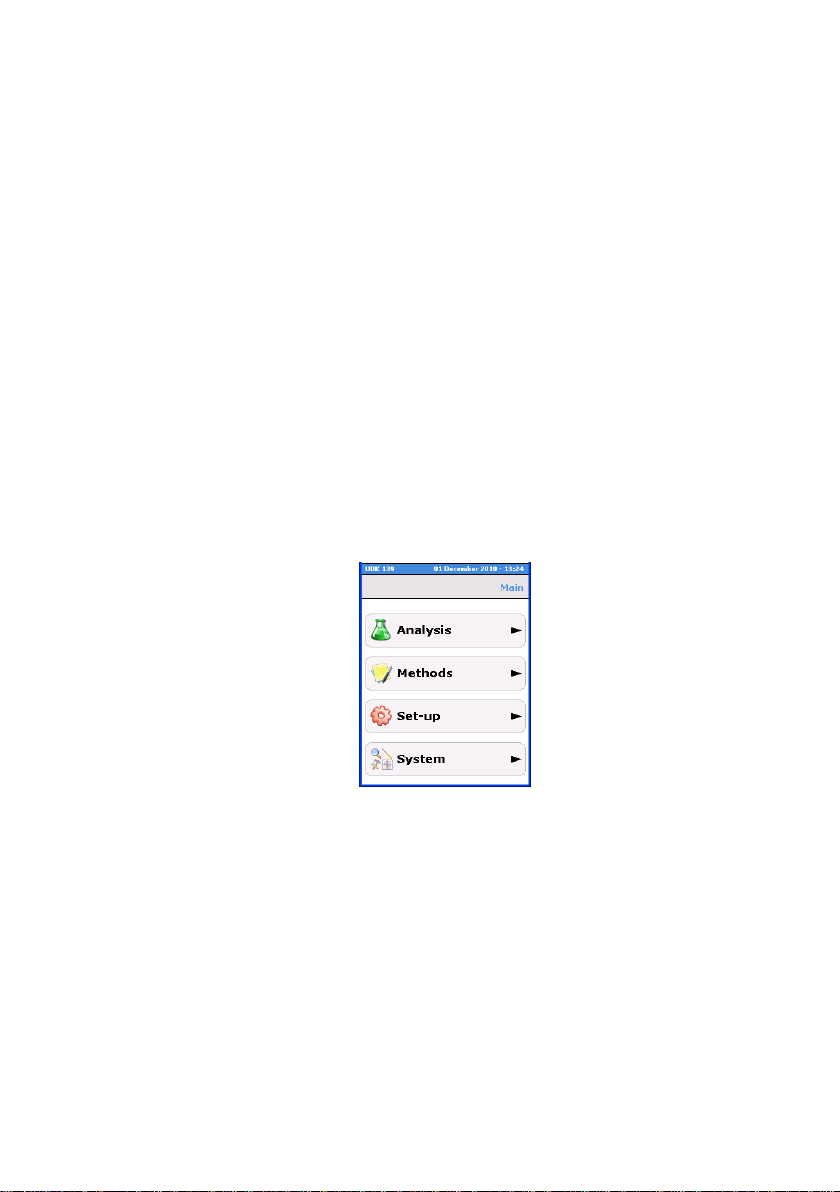

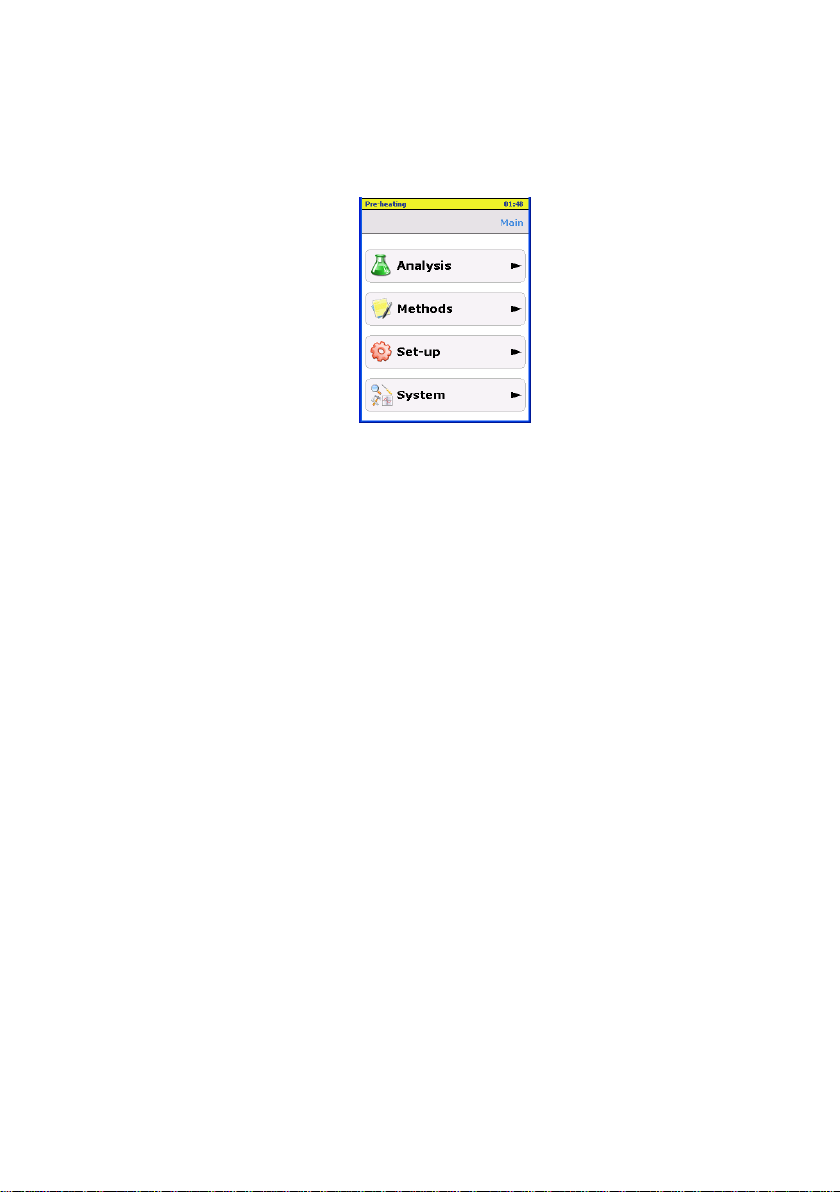

4.2. Main menu

When the instrument is turned on, the display shows the name of the instrument and

the software version for a few seconds.

The main menu then appears:

The yellow strip at the top of the display (present on every page of the software)

indicates that preheating is in progress and shows the time left. During this phase it

is possible to navigate all the menus and submenus with the exception of work

processes that require steam production. An acoustic signal informs the operator that

preheating is complete. The band at the top of the display is now blue and reads

“UDK139” as well as giving the current date and time.

The second line gives the name of the menu viewed.

The main menu consists of 8 submenus that can be selected using the touch screen

or the pointer of the mouse (where present).

The "Main Menu" consists of the following submenus:

1. Analysis

1. Wash-down

2. Distillation

2. Methods

3. Set-up

1. Date

2. Time

3. Language

4. Frequency

5. Keyboard Sounds

6. Lab. name

7. Print

4. System

1. Check-up

2. Calibration

3. Maintenance

4. Service

10004762/B5

Velp Scientifica – UDK139 Operating Manual

20

207

In each sub-menu the arrow in the upper left corner allows you to return to the

previous screen.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

21

208

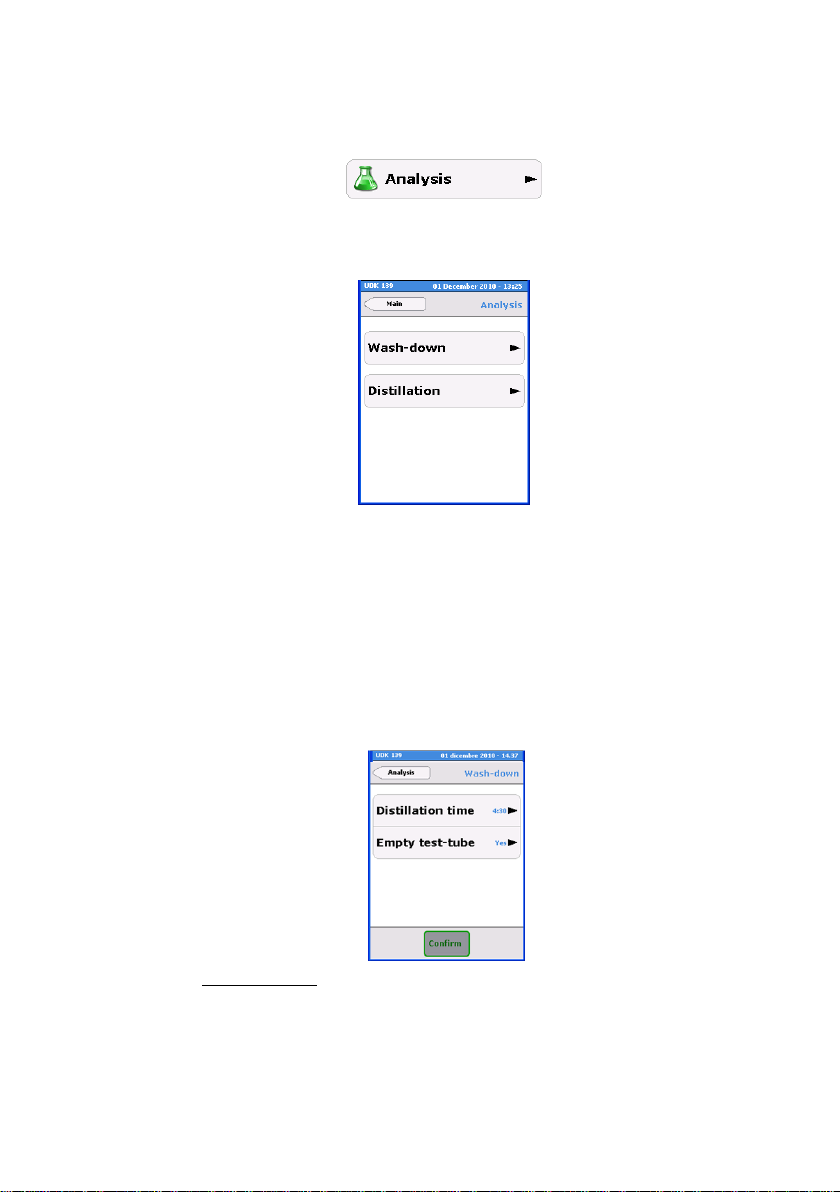

4.3. Analysis

Select "Analysis" from the main menu:

The sub-menus are shown below:

To return to the main menu press the arrow in the upper left corner.

4.3.1. Wash-down

During wash-down distillation is carried out using distilled water as a reagent in order

to “wash” the internal parts of the splash head and condenser. Wash-downs can be

carried out at any time.

Use the touch-screen to select "Wash-down", the following window appears:

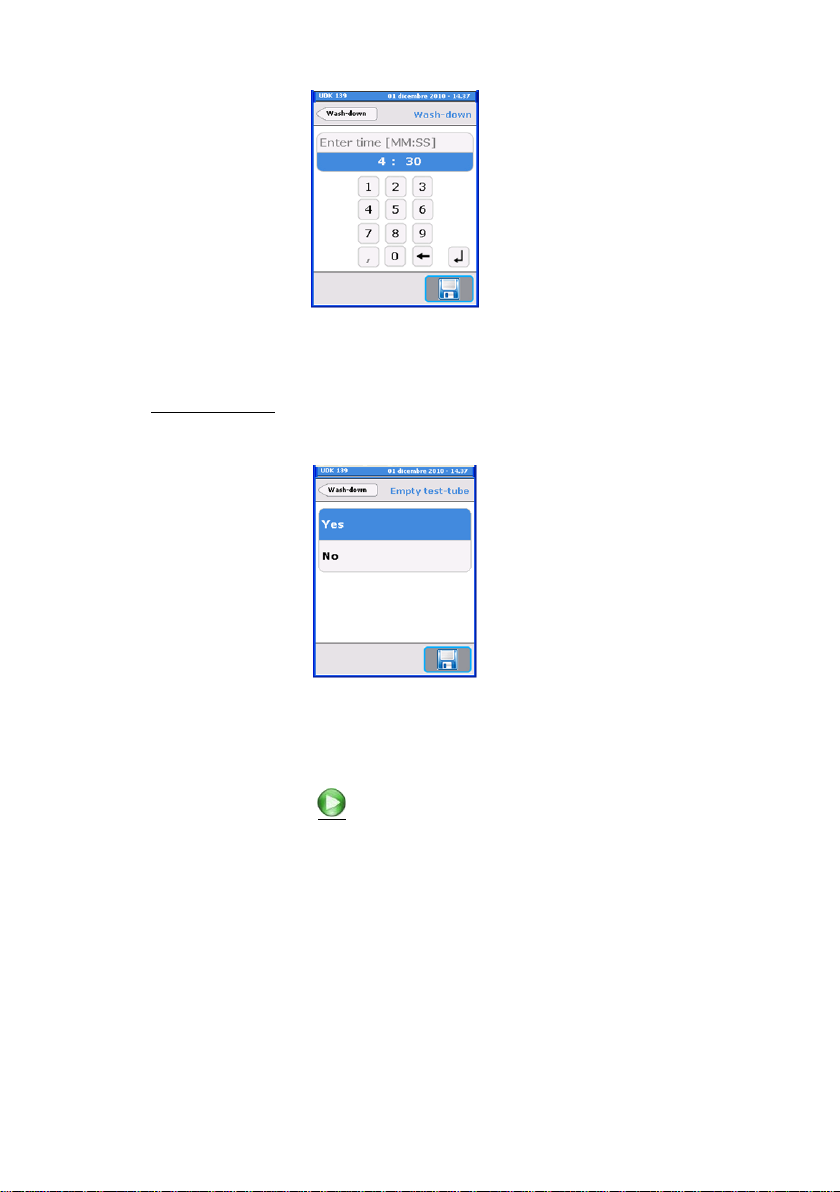

Pressing “Distillation time”, the alphanumeric keypad appears. Use it to set the wash

down time: min 2:00 – max 7:30.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

22

209

To return to the “Wash down” menu press the arrow in the upper left corner.

Pressing “Empty test tube”, it is possible to select or not the residues removing at the

end of wash down, with “Yes” or “No”.

To return to the “Wash down” menu press the arrow in the upper left corner.

To return to the “Analysis” menu press the arrow in the upper left corner.

To carry out a wash cycle press .

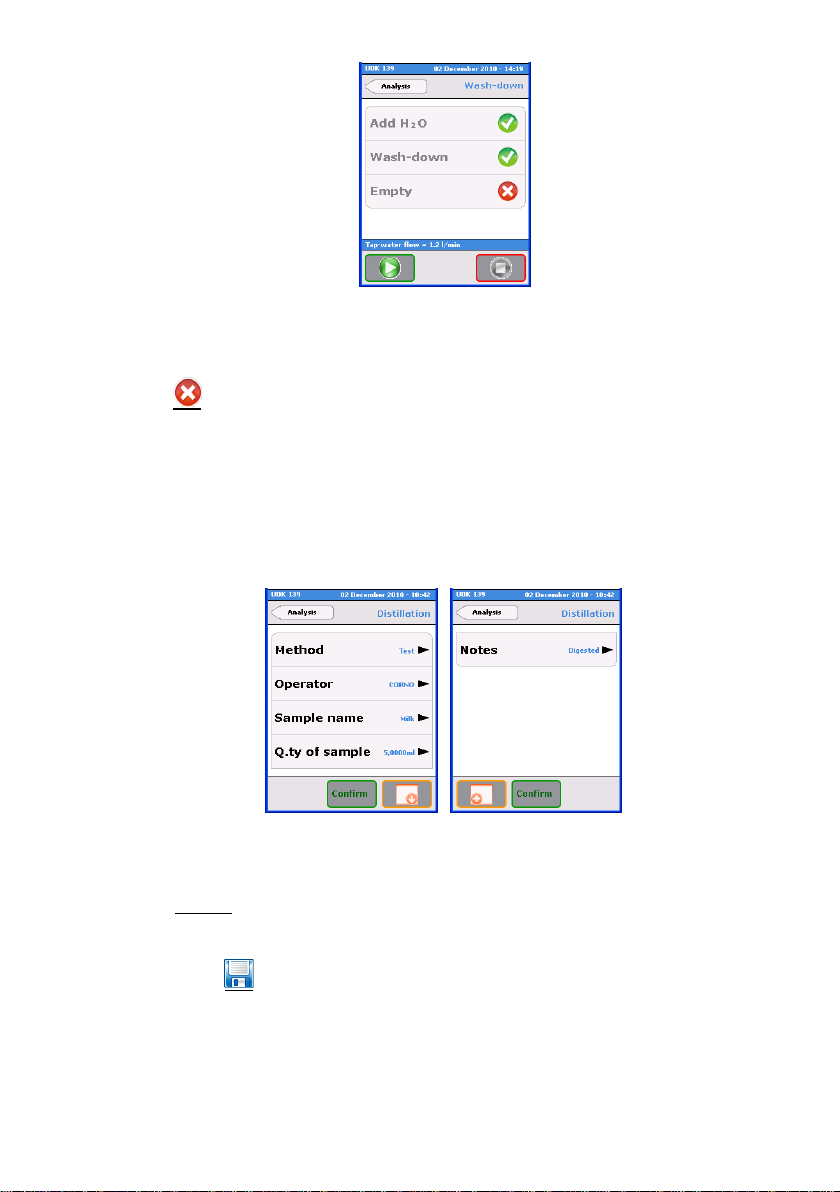

During the wash-down cycle the following three phases are carried out:

- Add H2O

- Washing

- Empty

10004762/B5

Velp Scientifica – UDK139 Operating Manual

23

210

The green flag on the right indicates that the phase was carried out correctly, a red X

indicates that the phase did not terminate correctly. The blue line at the bottom of the

display indicates the cooling water flow rate (e.g. Tap-water flow = 1.2 l/min).

Press to stop the process at any time.

NOTE: Velp recommends that a wash-down is carried out every day before starting

sample analysis and at the end of the daily work-session.

4.3.2. Distillation

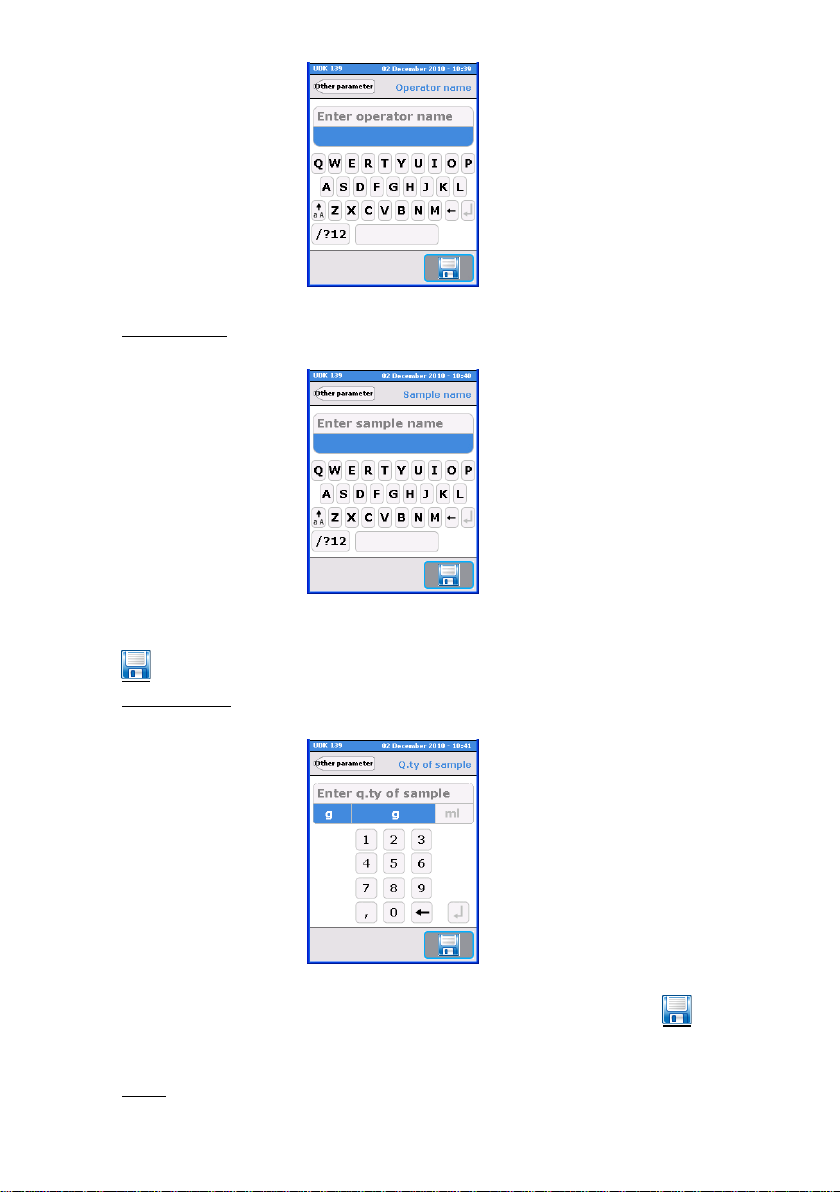

Select "Distillation” from the "Analysis" menu. The following window appears:

To return to the “Analysis” menu press the arrow in the upper left corner.

Select the various fields and enter the required analysis parameters.

Press Method to access the "Methods" menu (see Chapter 4.4 Methods). Choose

the method of interest.

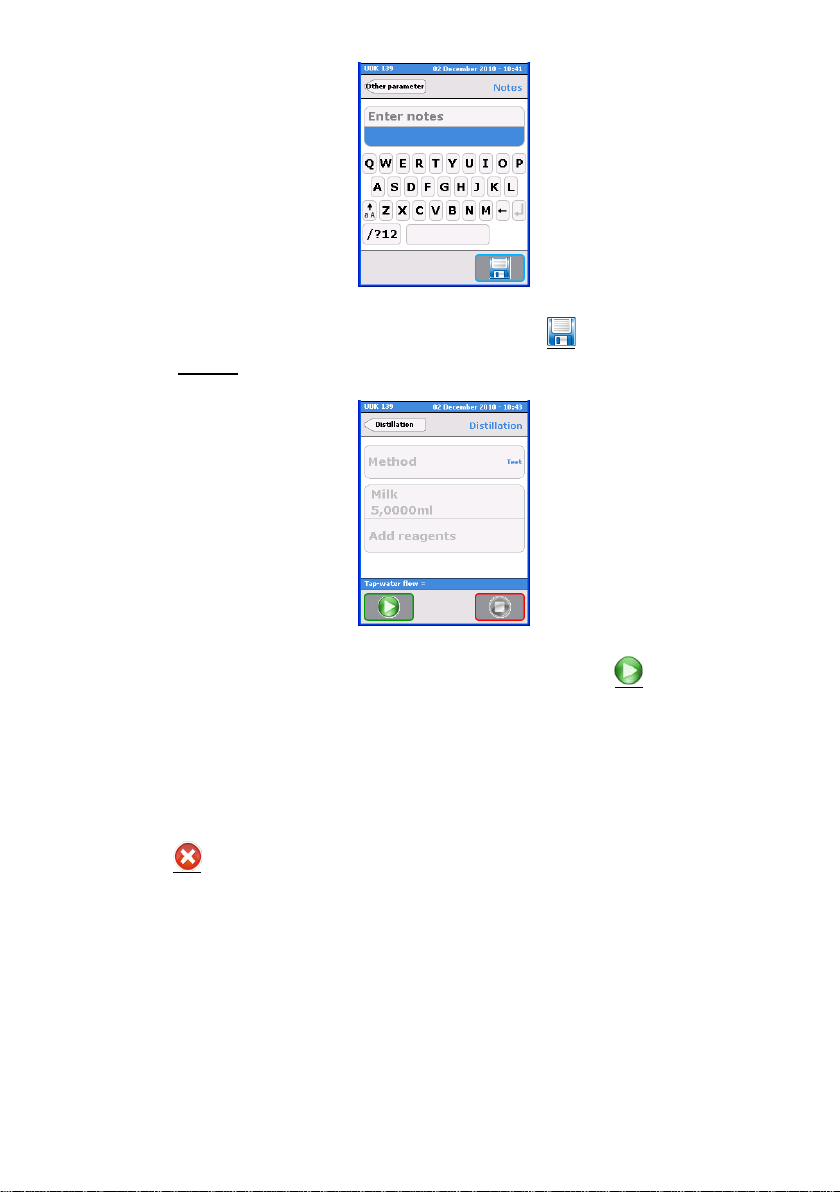

Press Operator and use the alphanumeric keypad to enter or modify the operator

name. Press to confirm.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

24

211

Press Sample name. The following window appears:

Enter the sample name (max. 13 characters) using the alphanumeric keypad.

Press to confirm.

Press Q.ty of sample and enter the sample quantity using the alphanumeric keypad:

Use the touch-screen to select the unit of measure required and press to

confirm.

Press Notes. The following window appears:

10004762/B5

Velp Scientifica – UDK139 Operating Manual

25

212

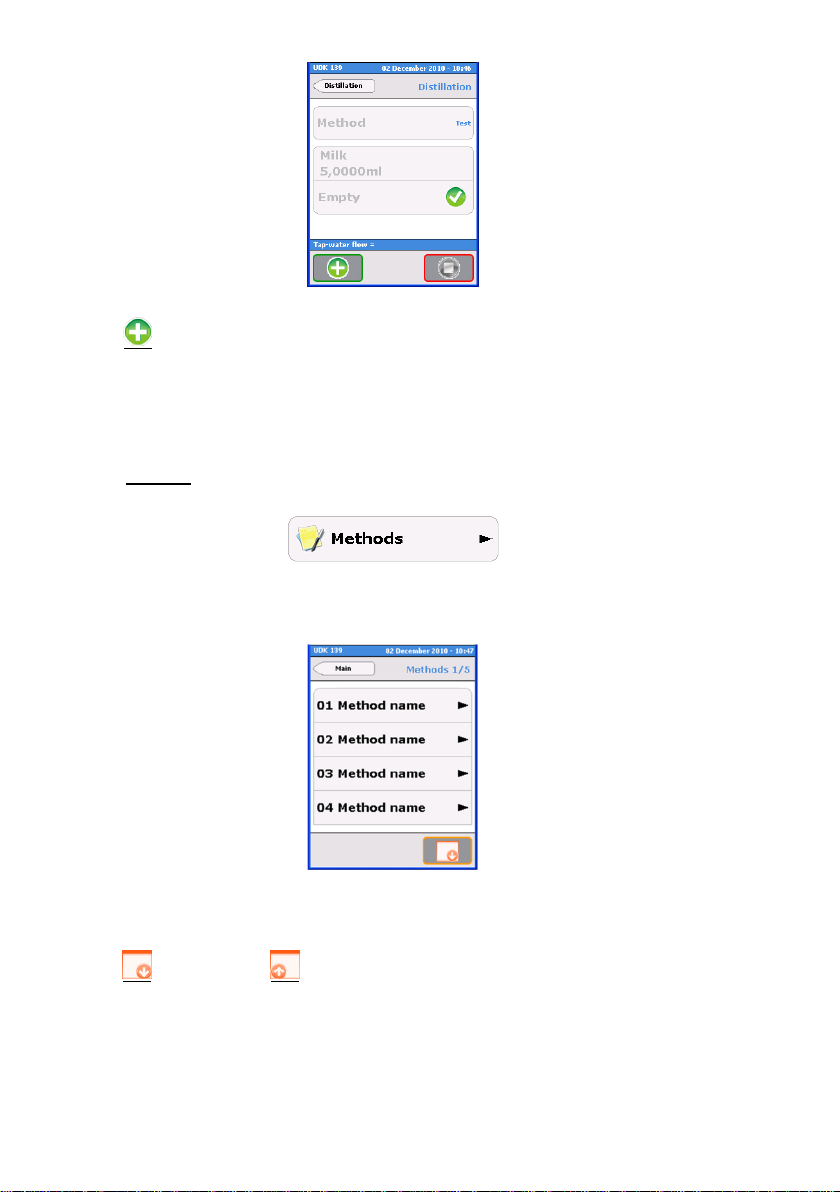

Use the alphanumeric keypad to enter notes and press to confirm.

Press Confirm to confirm the parameter settings of the analysis. The following

window appears:

Position the test tube containing the sample in its seat and press .

During the distillation the following three phases are carried out in sequence:

- Add reagents

- Analysis

- Residues removal (only if previously selected)

The green flag on the right indicates that the analysis was carried out correctly, a red

X indicates that the phase did not terminate correctly.

Press to interrupt the process at any time.

The distillation time countdown is shown on the display during analysis.

The name and quantity of the sample selected in “Distillation" are also displayed.

At the end of distillation the display shows the following window:

10004762/B5

Velp Scientifica – UDK139 Operating Manual

26

213

Press or the "Distillation" arrow top left to print the analysis data (if automatic

print-out has been selected) and return to the "Distillation" menu in order to with a

new analysis.

4.4. Methods

Select Methods from the "Main" menu.

The following window appears:

To return to the “Main” menu press the arrow in the upper left corner.

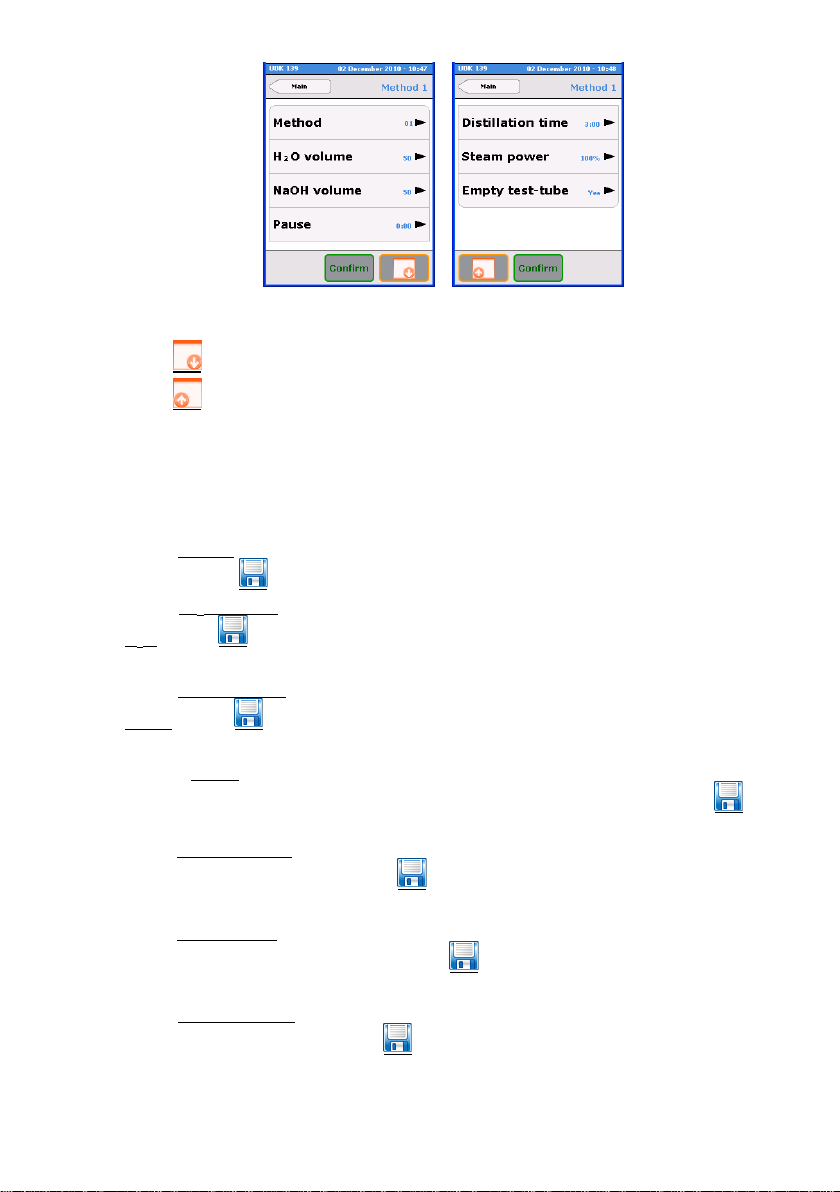

Press (next page) or (previous page) to scroll through the 20 customizable

methods listed.

Use the touch-screen to select the method required.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

27

214

Press button to move to the next window.

Press button to return to the previous window.

NOTE: upon receipt of the instrument all customizable methods include default

parameters entered by Velp.

Use the touch-screen to select each parameter and modify the value.

Select Method and use the alphanumeric keypad to enter or modify the name of the

method. Press to confirm.

Select H2O volume and use the numeric keypad to enter or modify the volume of

H2O . Press to confirm.

Select NaOH volume and use the numeric keypad to enter or modify the volume of

NaOH . Press to confirm.

Select Pause and use the numeric keypad to enter or modify the time lapse

between the entry of reagents and the beginning of steam production. Press to

confirm.

Select Distillation time and use the numeric keypad to enter or modify the distillation

time (steam production time). Press to confirm.

Select Steam power and use the numeric keypad to enter or modify the steam power

during distillation (from 10 to 100%). Press to confirm.

Select Empty test-tube and choose from the two options available. Select automatic

residues aspiration if needed. Press to confirm.

10004762/B5

Velp Scientifica – UDK139 Operating Manual

28

215

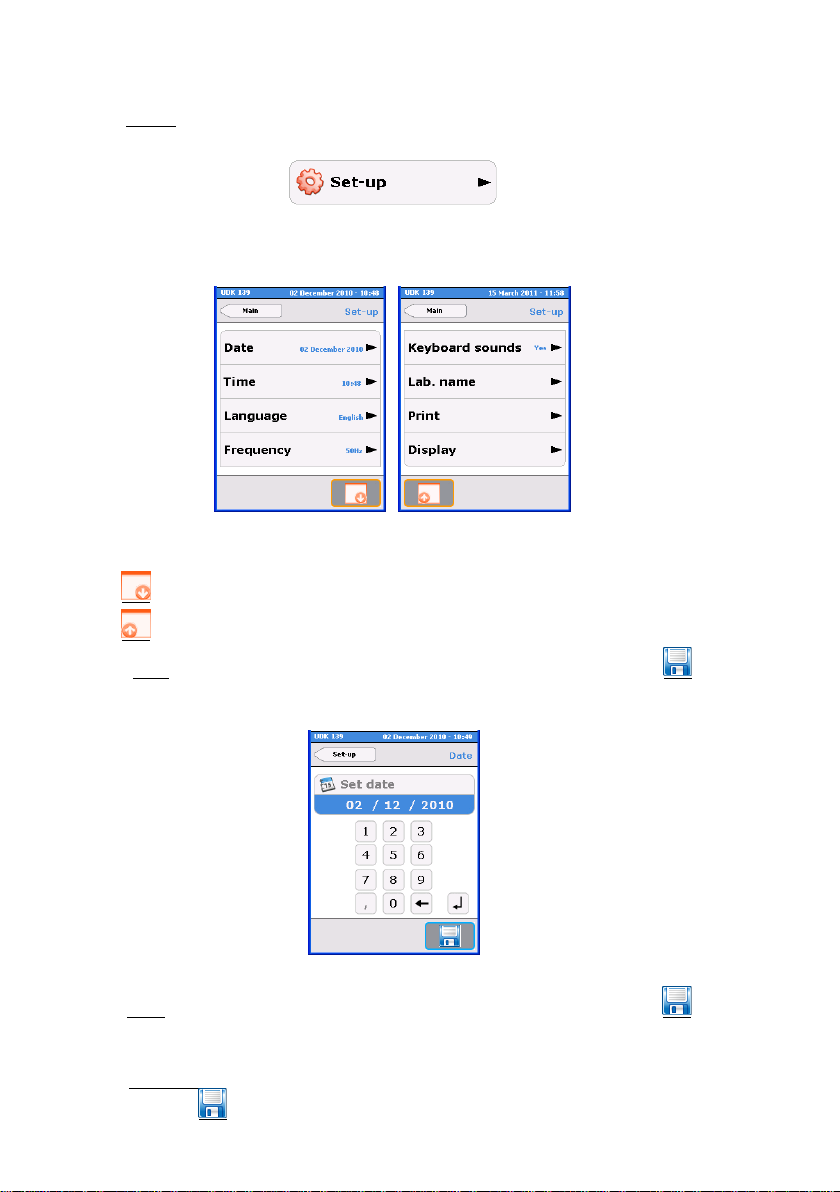

4.5. Set-up

Select Set-up from the "Main" menu.

The following submenus are listed:

To return to the "Main" menu press the arrow top left.

Press to move to the next window.

Press to return to the previous window.

Select Date and use the numeric keypad to enter or modify the date. Press to

confirm.

Select Time and use the numeric keypad to enter or modify the time. Press to

confirm.

Select Language and use the touch-screen to choose from the list of languages

available. Press to confirm..

10004762/B5

Velp Scientifica – UDK139 Operating Manual

29

216

Select Frequency and use the touch-screen to select the frequency of the power

supply at the place of installation . Press to confirm.

Select Keyboard sounds and use the touch-screen to select YES/NO to

enable/disable the acoustic signal when touch-screen keys are pressed. Press

to confirm.

Select Laboratory name and use the alphanumeric keypad to enter or modify the

name of the laboratory. Press to confirm.

The name of the laboratory will be printed on the report.

Select Print. The display shows:

Select Type and choose from the options available: Standard / Compressed. Press

to confirm.

10004762/B5

30

Standard

Compressed

VELP SCIENTIFICA

Distillator: UDK139

Software Version: 1.0.0

______________________

Date:

20/09/2010

Time:

14.49

Laboratory name:

Velp Scientifica

Operator:

Paolo

ID:

4

Sample:

Milk

Q.ty sample:

5,0000ml

Method:

Test

H2O:

50ml

NaOH:

20ml

Pause:

00:00

Distill. Time:

03:00

Steam:

100%

Empty test tube:

Yes

Notes:

______________________

VELP SCIENTIFICA

Distillator: UDK139

Software Version: 1.0.0

______________________

Date:

20/09/2010

Time:

15.00

ID:

5

Sample:

Milk

Q.ty sample:

5,0000ml

Notes:

______________________

217

Select Automatic and choose YES/NO to enable/disable automatic print-out

at the end of each analysis when or the back arrow is pressed.

Press to confirm.

Select Display. Use the two sliding bars to adjust the contrast and brightness of the

display. Press to confirm.

Velp Scientifica – UDK139 Operating Manual

10004762/B5

Loading...

Loading...